16

Disc Ceramic Capacitors

General Specifications - Class III General Purpose

Measured at

1.0 kHz / 0.1 Vrms / 25ºC

Dissipation C

R

≤

22 nF

→

Y5V, Y5U

≤

7.5%

Factor

C

R

> 22 nF

→

Y5V, Y5P

≤

5.0%

Capacitance

Y5P

→

±20% / -20 +50%

Tolerance

Y5U

→

±20% / -20 +80%

Y5V

→

±20% / -20 +80%

Climatic

30 / 085 / 21

Category

Insulation

Y5P

≥

12 M

Ω

Resistance

Y5U

4.7 nF...100 nF

→ ≥

10 M

Ω

@ V

R

200 nF

→ ≥

1 M

Ω

Y5V

≥

100 M

Ω

Dielectric Strength

Between

Vt = 1.25 V

R

NOTE: Charging

leads

current limited

Body

V

R

= 25V Vt = 100V (DC)

to 50 mA

insulation

V

R

= 50V Vt = 150V (DC)

Operating

Temperature

-30... +85

Range (ºC)

PERFORMANCE CHARACTERISTICS CLASS III

Note: Damp Heat Steady State: 90... 95% R.H. 40ºC / 21 days. No voltage to be applied.

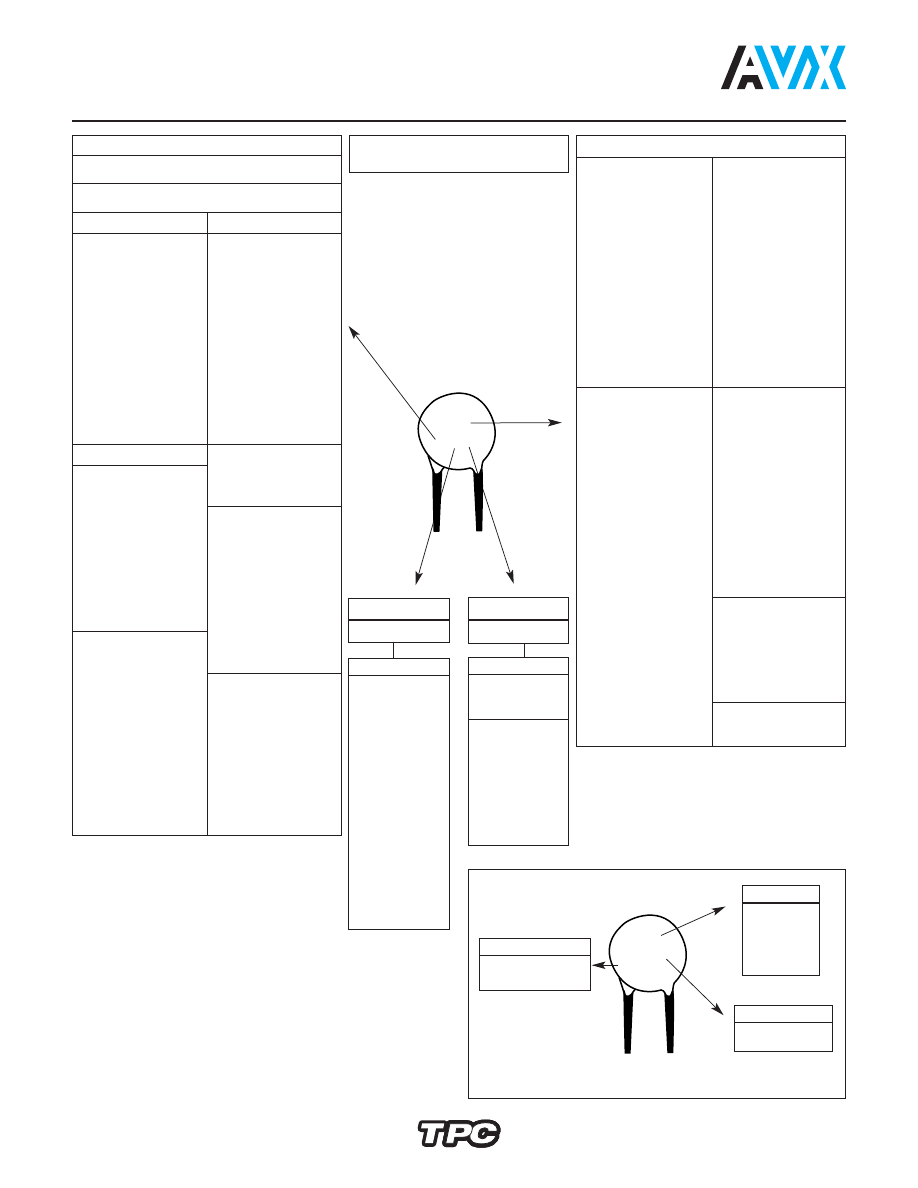

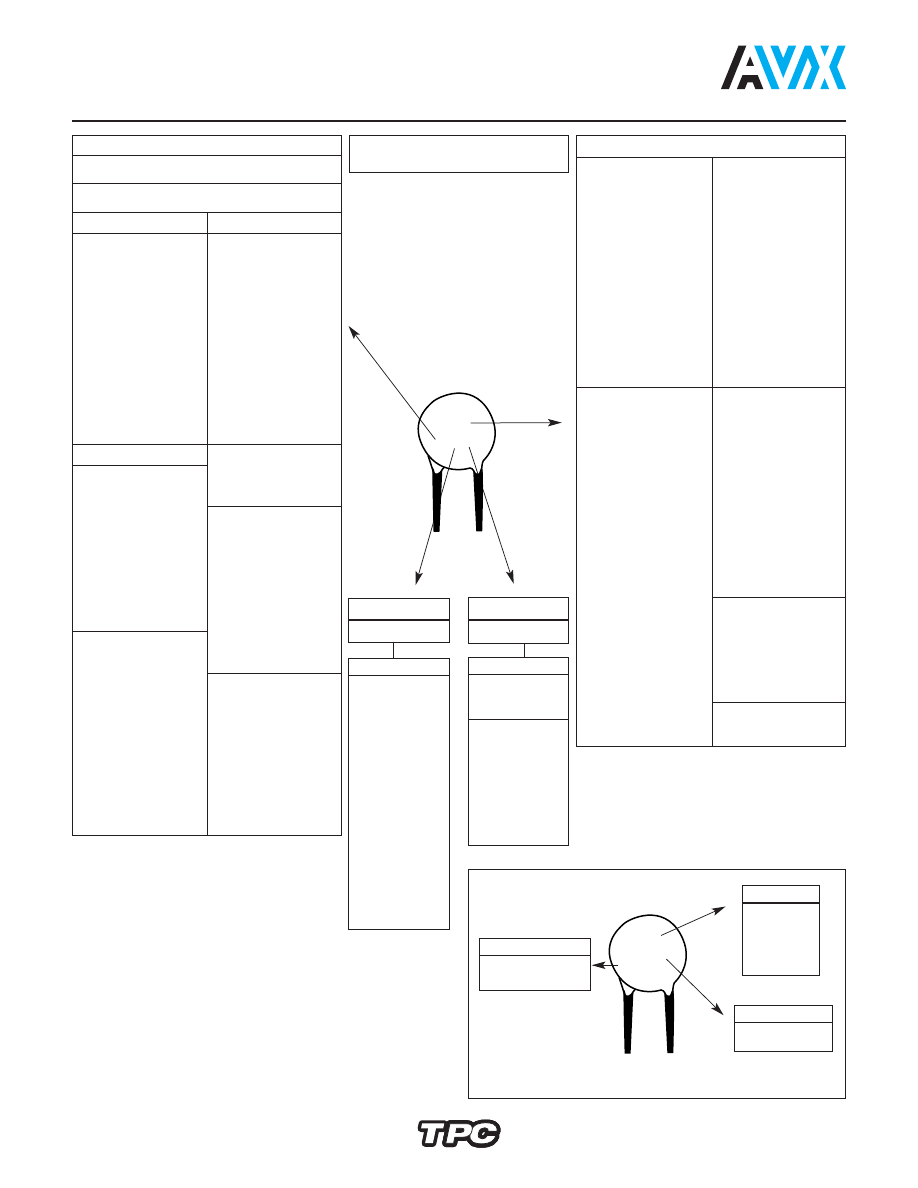

DIELECTRIC - CLASS III

A thin dielectric layer is grown on a disc of conductive

ceramic. Very large capacitances can be obtained due to

reduced thickness of this barrier layer and its inherently

high dielectric constant. Due its small dimensions, they

are a less expensive replacement of multilayer ceramic or

polyester capacitors. An equivalent circuit is shown below:

Meets IEC 324 (1970).

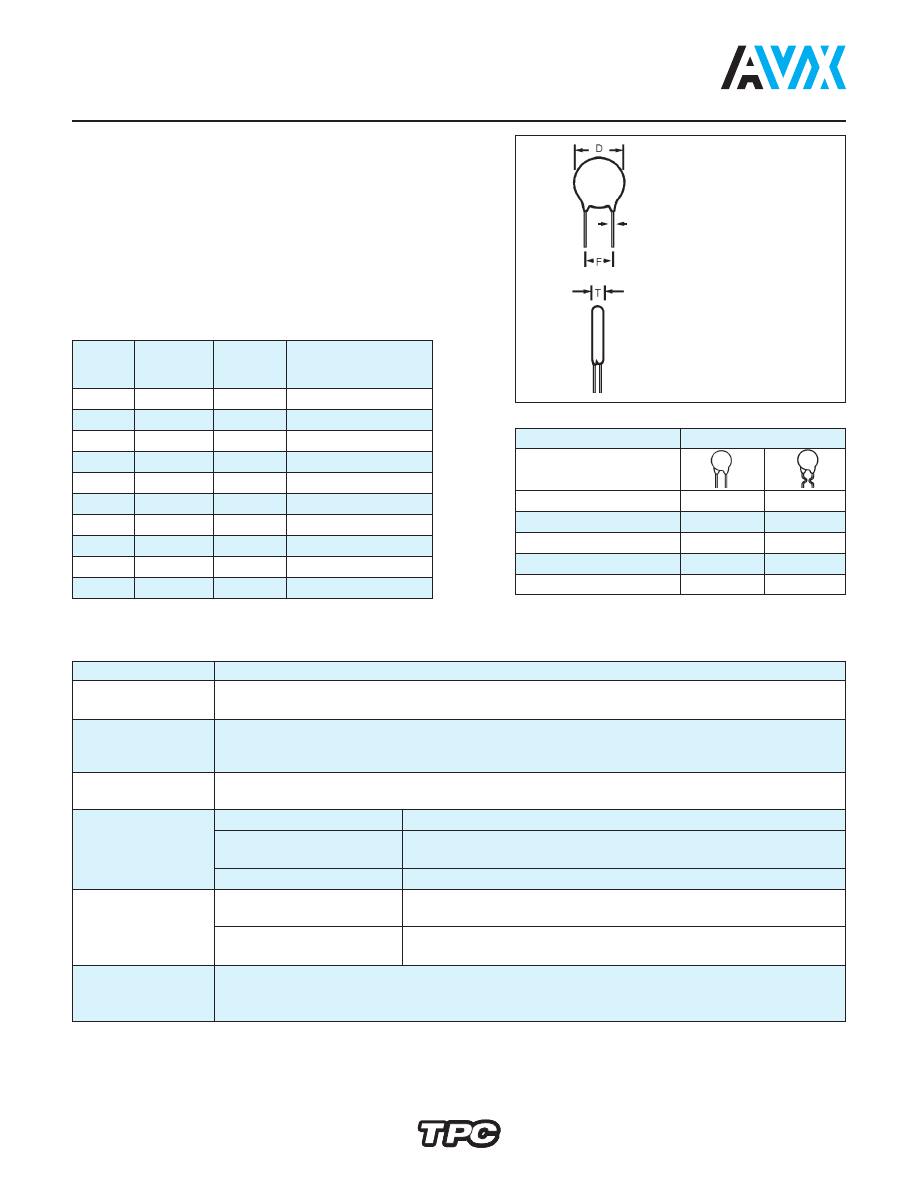

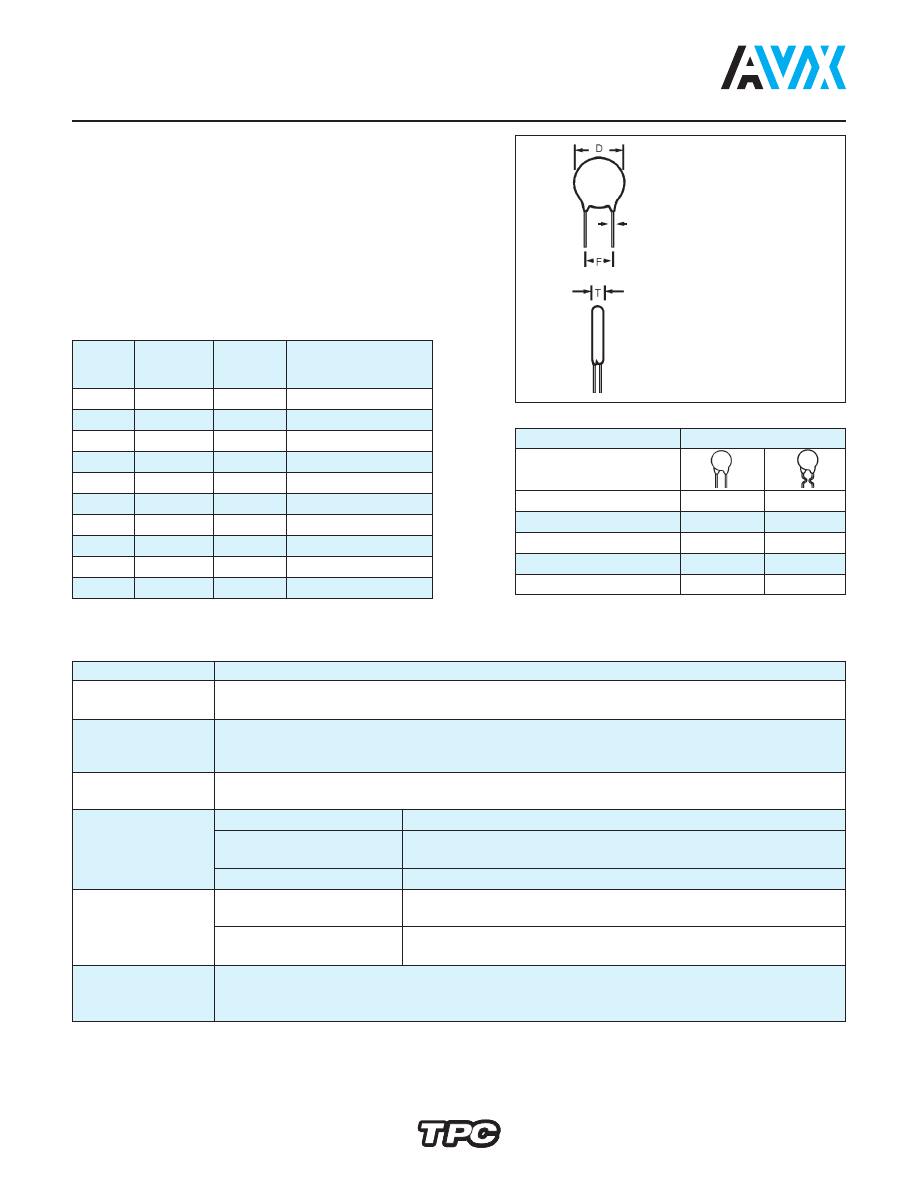

DIMENSIONS

millimeters (inches)

Digit 9

Available

of P.N.

D ± 2

T max.

Lead Spacing

(ø)

(0.079)

A

4.0 (0.157)

3.0 (0.118)

A,B,D,E,O,R

B

5.0 (0.197)

3.0 (0.118)

A,B,D,E,O,R,X

C

6.0 (0.236)

3.0 (0.118)

A,B,C,D,E,O,R,X

D

7.0 (0.276)

3.0 (0.118)

A,B,C,D,E,O,R,X

E

8.0 (0.315)

3.0 (0.118)

A,B,C,D,E,O,R,X

F

9.0 (0.354)

3.0 (0.118)

A,B,C,E,O,R,X

G

10.0 (0.394) 3.0 (0.118)

A,B,C,E,O,R,X

H

11.0 (0.433) 3.0 (0.118)

A,B,C,E,O,R,W

J

13.0 (0.512) 3.5 (0.138)

B,C,R,W

K

15.0 (0.591) 4.0 (0.157)

B,C,R,W

Lead Spacing

Digit 8 of P.N.

F

2.5 (0.100)

D

—

5 (0.200)

A

O

6 (0.250)

E

X

7.5 (0.300)

B

R

10 (0.400)

C

W

Preferred lead spacing

F = 5 (0.197)

Ø = 0.6 ± 0.1

(0.024) (0.004)

millimeters (inches)

pa/AVX/Capacitors/Ceramic/Disc/AVX_Disc_Ceramic_Capacitors_Dielectric_classIII-html.html

17

Disc Ceramic Capacitors

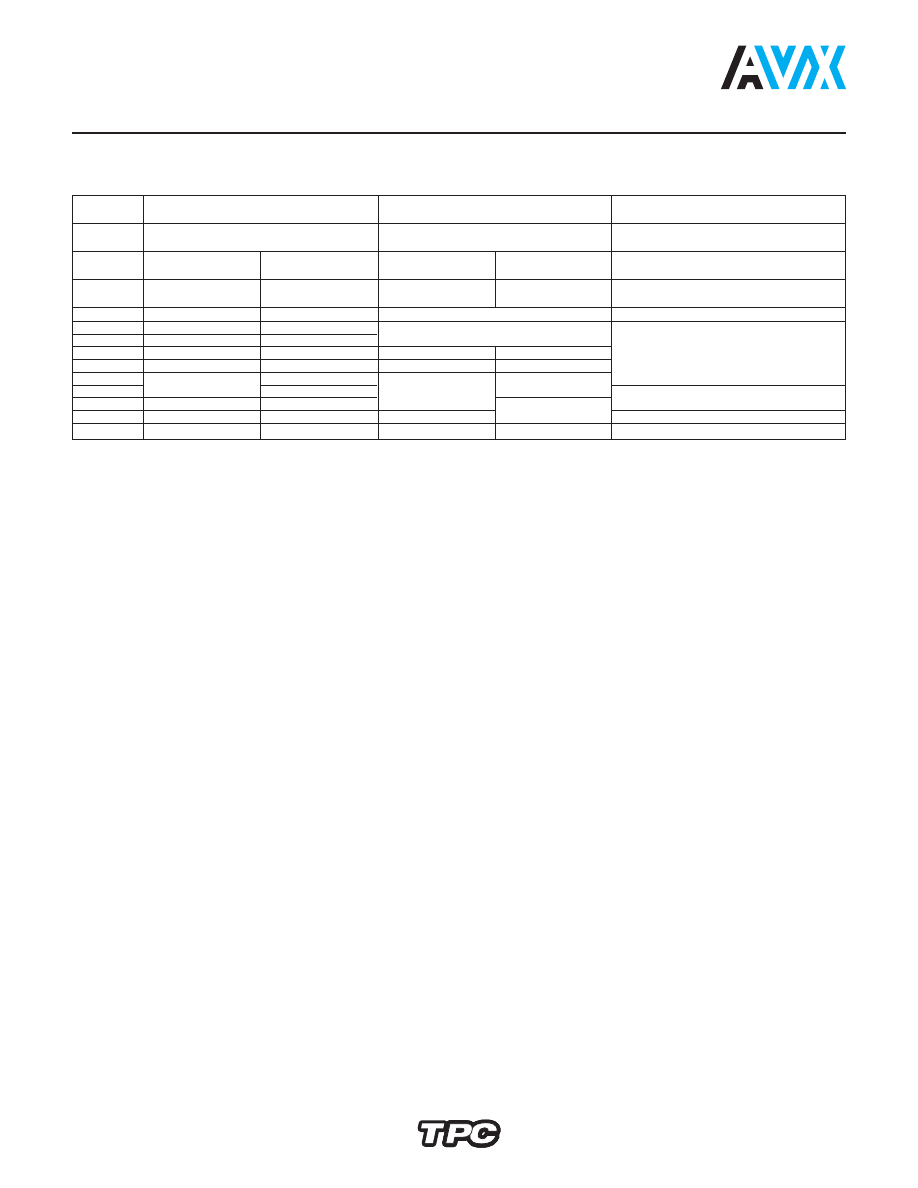

Dimension Table

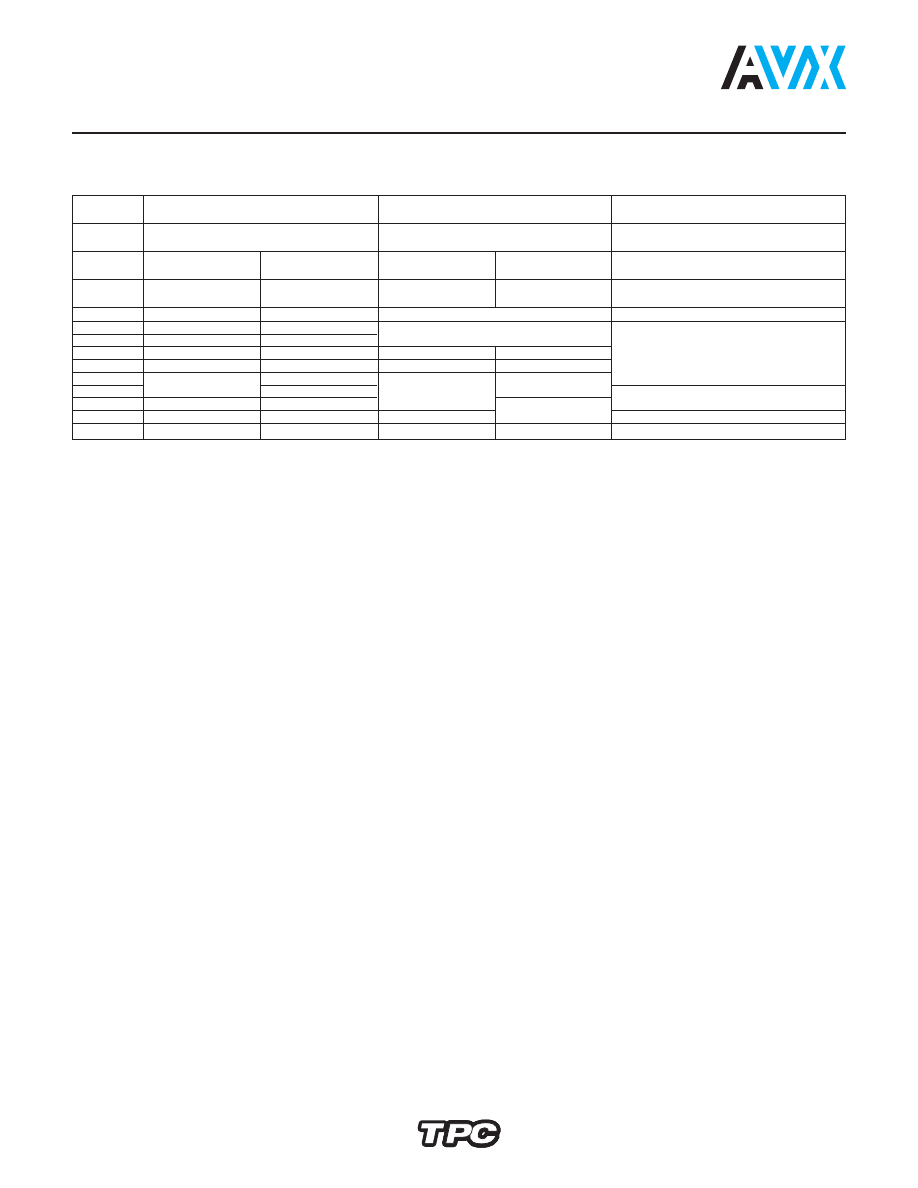

Barrier Layer Capacitors - Class III General Purpose

PHENOLIC COATED – CAPACITANCE VS. DISC DIAMETER

millimeters (inches)

Y5U, Y5V - Preferences

Diameter (

φ

) = 9th Part Number Digit

Class III

∆

C/C (max.)

Range

∆

C/C (max.)

Range

∆

C/C (max.)

Range

±12%

-30... +85ºC

+30 -65%

-30... +85ºC

+22 -85%

-30... +85ºC

Temp.

Y5P

Y5U

Y5V

Coefficient

Digits 1,2,3

5WF

5WH

5YF

5YH

5ZH

of P.N.

Rated

25 VDC

50 VDC

25 VDC

50 VDC

50 VDC

Voltage (V

R

)

C

R

(pF)

4,700

4.0 (0.157)

4.0 (0.157)

4.0 (0.157)

4.0 (0.157)

10,000

6.0 (0.236)

6.0 (0.236)

22,000

7.0 (0.276)

8.0 (0.315)

5.0 (0.197)

6.0 (0.236)

4.0 (0.157)

33,000

8.0 (0.315)

9.0 (0.354)

6.0 (0.236)

7.0 (0.276)

47,000

11.0 (0.433)

50,000

10.0 (0.394)

—

7.0 (0.276)

8.0 (0.315)

68,000

11.0 (0.433)

13.0 (0.512)

5.0 (0.197)

100,000

13.0 (0.512)

15.0 (0.591)

8.0 (0.315)

9.0 (0.354)

7.0 (0.276)

200,000

—

—

13.0 (0.512)

—

pa/AVX/Capacitors/Ceramic/Disc/AVX_Disc_Ceramic_Capacitors_Dielectric_classIII-html.html

4

5

General Purpose

5A = NP0 / I

*5B = P100 / I

*5C = N150 / I

*5D = N220 / I

*5E = N330 / I

*5F = N470 / I

5G = N750 / I

5H = N1500 / I

*5I = N2200 / I

*5J = N4700 / I

5K = SL

5M = Y5E / II

5N = Y5F / II

5O = Y5P / II

*5P = Y5R / II

*5Q = Y5T / II

5S = Y5U / II

5T = Y5V / II

5U = Z5V / II

*5V = Z4V / III

5W = Y5P / III

5Y = Y5U / III

5Z = Y5V / III

O

Professional Switch Mode

Safety

6A = NP0 / I

*6B = P100 / I

*6C = N150 / I

*6D = N220 / I

*6E = N330 / I

*6F = N470 / I

6G = N750 / I

*6H = N1500 / I

*6I = N2200 / I

6J = N4700 / I

61 = SAFETY

62 = SAFETY

65 = SAFETY

67 = Y5U / SM

68 = Y5V / SM

6L = Y5P / SM

6M = X5E / II

6N = X5F / II

6O = X5P / II

*6P = X5R / II

*6Q = X5T / II

6S = X5U / II

6T = X5V / II

6U = Z5V / II

*6V = Z4V / III

6W = Y5P / III

6Y = Y5U / III

6Z = Y5V / III

Q

Rated Voltage (dc)

D = 16V

F = 25V

H = 50V

K = 100V

N = SAFETY

O = SAFETY

Q = 500V

R = 1000V

S = 2000V

T = 3000V

U = 4000V

V = SAFETY

W = 5000V

*X = 6000V

*Y = 7500V

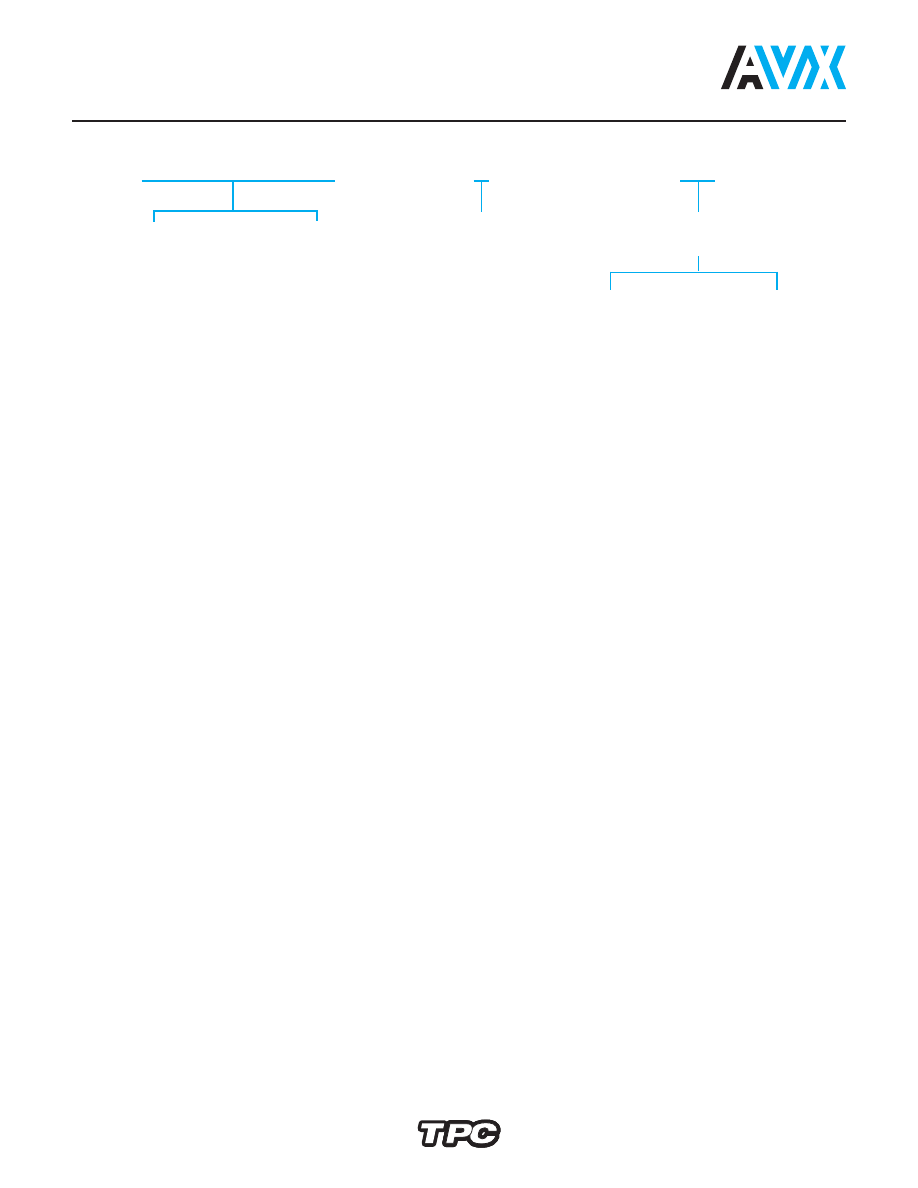

HOW TO ORDER

222

Capacitance

222 = 2.2 nF

Disc Ceramic Capacitors

Ordering Code

Capacitance = TPC code

1 pF = 1R0

1.2pF = 1R2

1.5pF = 1R5

1.8pF = 1R8

2.2pF = 2R2

2.7pF = 2R7

3.9pF = 3R9

4.7pF = 4R7

5.6pF = 5R6

6.8pF = 6R8

8.2pF = 8R2

10pF = 100

12pF = 120

15pF = 150

18pF = 180

22pF = 220

27pF = 270

33pF = 330

39pF = 390

47pF = 470

56pF = 560

68pF = 680

82pF = 820

Capacitance = TPC code

100pF = 101

120pF = 121

150pF = 151

180pF = 181

220pF = 221

270pF = 271

330pF = 331

390pF = 391

470pF = 471

560pF = 561

680pF = 681

820pF = 821

1nF = 102

1.2nF = 122

1.8nF = 182

2.2nF = 222

2.7nF = 272

3.3nF = 332

3.9nF = 392

4.7nF = 472

5.6nF = 562

6.8nF = 682

8.2nF = 822

10nF = 103

15nF = 153

22nF = 223

33nF = 333

47nF = 473

100nF = 104

200nF = 204

*Upon Request

pa/AVX/Capacitors/Ceramic/Disc/AVX_Disc_Ceramic_Capacitors_Dielectric_classIII-html.html

5

M

Tolerance

C = ±0.25 pF

D = ±0.50 pF

J = ±5%

K = ±10%

M = ±20%

S = -20+50%

Z = -20+80%

P = 0+100%

A

E

Capacitor Diameter

± 2 (0.079)

A = 4 (0.157)

B = 5 (0.197)

C = 6 (0.236)

D = 7 (0.276)

E = 8 (0.315)

F = 9 (0.354)

G = 10 (0.394)

H = 11 (0.433)

J = 13 (0.512)

K = 15 (0.591)

M* = 19 (0.748)

A

A

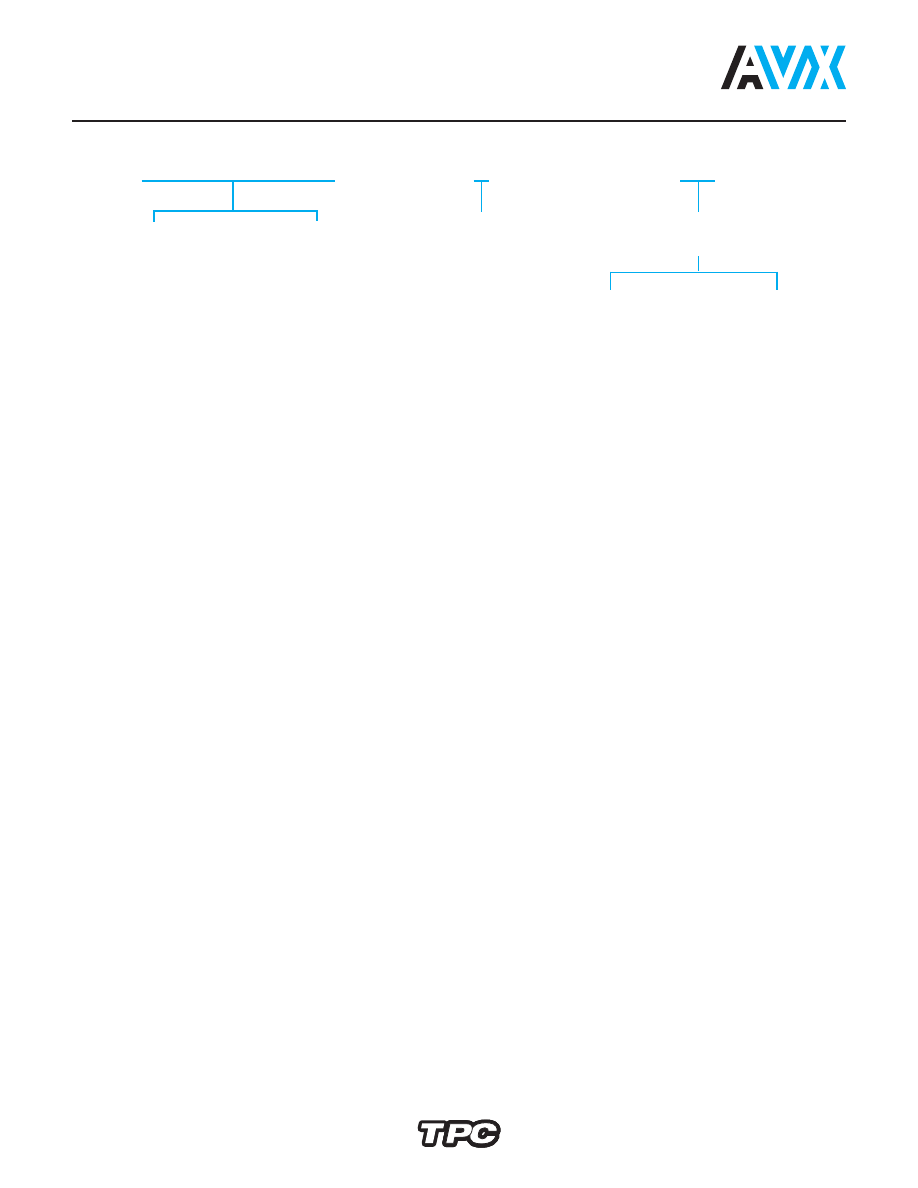

Packaging

Disc Ceramic Capacitors

Ordering Code

Lead Forming

mm

inches

2.5 ±0.5

.1 ± .025

D

–

–

5

+0.6

.2 ± .025

A

O

N

-0.2

6

+0.6

.25 ± .025

E

X

–

-0.2

7.5

+1

.3 ± .05

B

R

Q

-0.5

10

+0.5

.4 ± .05

C

W

–

-1.0

12.5

+1

.5 ± .05

P

–

–

-0.5

Low Voltage

A =

(

General

)

Q = Waxed phenolic

Phenolic

Purpose

S = Epoxy (Professional) cap. diameter

≤

8 (0.315)

D = Epoxy (Professional) cap. diameter

> 8 (0.315)

High Voltage

C = Epoxy wire diameter

0.6

±

0.1

(0.024)

(0.004)

I = Epoxy wire diameter

0.8

±

0.1

(0.031)

(0.004)

L = Phenolic wire diameter

0.6

±

0.1

(0.024)

(0.004)

Finishing

Coating does not

surpass the bend

Diam

≤

9 (0.354) and

F = 5.00 (0.197)

For every other:

Avisert

Panasert

H

L

L

J

L

L

F = Measured

from the

center of

leads

Cardboard Strips

A

=

Bulk

E

= 5 (0.197) ± 1 (0.039) free wire length

C

= 10 (0.394) ± 1 (0.039) free wire length

D

= 25 (0.984) ± 1 (0.039) free wire length

Taping

Reel

Ammo

Pack

Please note that not all code combinations

are either possible or available.

*Wire 0.8 (0.031) recommended

Avisert

Panasert

I

M M

K

M

M

pa/AVX/Capacitors/Ceramic/Disc/AVX_Disc_Ceramic_Capacitors_Dielectric_classIII-html.html

28

Disc Ceramic Capacitors

Marking

DIG. 2

O

TC / Class

General Purpose

A = NP0 / I

*B = P100 / I

*C = N150 / I

*D = N220 / I

*E = N330 / I

*F = N470 / I

G = N750 / I

H = N1500 / I

*I = N2200 / I

*J = N4700 / I

K = SL

M = Y5E / II

N = Y5F / II

O = Y5P / II

P = Y5R / II

Q = Y5T / II

S = Y5U / II

T = Y5V / II

U = Z5V / II

V = Z4V / III

*W = Y5P / II

*X = Y5R / II

Y = Y5U / II

Z = Y5V / II

Professional

A = NP0 / I

B = P100 / I

C = N150 / I

D = N220 / I

E = N330 / I

F = N470 / I

G = N750 / I

H = N1500 / I

I = N2200 / I

J = N4700 / I

7 = Y5U / SM

8 = Y5V / SM

L = Y5P / SM

M = X5E / II

N = X5F / II

O = X5P / II

P = X5R / II

Q = X5T / II

S = X5U / II

T = X5V / II

U = Z5V / II

V = Z4V / III

W = Y5P / III

X = Y5R / III

Y = Y5U / III

Z = Y5V / III

Capacitance

1pF = 109

1.2pF = 129

1.5pF = 159

1.8pF = 189

2.2pF = 229

2.7pF = 279

3.9pF = 399

4.7pF = 479

5.6pF = 569

6.8pF = 689

8.2pF = 829

10pF = 100

12pF = 120

15pF = 150

18pF = 180

22pF = 220

27pF = 270

39pF = 390

47pF = 470

56pF = 560

68pF = 680

82pF = 820

EIA

100pF = 101

120pF = 121

150pF = 151

180pF = 181

220pF = 221

270pF = 271

390pF = 391

470pF = 471

560pF = 561

680pF = 681

820pF = 821

1nF = 102

1.2nF = 122

1.8nF = 182

2.2nF = 222

2.7nF = 272

3.9nF = 392

4.7nF = 472

5.6nF = 562

6.8nF = 682

8.2nF = 822

10nF = 103

15nF = 153

22nF = 223

33nF = 333

47nF = 473

100nF = 104

200nF = 204

Logo: Only in diam.

≥

6mm

DIG. 3

Q

Rated Voltage

D = 16V

F = 25V

H = 50V

K = 100V

Q = 500V

R = 1000V

S = 2000V

T = 3000V

U = 4000V

W = 5000V

X = 6000V

Y = 7500V

Tolerance

C = ±0.25pF

D = ±0.5pF

J = ±5%

K = ±10%

M = ±20%

S = -20 +50%

Z = -20 +80%

P = 0 +100%

DIG. 7

M

Type

61V

620

65N

Tolerance

As above

Capacitance

As above

Safety

Front

Back: (Approval marks)

61V

471M

TC – Temperature coefficient.

DIG – for better understanding, check pages 3 and 4.

222

OQM

*Upon Request

pa/AVX/Capacitors/Ceramic/Disc/AVX_Disc_Ceramic_Capacitors_Dielectric_classIII-html.html

29

29

Disc Ceramic Capacitors

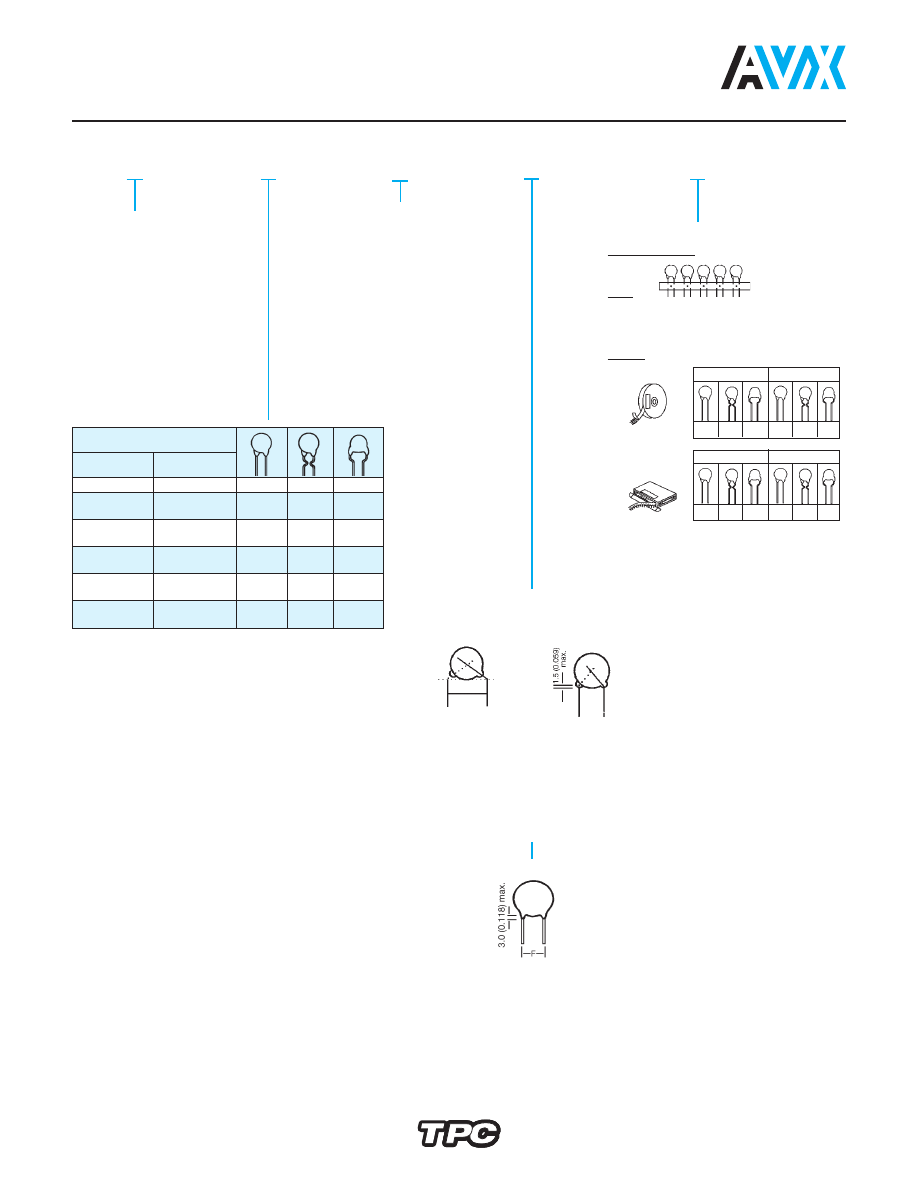

Packaging

TAPED PARTS QUANTITY TABLE

millimeters (inches)

CARDBOARD STRIPS QUANTITY TABLE

millimeters (inches)

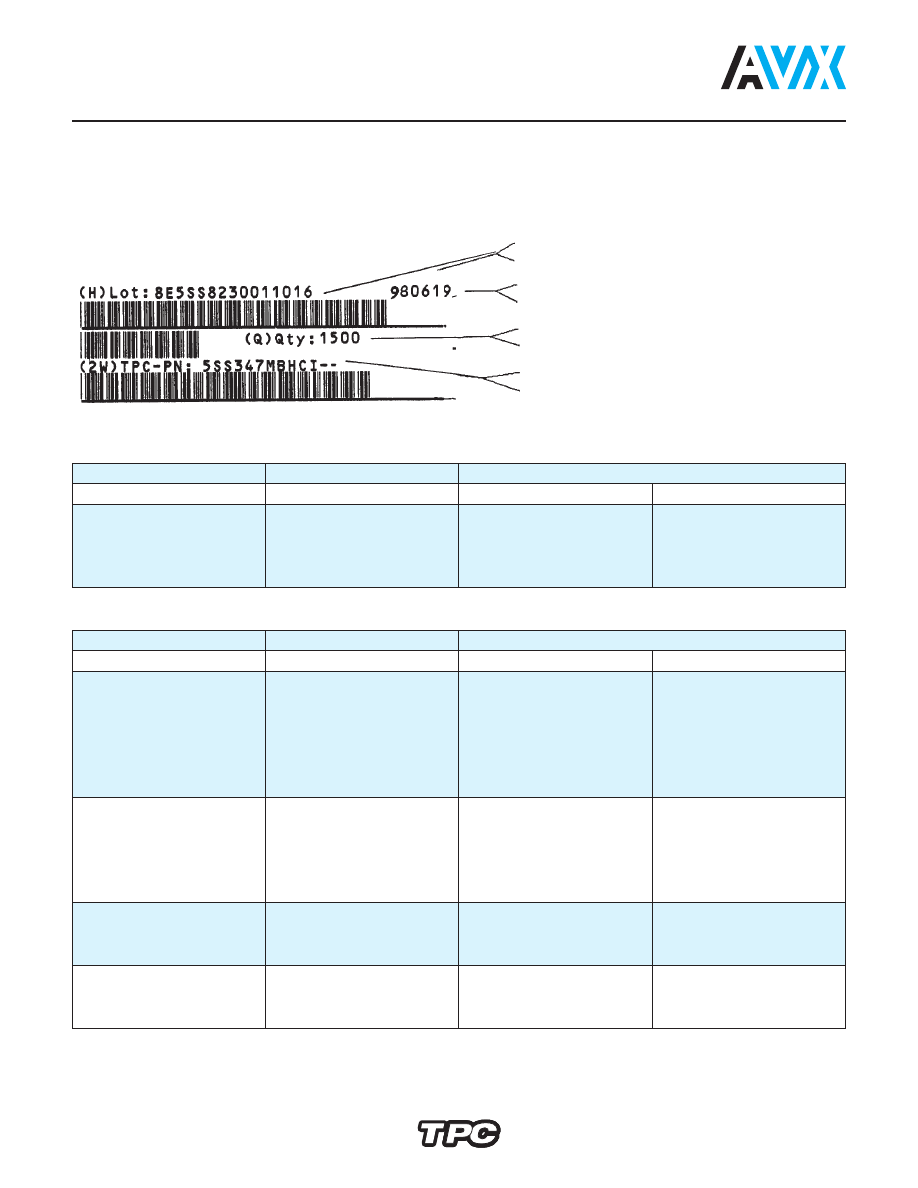

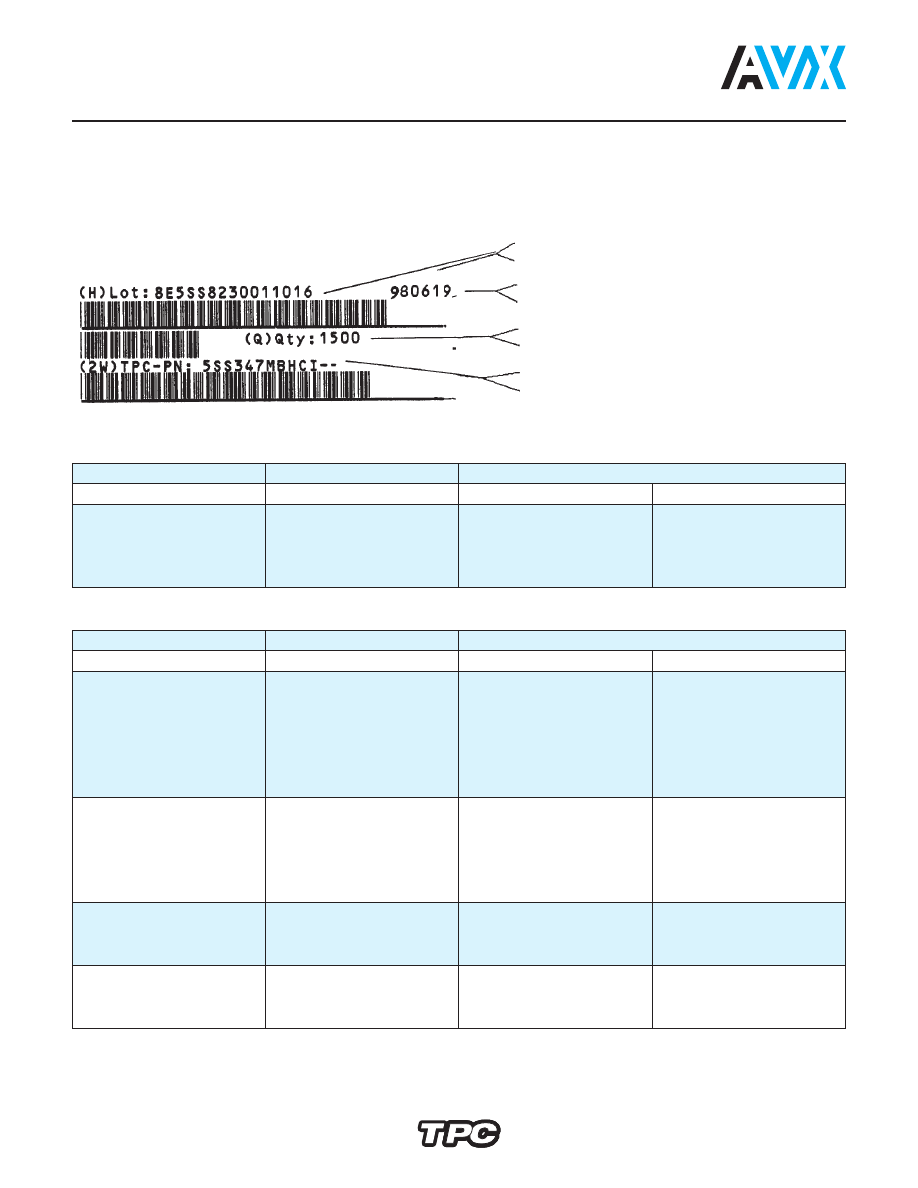

IDENTIFICATION AND TRACEABILITY

On all TPC ceramic capacitors

packages, you will find a bar code label

with the following information:

Rated Voltage

Diameter

Quantities

(Vr)

D

Ammopack

Reel

Vr <= 500V

D

⬉

7 (0.276)

2000

2500

7 < D

⬉

11 (0.433)

2000

2000

500V<Vr<=2KV

D

⬉

11 (0.433)

1500

2000

2KV<Vr=5KV

D

⬉

11 (0.433)

1000

1500

Quantities for other package alternative, upon request.

Lot number

Manufacturing date

Quantity of parts per packaging

Product part number

Rated Voltage

Diameter

Lead Space

(Vr)

D

< = 5 (0.197)

> 5 (0.197)

Vr <= 500V

D

⬉

8 (0.315)

2500

1500

8 (0.315)

⬉

D

⬉

11 (0.433)

1500

-

8 (0.315)

⬉

D

⬉

13 (0.512)

-

1000

11 (0.433)

⬉

D

⬉

15 (0.591)

1000

-

13 (0.512)

⬉

D

⬉

19 (0.748)

-

500

D

⬉

19 (0.748)

500

-

500V<Vr<=2KV

D

⬉

9 (0.354)

1500

1000

9 (0.354)

⬉

D

⬉

11 (0.433)

-

1000

9 (0.354)

⬉

D

⬉

13 (0.512)

1000

-

11 (0.433)

⬉

D

⬉

19 (0.748)

-

500

13 (0.512)

⬉

D

⬉

19 (0.748)

500

-

2KV<Vr<=5KV

D

⬉

9 (0.354)

1500

-

Safety 65N 62O

D

⬉

11 (0.433)

-

1000

D

⬉

13 (0.512)

500

500

Safety

D

⬉

6 (0.236)

1500

1500

61V

7 (0.275)

⬉

D

⬉

9 (0.354)

1000

1000

9 (0.354)

⬉

D

500

500

pa/AVX/Capacitors/Ceramic/Disc/AVX_Disc_Ceramic_Capacitors_Dielectric_classIII-html.html

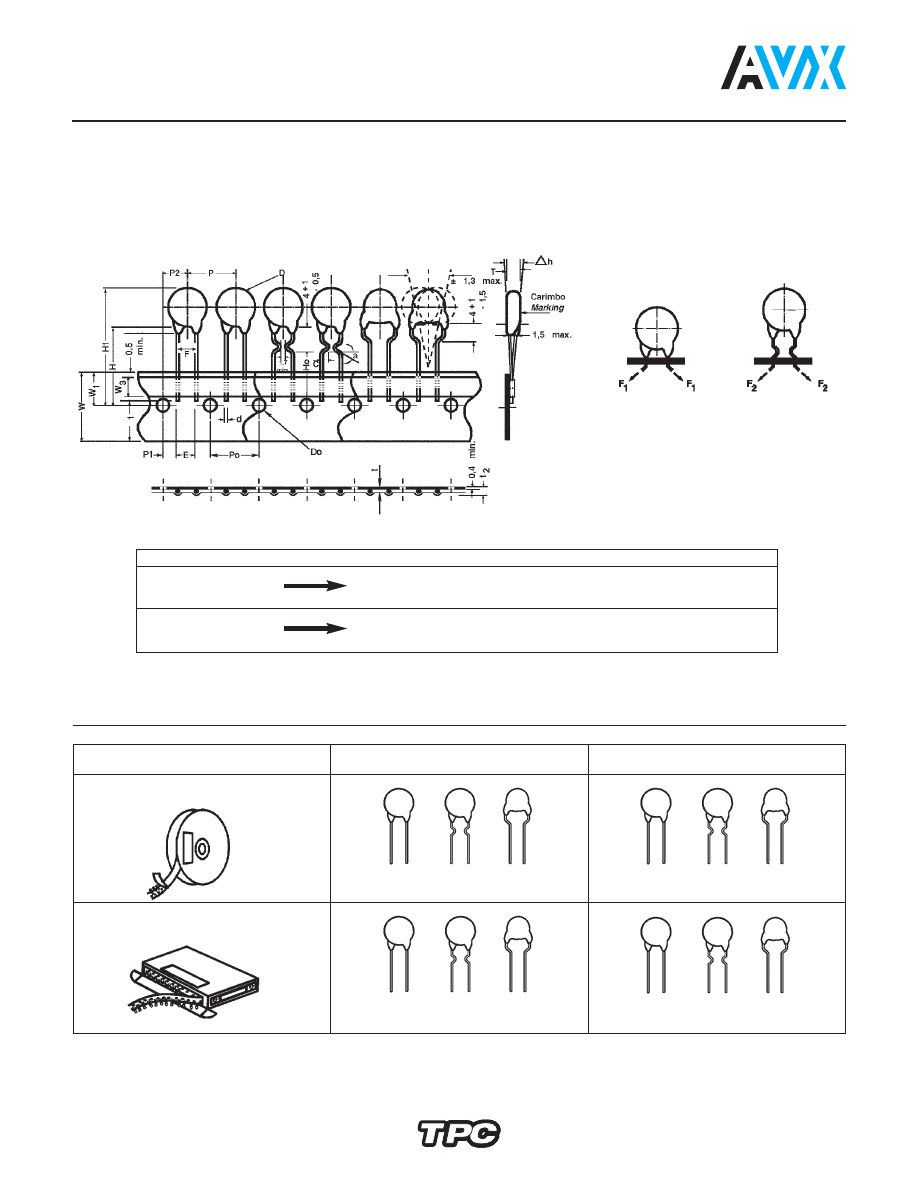

30

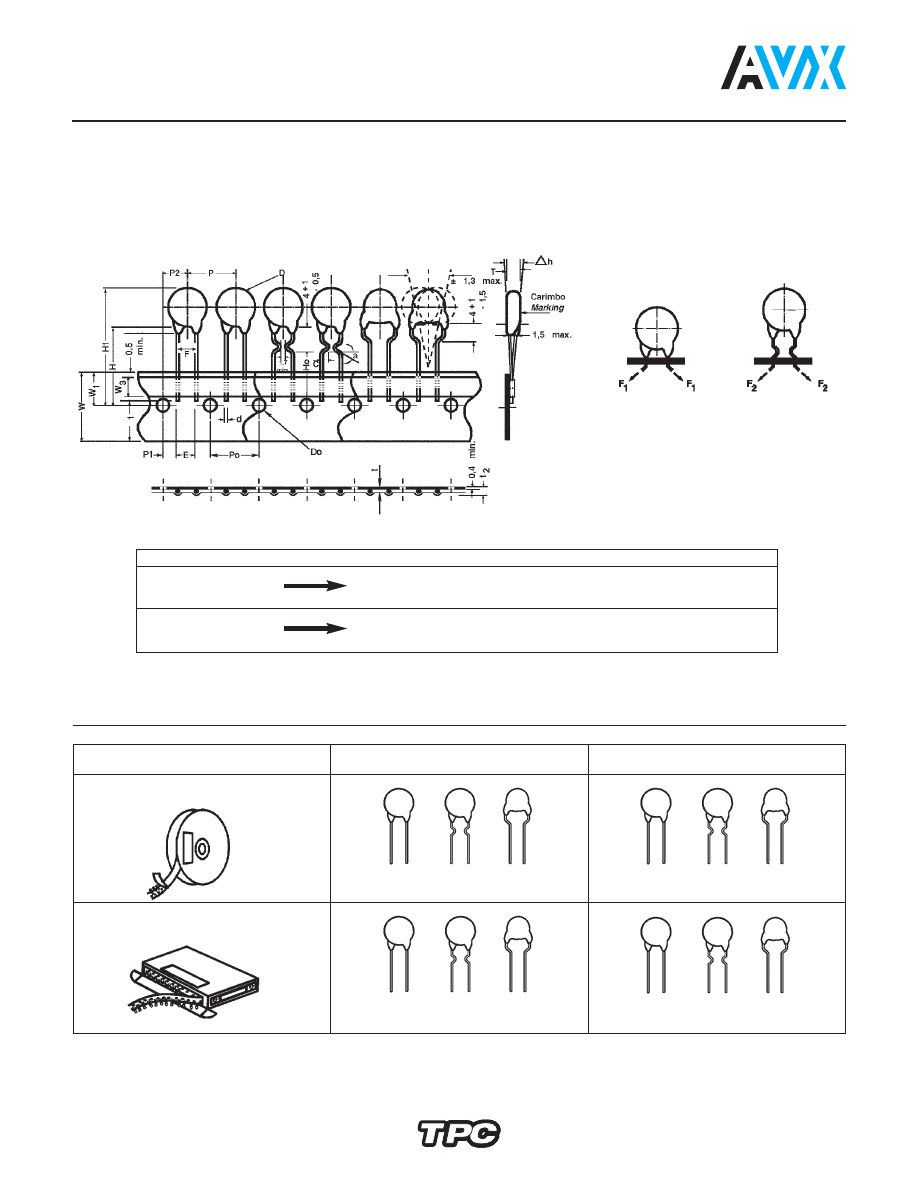

Disc Ceramic Capacitors

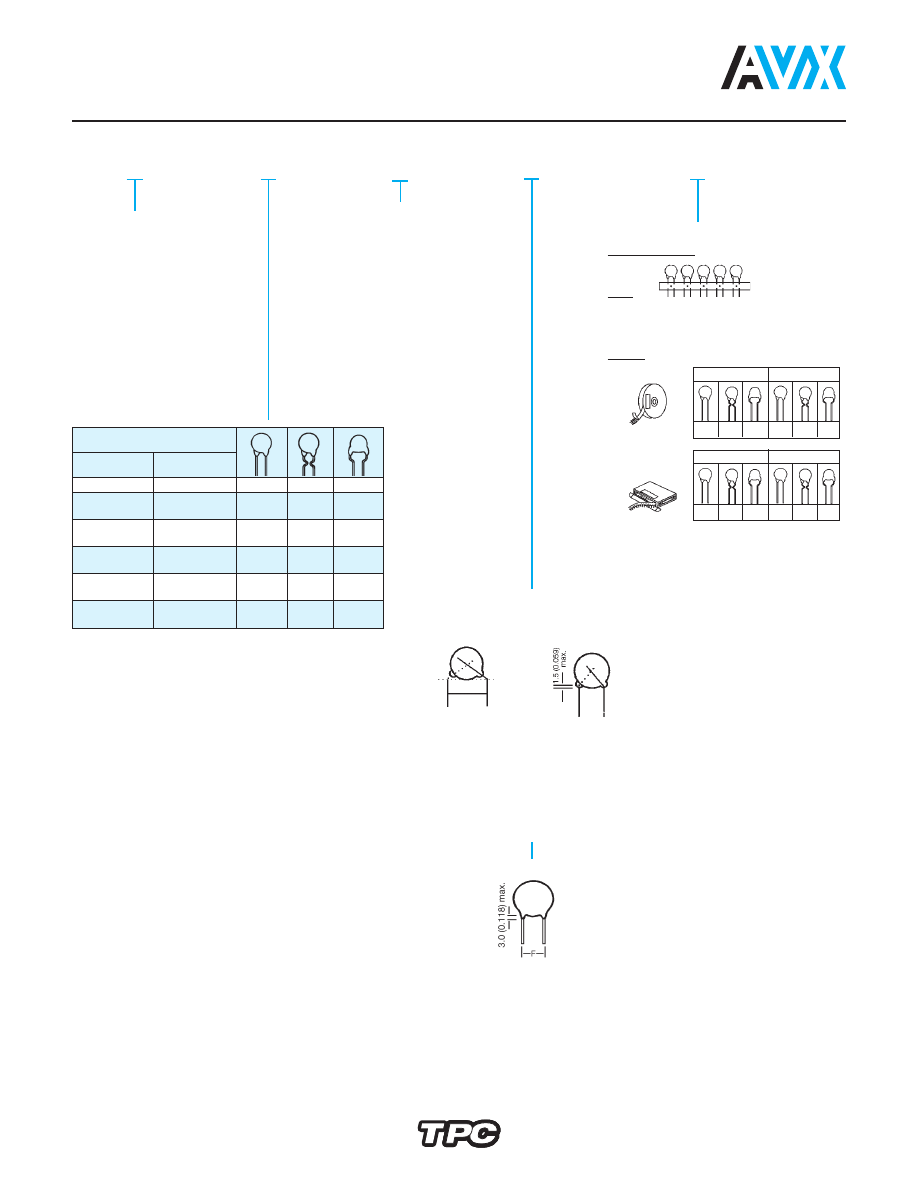

Tape and Reel Specifications

Straight leads

Maximum pull force during insertion and lead cut

F

1

F

2

4 (0.157)

≤

D < 6 (0.236)

12N

20N

D

≥

6 (0.236)

20N

25N

Crimped leads

Digit 11

Available Tapings

Digit 9

L

Sizes

4 (0.157)

≤

D

≤

11 (0.433)

A... H

M

J H

Sizes

6 (0.236)

≤

D

≤

11 (0.433)

C... H

K I

There are two types of taped disc ceramic capacitors:

Straight or crimped leads.

Both types can be shipped on reels or ammopack.

The standard packaging quantities are shown bellow:

TPC Code Digit 11

Packaging

Avisert

Panasert

H

FIGURE 1

L

FIGURE 2

L

FIGURE 3

I

FIGURE 1

M

FIGURE 2

M

FIGURE 3

J

FIGURE 1

L

FIGURE 2

L

FIGURE 3

K

FIGURE 1

M

FIGURE 2

M

FIGURE 3

Ammopack

Reel

Figure 2: Inside Crimp 100V... 1000V

Figure 3: Outside Crimp 1000V

Fig. 1

Fig. 2

Fig. 3

millimeters (inches)

pa/AVX/Capacitors/Ceramic/Disc/AVX_Disc_Ceramic_Capacitors_Dielectric_classIII-html.html

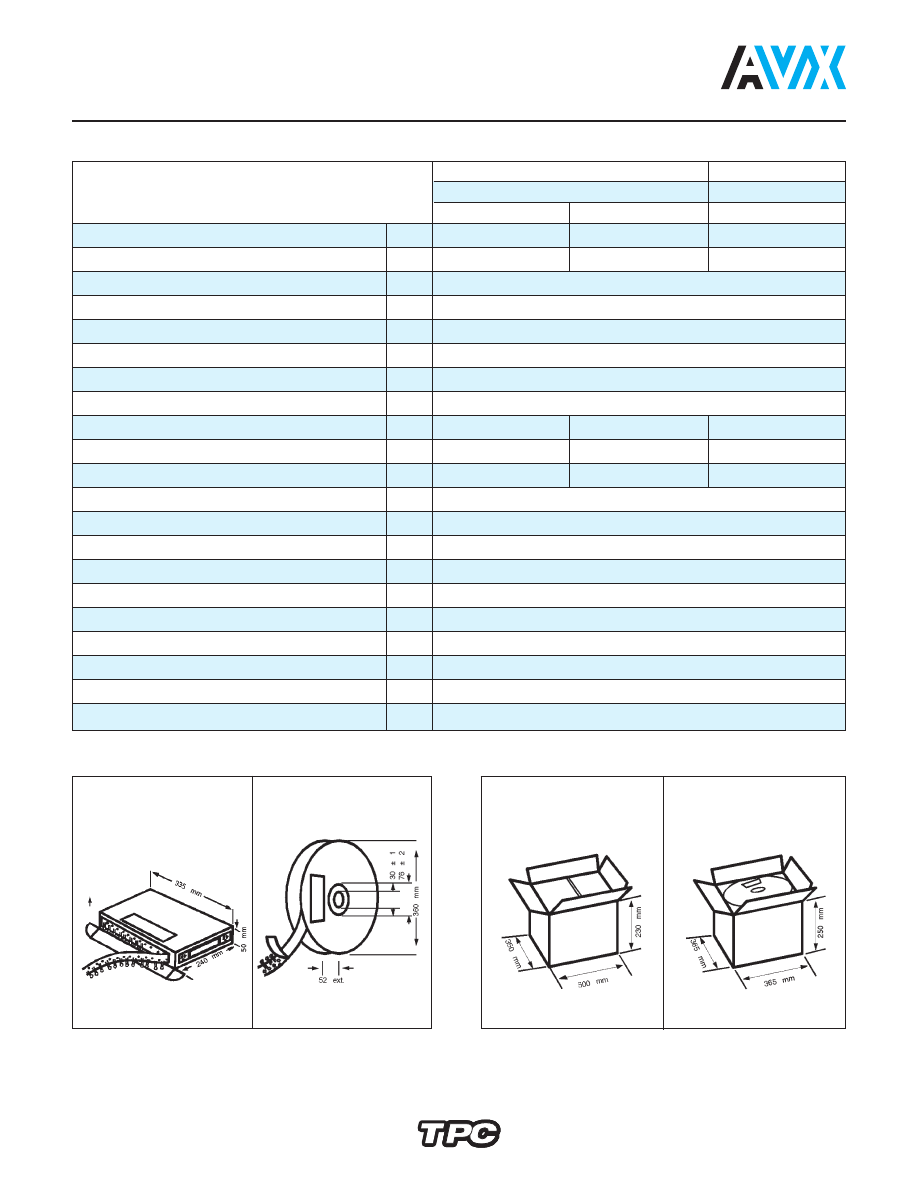

31

Disc Ceramic Capacitors

Tape and Reel Specifications

Straight Leads

Crimped

Figure 1

Figure 2 & 3

Description of Symbols

A (Avisert)

P (Panasert)

Avisert & Panasert

Crimp angle

∝

—

—

20º...45º

Crimp length

C

—

—

1.7 min.

Lead diameter

d

0.60 ± 0.1

Disc diameter

D

11 max.

Lead hole diameter

Do

4.0 ± 0.2

Disc thickness

T

See Catalog

Lead spacing

F

5.0

Component alignment, front-rear

∆

h

0 ± 1

Height of component from tape center

H

19.5 ± 0.5

16.5 ± 0.5 - 0

—

Height from tape center to crimp

Ho

—

—

16 + 0.5 - 0

Component height

H1

32.25 max.

32.25 max.

Distance from component leads to tape bottom

ᐍ

1

12 max.

Tape width

W

18

Bonding tape width

W

3

5.5 min.

Feed hole position

W

1

9.0 ± 0.5

Pitch between discs

P

12.7 ± 1

Feed hole pitch

Po

12.7 ± 0.3

Hole center to lead

P1

3.85 ± 0.7

Feed hole center to component center

P2

6.35 ± 1

Tape + bonding tape thickness

t

0.7 ± 0.2

Total tape thickness. including lead

t

2

1.5 max.

millimeters (inches)

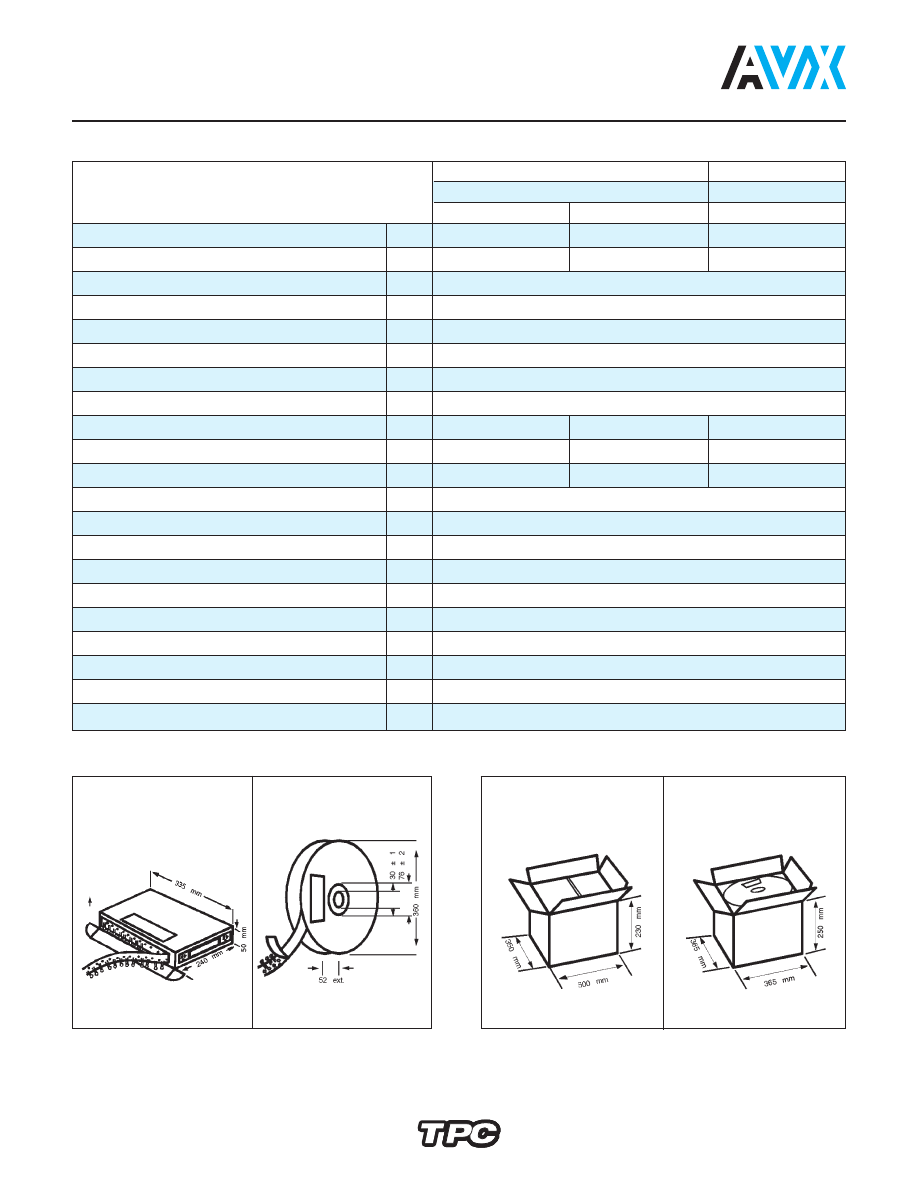

PACKAGING

SHIPPING CONTAINER

Ammopack

Reel

max. stacking: 10 boxes

max. stacking: 10 reels

8 Ammopack

5 Reel

This side up

during storage

and transportation

+0.6

-0.2

+1

-0.5

>23.5

<32.25