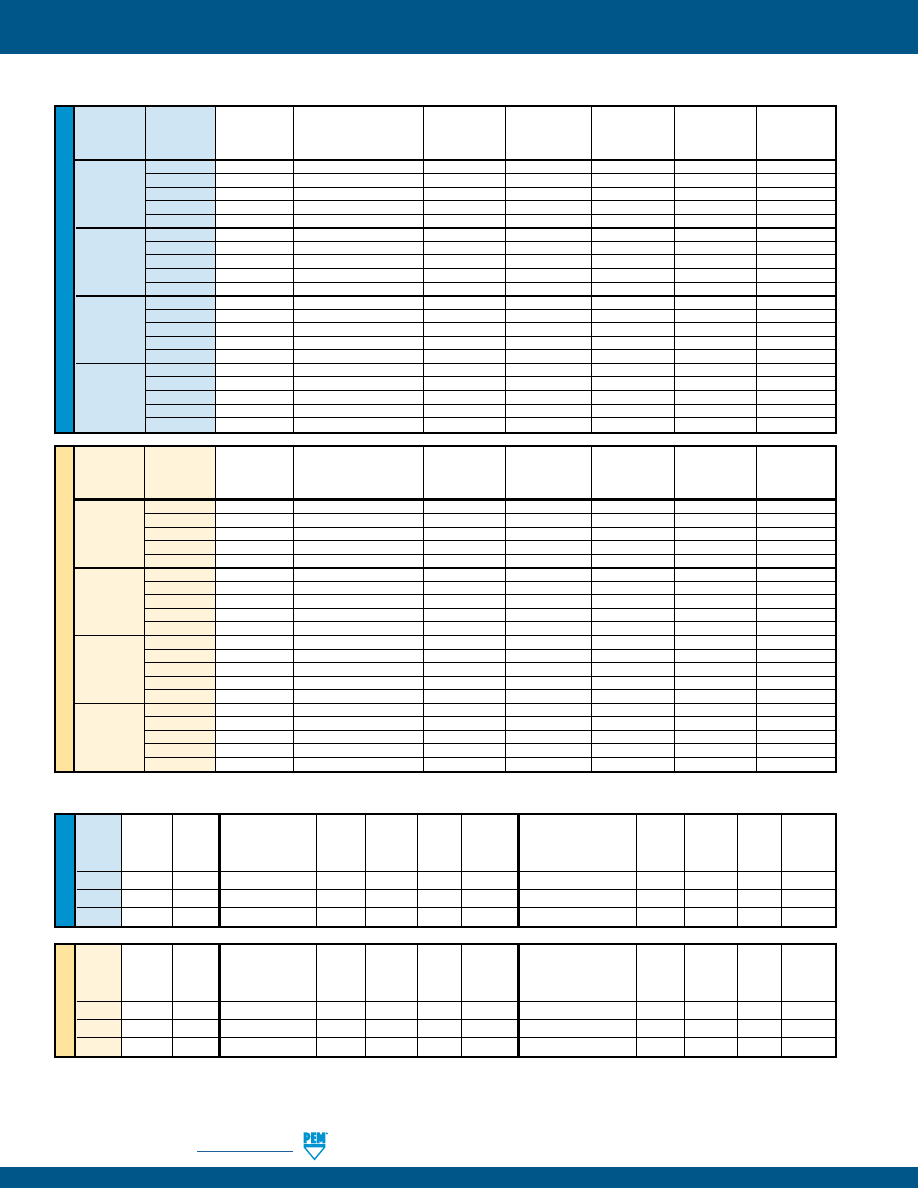

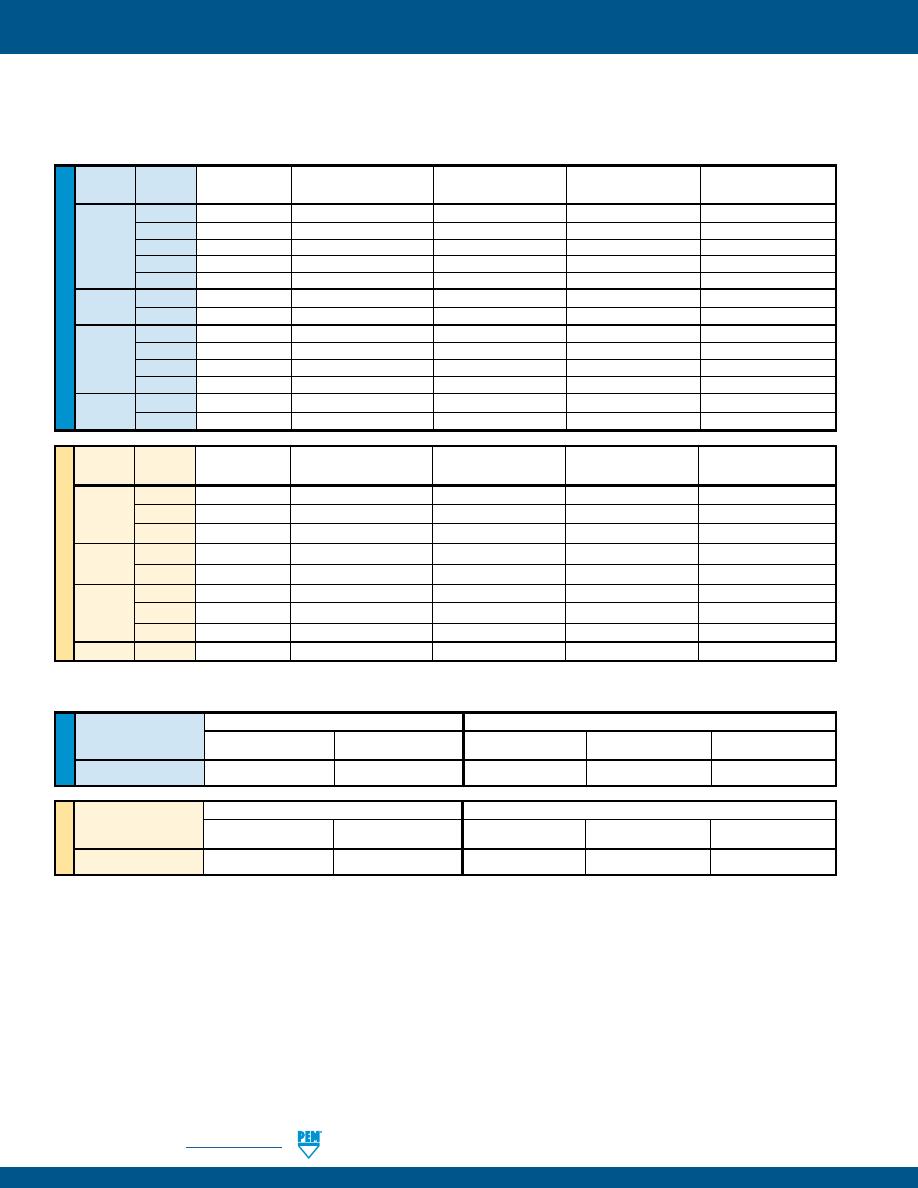

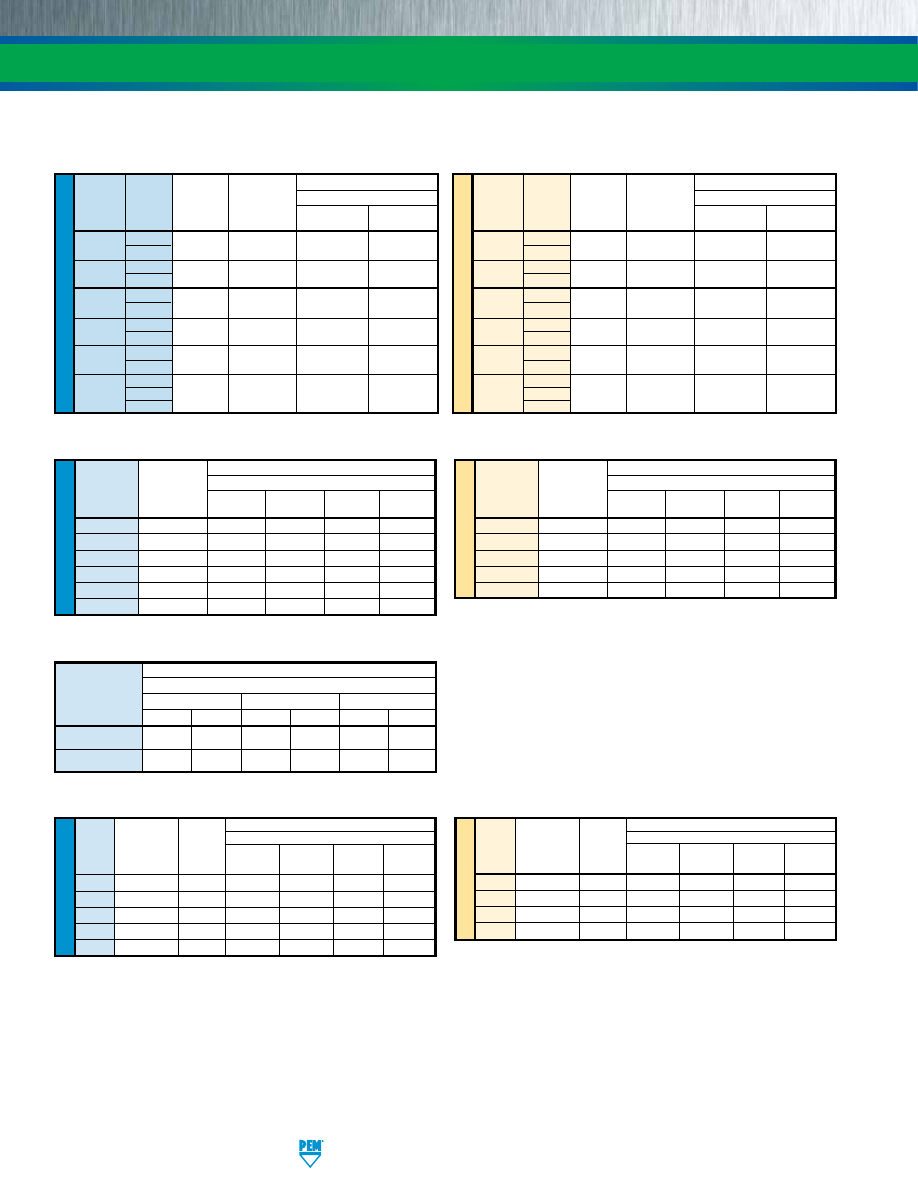

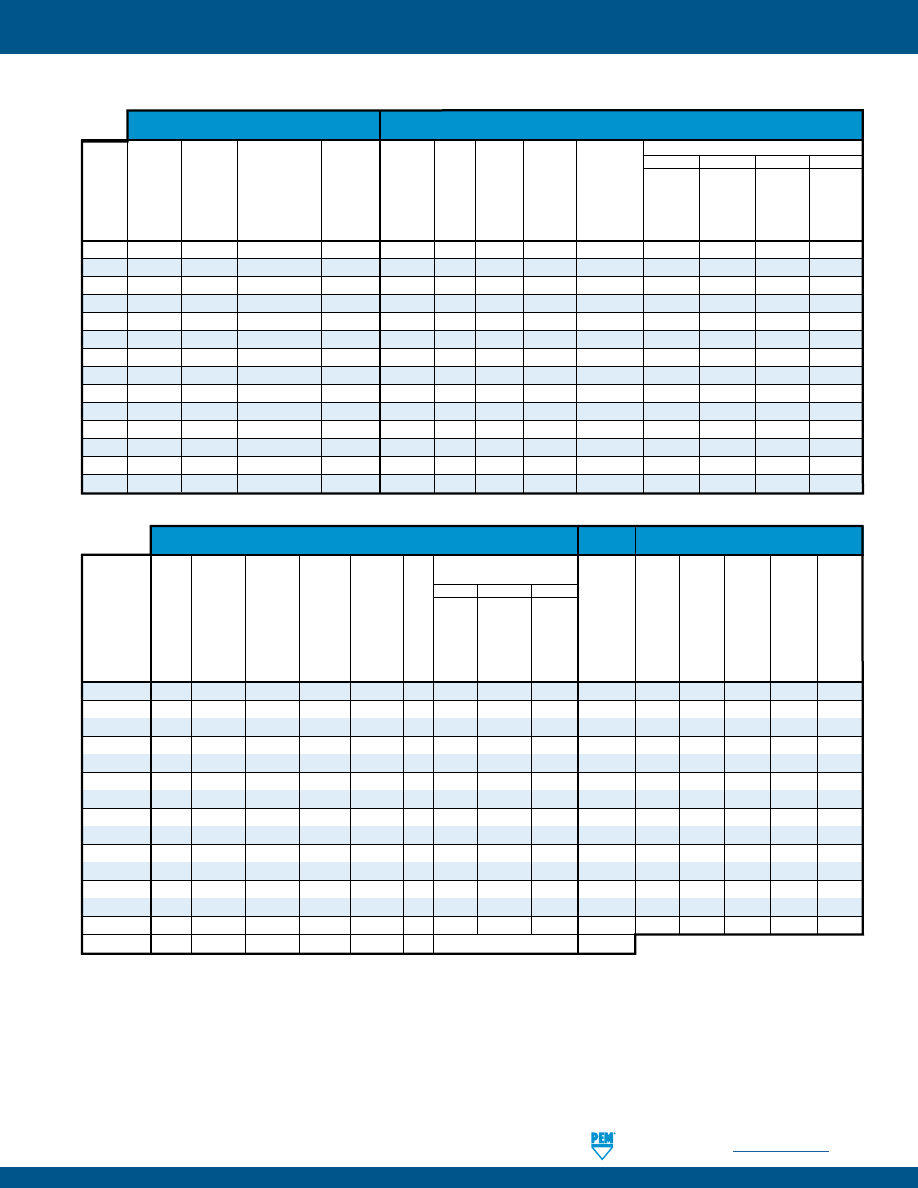

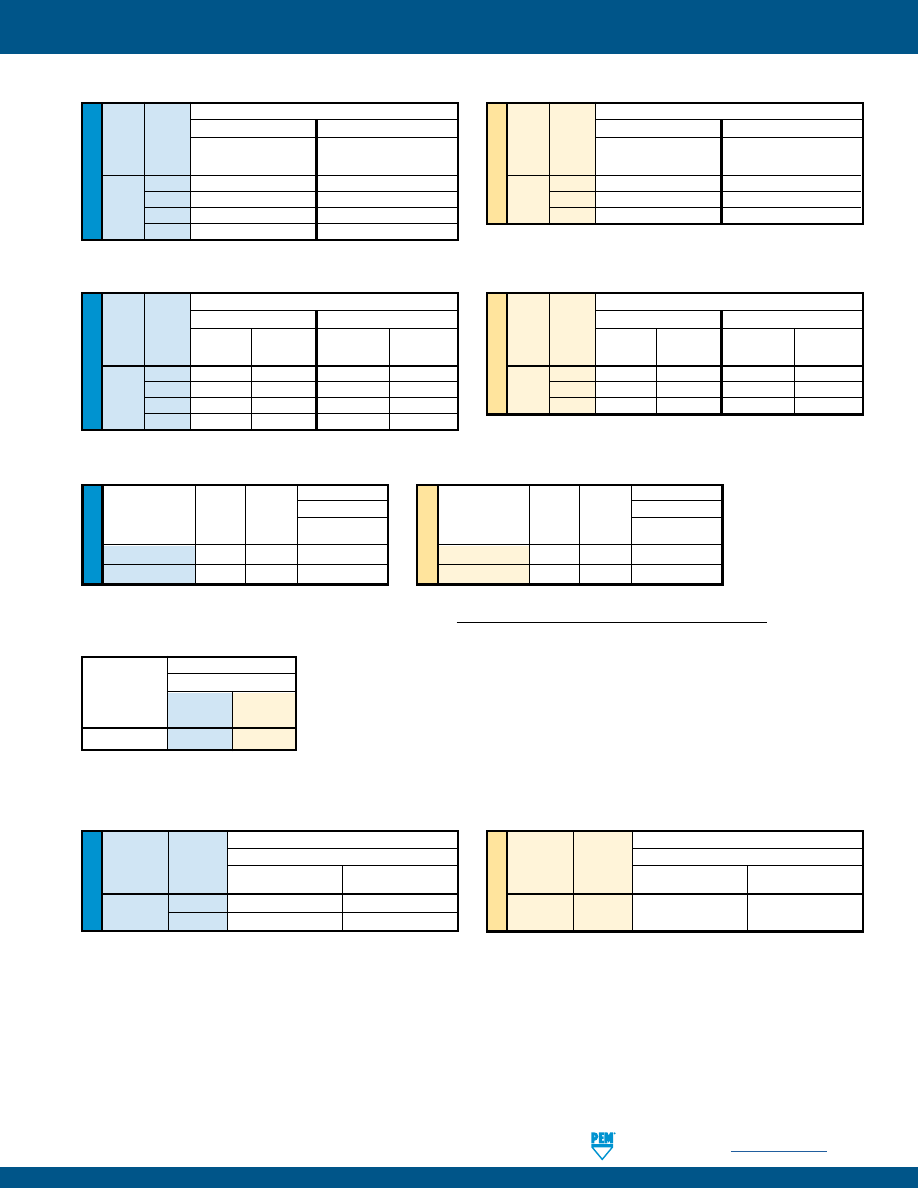

INDEX

QUICK PRODUCT

LOCATOR

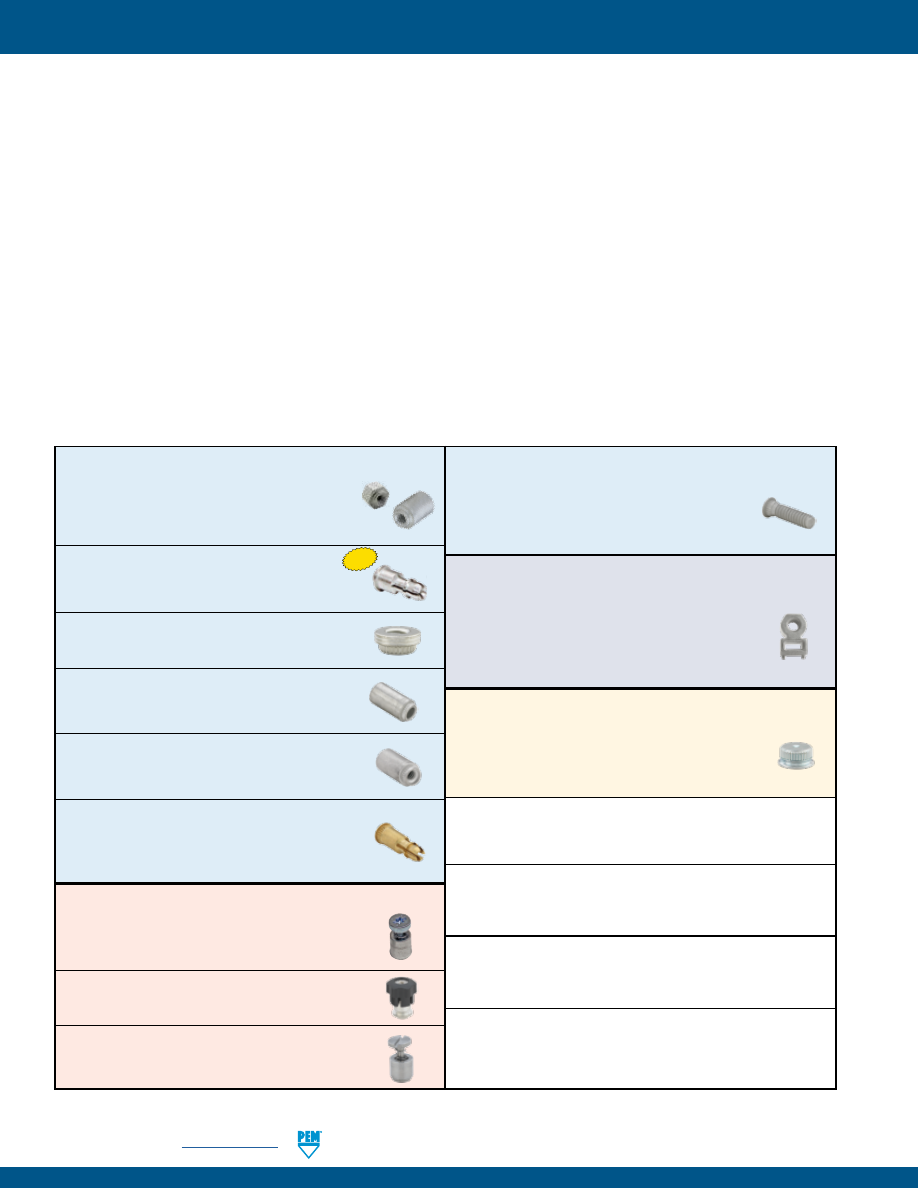

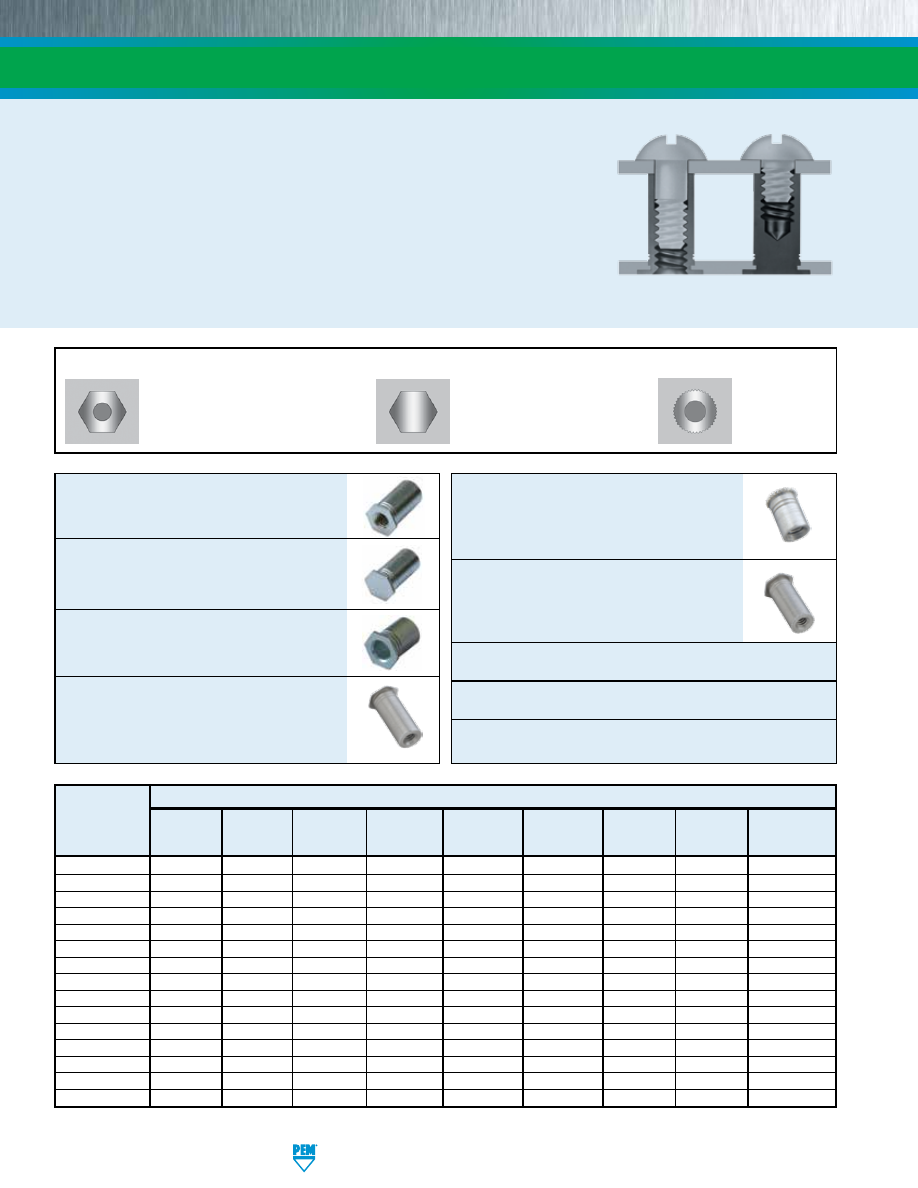

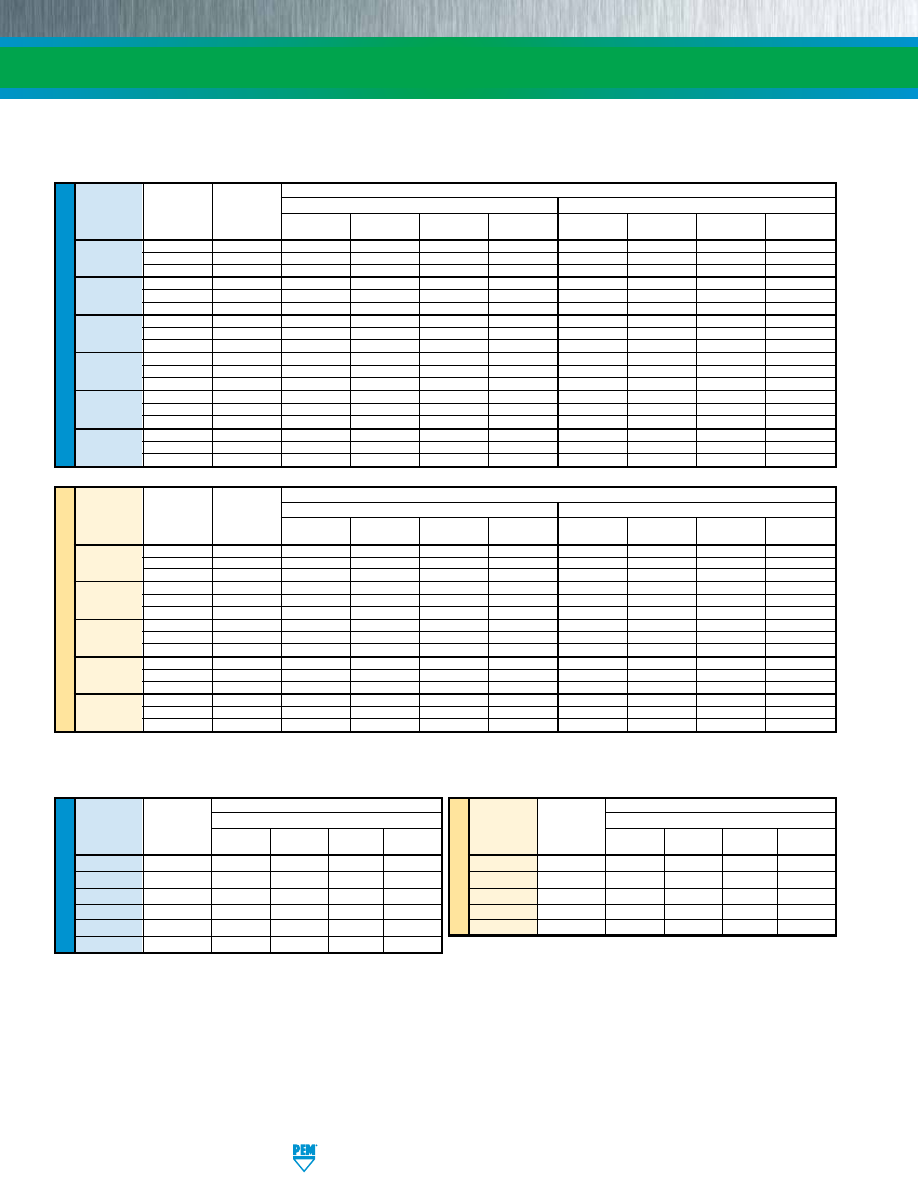

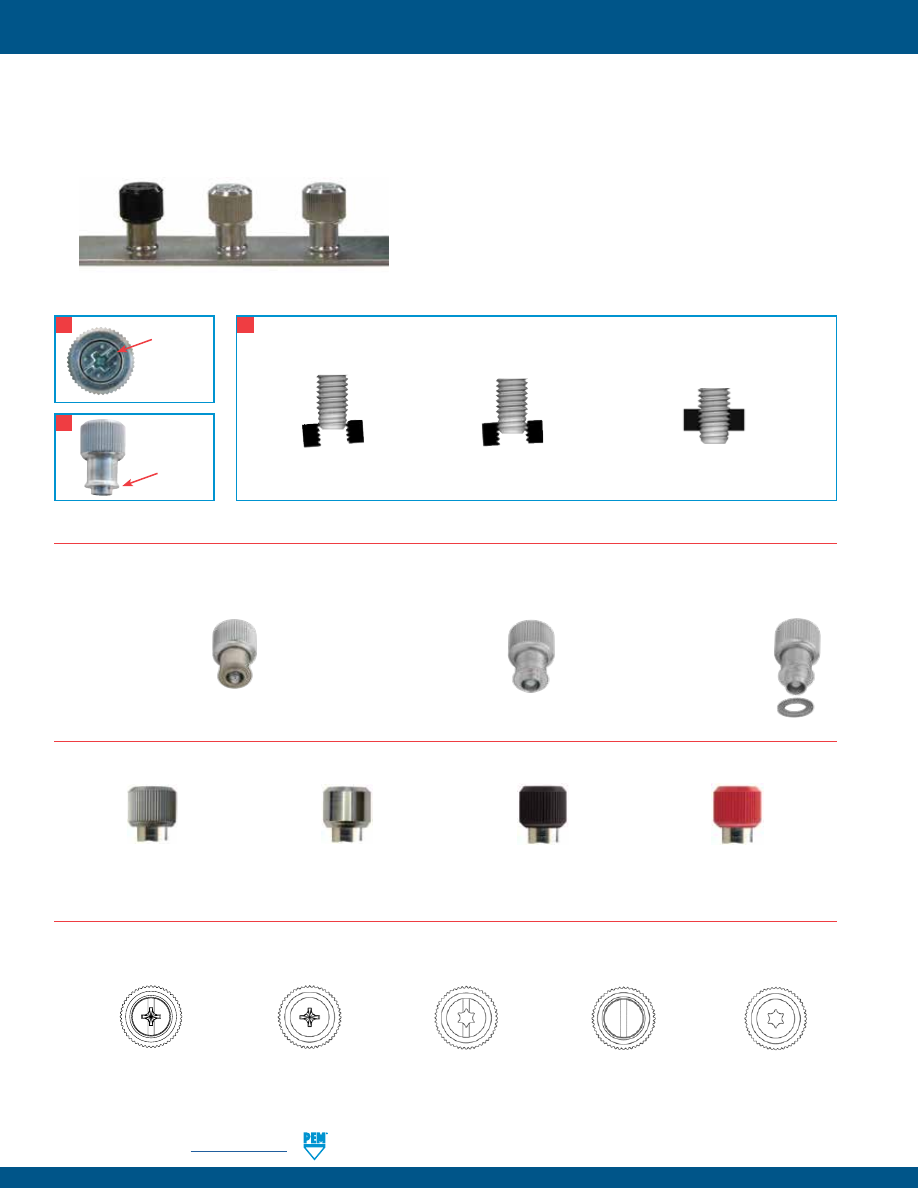

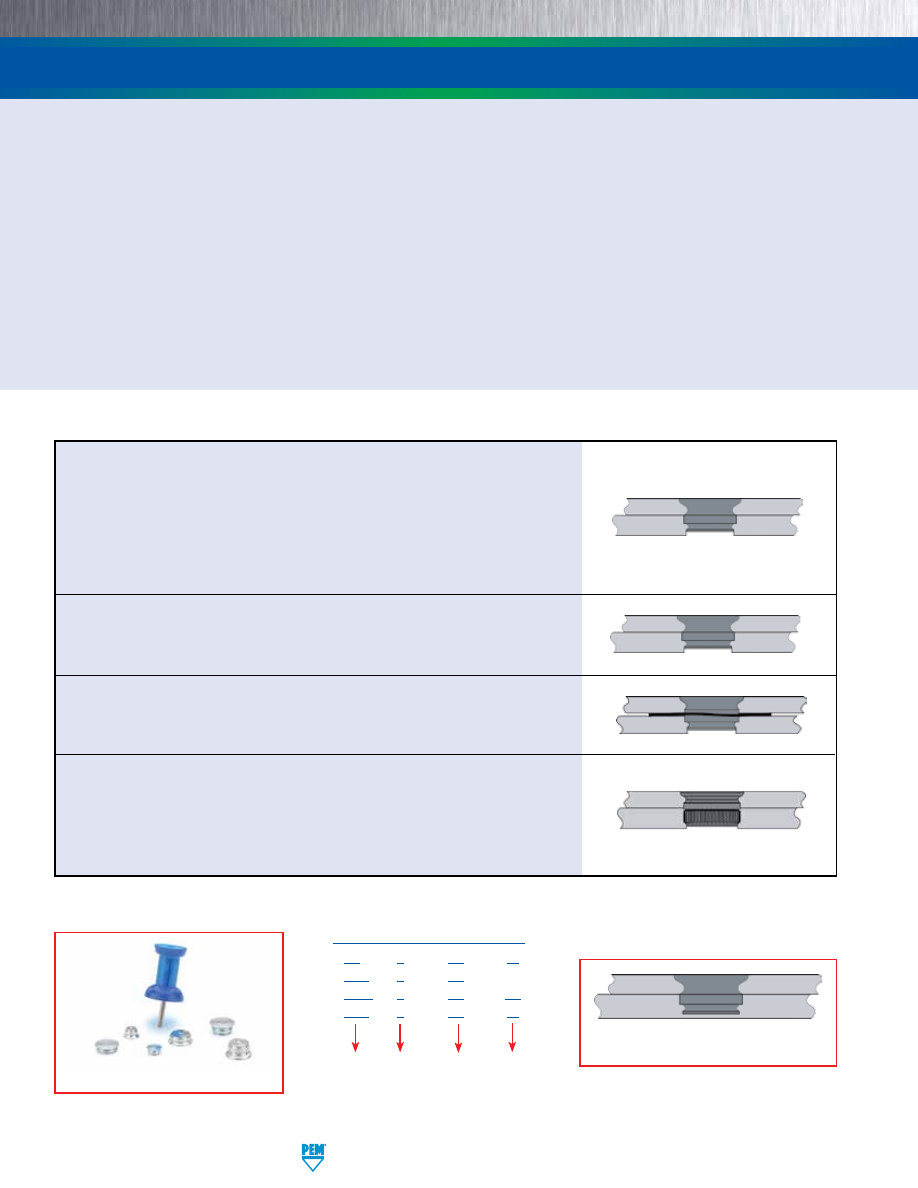

PEM® brand fasteners utilize self-clinching,

broaching, flaring, surface mount, bonding

or weld technology to provide strong,

reusable, and permanent threads and

mounting points in thin sheet metal, P.C.

board or other rigid materials.

Bulletin INDEX-118

pem-html.html

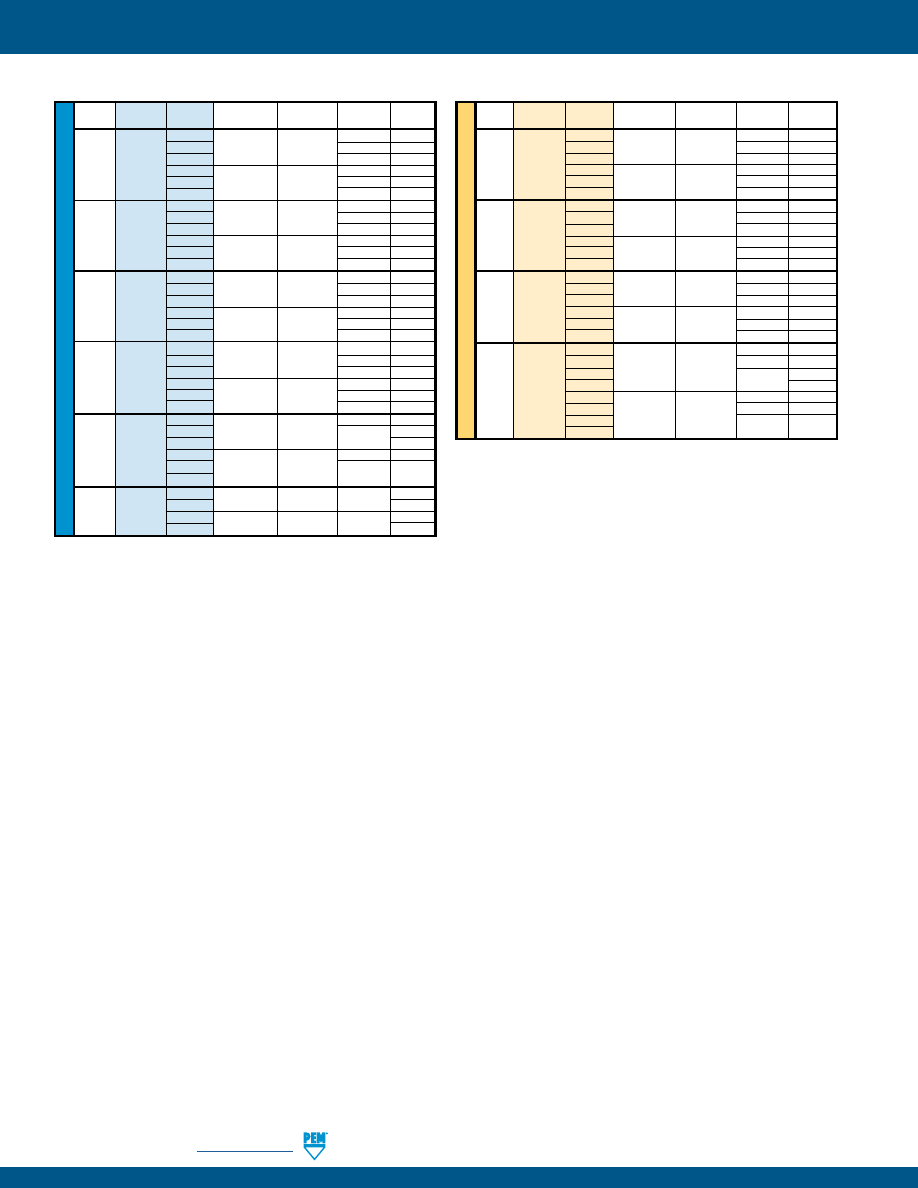

To help you identify genuine PEM® brand fasteners, most are marked by one of our trademarks or identifiers. Genuine PEM fasteners can only be

purchased from one of our authorized worldwide distributors. For a complete listing of these distributors, check our web site:

www.pemnet.com.

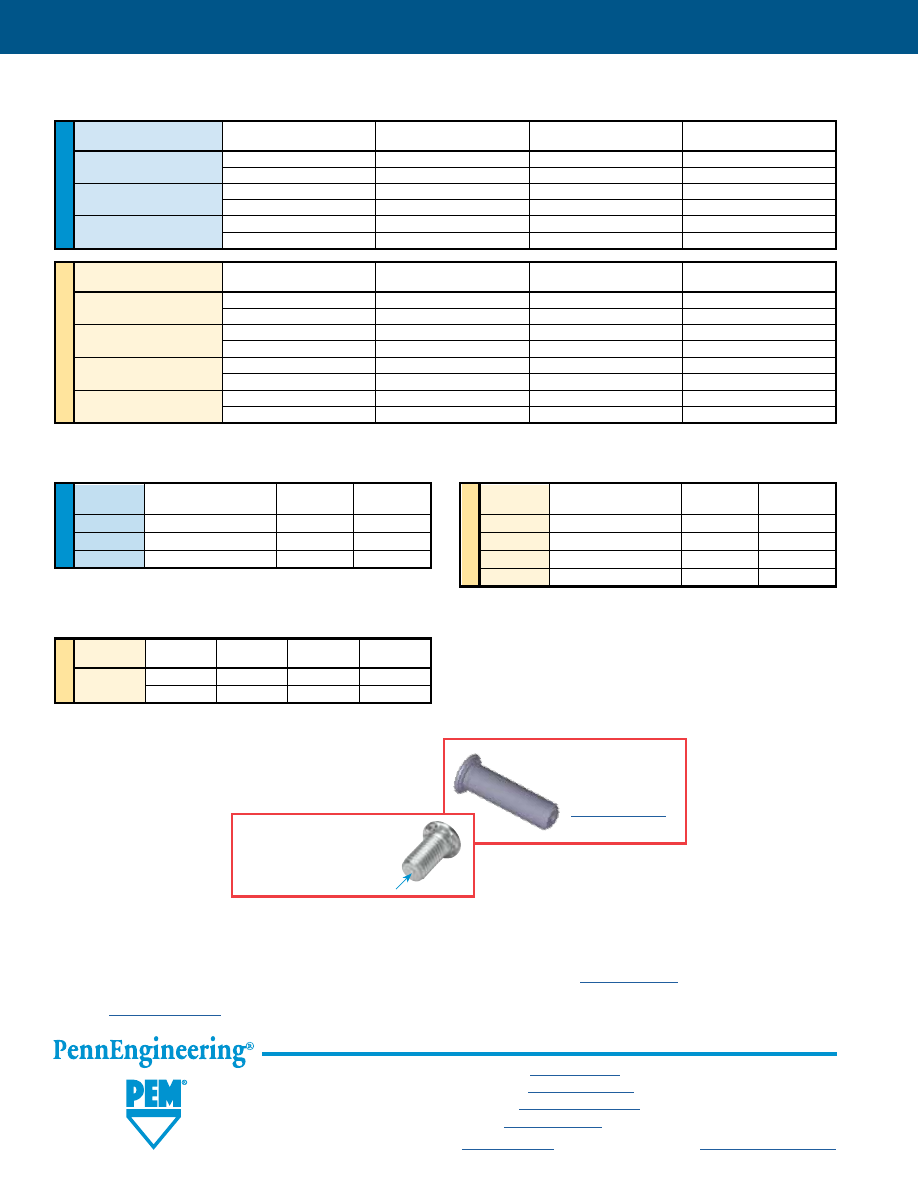

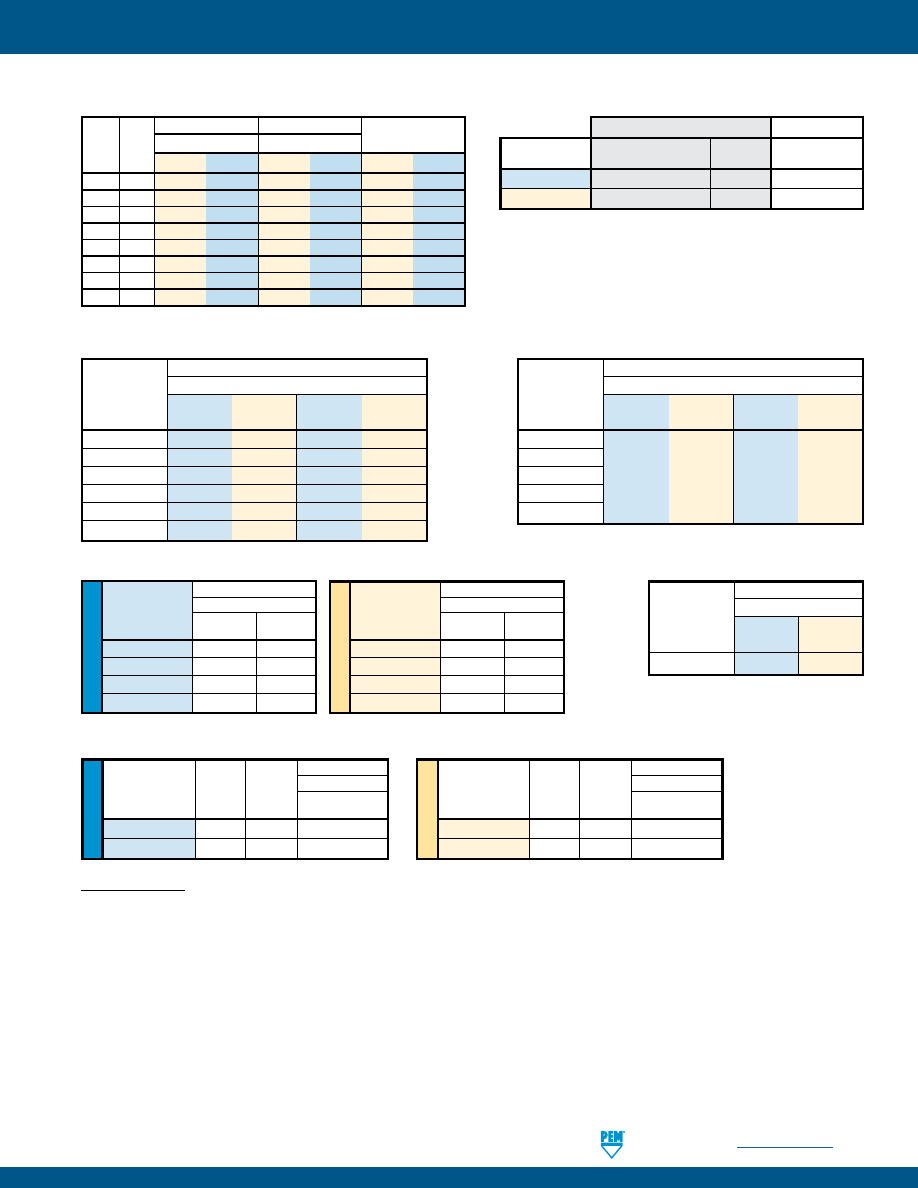

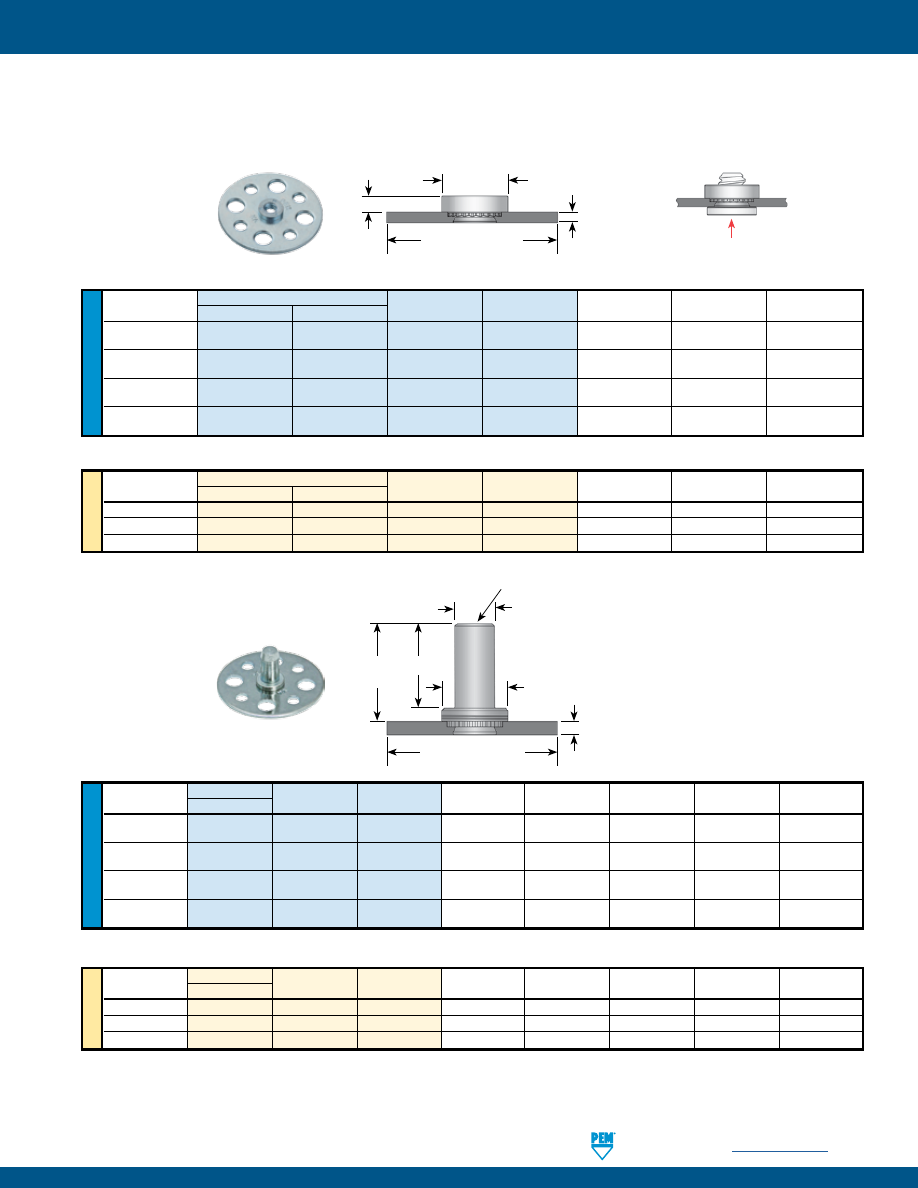

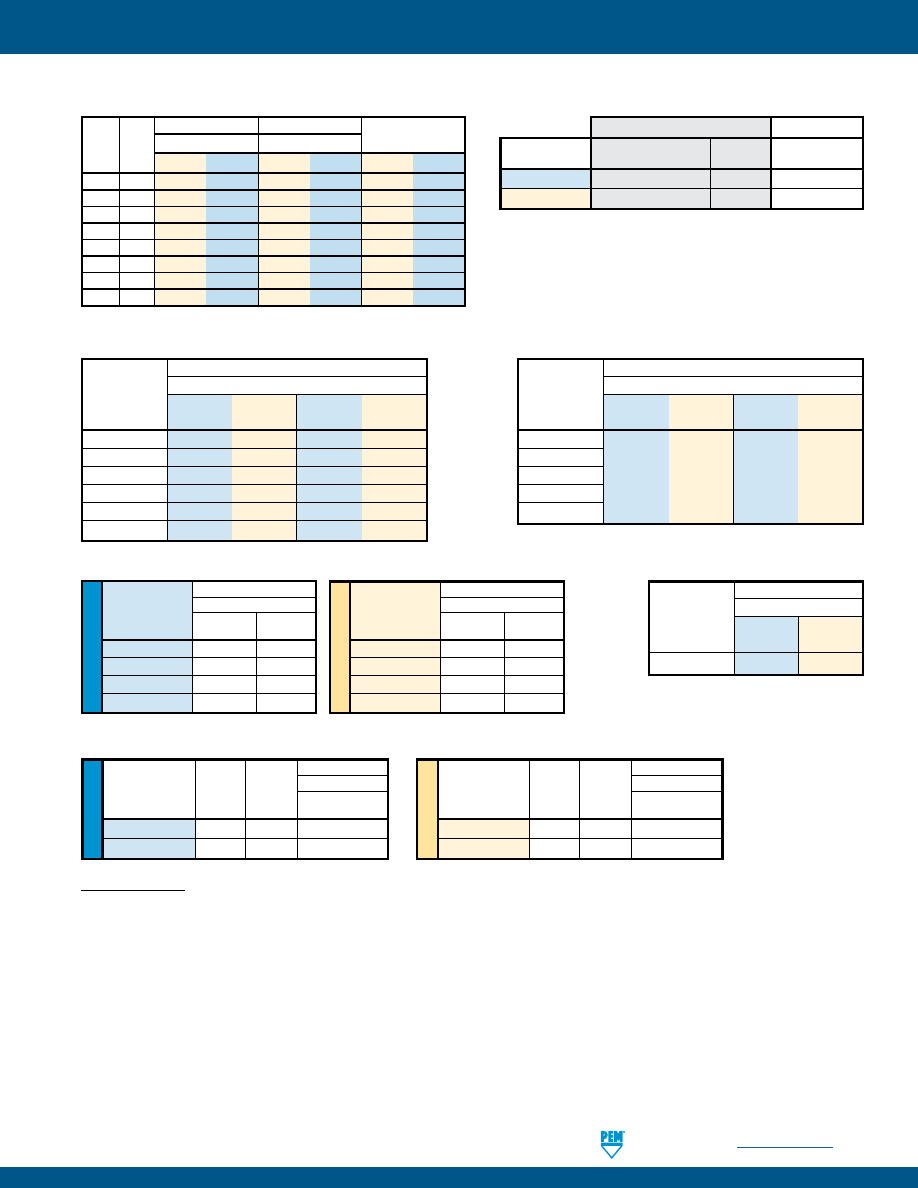

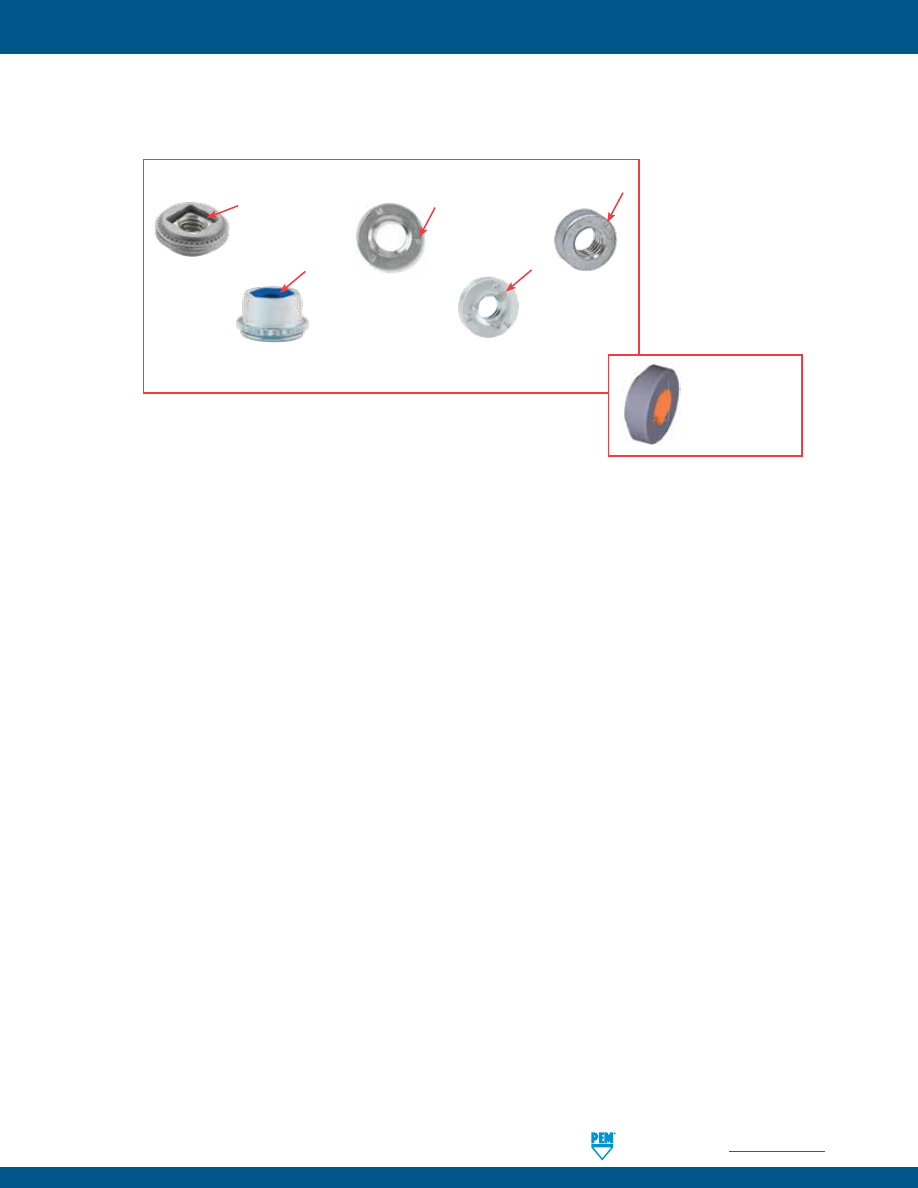

PEM® FASTENER IDENTIFICATION MARKS

Trademark ATLAS® AE Stamp

MaxTite® and Plus+Tite® products

Trademark PEM® Skirted Shoulder

PF11, PF11M, PF11MF, PF11MW, PF11PM,

PF12, PF12M, PF12MF,

PF12MW, PF7M, and PF7MF fasteners

Trademark

PEM® C.A.P.S.®

Dot Pattern

PF11PM fastener

Trademark PEM® Dimple

CFHA, CFHC, CHA, CHC, FH, FH4, FHA, FHL, FHLS, FHP, FHS, FHX, HF109, HFG8, HFE, HFH,

HFHB, HFHS, HFLH, HSCB, KFH, KSSB, MPP, PF10, PF30, PF31, PF32, PF50, PF51, PF52, PF60, PF61,

PF62, PF11, PF11M, PF11MF, PF11MW, PF11PM, PF12, PF12M, PF12MF, PF12MW, PF7M, PF7MF, PFC2,

PFC2P, PFC4, PFHV, PFK, PFS2, PSHP, SCB, SCBJ, SCBR, SF, SFK, SFP, SFW, SGPC, SKC, SKC-F,

SMTPFLSM, SSA, SSC, SSS, T, T4, TFH, TFHS, THFE, TK4, TKA, TP4, TPS, TPXS, and TS fasteners

Trademark PEM®

“Single Groove”

A4, BSO4, LA4, MSO4, PFC4,

SO4, SP (Select sizes), and

TSO4 fasteners

Trademark PEM®

“Two Groove”

B, BS, BSO, BSON, BSOS, CSOS, CSS,

DSO, DSOS, HSR, KF2, KFB3, KFE, KFS2,

KFSE, PF7M, PF7MF, SMTSO, SMTSOB,

SMTPFLSM, SO, SOA, SOAG, SON, SOS,

SOSG, TSO, TSOA, and TSOS fasteners

Trademark PEM®

“Double Squares”

A4, AC, AS, LA4, LAC, and LAS

fasteners

Trademark PEM® Blue Nylon

Locking Element

PL, PLC and CFN fasteners

Trademark PEM®

Circle on Pedestal

RAS fastener

Trademark PEM® Double Notch

microPEM® SMTSO fastener

Trademark PEM® Stamp

CLS, CLSS, H, HN, HNL, PSHP,

S, SFN, SL, SMPP, SMPS, SS,

and WN fasteners

Trademark PEM

VM® Stamp

(Both Sides)

VariMount™ Base Plates

Trademark PEM® SP Stamp

SP fasteners

Trademark PEM® SH Stamp

SH fasteners

PEM® Blue Nylon Ring

PFC4, PFC2P, PFC2, PFS2,

and PFK fasteners

PEM® RT Stamp

S-RT fasteners

INDEX-2

PennEngineering •

www.pemnet.com

pem-html.html

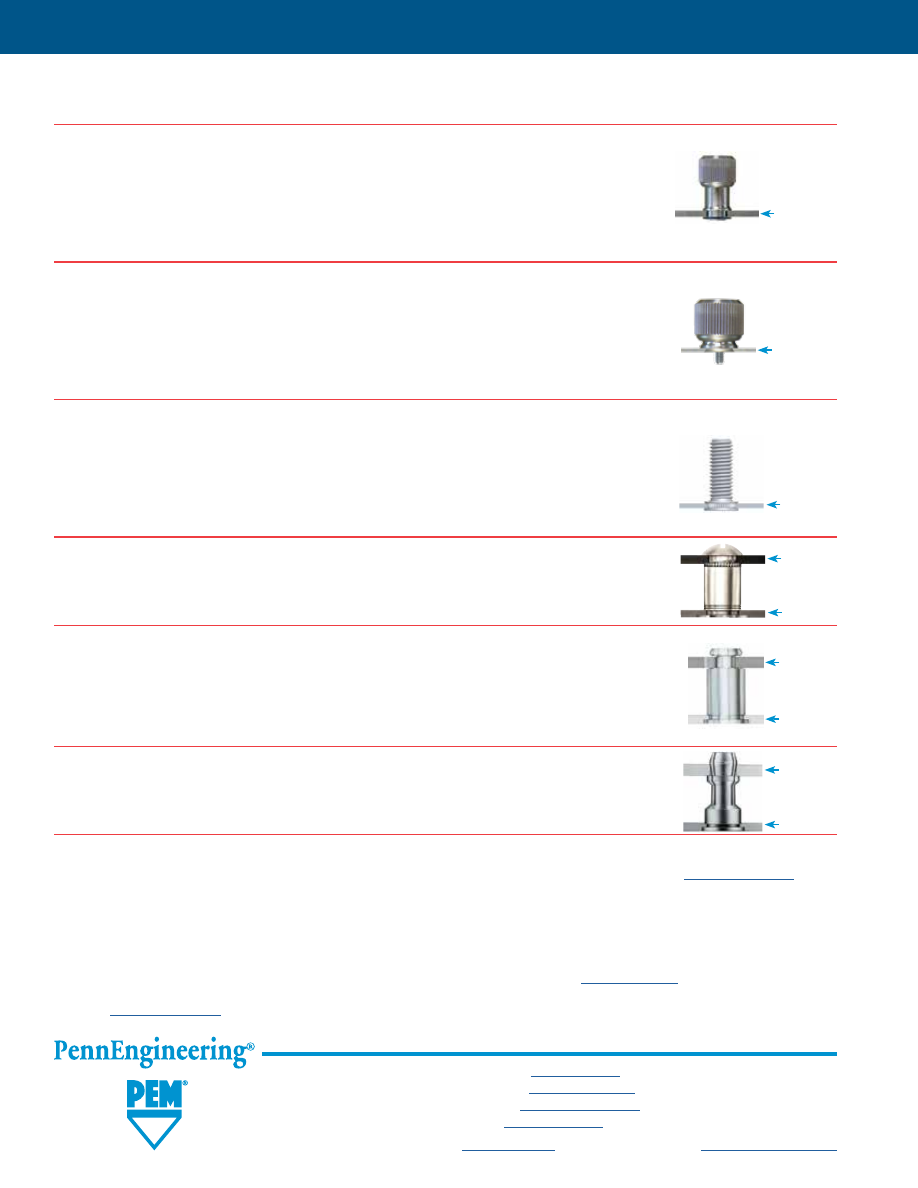

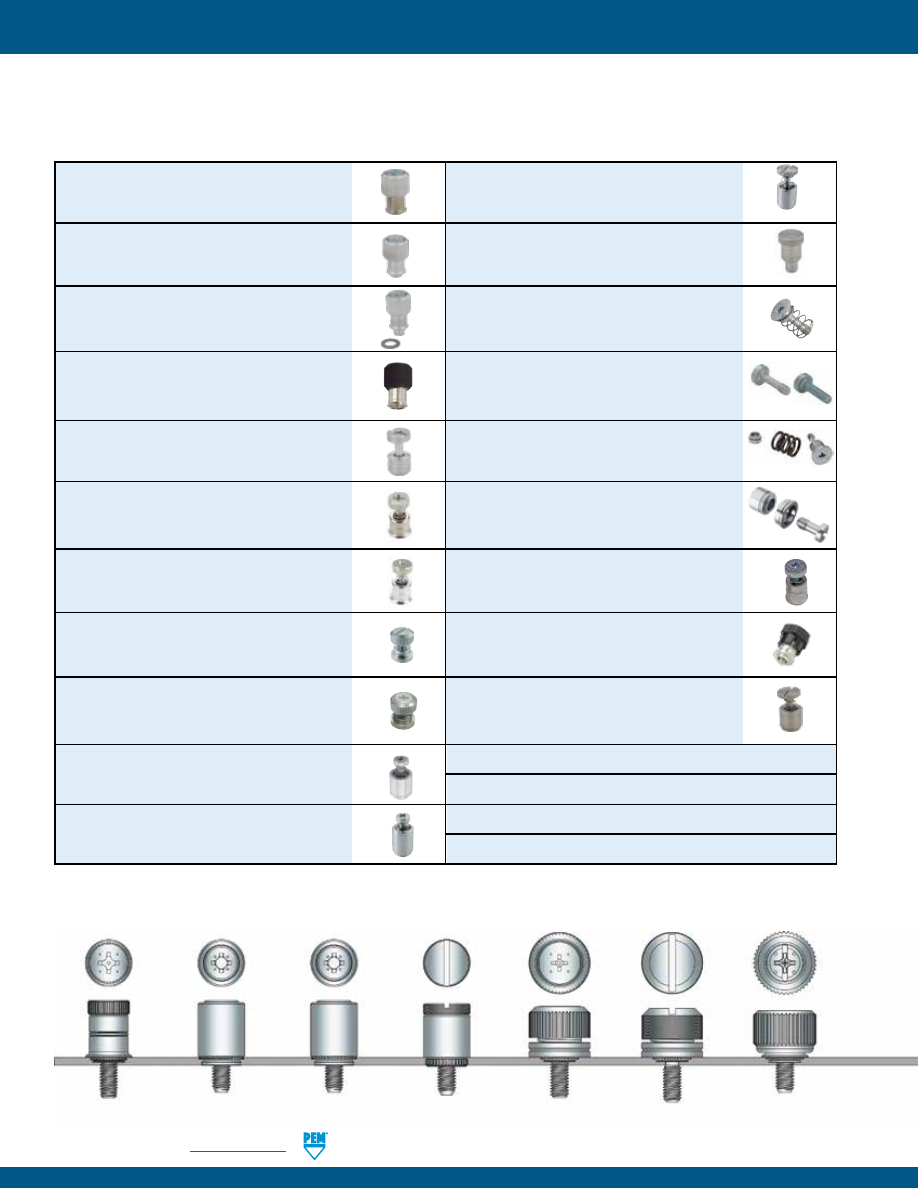

HFH, HFHB, HFHS

Bulletin FH

Studs for high-strength applications with high pull through

resistance.

Nuts with load-bearing, non-locking threads that permits up

to .030”/0.76mm adjustment for mating hole misalignment.

A4, AC, AS

Bulletin ALA

B, BS

Bulletin B

Nuts used in applications requiring closed thread ends. Blind

end limits screw penetration and excludes foreign matter.

BSO, BSO4, BSOA, BSOS

Bulletin SO

Blind threaded standoffs installed with their heads flush with

one surface of the mounting sheets.

CFN

Bulletin LN

Broaching, nylon insert, self-locking nuts for use in thinner

sheet, close-to-edge applications.

CFHA, CFHC, CHA, CHC

Bulletin CH

Concealed-head studs installed into a blind milled hole where

surface opposite stud must remain unmarred.

CLA, CLS, CLSS

Bulletin CL

Nuts that provide load-bearing threads in thin sheets with

high pushout and torque-out resistances.

CSOS, CSS

Bulletin CH

Concealed-head standoffs installed into a blind milled hole

where surface opposite standoff must remain unmarred.

DSO, DSOS

Bulletin SO

Threaded standoffs for use in close-to-edge applications.

F, F4

Bulletin F

PEMSERT® flush fasteners are flush with both sides of the

sheet.

FE, FEO, FEOX, FEX

Bulletin FE

Miniature nuts with strong threads. Available with locking or

non-locking threads.

FH, FH4, FHA, FHP, FHS

Bulletin FH

Flush-head studs with high pushout and torque-out

resistances.

FHL, FHLS

Bulletin FH

Low-displacement head studs can be installed close to the

edge of a sheet without causing the edge to bulge.

H, HNL

Bulletin CL

Nuts with self-locking or non-locking threads that provide

high pushout and torque-out resistances.

HFE

Bulletin FH

Studs designed with an enlarged head diameter to provide

high-strength in thin sheets.

SC

HF109

Bulletin FH

Property class 10.9 high tensile strength studs meeting 1040

MPa minimum.

HFG8

Bulletin FH

Grade 8 high tensile strength studs meeting 150 ksi minimum.

FHX

Bulletin FH

Flush-head studs with X-Press™ thread profile are typically

used with push-on or other plastic fasteners.

PennEngineering •

www.pemnet.com

INDEX-3

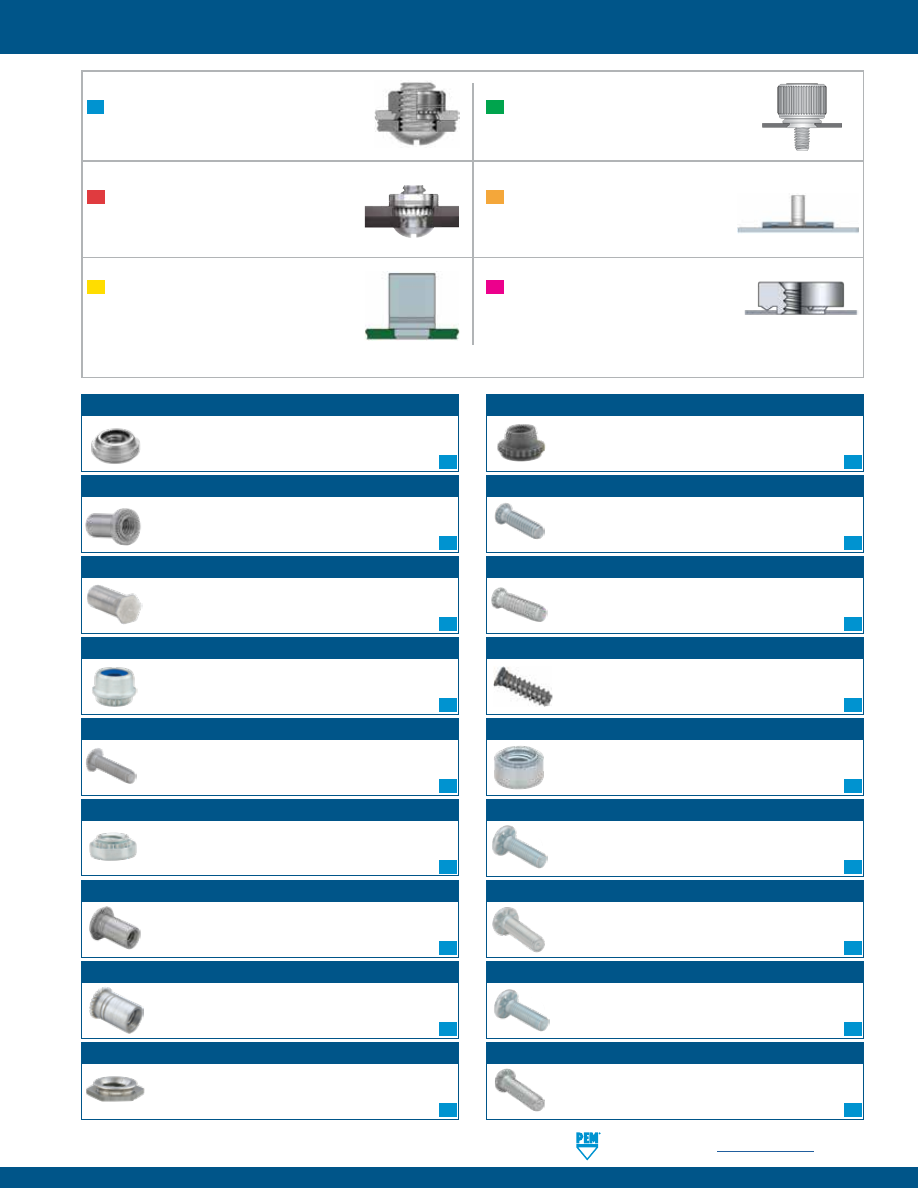

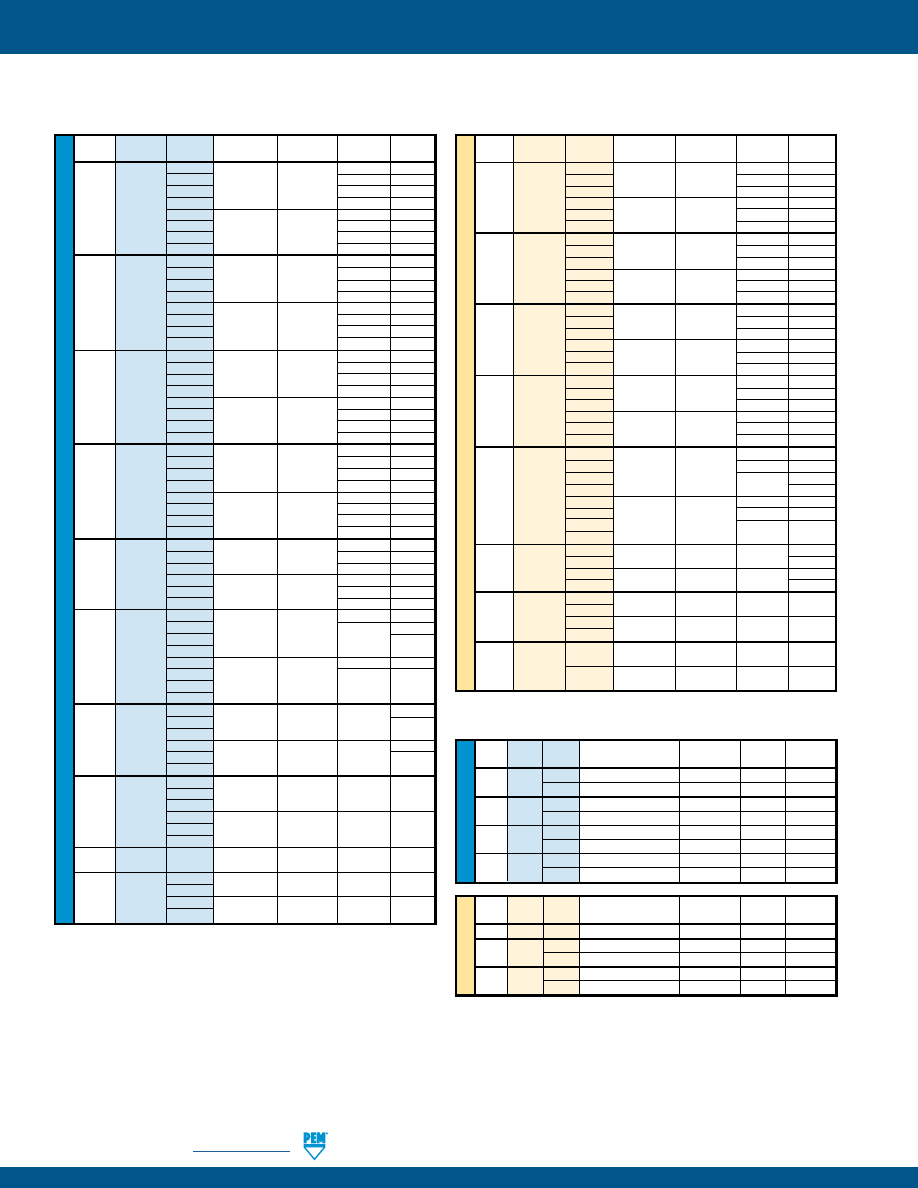

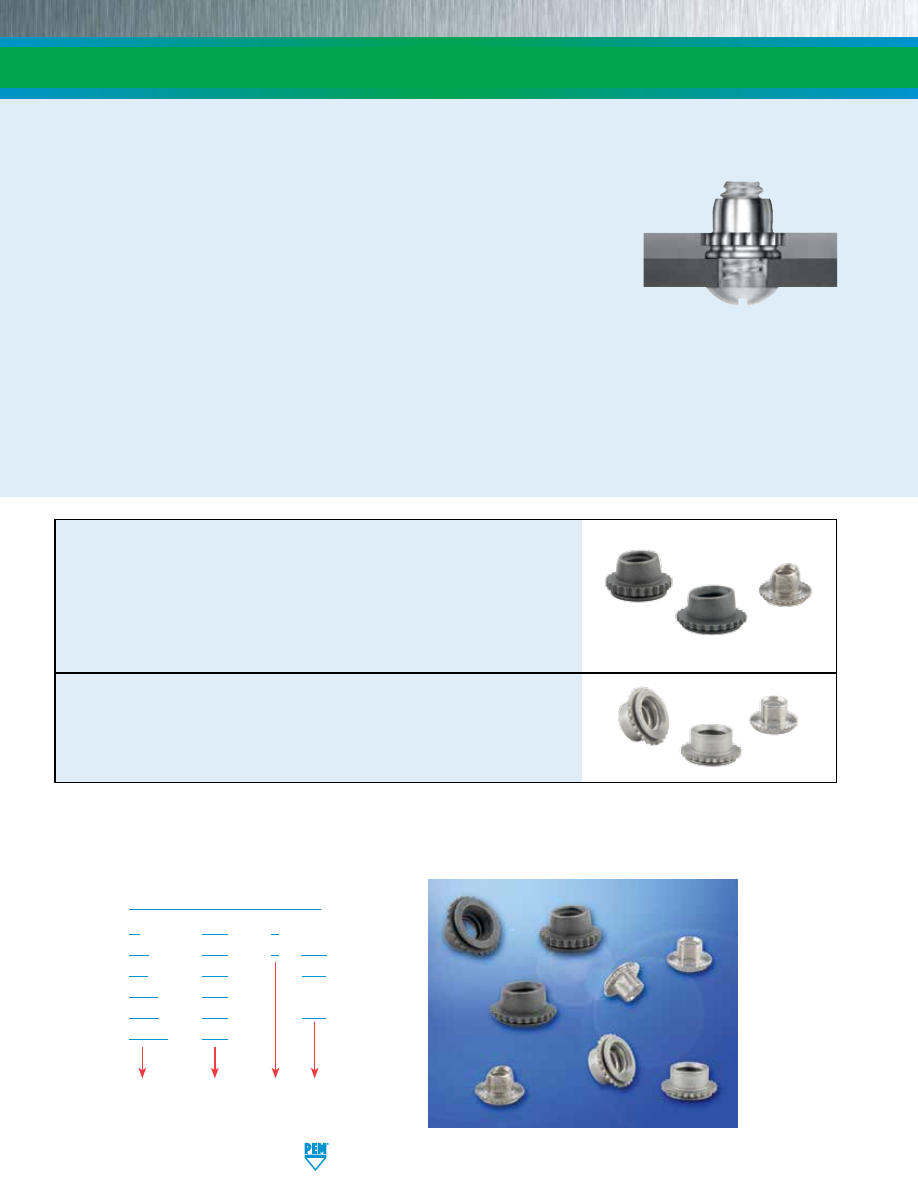

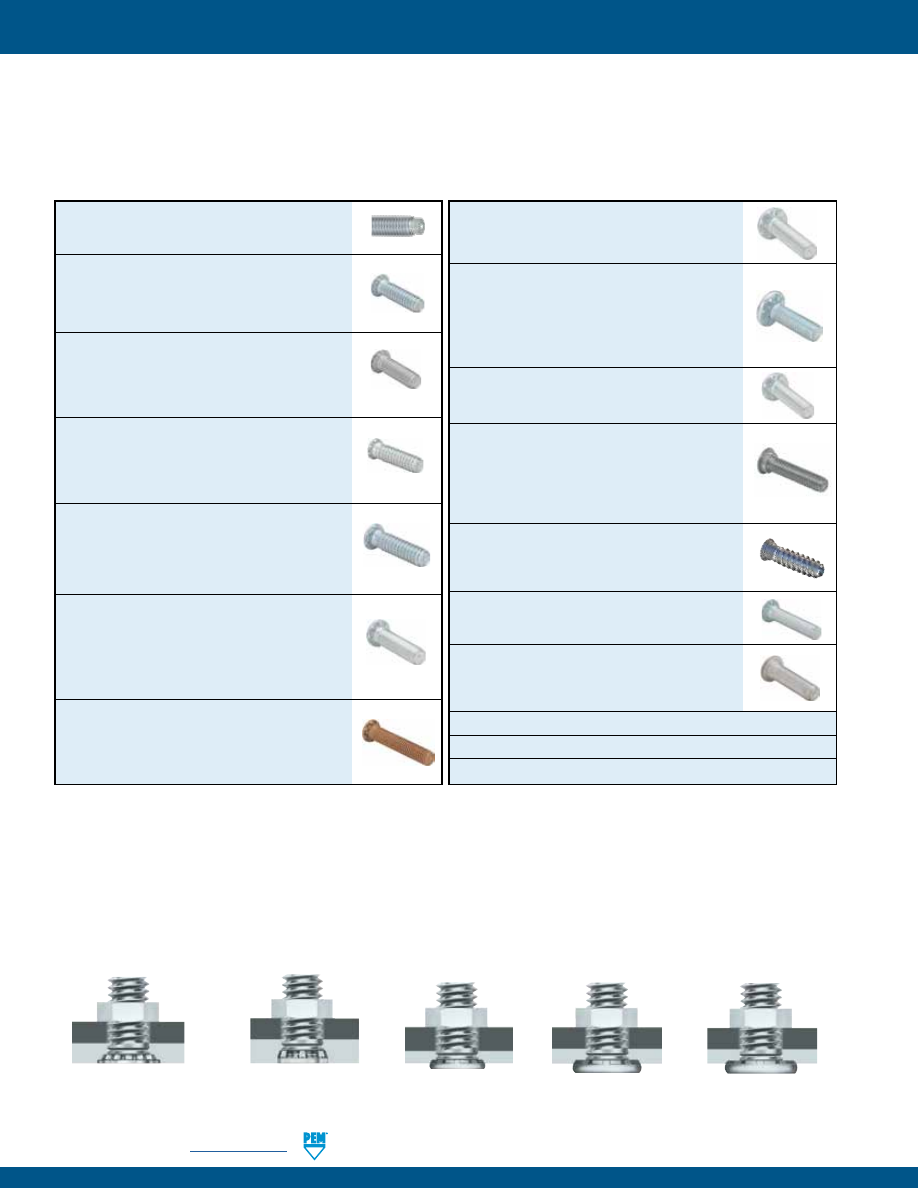

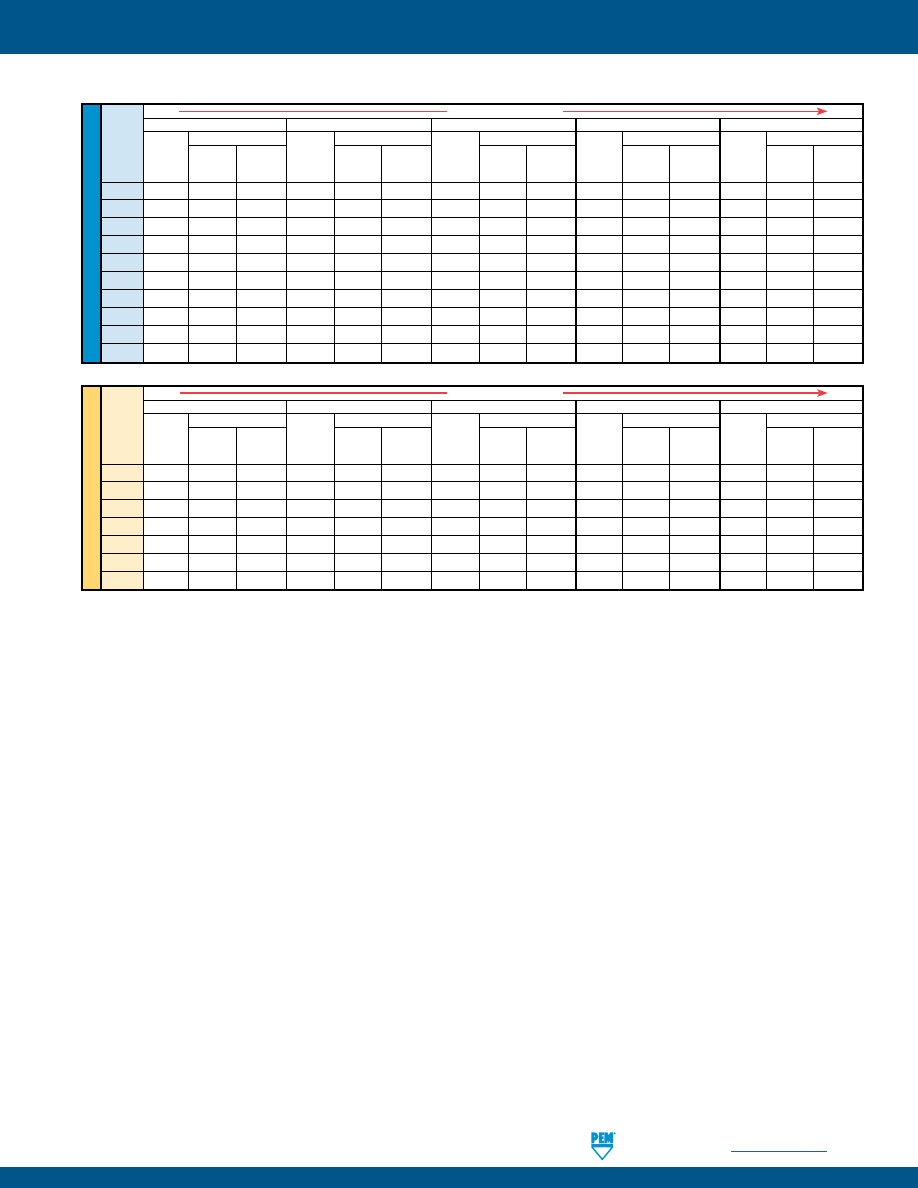

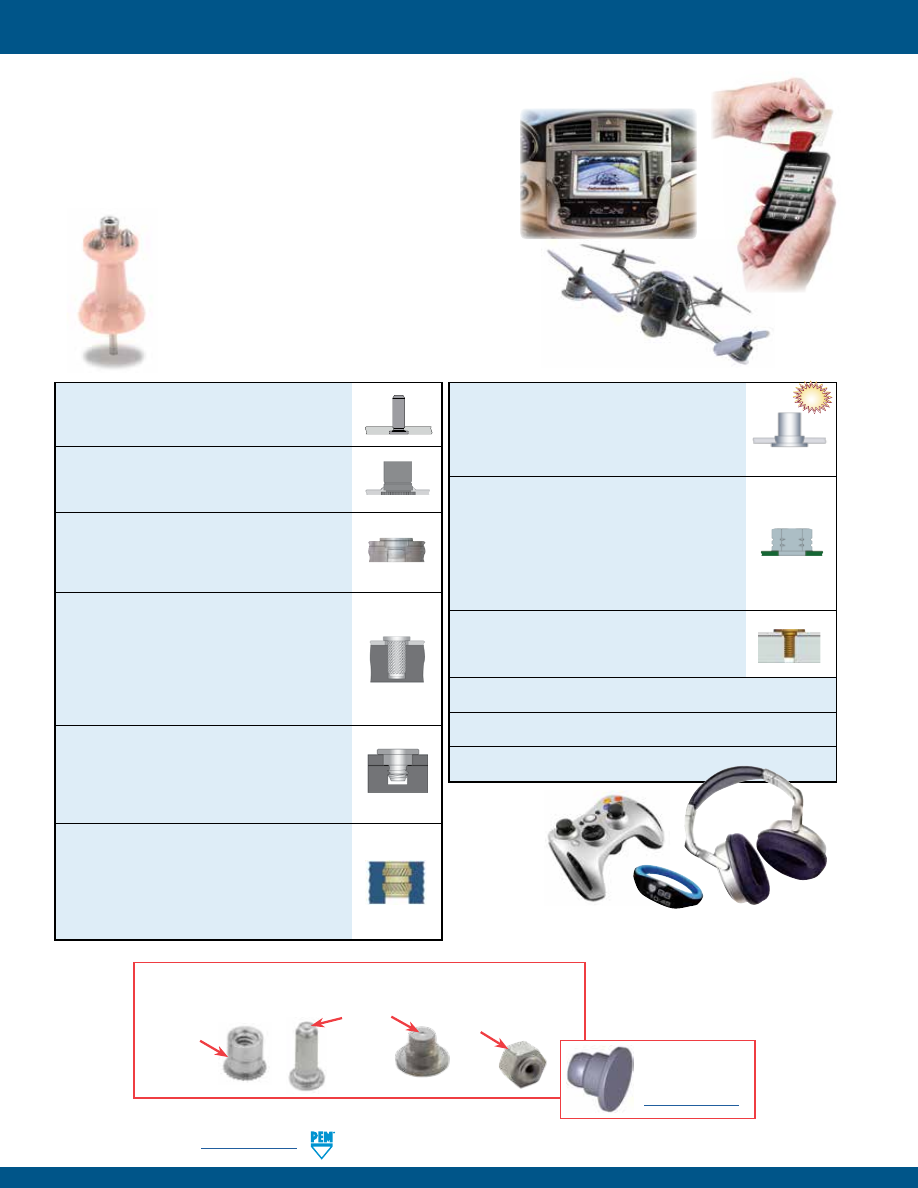

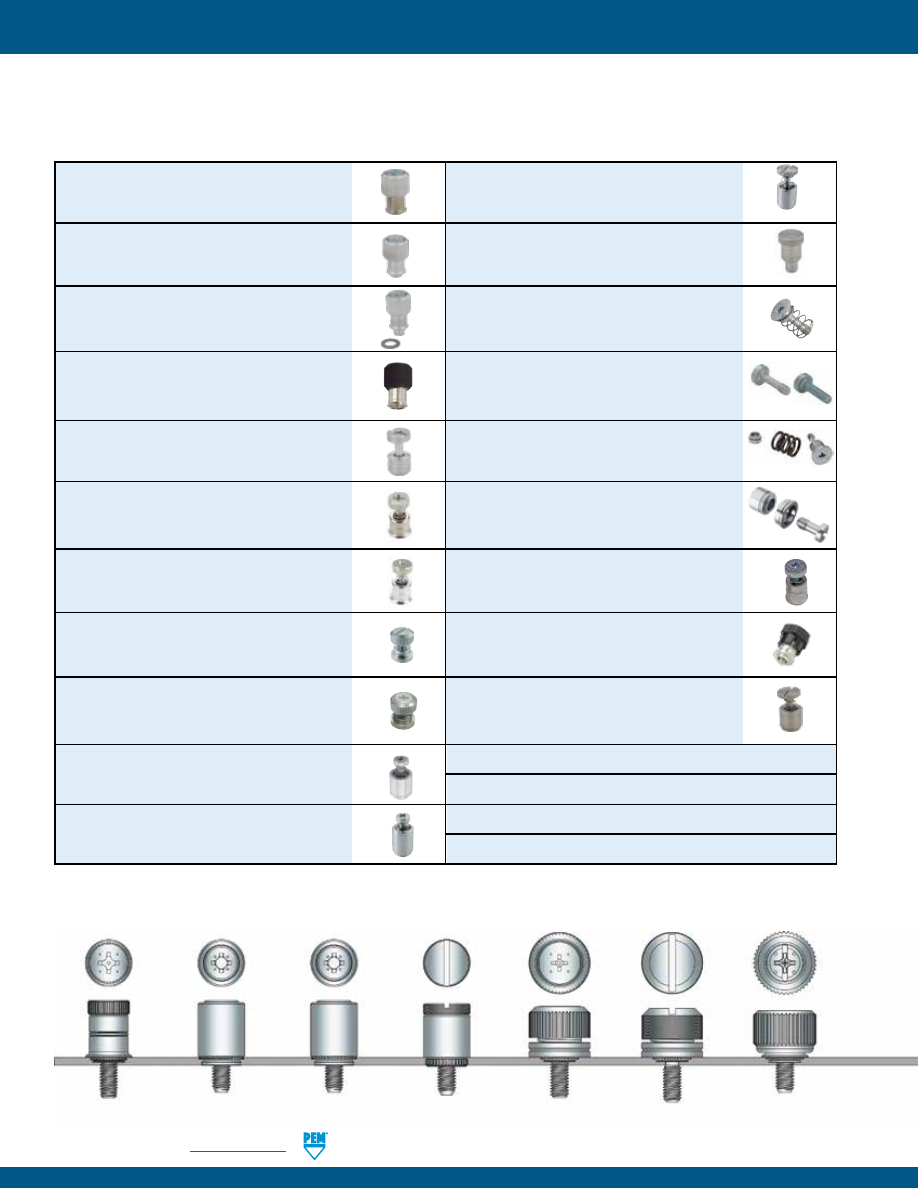

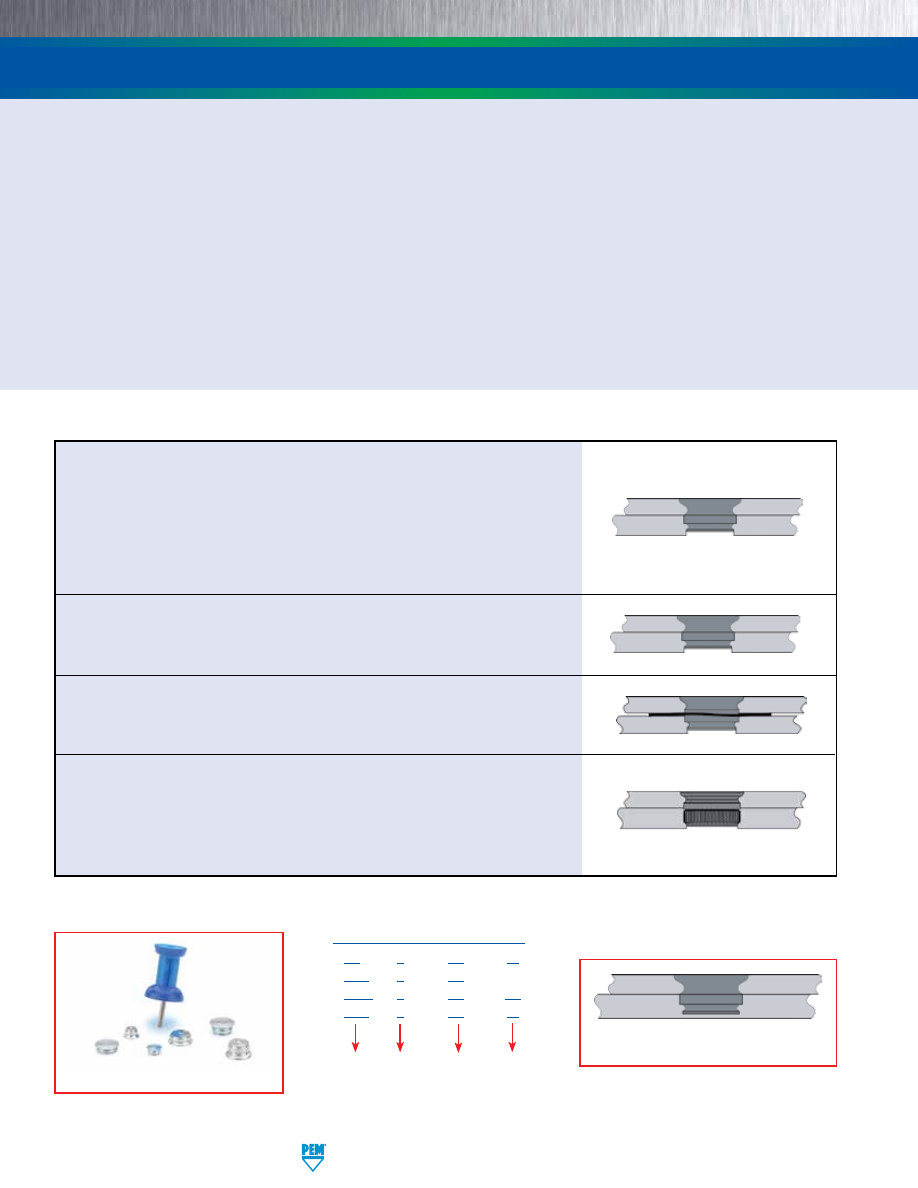

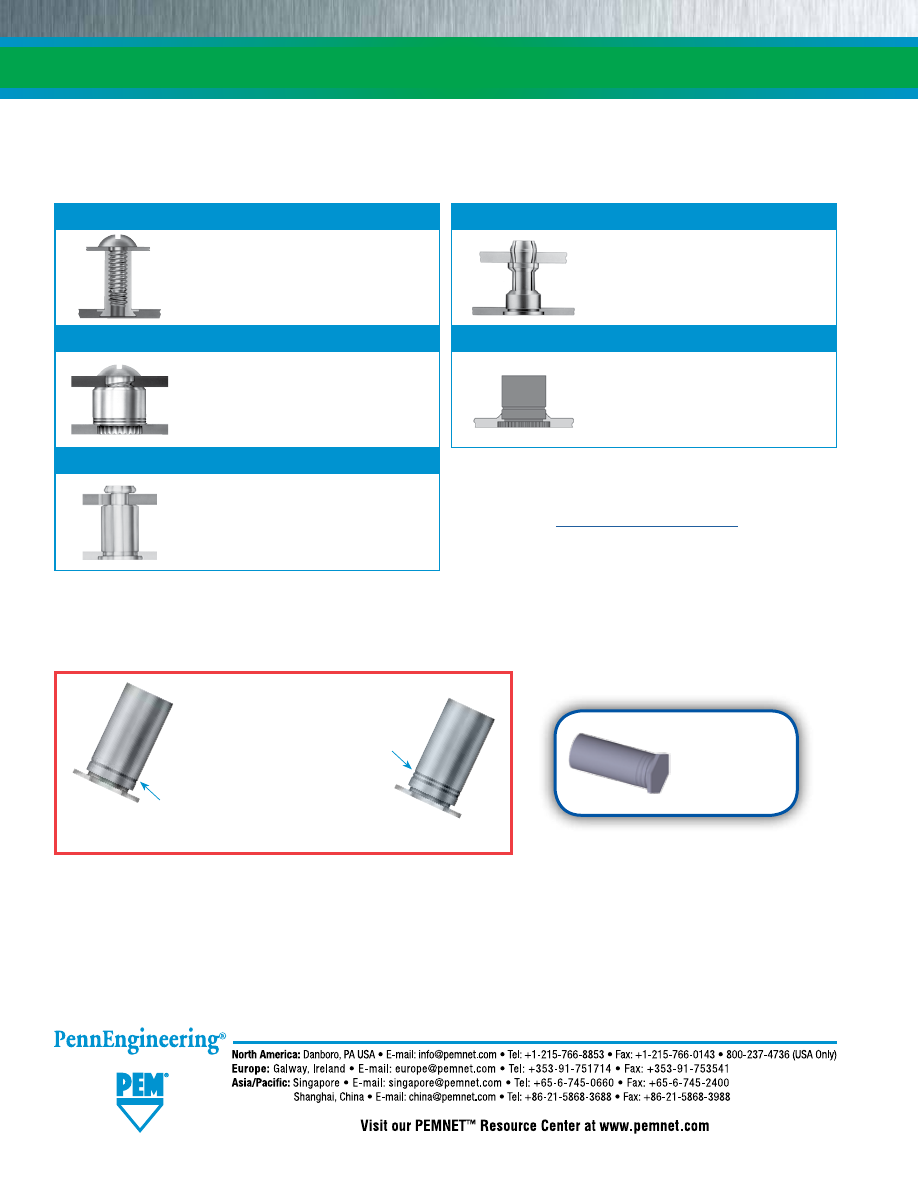

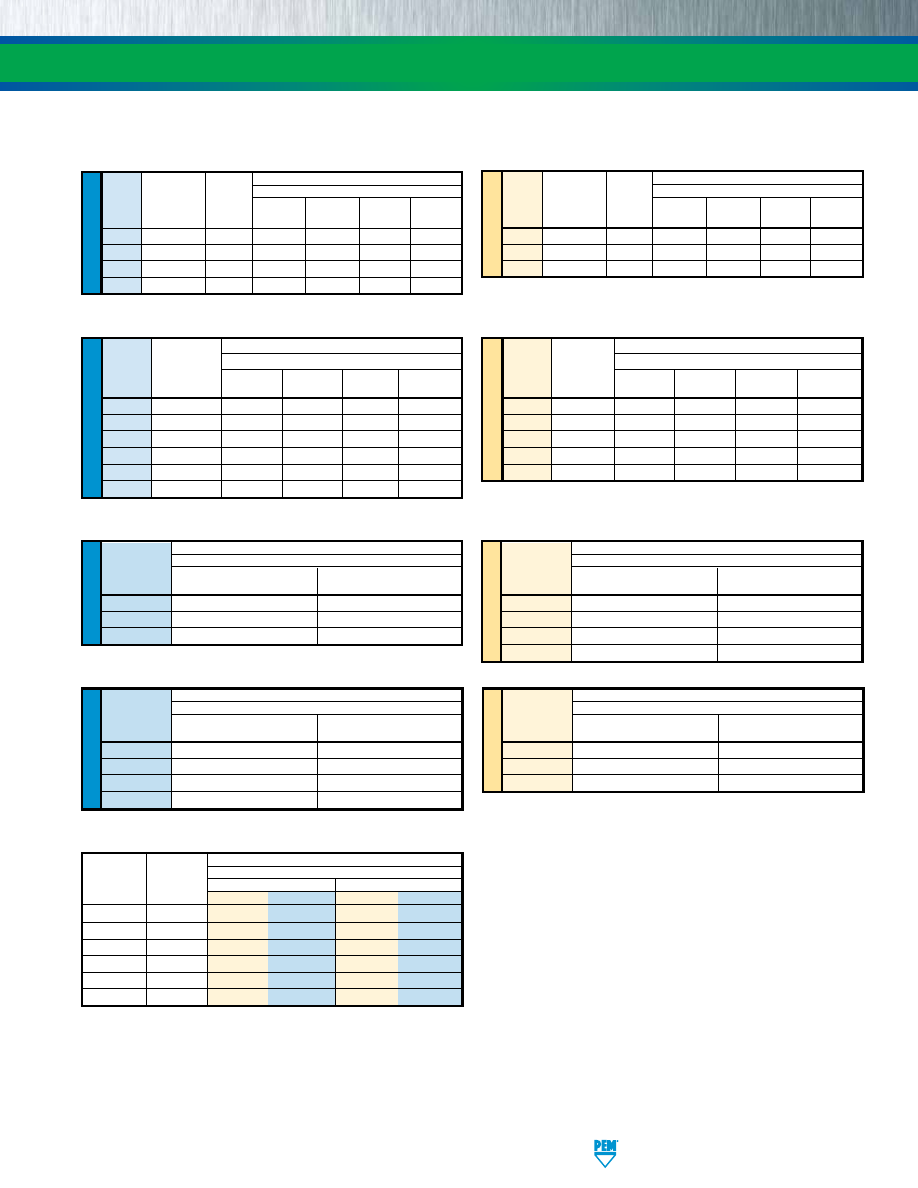

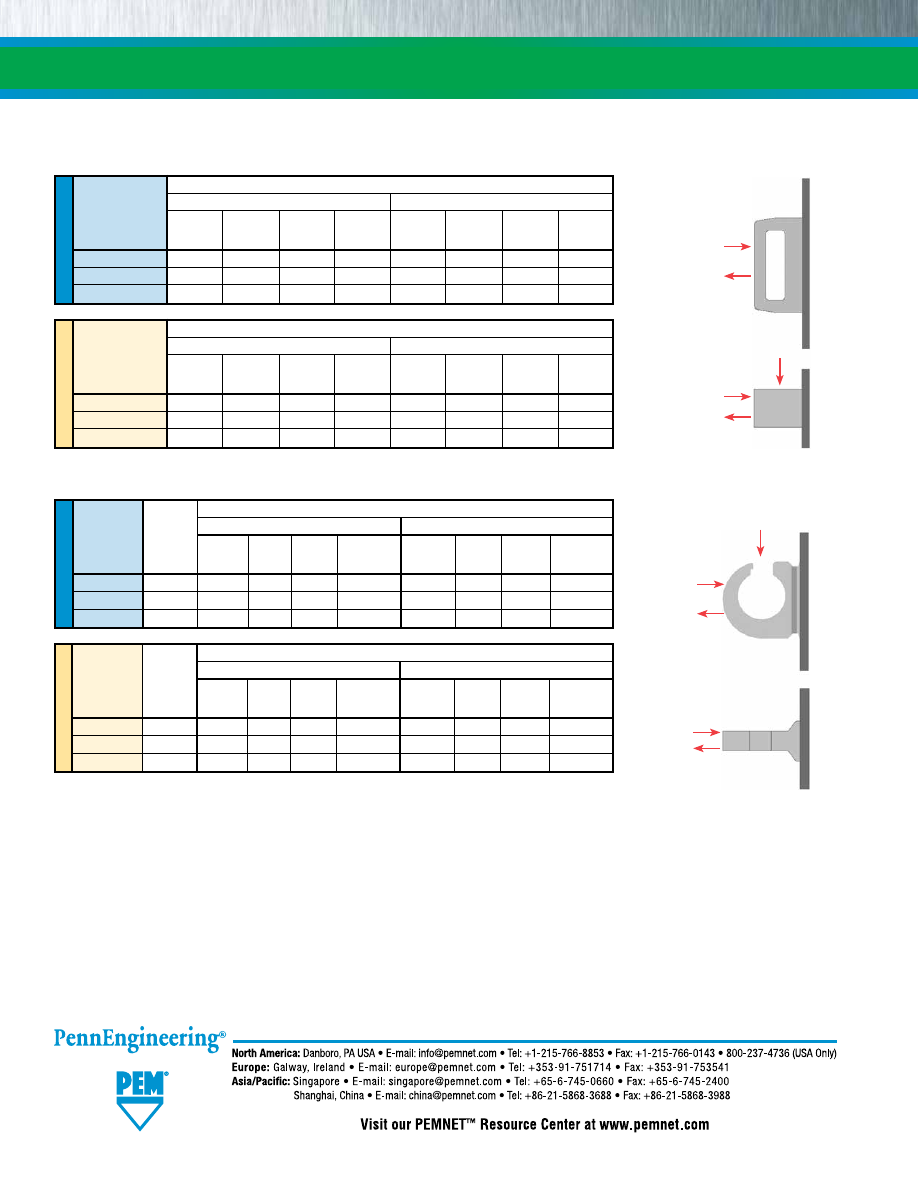

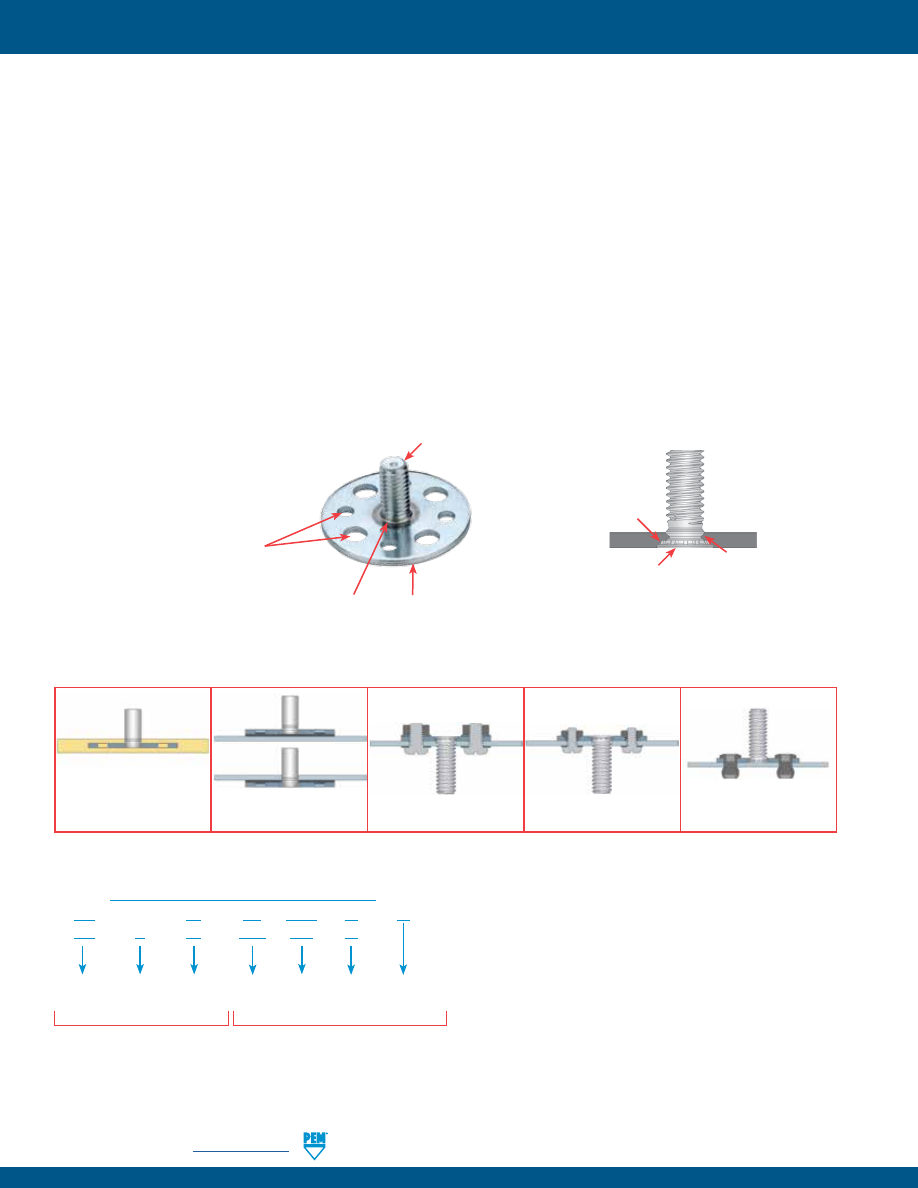

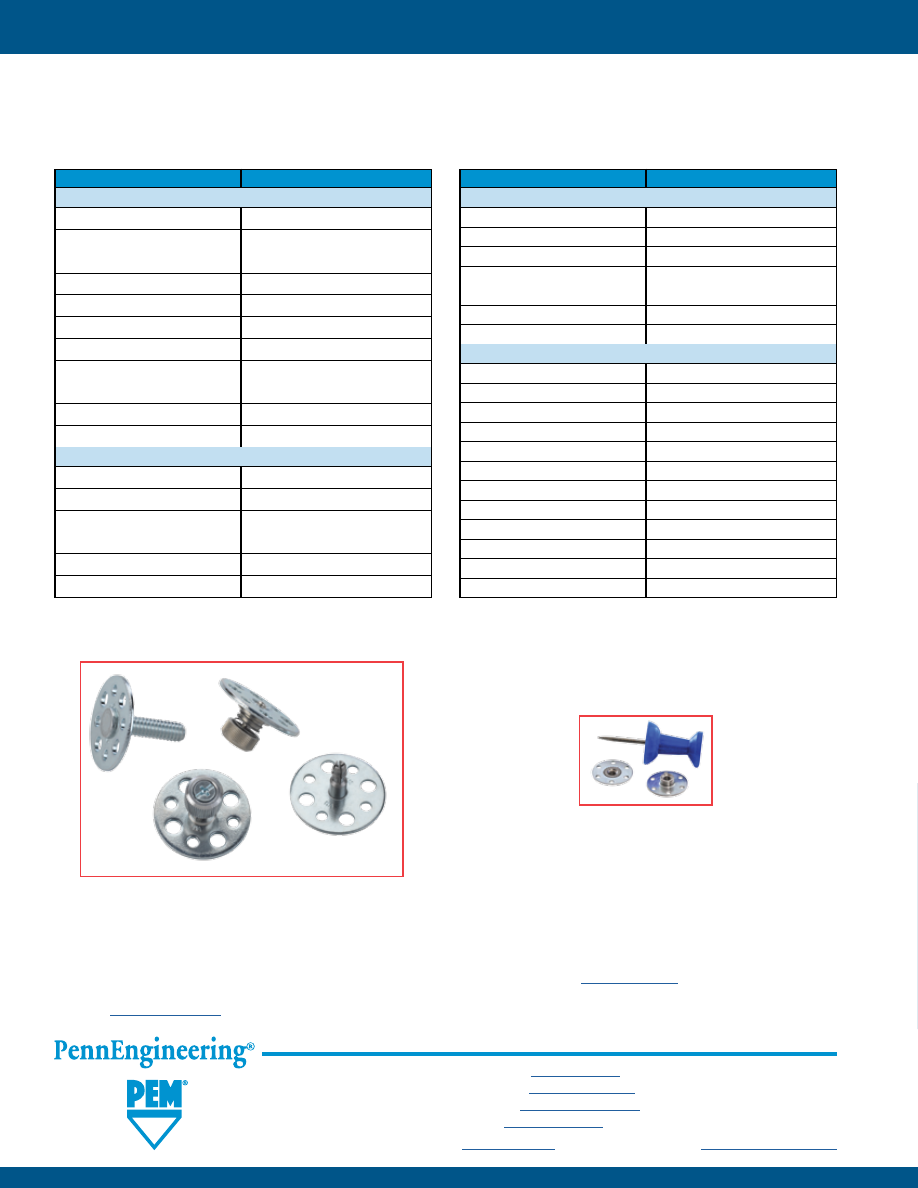

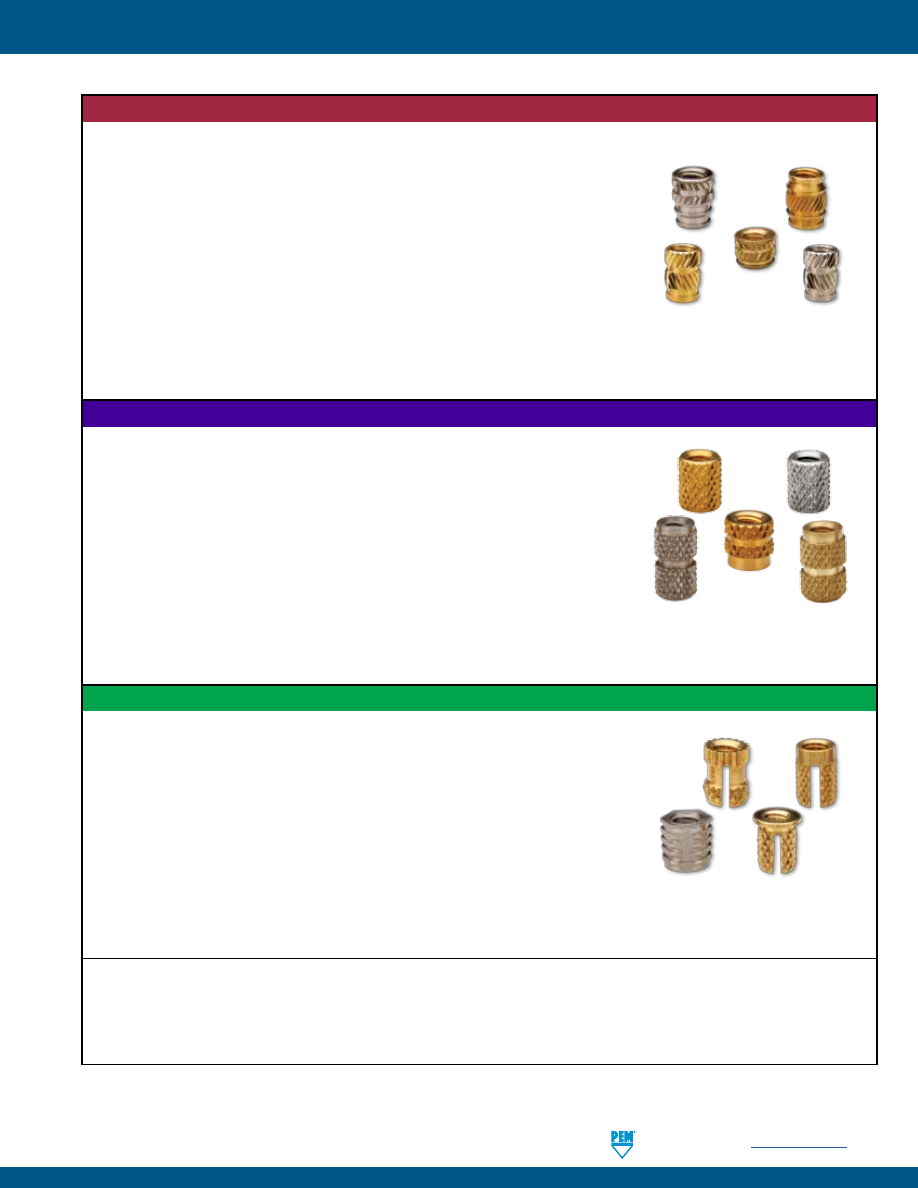

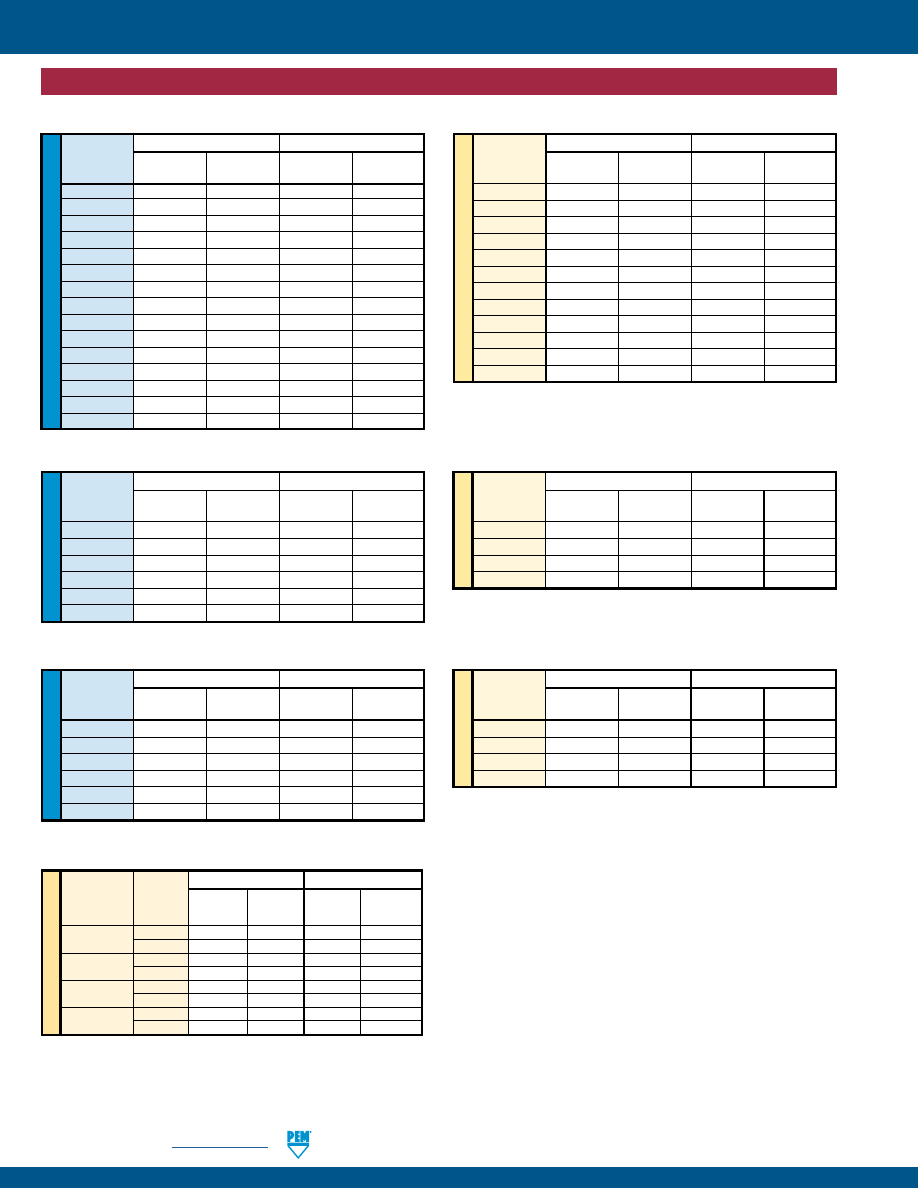

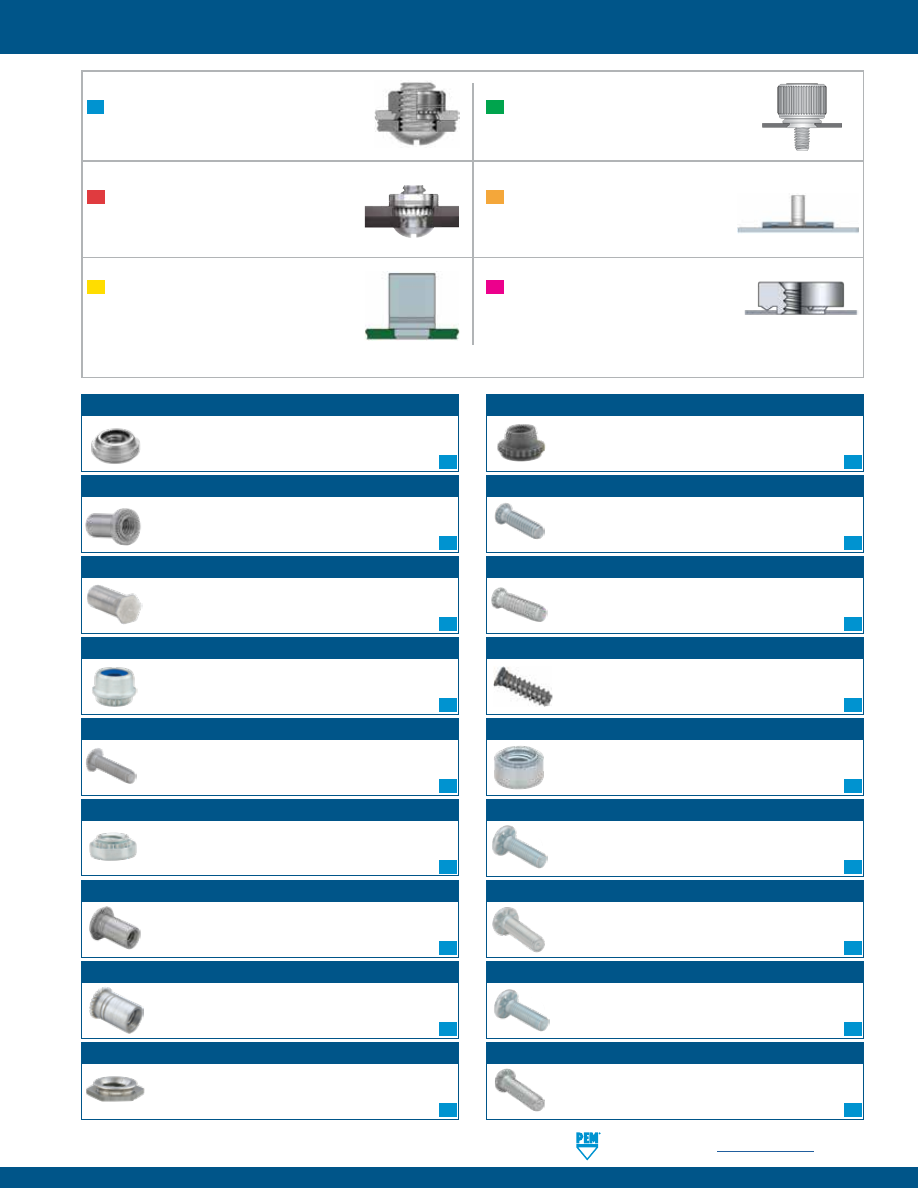

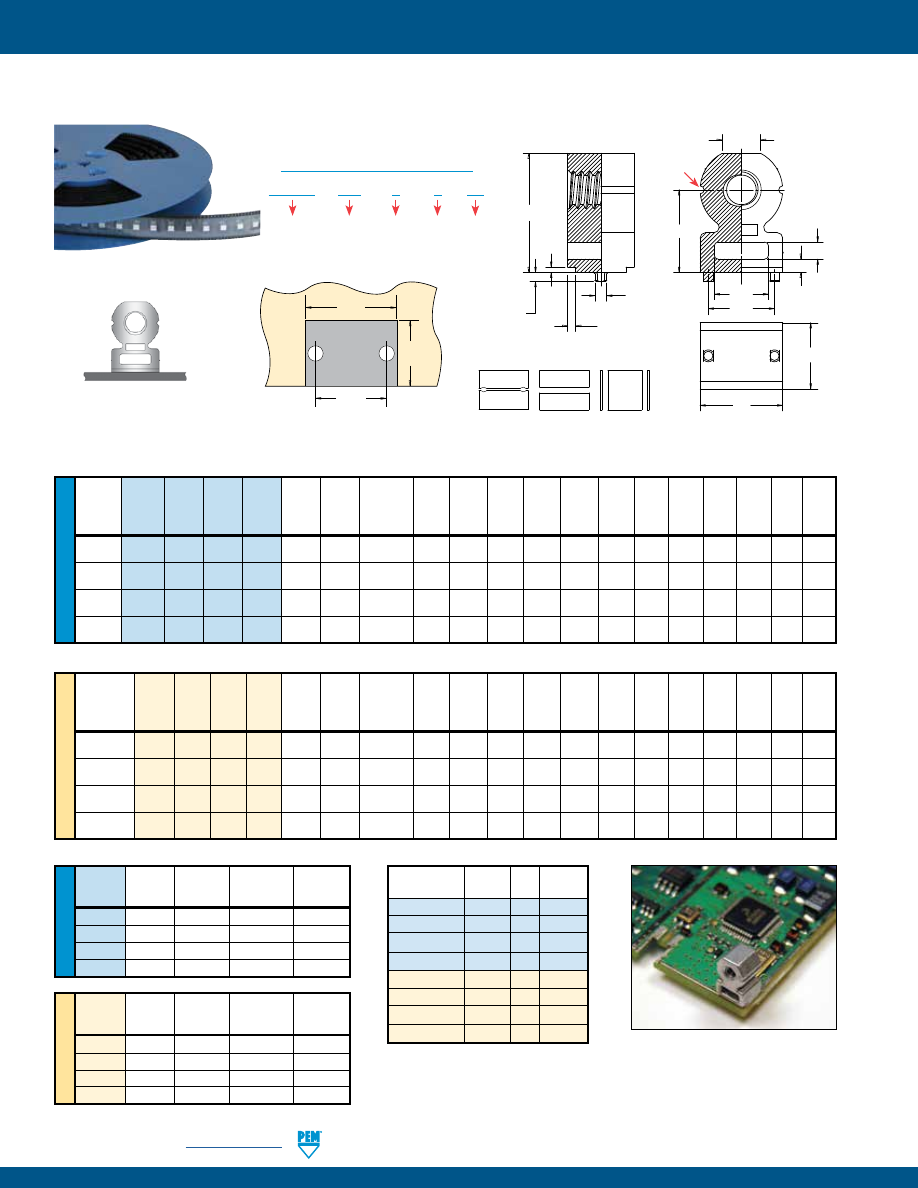

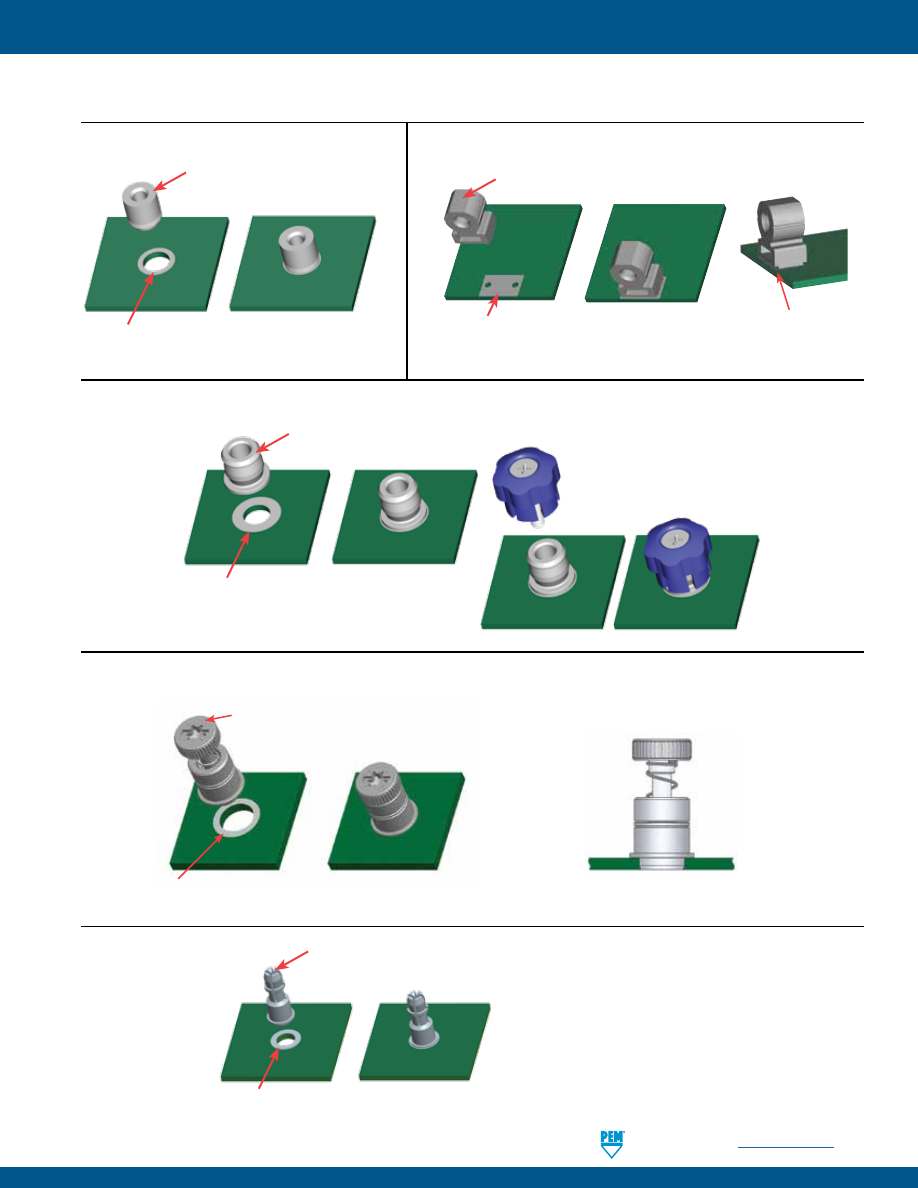

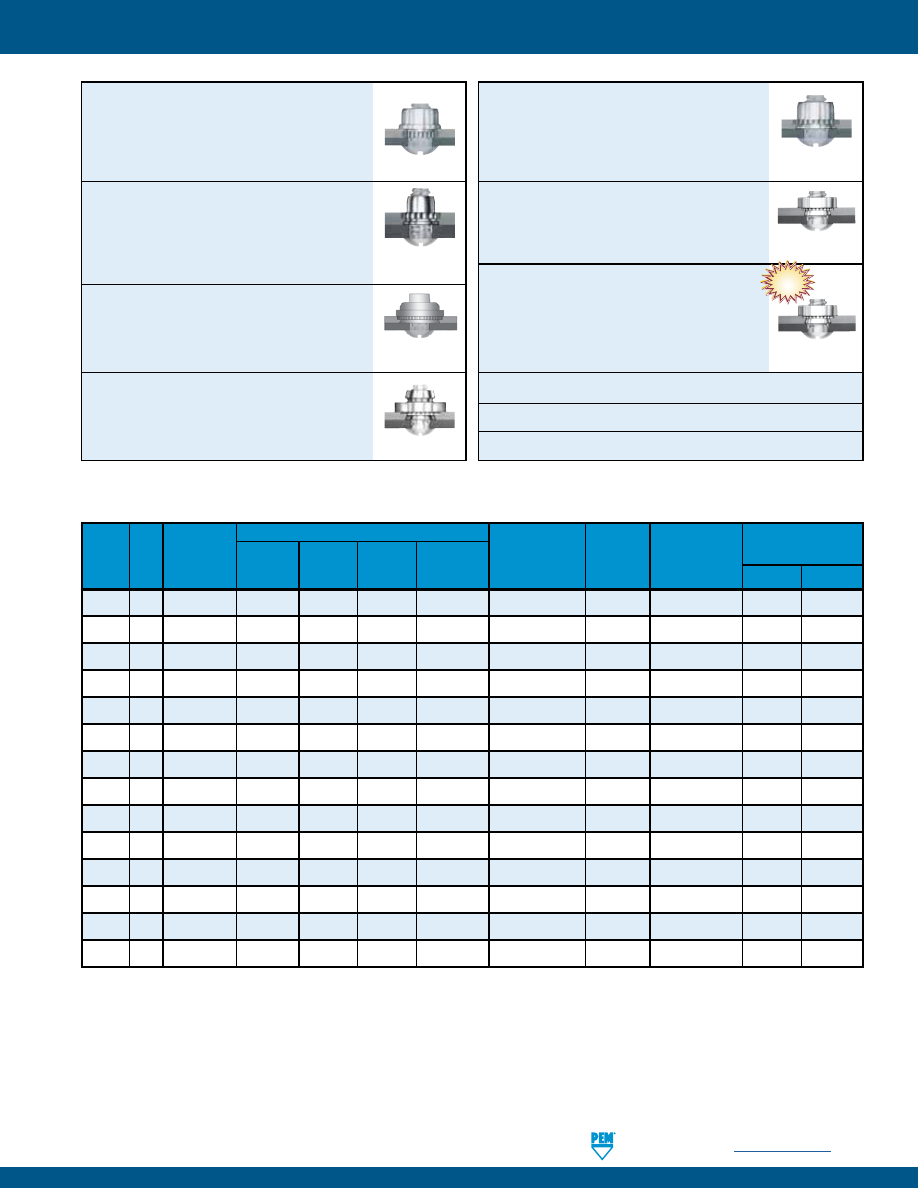

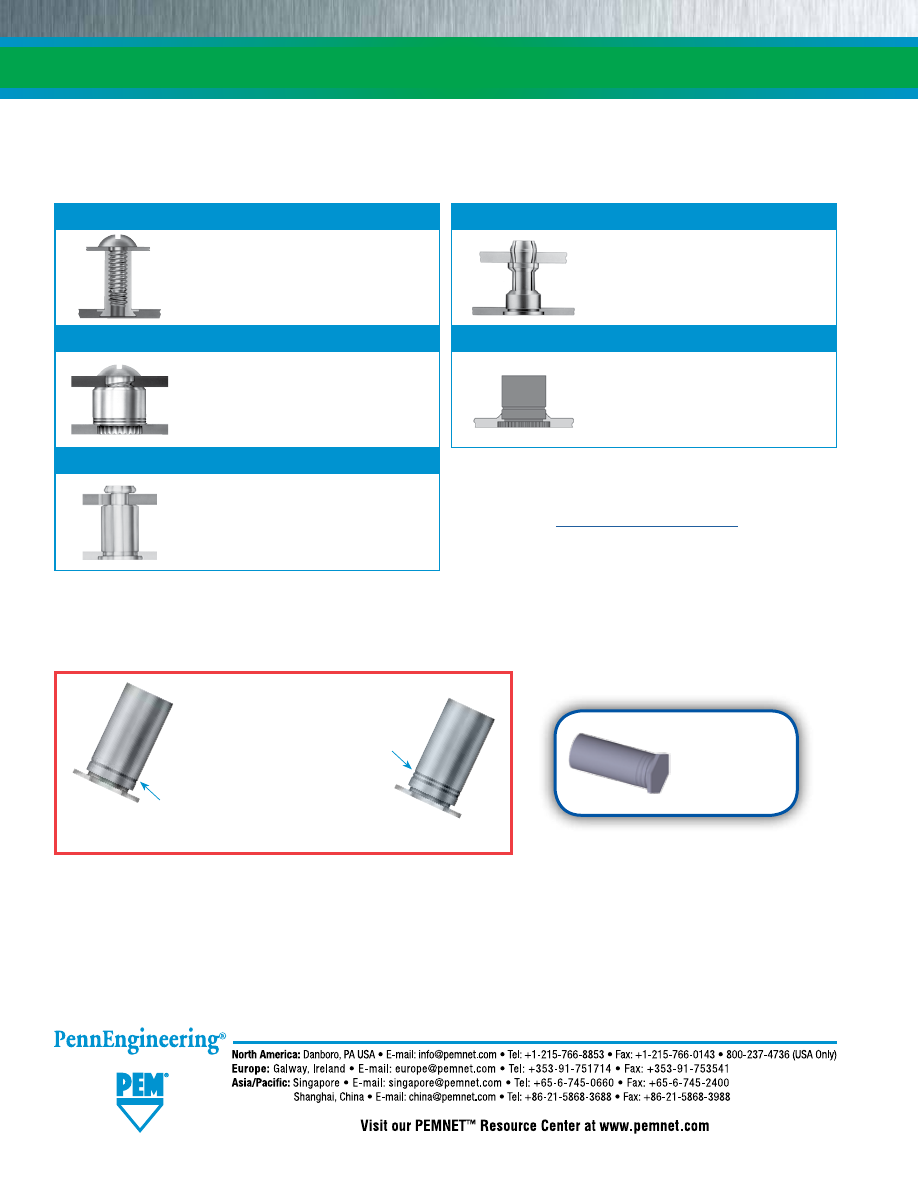

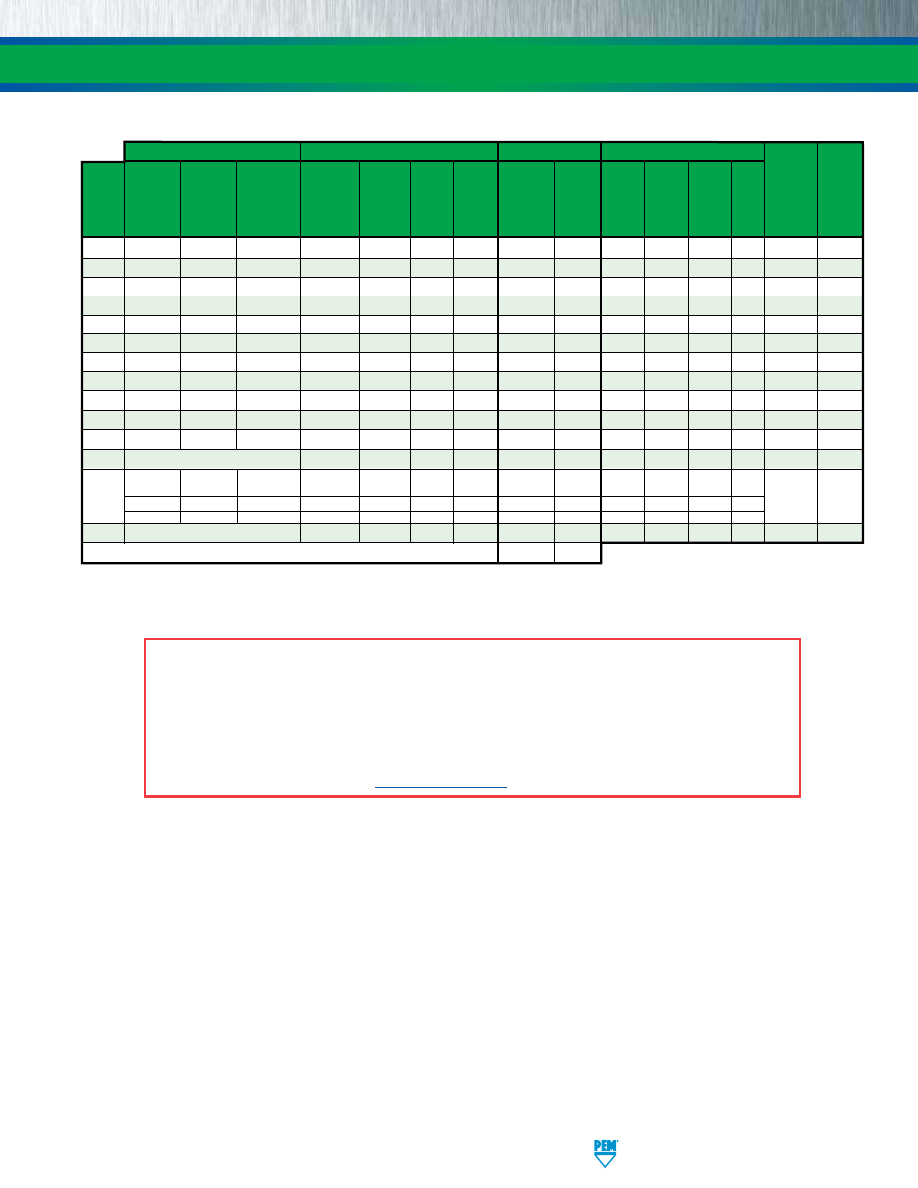

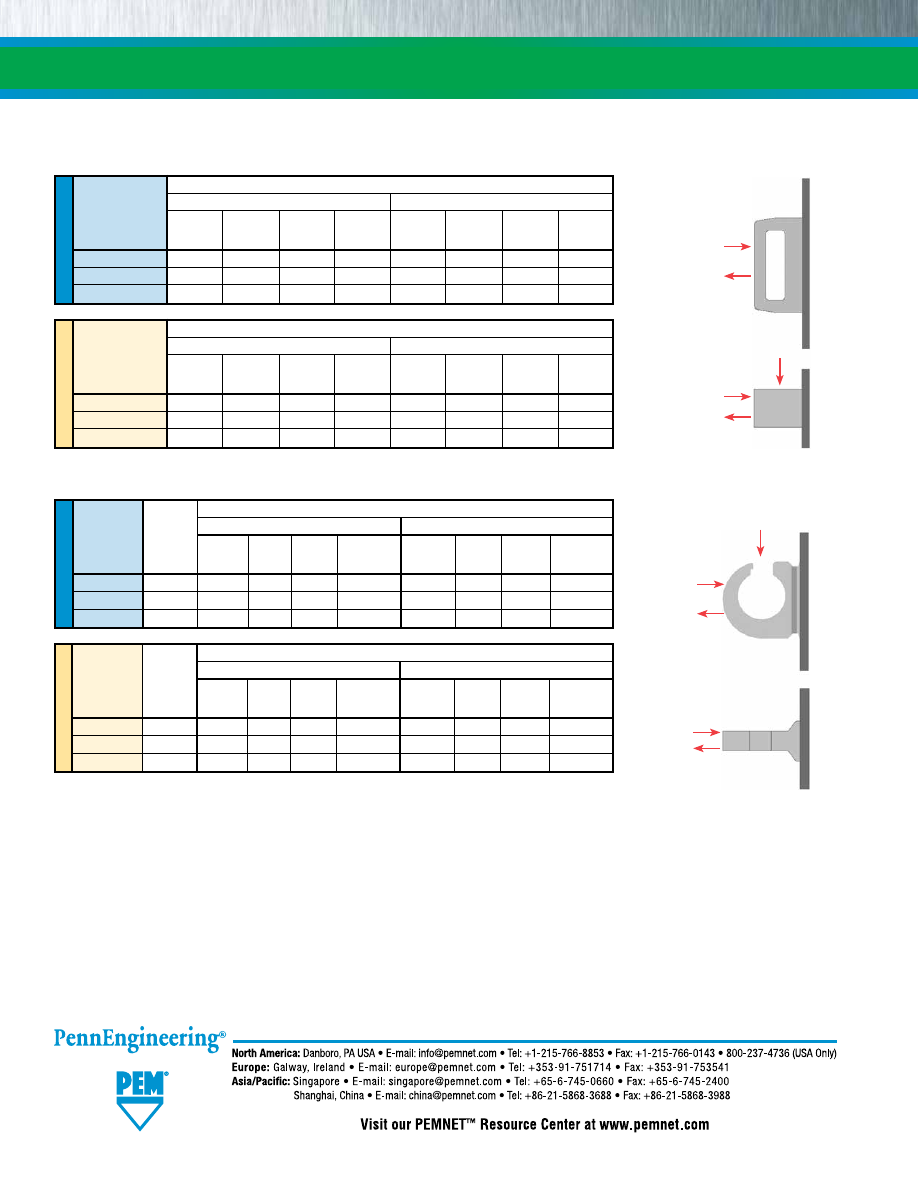

Self-clinching

fasteners are pressed into sheet

metal panels as this as .016” / 0.4 mm.

Broaching

fasteners are pressed into

P.C. board or other plastic materials

as thin as .060” / 1.53 mm.

Surface Mounted

fasteners on tape and reel

are soldered to a PC board in the same way

as other surface mount components.

Flare Mounted

fasteners can be installed into

almost any rigid type of panel.

VariMount® bonding fasteners

are assemblies

comprised of a standard PEM fastener

mounted permanently into base plates.

Weld

nuts are designed specially to be

welded into place.

(

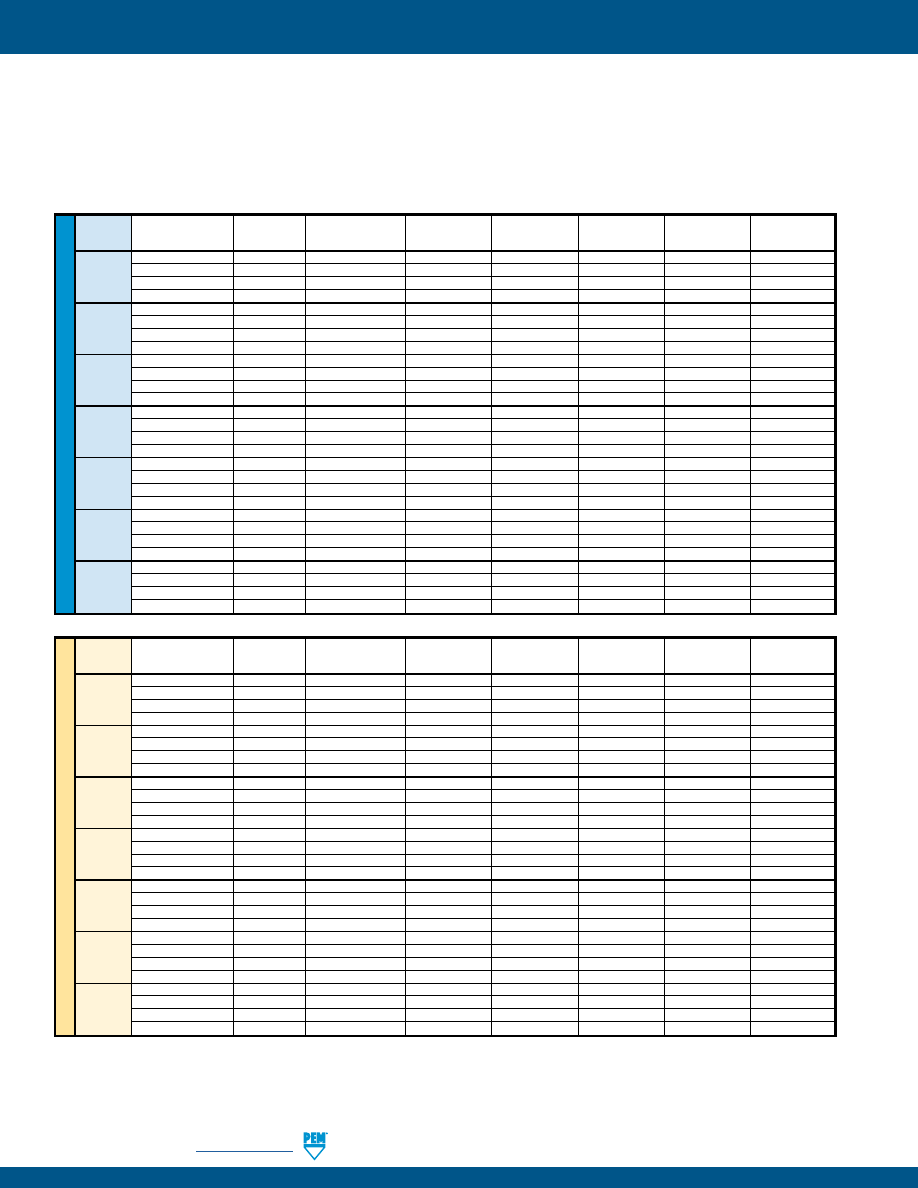

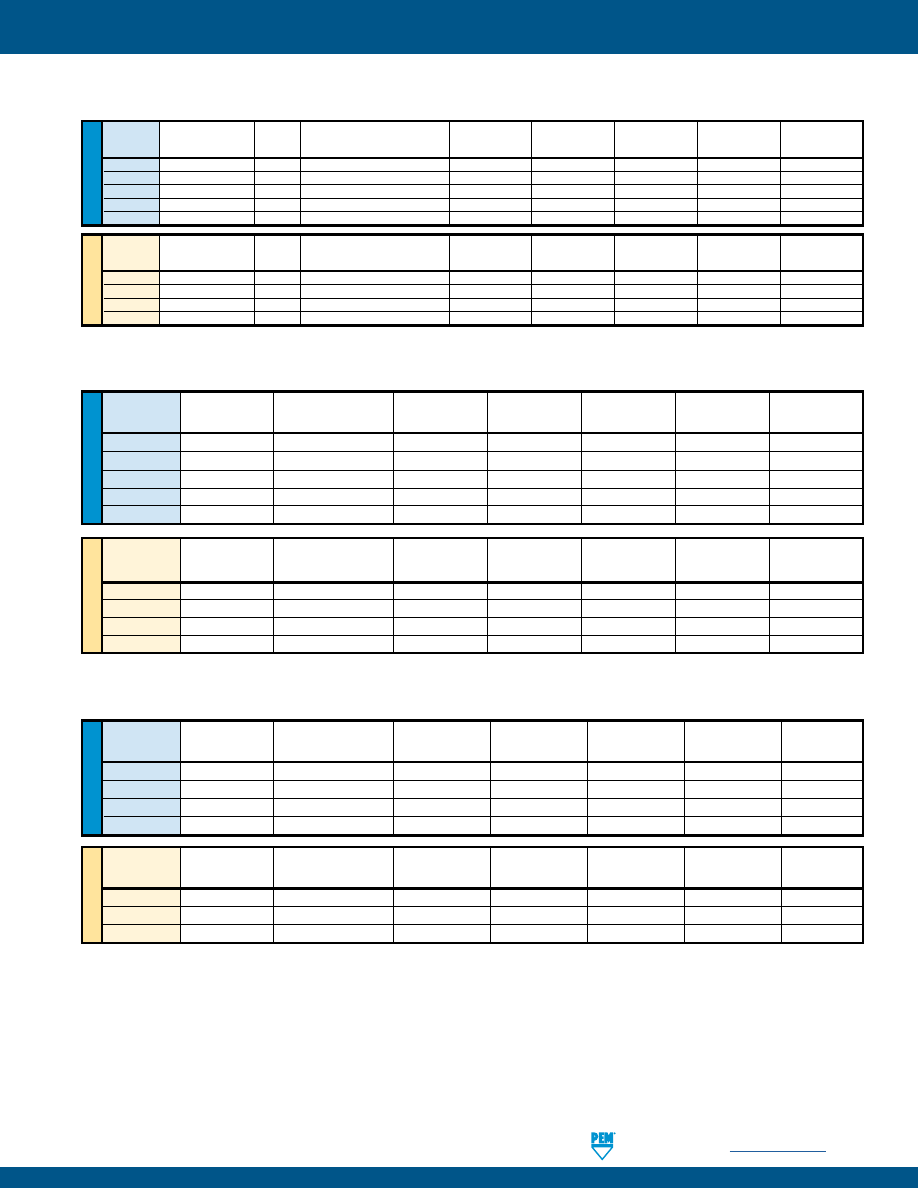

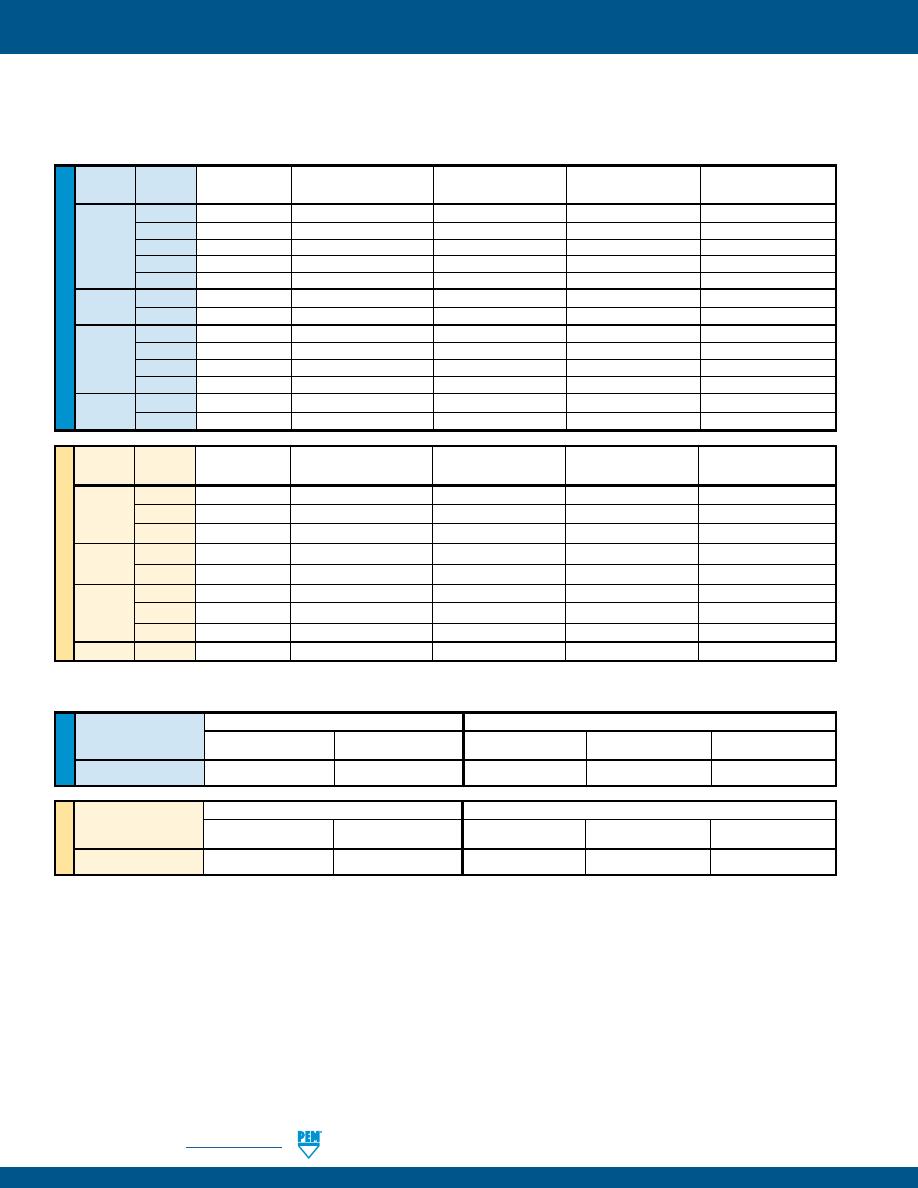

Products are listed alphabetically by type. Refer to matching color square for mounting style)

B

SM

FM

VM

W

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

pem-html.html

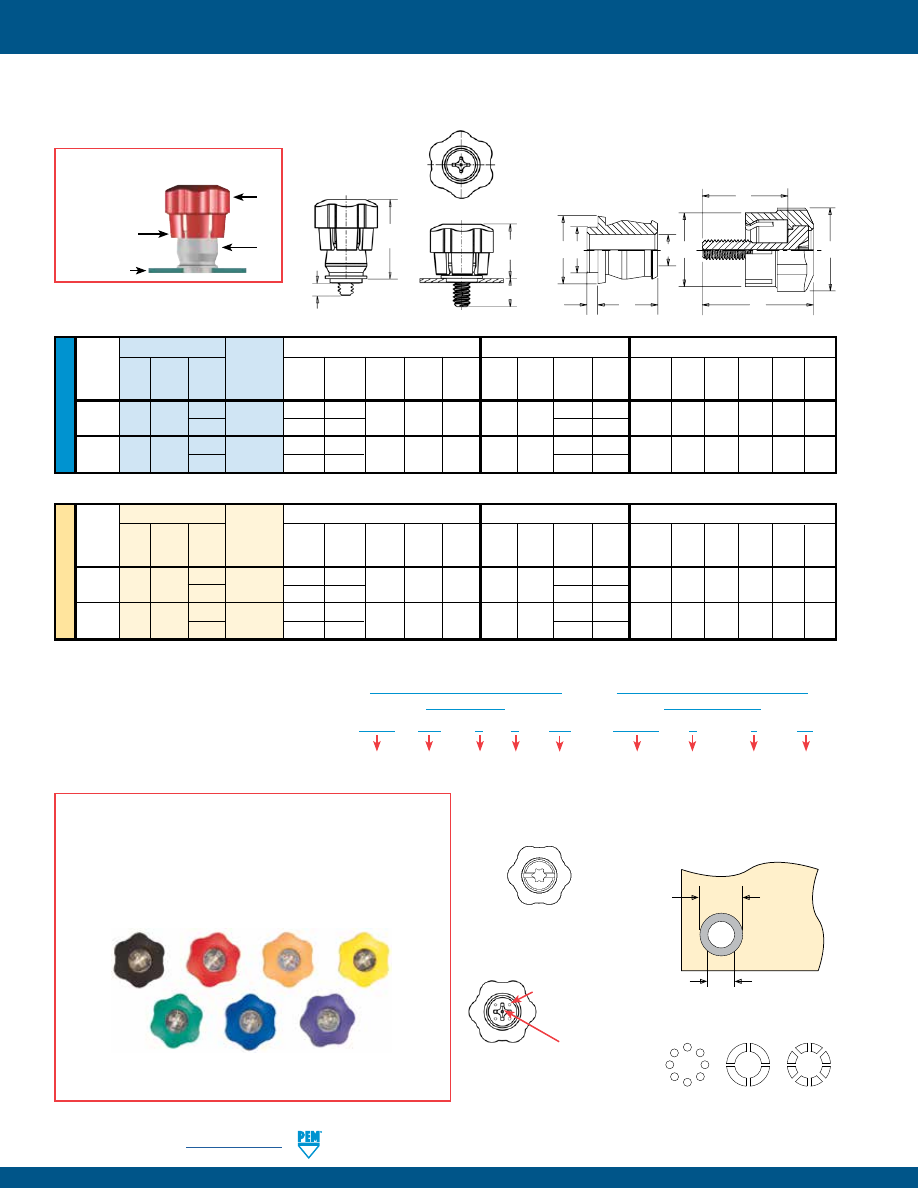

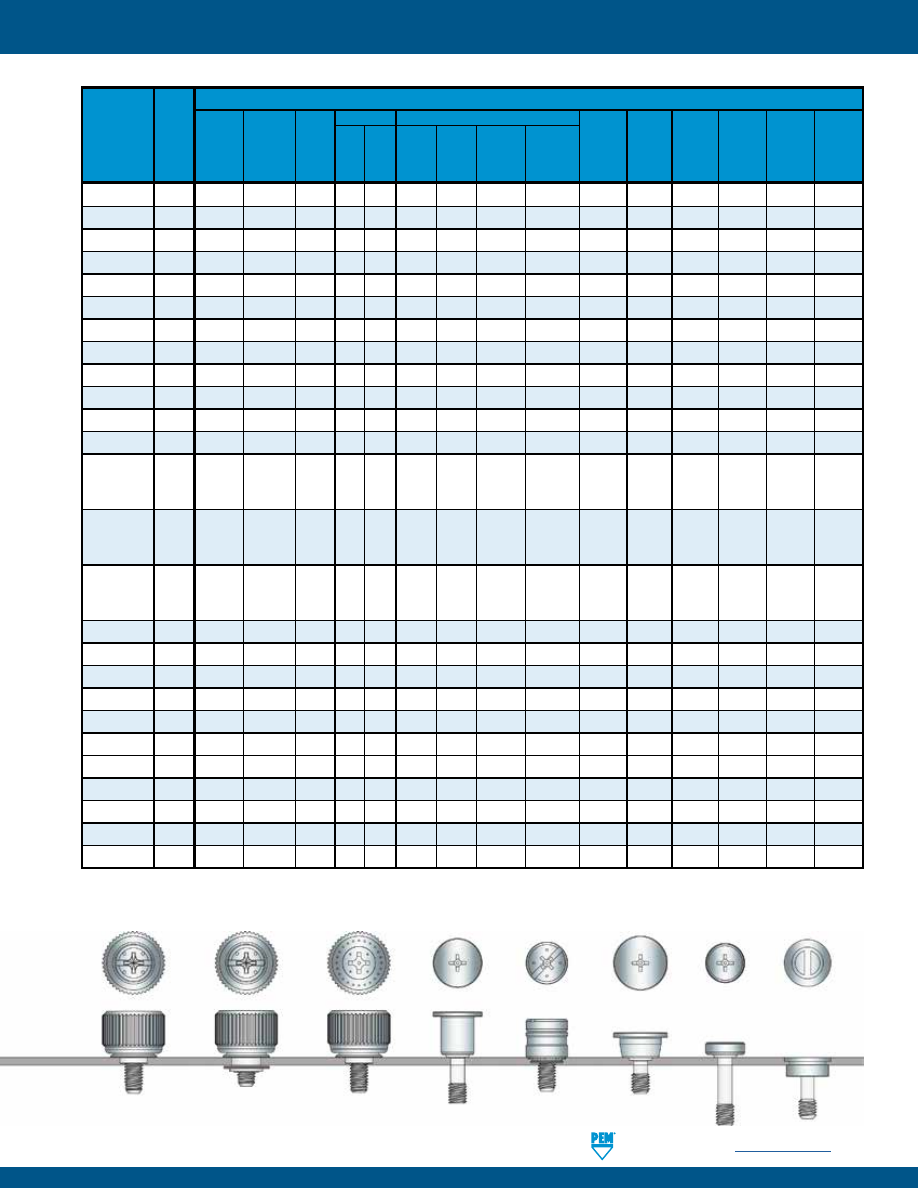

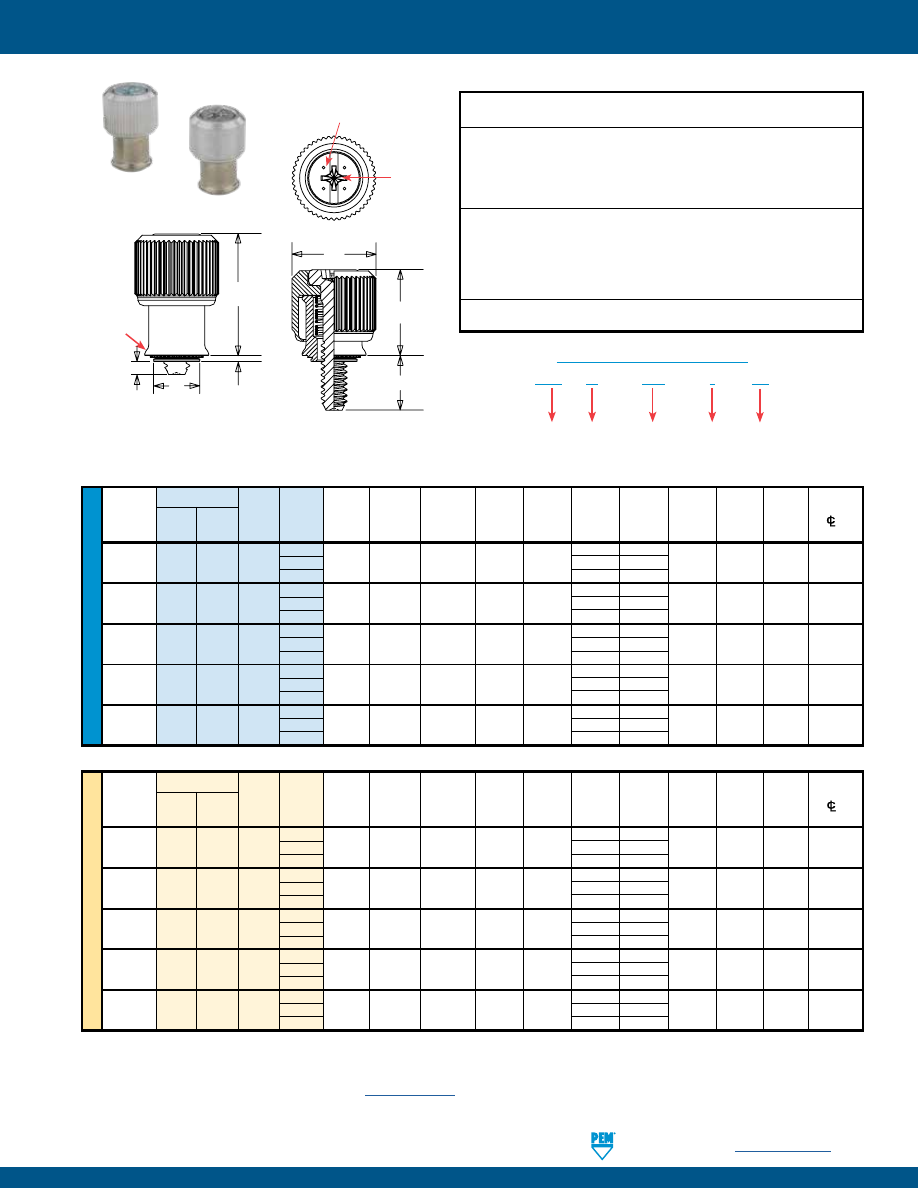

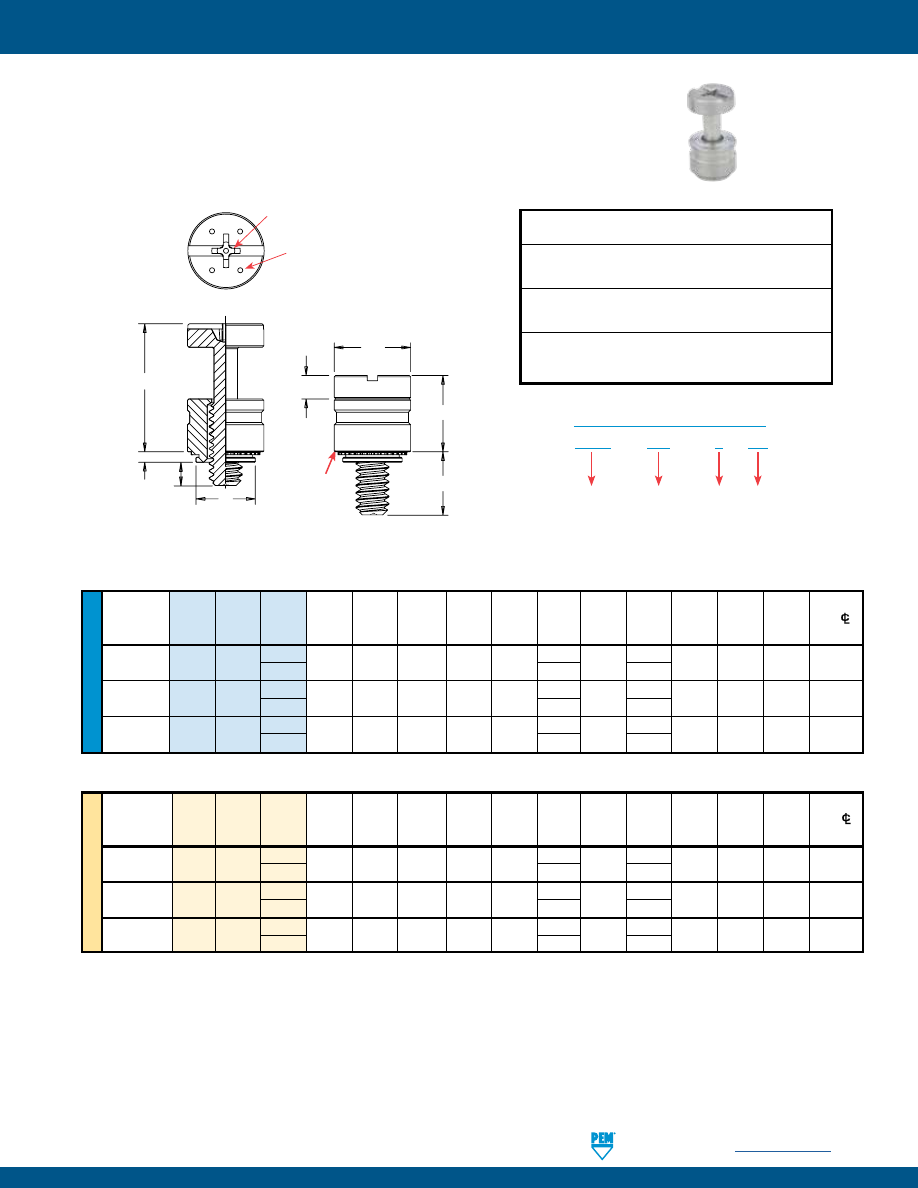

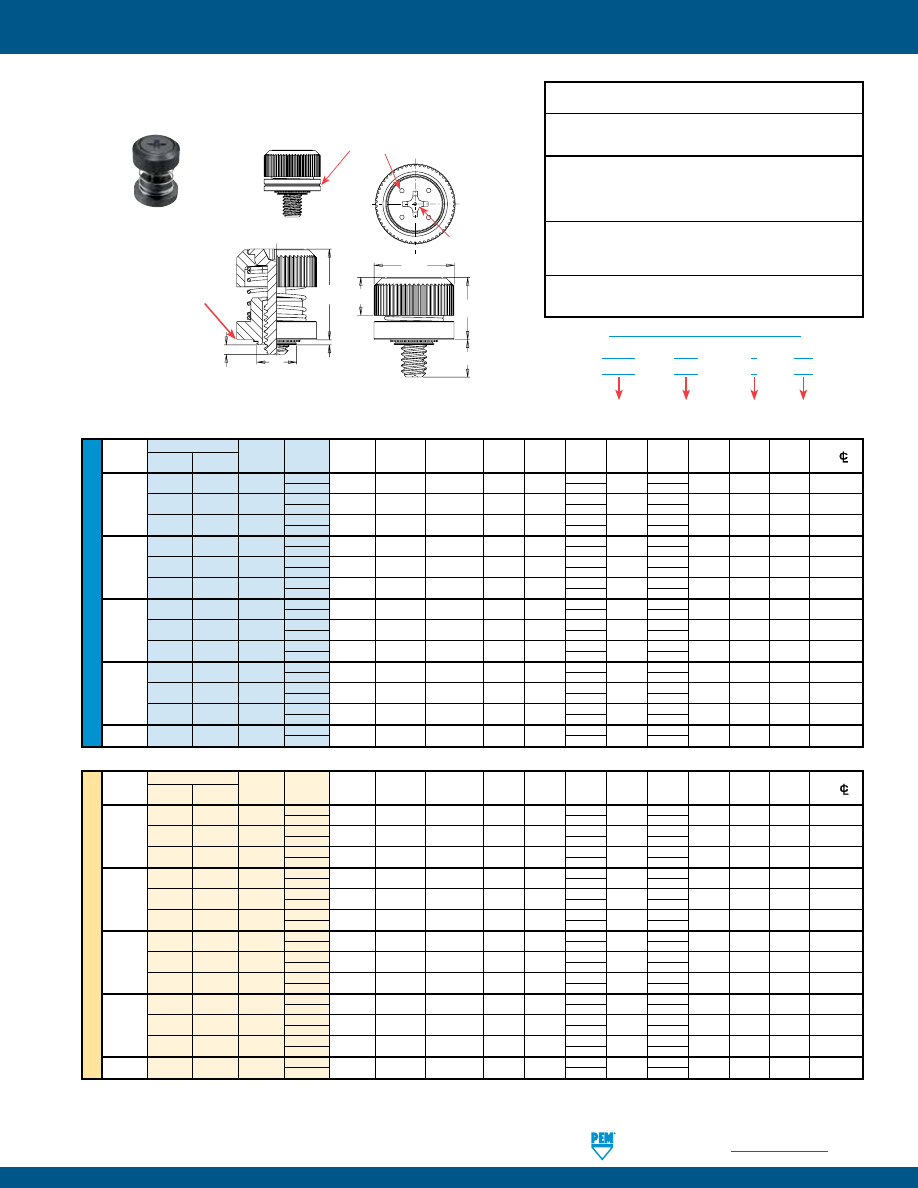

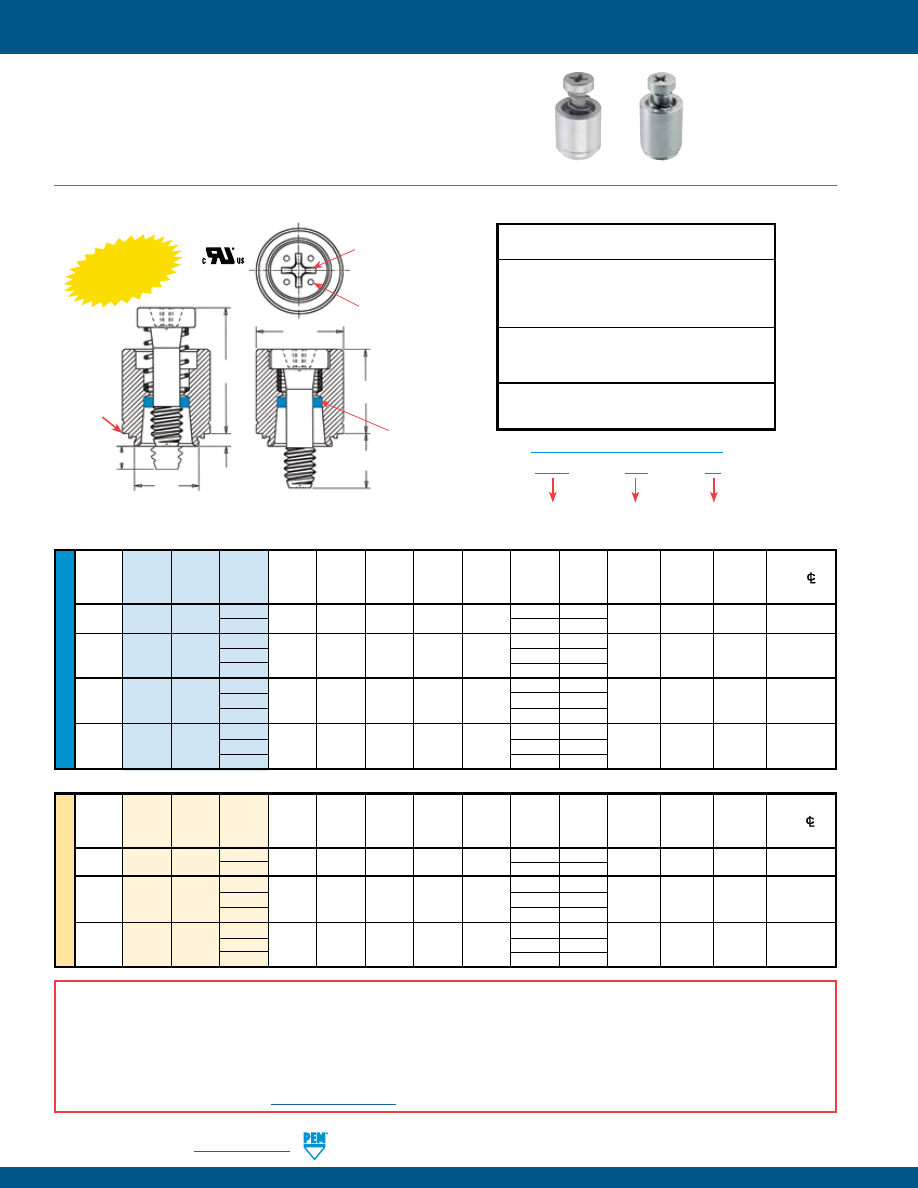

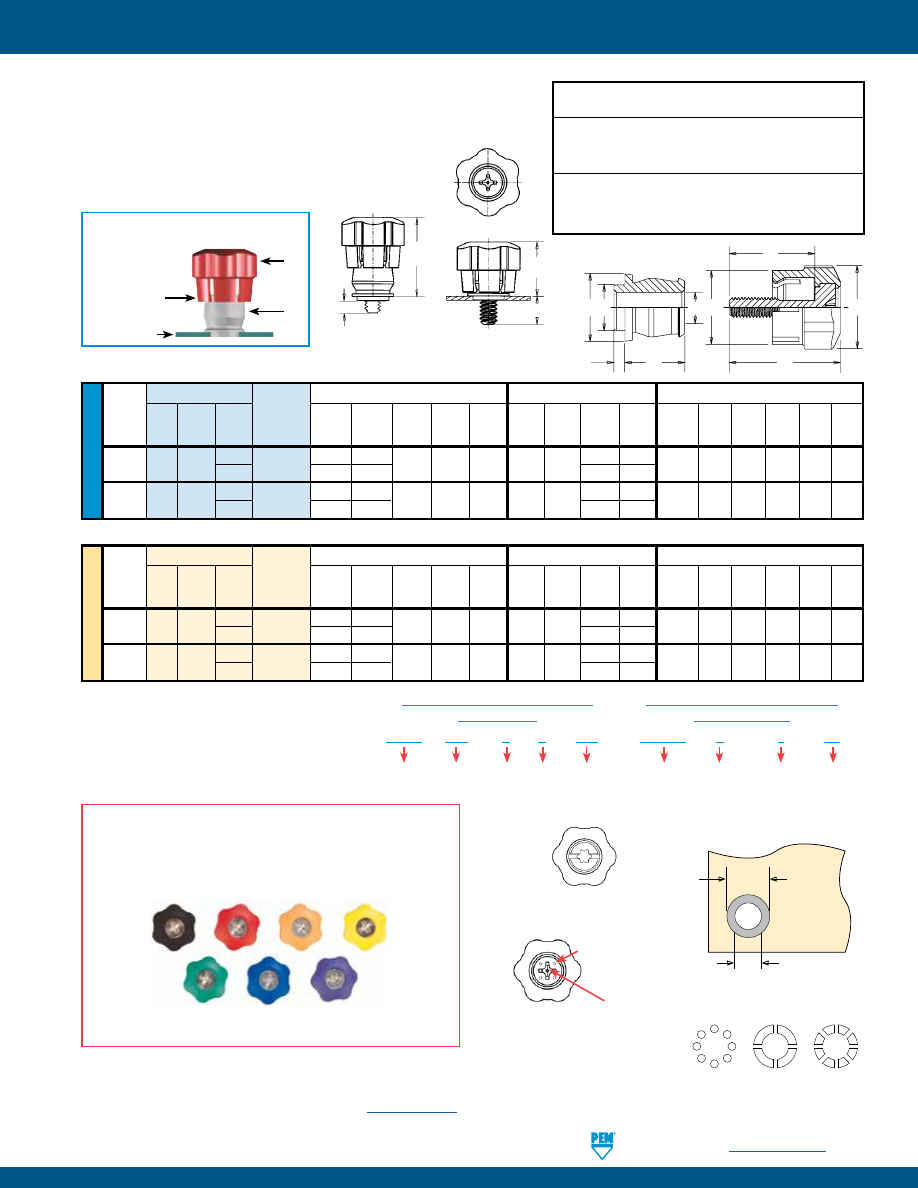

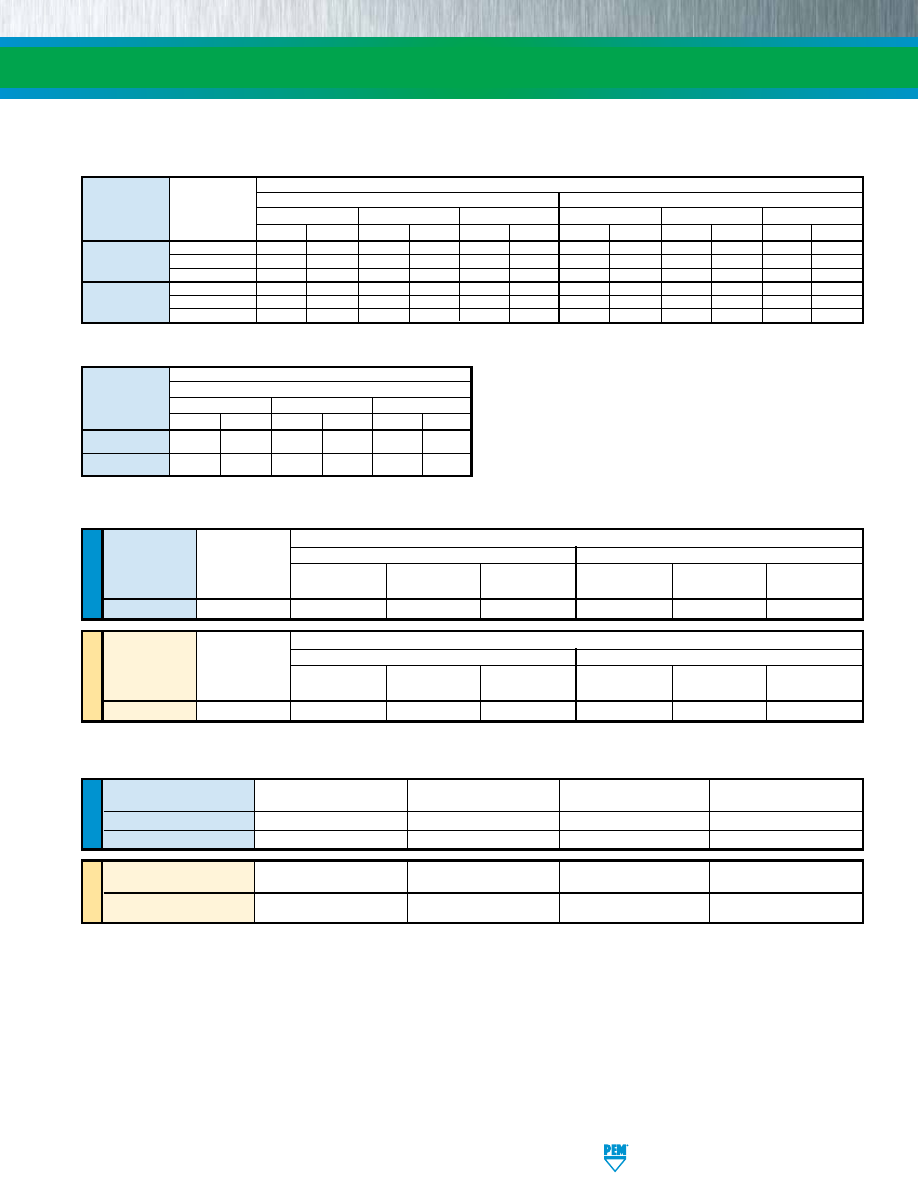

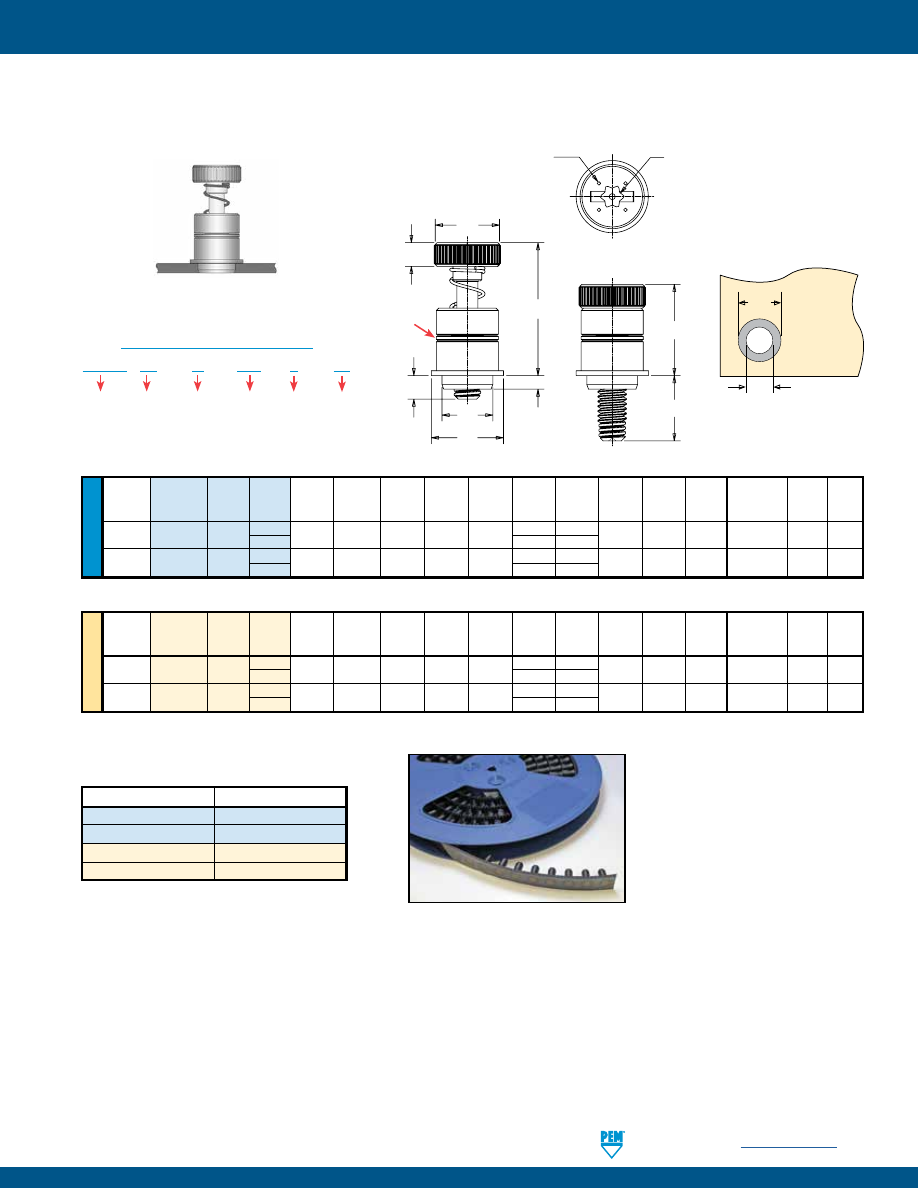

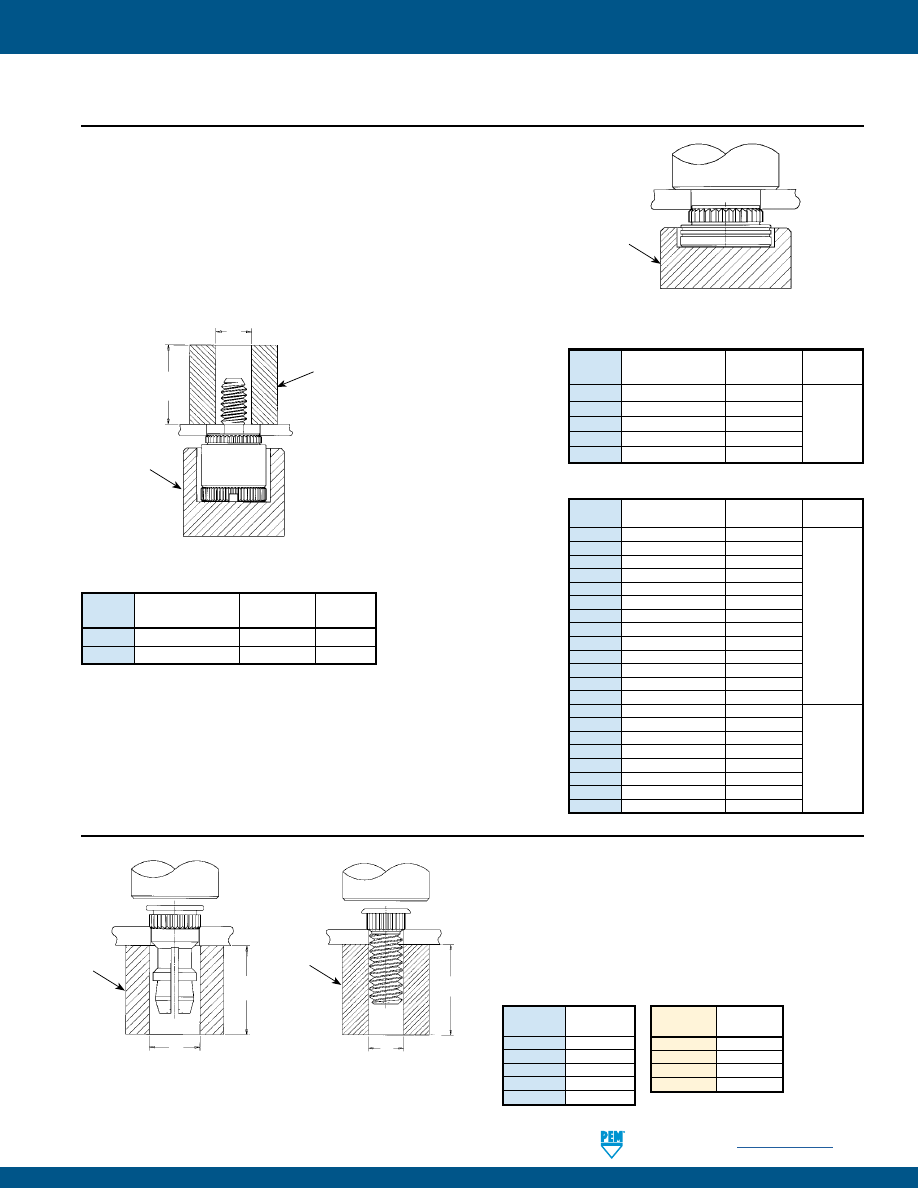

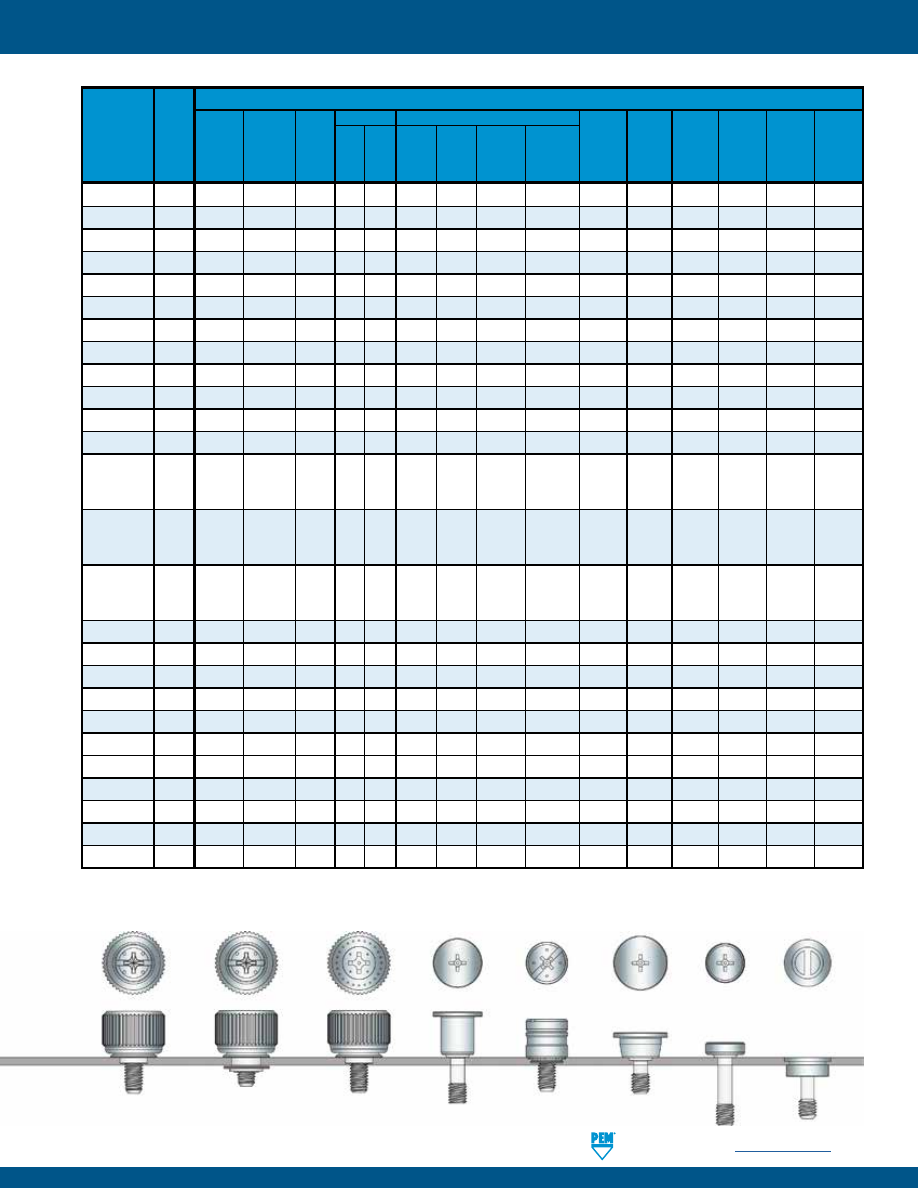

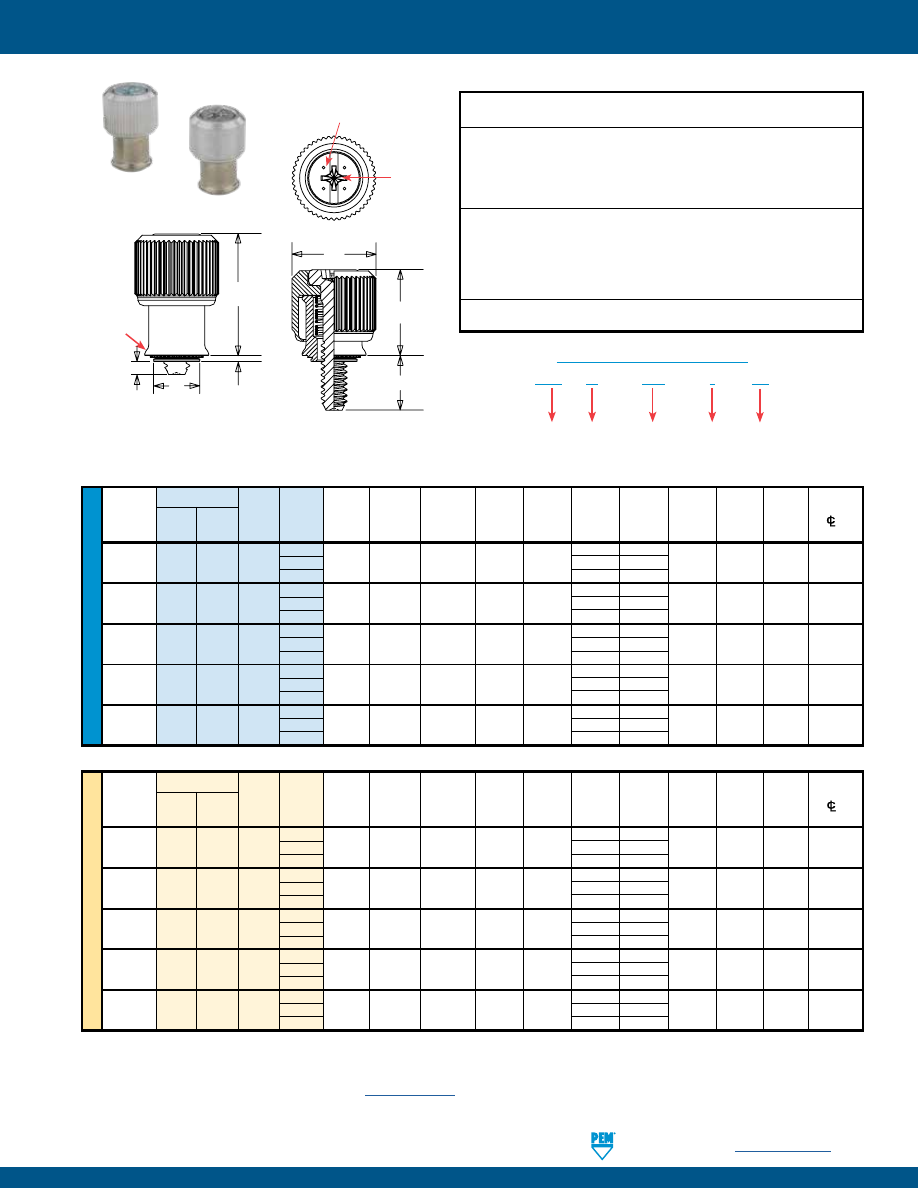

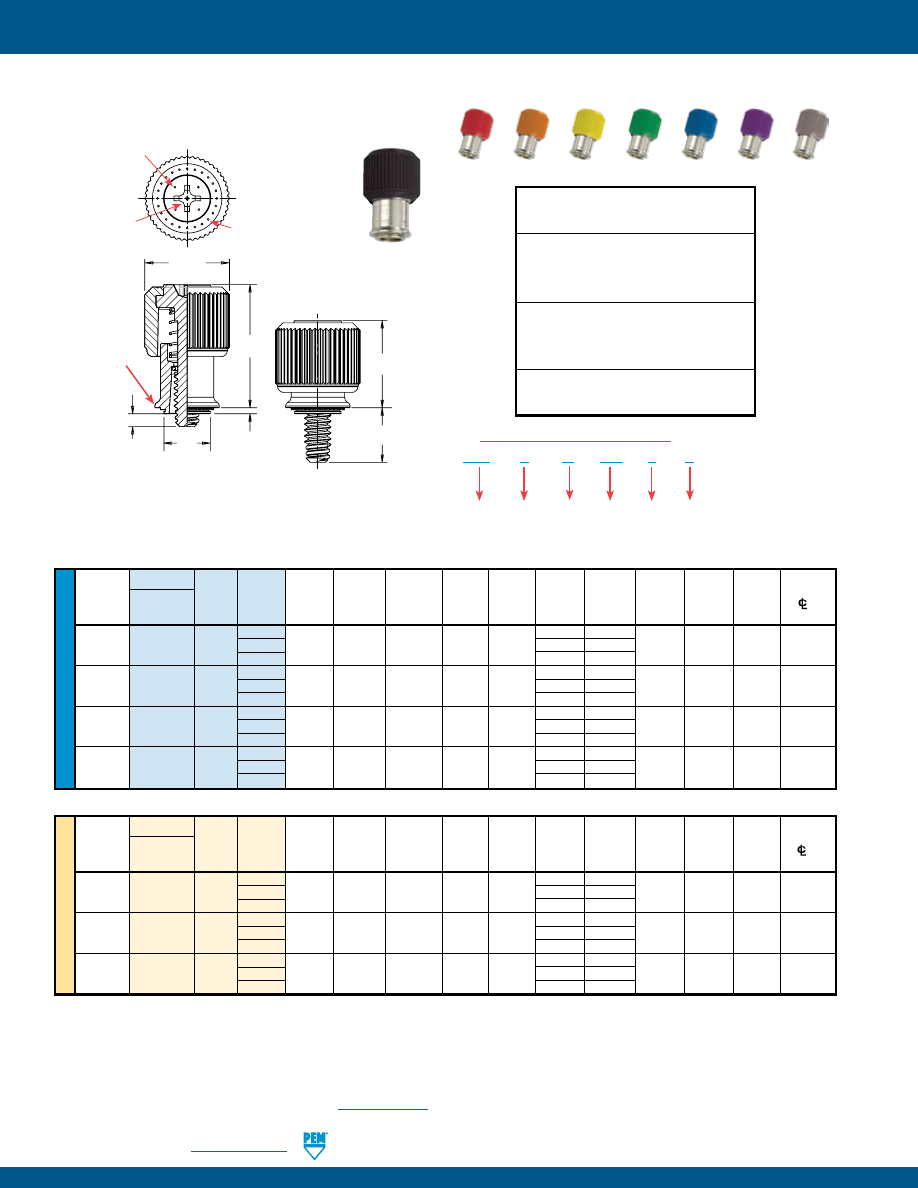

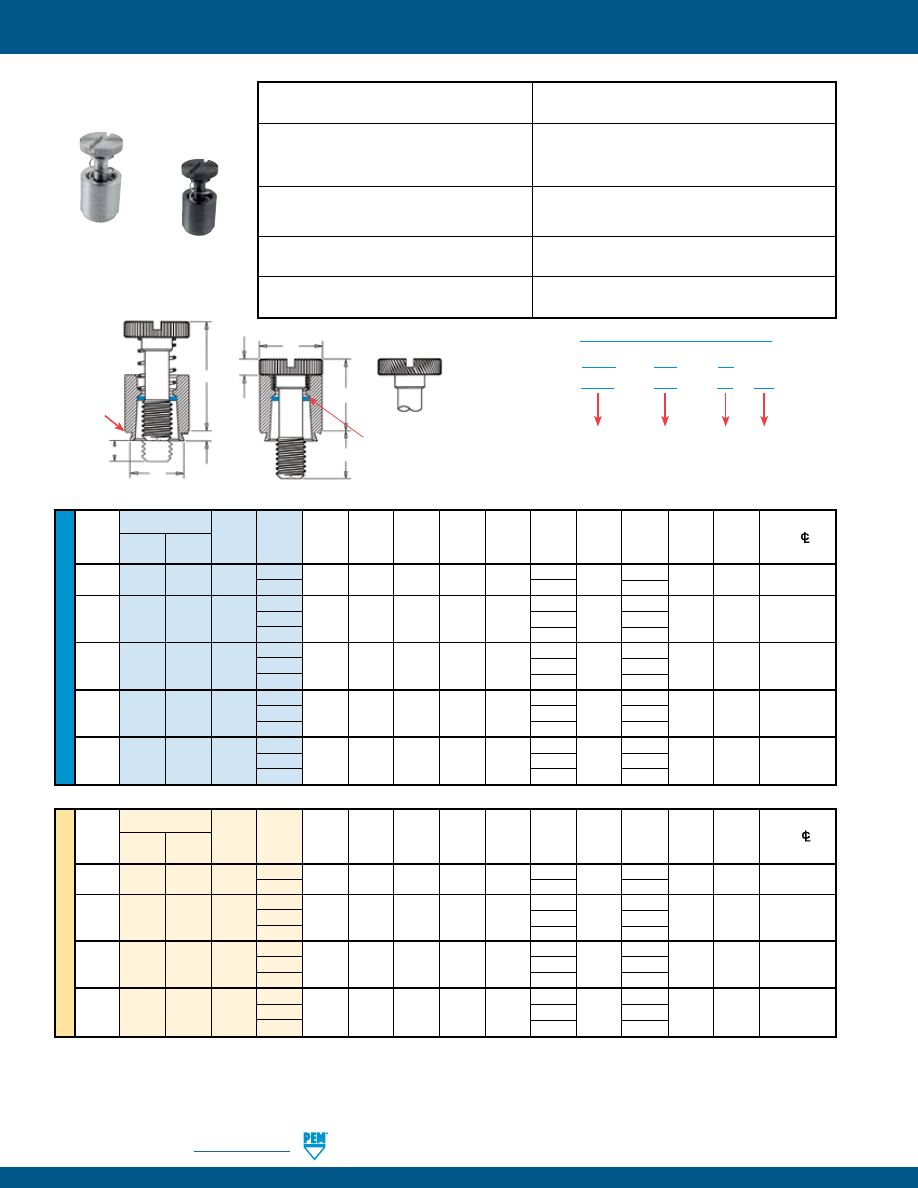

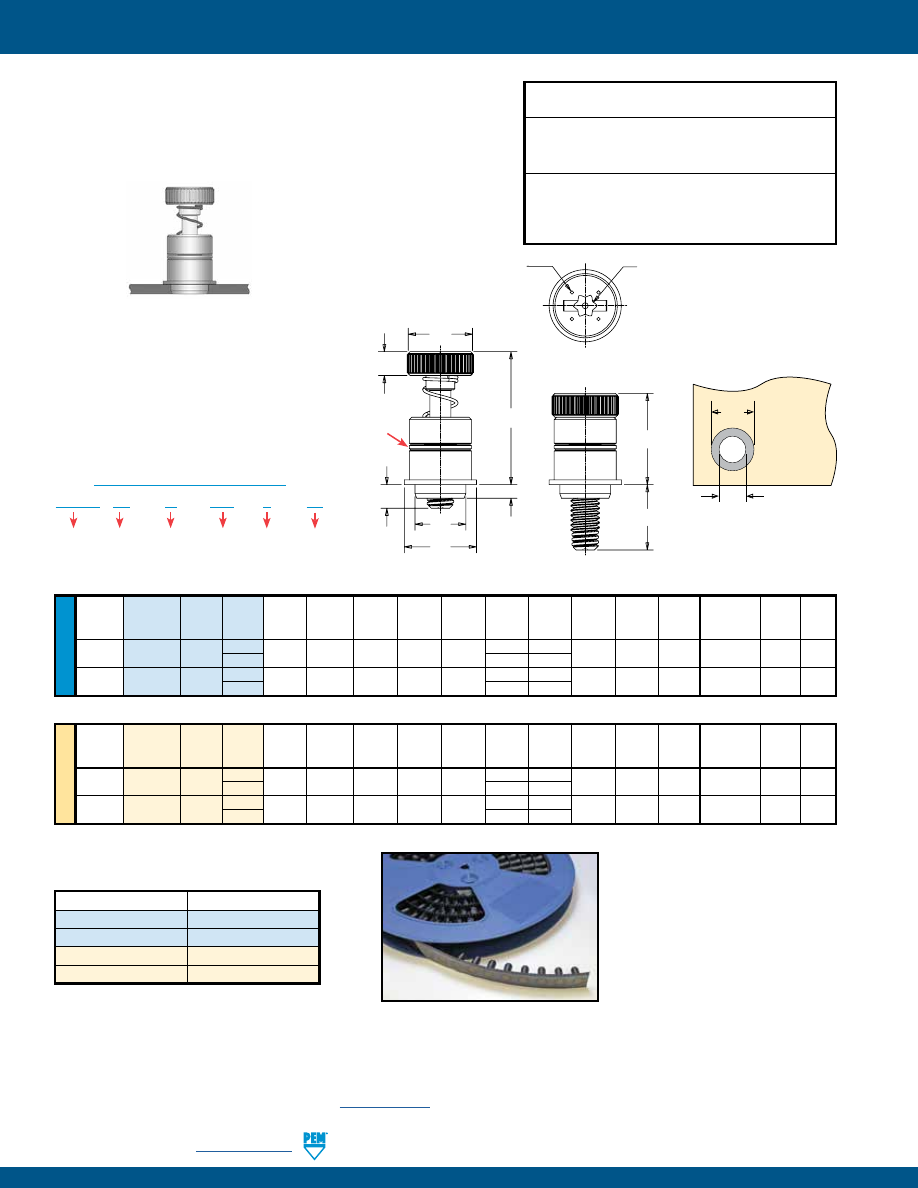

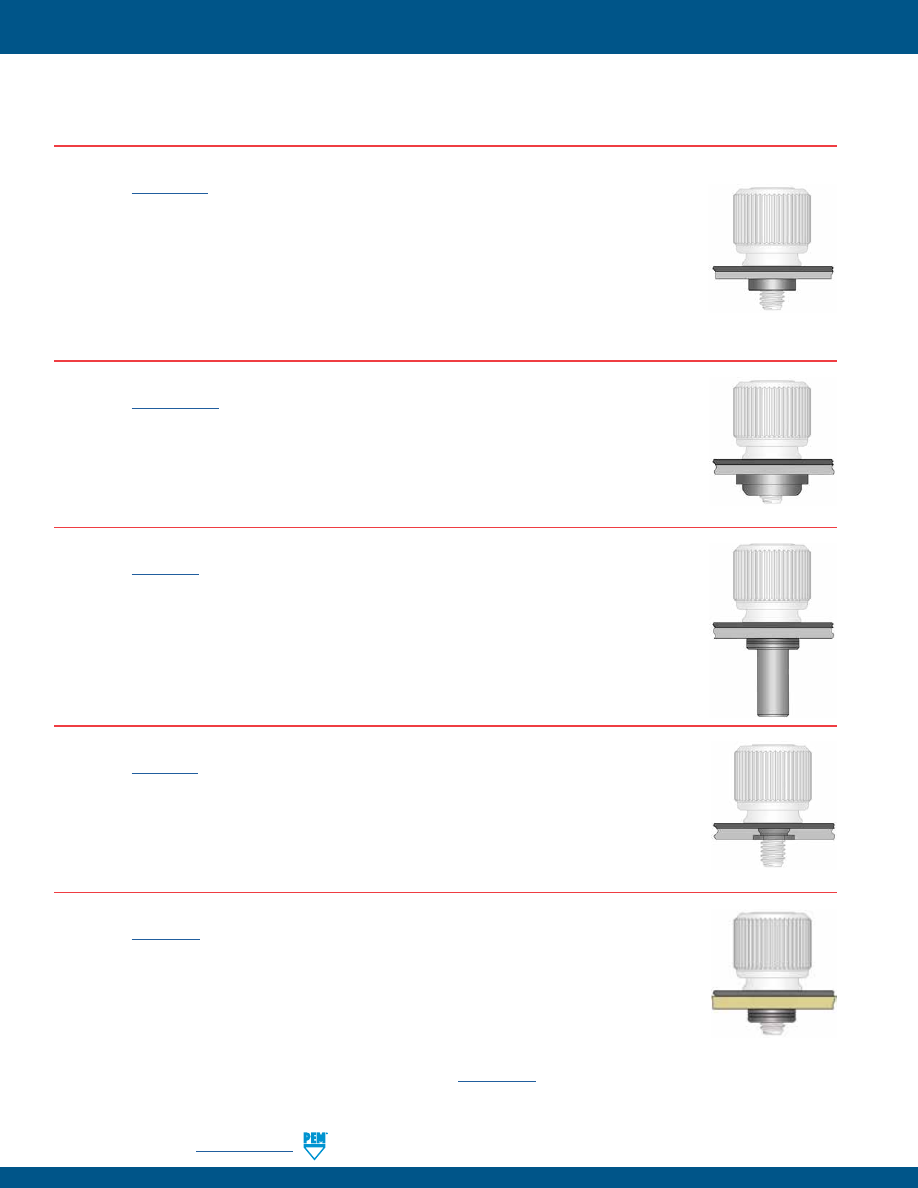

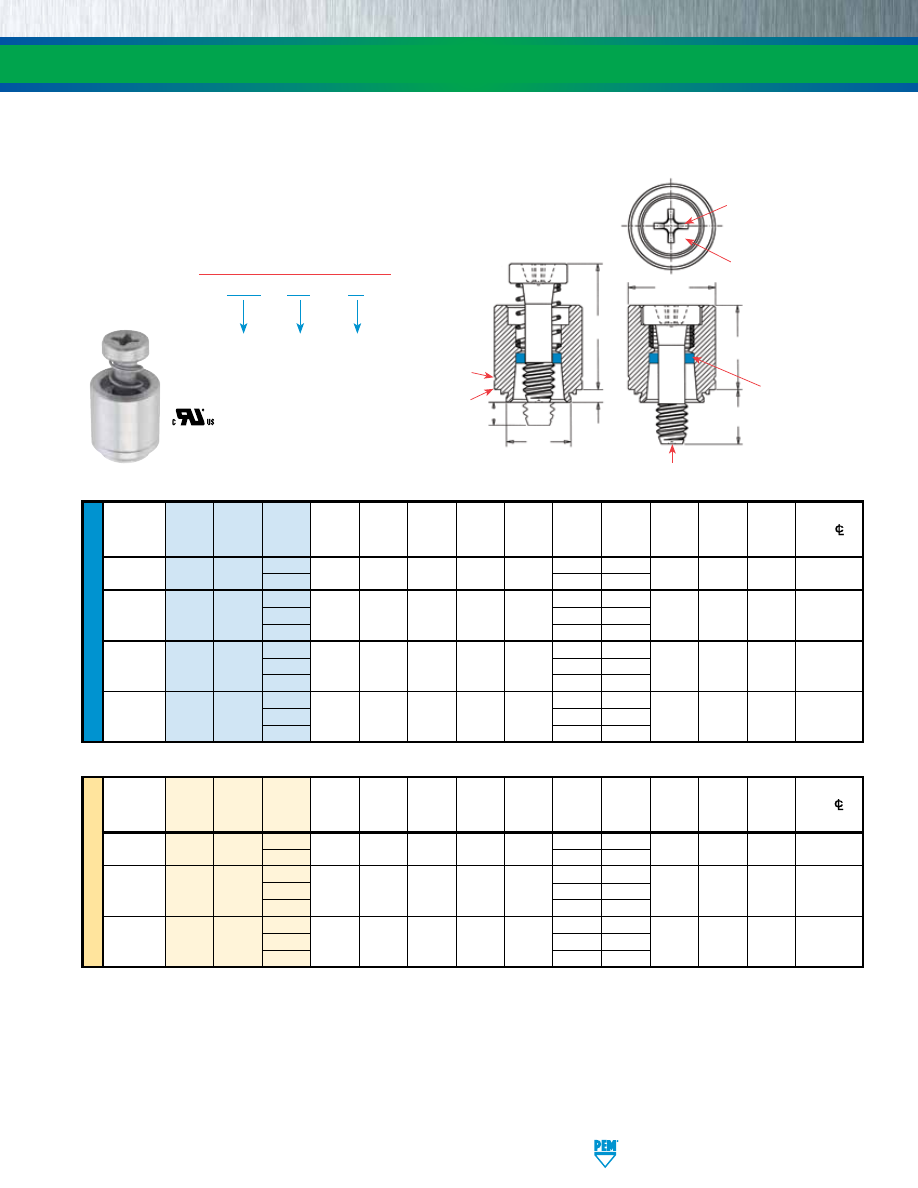

PF11, PF11M

Bulletin PF

Panel fastener assembly with knurled cap and universal slot/

Phillips recess. Available with anti cross-thread feature.

PF12, PF12M

Bulletin PF

Panel fastener assembly with smooth cap and universal slot/

Phillips recess. Available with anti cross-thread feature.

PF30, PF31, PF32

Bulletin PF

Low-profile panel fastener assembly with large knurled head

for tool or hand operation.

PF50

Bulletin PF

Low-profile panel fastener assembly with large knurled cap

and Phillips recess for tool or hand operation.

PF60

Bulletin PF

Low-profile panel fastener assembly with large smooth cap

and Phillips recess for tool or hand operation.

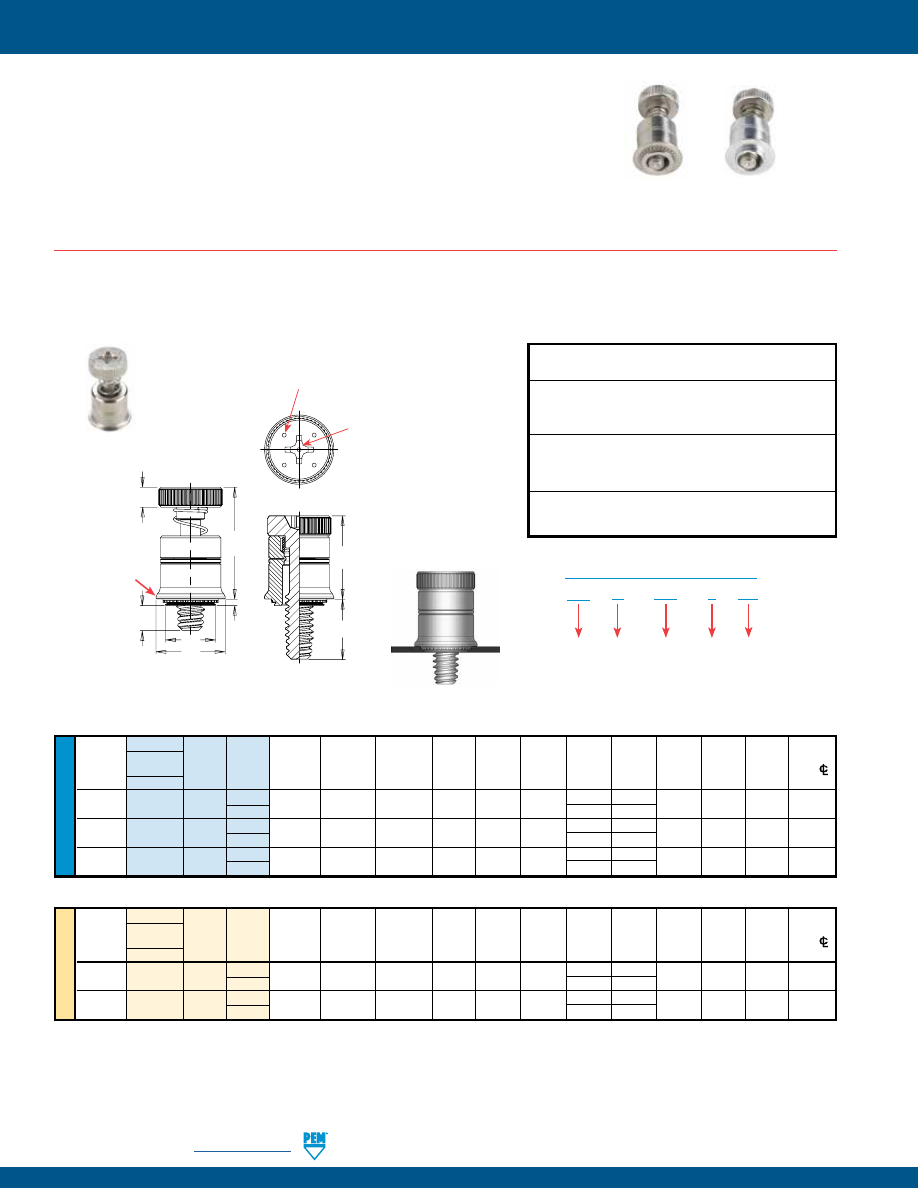

PF11MF

Bulletin PF

Flare-mounted captive screw assembly with anti cross-

thread feature.

PF12MF

Bulletin PF

Flare-mounted captive screw assembly with anti cross-

thread feature.

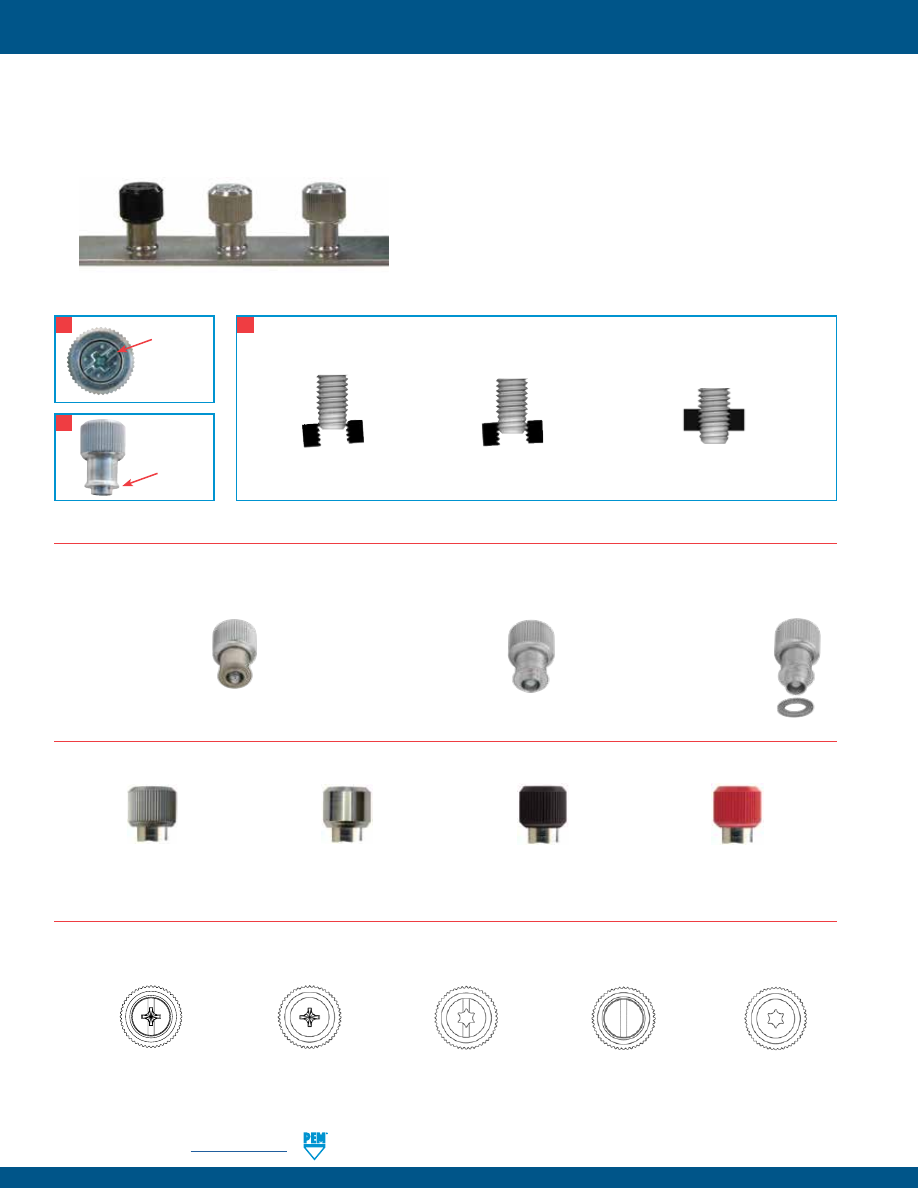

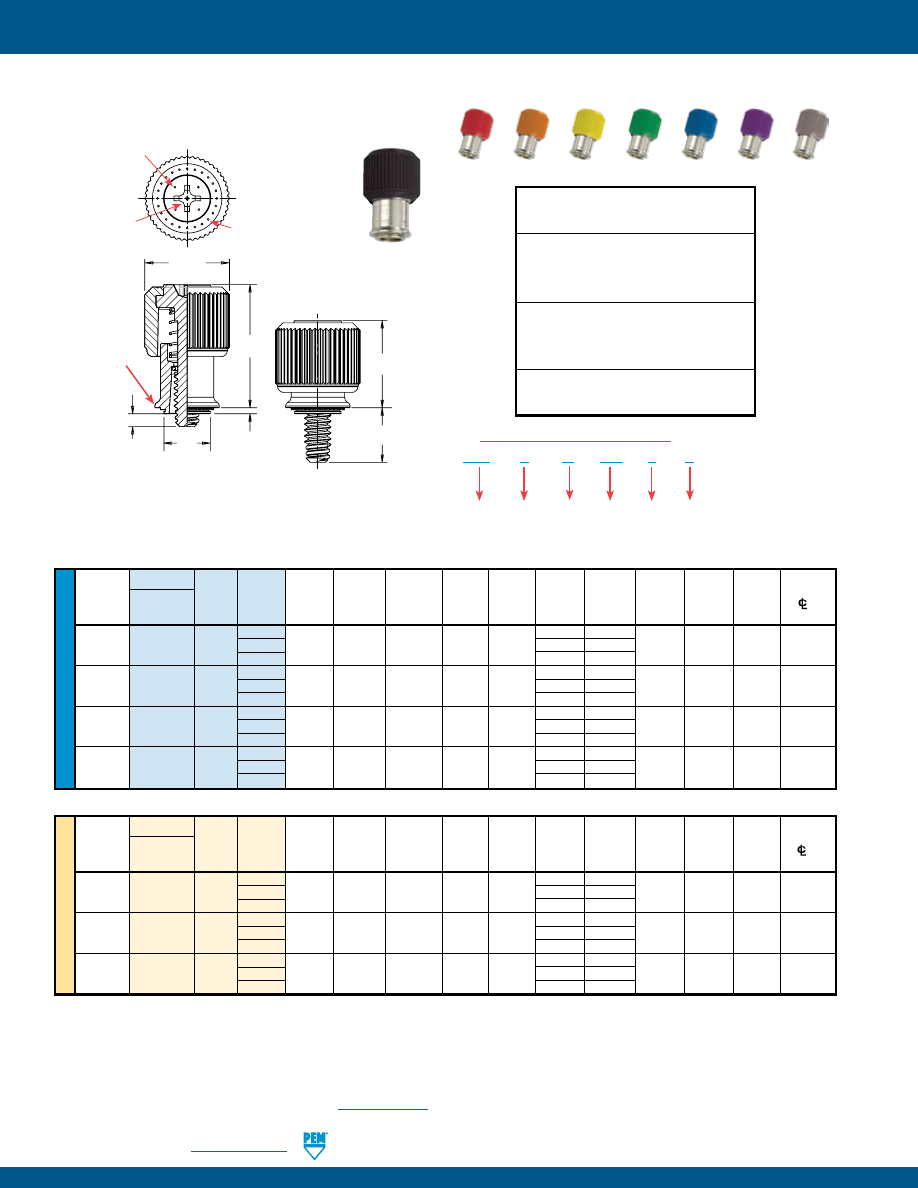

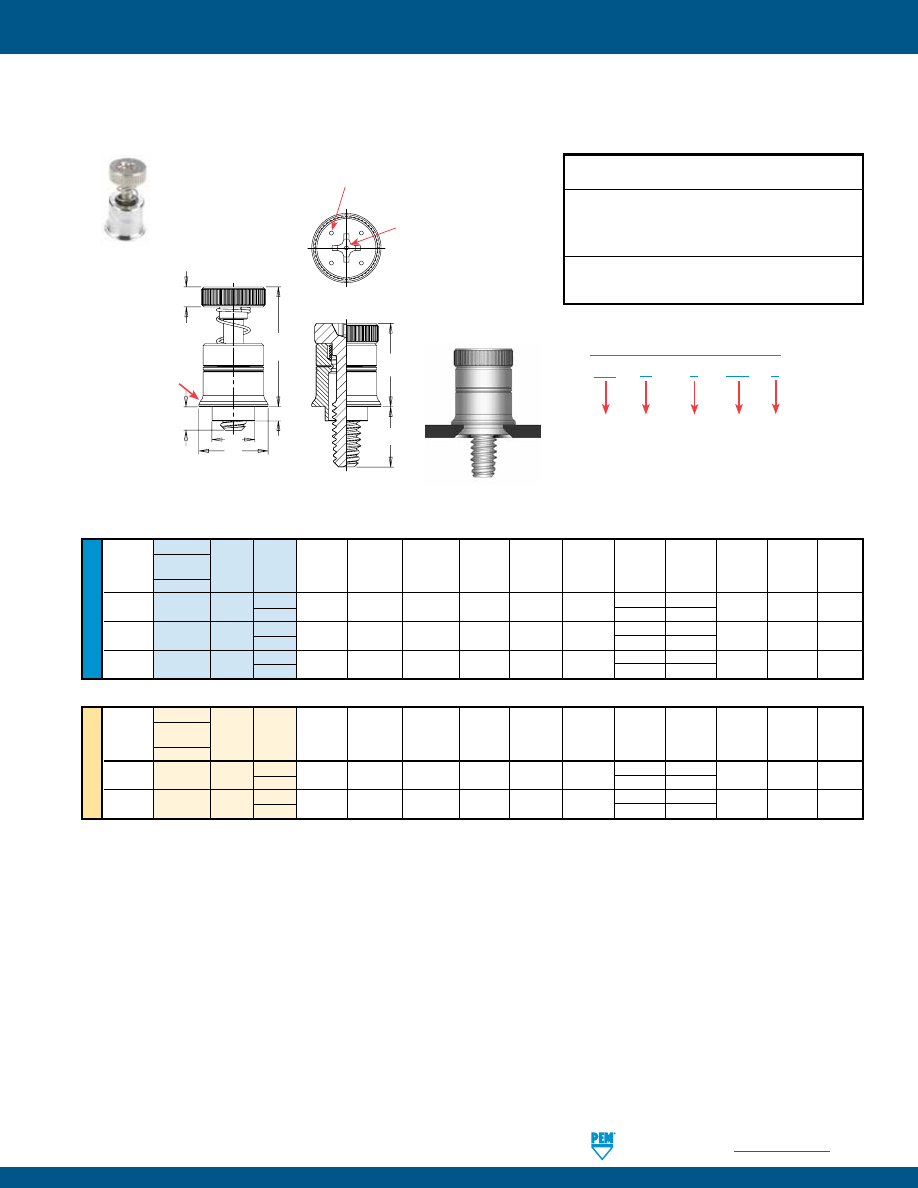

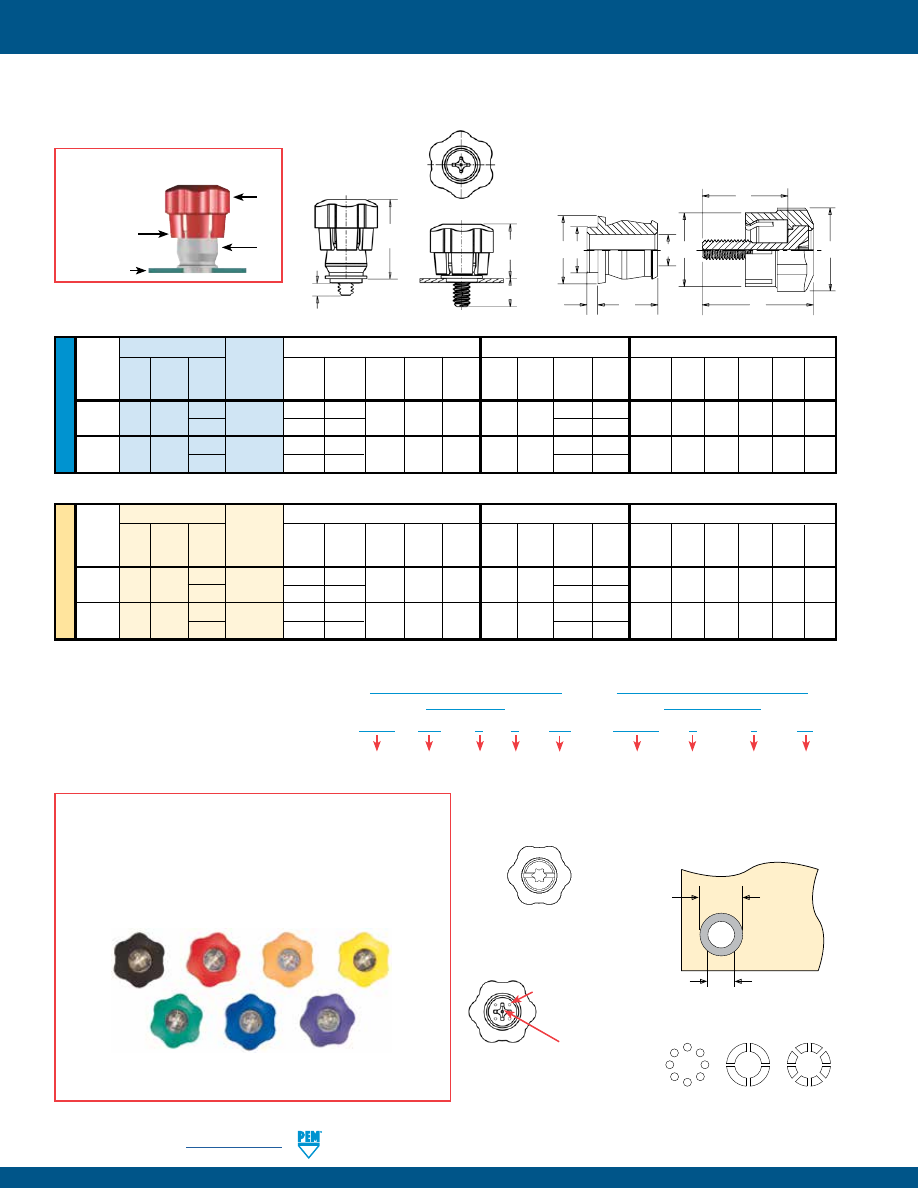

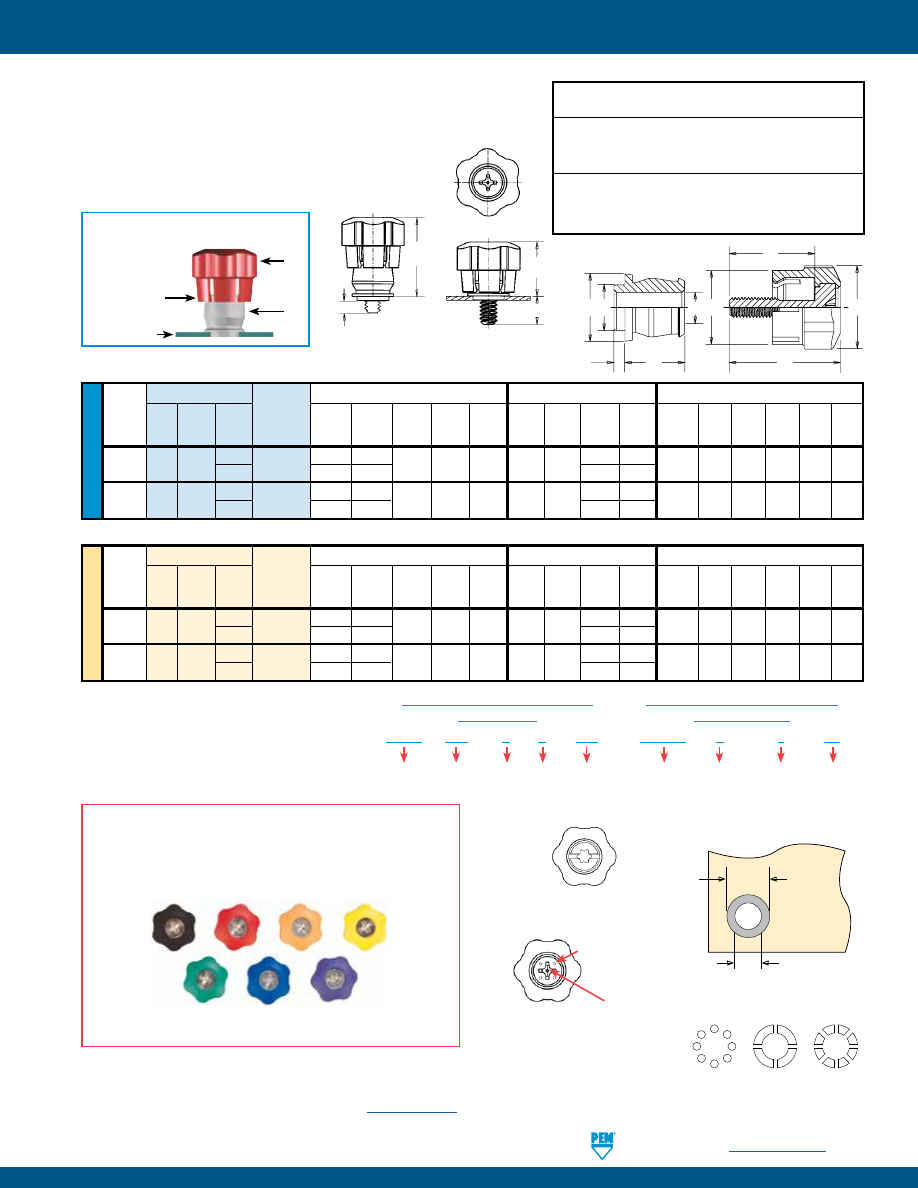

PEM C.A.P.S.®

Bulletin PF

Colored Access Panel Screws with plastic cap. Key features

include Phillips drive and MAThread® anti-cross threading

feature.

MPP

Bulletin MPF

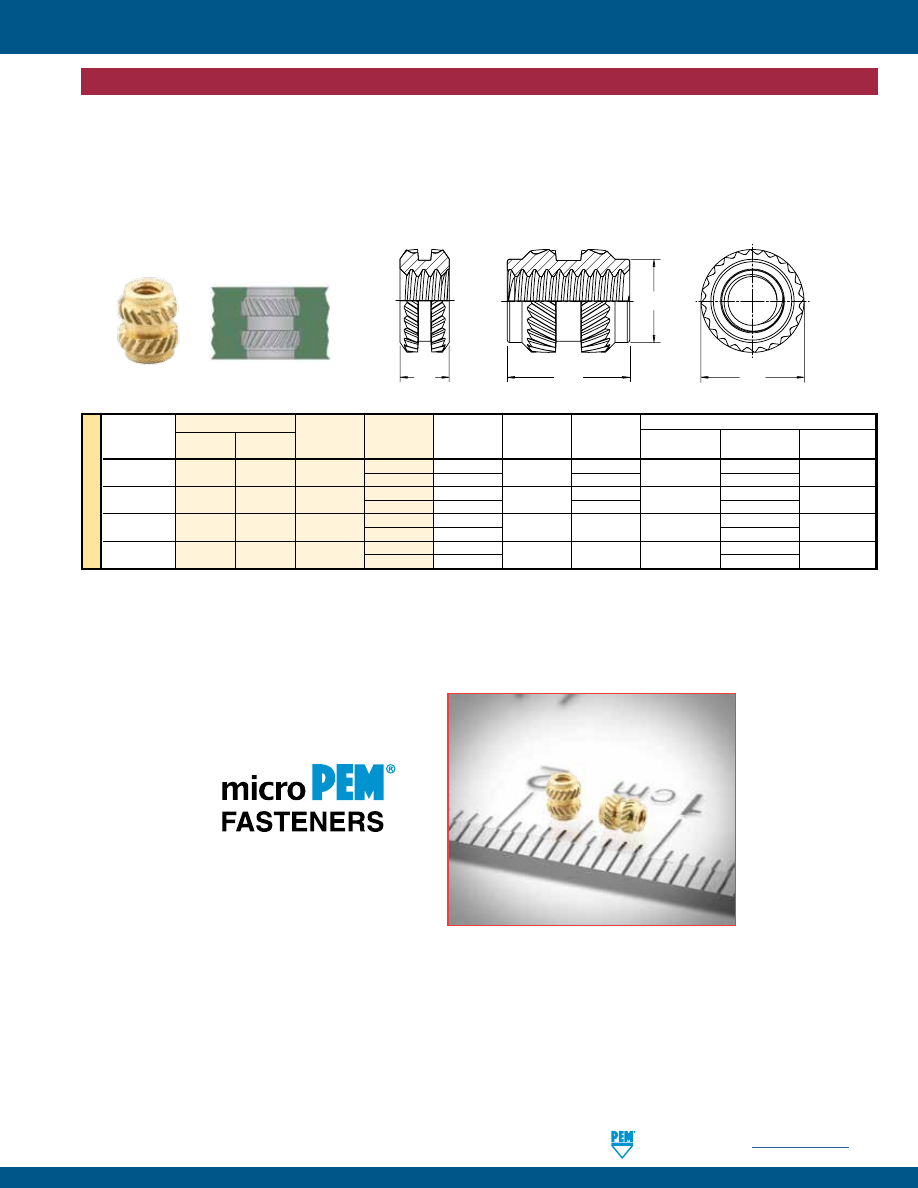

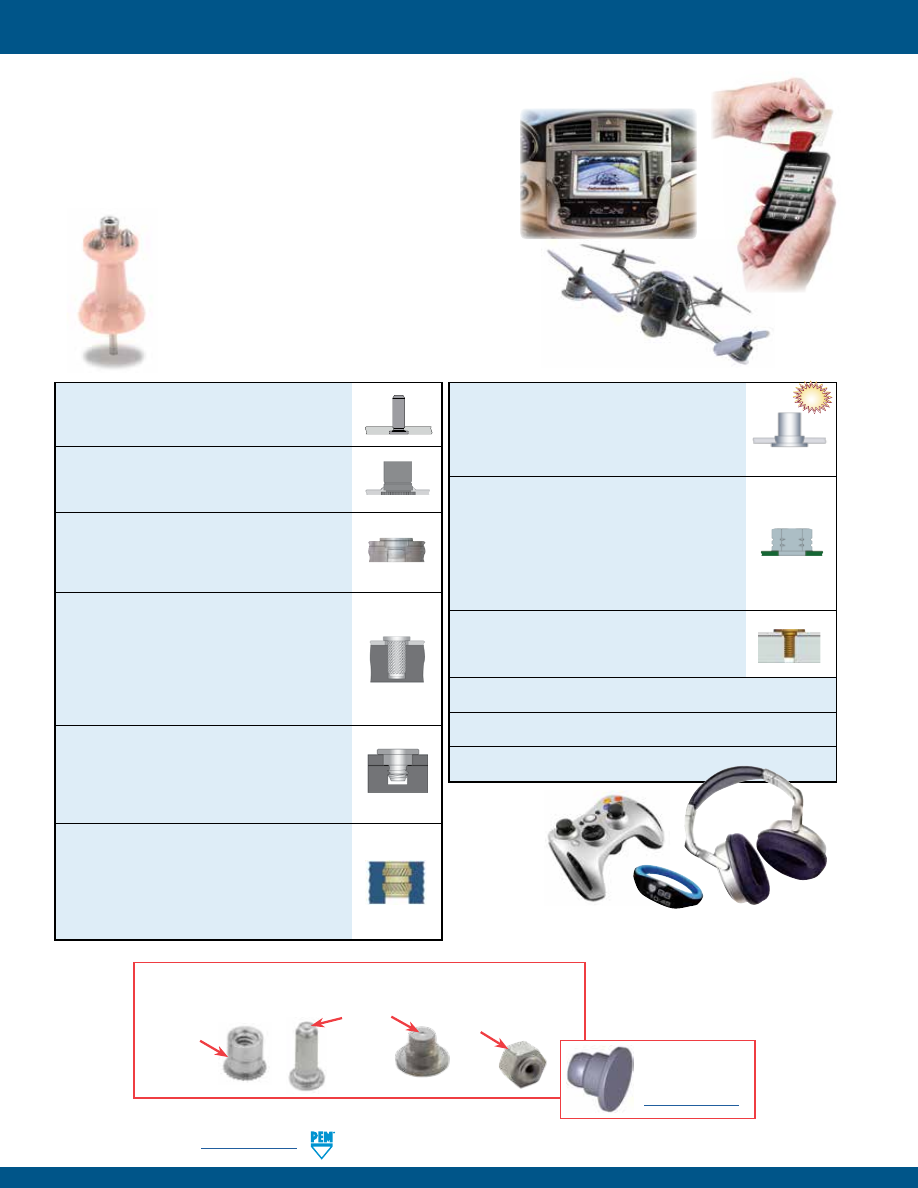

microPEM® pins that can be installed into sheets as thin as

0.5 mm.

MSO4

Bulletin MPF

microPEM® standoffs that can be installed into sheets as thin

as .016” / 0.4 mm.

PF10

Bulletin PF

Flush-mounted panel screw components.

N10 (nut), PR10 (retainer) and PS10 (screw).

PR10

N10

PS10

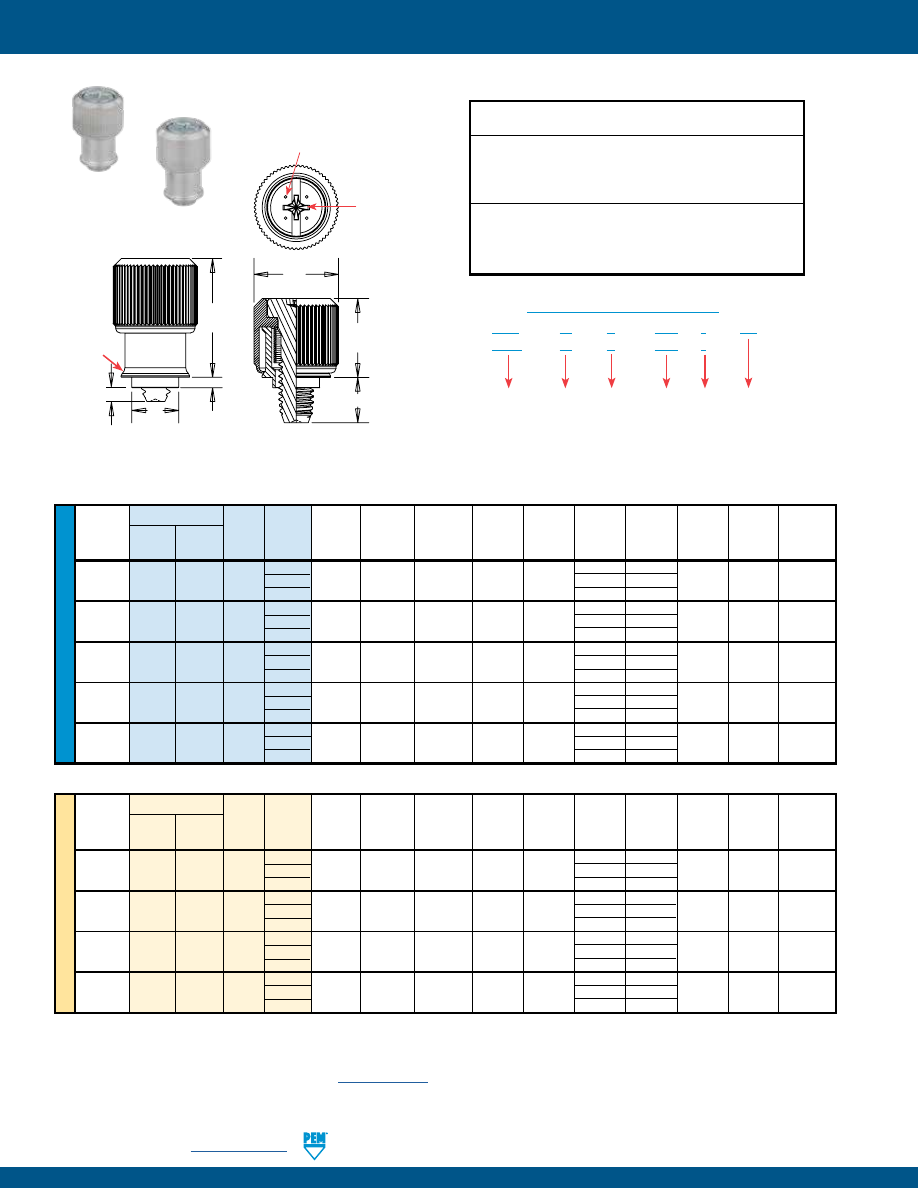

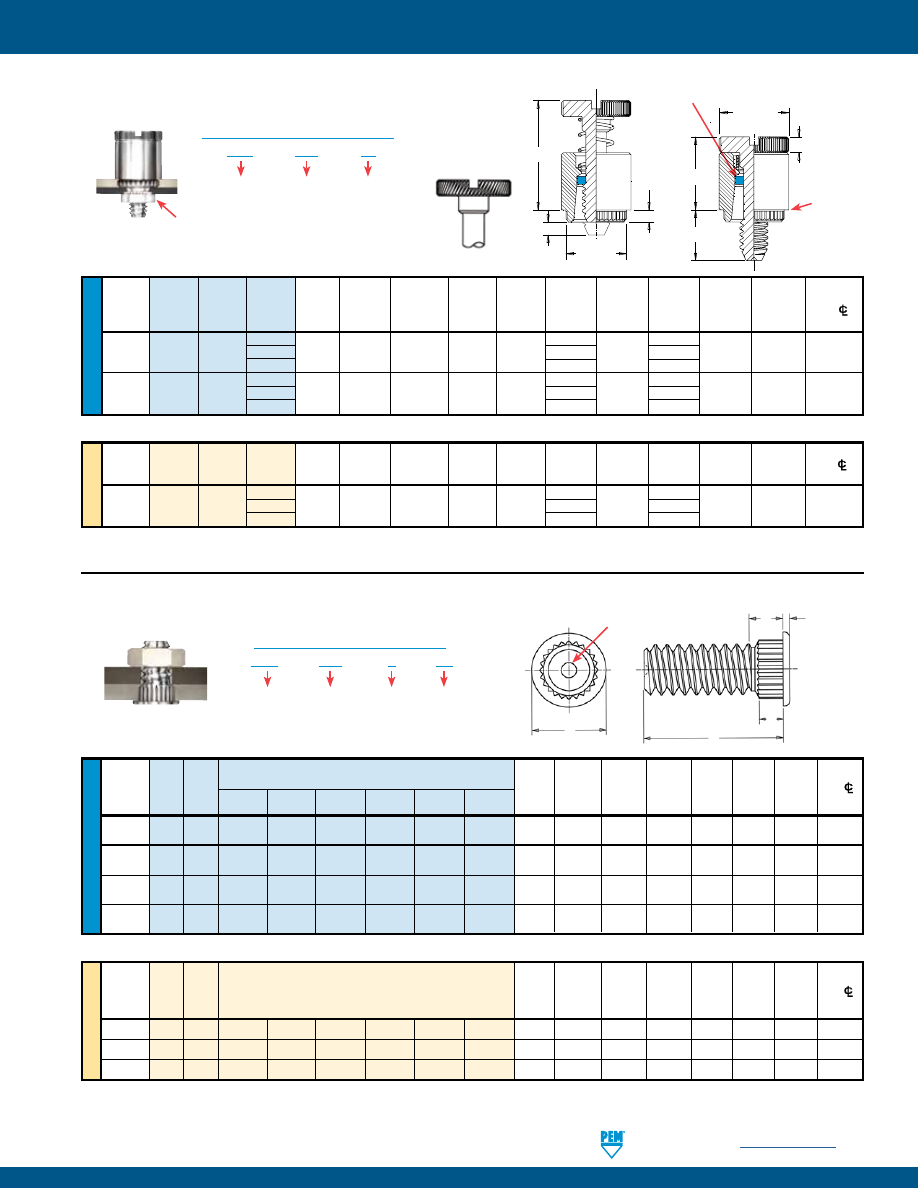

PF11MW

Bulletin PF

Floating captive screw assembly allows for mating hole

misalignment.

PF12MW

Bulletin PF

Floating captive screw assembly allows for mating hole

misalignment.

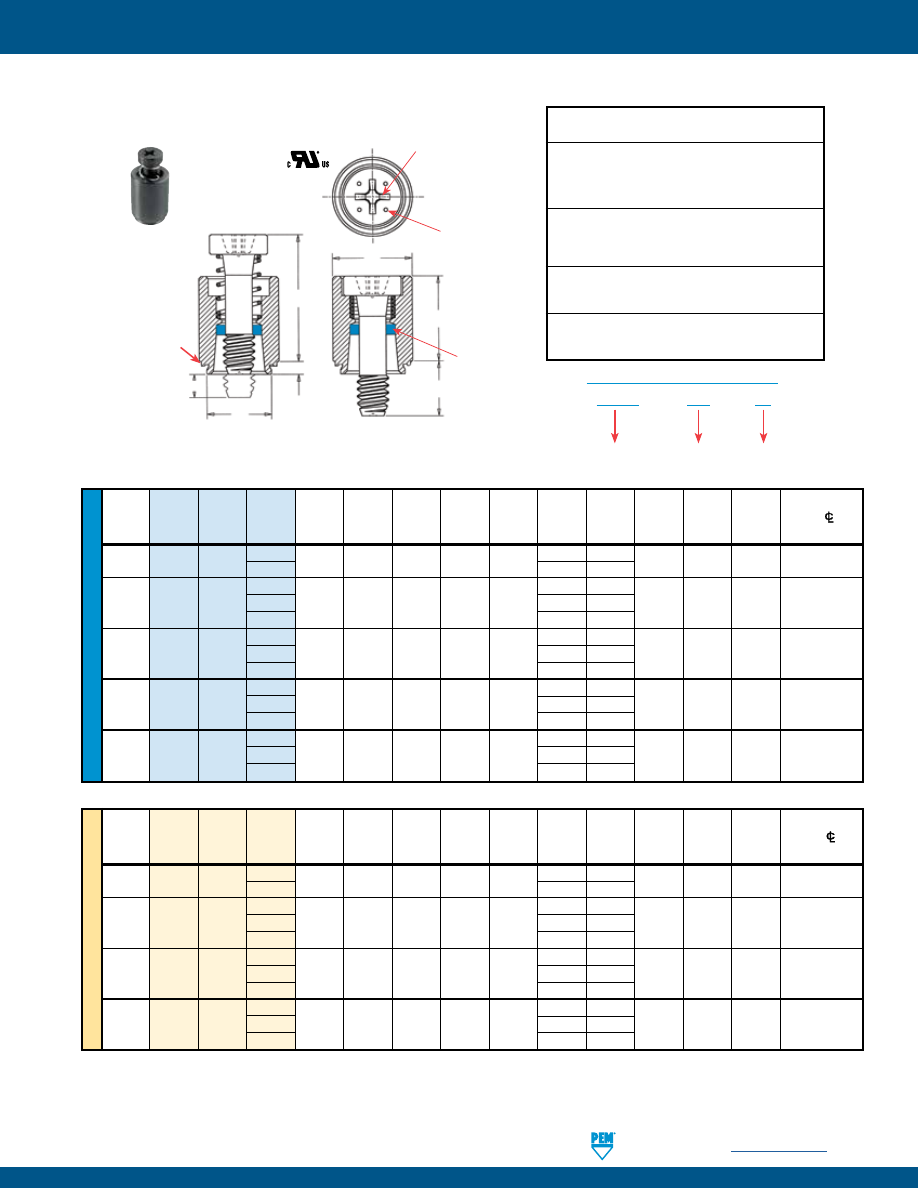

PF7M

Bulletin PF

Small, compact, and low-profile self-clinching captive panel

screws designed for limited access areas.

PF7MF

Bulletin PF

Small, compact, and low-profile flaring captive panel screws

designed for limited access areas.

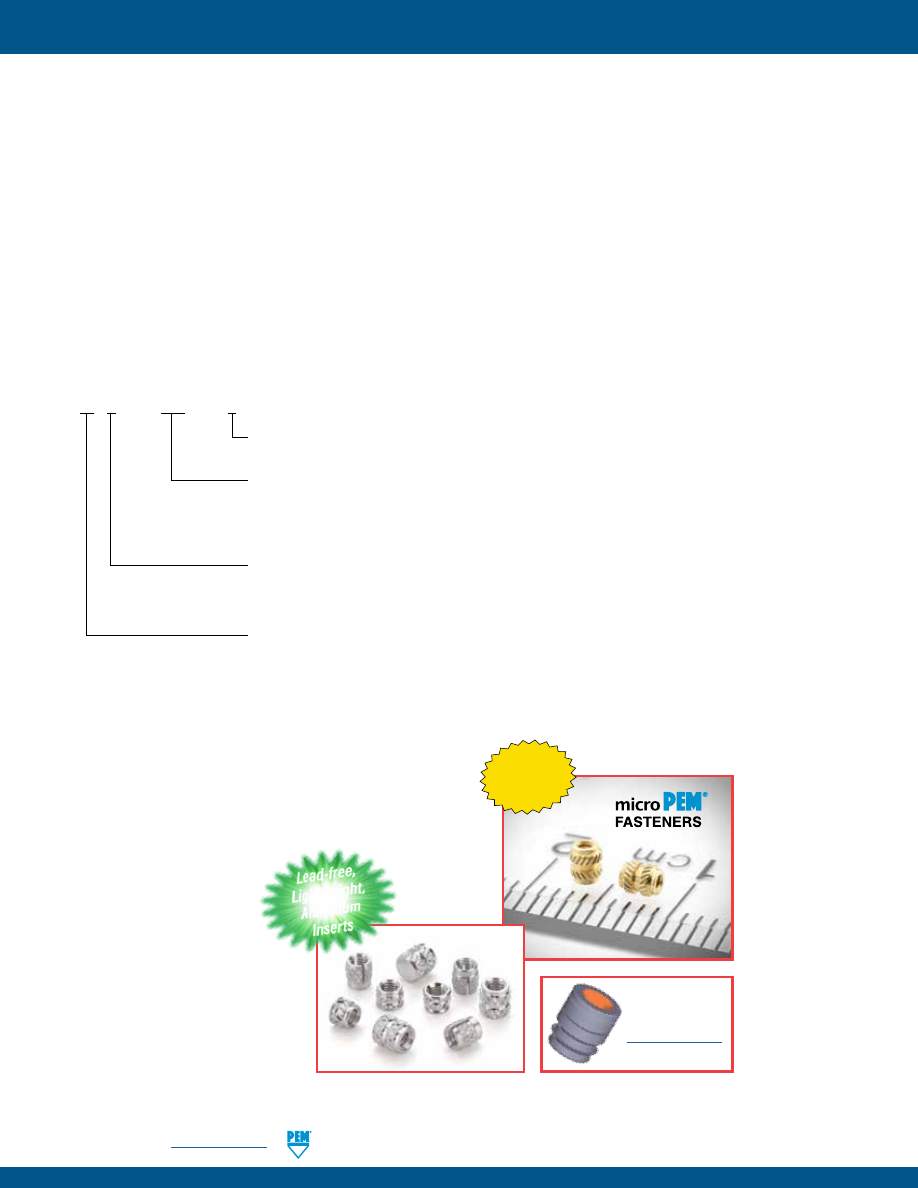

MSIB

Bulletin MPF

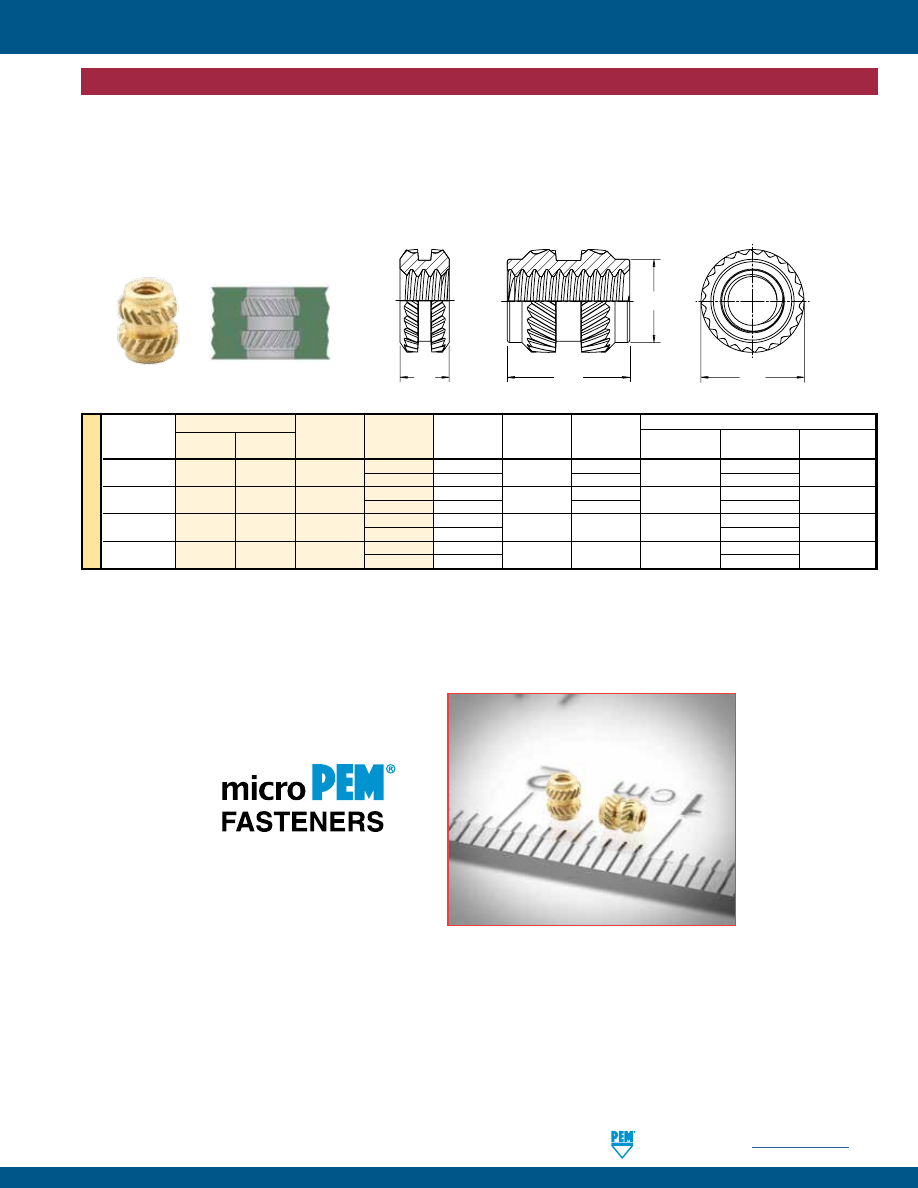

microPEM® symmetrical designed thru-threaded inserts for

plastics for use in straight or tapered holes.

LA4, LAC, LAS

Bulletins ALA & LN

Nuts with load-bearing, self-locking threads that permits up

to .030” / 0.76 mm adjustment for mating hole misalignment.

LK, LKA, LKS

Bulletin LN

Nuts with a unique PEMFLEX® self-locking feature permitting

repeated use and effective prevailing locking torque.

KF2, KFS2

Bulletin K

Nuts, internally threaded, for mounting on P.C. boards.

KFB3

Bulletin K

Flare-mounted standoffs for mounting on P.C. boards with

greater pullout performance.

KFE, KFSE

Bulletin K

Threaded or unthreaded standoffs mounted on P.C. boards for

stacking or spacing.

KFH

Bulletin K

Threaded studs for use as solderable connectors or as

permanently mounted studs on P.C. boards.

KSSB

Bulletins K & SSA

SNAP-TOP® standoffs featuring a spring action to hold a P.C.

Board securely without screws or threaded hardware.

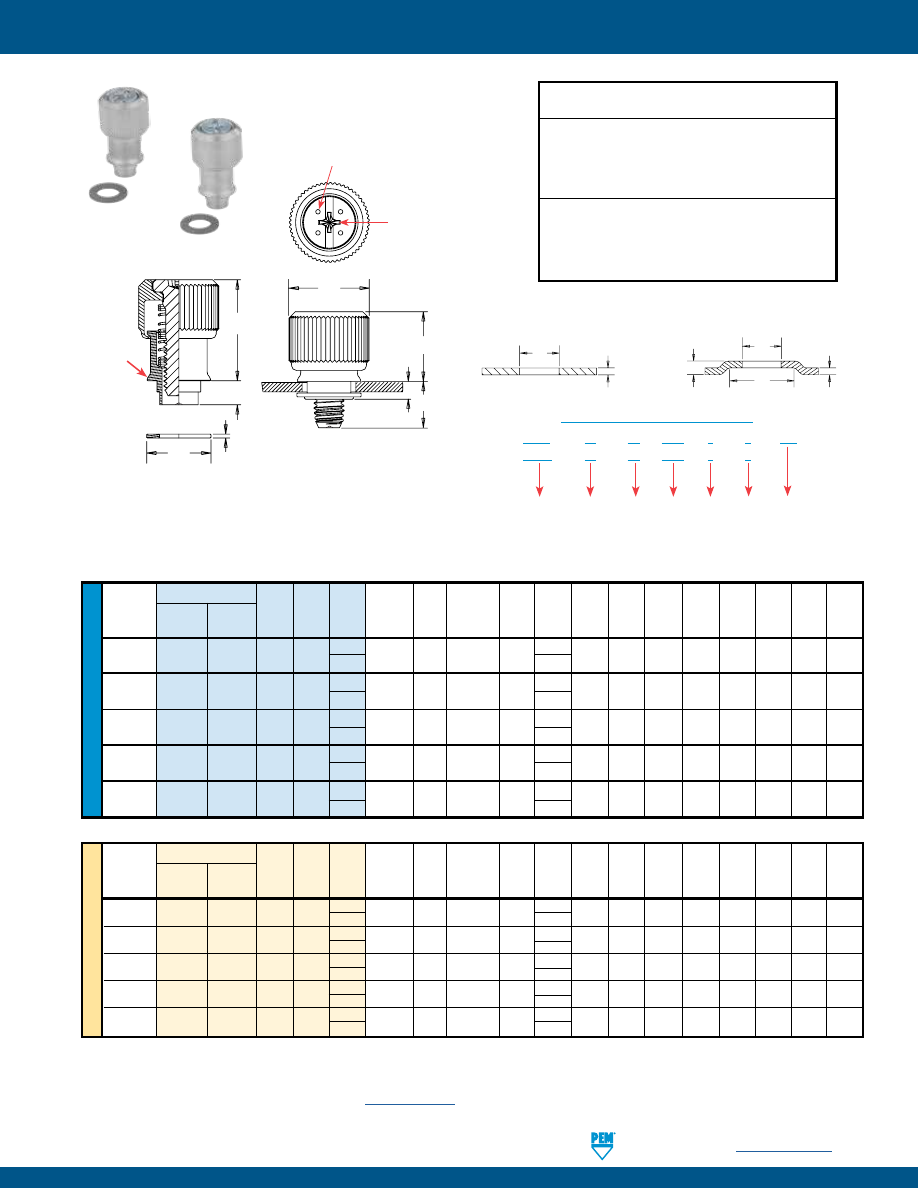

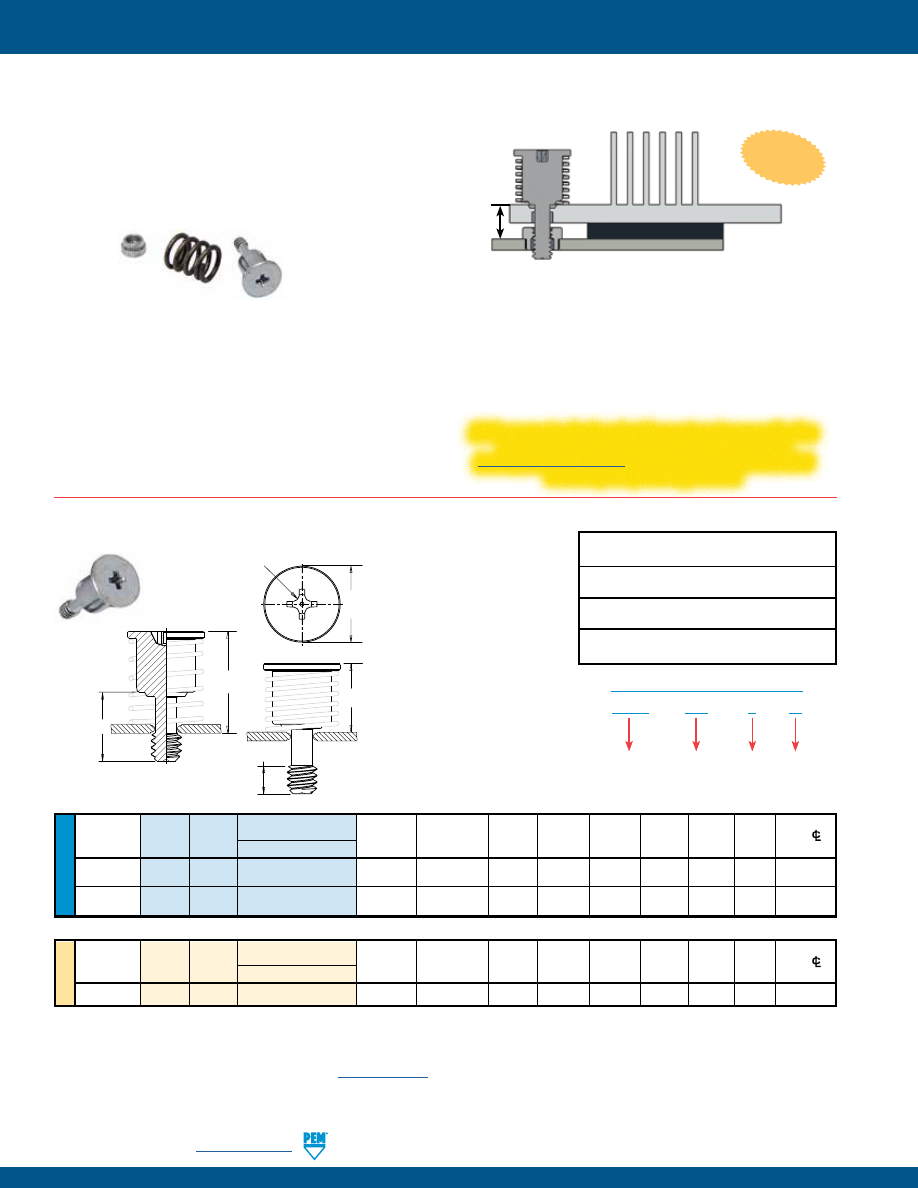

HSCB

Bulletin PF

Heat sink mounting system.

HSCB (screw), HSR (nut) and HSL (spring).

HSCB

HSR

HSL

HFLH

Bulletin FH

Studs are for installation into thin, harder, high-strength

materials.

PennEngineering •

www.pemnet.com

INDEX-4

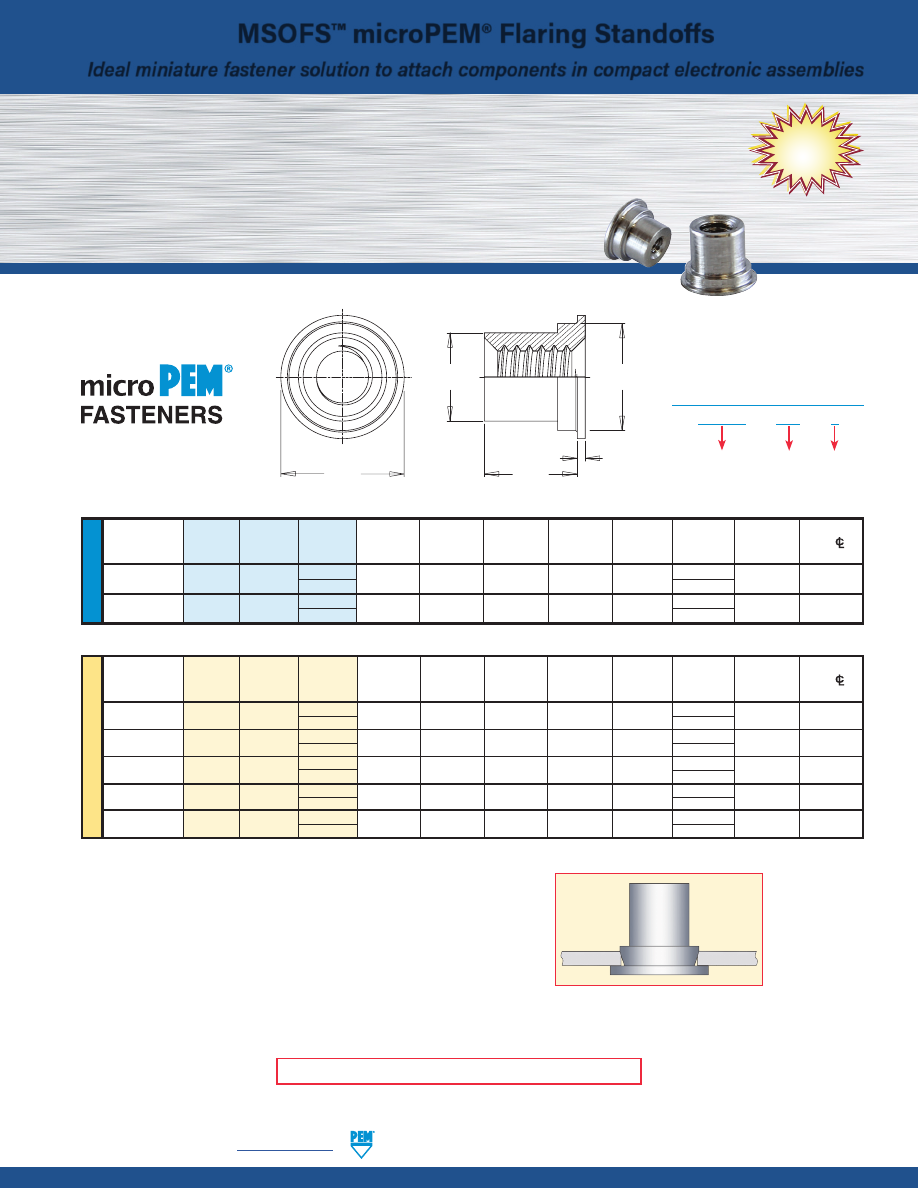

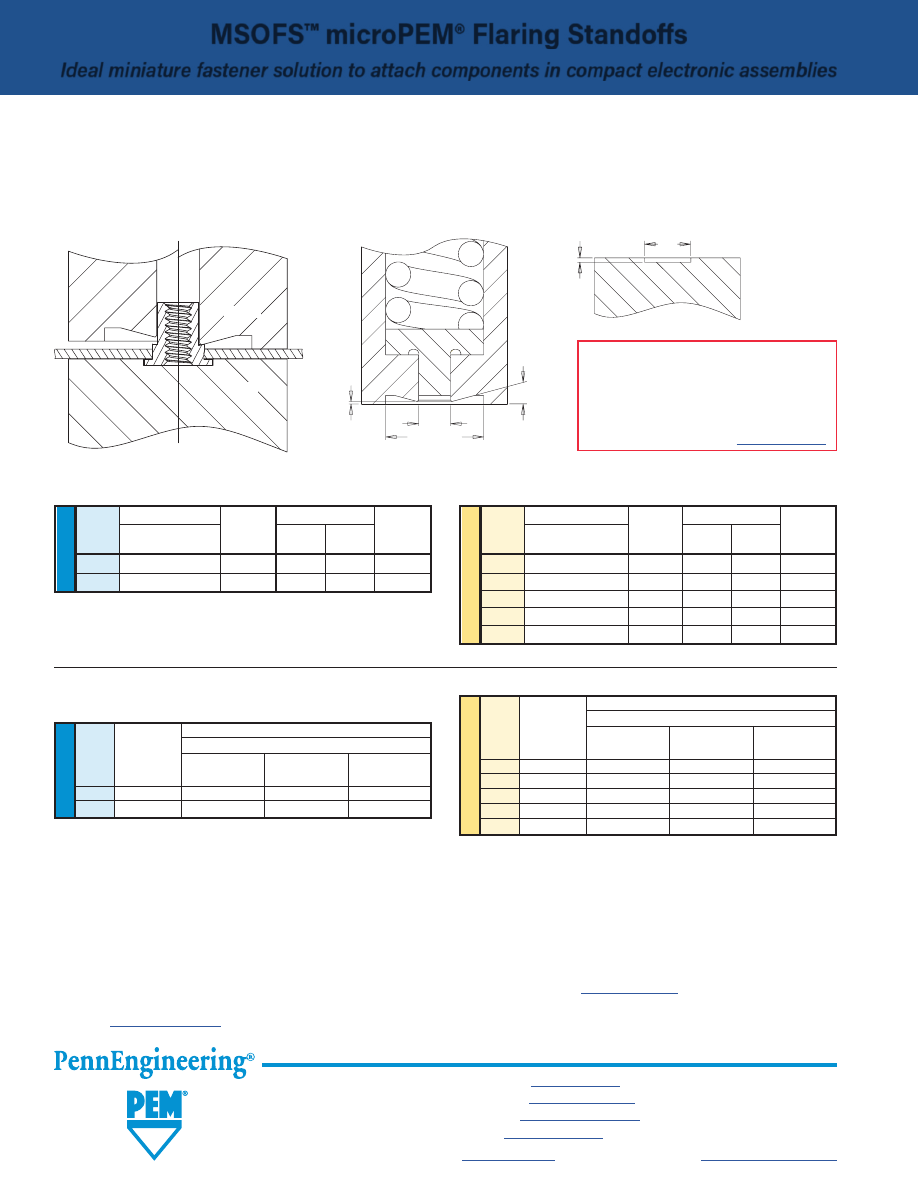

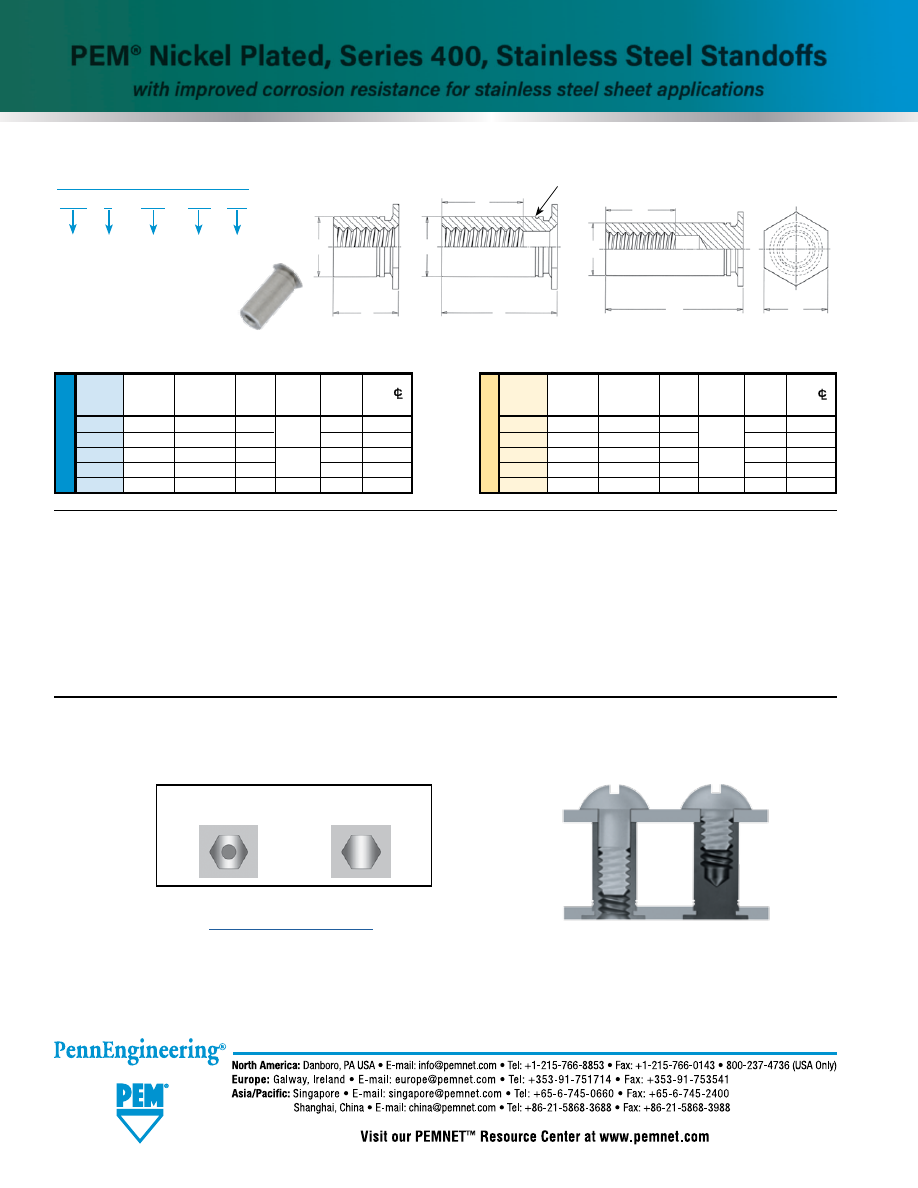

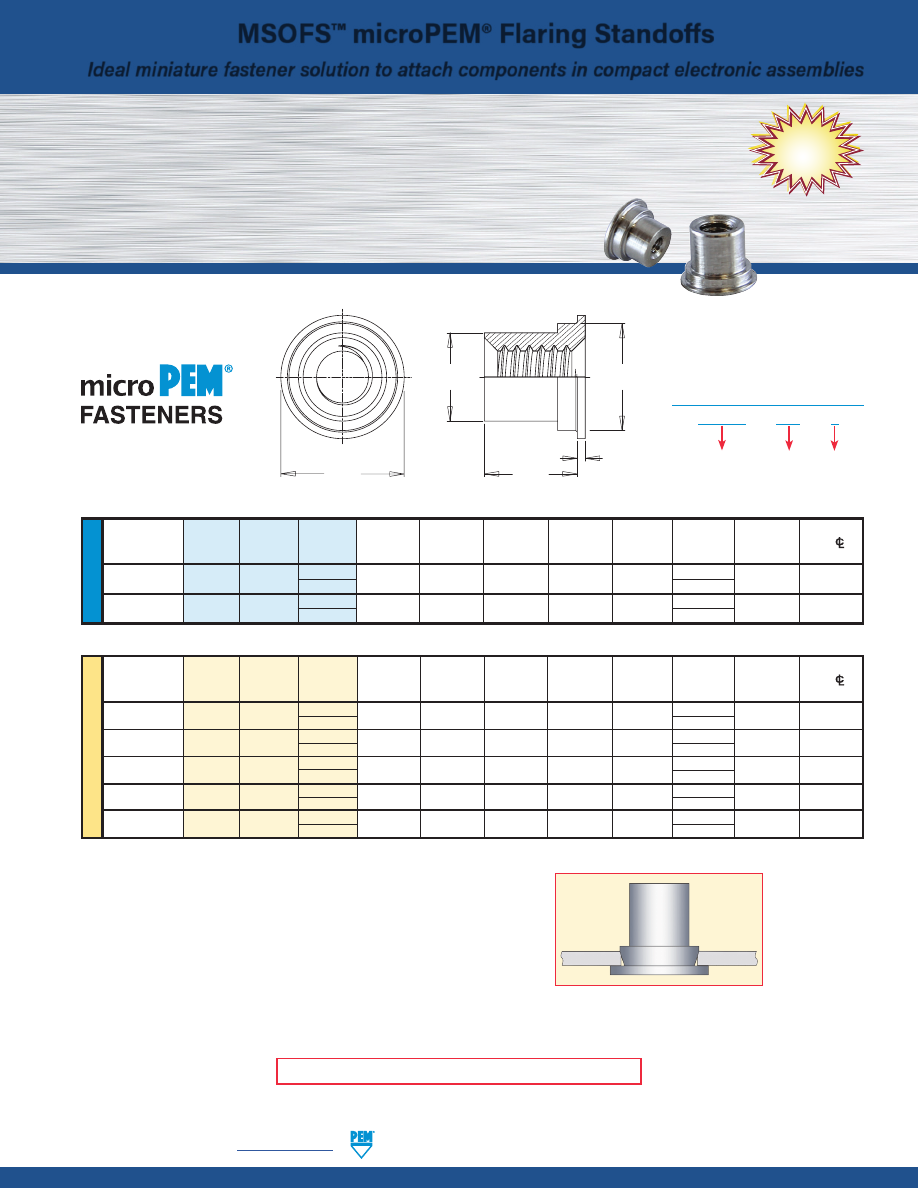

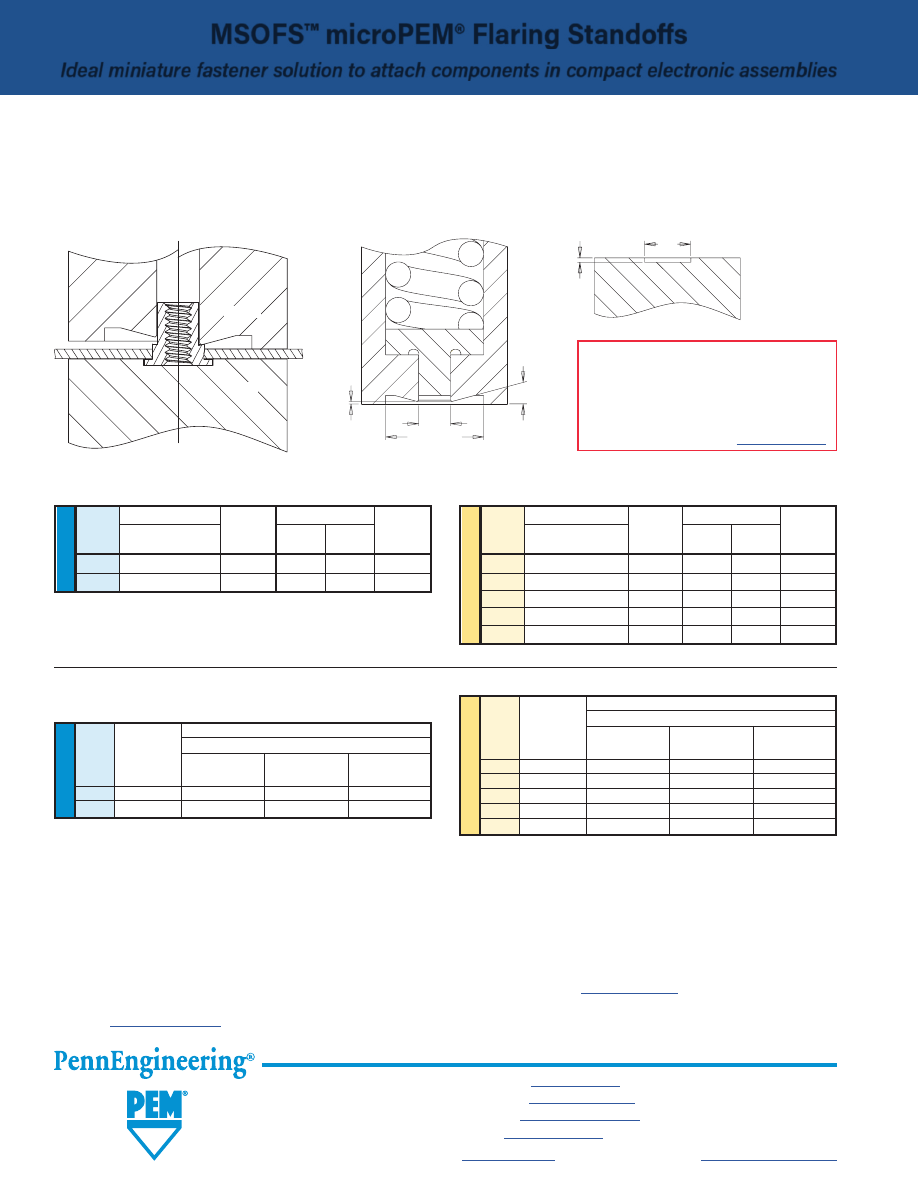

MSOFS

Bulletin MPF

microPEM® flaring standoffs attached permanently in panels

as thin as .008” / 0.2 mm of any hardness including stainless

steel.

B

B

SC

SC

SC

SC

Inserts

SC

FM

SC

SC

B

B

B

FM

SC

FM

FM

SC

SC

SC

SC

FM

FM

SC

FM

SC

SC

pem-html.html

FM

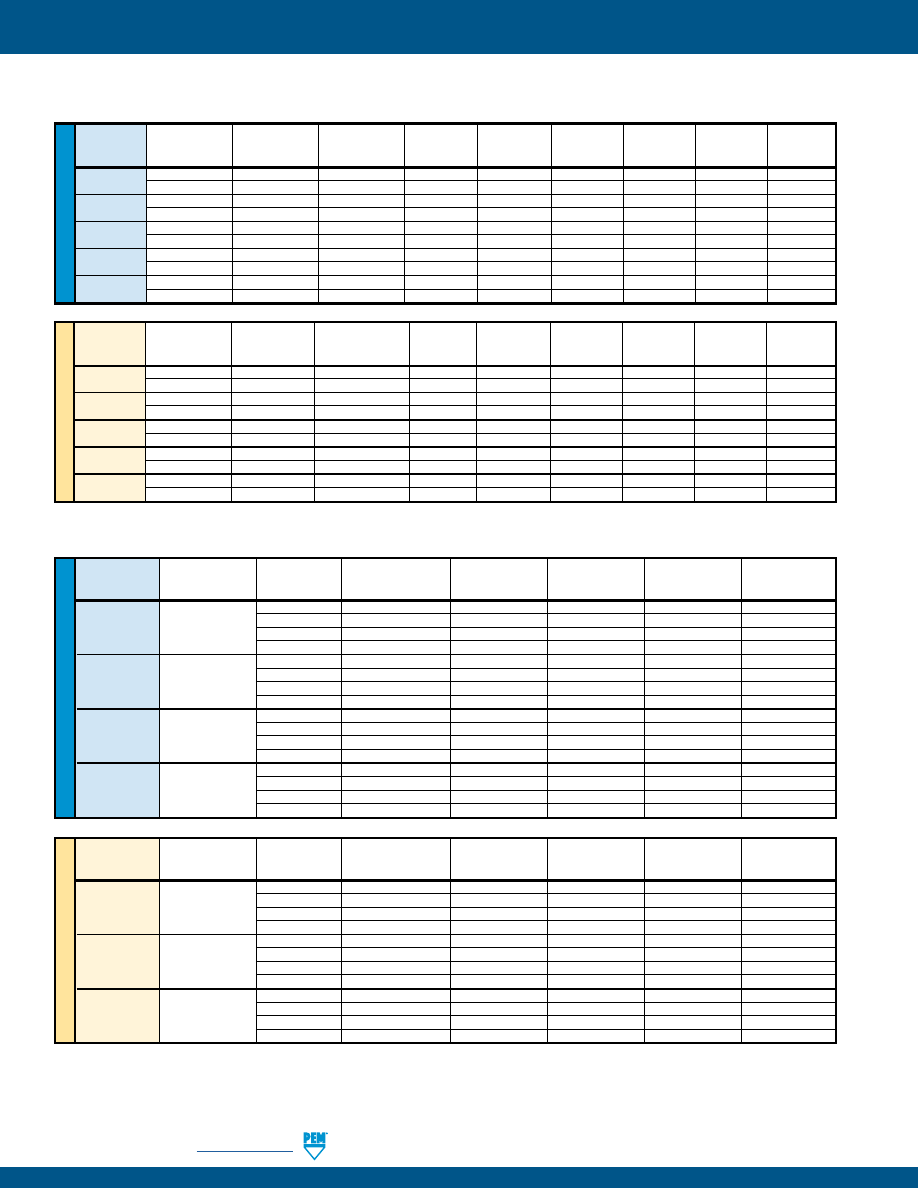

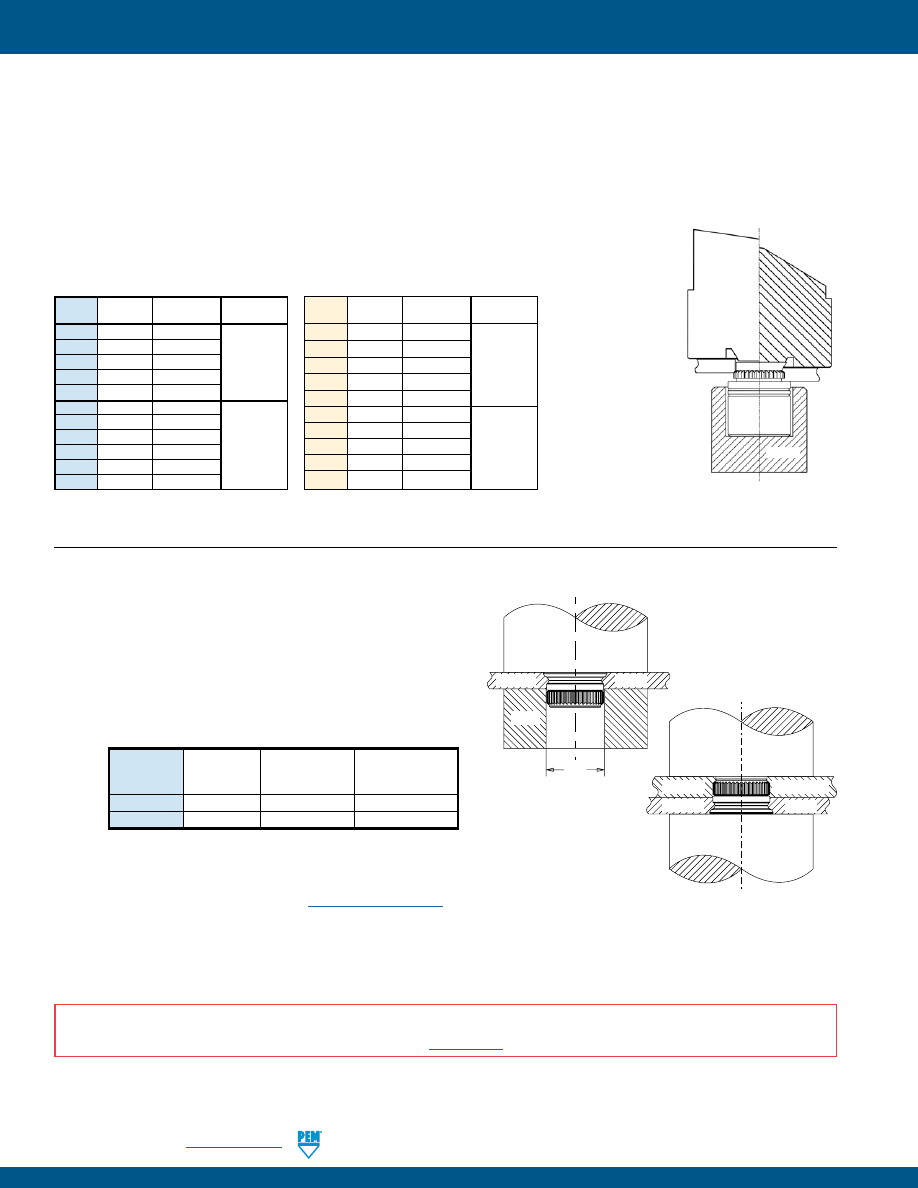

PL, PLC

Bulletin LN

PEMHEX® self-locking nuts with a nylon hexagonal element to

provide a reusable prevailing torque thread lock.

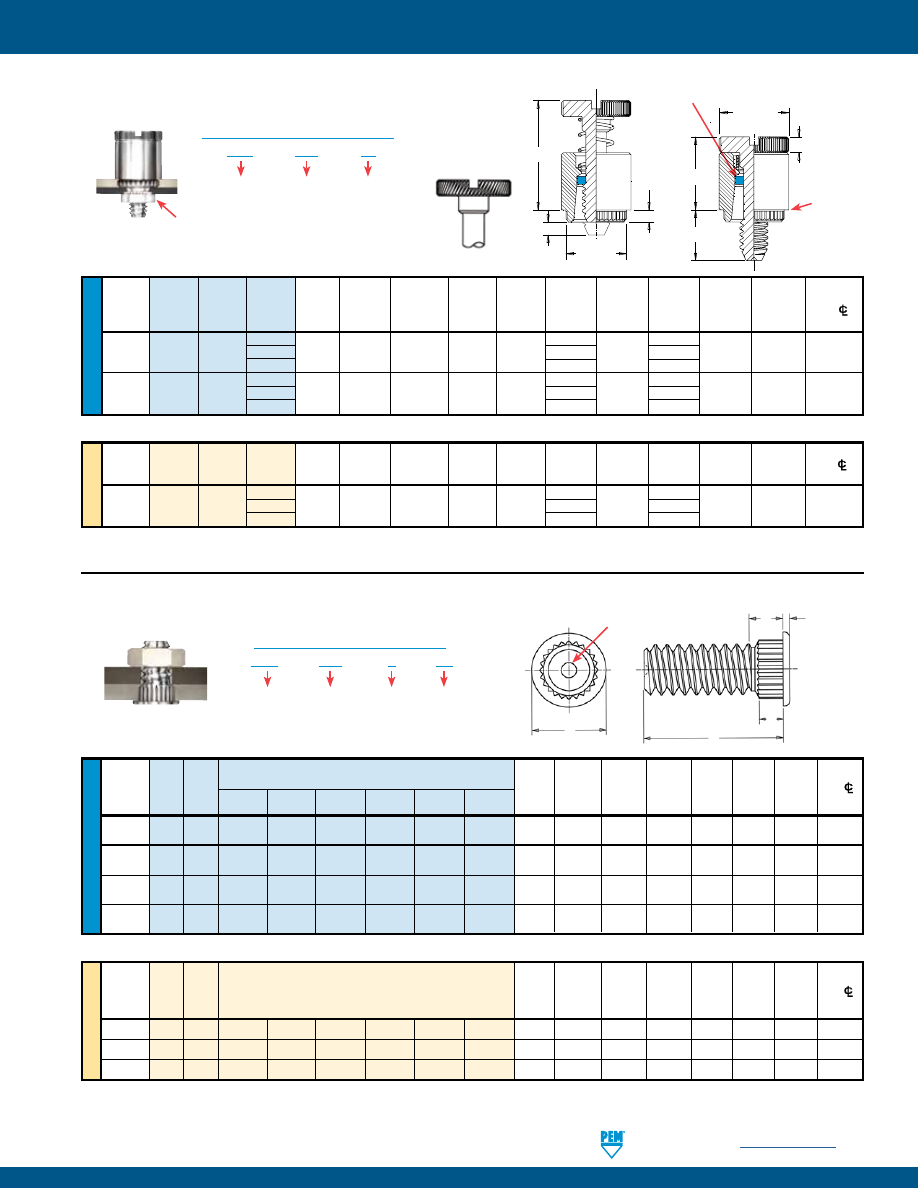

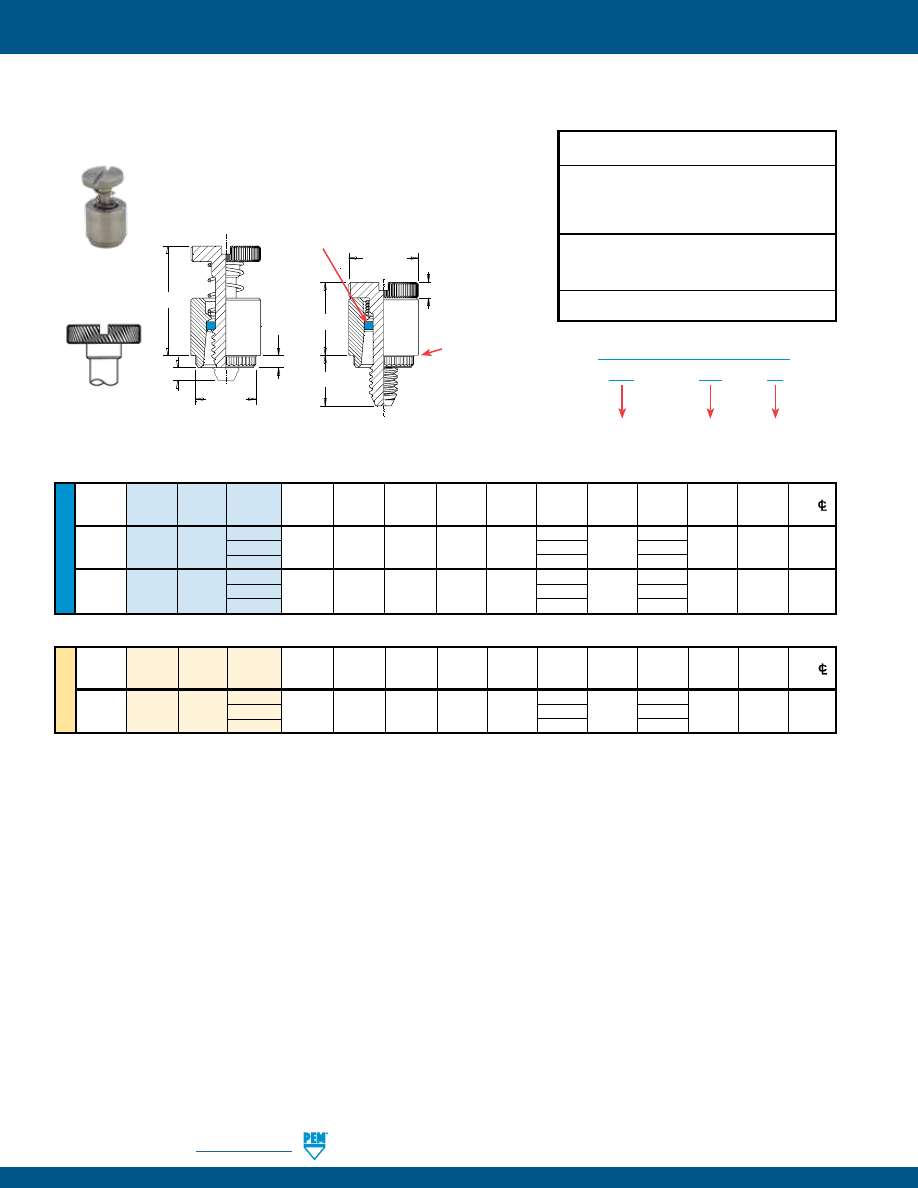

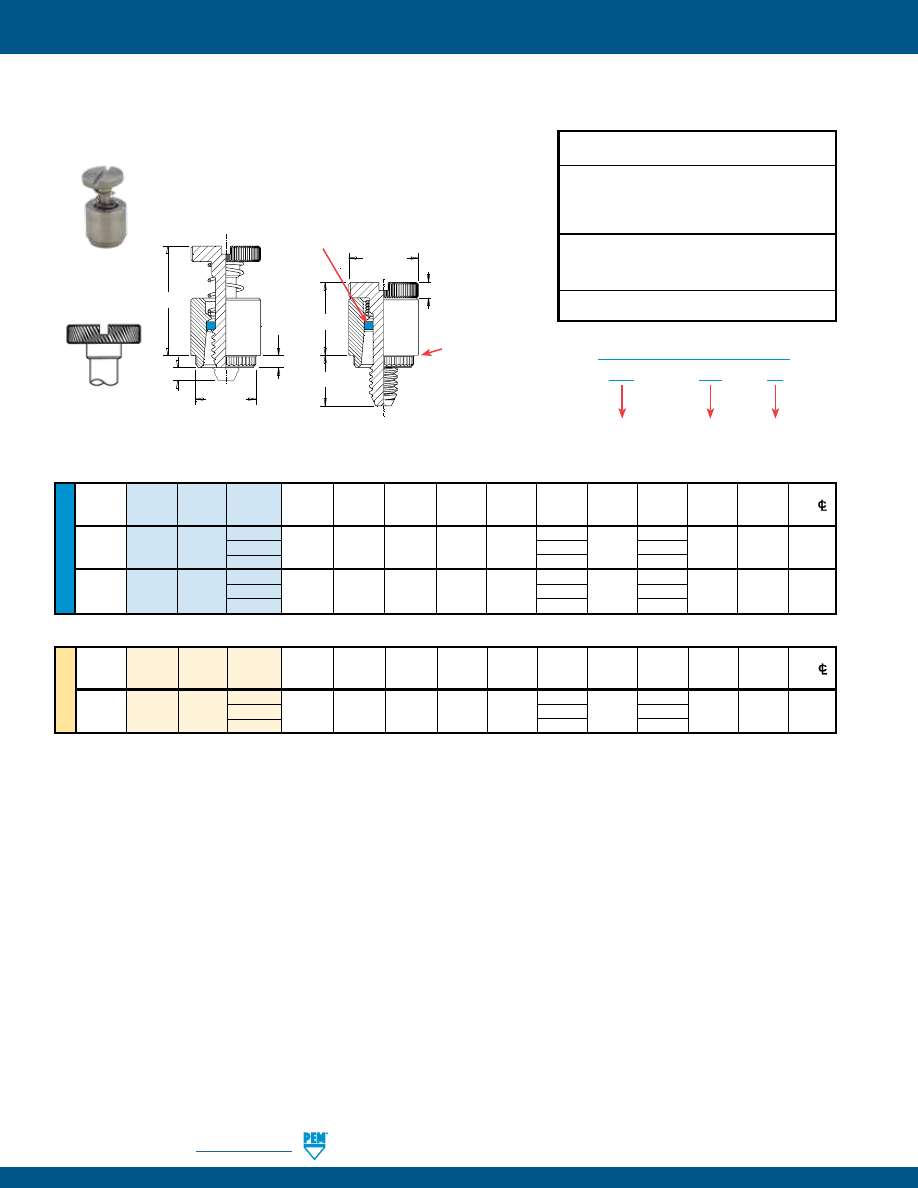

PSL2, PTL2

Bulletin PF

Spring-loaded plunger assembly. Quick lockout feature on

Type PTL2 holds plunger in retracted position.

RAA

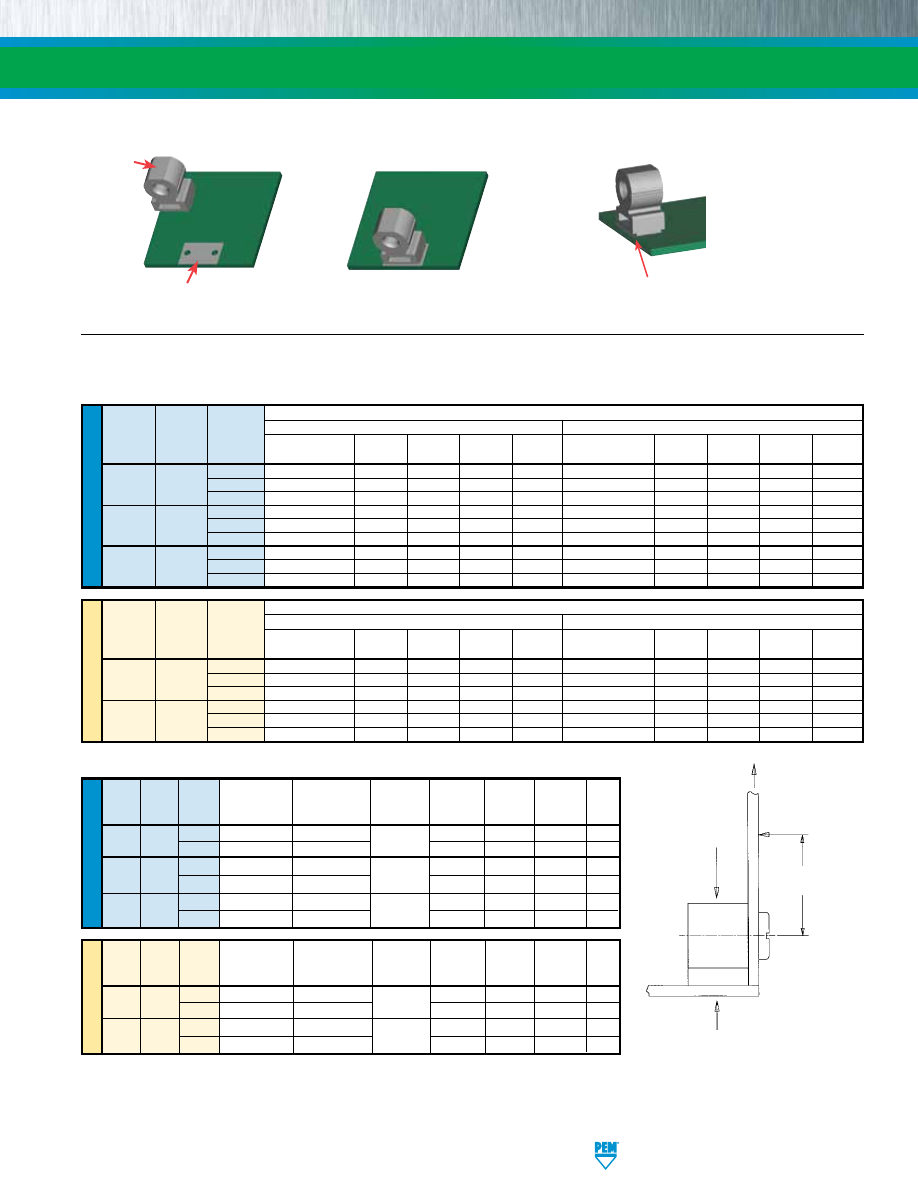

Bulletin RA

Self-tapping R’ANGLE® fasteners provide strong right angle

attachment points in thin sheets.

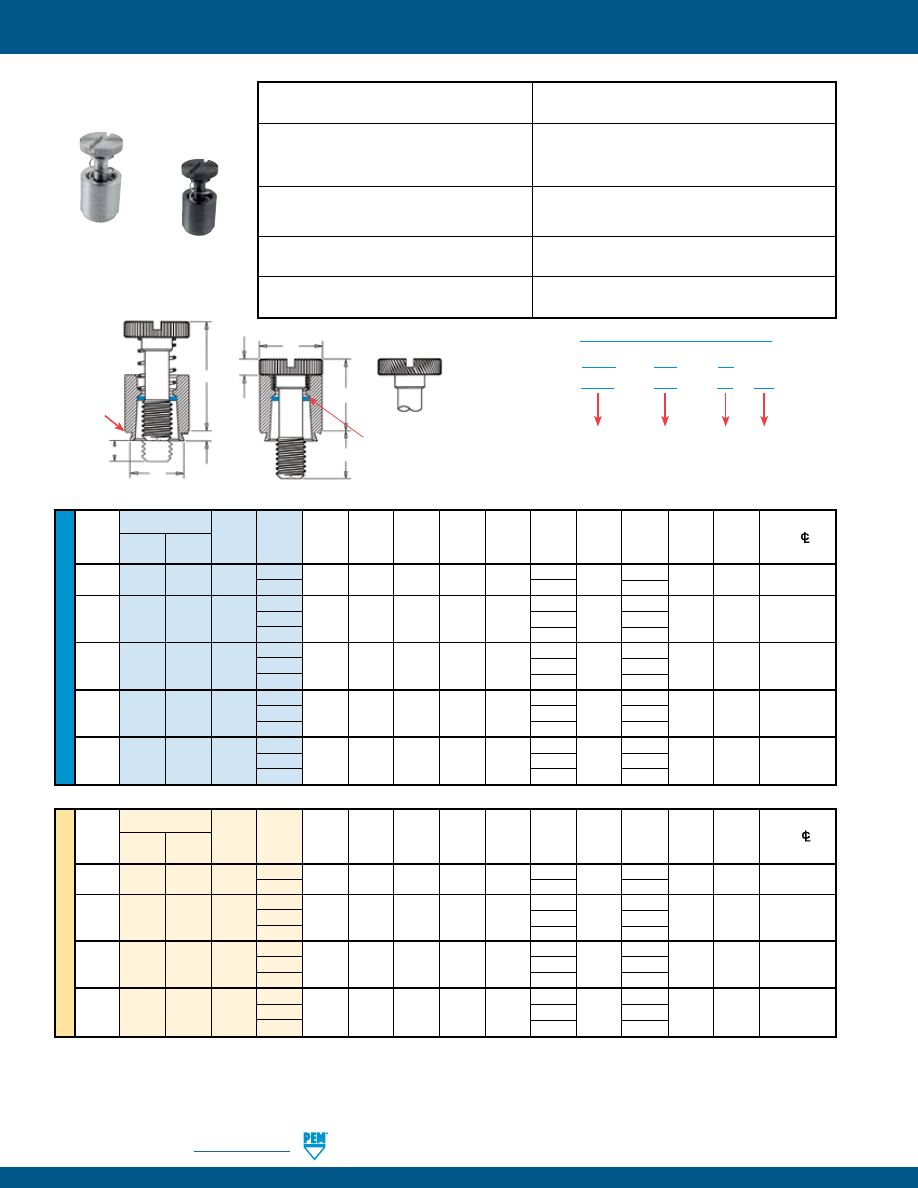

PFC2, PFS2

Bulletin PF

Spring-loaded panel fastener assembly for tool or hand

operation.

PFC2P

Bulletin PF

Panel fastener assembly with Phillips recess for tool only

operation.

PFHV

Bulletin PF

Low-cost panel fastener assembly with universal slot/Phillips

recess for tool or hand operation.

PFK

Bulletins K & PF

Panel fastener assembly for mounting on P.C. boards.

SL

Bulletins CL & LN

Locknuts designed with a unique TRI-DENT® locking feature,

which meets demanding locking performance requirements.

SMPS, SMPP

Bulletin CL

Nuts that feature a lower profile and can be mounted closer to

the edge of a sheet than standard self-clinching nuts.

RAS

Bulletin RA

Threaded R’ANGLE® fasteners provide strong right angle

attachment points in thin sheets.

S, SS

Bulletin CL

Nuts that provide load-bearing threads in thin sheets with

high pushout and torque-out resistances.

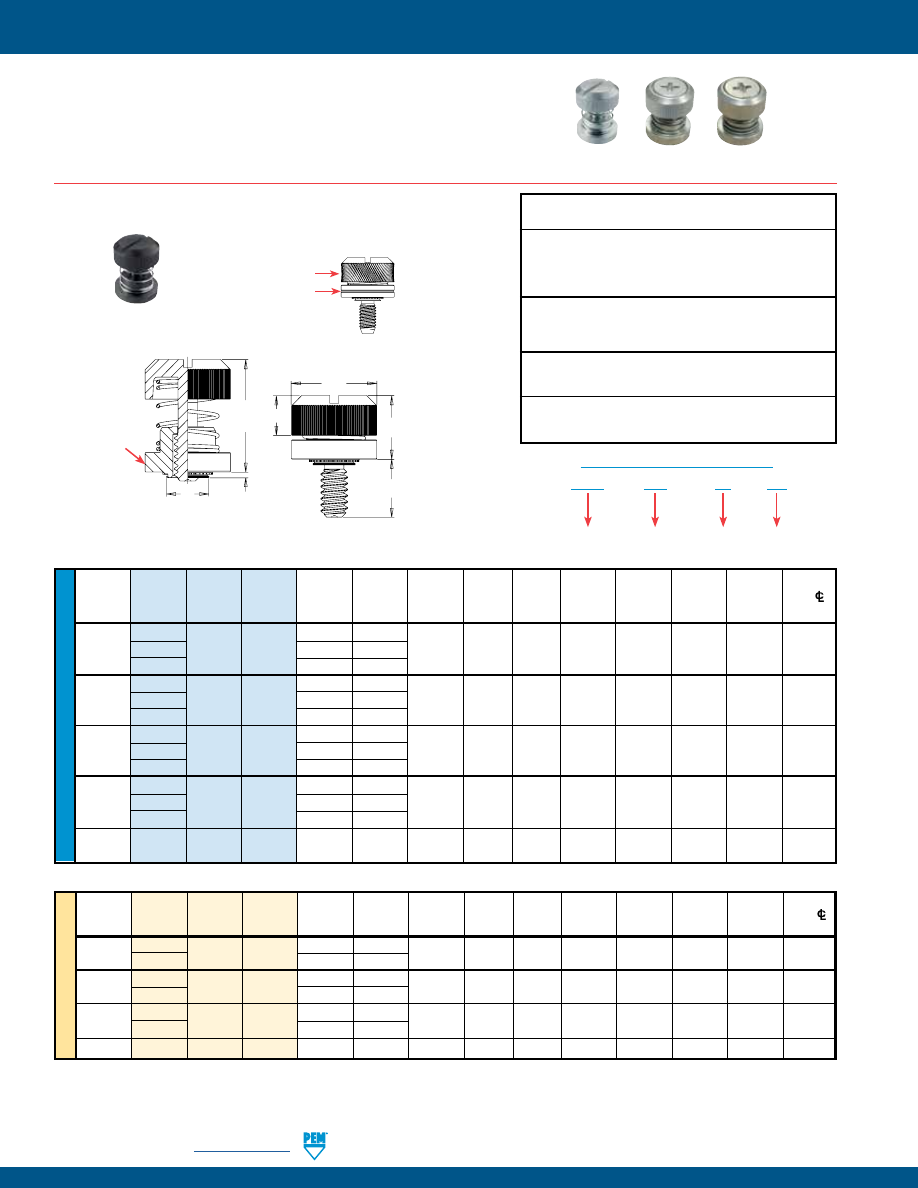

SCB

Bulletin PF

The spinning clinch bolt with axial float installs captive in

panel and still spins freely.

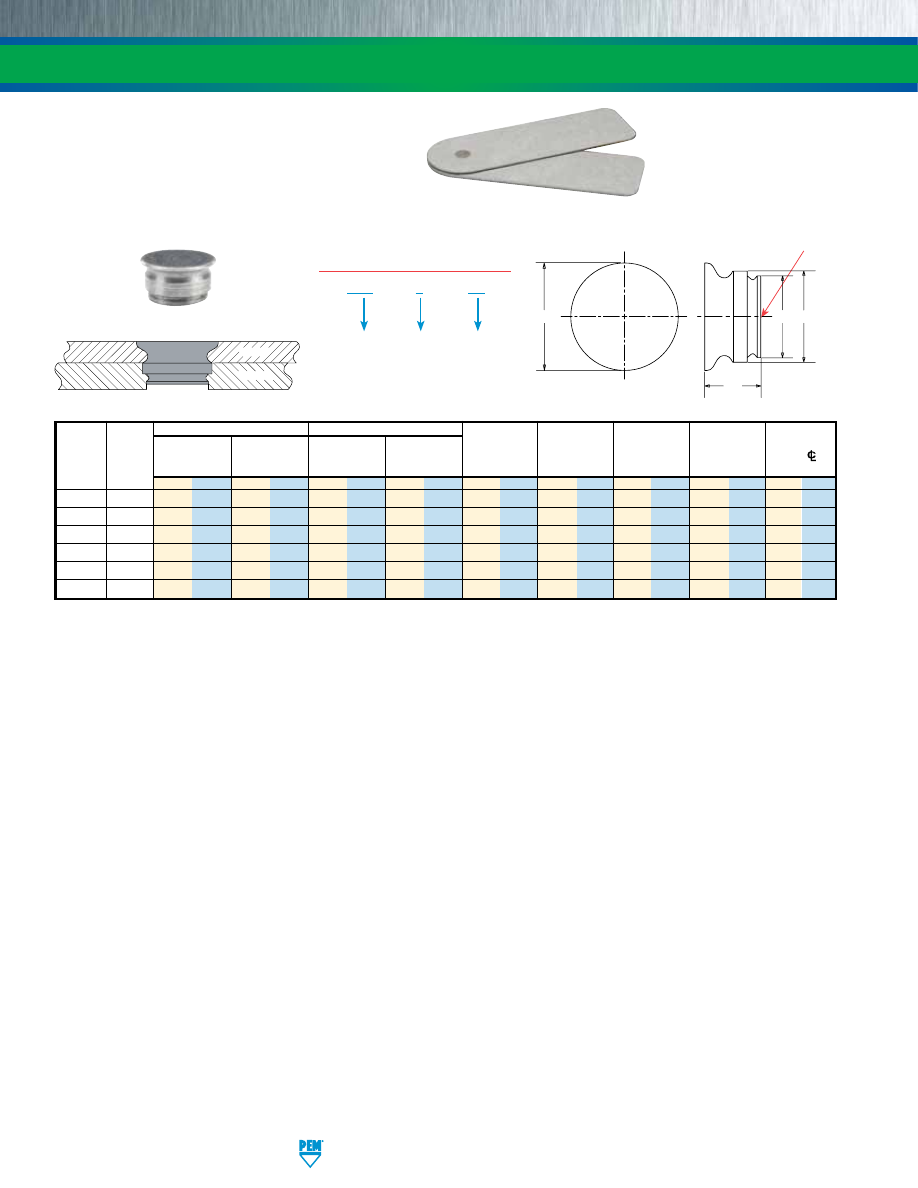

SF, SFP

Bulletin SF

SpotFast® self-clinching fasteners create a permanent, flush

joining of two sheets of metal.

SKC

Bulletin SK

KEYHOLE® standoffs designed for a board to be quickly slipped

into place and removed by sliding it sideways and lifting it off.

SKC-F

Bulletin SK

KEYHOLE® sheet joining fasteners designed to quickly join

two sheets flat against each other and then can be removed.

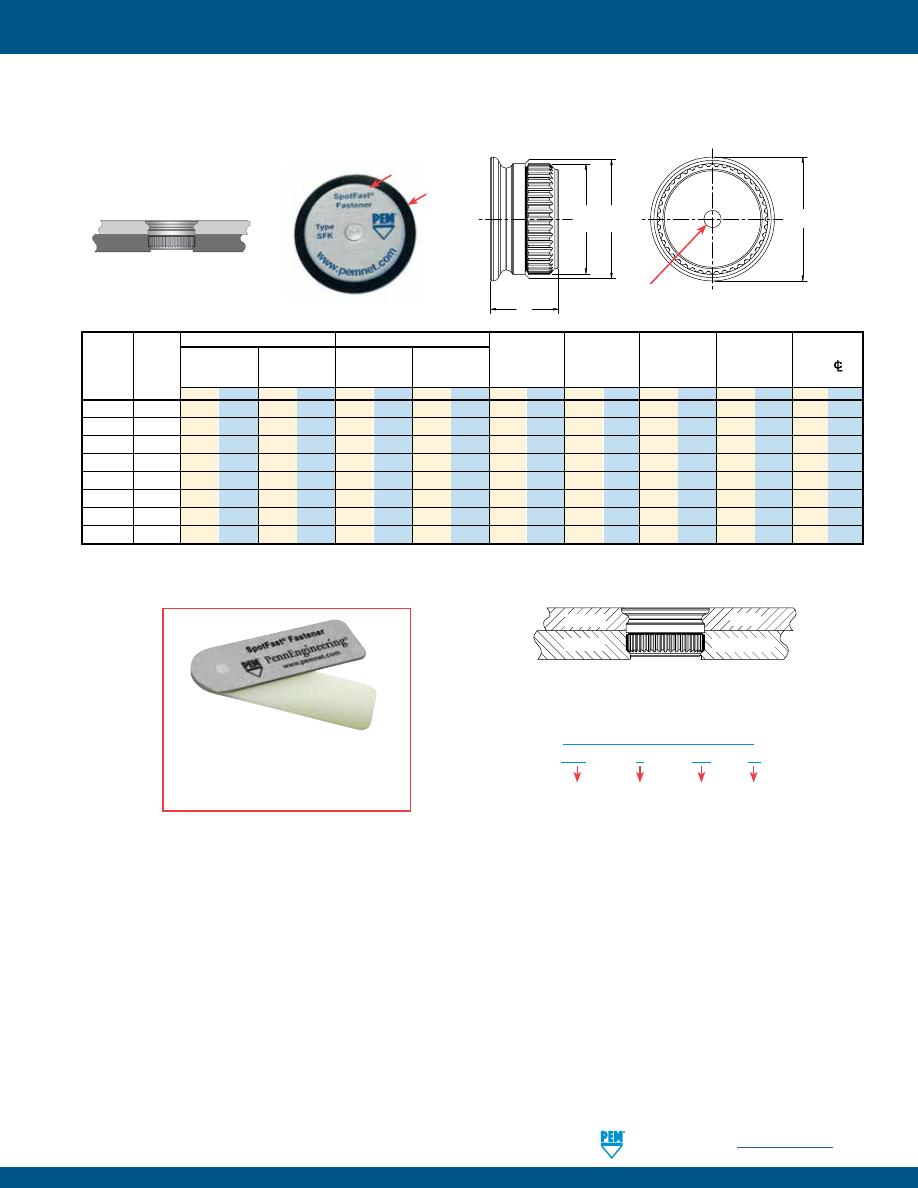

SFW

Bulletin SF

SpotFast® self-clinching fasteners create a permanent, flush

joining of two sheets of metal. The washer allows for consistent

pivoting of the two metal panels.

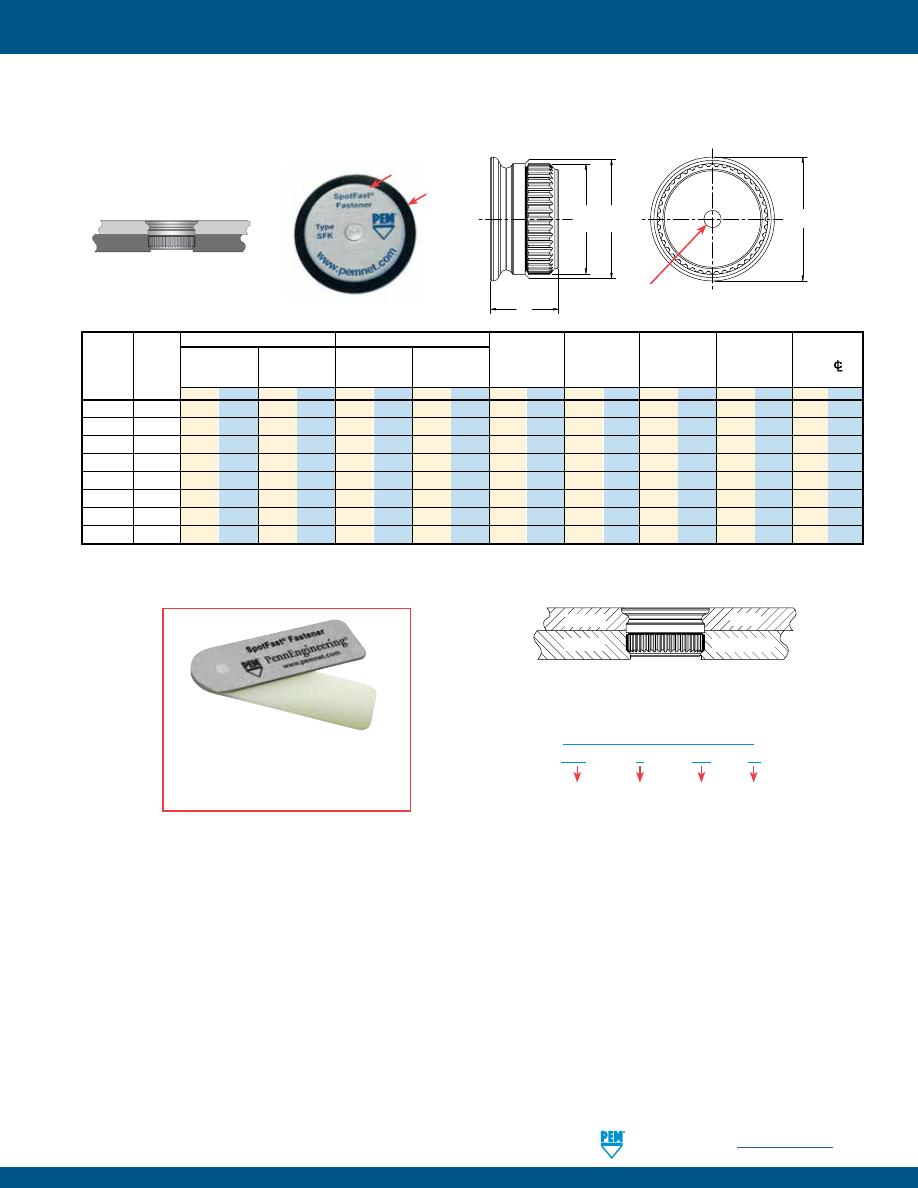

SFK

Bulletin SF

SpotFast® self-clinching fasteners create a permanent, flush

joining of metal to PCB or plastic panels.

PFC4

Bulletin PF & SS

Panel fastener assembly for installation into stainless steel

sheets with Phillips recess for tool only operation.

PSHP

Bulletin K

Surface mount panel fastener screw that is used with Type

SMTPR retainer.

SCBJ

Bulletin PF

The spinning clinch bolt with jacking feature installs captive

in panel and still spins freely.

SGPC

Bulletin FH

Install into most panel material, provide strong torque-out

resistance and are suitable for close centerline-to-edge

situations.

SCBR

Bulletin PF

The spinning clinch bolt with axial float utilizes self-retracting

spring.

SFN

Bulletin SFN

Spinning flare nut is a one-piece, flanged hex nut that is

permanently captive and still spins freely in the sheet.

SH

Bulletin CL

Nuts are for installation into thin, harder, high-strength

materials.

SMTPFLSM

Bulletin K

Surface mount spring-loaded captive panel screws.

PennEngineering •

www.pemnet.com

INDEX-5

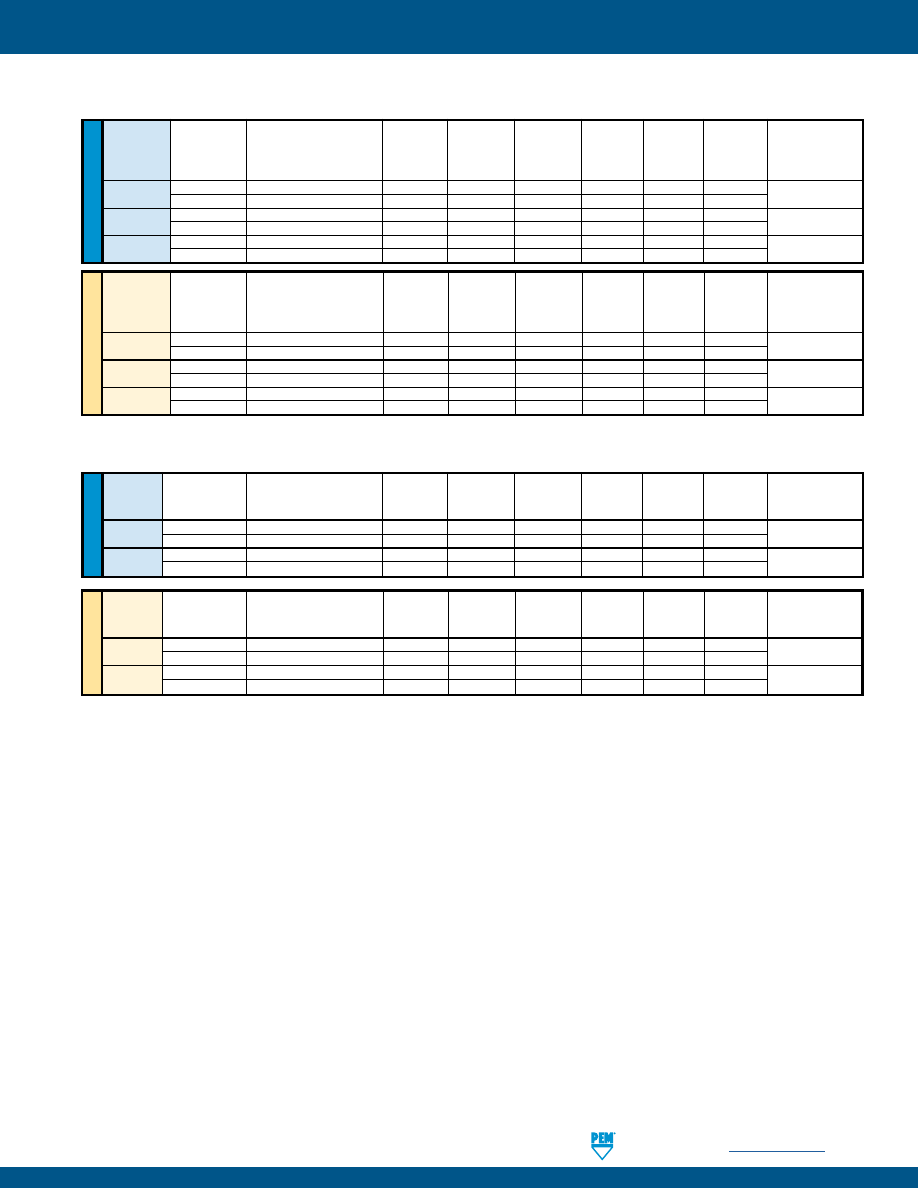

S-RT

Bulletin CL

Free-running locknuts with a thread form that creates a lock

when clamp load is applied.

B

SC

SM

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SC

SM

SC

SC

B

SC

FM

SC

pem-html.html

SMTRA

Bulletin K

Surface mount R’ANGLE® fasteners provide strong re-usable

threads at right angle to PC board.

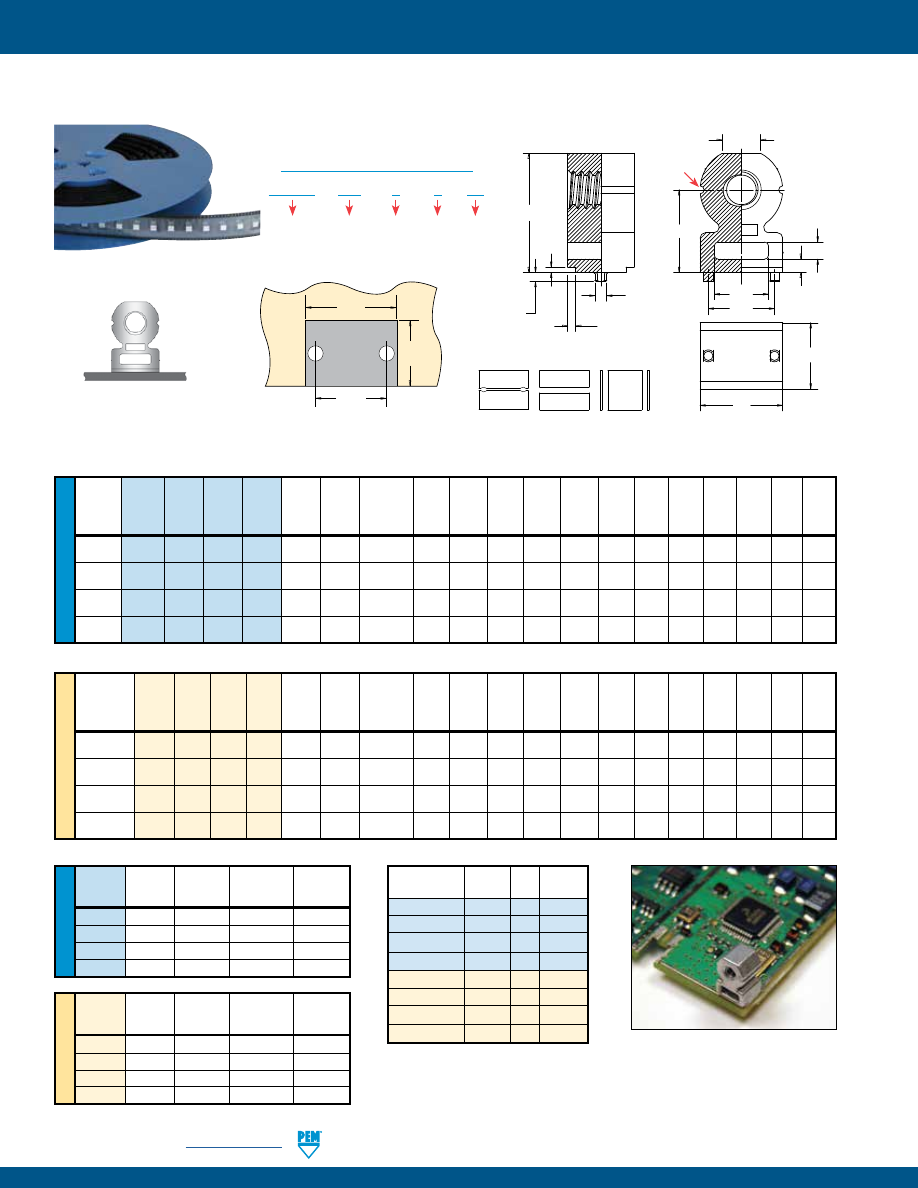

SMTSO, SMTSOB

Bulletin K

Surface mount spacers and nuts are available threaded and

unthreaded.

TPS, TP4

Bulletin FH

Flush-mounted pilot pins with chamfered end to make mating

hole location easy.

TPXS

Bulletin FH

Alignment pin for ATCA® faceplate fastening solutions.

TSO, TSOA, TSOS

Bulletin SO

Standoffs provide permanent threads in ultra-thin sheets.

SO, SO4, SOA, SOS

Bulletin SO

Thru-hole threaded and unthreaded standoffs installed with

their heads flush with one surface of the mounting sheets.

SOAG, SOSG

Bulletin SO

Grounding standoffs for clinching into metal chassis with

“gripping teeth” at opposite end to firmly contact mating

board.

SP

Bulletins CL & SS

Specially hardened self-clinching nuts for installation into

stainless steel sheets.

SSA, SSC, SSS

Bulletin SSA

SNAP-TOP® standoffs featuring a spring action to hold a P.C.

board securely without screws or threaded hardware.

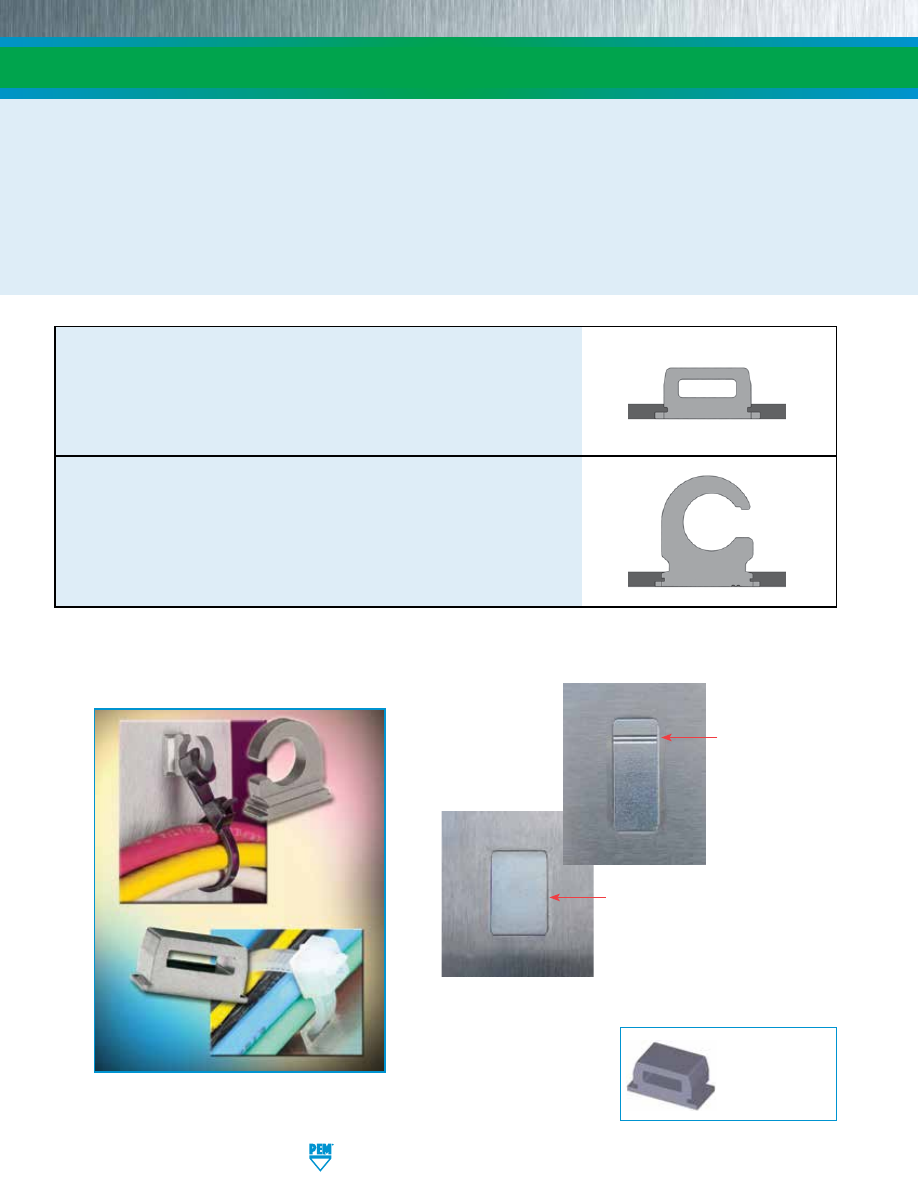

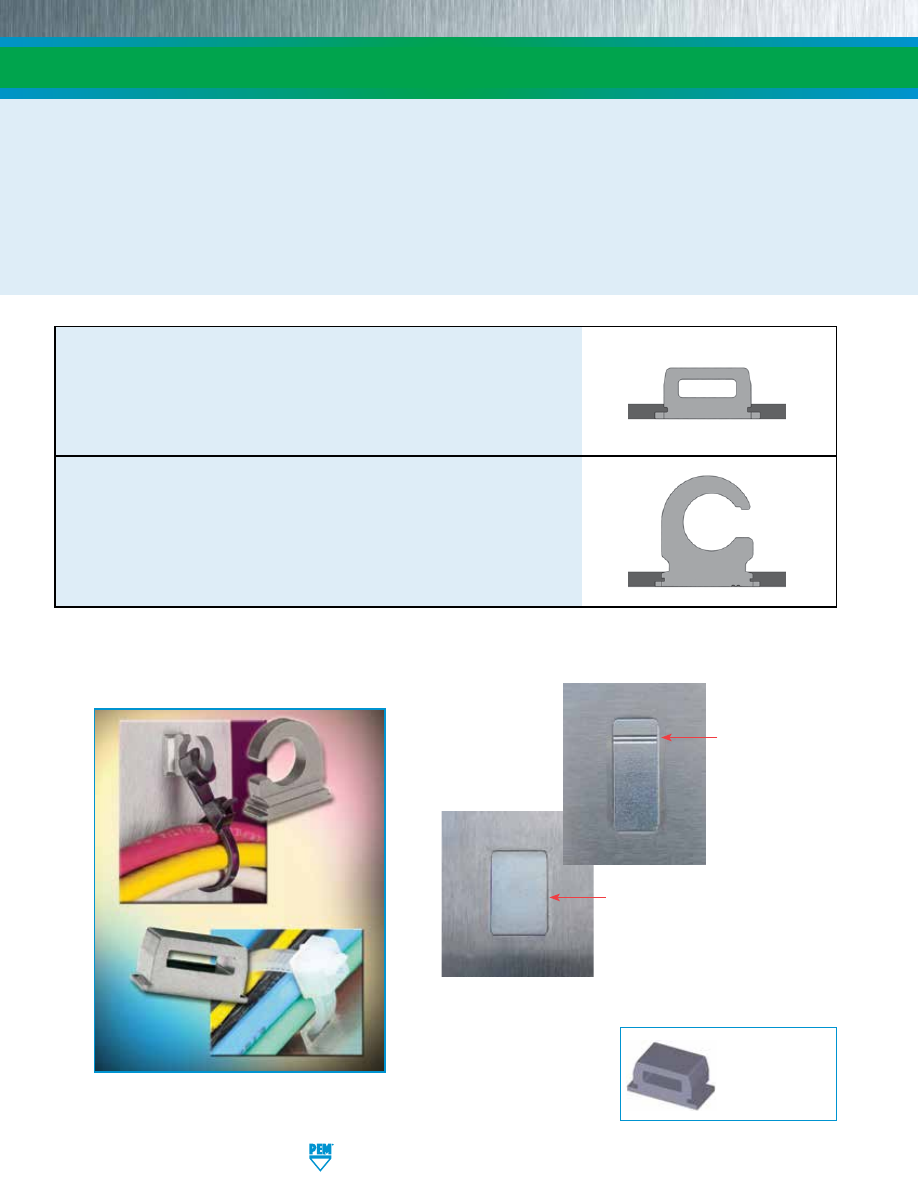

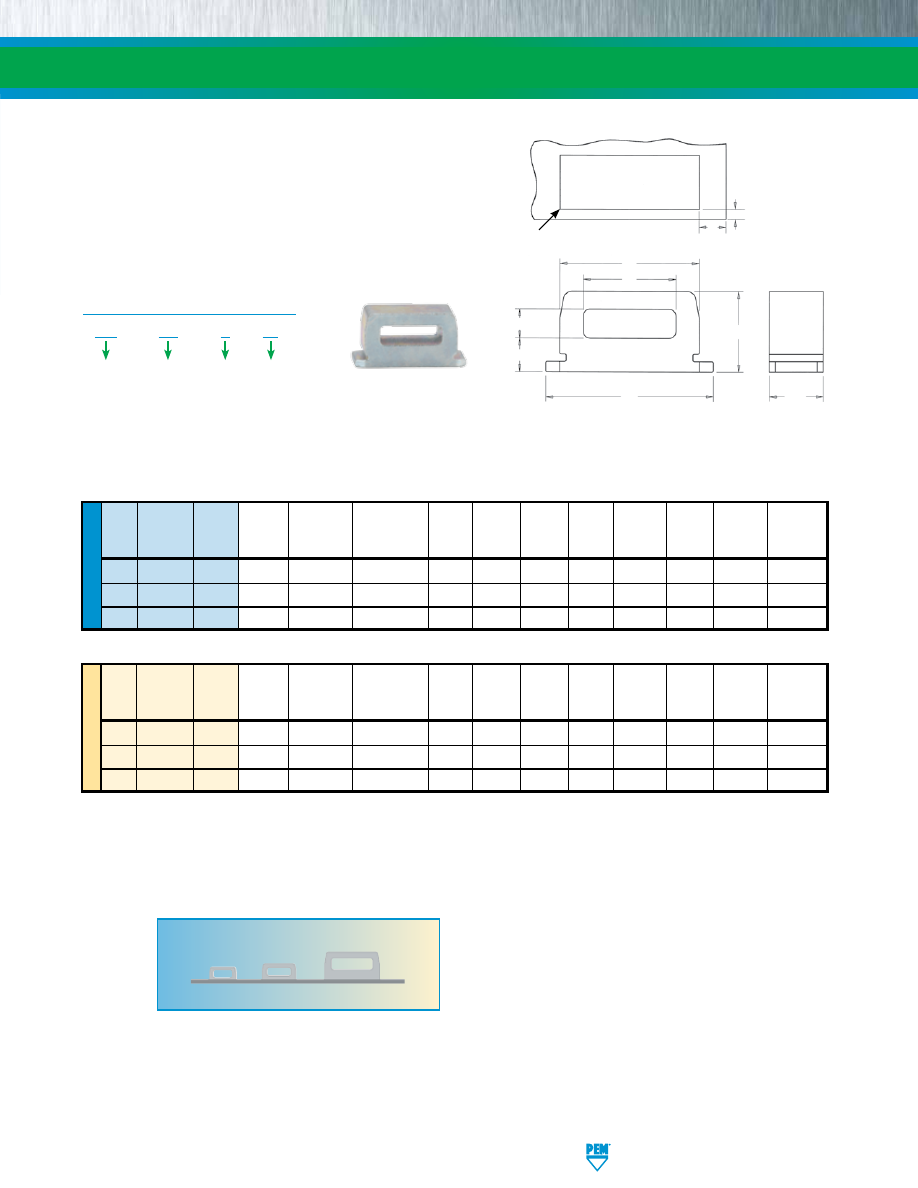

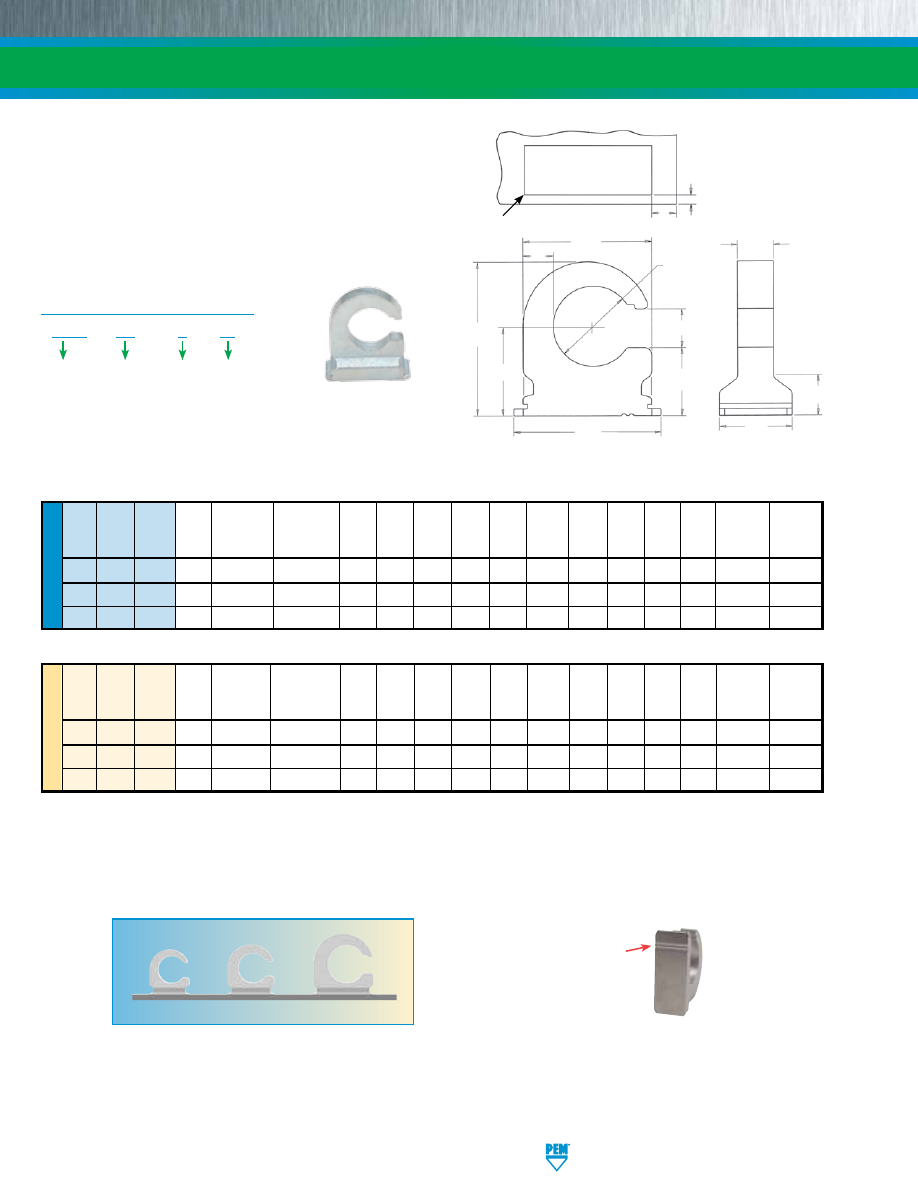

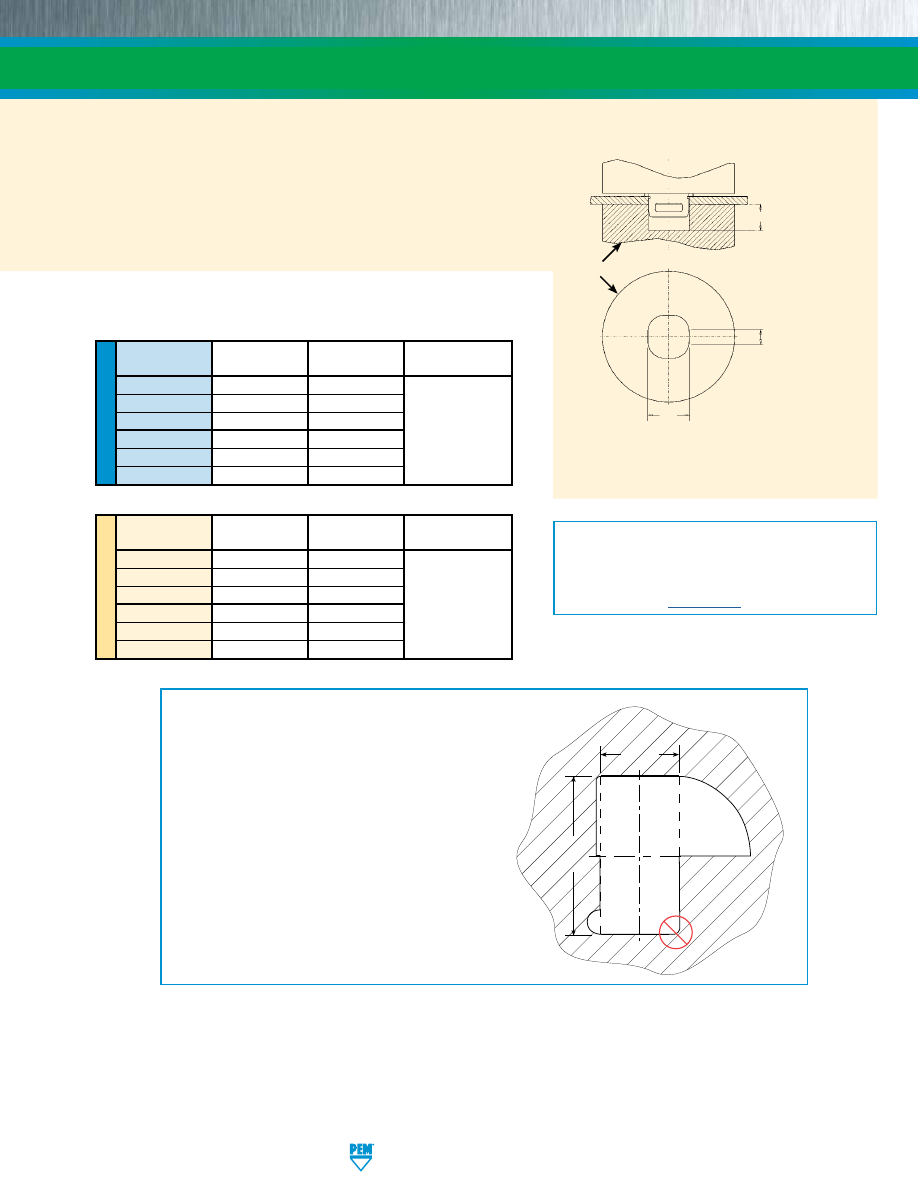

TD

Bulletin TD

TY-D® self-clinching tie-mounts provide secure attachment

points for mounting wires to electronic chassis or enclosure.

TDO

Bulletin TD

TY-D® self-clinching hooks enable users to easily attach,

remove, and return tie-bundled wires to their mounting

points.

TFH, TFHS

Bulletin FH

Non-flush studs for sheets as thin as .020” / 0.51 mm.

SMTPR

Bulletin K

Surface mount panel fastener retainer that is used with Type

PSHP screw.

T, T4

Bulletin MPF

microPEM® TackPin® fasteners for compact electronic

assemblies enable sheet-to-sheet attachment.

TSO4

Bulletin SO

Standoffs for installation into ultra-thin stainless steel sheets

as thin as .025” / 0.63 mm.

TK4, TKA

Bulletin MPF

microPEM® TackSert® pins designed to hold a top panel to a

bottom panel by broaching into the bottom panel.

THFE

Bulletin FH

Heavy-duty studs for sheets as thin as .031” / 0.8 mm.

U, UL

Bulletin FE

Miniature nuts with strong threads. Available with locking or

non-locking threads.

WN, WNS

Bulletin WN

Self-locating projection weld nuts. The engineered

projections prevent burn-outs in thin sheets.

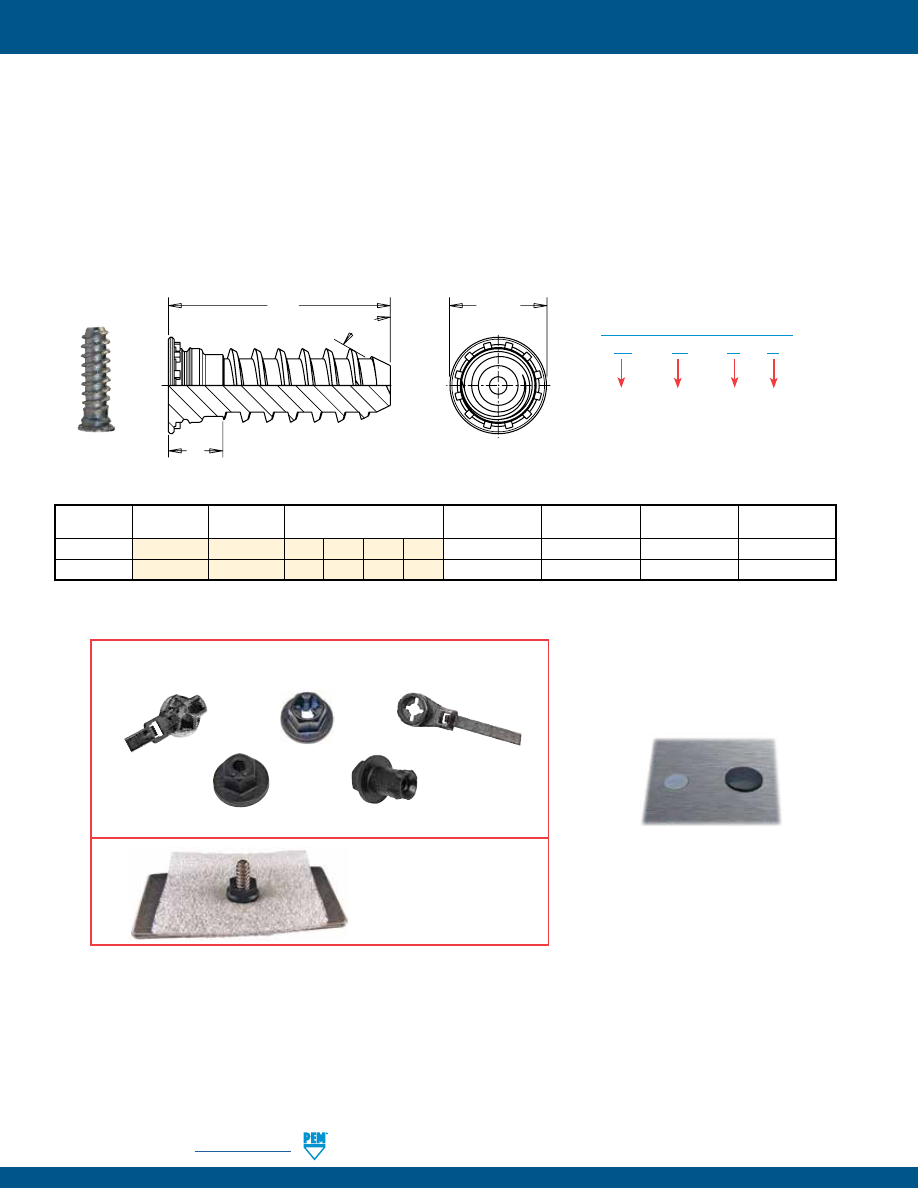

TS

Bulletin MPF

TackScrew® fasteners enable cost-effective sheet-to-sheet

attachment by simply pressing into place. Can be removed

by simply unscrewing.

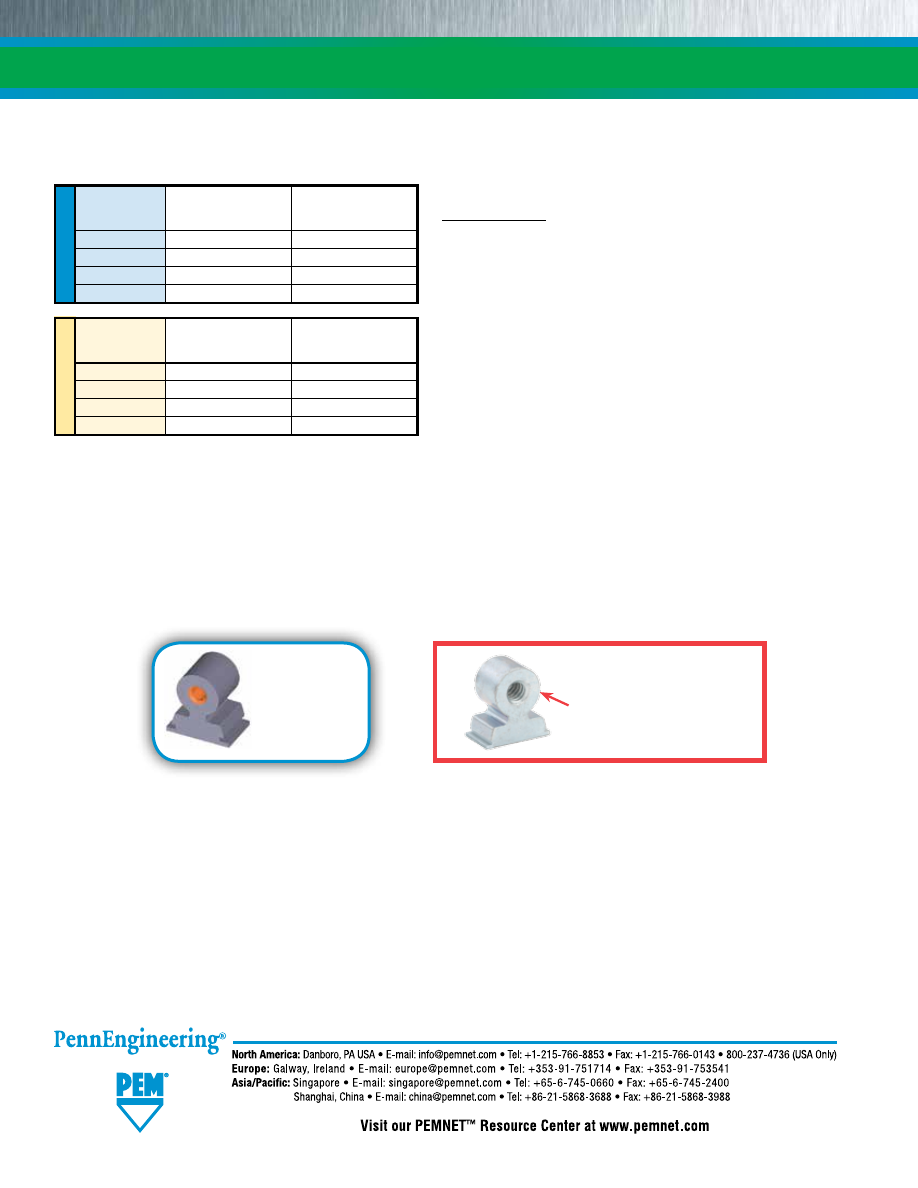

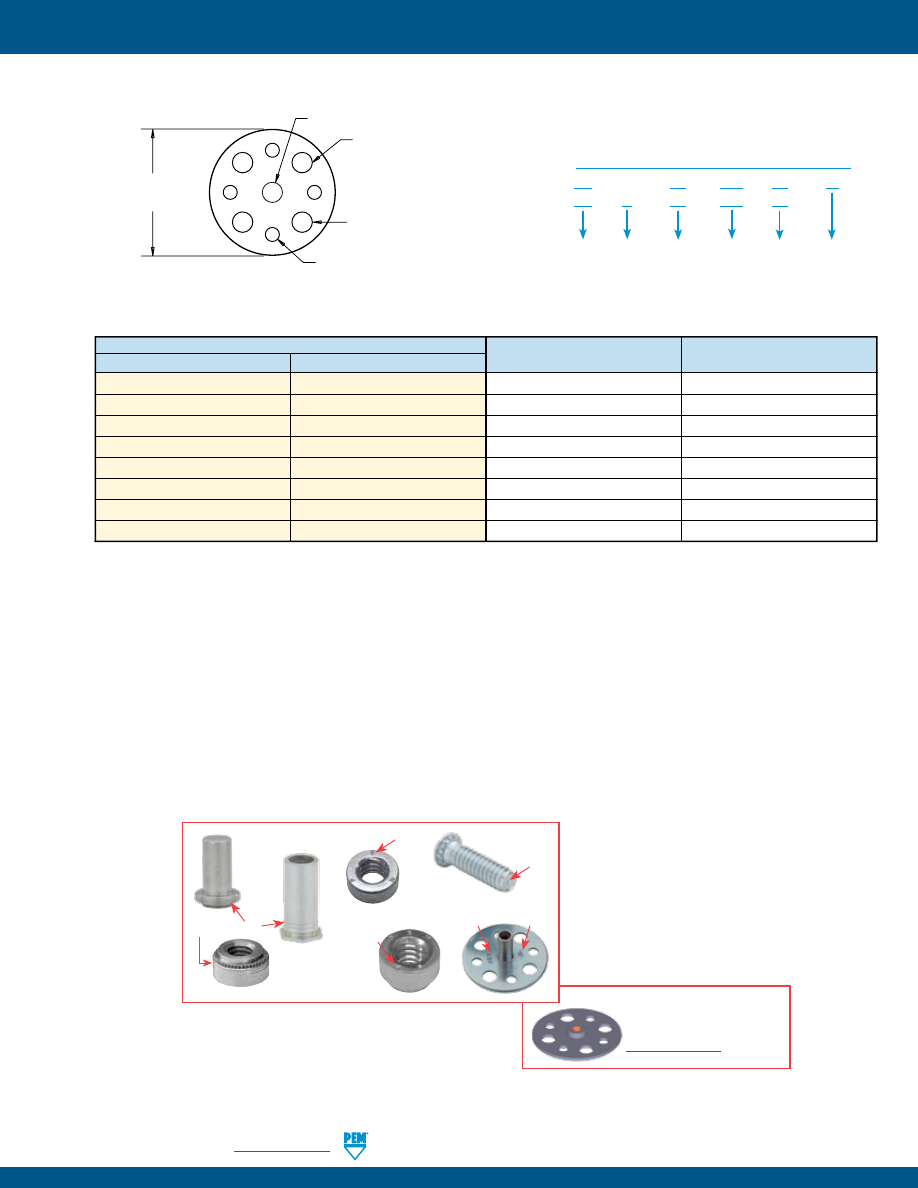

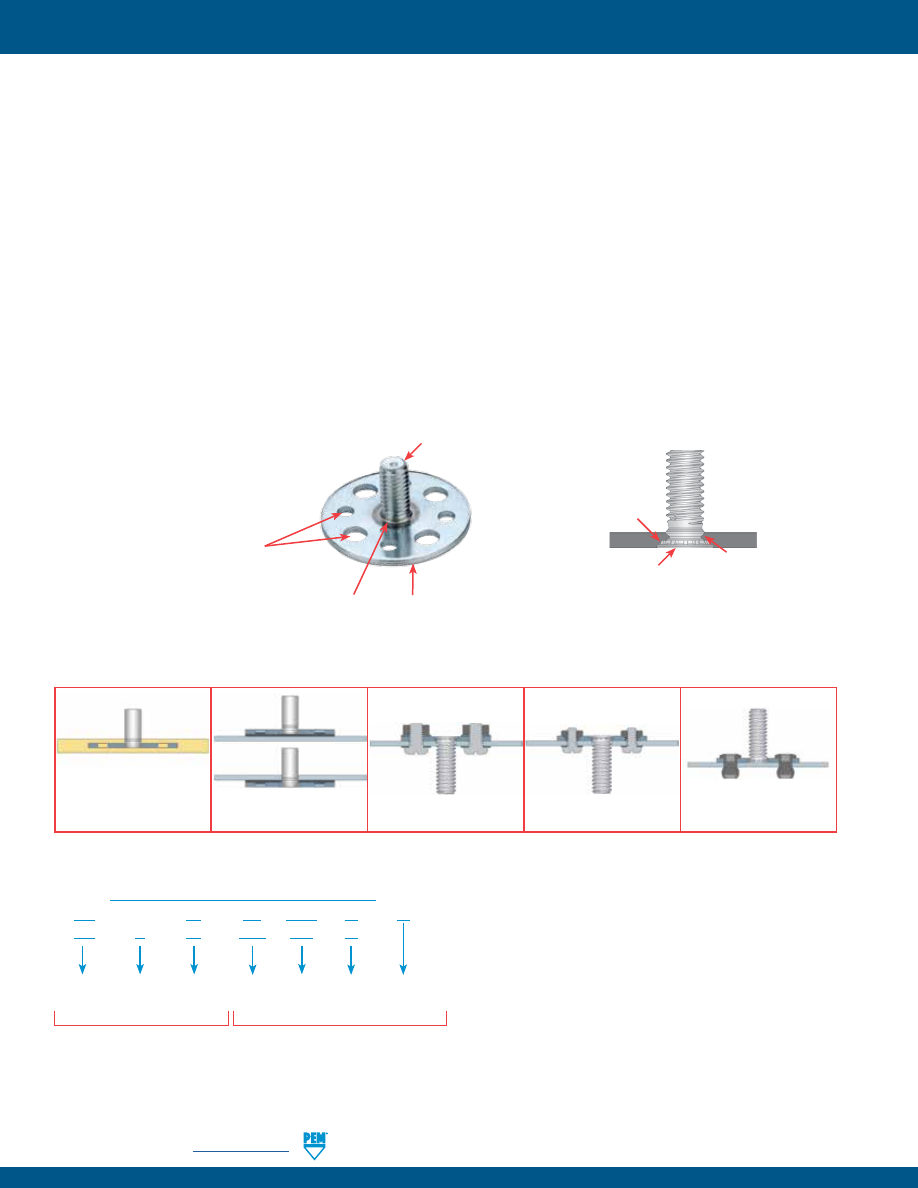

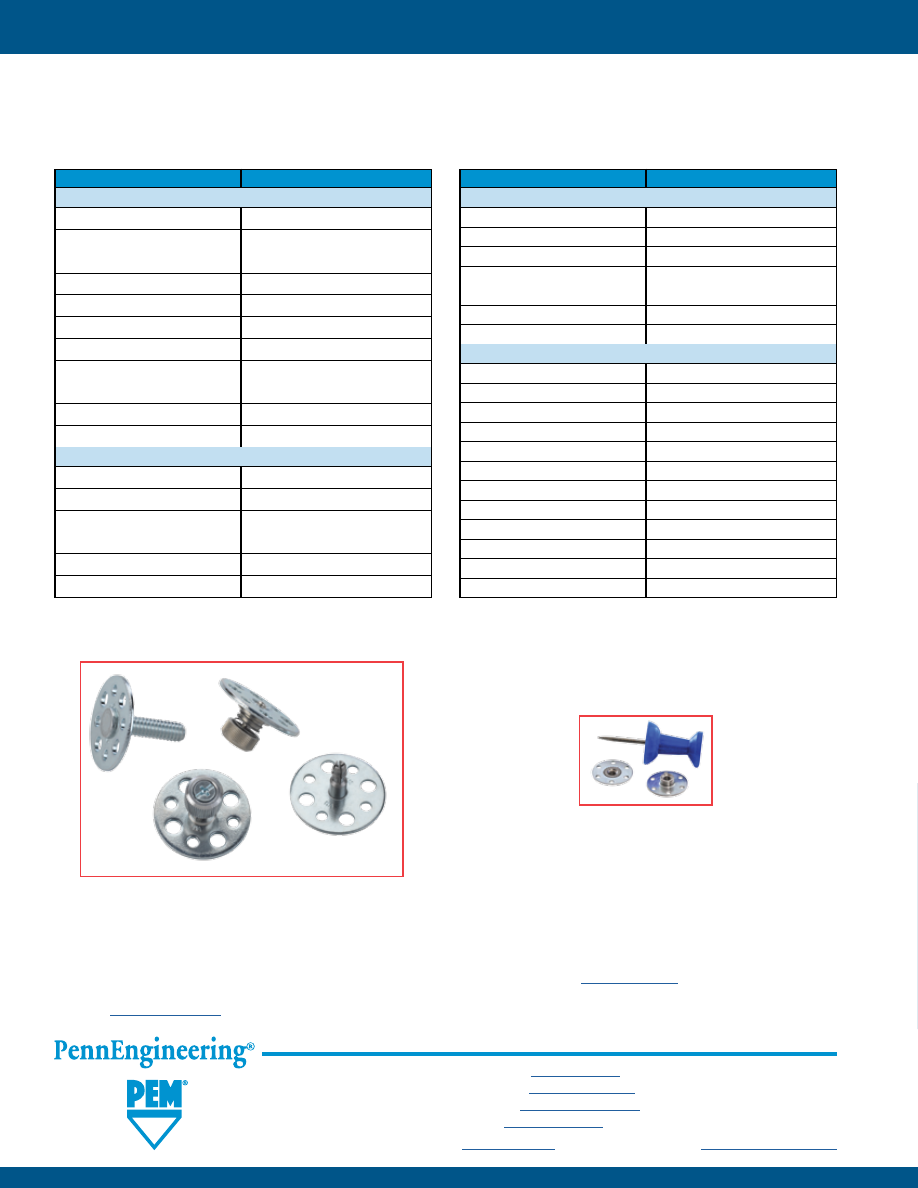

VM

Bulletin VM

The PEM® VariMount® bonding fasteners are assemblies

comprised of a standard PEM fastener mounted permanently

into base plates.

PennEngineering •

www.pemnet.com

INDEX-6

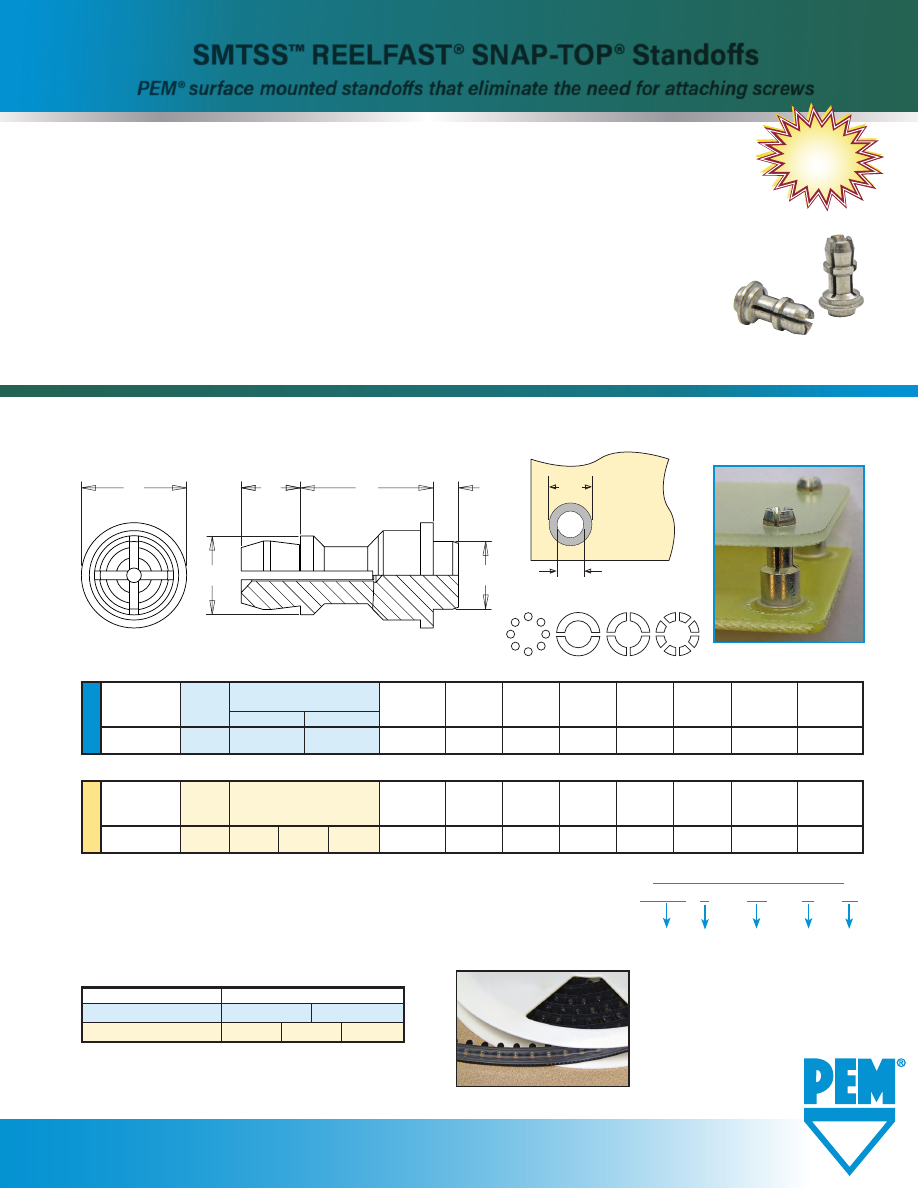

SMTSS

Bulletin K

Surface mount standoffs that eliminate the need for attaching

screws.

SC

SC

SC

SC

SC

SC

SC

SM

SM

SM

SM

SC

SC

SC

SC

VM

W

SC

B

SC

SC

SC

pem-html.html

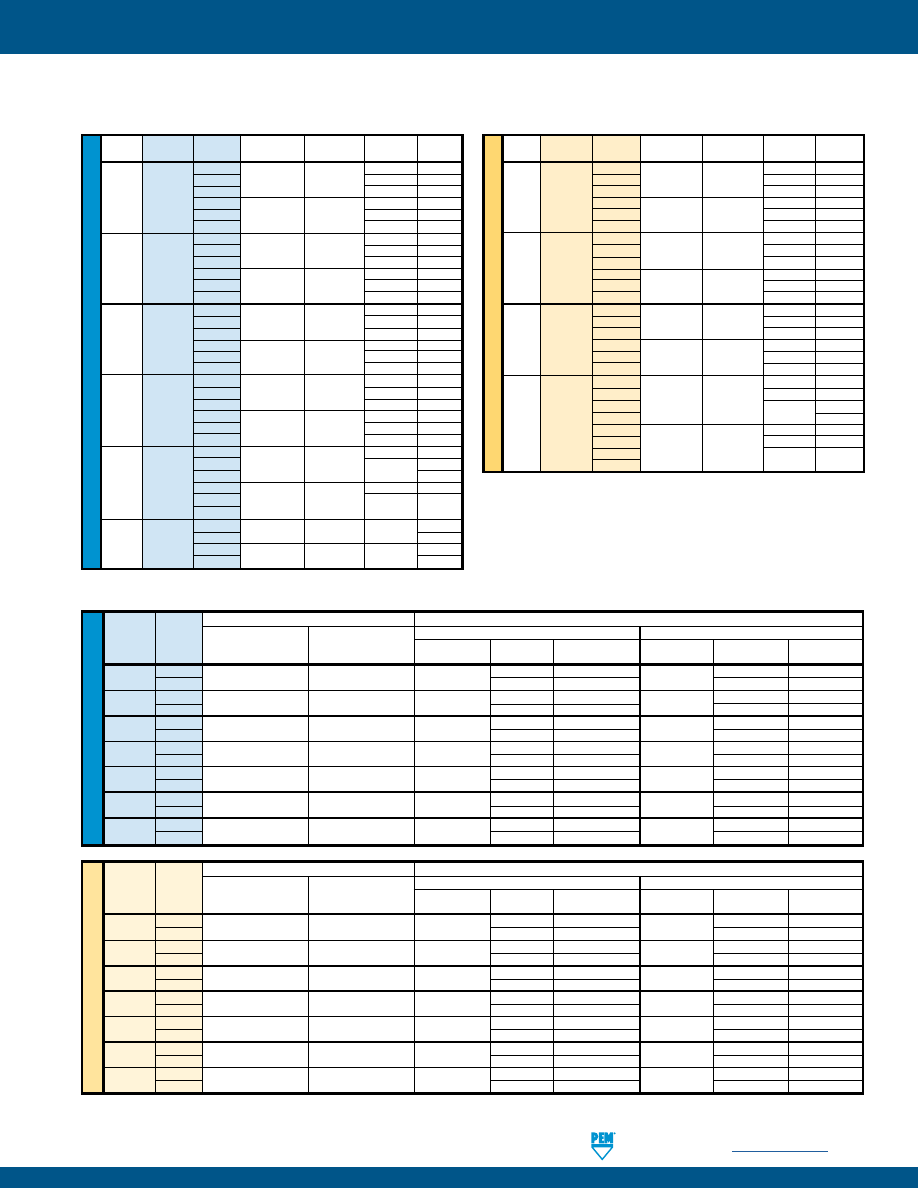

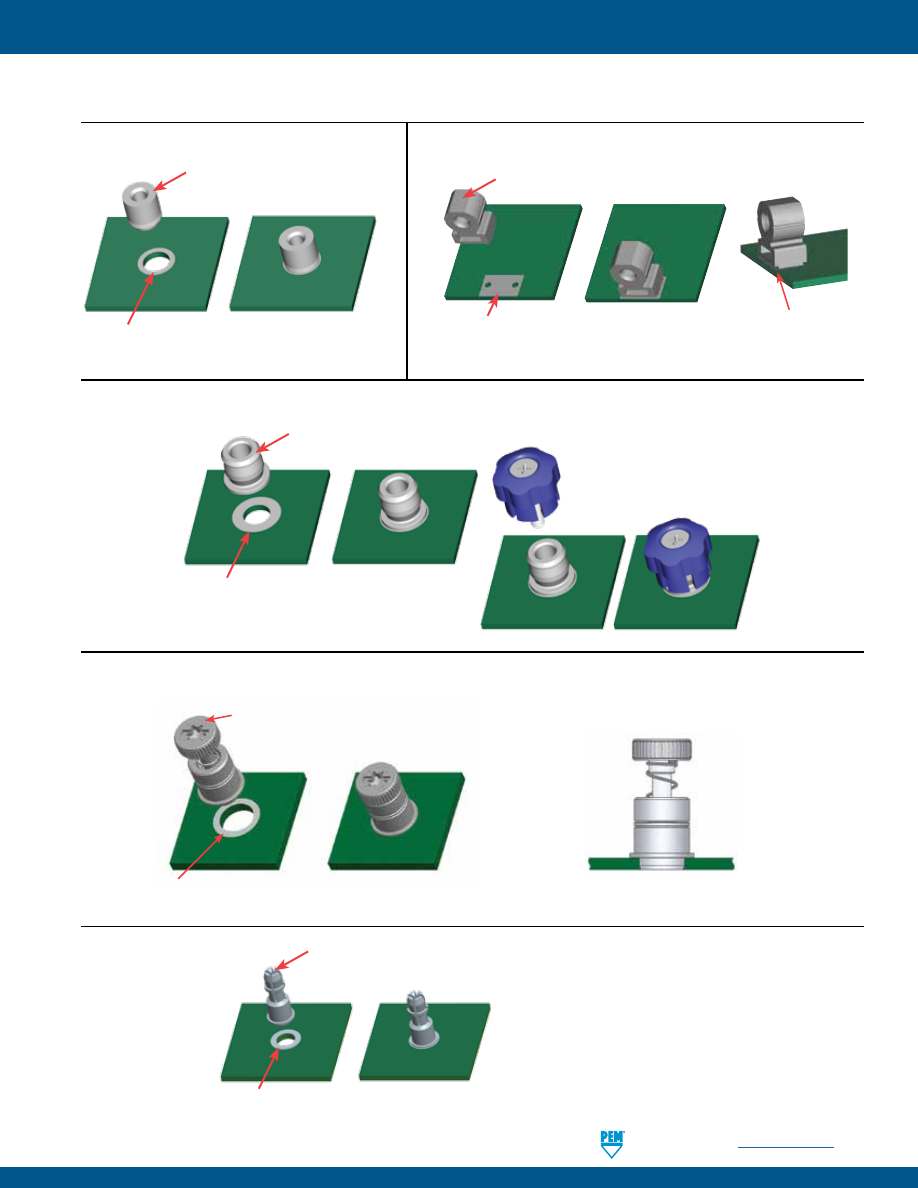

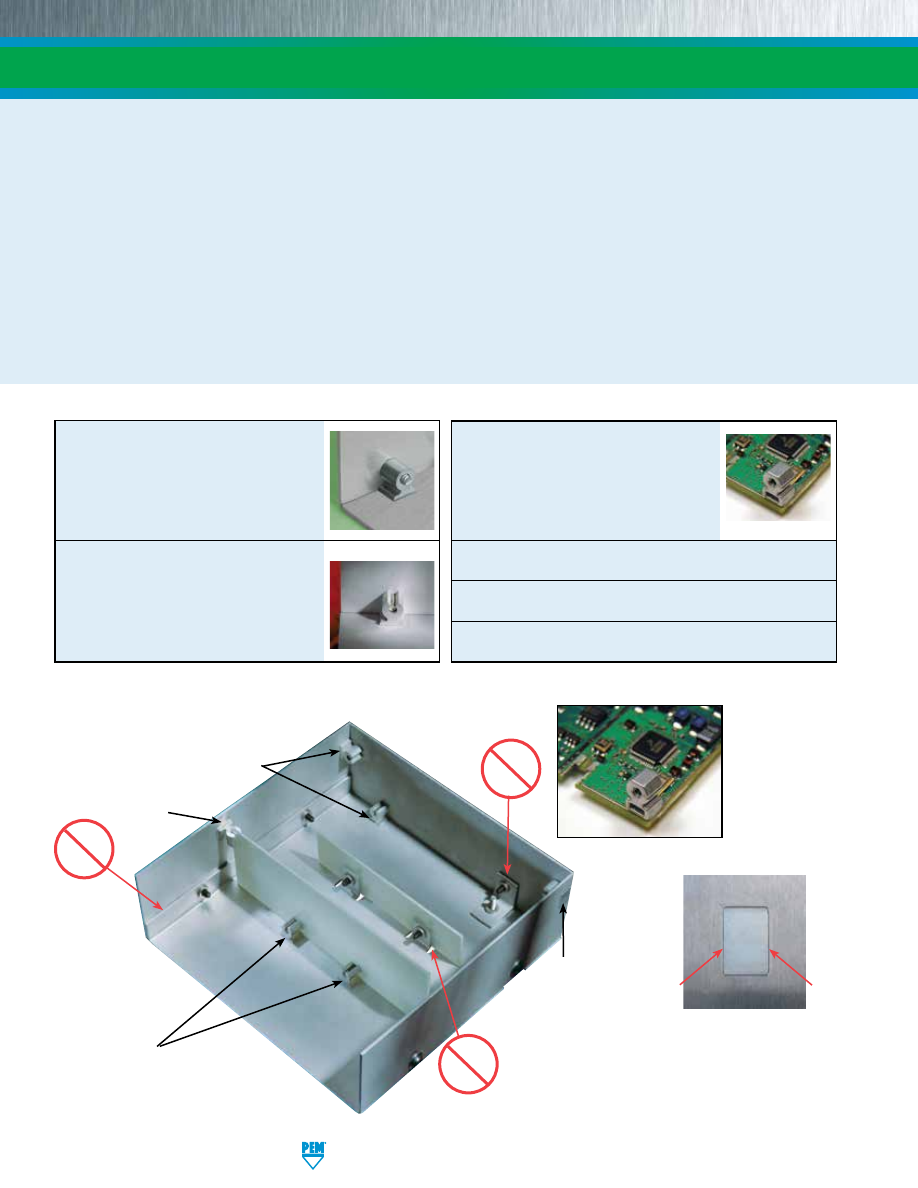

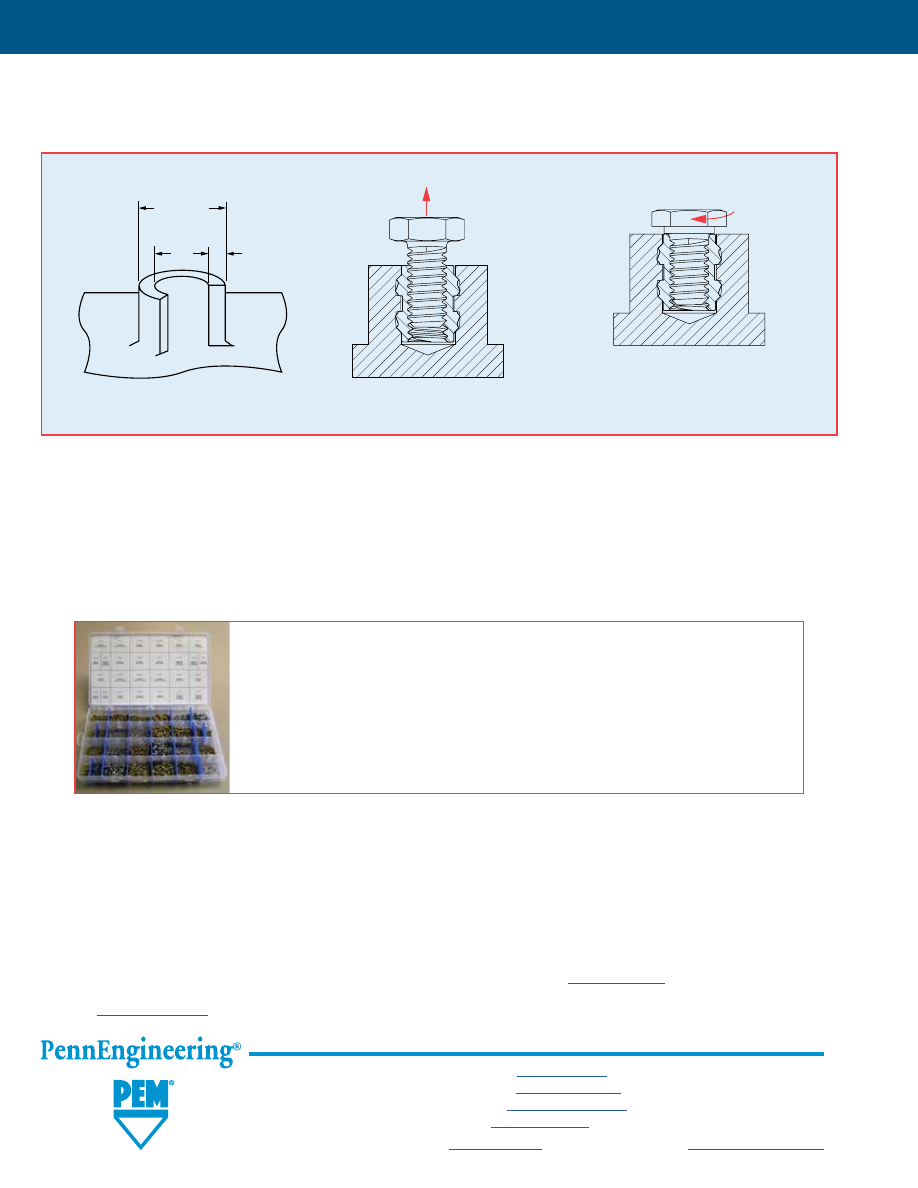

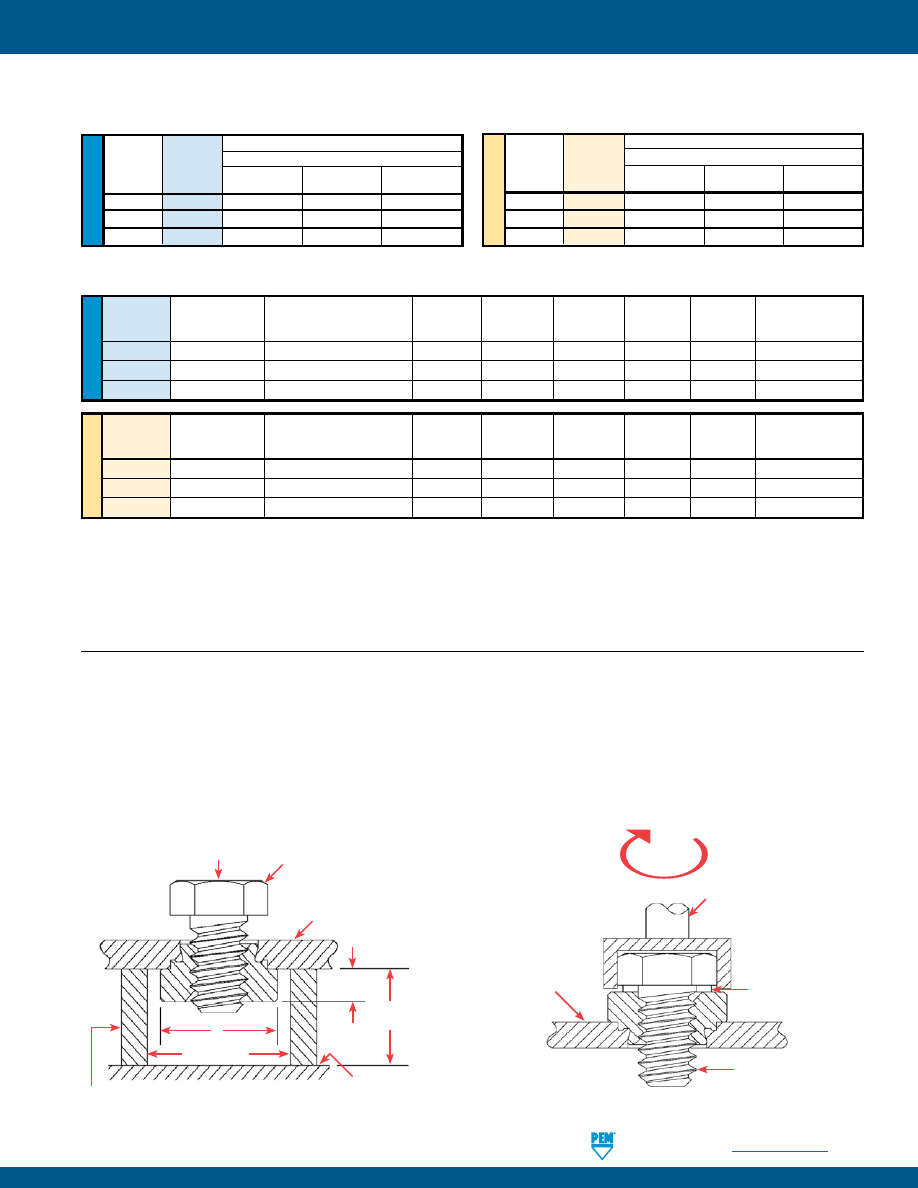

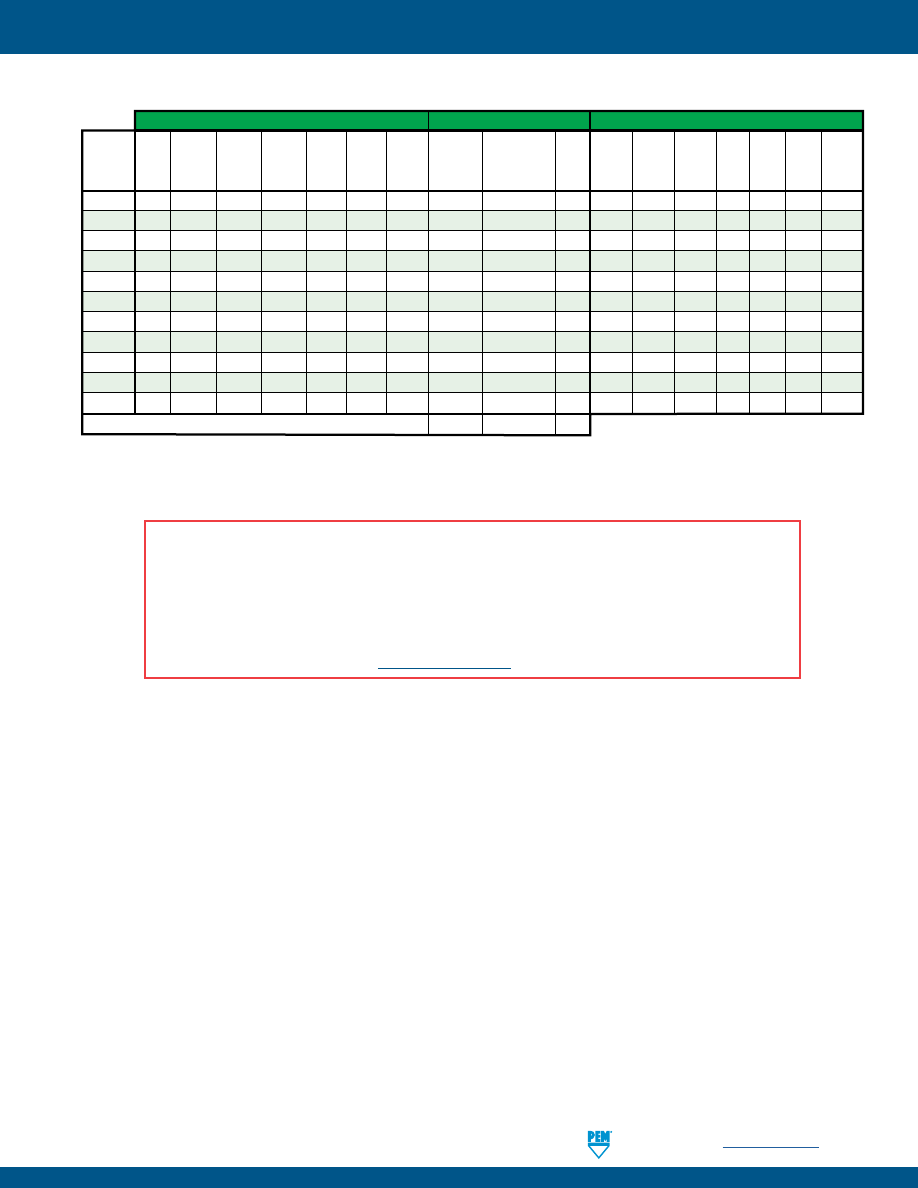

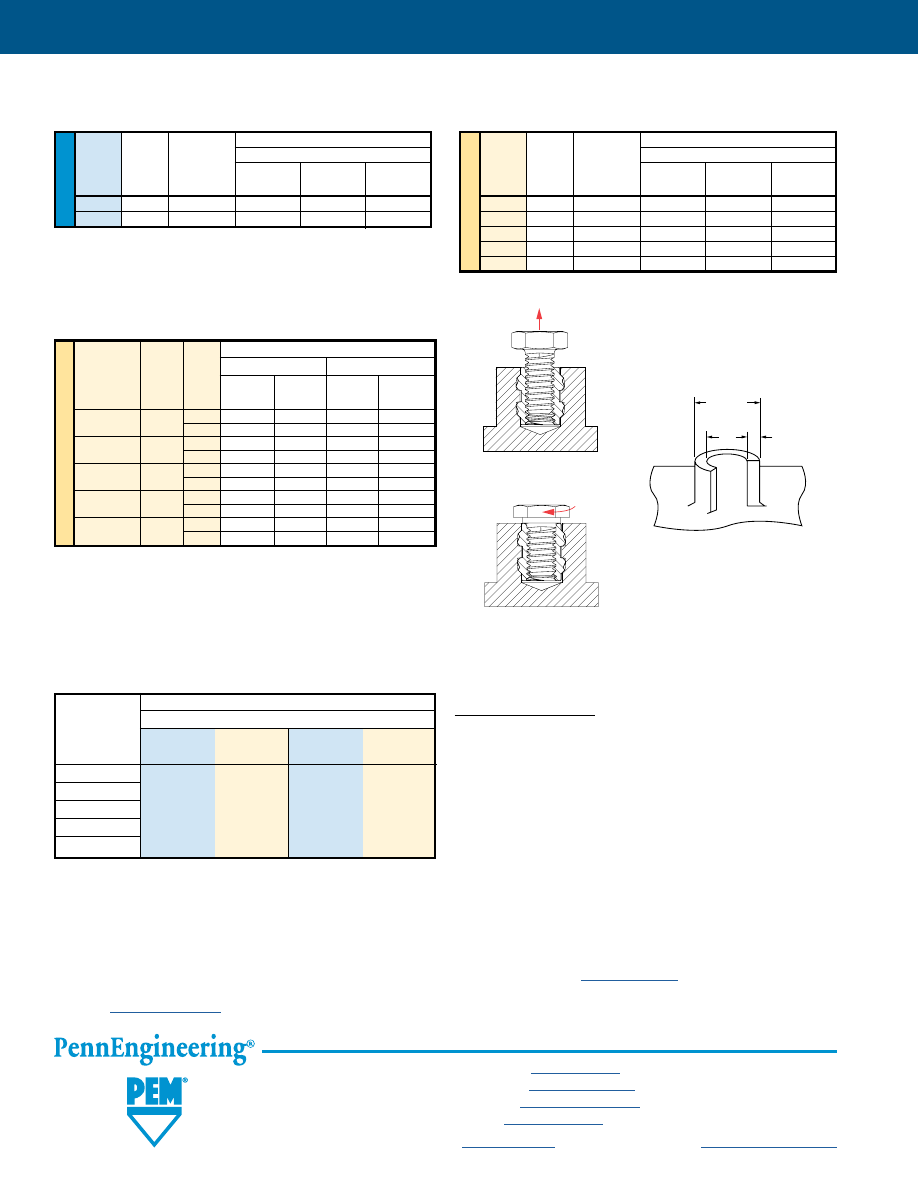

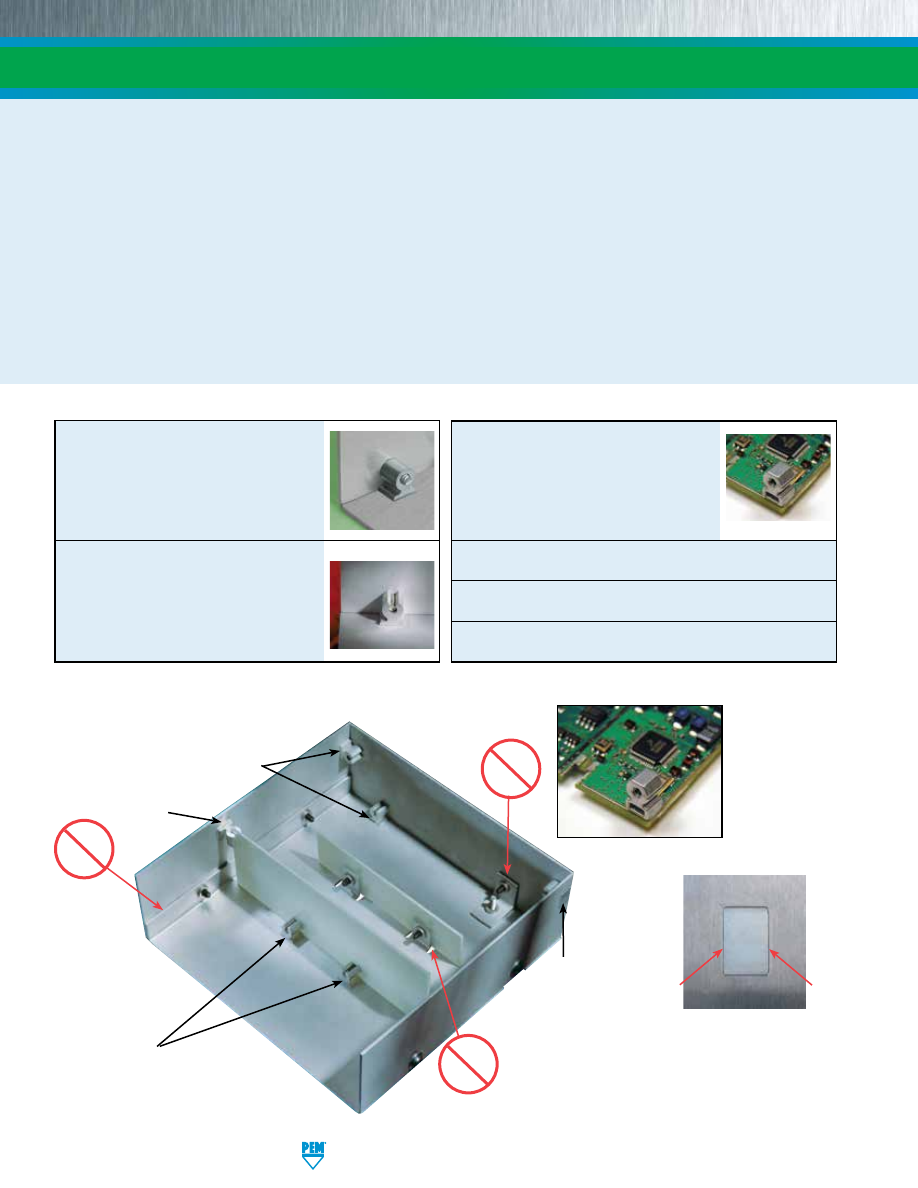

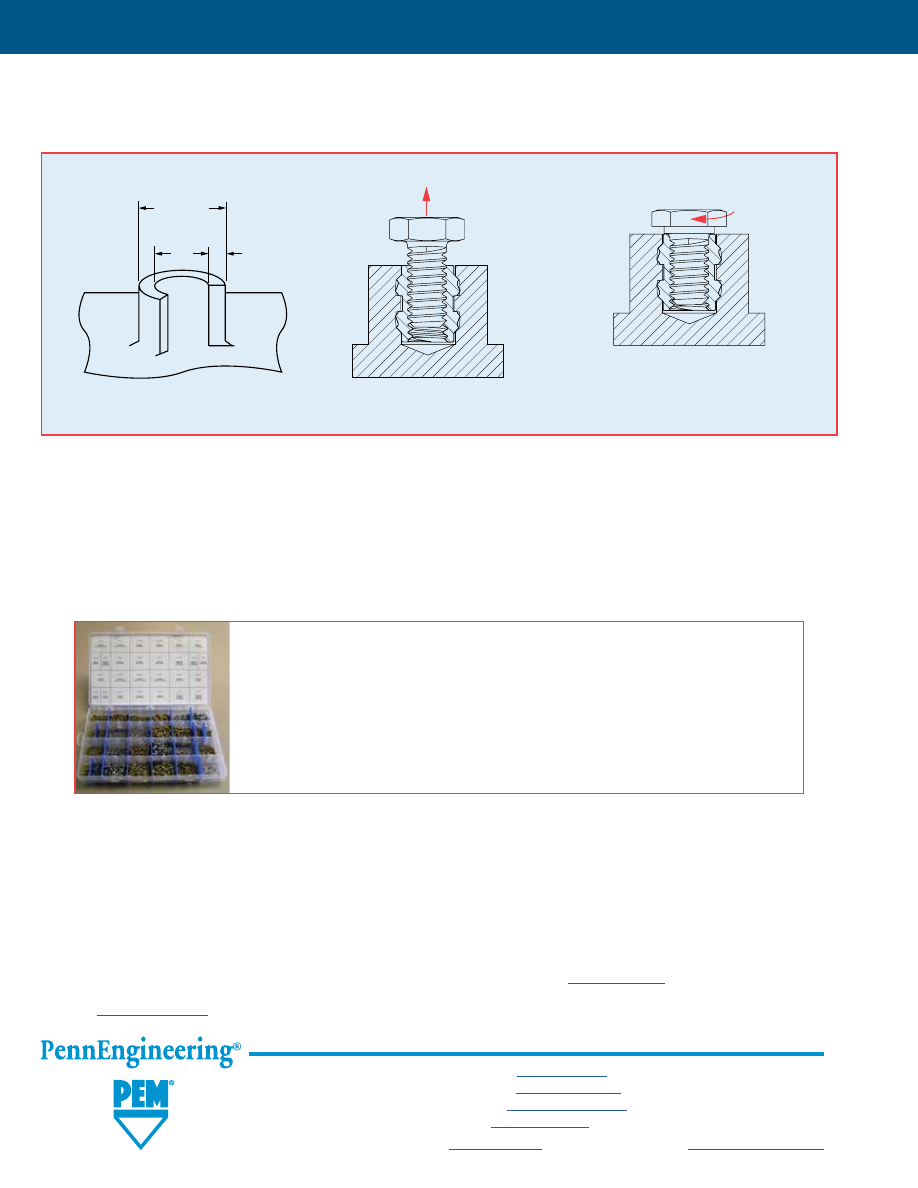

“Dos”

Do

provide mounting hole of specified size for each fastener.

Do

install fastener into punch side of sheet.

Do

make certain that shank (or pilot) is within hole before applying installation force.

Do

apply squeezing force between parallel surfaces.

Do

apply sufficient force to totally embed clinching ring around entire circumference and to bring shoulder squarely in contact with

sheet. For some fasteners, installation will be complete when the head is flush with the panel surface.

“Don’ts”

Don’t

attempt to install a 300 series stainless steel fastener into a stainless steel sheet.

Don’t

install steel or stainless steel fasteners in aluminum panels before anodizing or finishing.

Don’t

deburr mounting holes on either side of sheet before installing fasteners – deburring will remove metal required for clinching

fastener into sheet.

Don’t

install fastener closer to edge of sheet than minimum edge distance indicated by manufacturer – unless a special fixture is

used to restrict bulging of sheet edge.

Don’t

over-squeeze. It will crush the head, distort threads, and buckle the sheet. Approximate installation forces are listed in performance

data tables. Use this info as a guide. Be certain to determine optimum installation force by test prior to production runs.

Don’t

attempt to insert fastener with a hammer blow – under any circumstances. A hammer blow won’t permit the sheet metal to flow

and develop an interlock with the fastener’s contour.

Don’t

install screw in the head side of fastener. Install from opposite side so that the fastener load is toward sheet. The clinching force

is designed only to hold the fastener during handling and to resist torque during assembly.

Don’t

install fastener on pre-painted side of panel.

SELF-CLINCHING FASTENER INSTALLATION DOS AND DON’TS

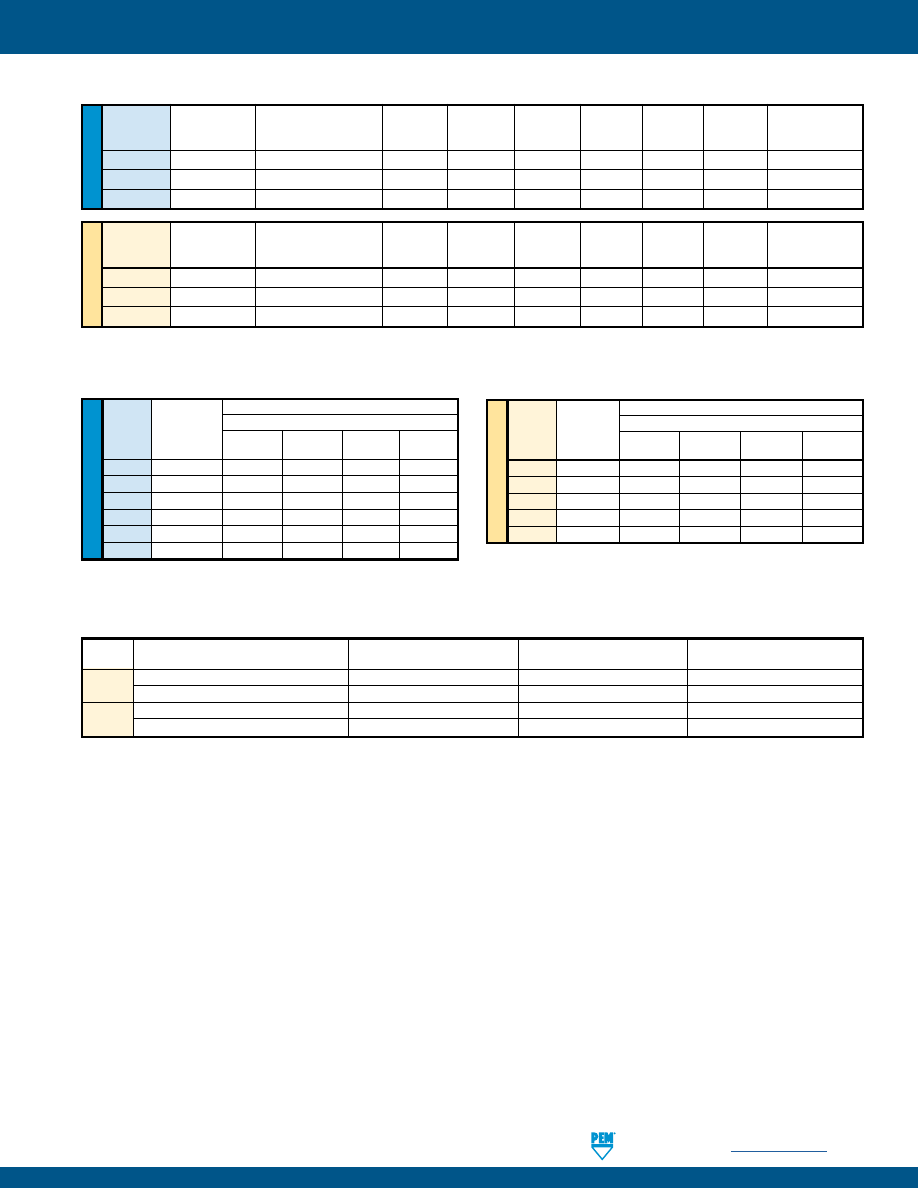

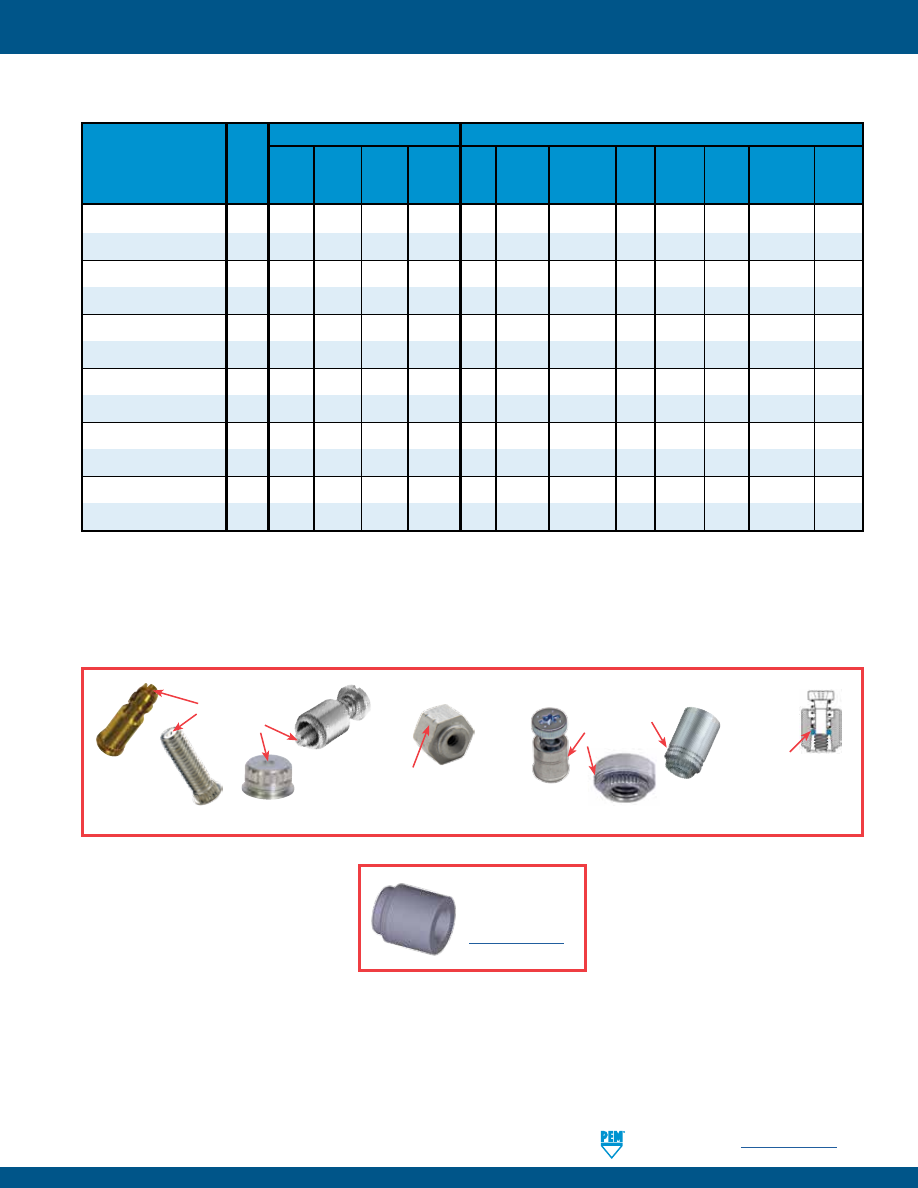

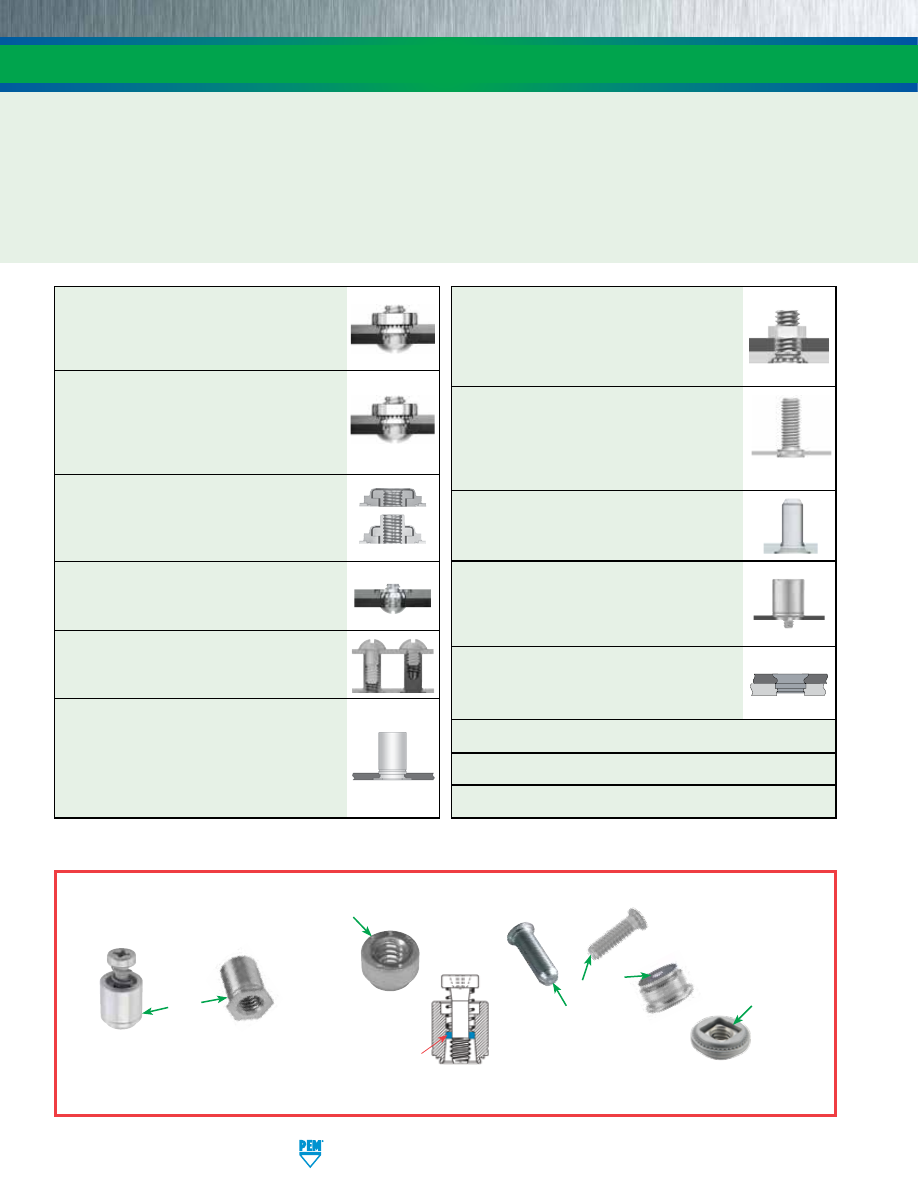

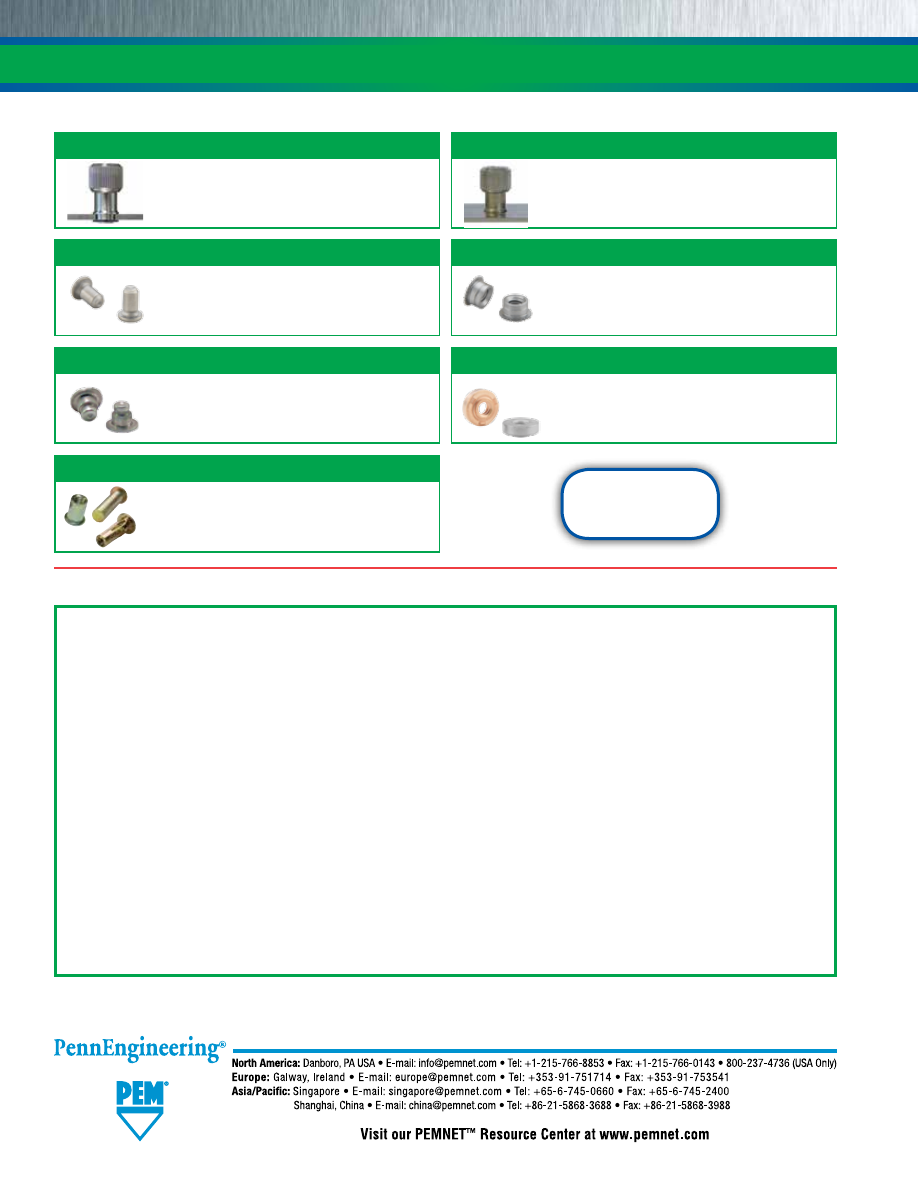

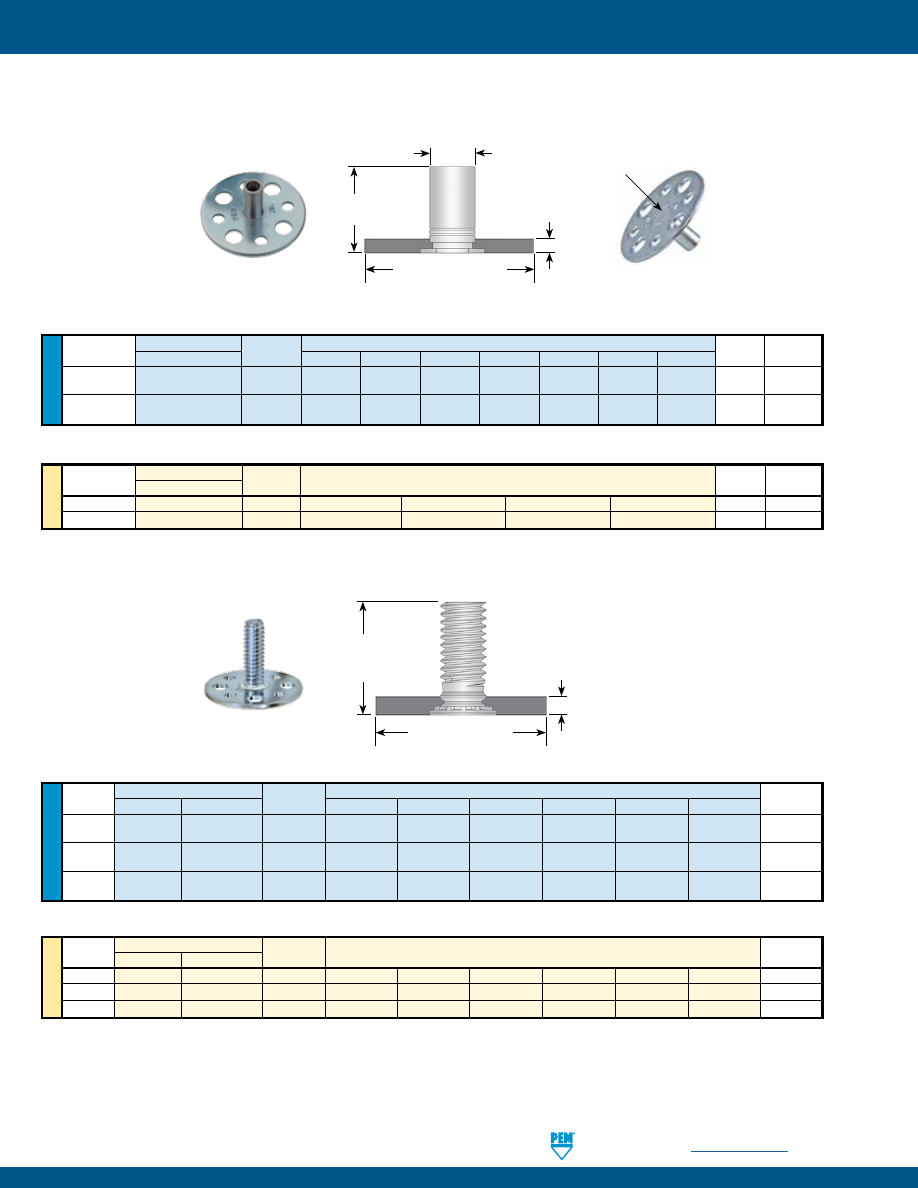

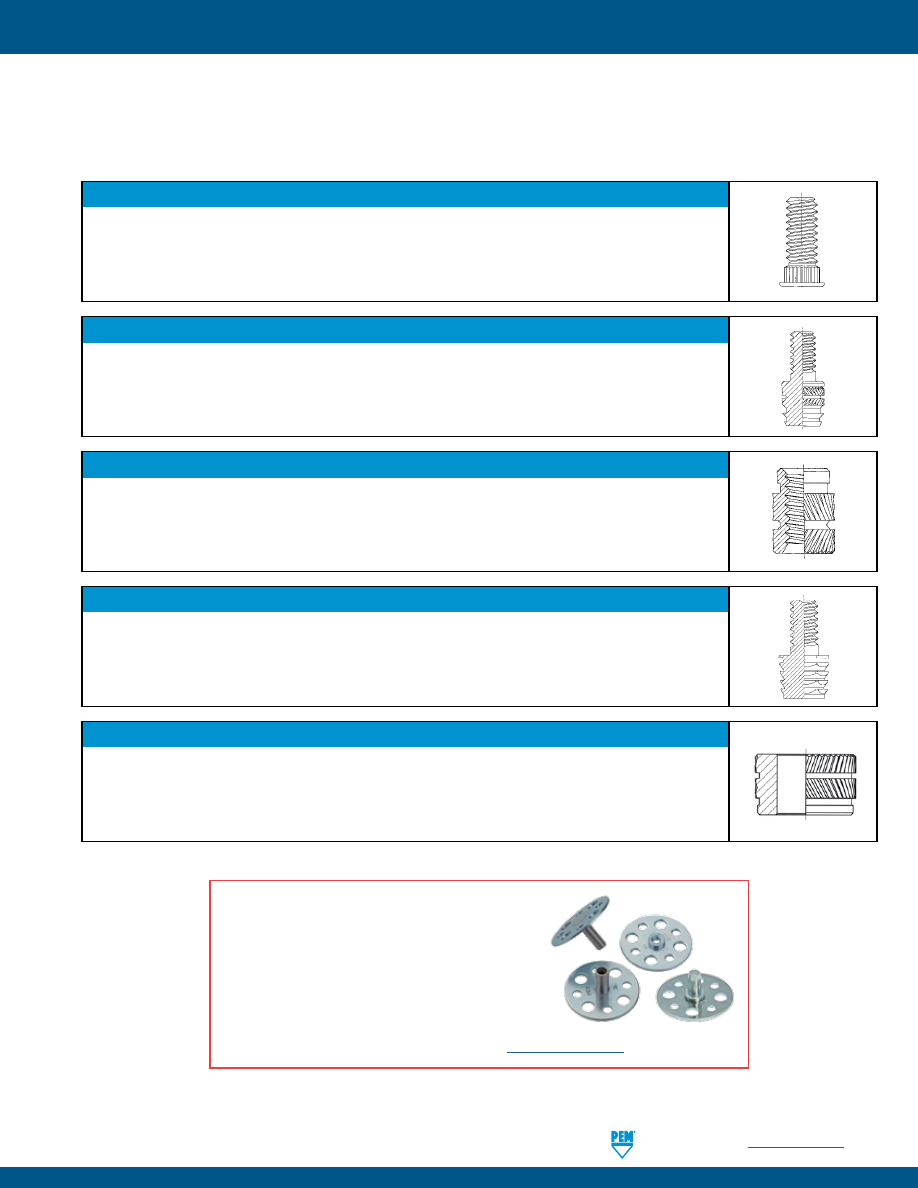

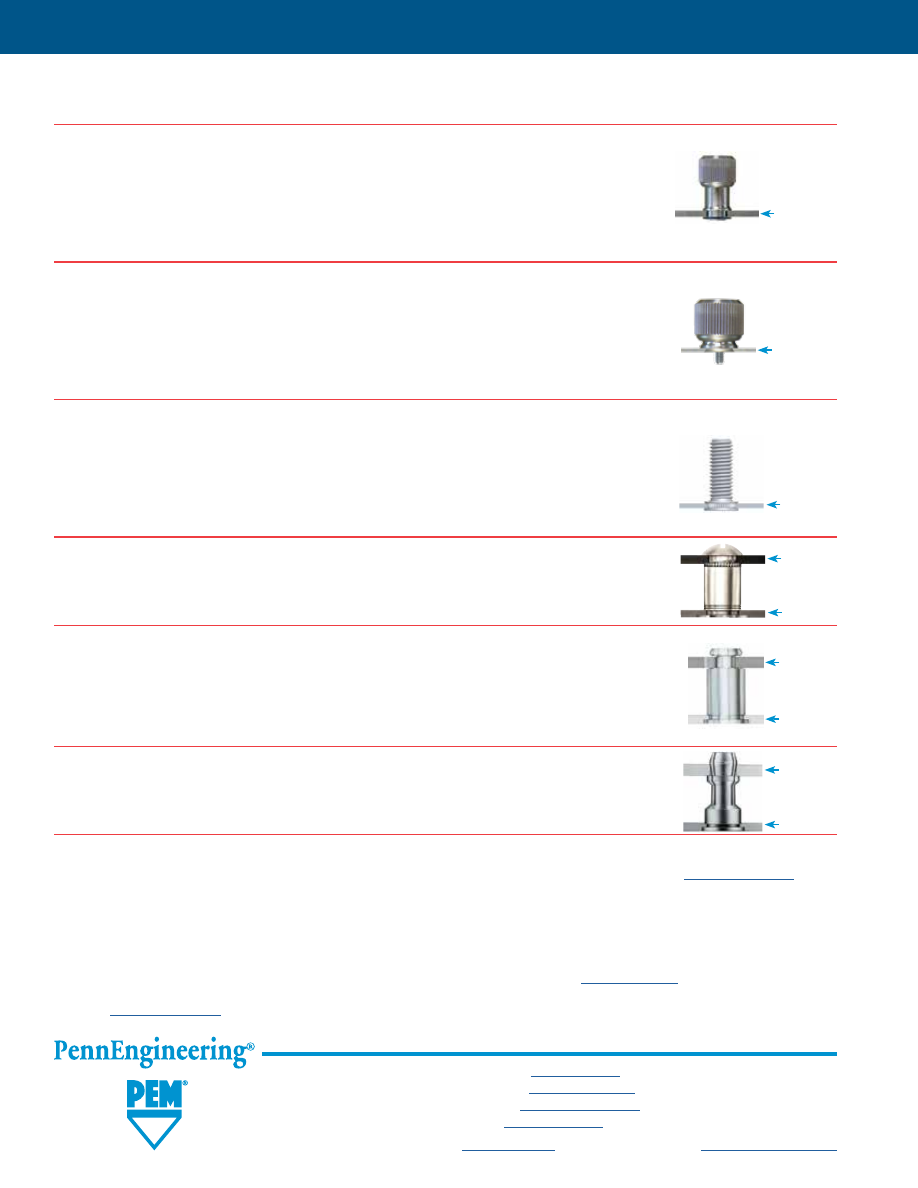

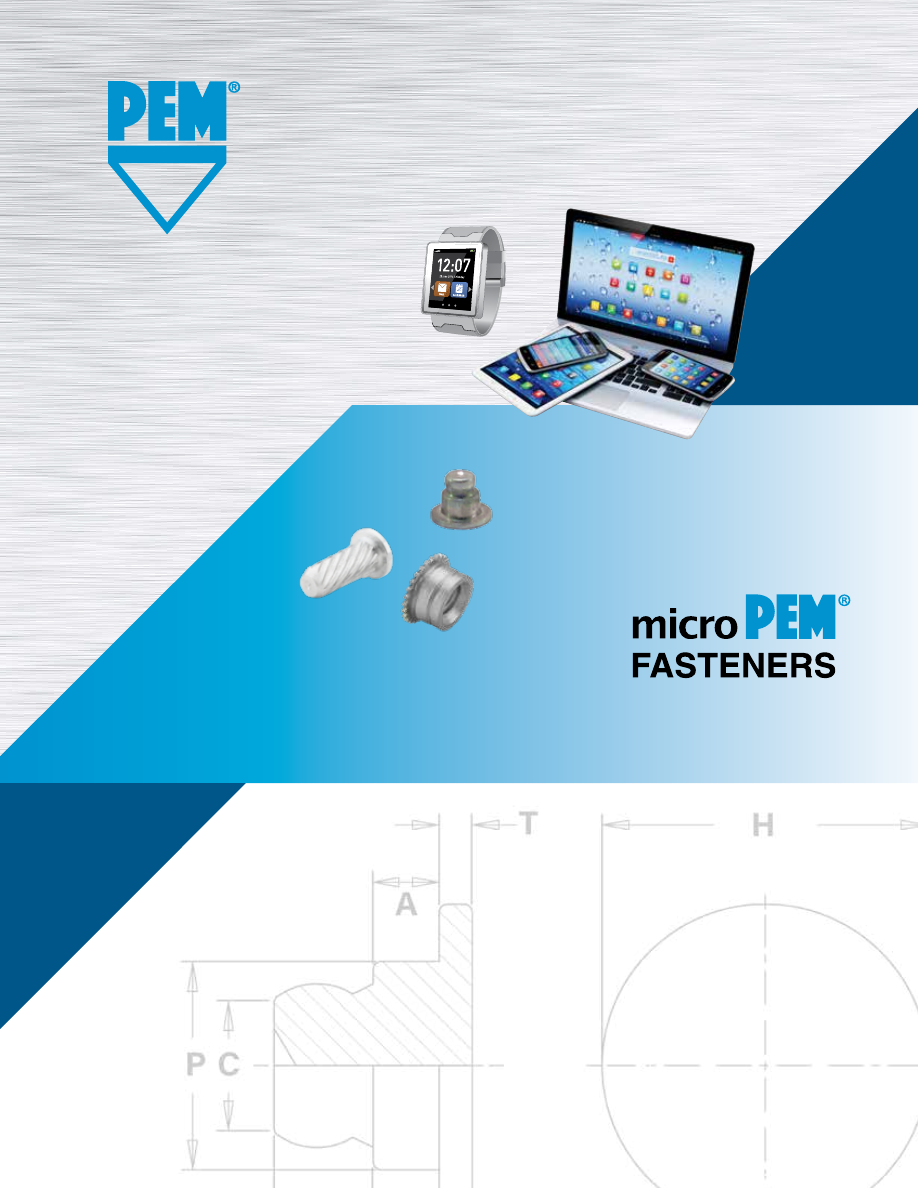

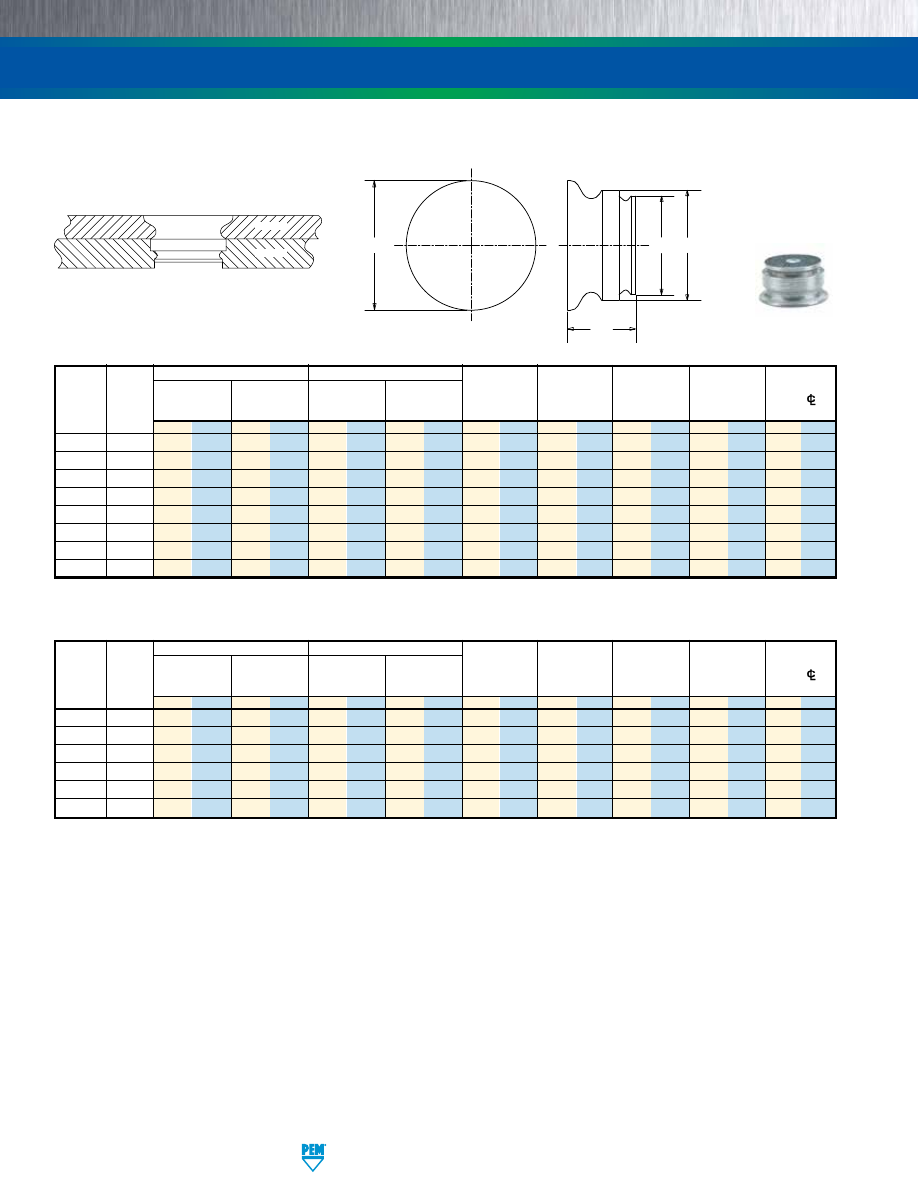

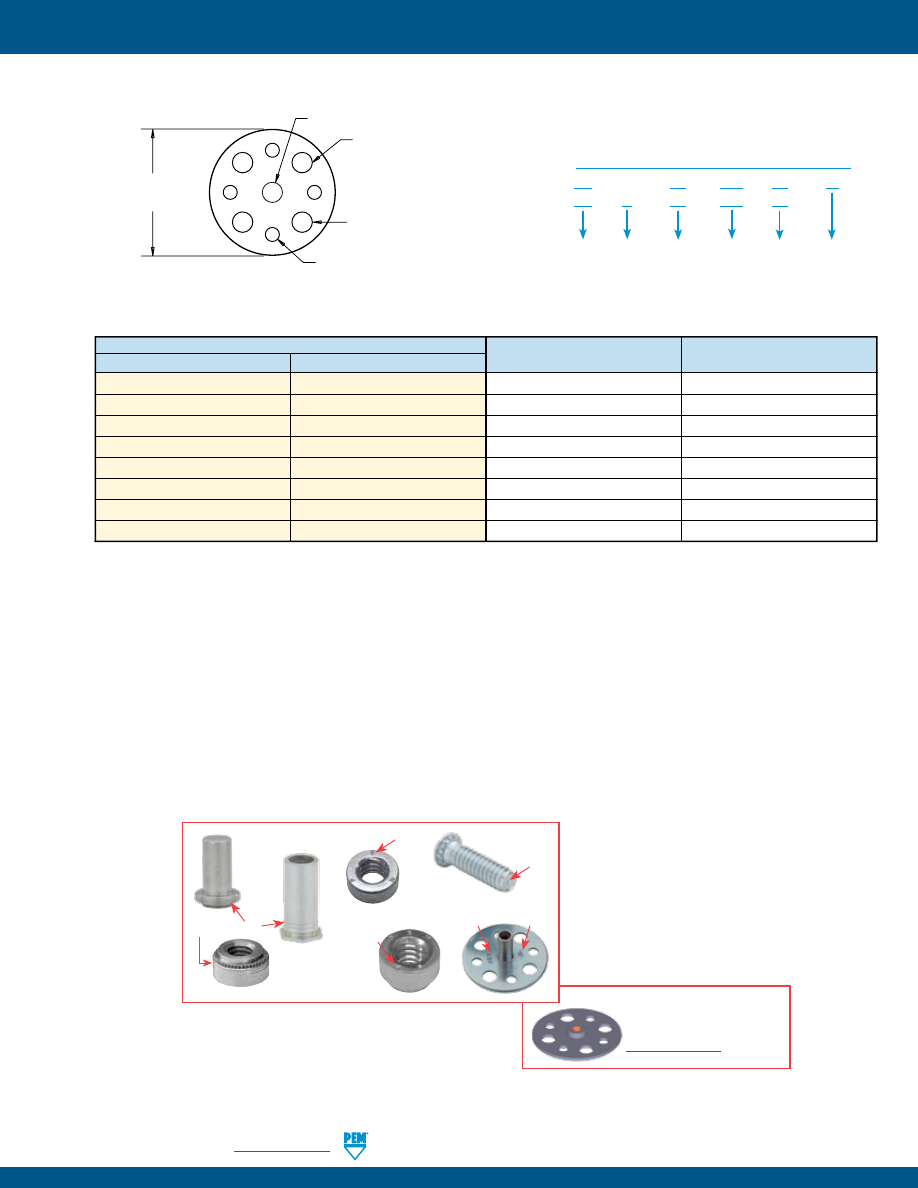

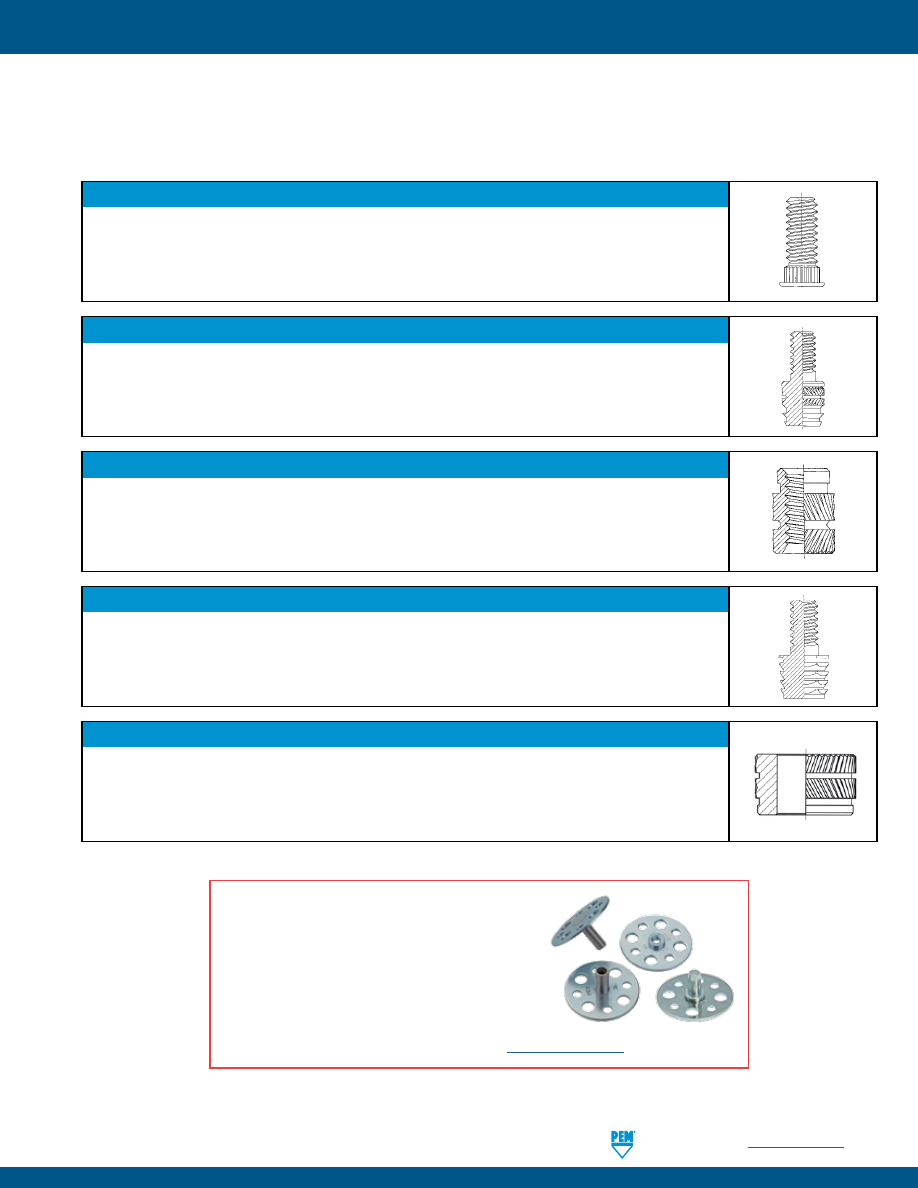

PEM® FASTENER PROTOTYPE KIT

The PEM prototype kit contains a wide variety of PEM fasteners for your prototype needs.

The kit contains over 1,000 different nuts, studs, standoffs, and panel fasteners of various

types and sizes, so you can choose the one which will best suit your specific design

requirements. The kit is available with unified or metric parts. Price U.S. $99.00 (subject to

change without notice).

INDEX-7

PennEngineering •

www.pemnet.com

pem-html.html

HOW CAN WE HELP?

PennEngineering offers a wide range of technical support assistance. Let us put our expertise to work for you. We can provide:

Training

▶

On customer site group or individual training by a technical representative and/or PEM® factory personnel

▶

Tutorial materials on website

Global Network of Engineering Representatives to:

▶

Provide local company liaison

▶

Provide application review/product selection

▶

Provide technical materials

▶

Provide on-site product training and new product updates

▶

Assist with quotations

▶

The representative nearest you can be found on our website.

rep/distributor locator

Application Engineering Services and Online Tools

▶

Application analysis/review

▶

Custom solutions

▶

Online technical papers

▶

Get answers to technical questions at

techsupport@pemnet.com

▶

Customer assist performance testing

▶

Cost Savings Investigation (CSI)

▶

Custom design and product development

▶

Customer drawings

▶

Finite Element Analysis (FEA)

▶

Free samples on standard (catalog) products

▶

3D Models (download or direct insert free on website)

▶

Free design PEMspec™ APP

▶

Instructional videos and animations

Technical Lab Services

- Complete testing in accordance with NASM 25027, 45938 and ASTM as well as PEM® fastener test specs and customer parameters.

▶

Mechanical testing

▶

Tensile strength

▶

Compression

▶

In sheet performance

▶

Micro hardness (Knoop, Rockwell and superficial)

▶

Thermal Cycling

▶

Image analysis

▶

Corrosion and plating issues and analysis

Prototype Development Center

- Shop equipped with latest CNC equipment to provide prototype or short run samples and necessary installation tooling.

Capabilities include:

▶

Turning

▶

Milling

▶

Drilling

▶

3D Printing

▶

Installation

▶

Reaming

▶

Punching

▶

Grinding

▶

Assembly

Installation Equipment

We can assess your application and recommend equipment that helps you achieve your lowest installed cost. PEMSERTER® systems can be developed to

handle multiple fastener types simultaneously or even in-die equipment to address challenging component handling and fastener installation. For more

information call us at 800-523-5321 (USA only) or 215-766-8853 or visit us at

www.pemnet.com

.

INDEX-8

All PEM® products meet our stringent quality standards. If you require additional industry or other specific

quality certifications

, special procedures and/or part

numbers are required. Please contact your local sales office or representative for further information.

Regulatory

compliance information

is available in Technical Support section of our website. Specifications subject to change without notice. See our website for the

most current version of this bulletin.

North America:

Danboro, Pennsylvania USA

•

E-mail:

info@pemnet.com

•

Tel: +1-215-766-8853

•

800-237-4736 (USA)

Europe:

Galway, Ireland

•

E-mail:

europe@pemnet.com

•

Tel: +353-91-751714

Asia/Pacific:

Singapore

•

E-mail:

singapore@pemnet.com

•

Tel: +65-6-745-0660

Shanghai, China

•

E-mail:

china@pemnet.com

•

Tel: +86-21-5868-3688

Visit our PEMNET™ Resource Center at

www.pemnet.com

•

Technical support e-mail:

techsupport@pemnet.com

Stay connected to PennEngineering

Now you can follow us for the latest news releases, new

products, bulletin updates, tech tips, videos and more.

pem-html.html

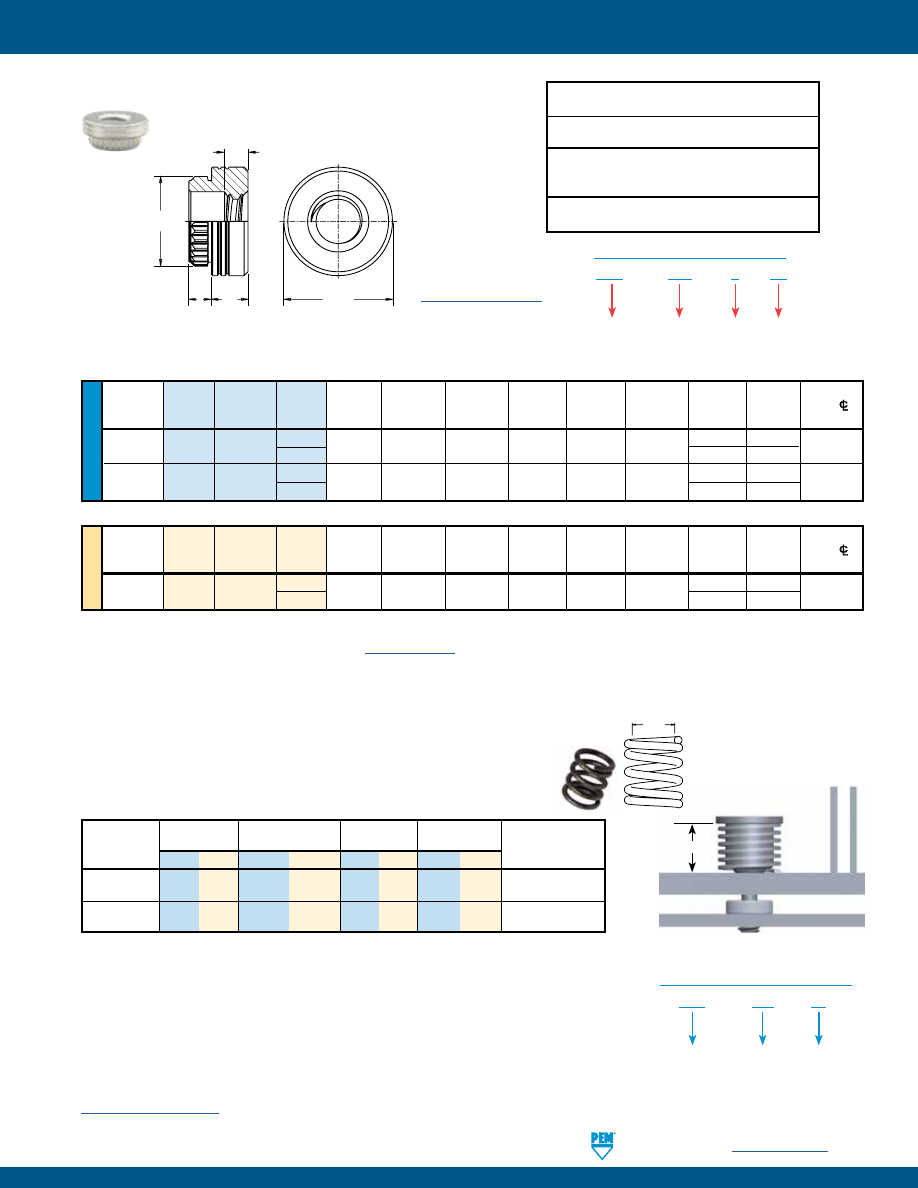

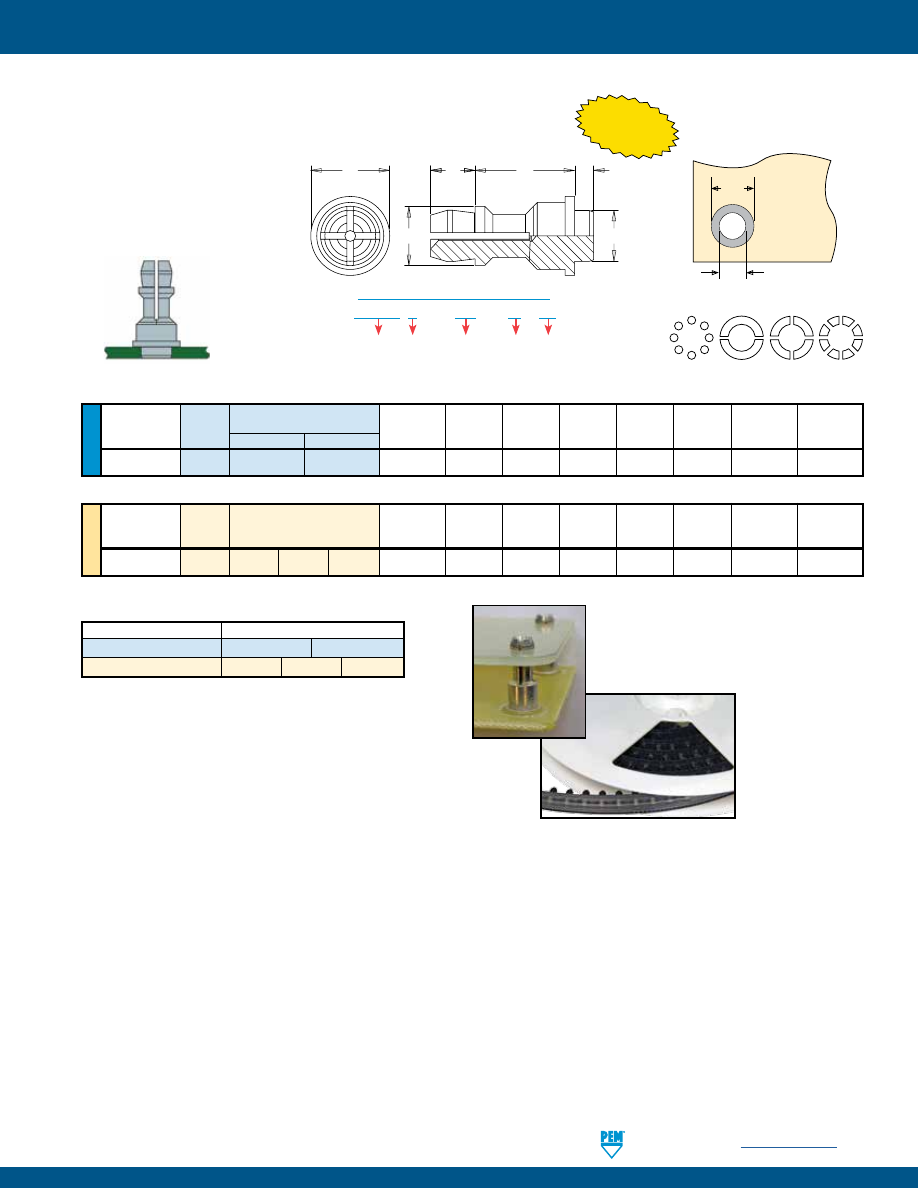

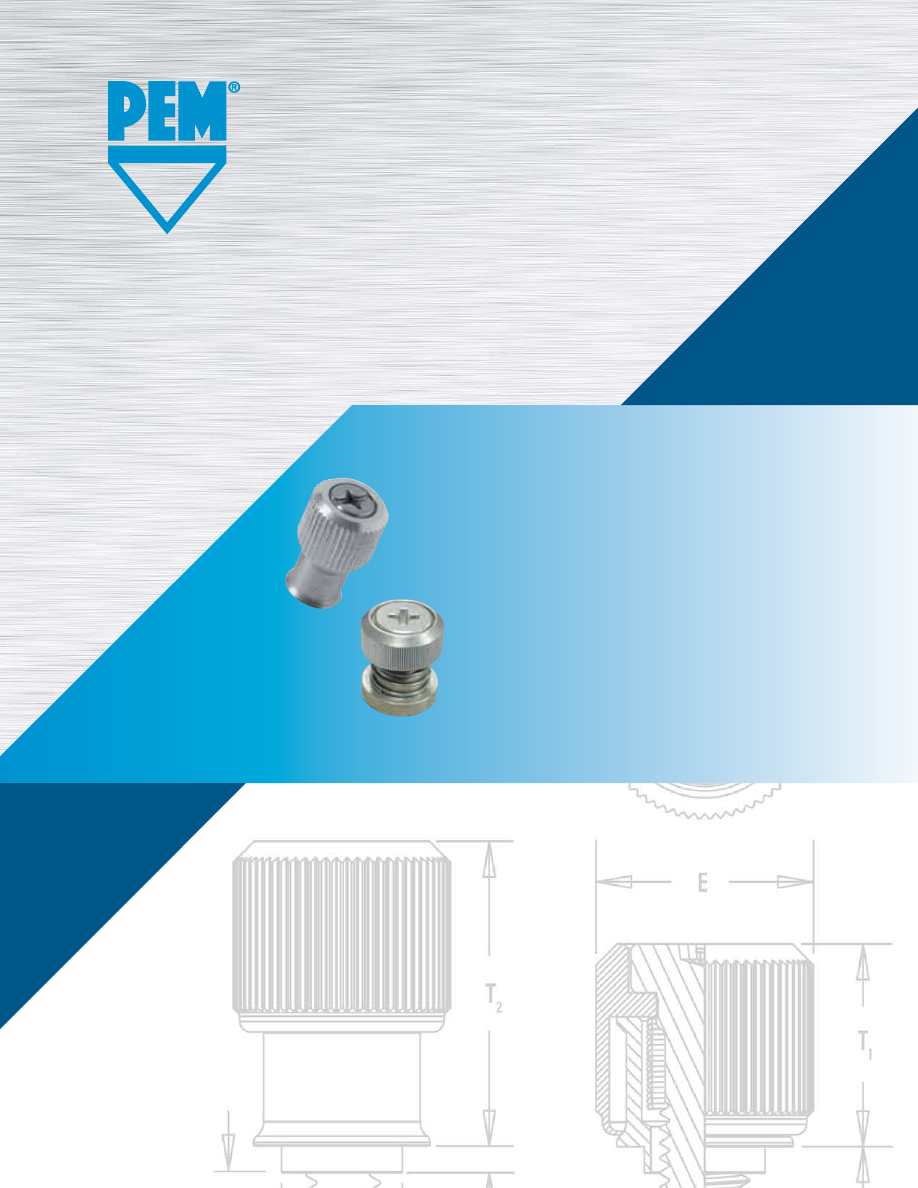

ALA

™

FLOATING

SELF-CLINCHING

FASTENERS

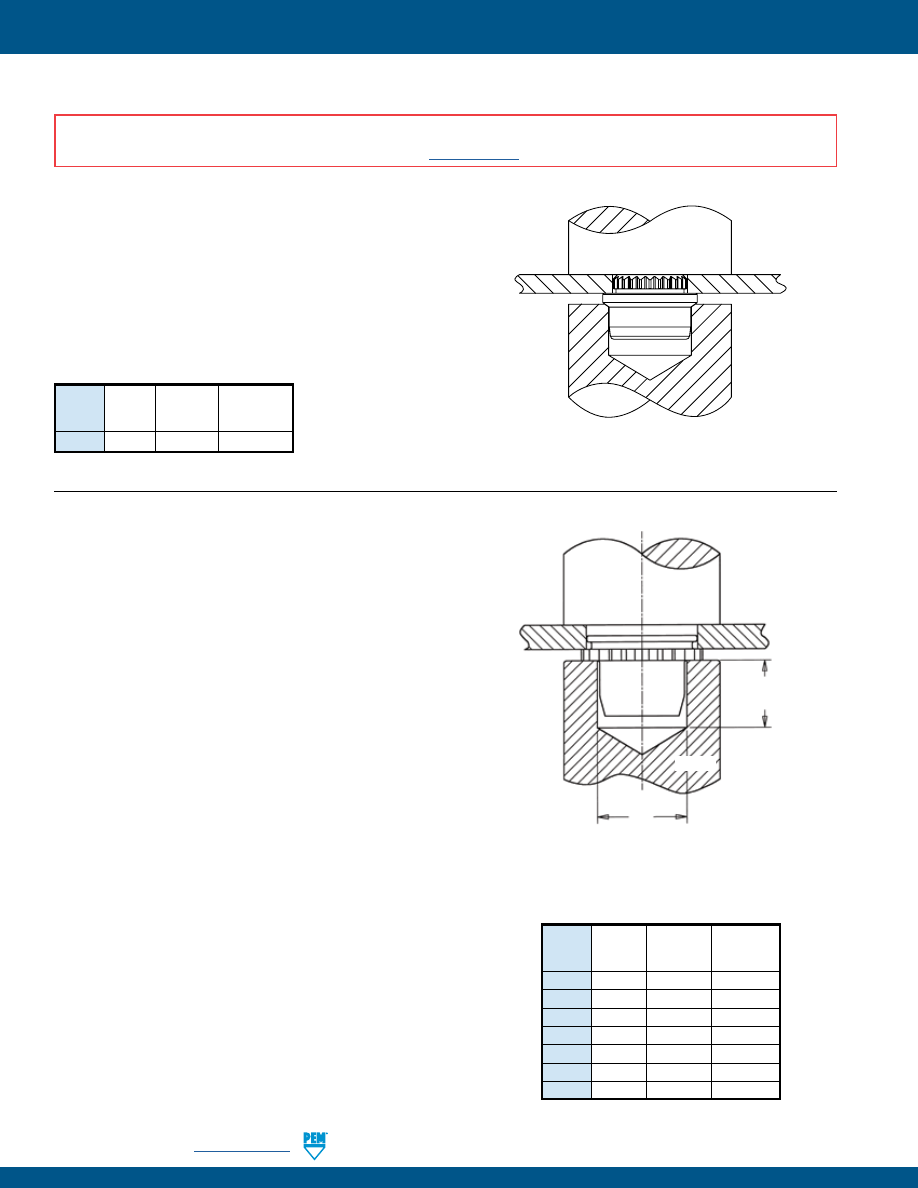

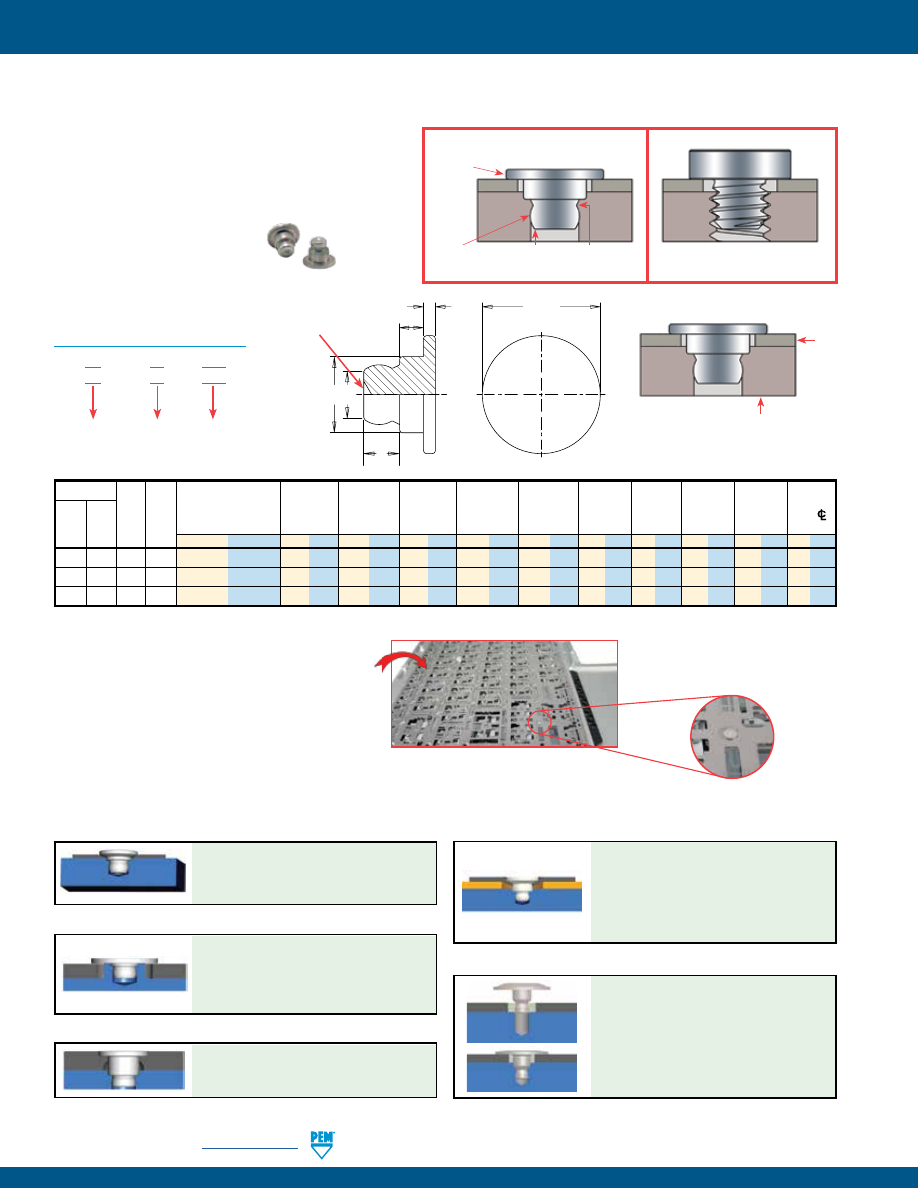

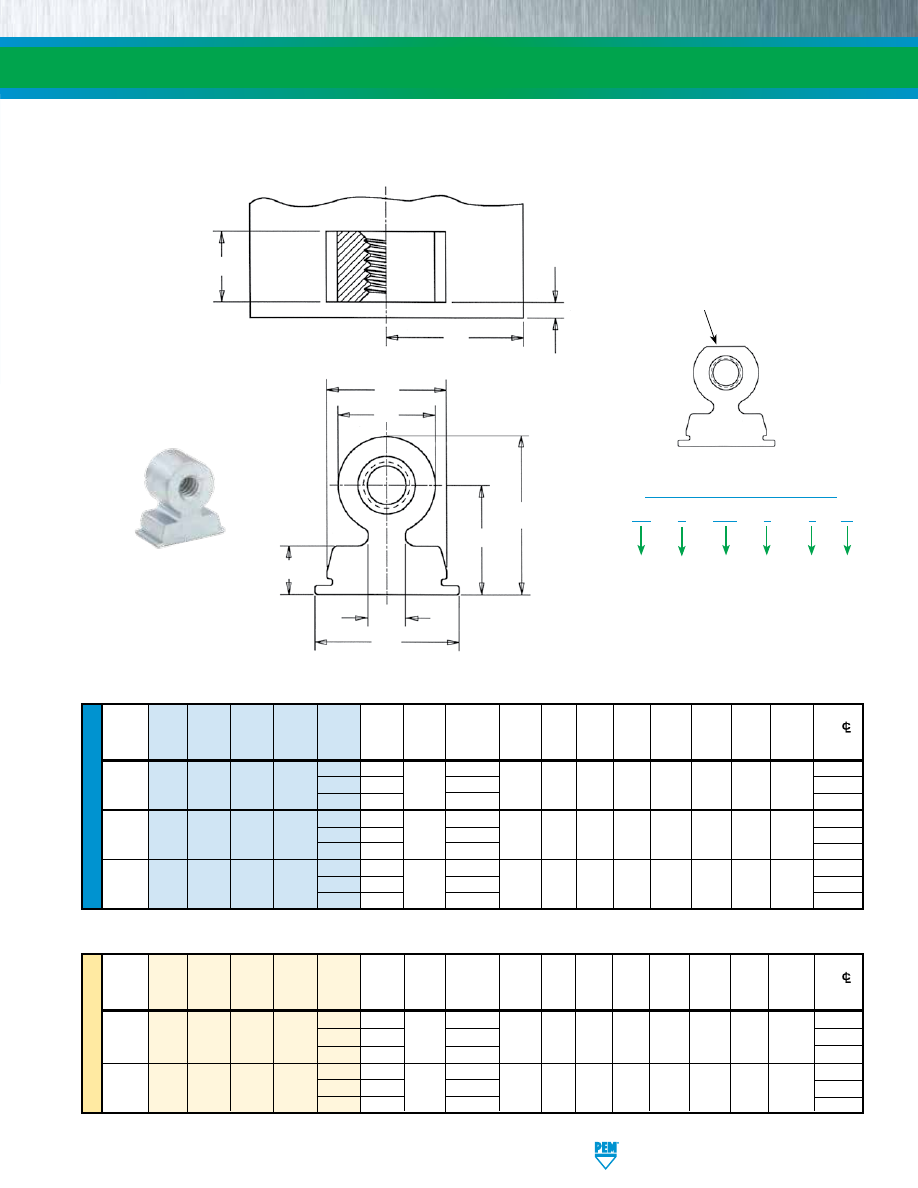

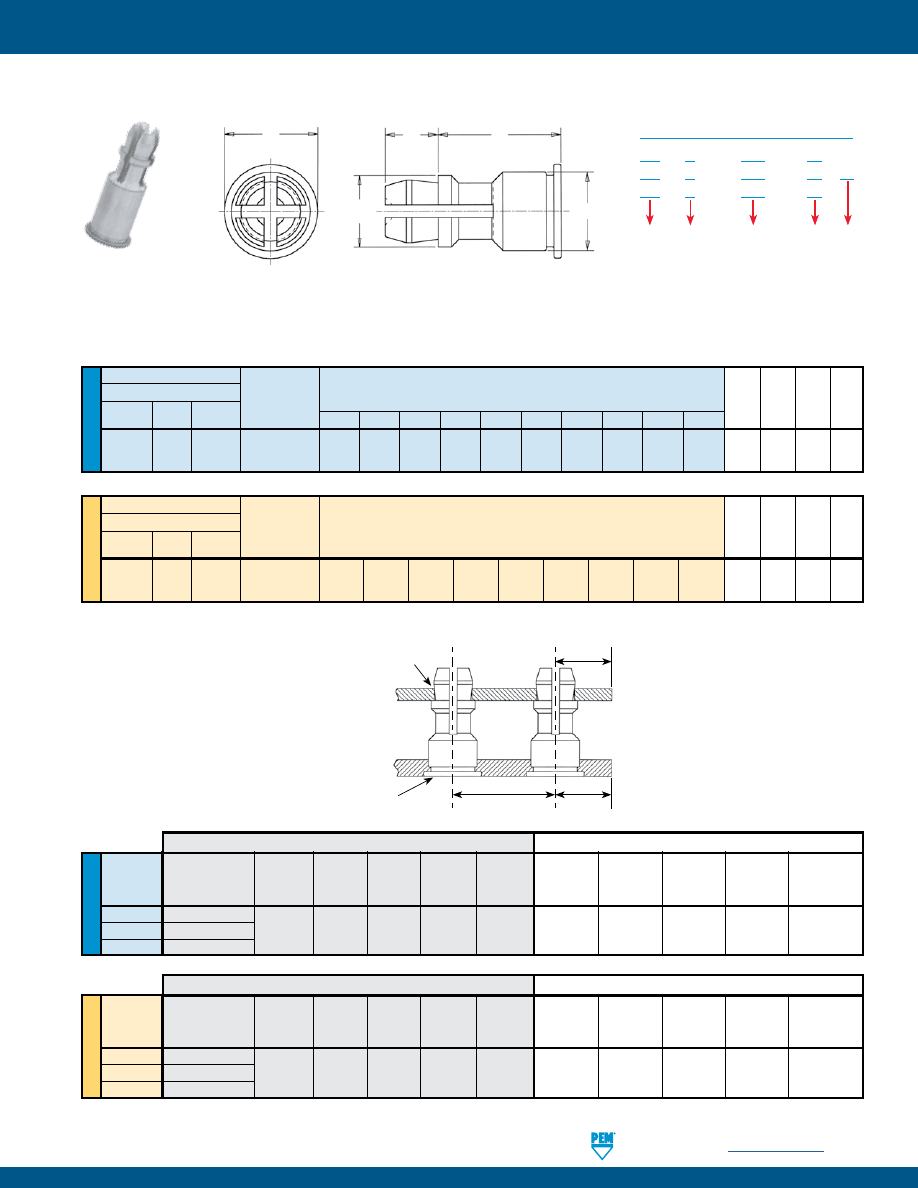

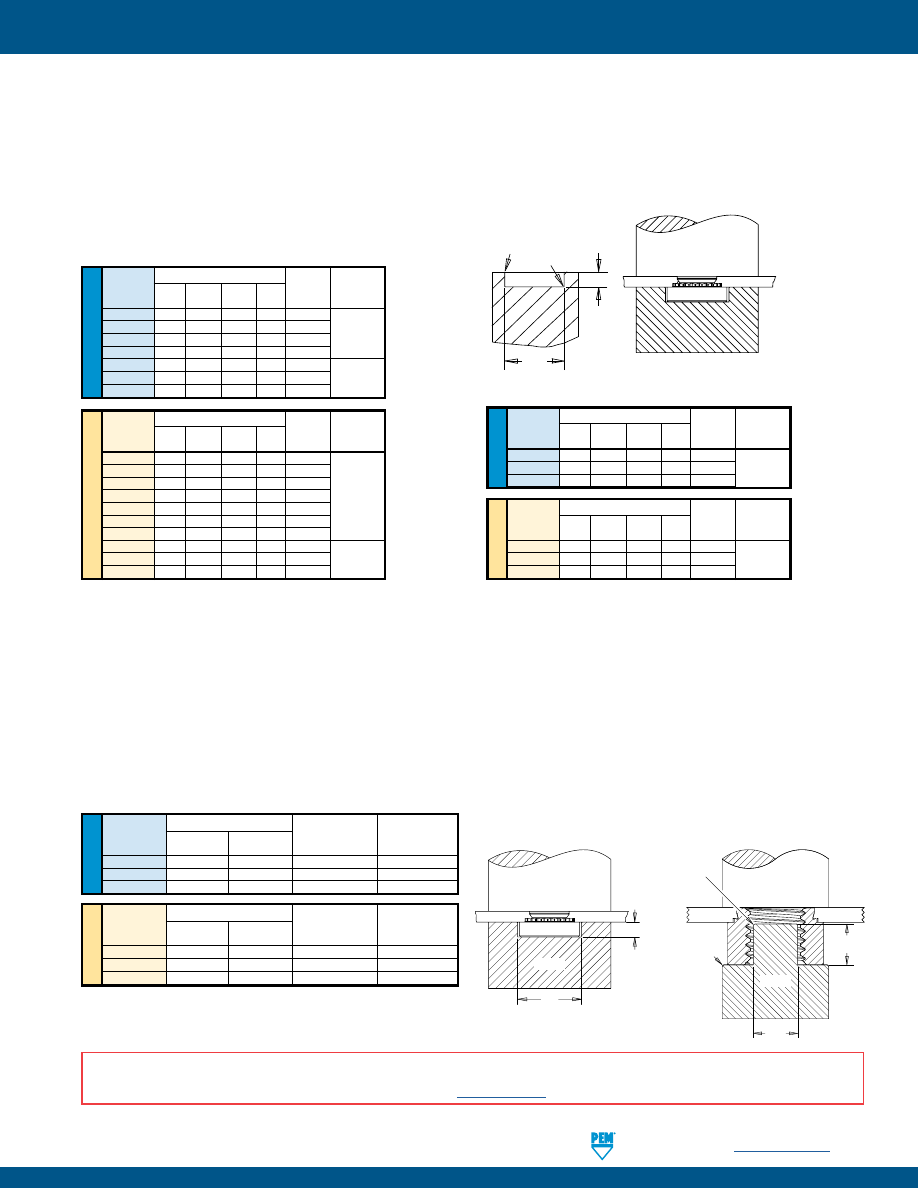

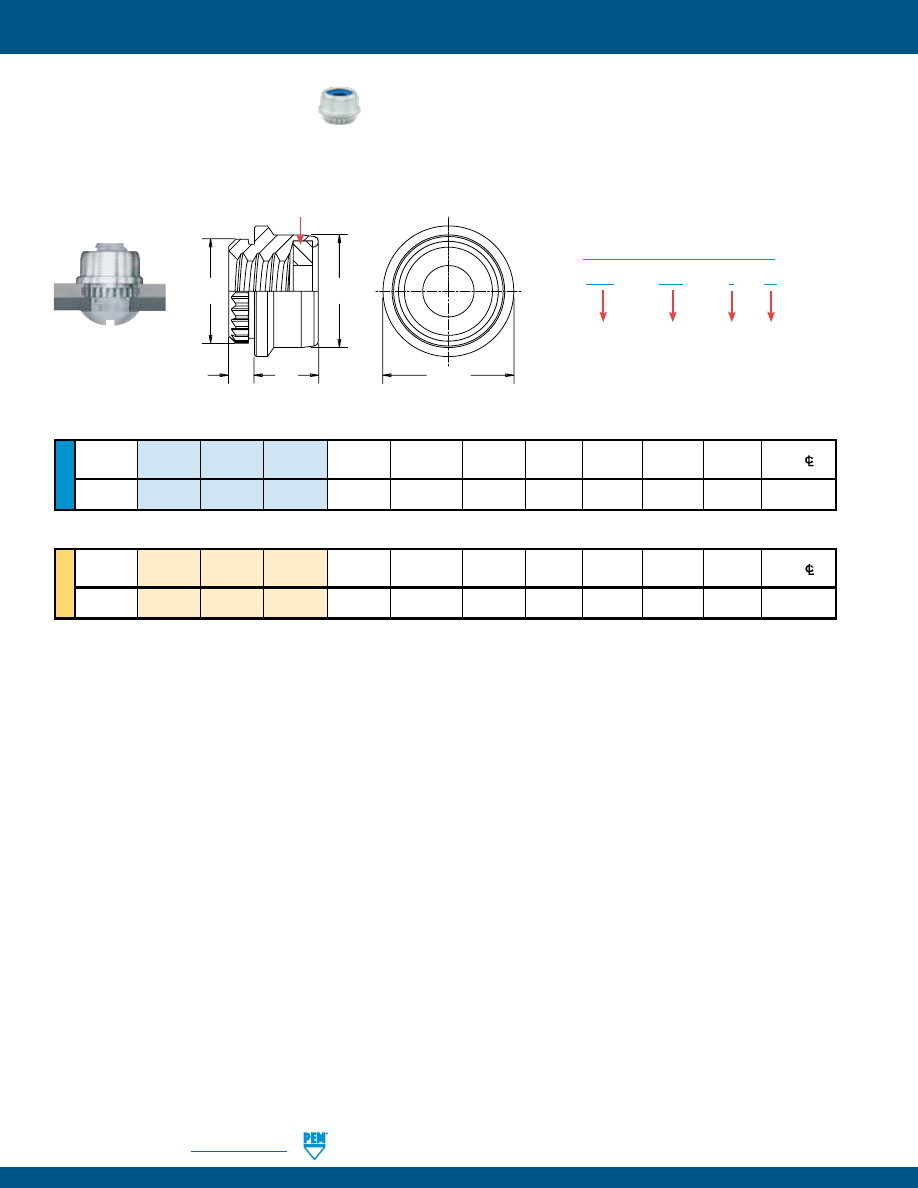

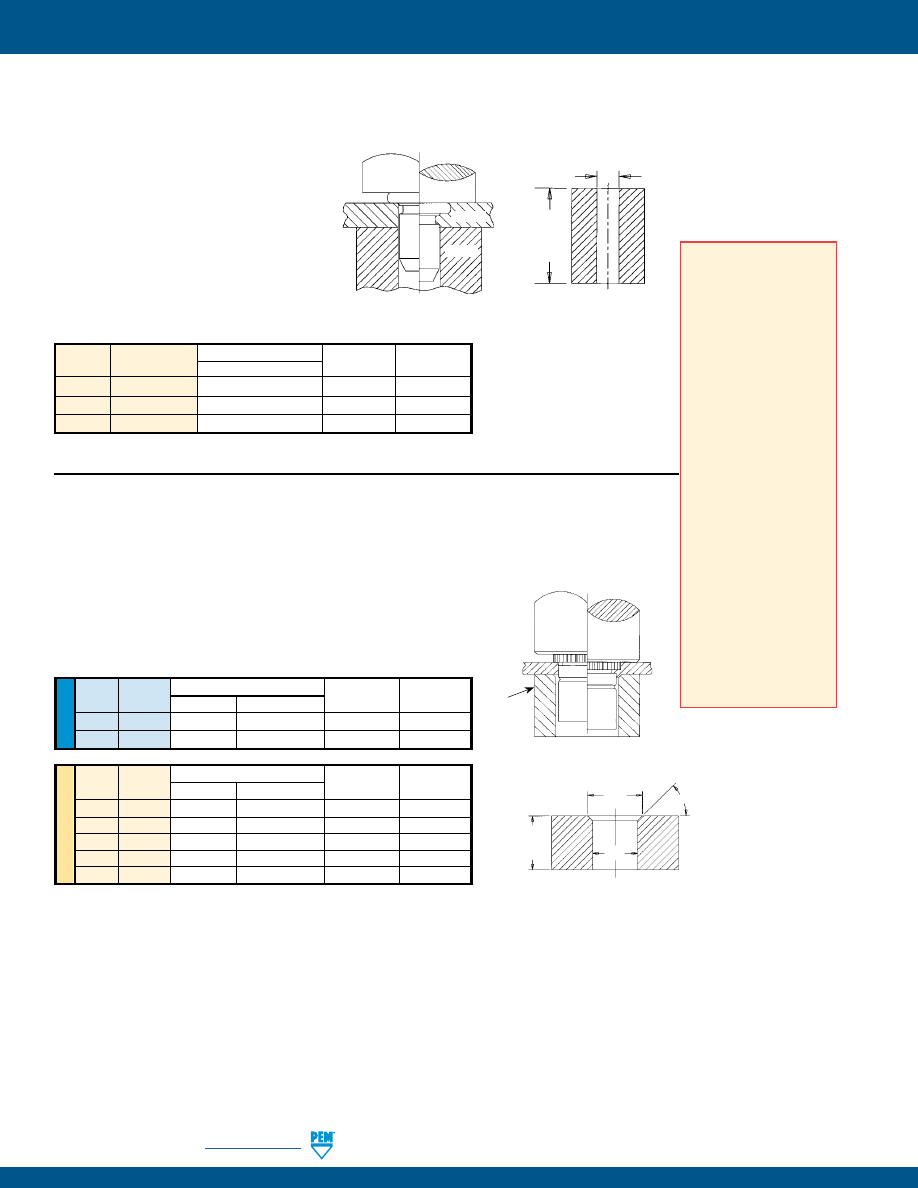

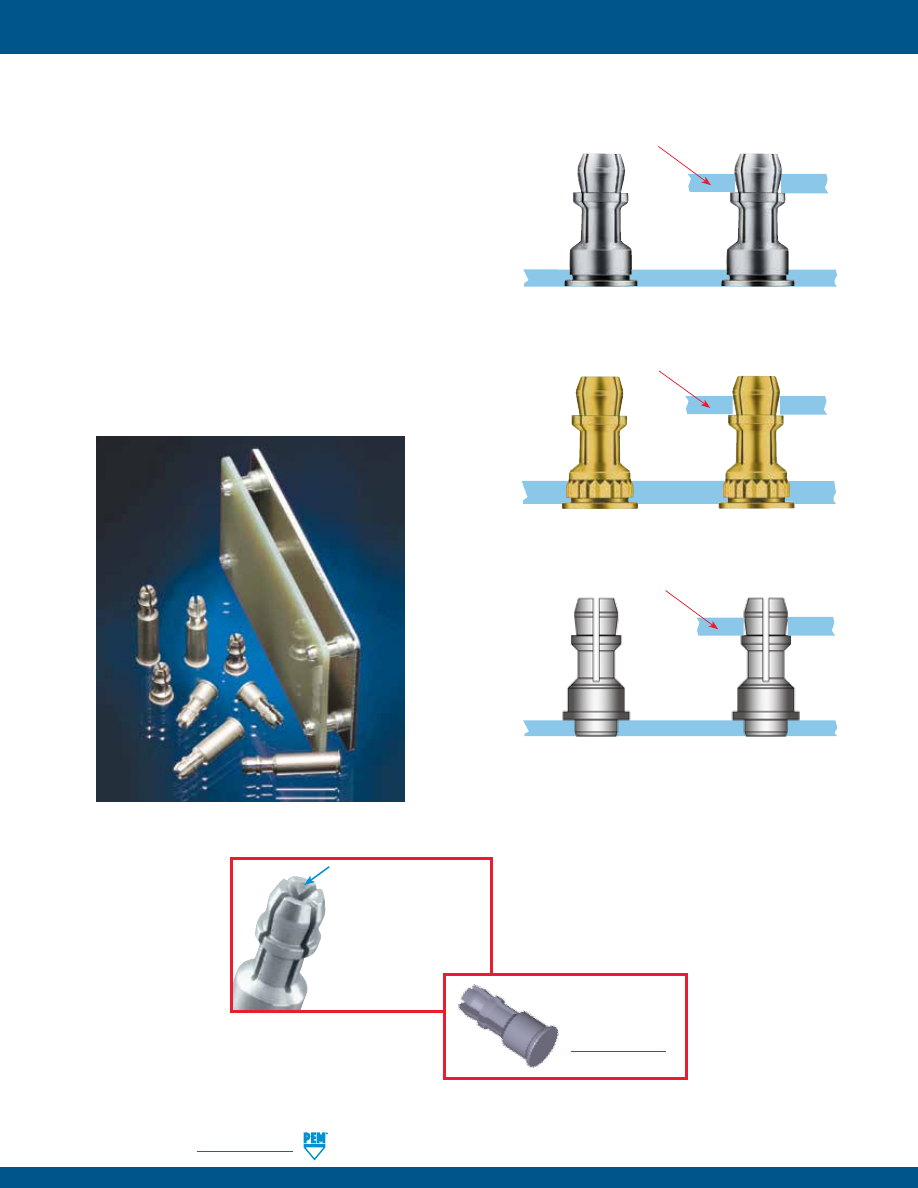

PEM® floating self-clinching fasteners

are available with or without locking

threads.

Bulletin ALA-1217

pem-html.html

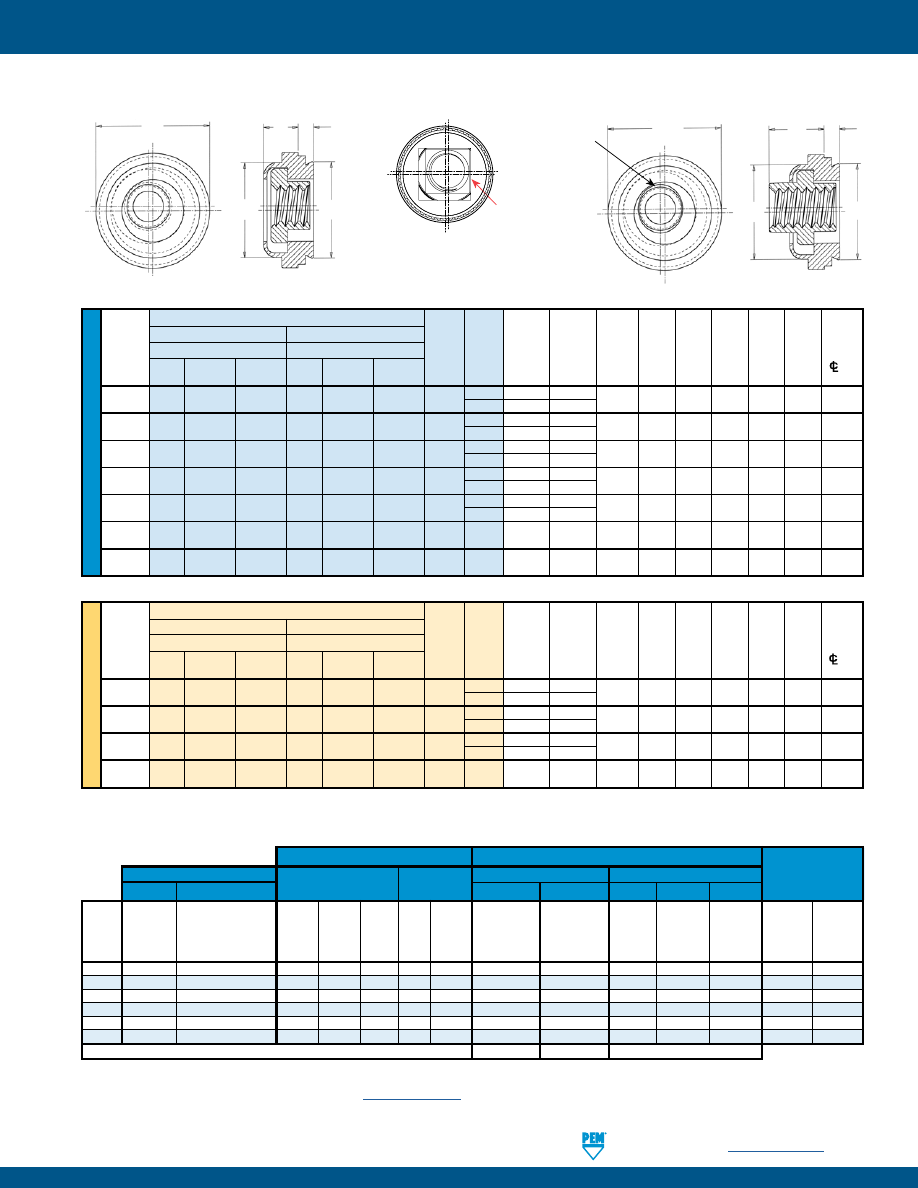

ALA-2

PennEngineering •

www.pemnet.com

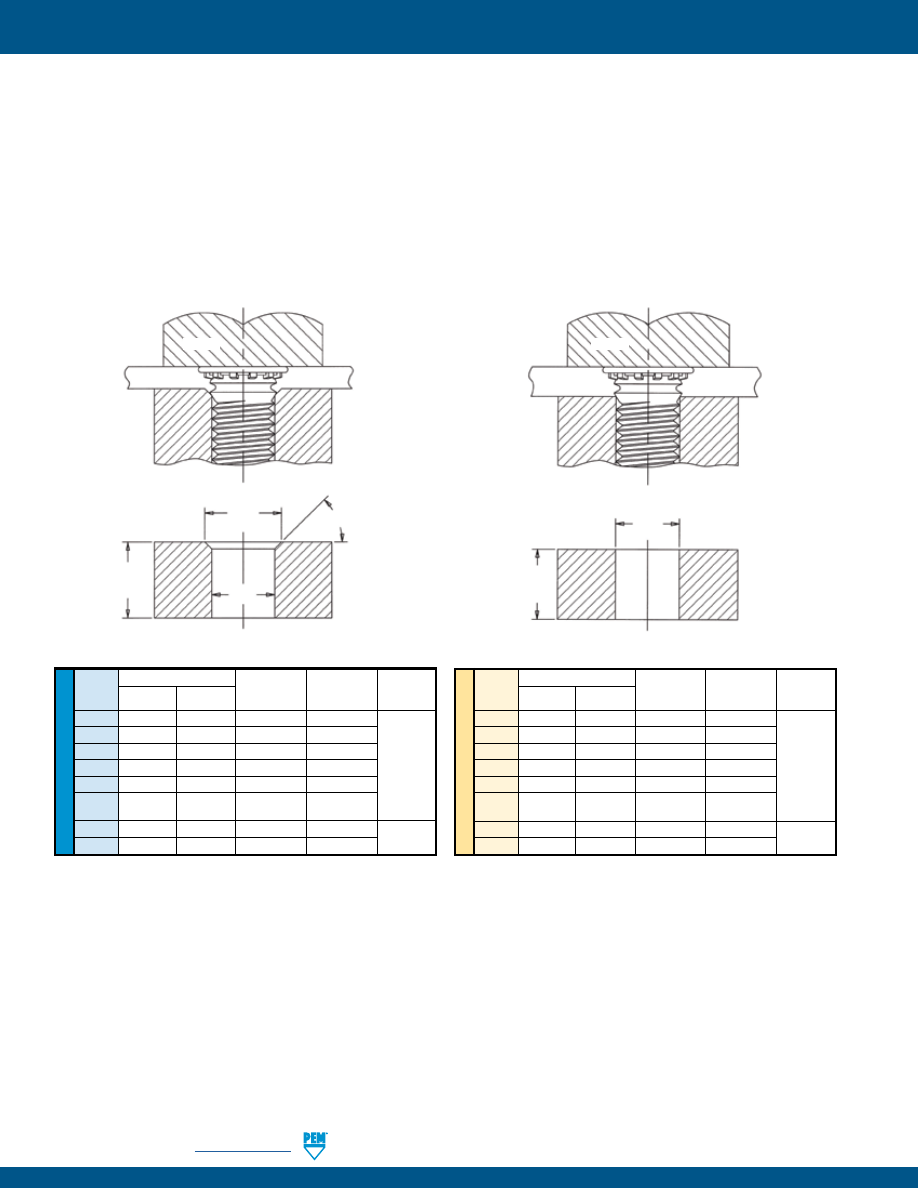

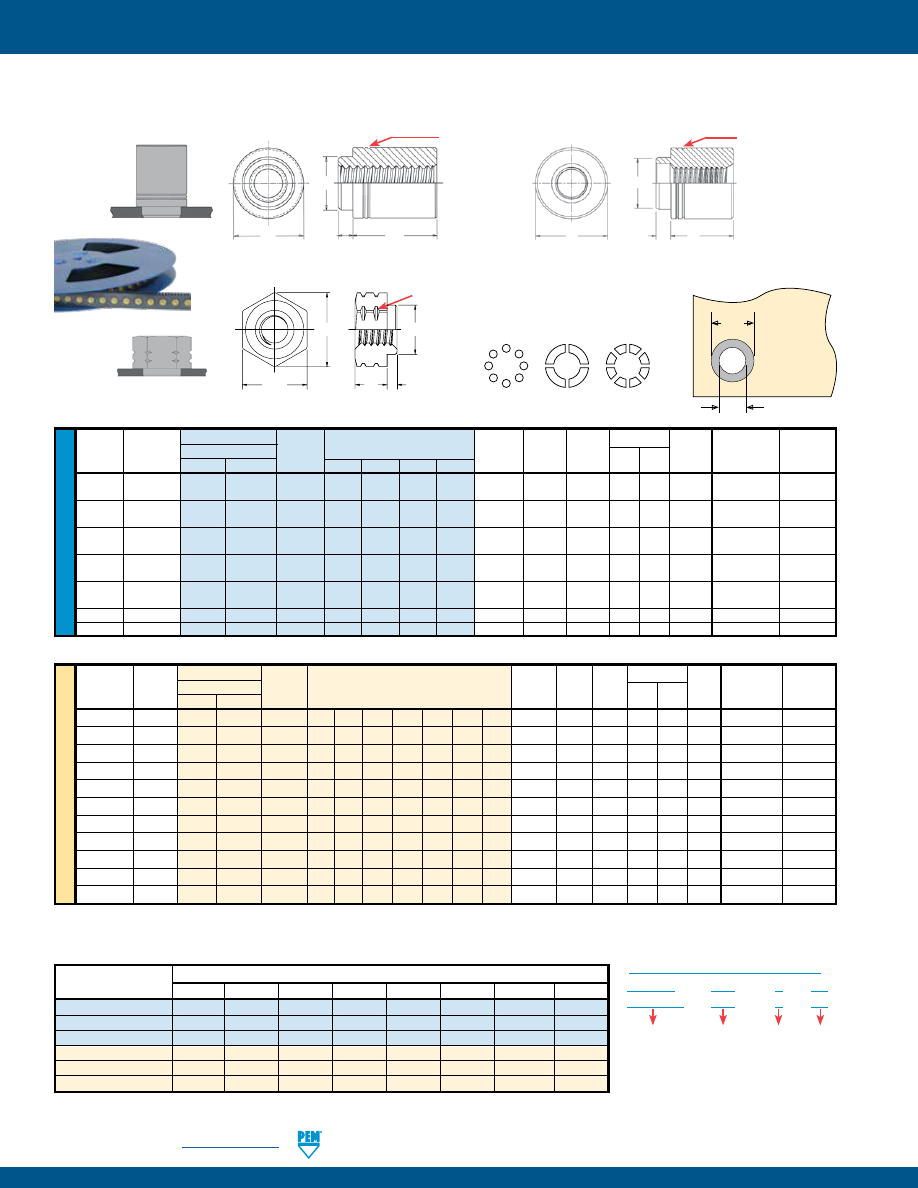

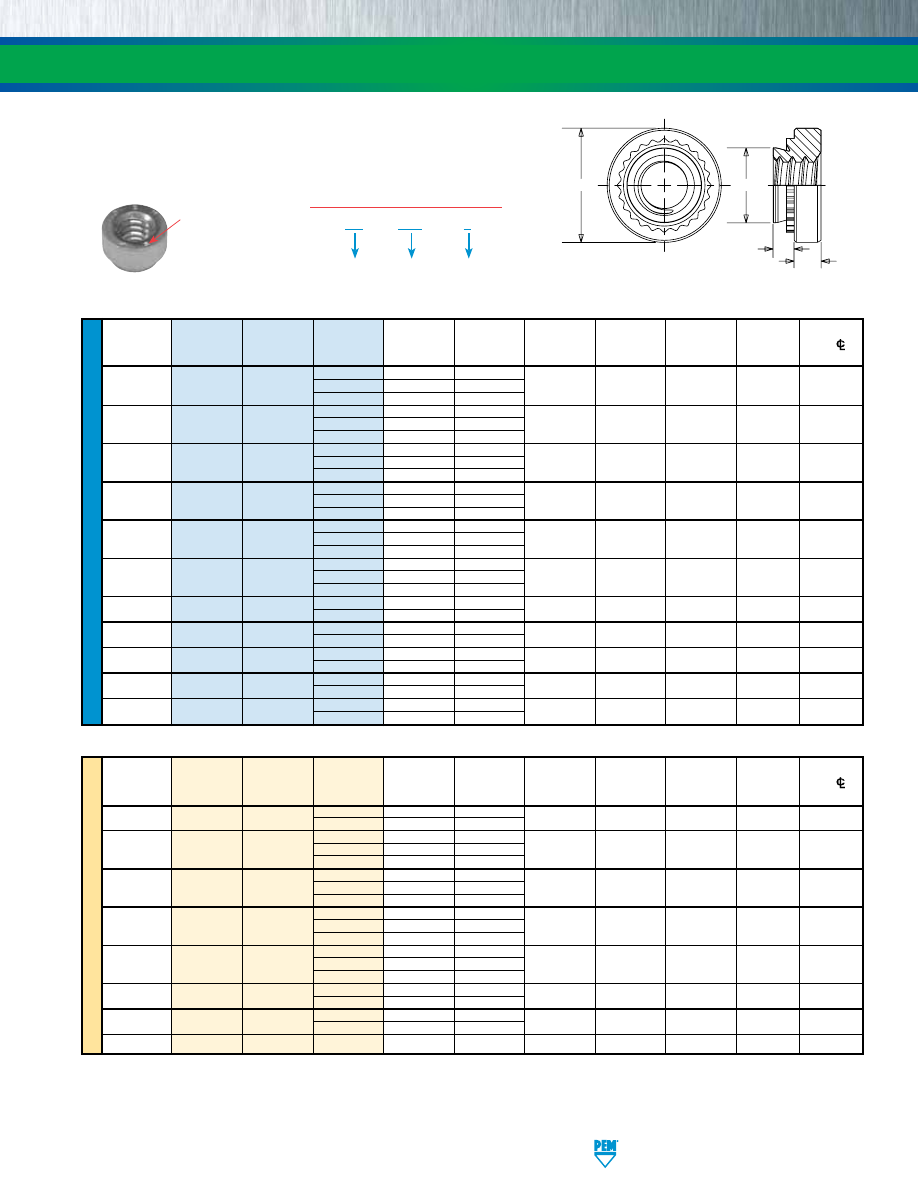

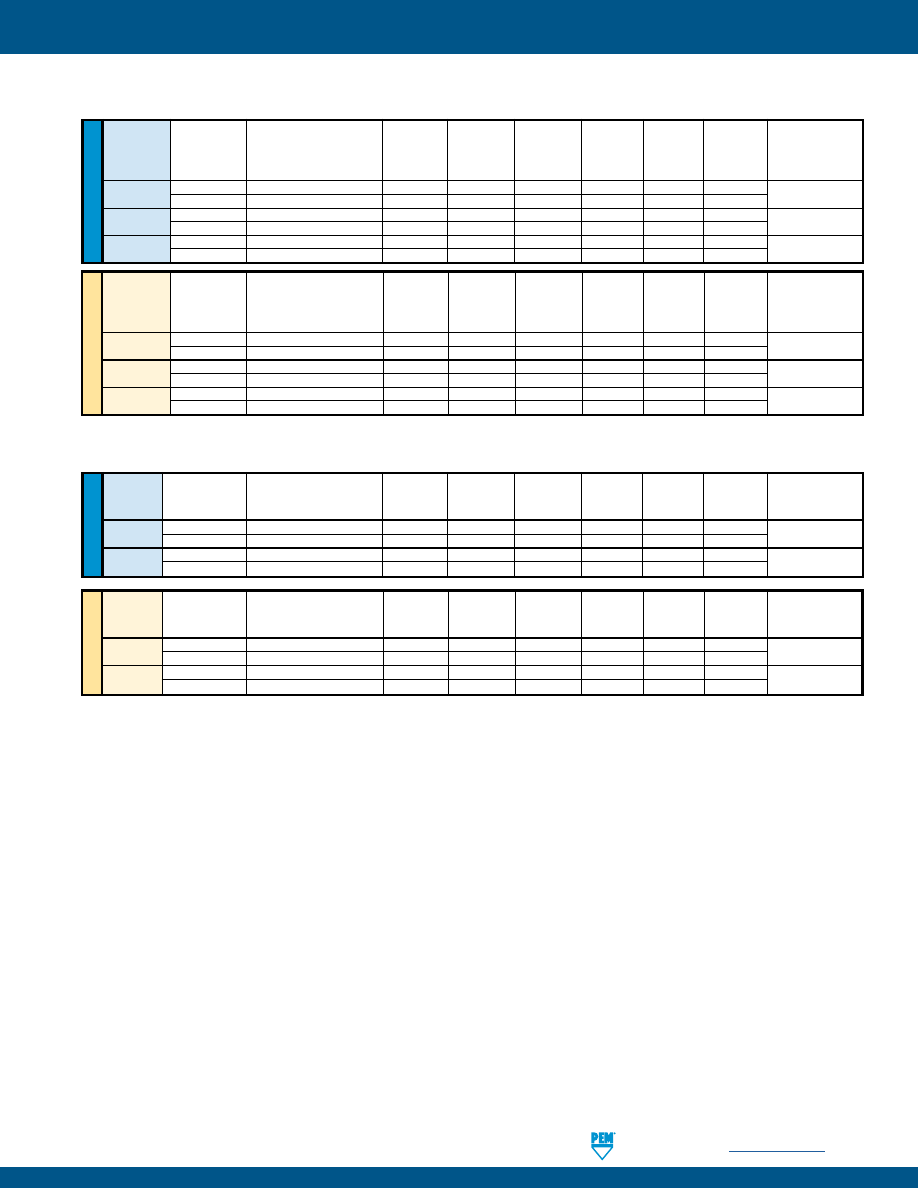

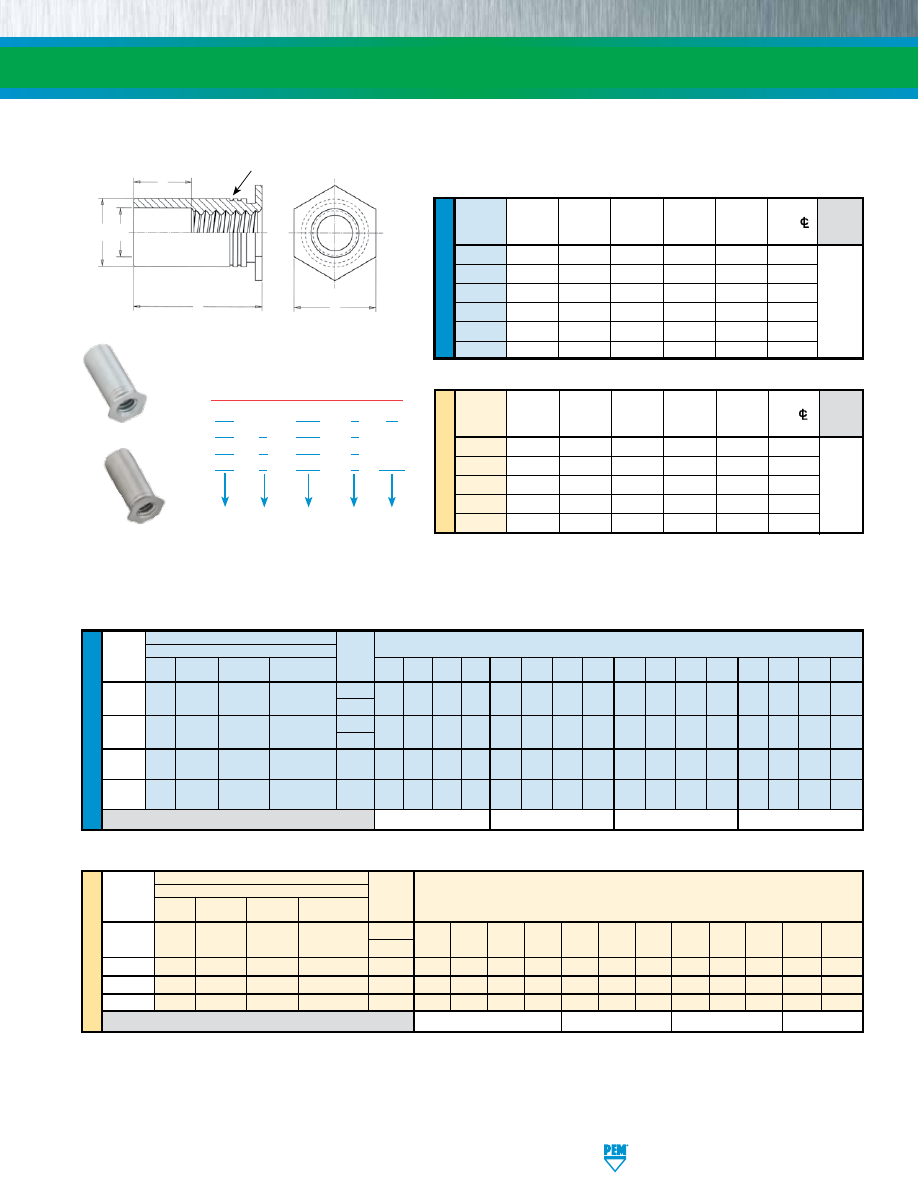

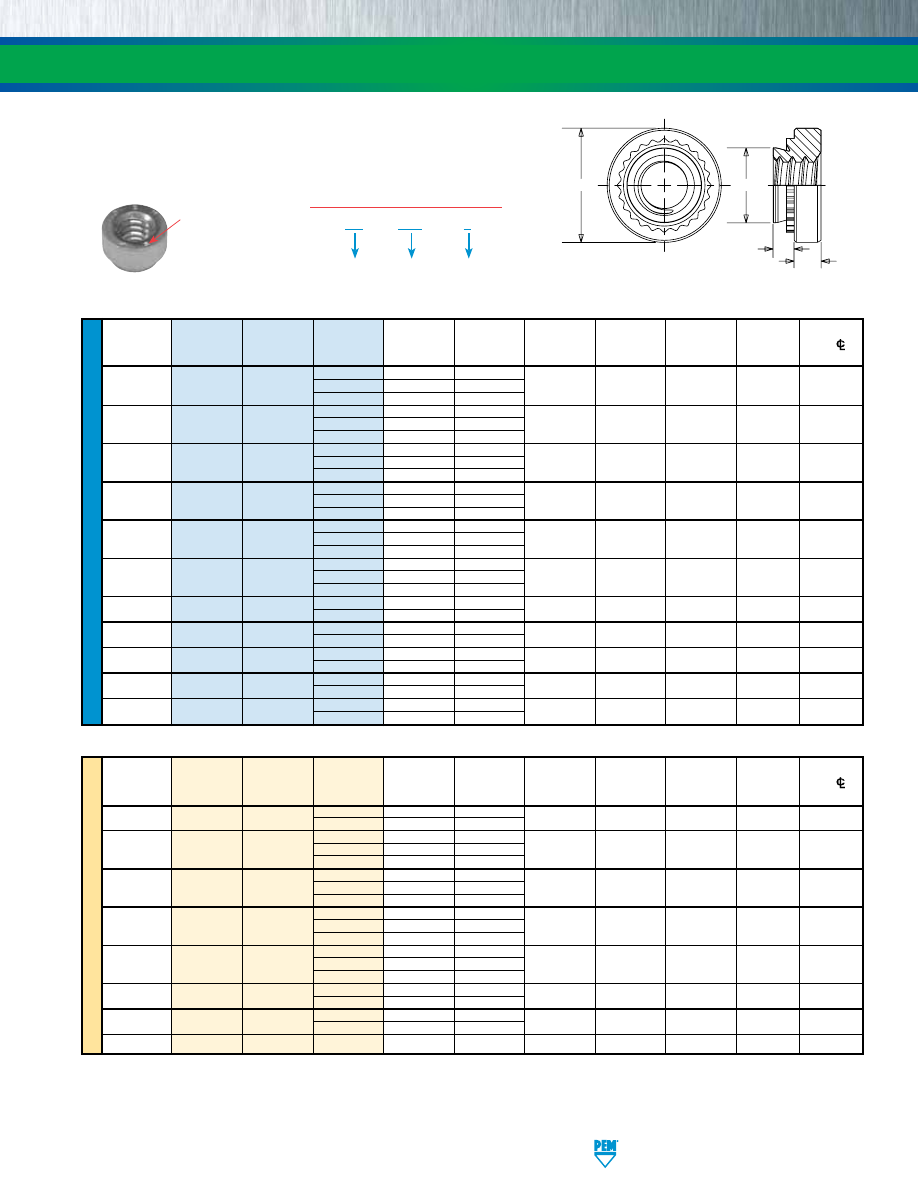

U

NIF

IE

D

NON-LOCKING

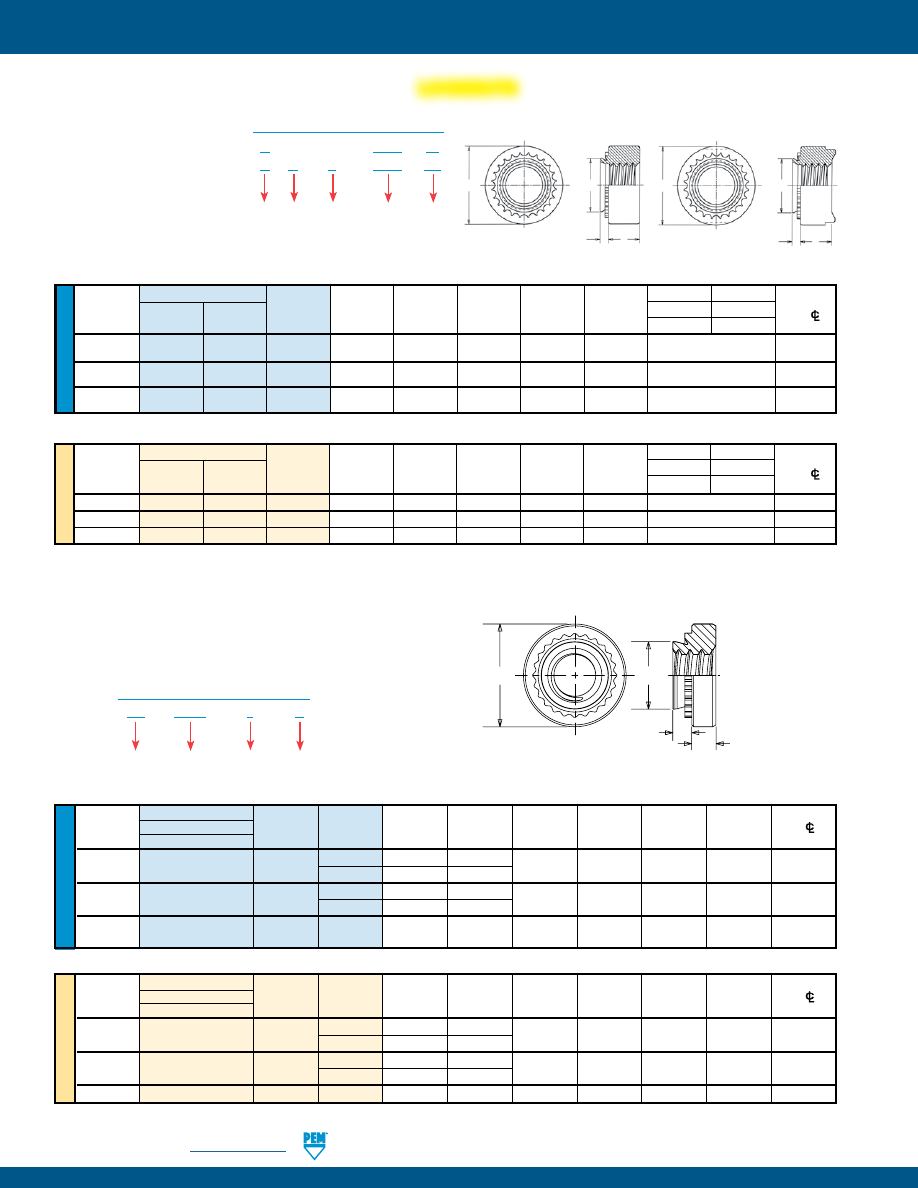

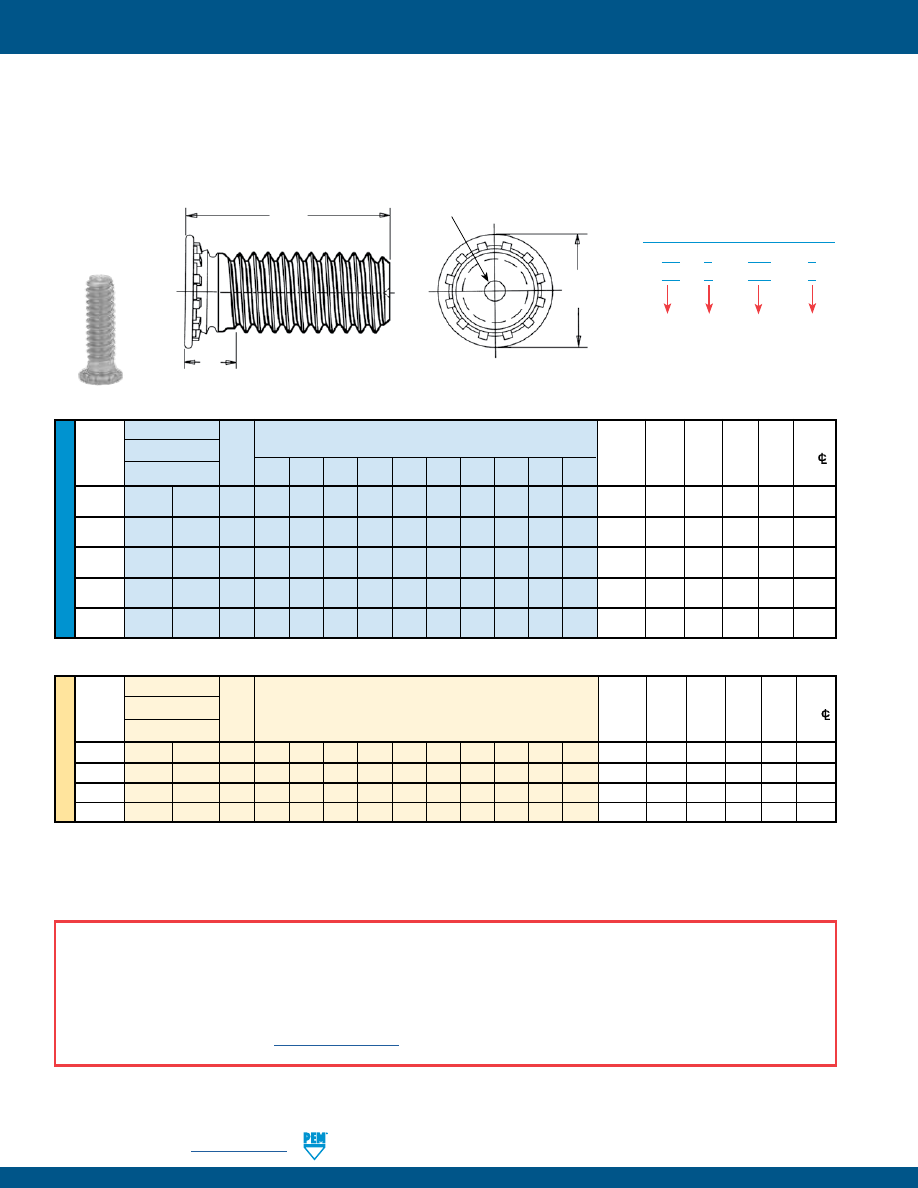

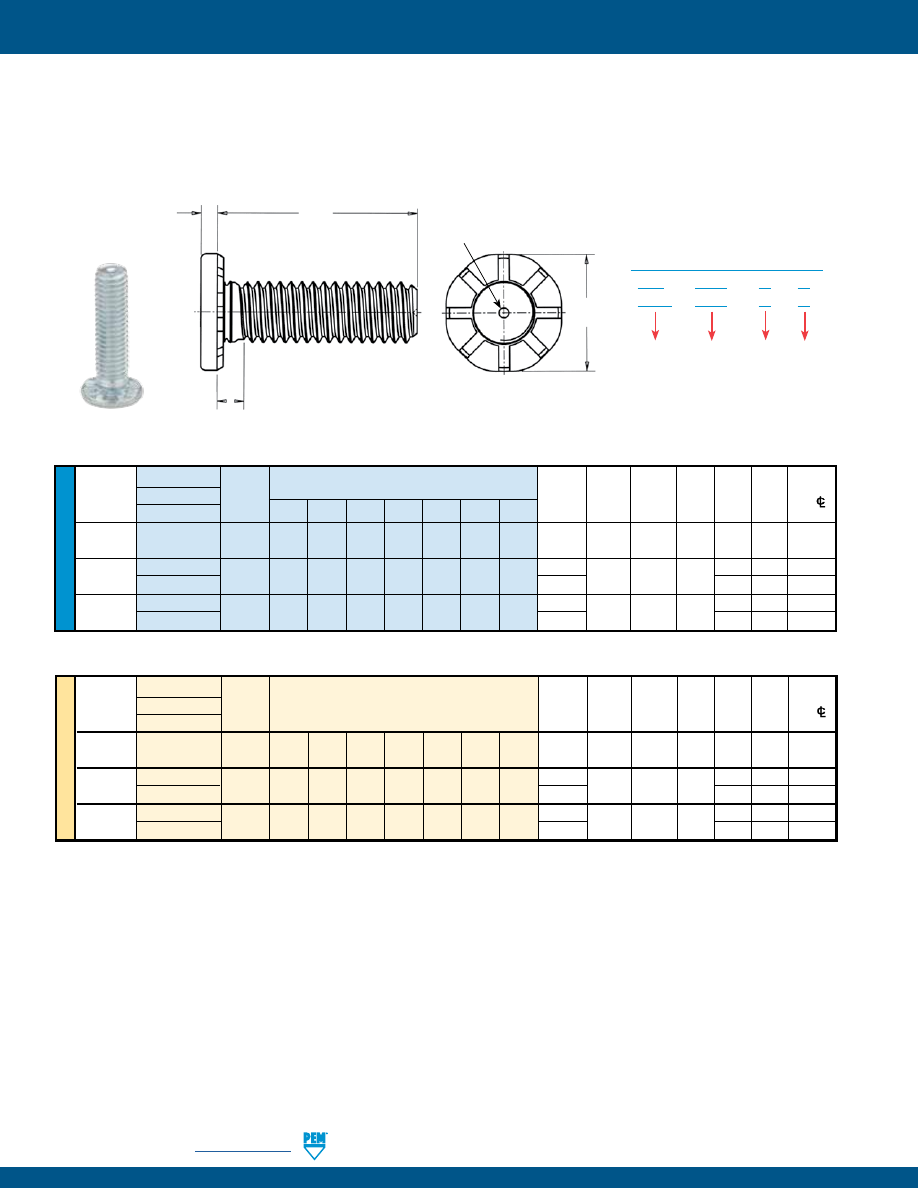

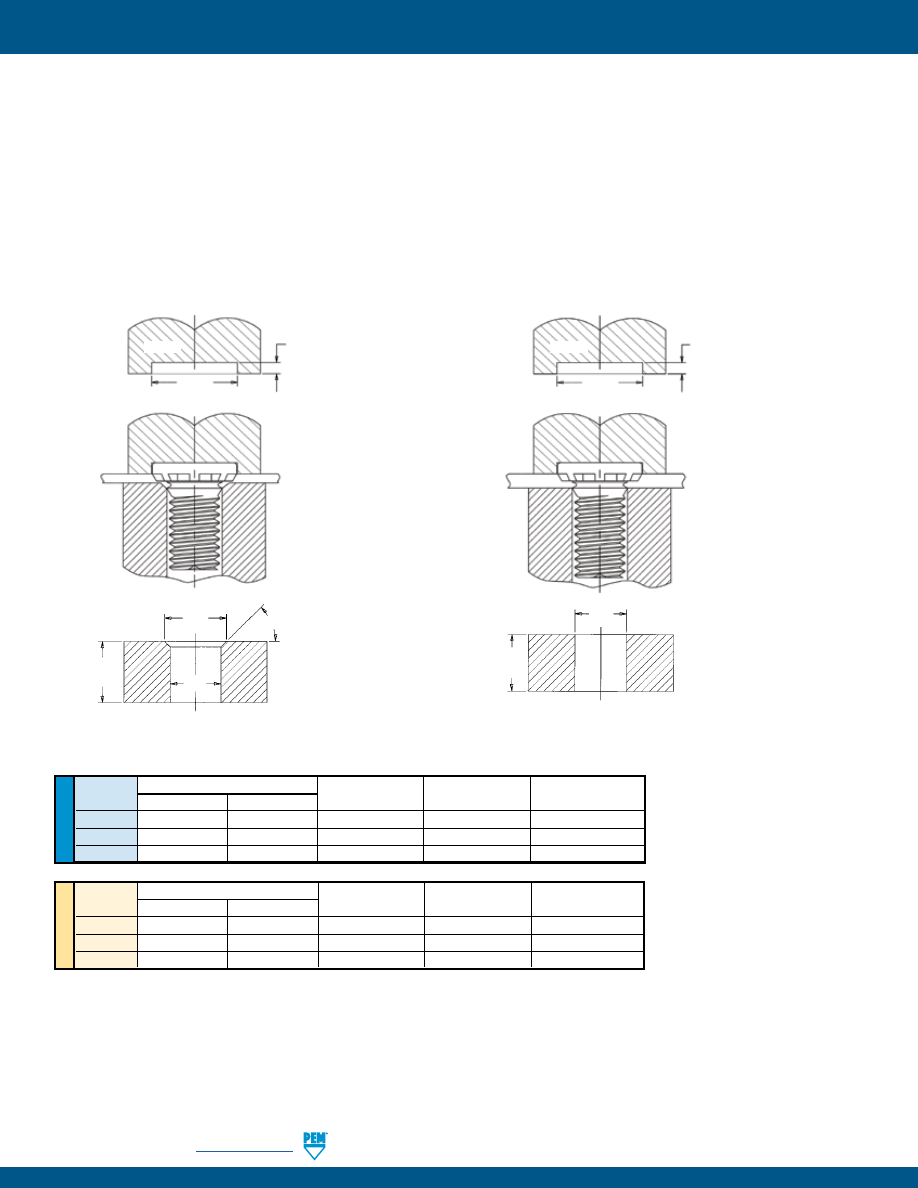

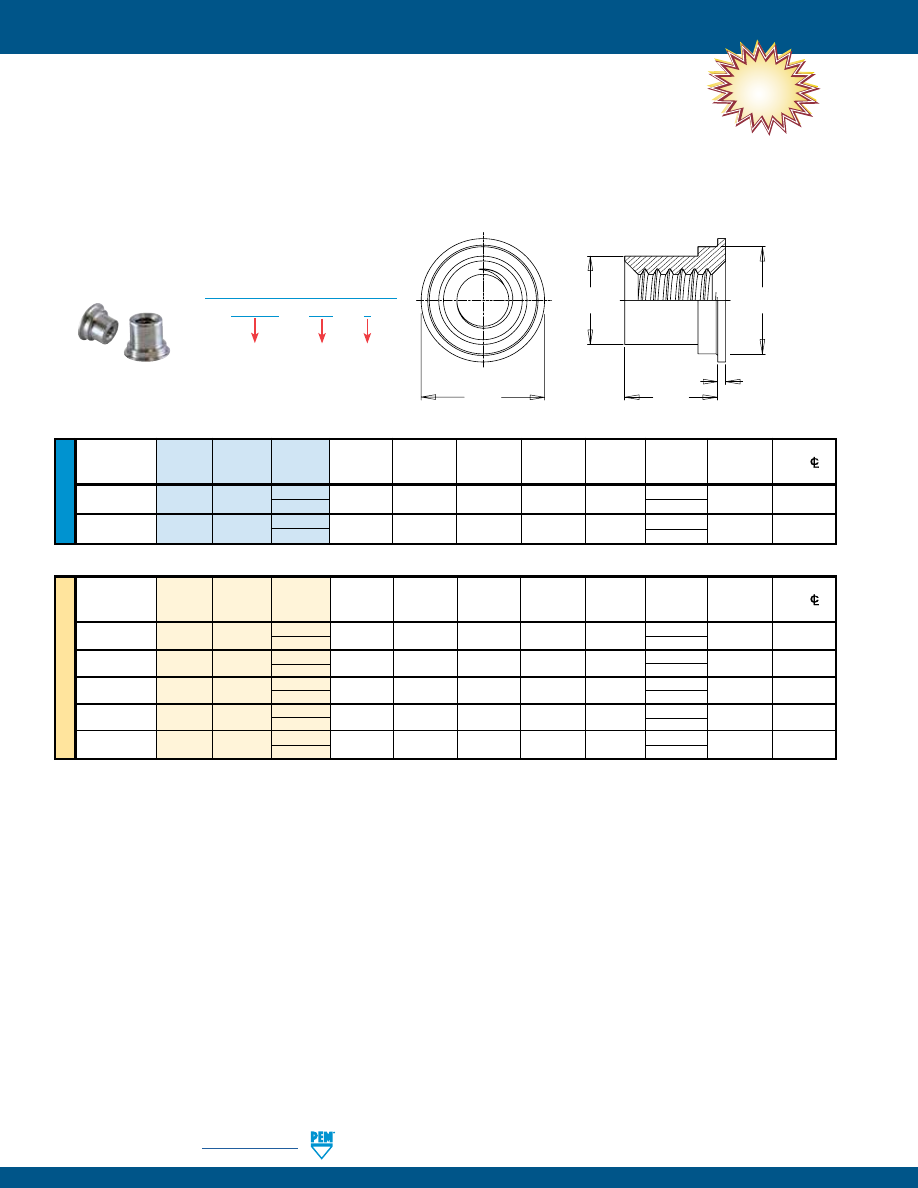

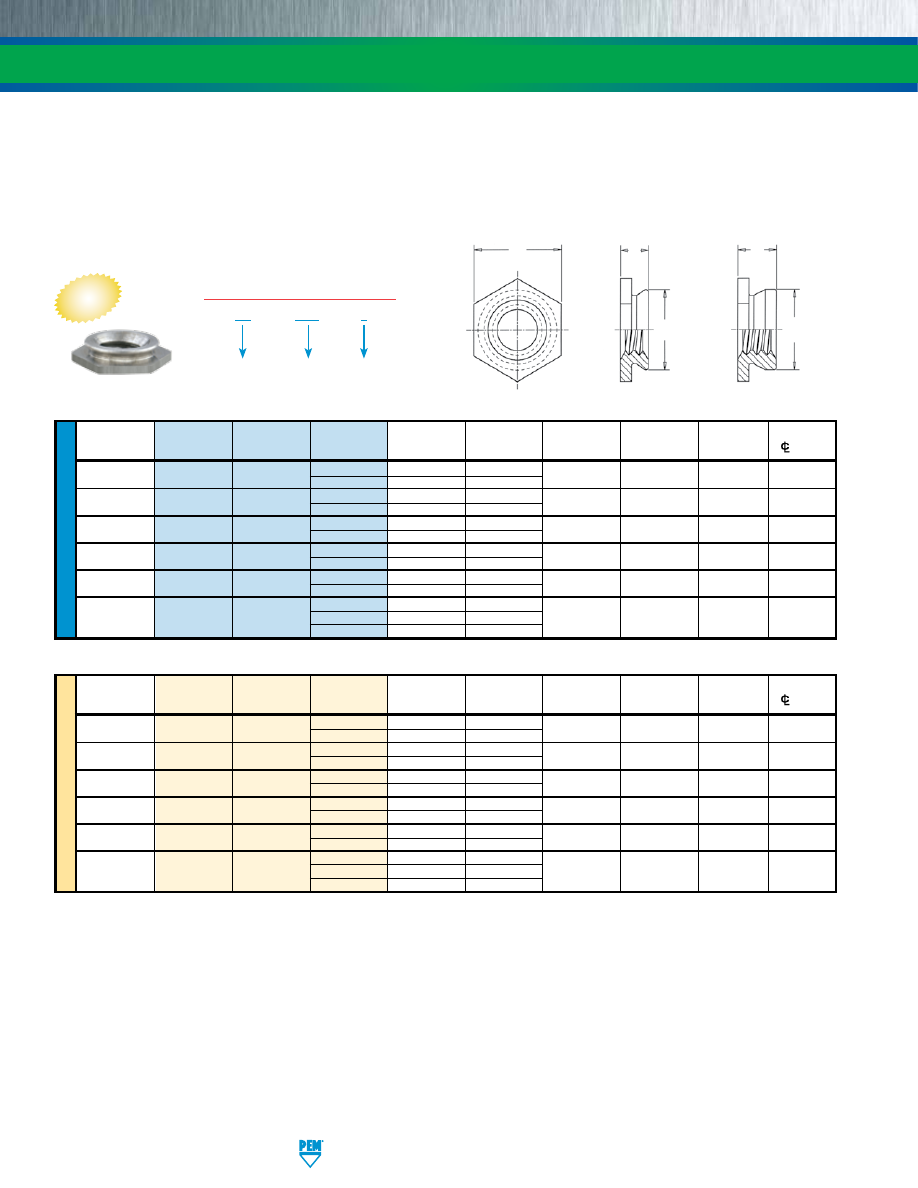

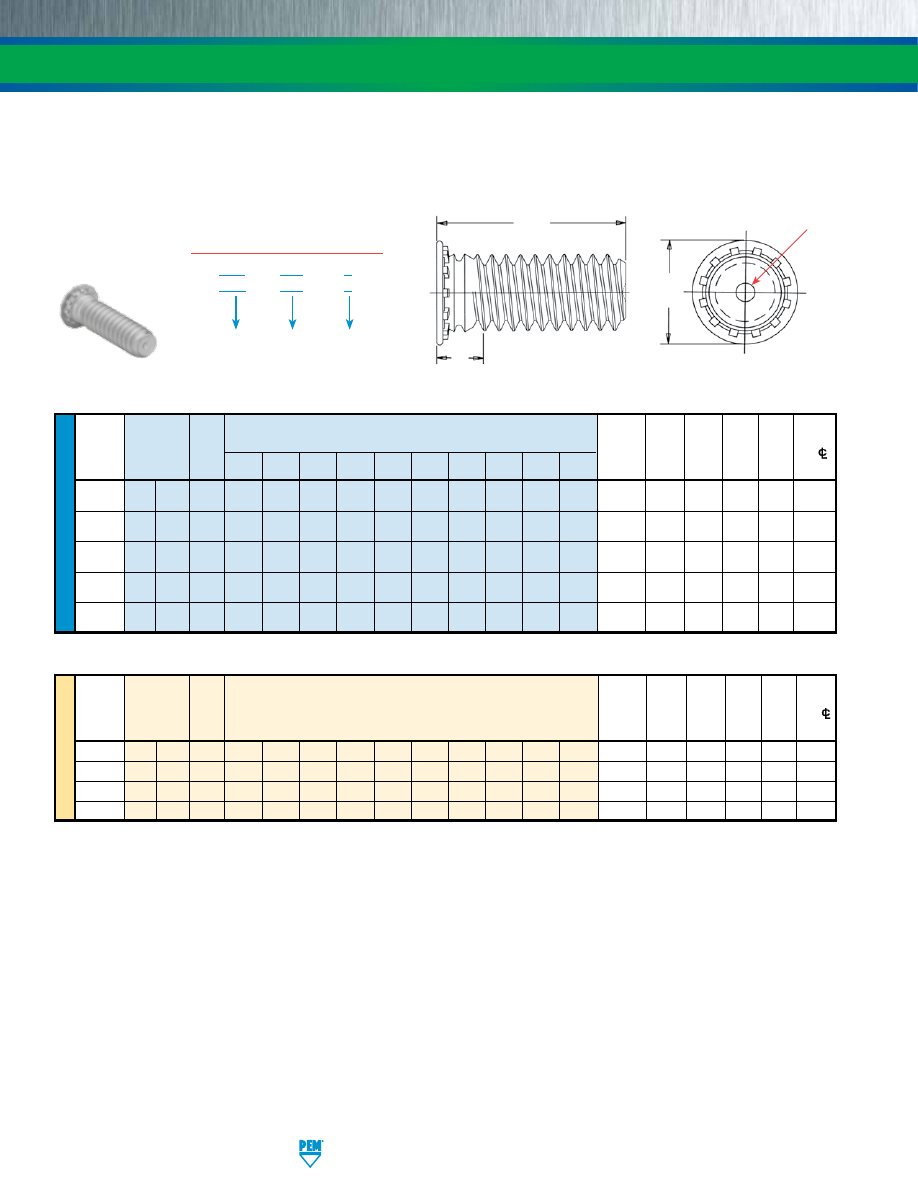

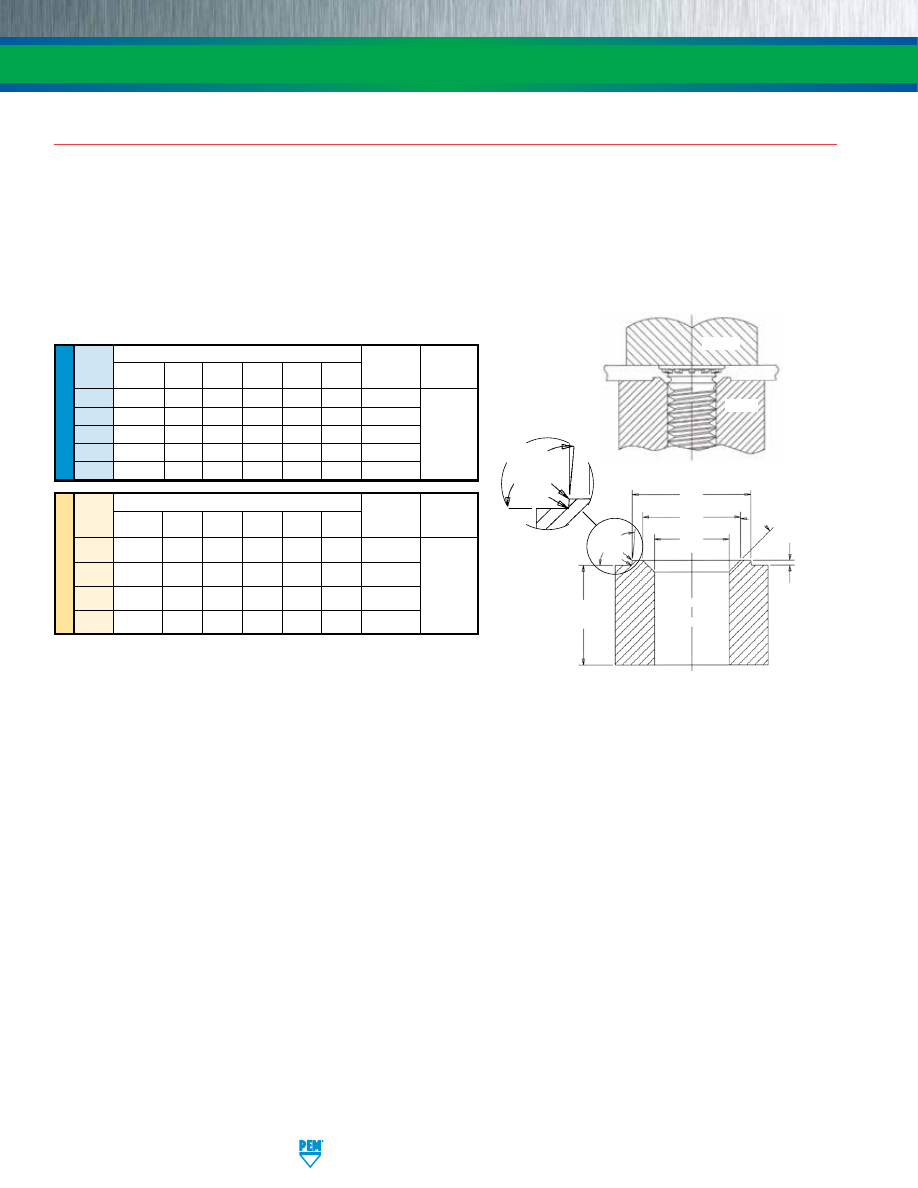

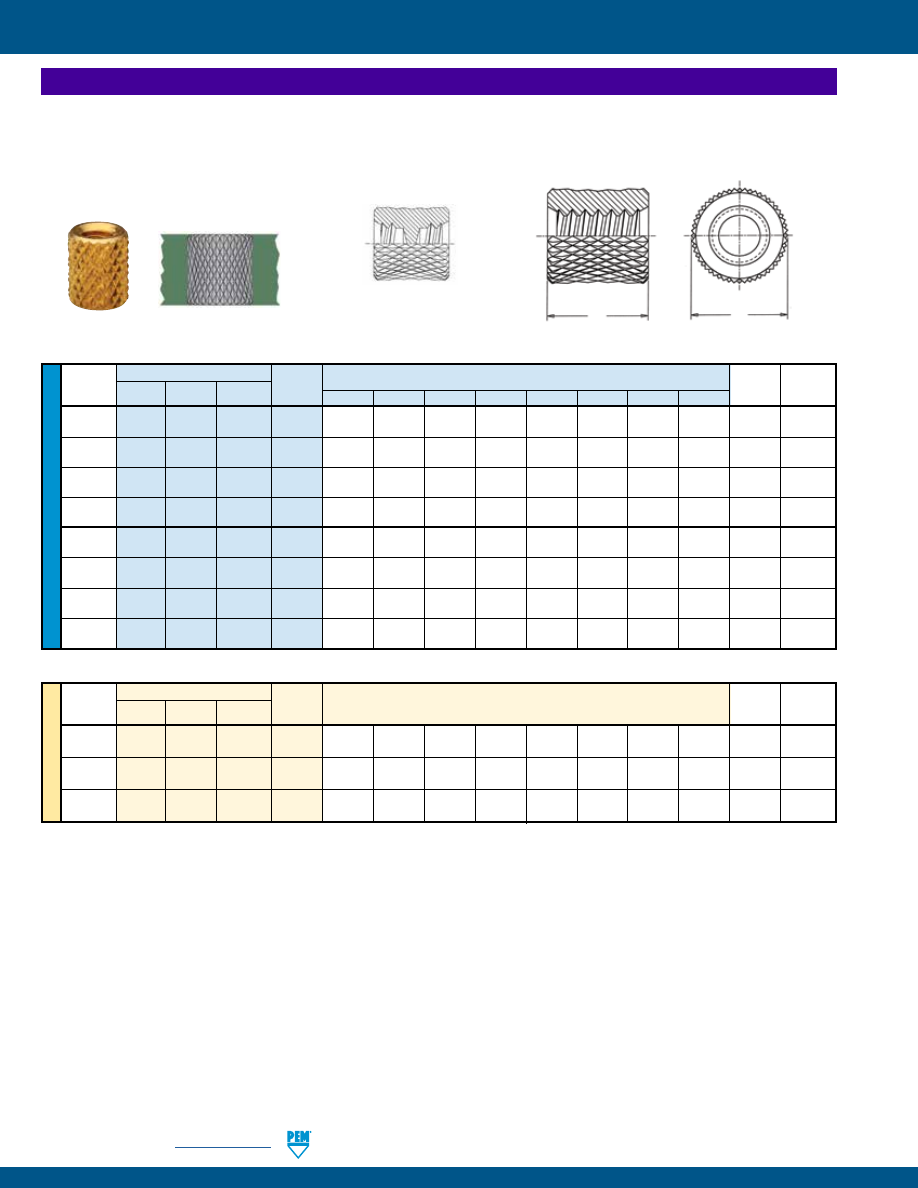

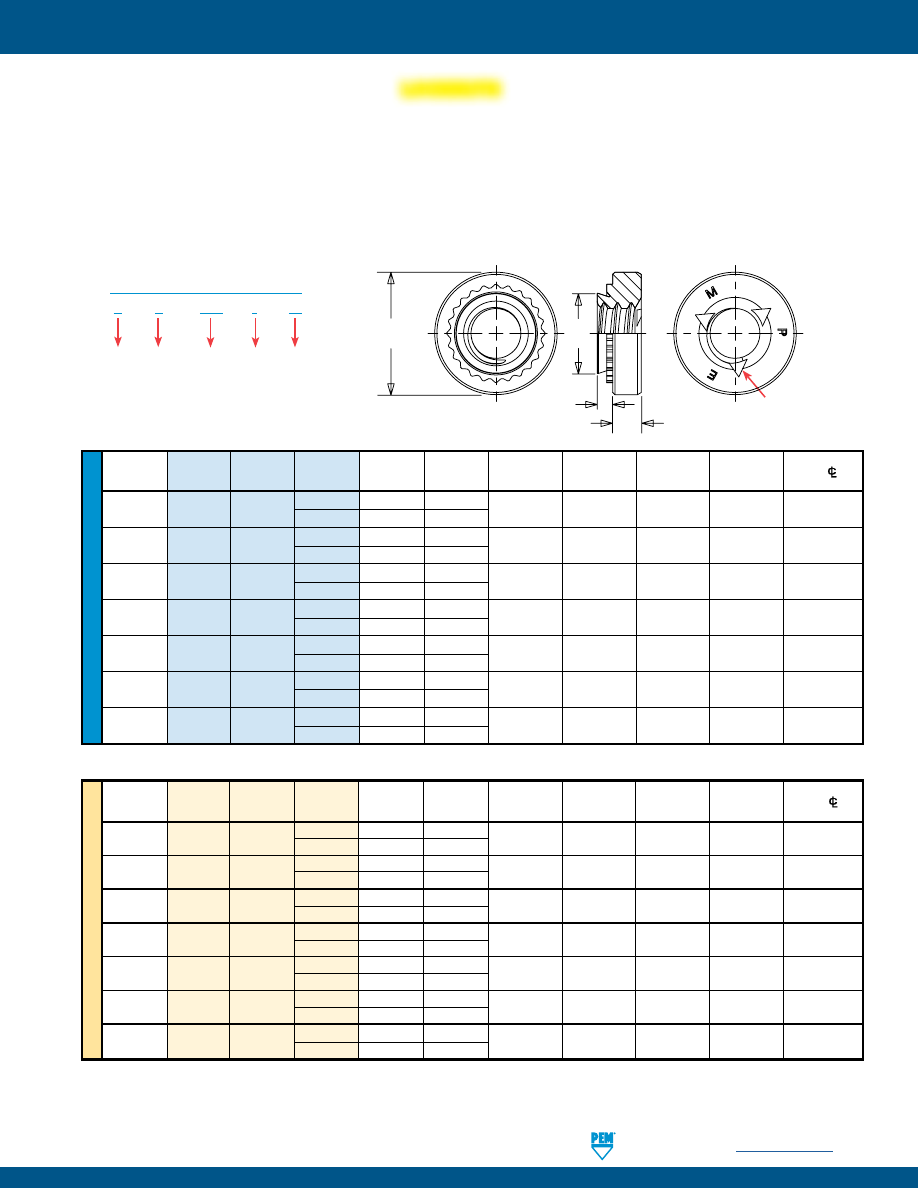

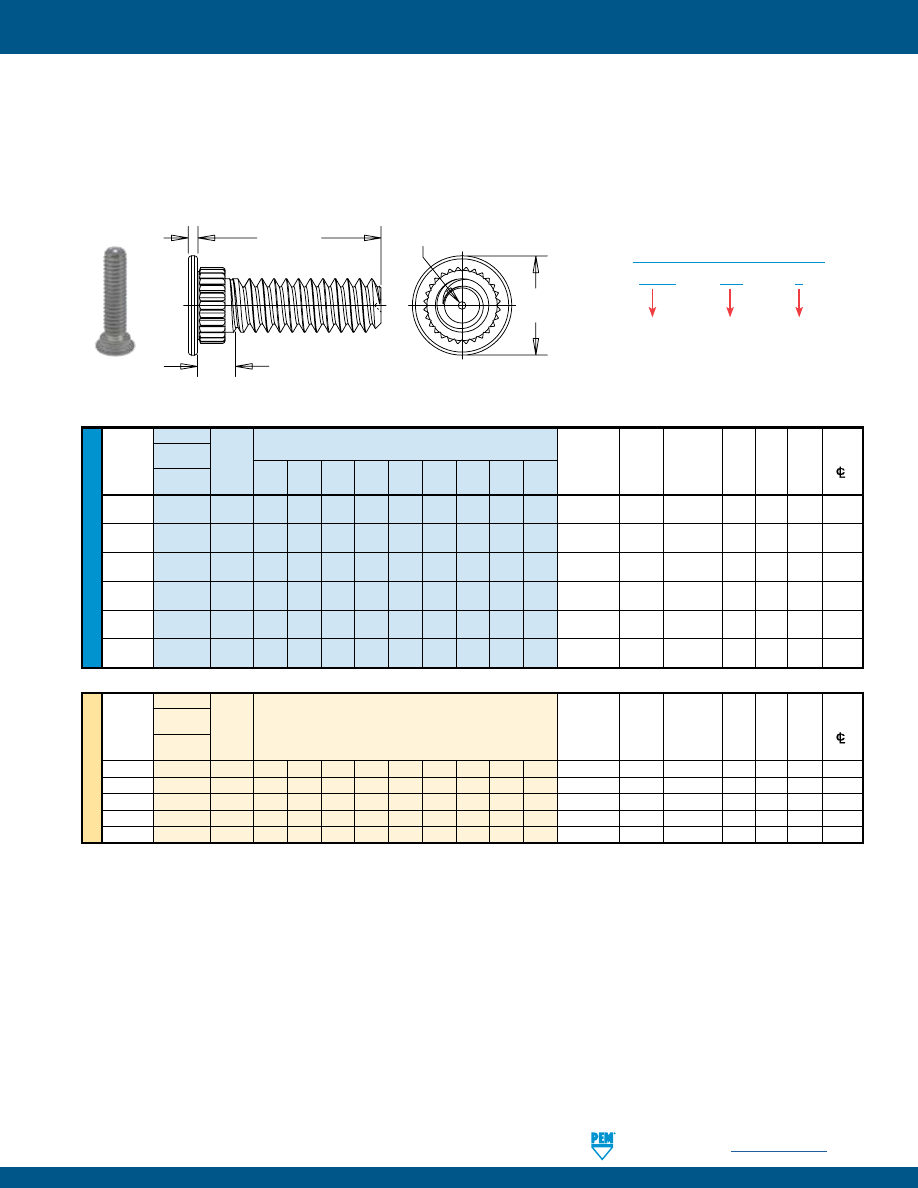

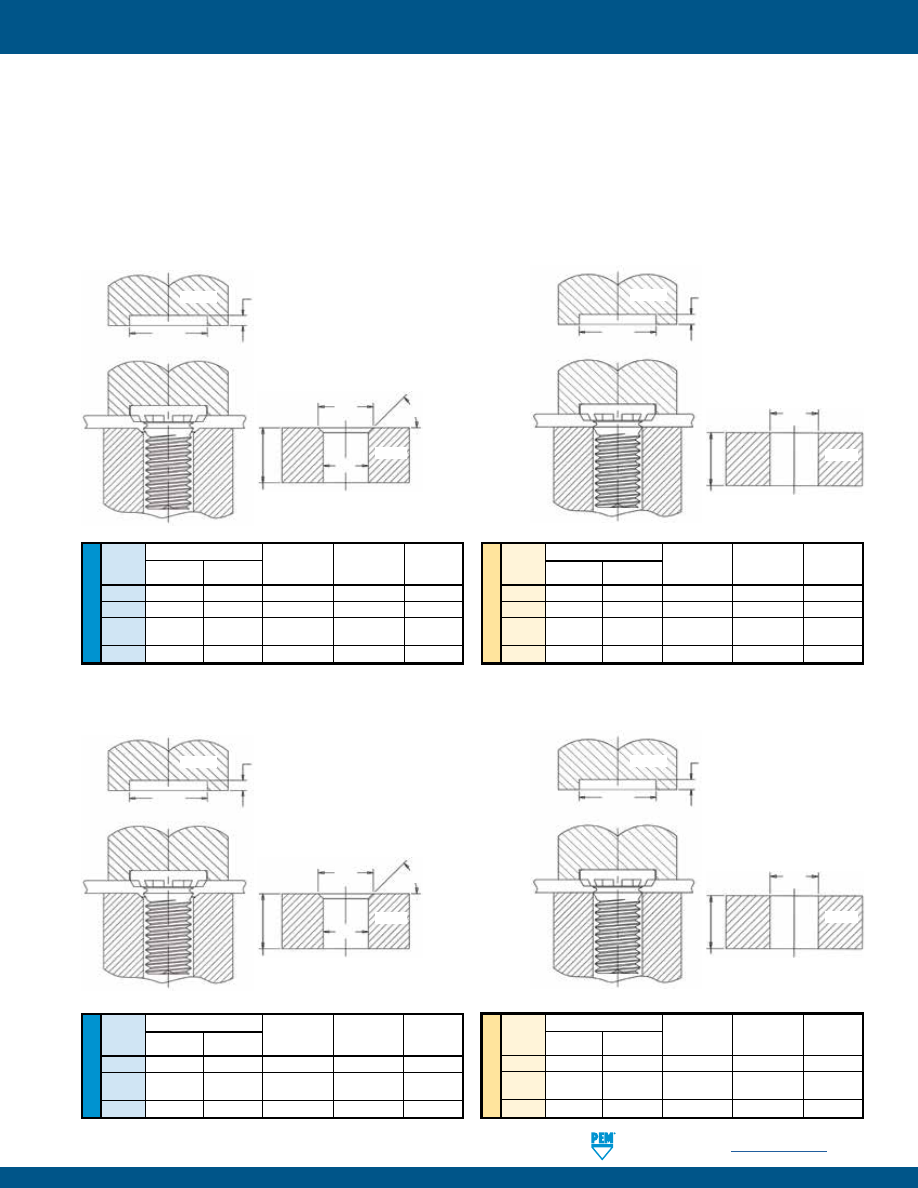

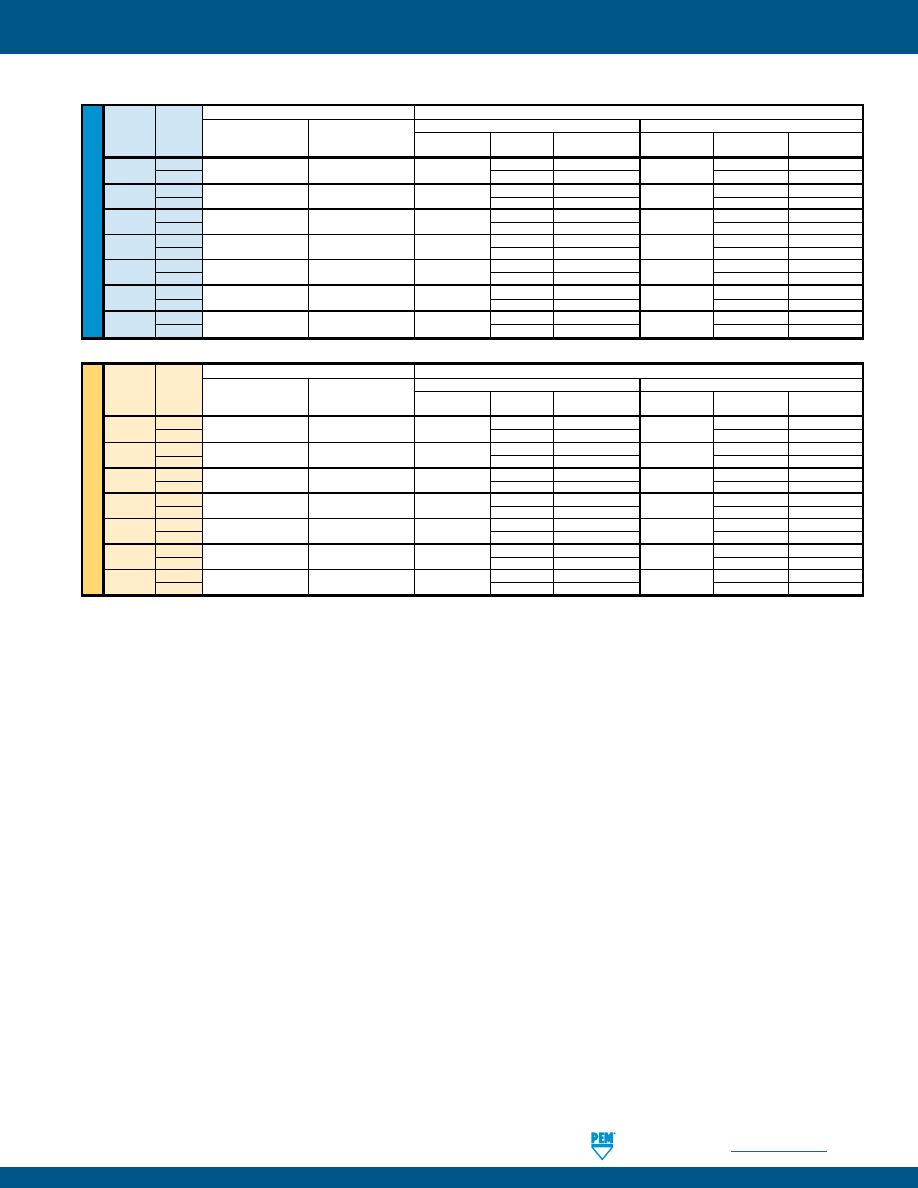

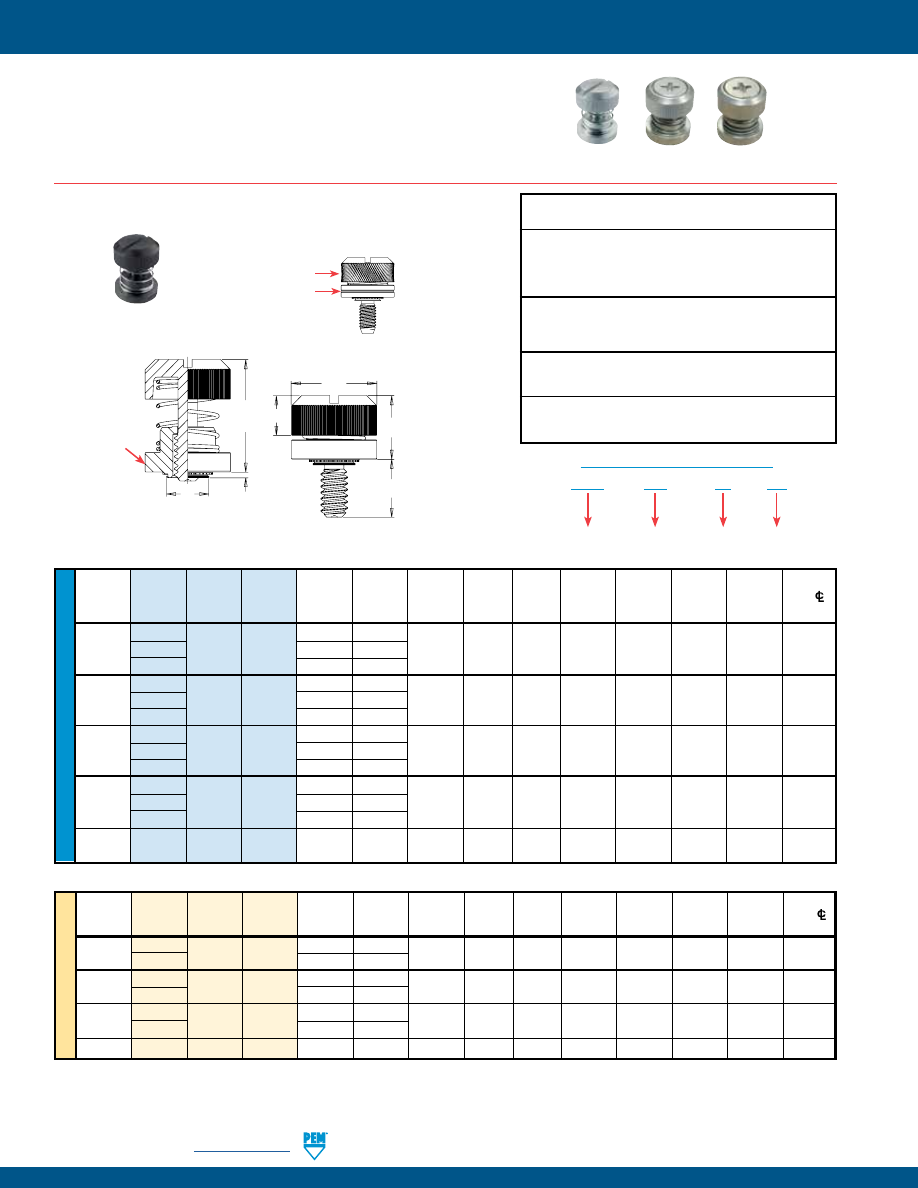

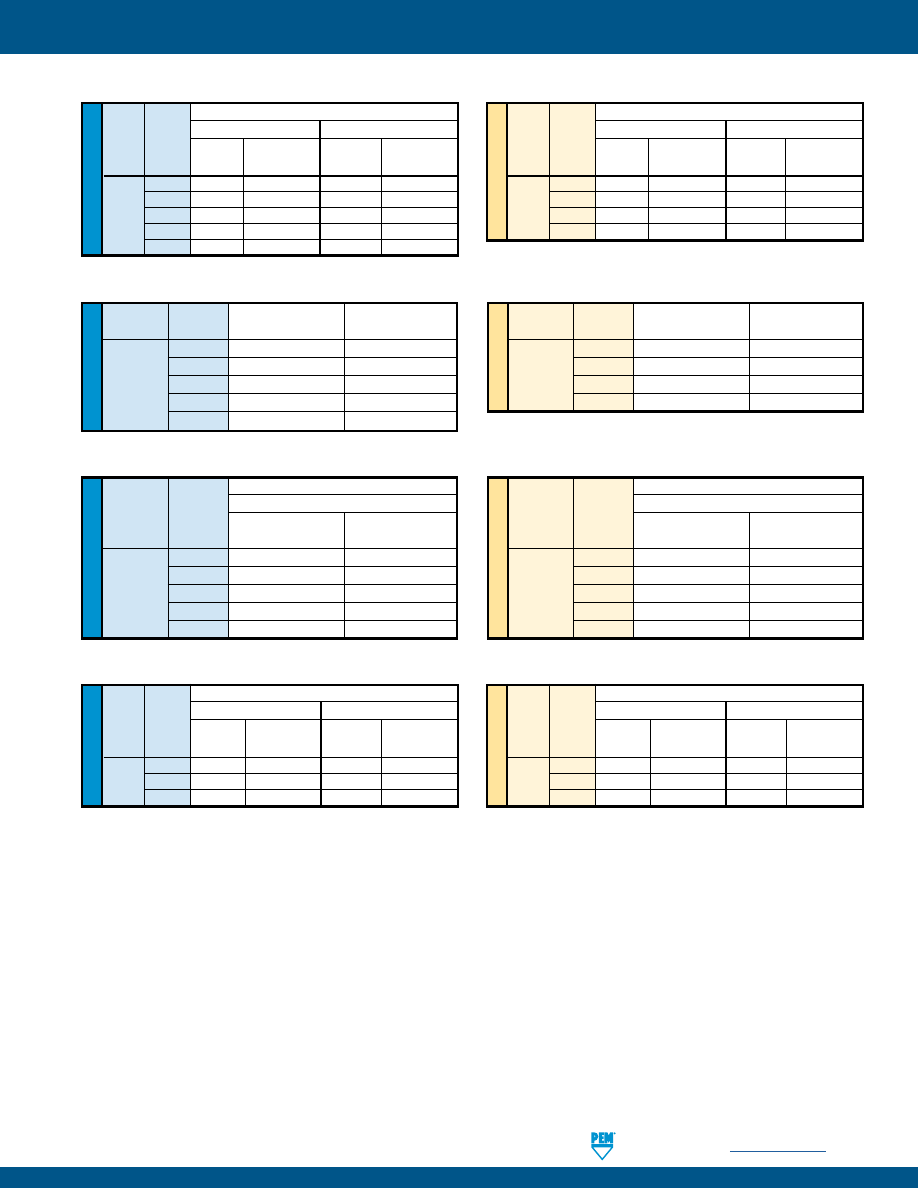

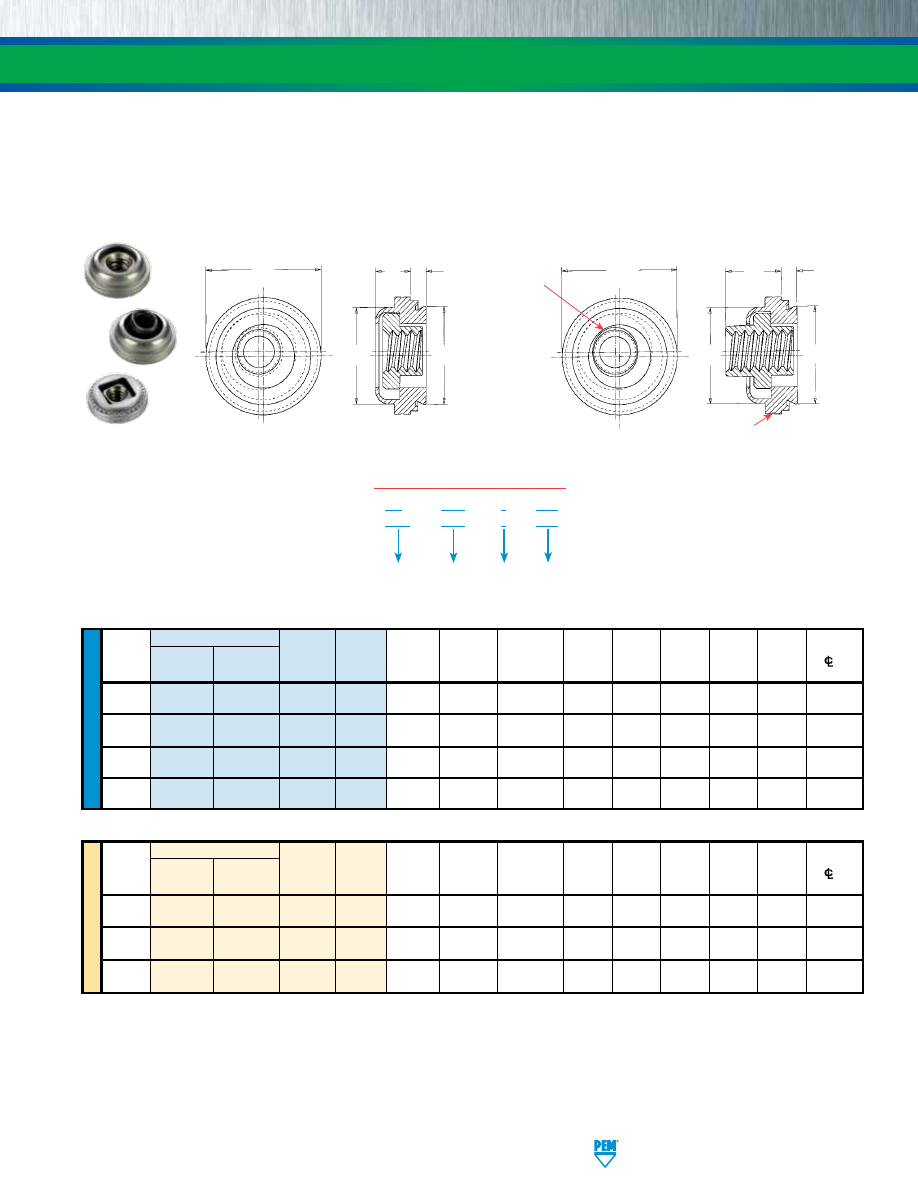

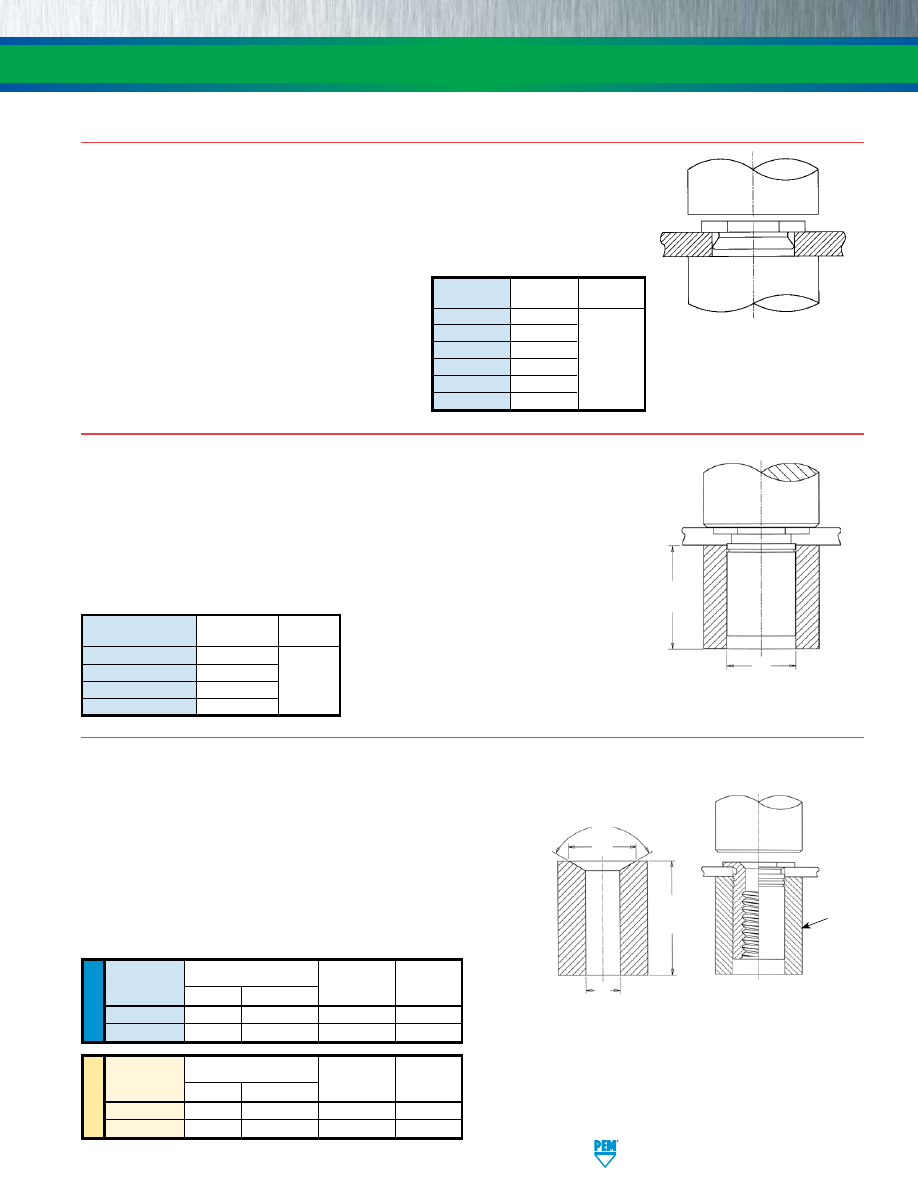

AS, AC, A4 Nuts

SELF-LOCKING

LAS, LAC, LA4 Nuts

No Protrusion

Threads Extend into

Retainer Shank

Positive

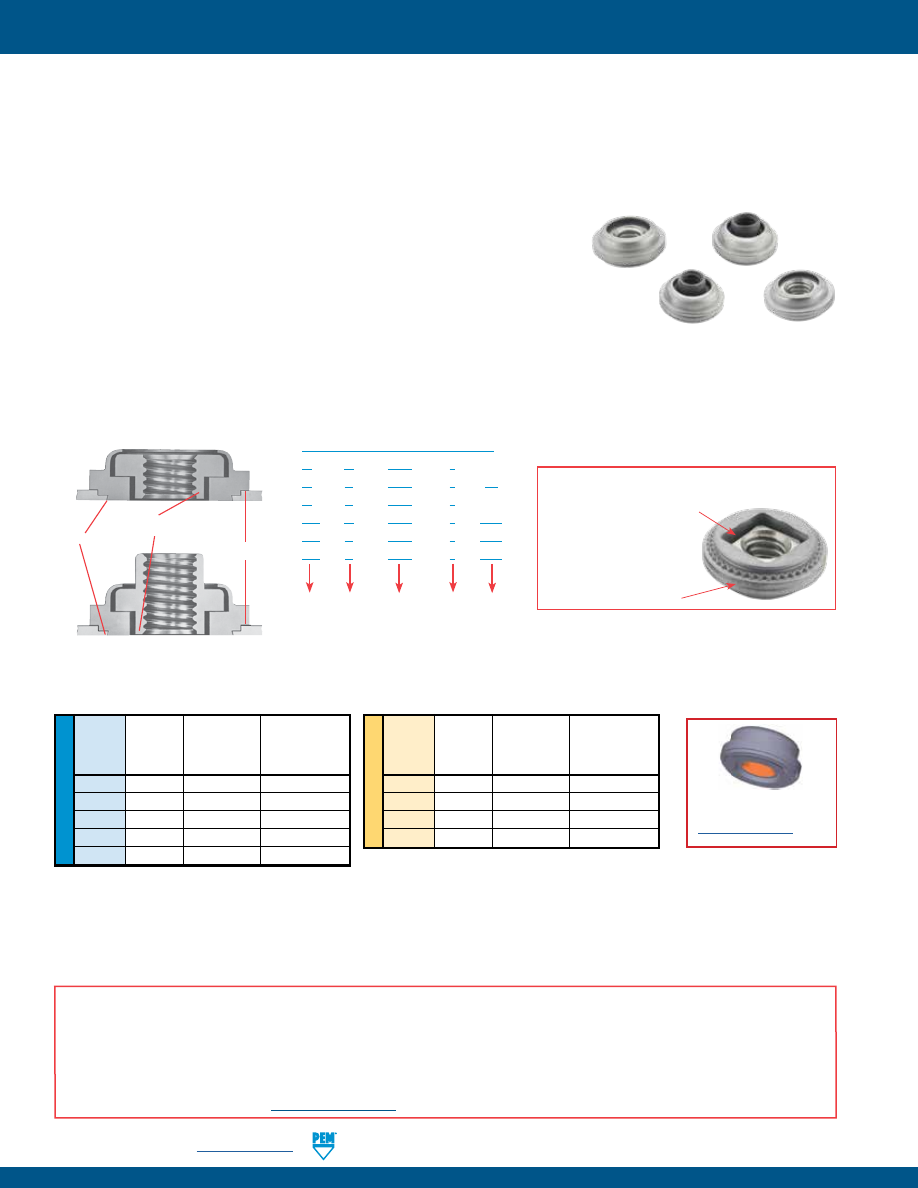

Stop

Locking and Non-locking Threads

•

Provide load-bearing threads in thin sheets

•

Permit a total of .030”/0.76 mm adjustment for mating hole misalignment.

•

Sheet remains flush on one side, and the fastener is permanently locked in place.

•

Threads of the floating nut extend into the retainer shank for extra strength and support in assembly.

AC™/AS™/LAC™/LAS™ floating Nuts

•

Designed for clinching into steel or aluminum panels and sheets.

•

Available with (LAC/LAS) or without (AC/AS) locking threads.

A4™/LA4™ floating nuts

•

Provide prevailing torque locking threads with performance equivalent to applicable

NASM25027 specifications

(1)

.

•

Designed for clinching into stainless steel panels and sheets.

•

Available with (LA4) or without (A4) locking threads.

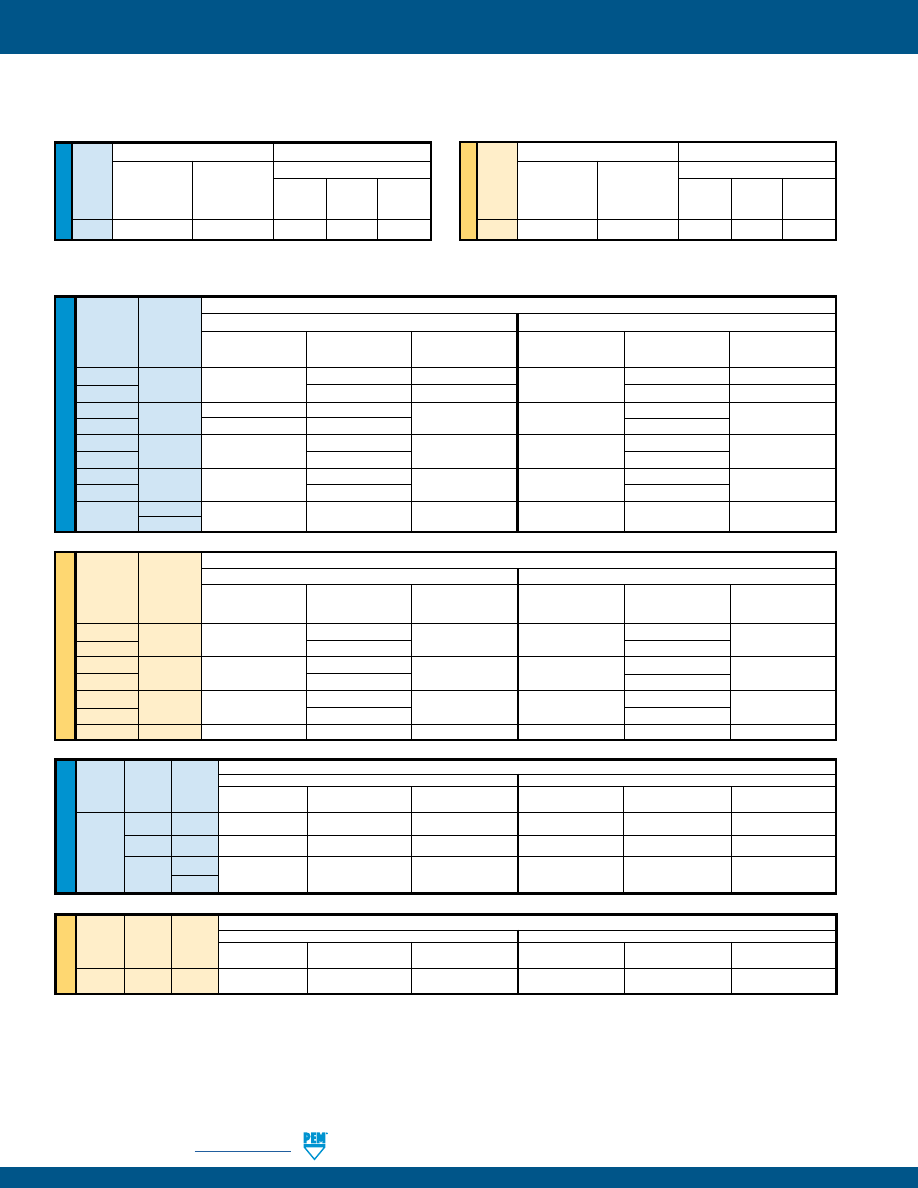

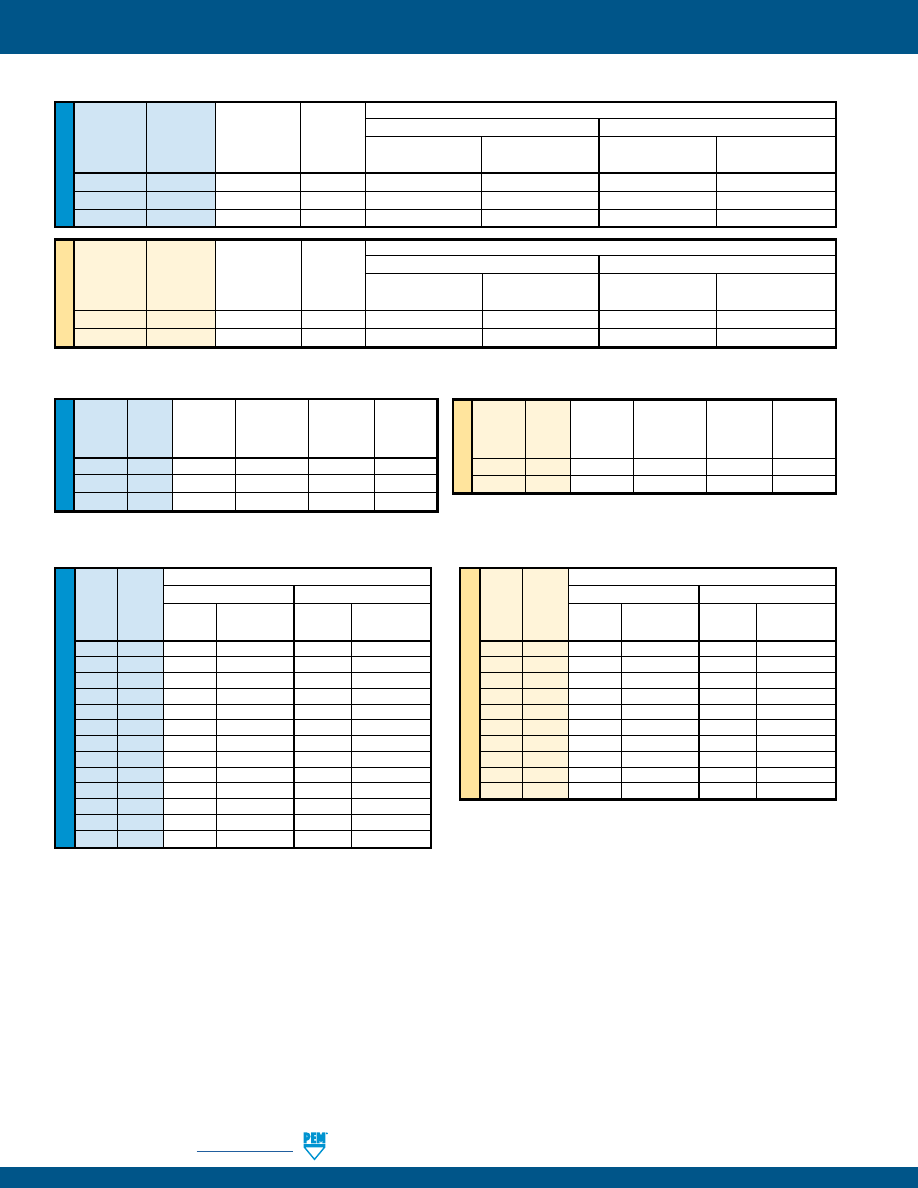

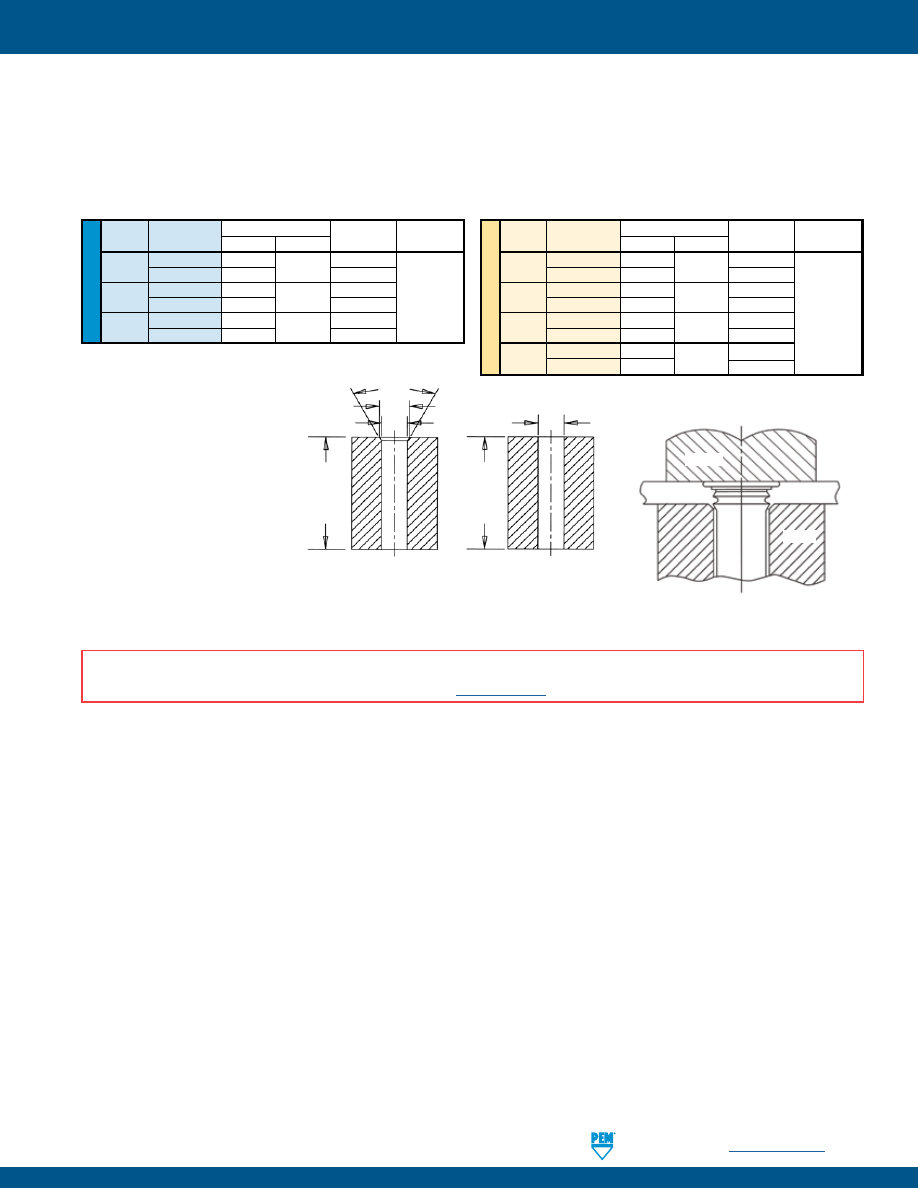

AC/AS

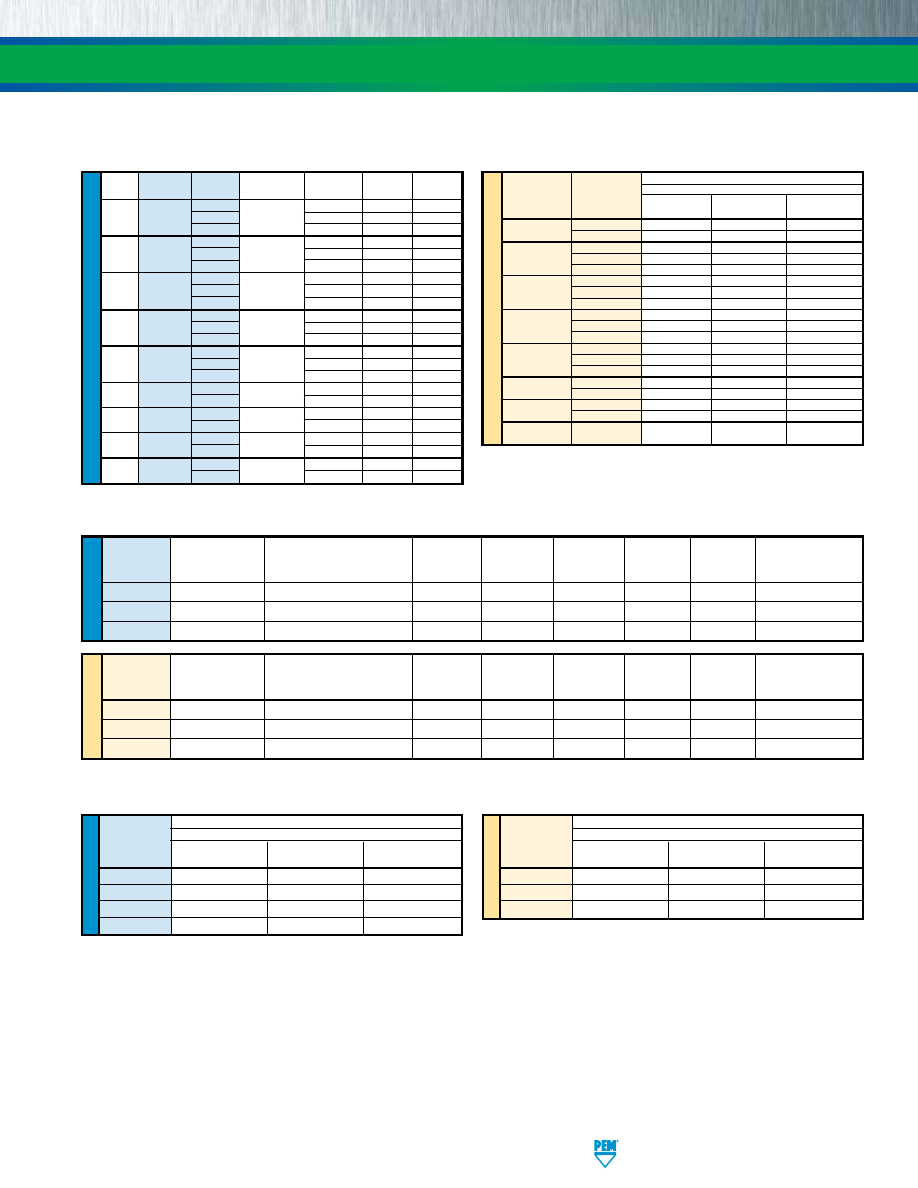

LAC/LAS

Type

A

C – 440 – 1

A

S – 440 – 1

ZI

A

4 – 440 – 1

LA

C – 440 – 1

MD

LA

S – 440 – 1

MD

LA

4 – 440 – 1

MD

Shank

Code

Thread

Size

Code

Finish

Code

Retainer

Material

Code

PART NUMBER DESIGNATION

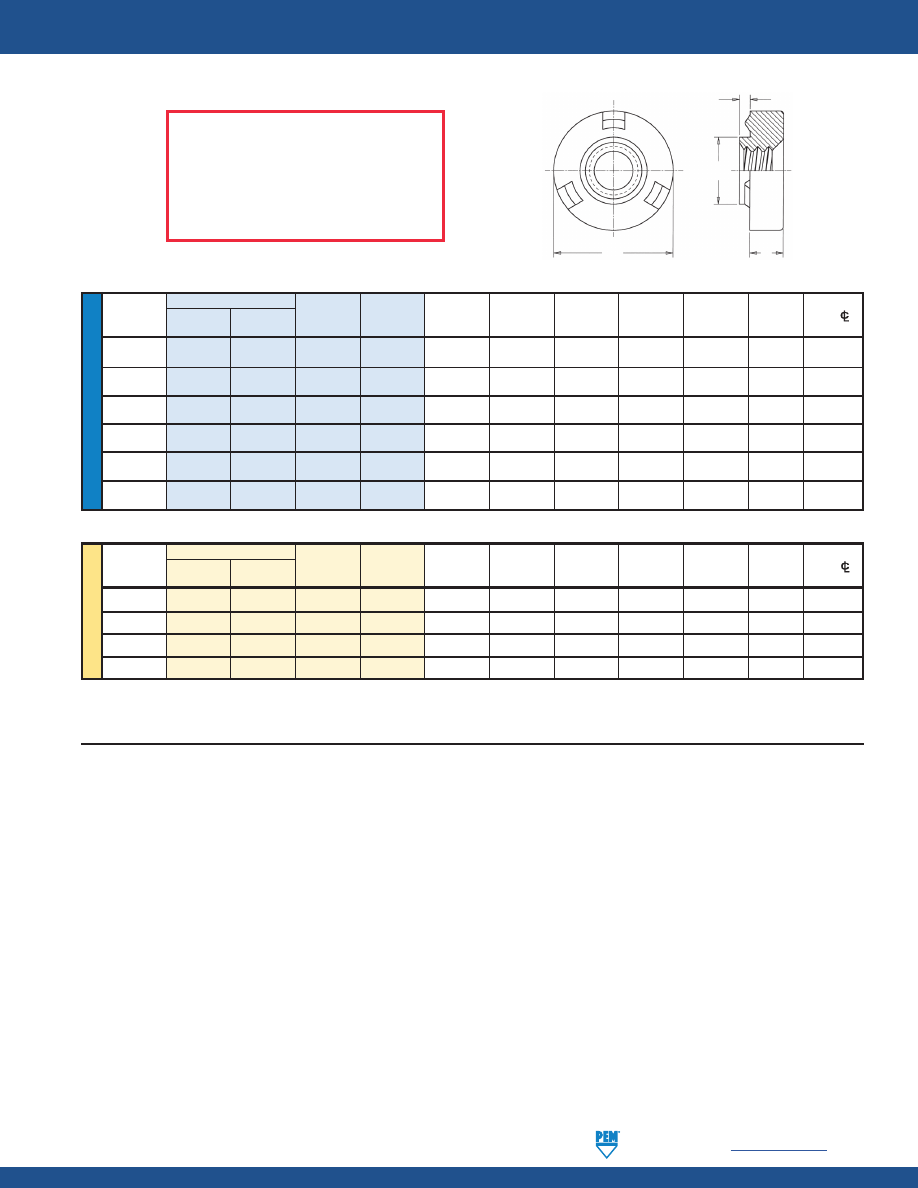

PEM® Single groove

(Registered Trademark)

Identifies product for

installation into stainless

steel sheets (A4 and LA4)

PEM® Double Squares

(Registered Trademark)

(1) To meet national aerospace standards and to obtain testing documentation, product must be ordered to US NASM45938/11 specifications. Check

our web site for a complete Military Specification and National Aerospace Standards Reference Guide (Bulletin NASM). Screws for use with PEM

self-clinching locking fasteners should be Class 3A/4h fit or no smaller than Class 2A/6g.

Fastener drawings and

models are available at

www.pemnet.com

Locknut

Mating Screw

Mating Screw

Min. Axial

Strength Level

Tightening Torque

Thread

Strength (1)

(1)

(2)

Code

(lbs.)

(ksi)

(in. lbs.)

440

1085

180

15.8

632

1636

180

29.4

832

2522

180

53.8

032

3600

180

88.9

0420

5728

180

186

AXIAL STRENGTH AND TIGHTENING TORQUE - TYPES LAC/LAS/LA4

(1) All LAC, LAS and LA4 locknuts have axial strength exceeding the minimum tensile strength of 180 ksi/Property Class 12.9 screws. Contact techsupport

regarding assemble strength for higher strength screws.

(2) Tightening torque shown will induce preload of 65% of locknut minimum axial strength with K or nut factor is equal to 0.20. In some applications

tightening torque may need to be adjusted based on the actual K value. All tightening torques shown are based on 180 ksi/ Property Class 12.9 screws.

For lower strength screws the tightening torque is proportionately less. For example, for 120 ksi screws, torque is 67% value shown. For 900 MPa screws

(Property Class 9.8) torque value is 74% of value shown.

ME

TR

IC

Locknut

Mating Screw

Mating Screw

Min. Axial

Strength Level

Tightening Torque

Thread

Strength (1)

(1)

(2)

Code

(kN)

(MPa)

(N•m)

M3

6.14

1220

2.39

M4

10.71

1220

5.57

M5

17.3

1220

11.2

M6

24.55

1220

19.1

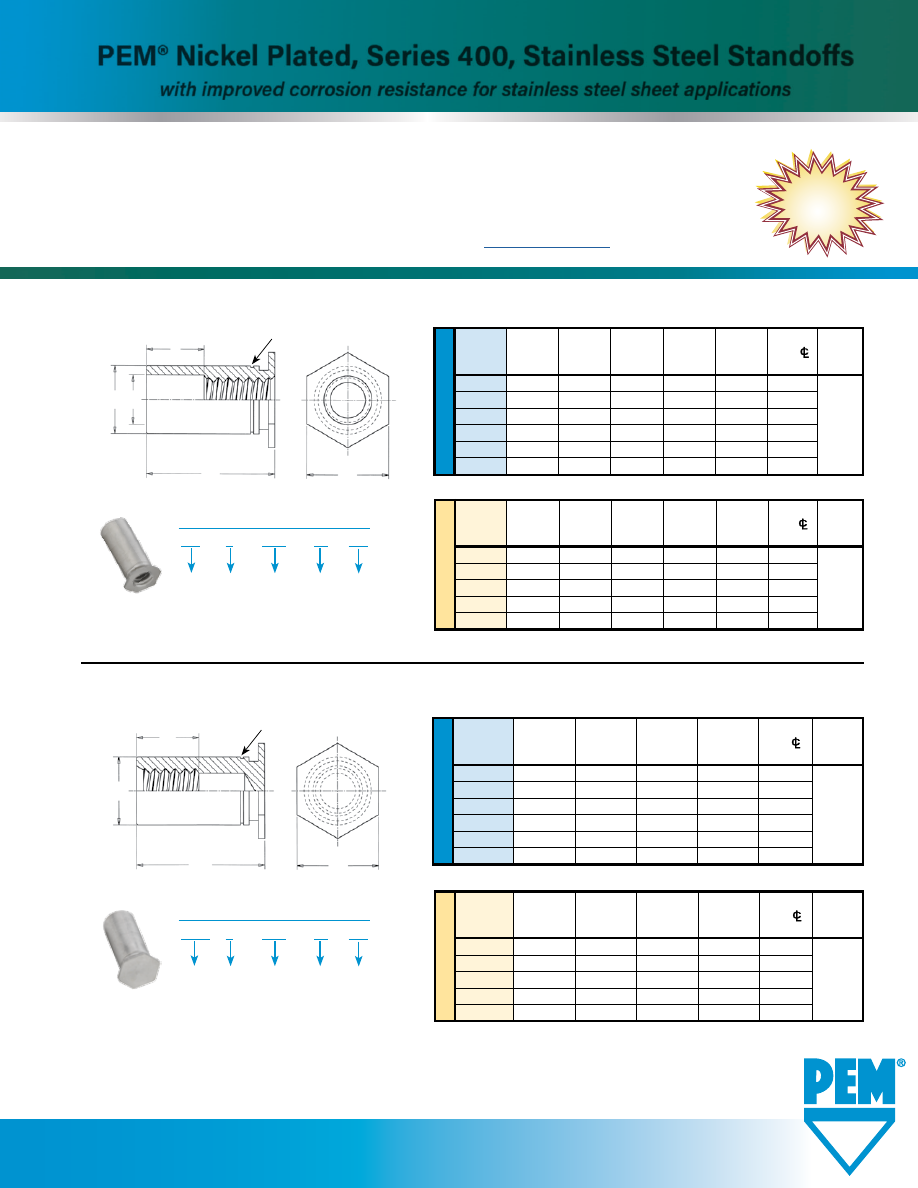

A NOTE ABOUT 400 SERIES FASTENERS FOR STAINLESS STEEL PANELS

In order for self-clinching fasteners to work properly, the fastener must be harder than the sheet into which it is being installed. In the case of stainless steel panels,

fasteners made from 300 Series Stainless Steel do not meet this hardness criteria. It is for this reason that 400 series fasteners are offered (Types A4 and LA4). How-

ever, while these 400 Series fasteners install and perform well in 300 Series stainless sheets they should not be used if the end product:

•

Will be exposed to any appreciable corrosive presence.

•

Requires non-magnetic fasteners.

•

Will be exposed to any temperatures above 300˚F (149˚C)

If any of the these are issues, please contact

techsupport@pemnet.com

for other options.

FLOATING SELF-CLINCHING FASTENERS

LA4

A4

pem-html.html

PennEngineering •

www.pemnet.com

ALA-3

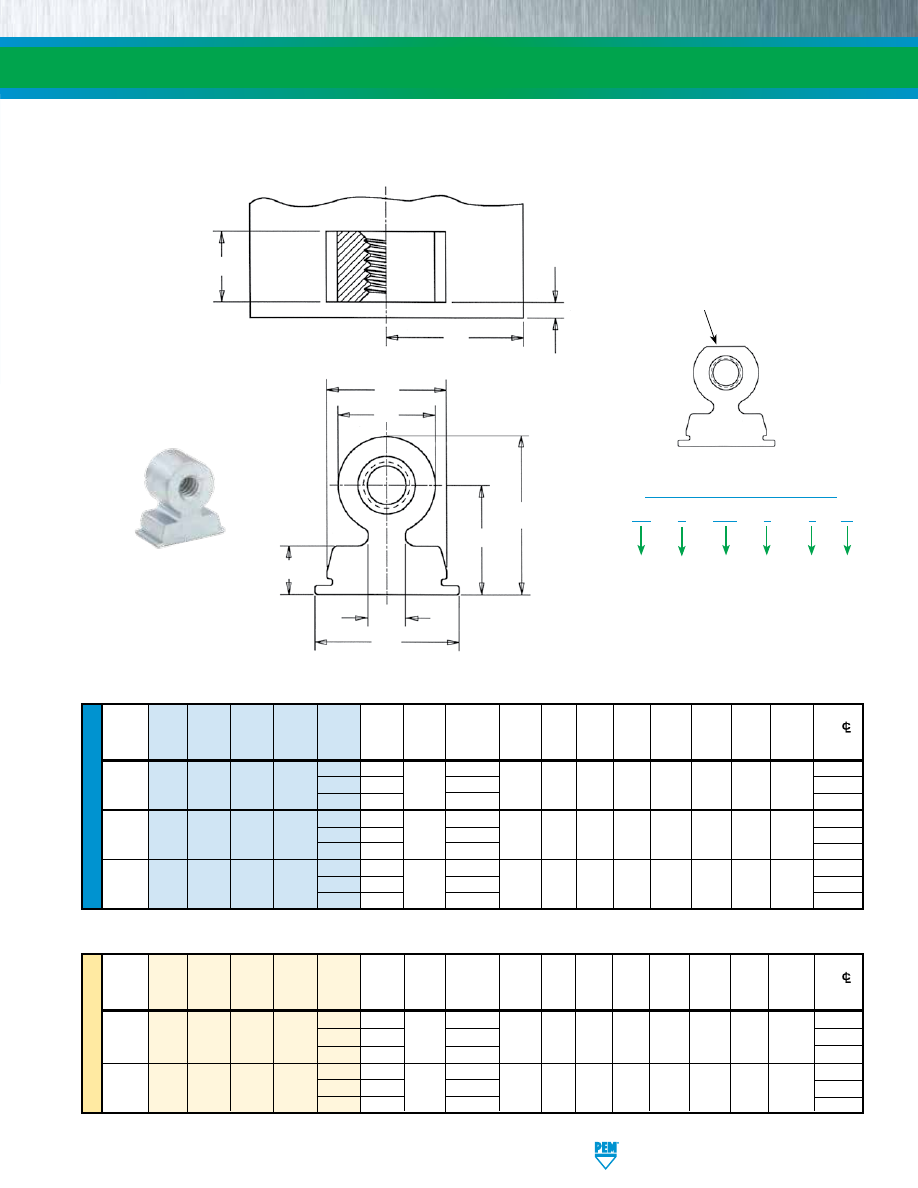

D

C

Threaded Top

Elliptically

Formed

A

SELF-LOCKING

LAS/LAC/LA4

T

2

E

U

NIF

IE

D

Internal,

Internal, UNJ Class 3B

Hardened

Zinc

Passivated

Zinc

Passivated

ASME

per ASME B1.15 /

400

300

300

Plated,

and/or

Plated,

and/or

Black

B1.1, 2B/

MJ Class 4H6H per

Hardened Series

Series

Series

5µm,

tested per

5µm,

tested per

Dry-film

HRB 70/

HRB 88/

ASME

ASME B1.21M

Carbon Stainless Stainless Carbon Stainless

Colorless

ASTM

Colorless

ASTM

Lubricant

HB 125

HB 183

Type

B1.13M, 6H

(M6 thread 4H5H)

Steel

Steel

Steel

Steel

Steel

(3)

A380

(3)

A380

(4)

or Less

or Less

AS

•

• •

•

•

AC

•

• •

•

•

A4

•

•

•

• •

LAS

•

• •

•

•

•

LAC

•

•

•

• • •

LA4

•

•

•

• • •

Part number codes for finishes

ZI

None

MD

Type

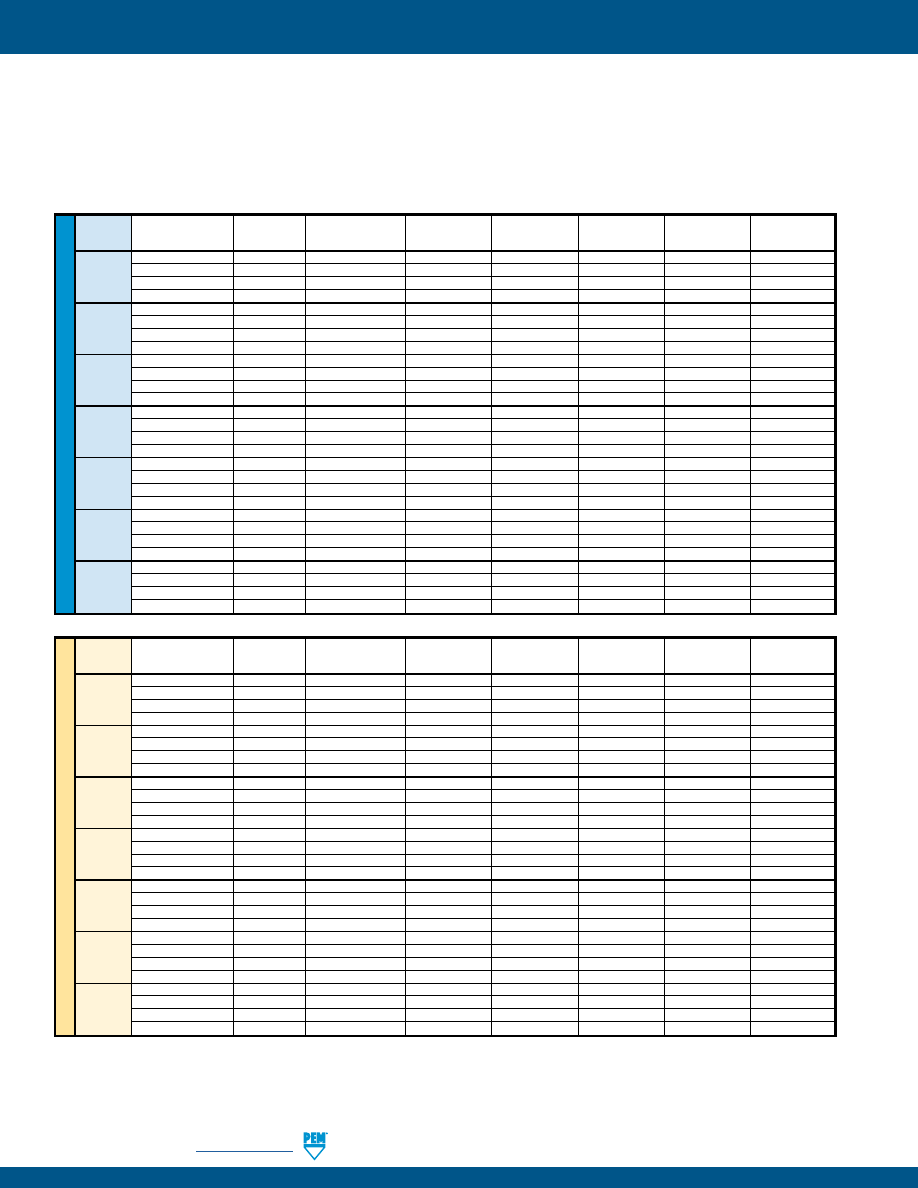

Non-Locking

Self-Locking

Hole

Min.

Thread

Thread Shank

A

Min.

Size in

C

D

E

T

1

T

2

Dist.

Size

Fastener Material

Fastener Material

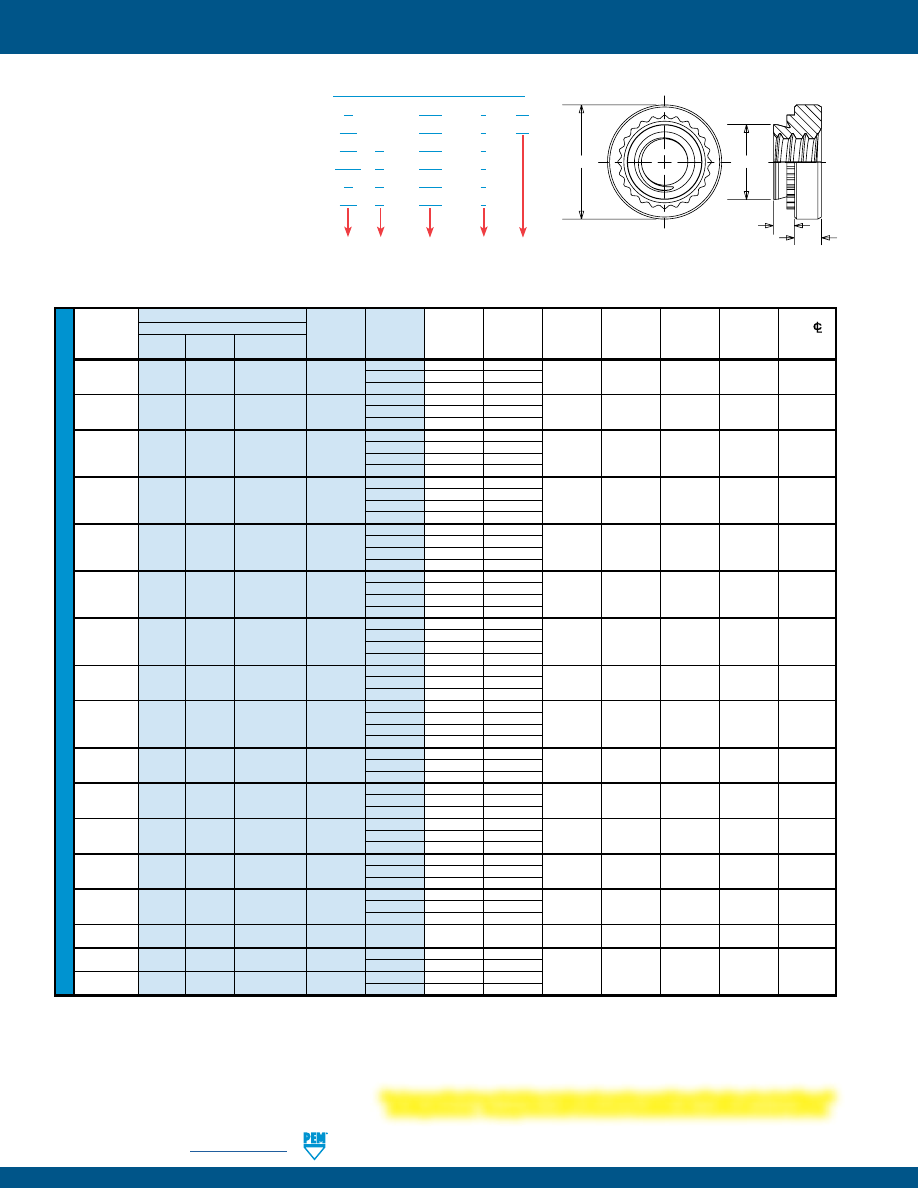

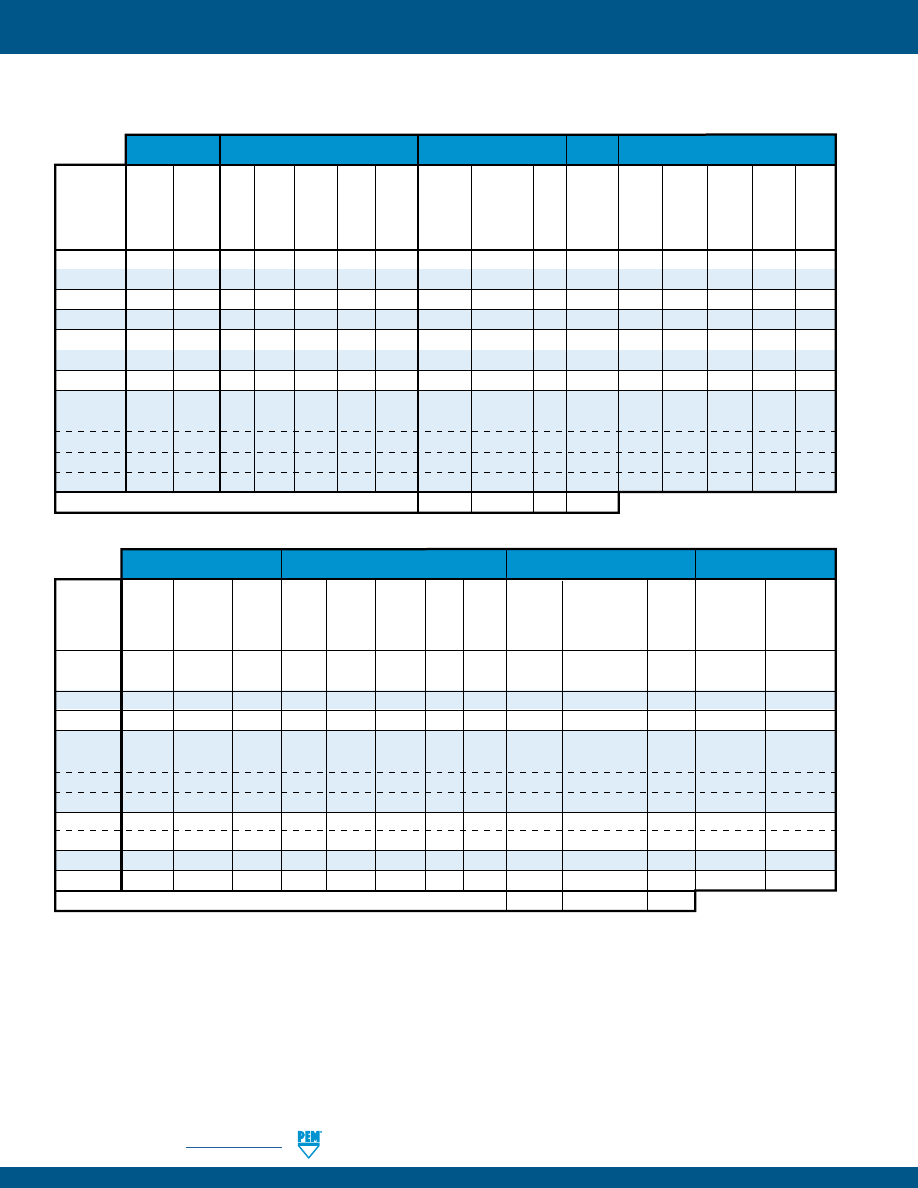

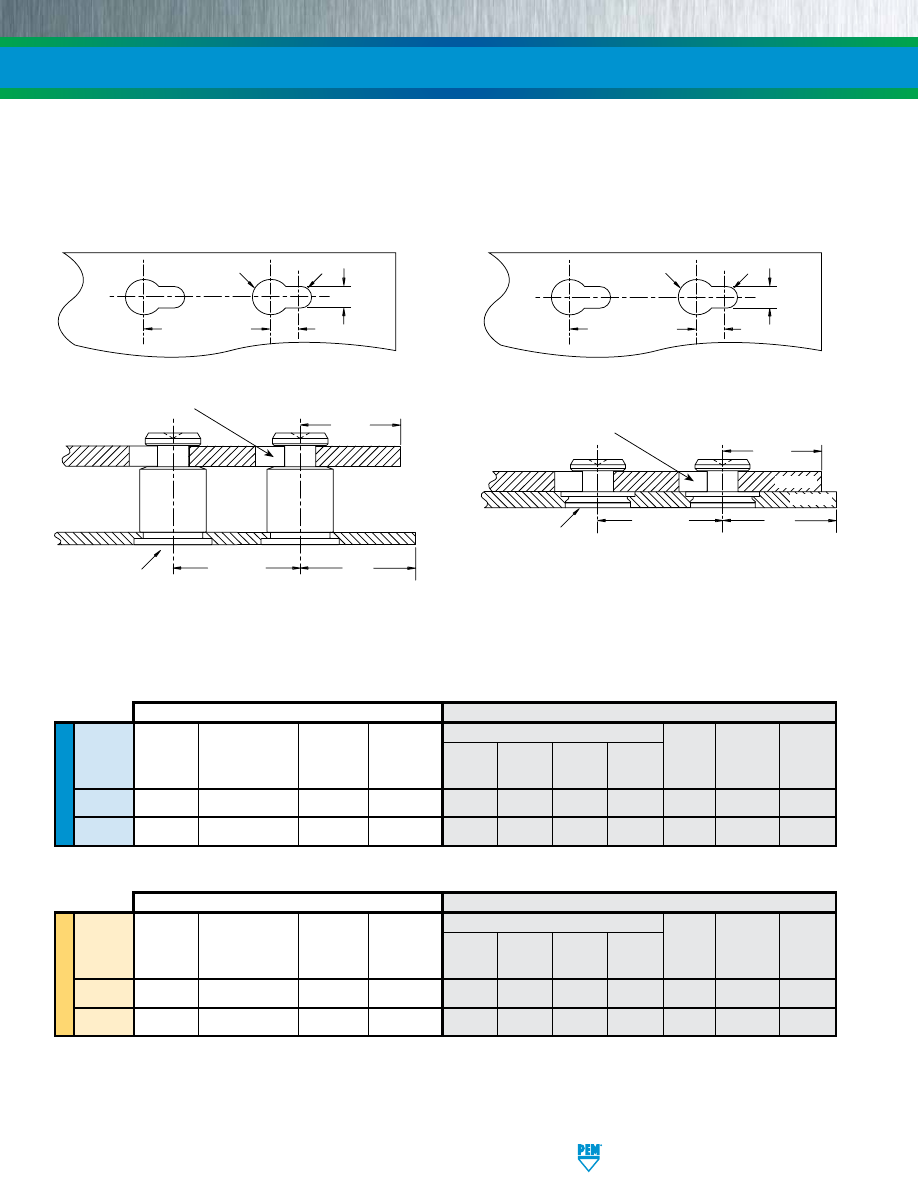

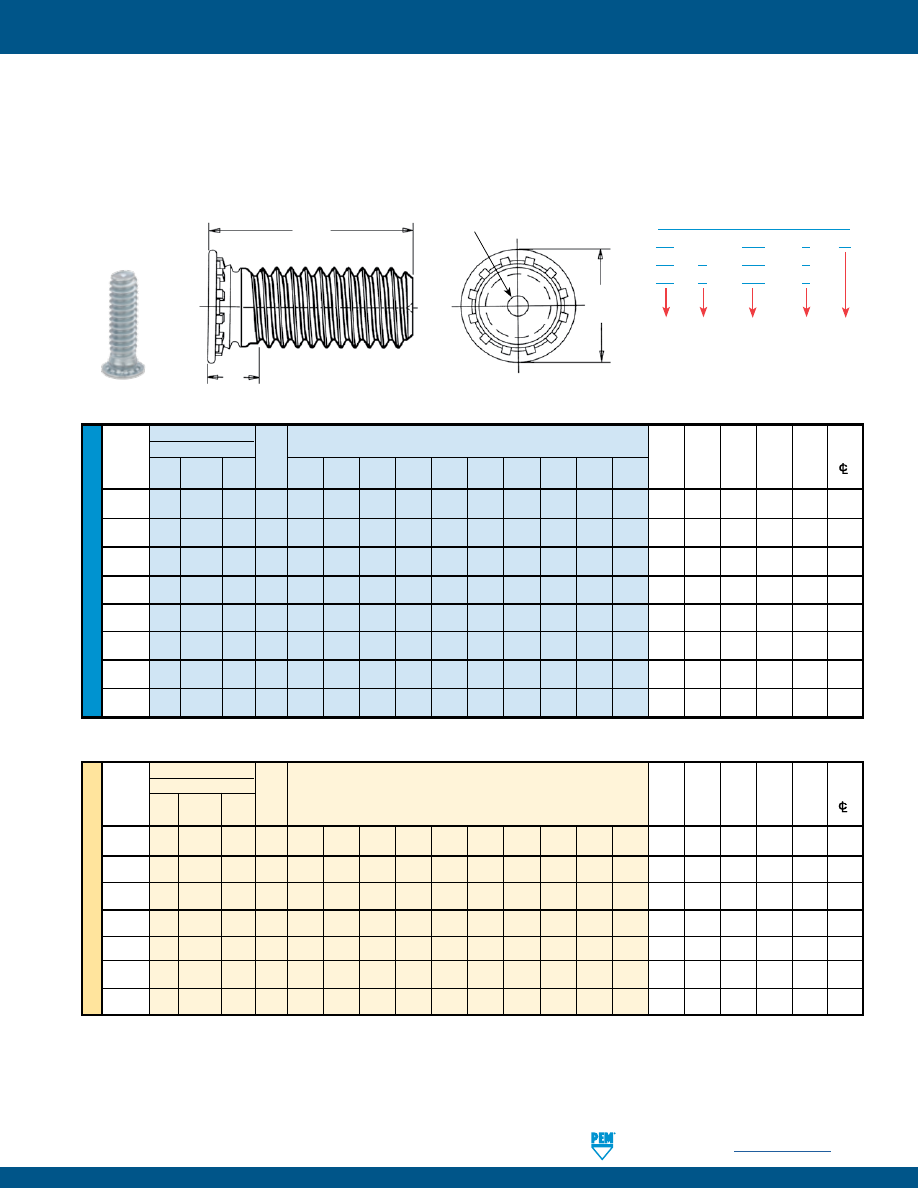

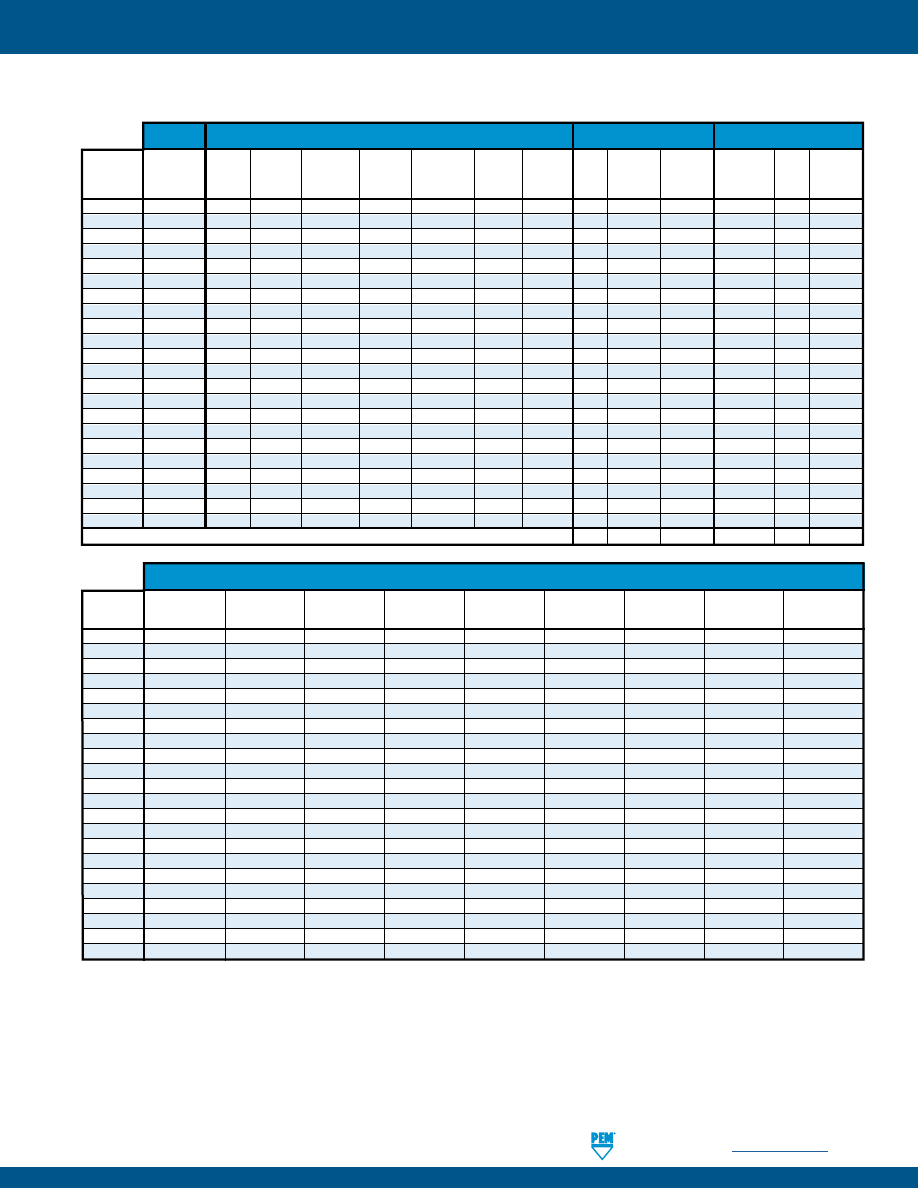

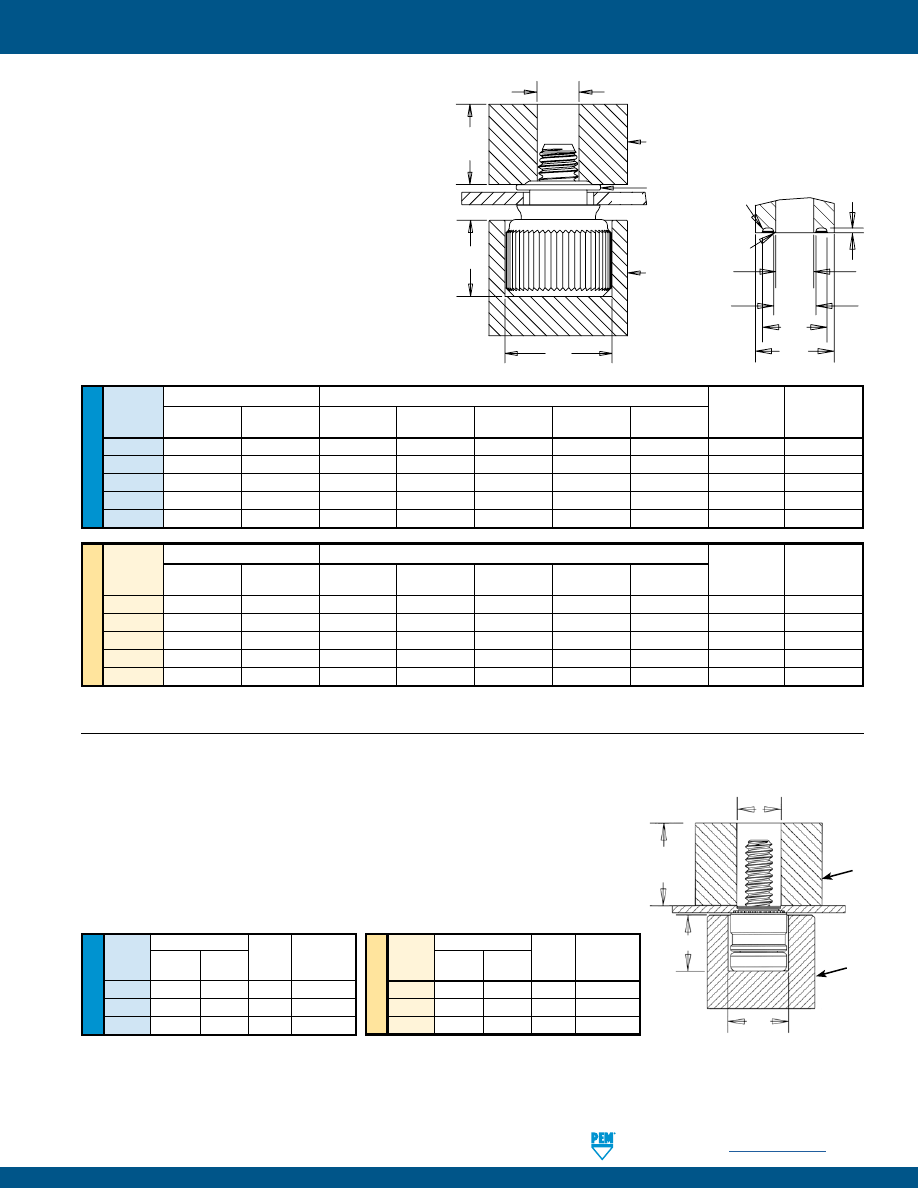

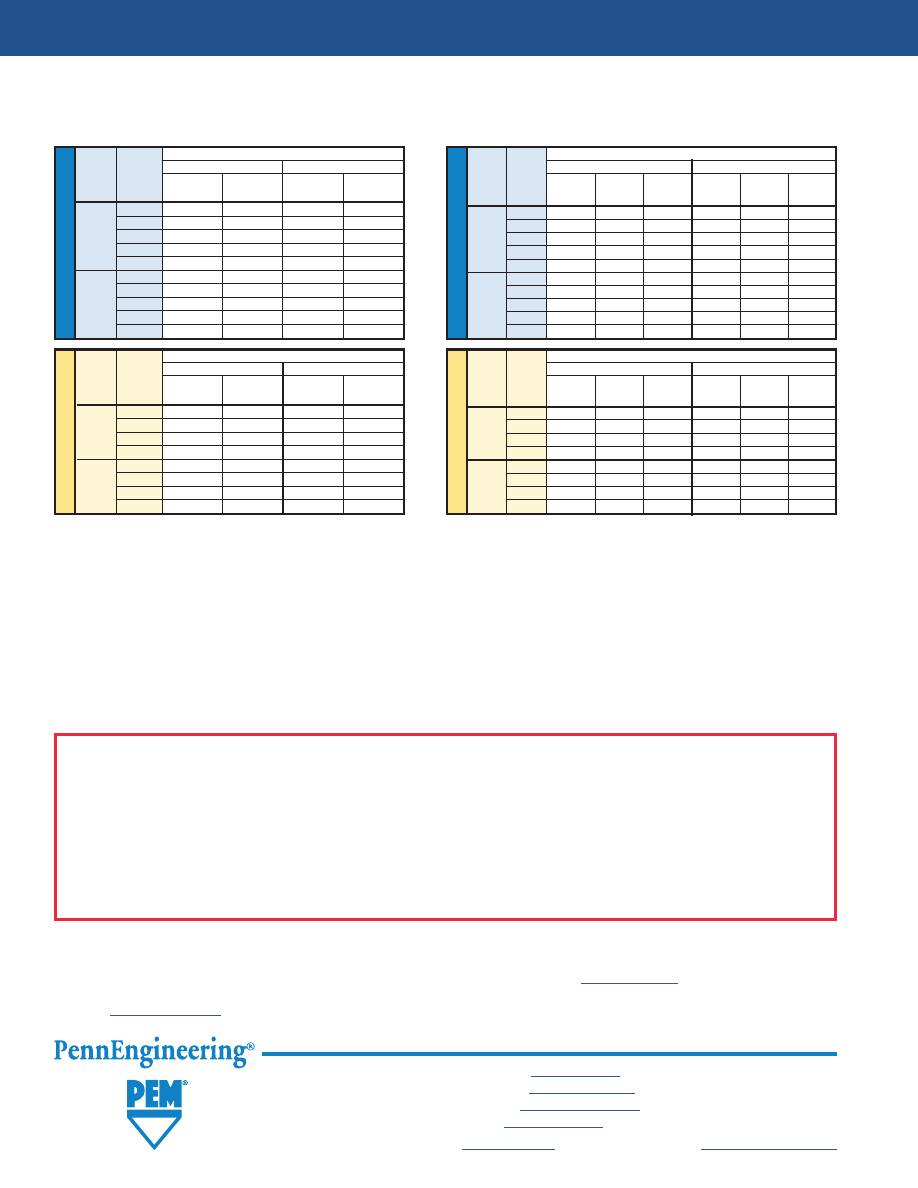

Code Code (Shank) Sheet Sheet Max. Max. ±.015 Max. Max. Hole

300 Series 400 Series

300 Series 400 Series

Max.

Thickness

+.003

C/L

To

Steel Stainless Stainless Steel Stainless Stainless

–.000

Edge

.112-40

AS AC A4 LAS LAC LA4 440

1 .038 .038

.290 .289 .290 .360 .130 .190 .30

(#4-40)

2

(1)

.054 .054

.138-32

AS AC A4 LAS LAC LA4 632

1 .038 .038

.328 .327 .335 .390 .130 .200 .32

(#6-32)

2

(1)

.054 .054

.164-32

AS AC A4 LAS LAC LA4 832

1 .038 .038

.368 .367 .365 .440 .130 .210 .34

(#8-32)

2

(1)

.054 .054

.190-24

AS AC A4 LAS LAC LA4 024 1 .038 .038 .406 .405 .405 .470 .170 .270 .36

(#10-24)

2

(1)

.054 .054

.190-32

AS AC A4 LAS LAC LA4 032 1 .038 .038 .406 .405 .405 .470 .170 .270 .36

(#10-32)

2

(1)

.054 .054

.250-20

AS AC

– LAS LAC

– 0420 2 .054 .054 .515 .514 .510 .600 .210 .310 .42

(1/4-20)

.250-28

AS AC

– LAS LAC

– 0428 2 .054 .054 .515 .514 .510 .600 .210 .310 .42

(1/4-28)

Float –

.015”/0.38 mm minimum,

in all directions from center,

.030”/0.76 mm total.

Fastener Materials

Standard Finishes

For Use In

Threads

Non-locking

Self-locking

Sheet Hardness

Non-locking

Self-locking

Retainer

Nut

Retainer & Nut Retainer & Nut Retainer

Retainer

Nut

(2)

MATERIAL AND FINISH SPECIFICATIONS

NON-LOCKING

AS/AC/A4

E

D

C

A

T

1

(2) HRB - Hardness Rockwell “B” Scale. HB - Hardness Brinell.

(3) See PEM Technical Support section of our web site

(www.pemnet.com)

for related plating standards and specifications.

(4) Temperature limit 400˚ F / 204˚ C.

All dimensions are in inches.

All dimensions are in millimeters.

(1) This shank code is not available for A4 and LA4 nuts.

ME

TR

IC

Type

Non-Locking

Self-Locking

Hole

Min.

Thread

Thread Shank

A

Min.

Size in

C

D

E

T

1

T

2

Dist.

Size x

Fastener Material

Fastener Material

Code Code (Shank) Sheet Sheet Max. Max. ±0.38 Max. Max. Hole

Pitch

300 Series 400 Series

300 Series 400 Series

Max.

Thickness

+0.08

C/L

To

Steel Stainless Stainless Steel Stainless Stainless

Edge

M3 x 0.5

AS

AC A4 LAS LAC LA4 M3

1 0.97 0.97

7.37 7.35 7.37 9.14 3.31 4.83 7.62

2

(1)

1.38 1.38

M4 x 0.7

AS

AC A4 LAS LAC LA4 M4

1 0.97 0.97

9.35 9.33 9.28 11.18 3.31 5.34 8.64

2

(1)

1.38 1.38

M5 x 0.8

AS AC A4 LAS LAC LA4 M5

1 0.97 0.97

10.31 10.29 10.29 11.94 4.32 6.86 9.14

2

(1)

1.38 1.38

M6 x 1

AS

AC

–

LAS

LAC

–

M6

2

1.38

1.38

13.08

13.06

12.96

15.24

5.34

7.88

10.67

Clinching profile may vary.

Clinching profile may vary.

PEM® Double Squares are a

registered trademark.

FLOATING SELF-CLINCHING FASTENERS

pem-html.html

All PEM® products meet our stringent quality standards. If you require additional industry or other specific

quality certifications

, special procedures and/or part

numbers are required. Please contact your local sales office or representative for further information.

Regulatory

compliance information

is available in Technical Support section of our website. Specifications subject to change without notice. See our website for the

most current version of this bulletin.

North America:

Danboro, Pennsylvania USA

•

E-mail:

info@pemnet.com

•

Tel: +1-215-766-8853

•

800-237-4736 (USA)

Europe:

Galway, Ireland

•

E-mail:

europe@pemnet.com

•

Tel: +353-91-751714

Asia/Pacific:

Singapore

•

E-mail:

singapore@pemnet.com

•

Tel: +65-6-745-0660

Shanghai, China

•

E-mail:

china@pemnet.com

•

Tel: +86-21-5868-3688

Visit our PEMNET™ Resource Center at

www.pemnet.com

•

Technical support e-mail:

techsupport@pemnet.com

ME

TR

IC

U

NIF

IE

D

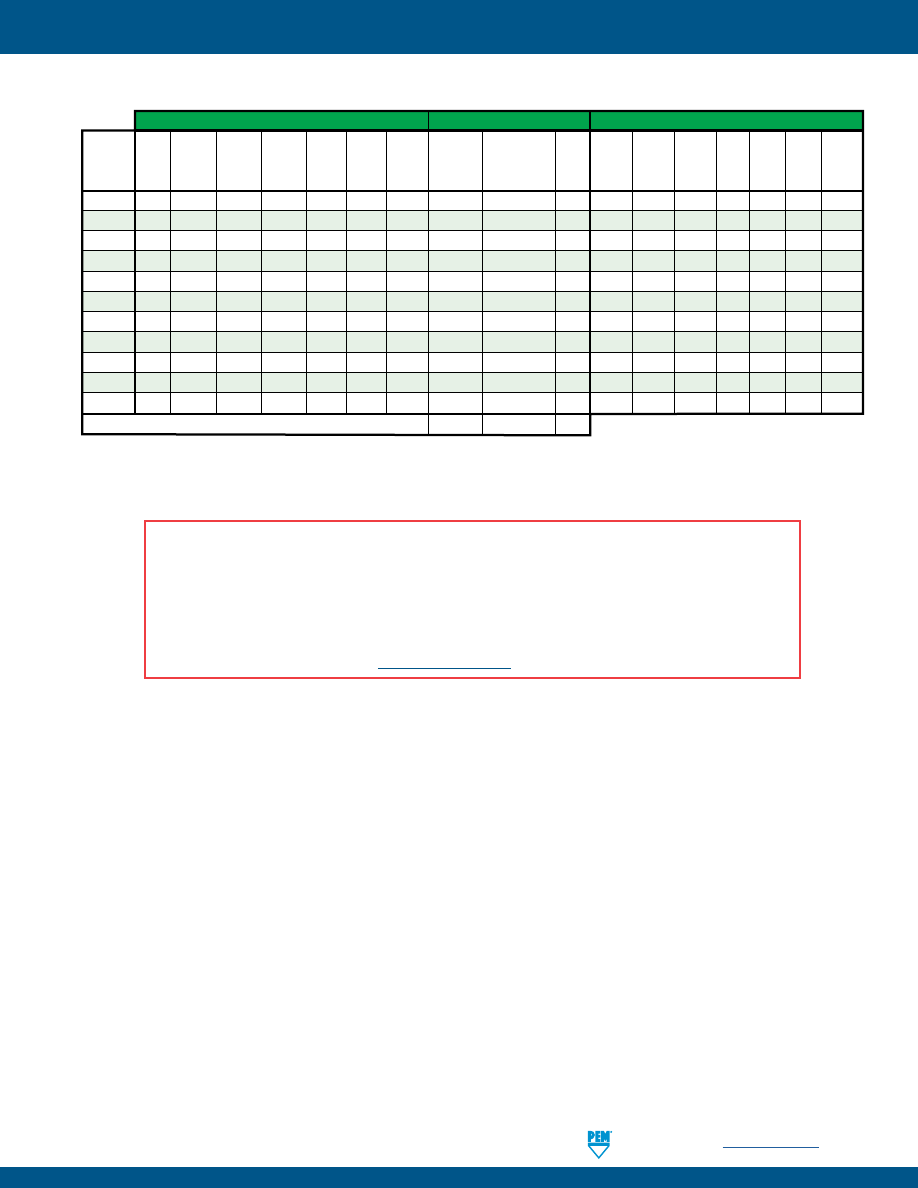

(1) Published installation forces are for general reference. Actual set-up and confirmation of complete installation should be made by observing proper

seating of fastener as described in the installation steps. Other performance values reported are averages when all proper installation parameters

and procedures are followed. Variations in mounting hole size, sheet material, and installation procedure may affect performance. Performance

testing this product in your application is recommended. We will be happy to provide technical assistance and/or samples for this purpose.

(2) For LAC, LAS and LA4 nuts, thread locking performance is equivalent to applicable NASM25027 specifications. Consult document PEM-REF25027 for details.

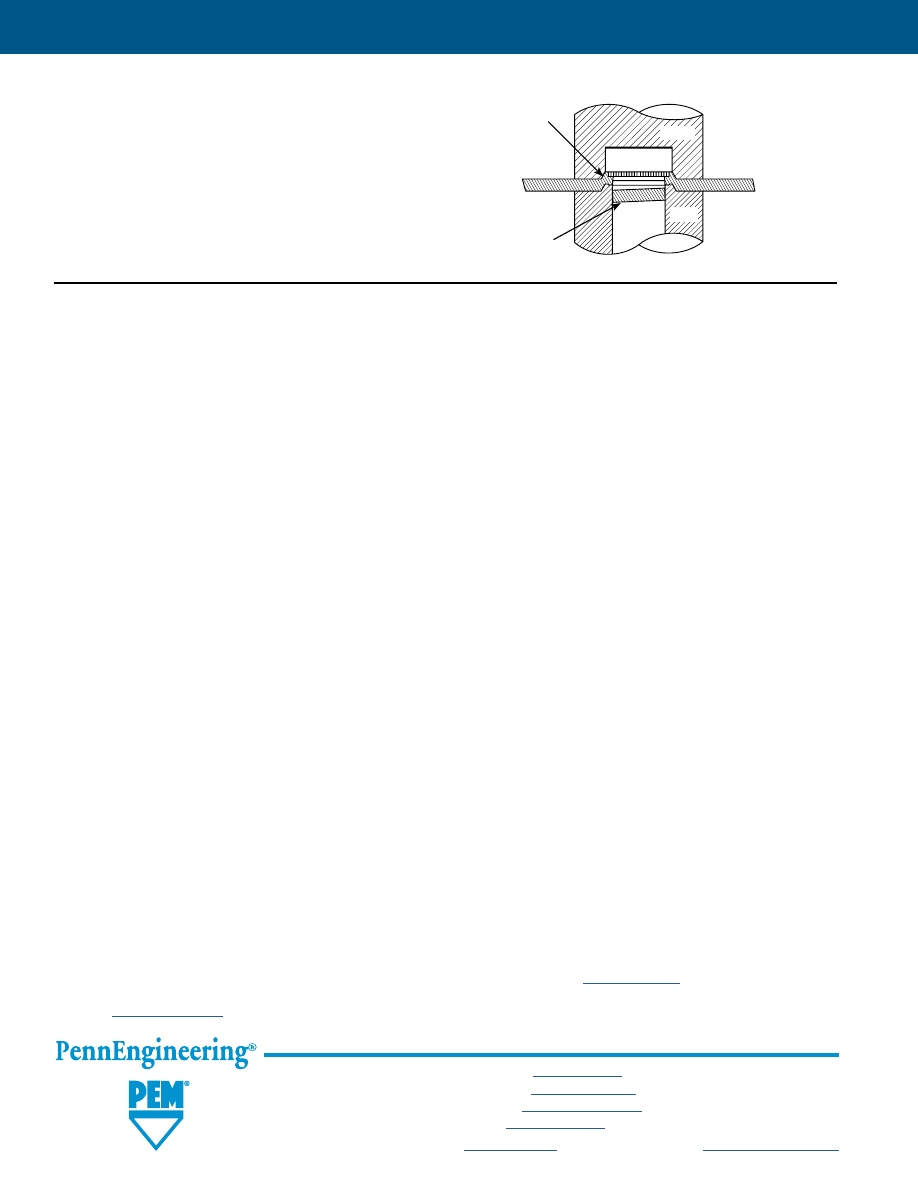

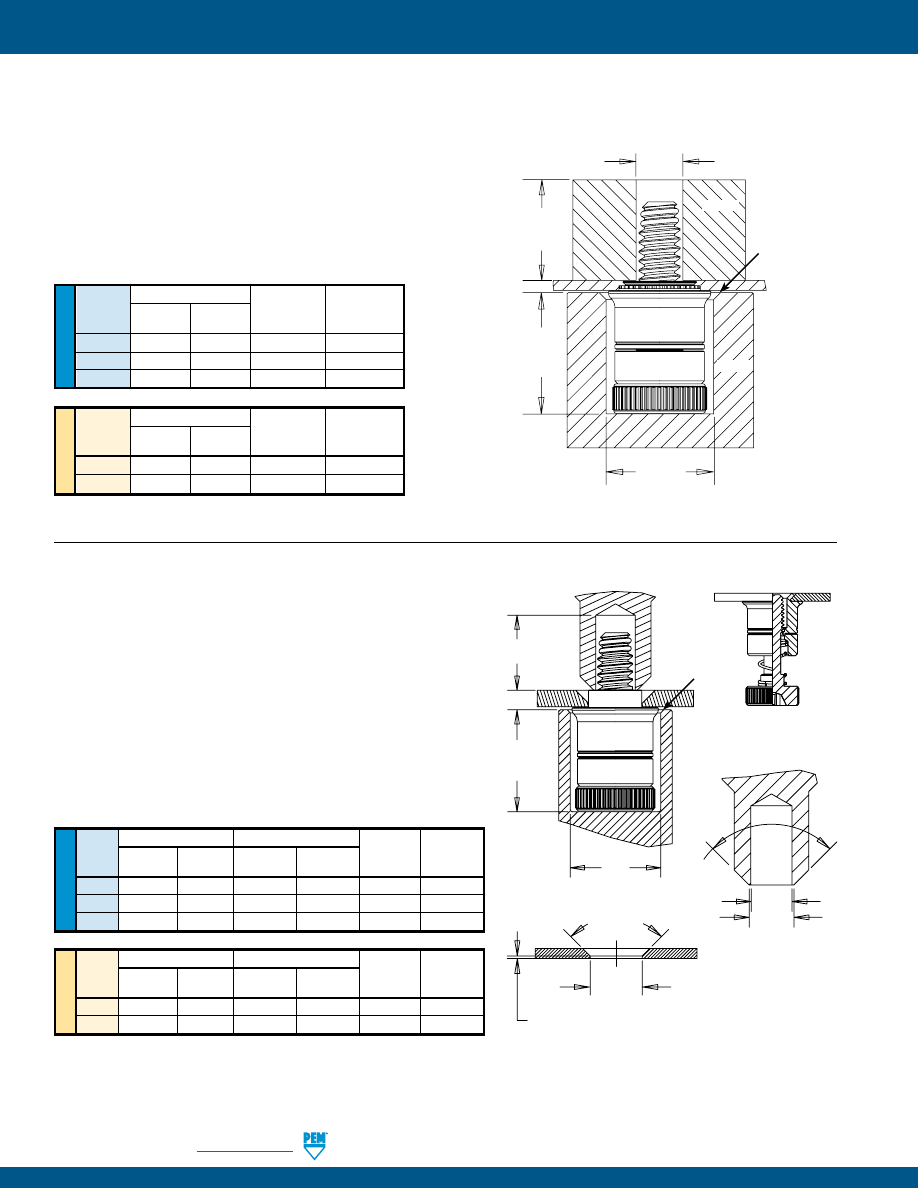

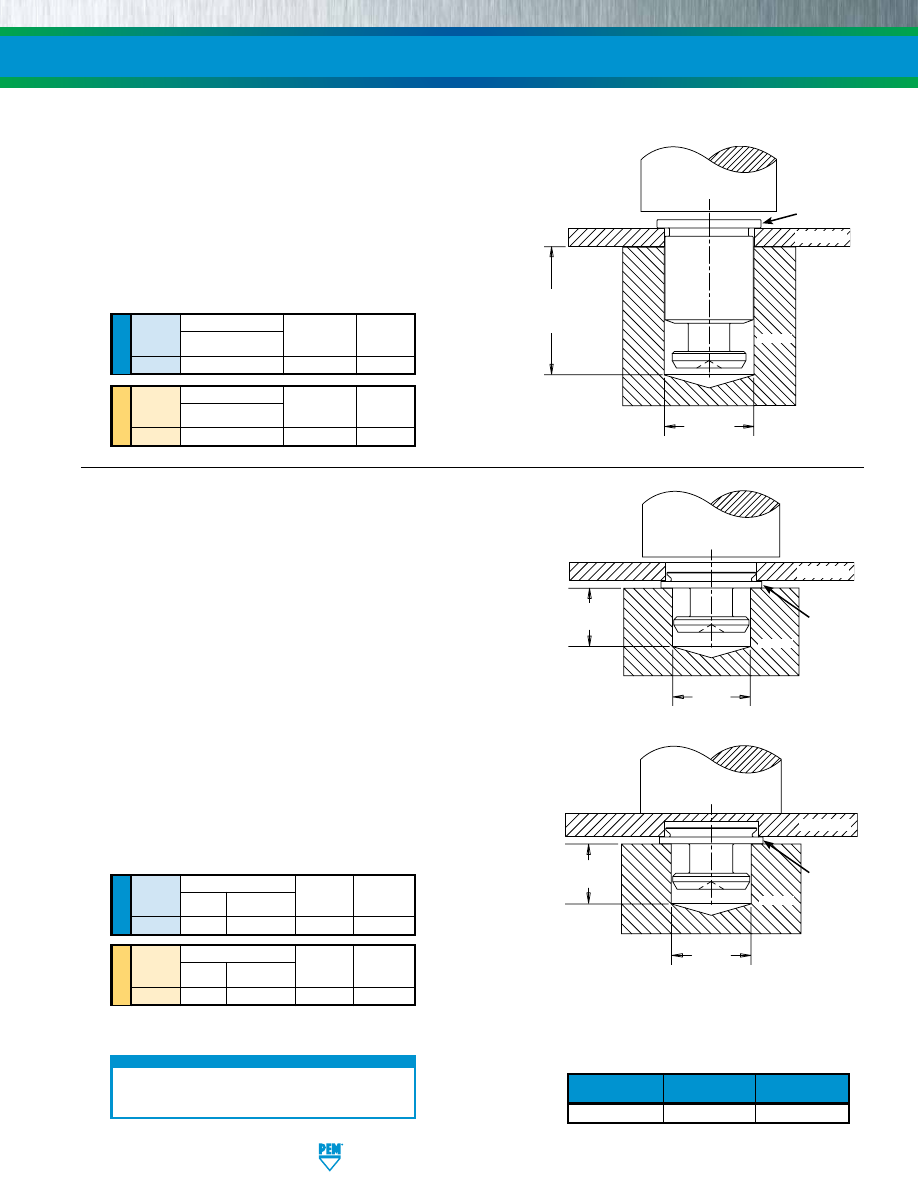

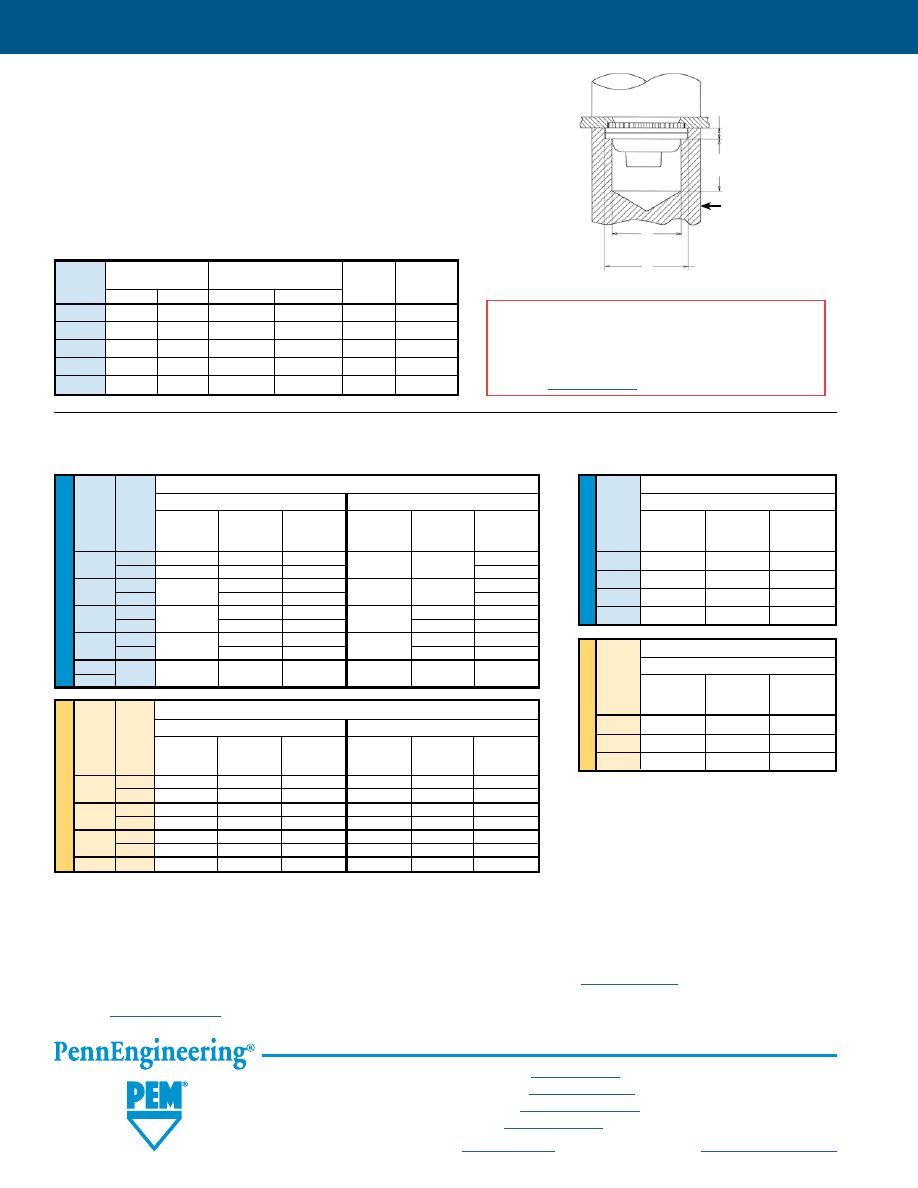

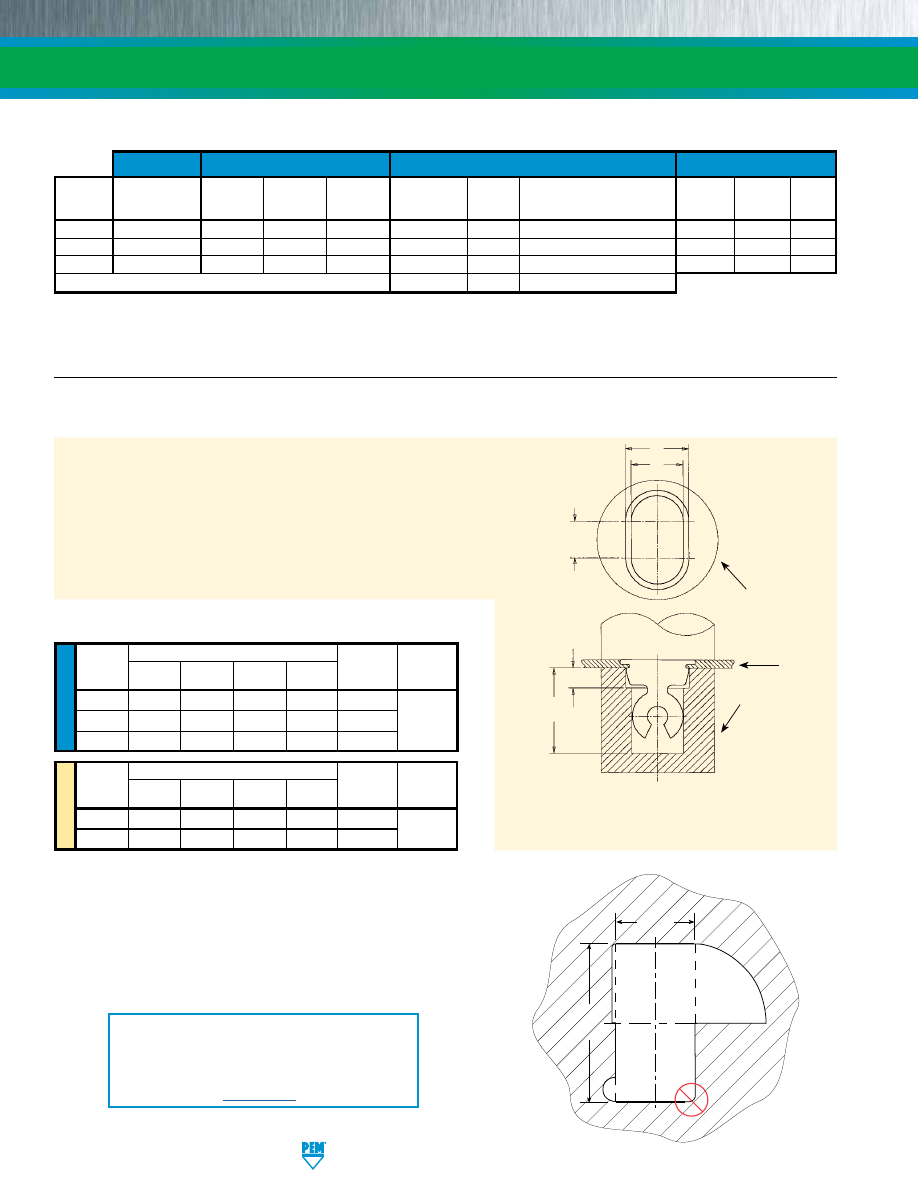

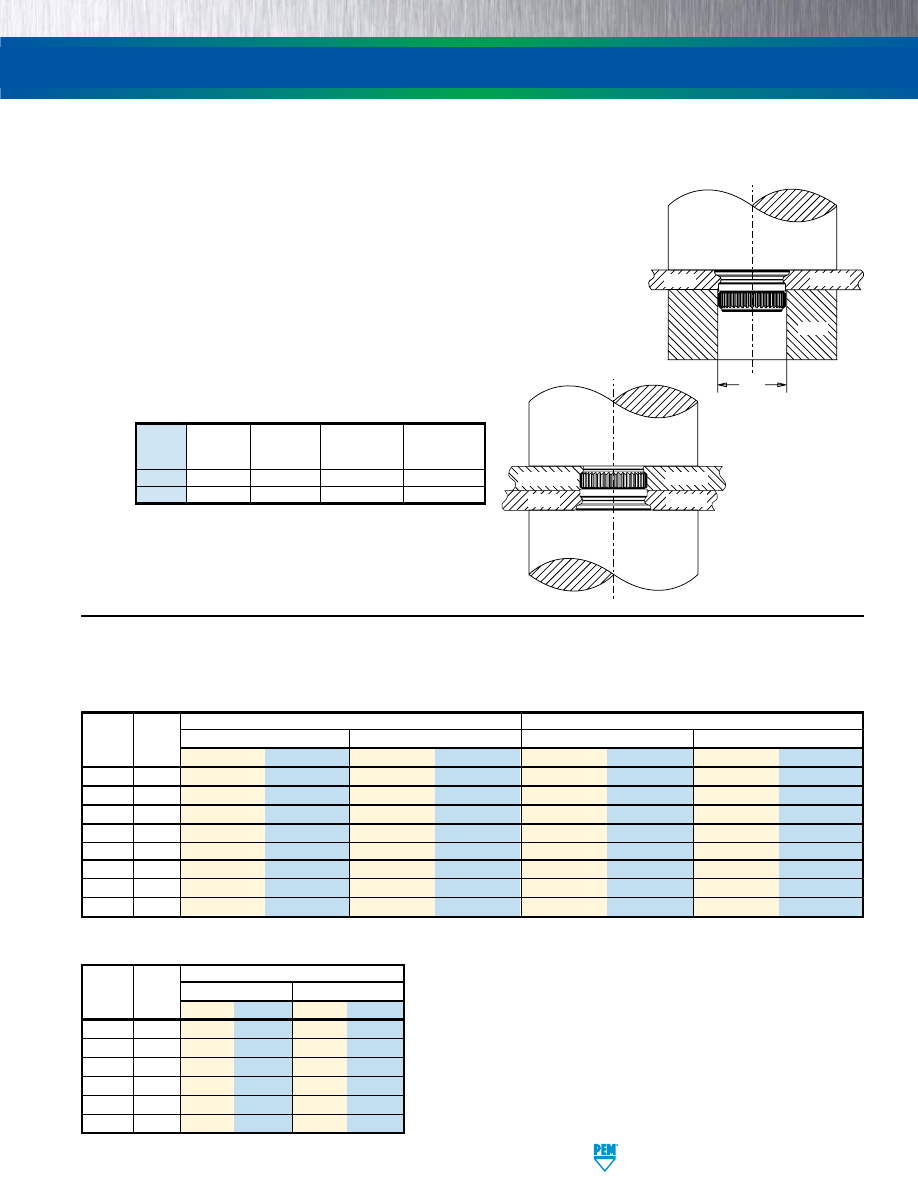

1.

Prepare properly sized mounting hole in sheet. Do not perform any secondary

operations such as deburring.

2.

Place fastener into the anvil hole and place the mounting hole (preferably the

punch side) over the shank of the fastener.

3.

With installation punch and anvil surfaces parallel, apply sufficient squeezing

force until anvil contacts the mounting sheet. Drawing shows suggested

tooling for applying these forces.

ALA-4

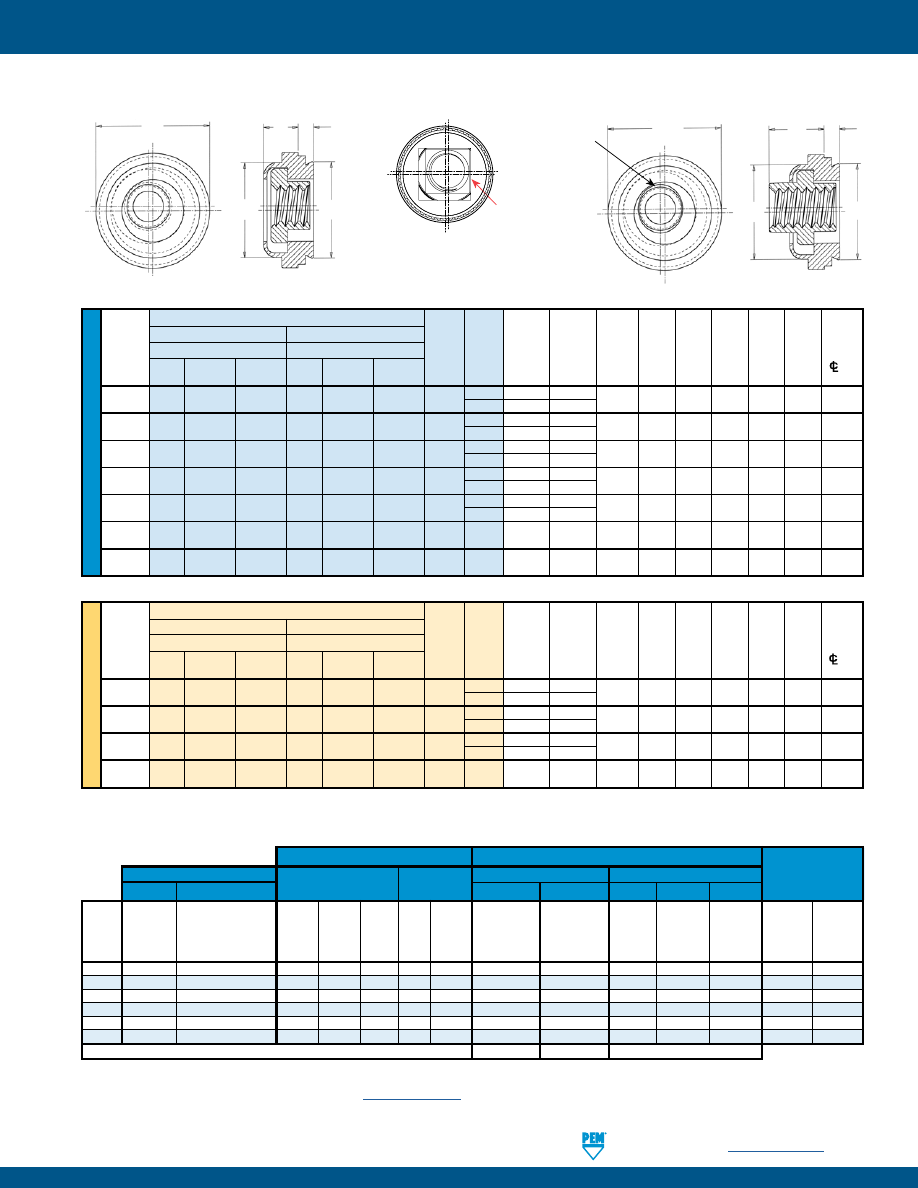

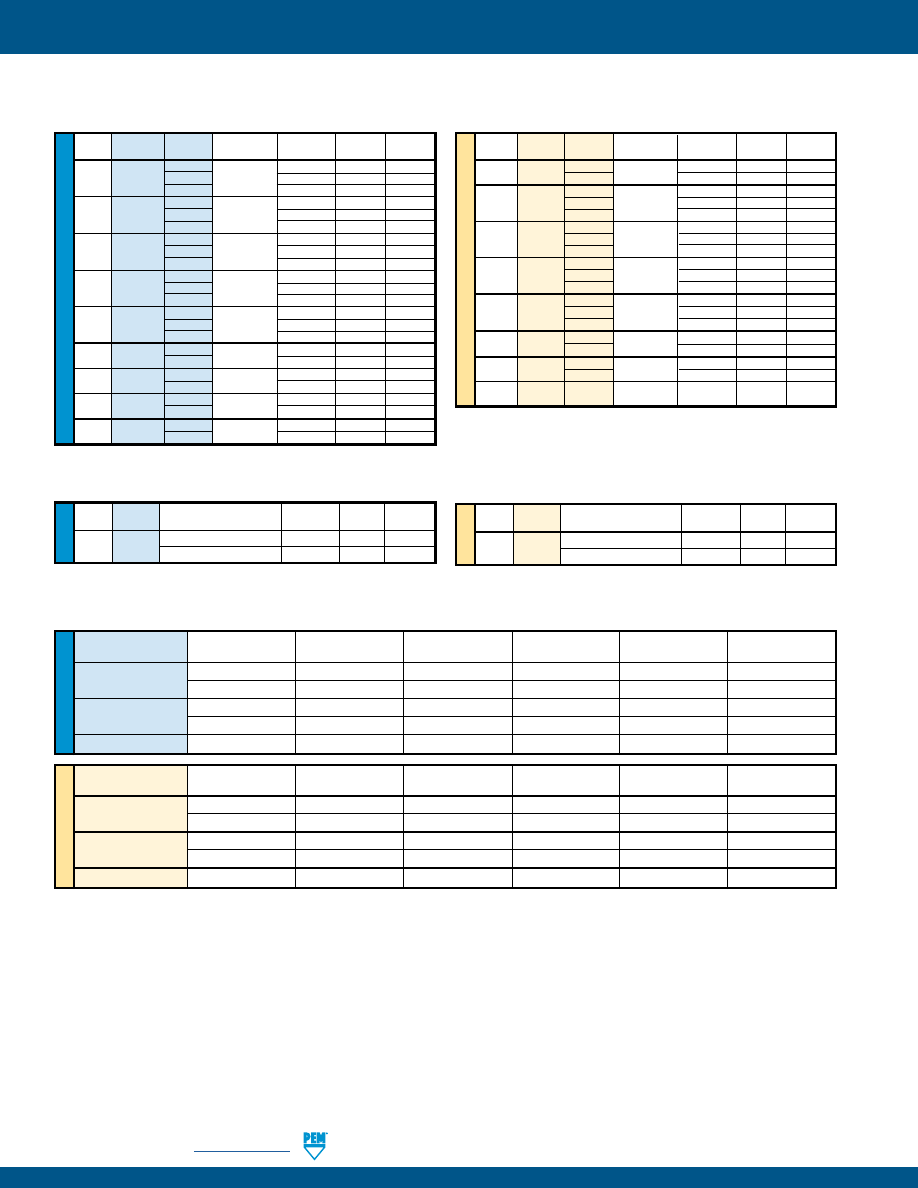

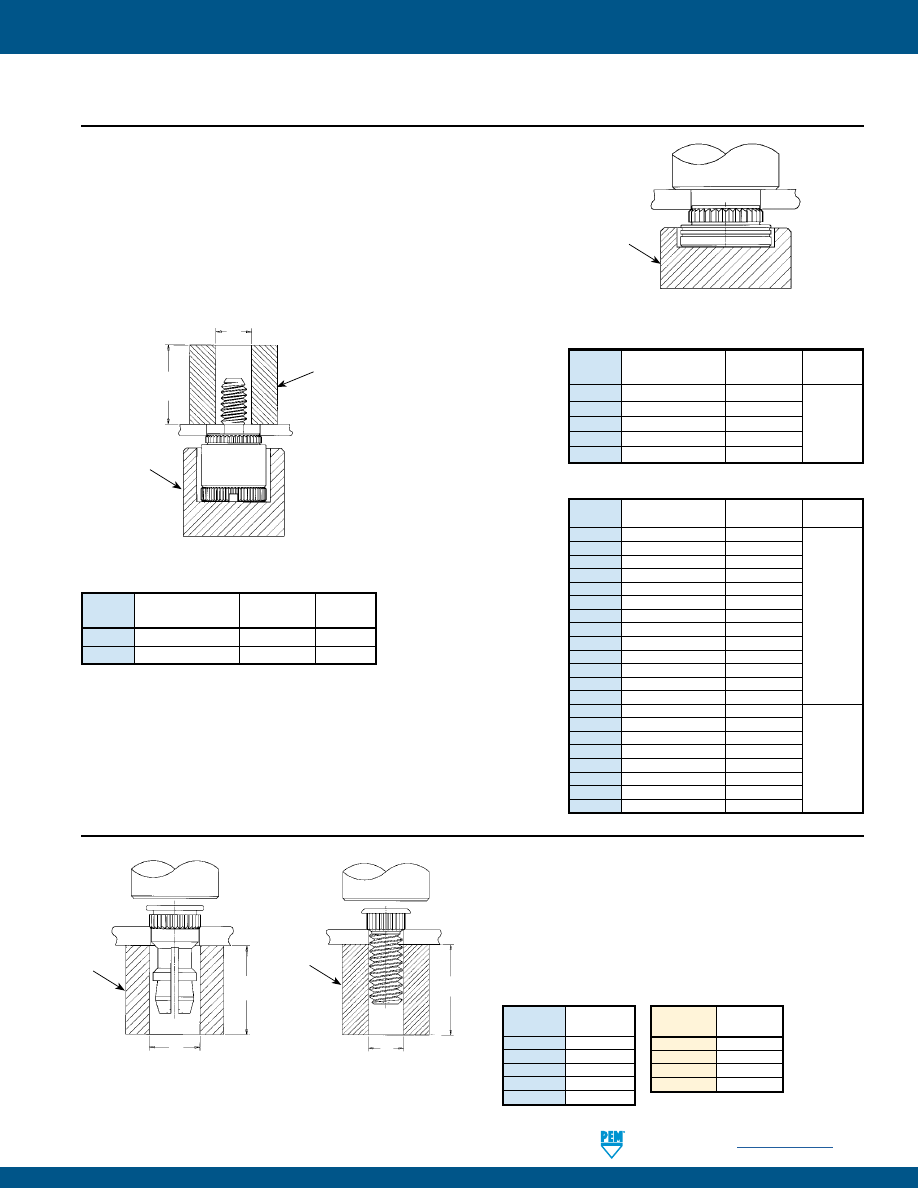

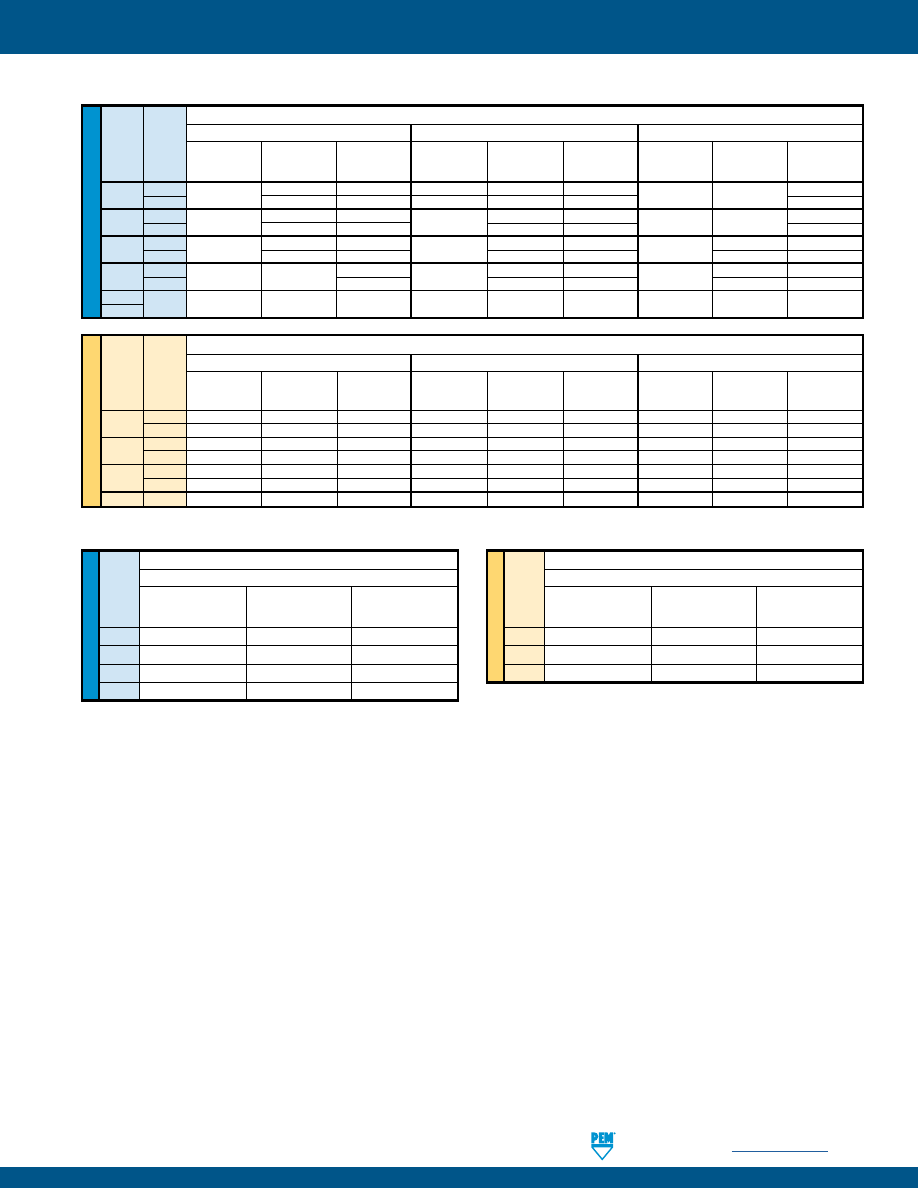

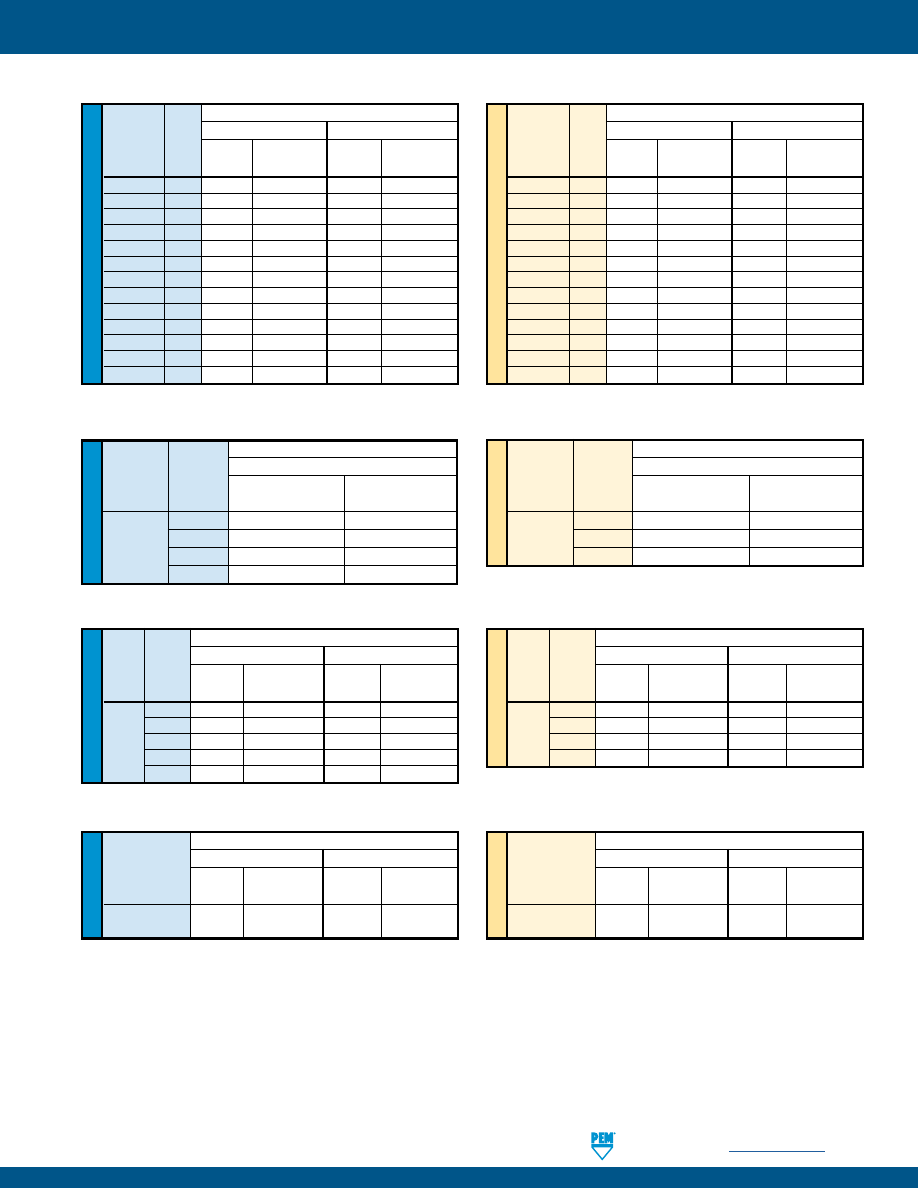

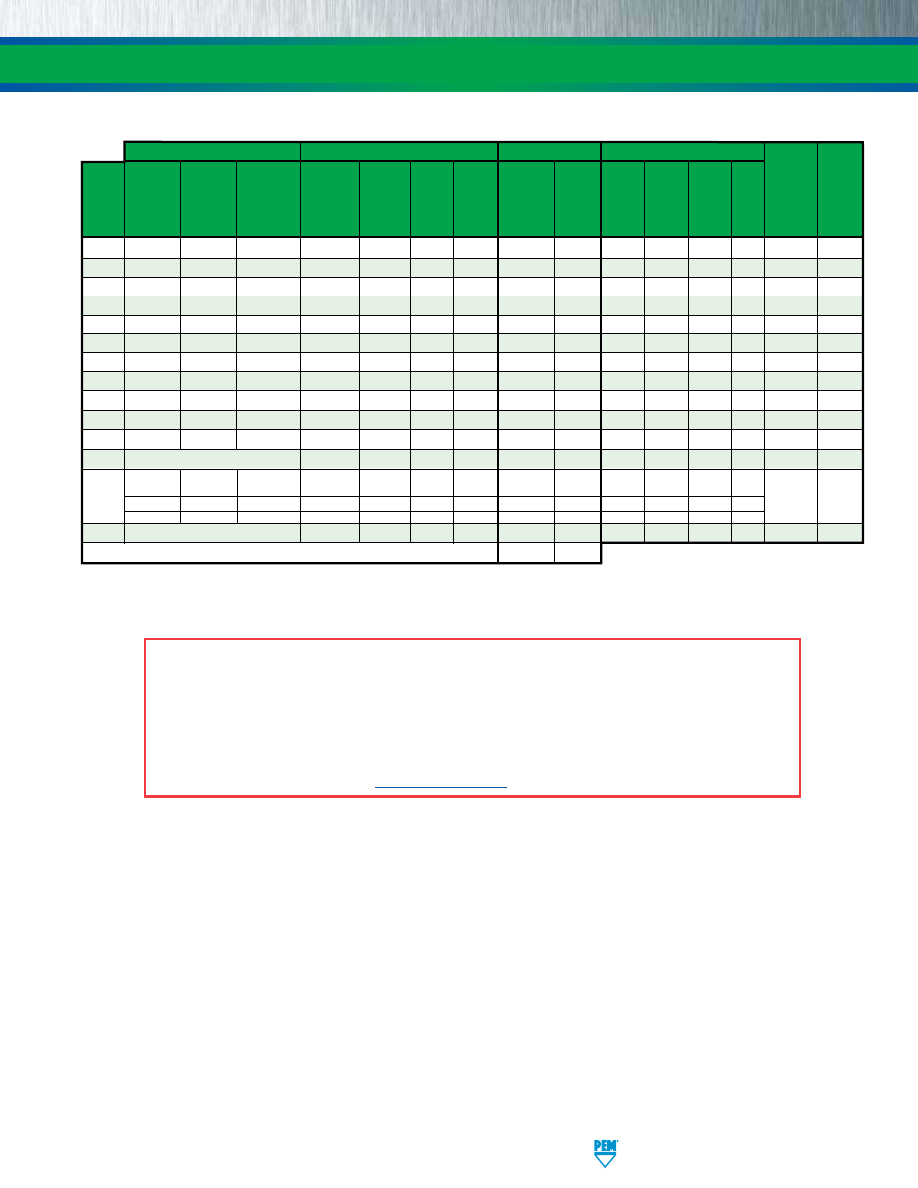

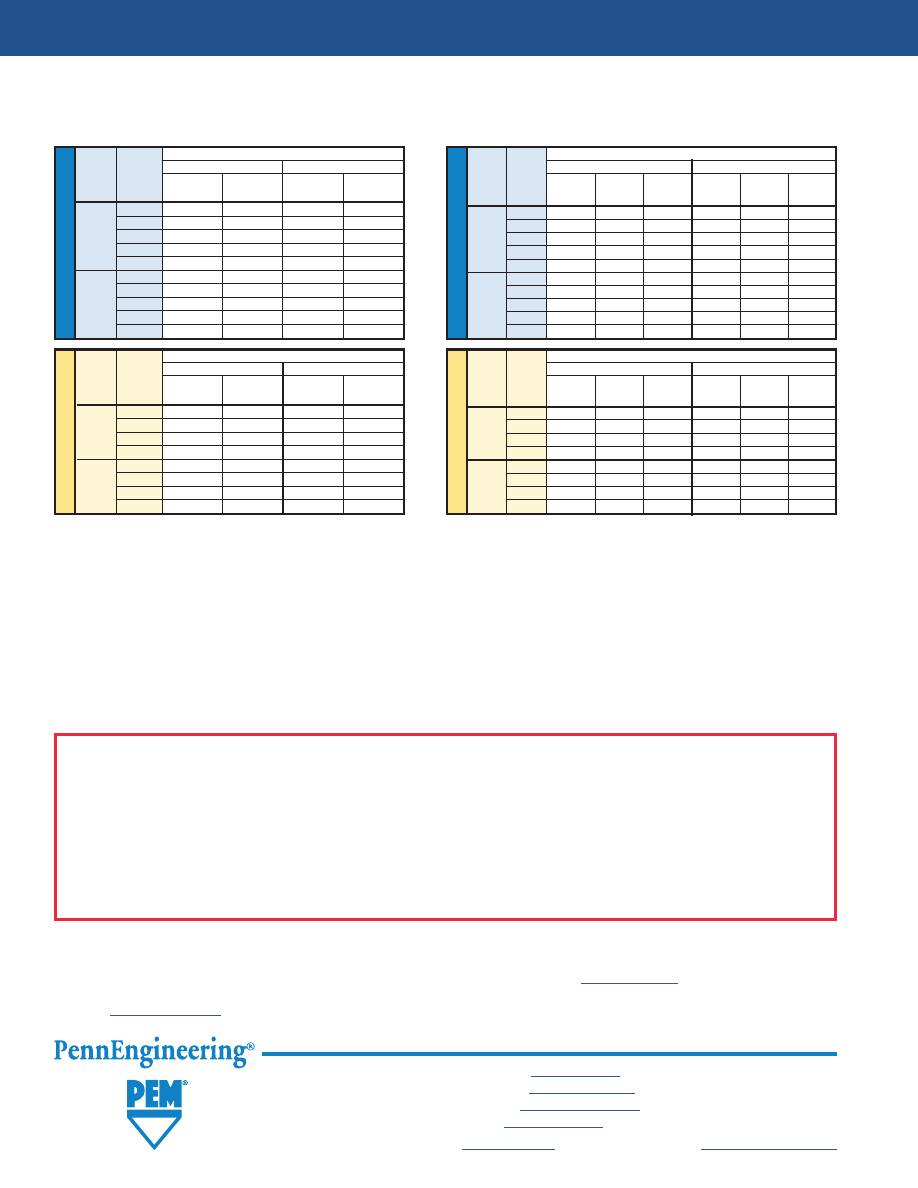

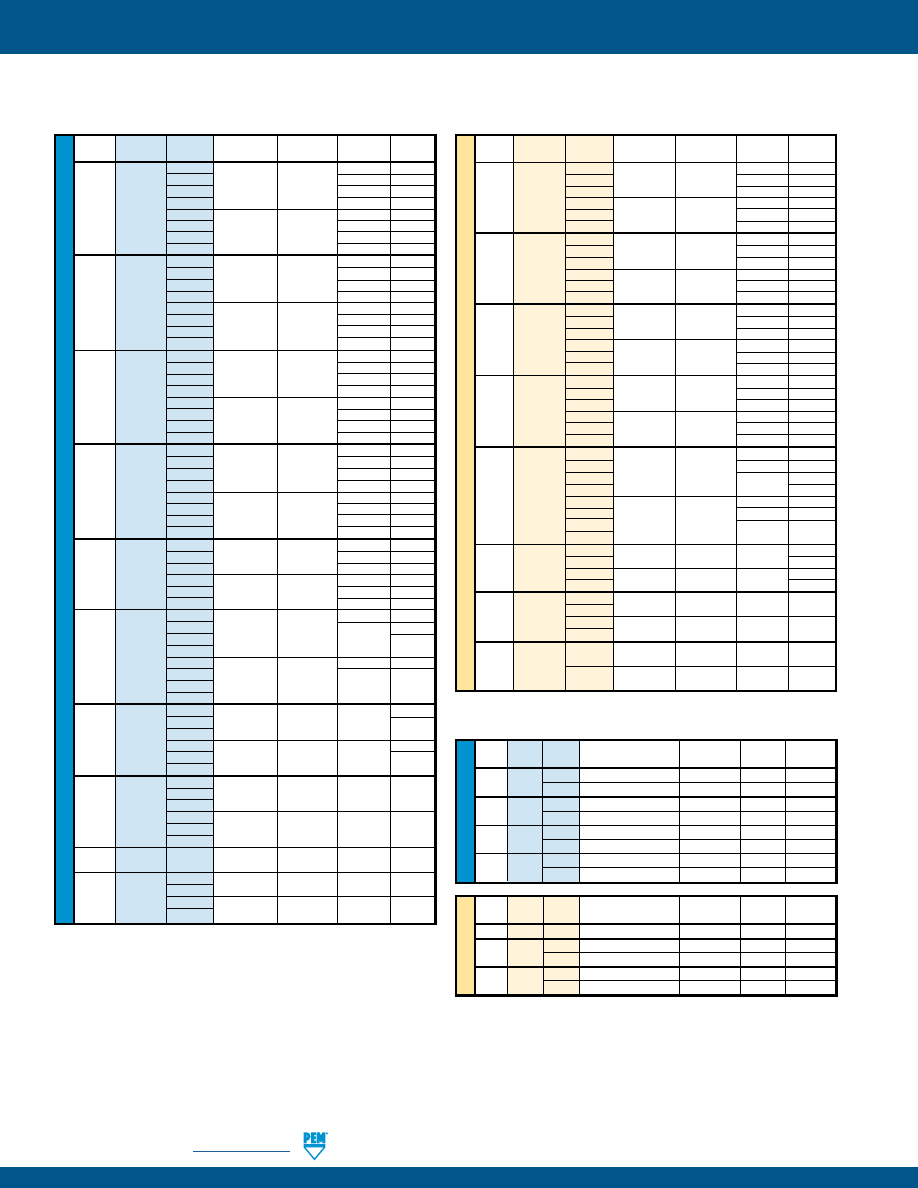

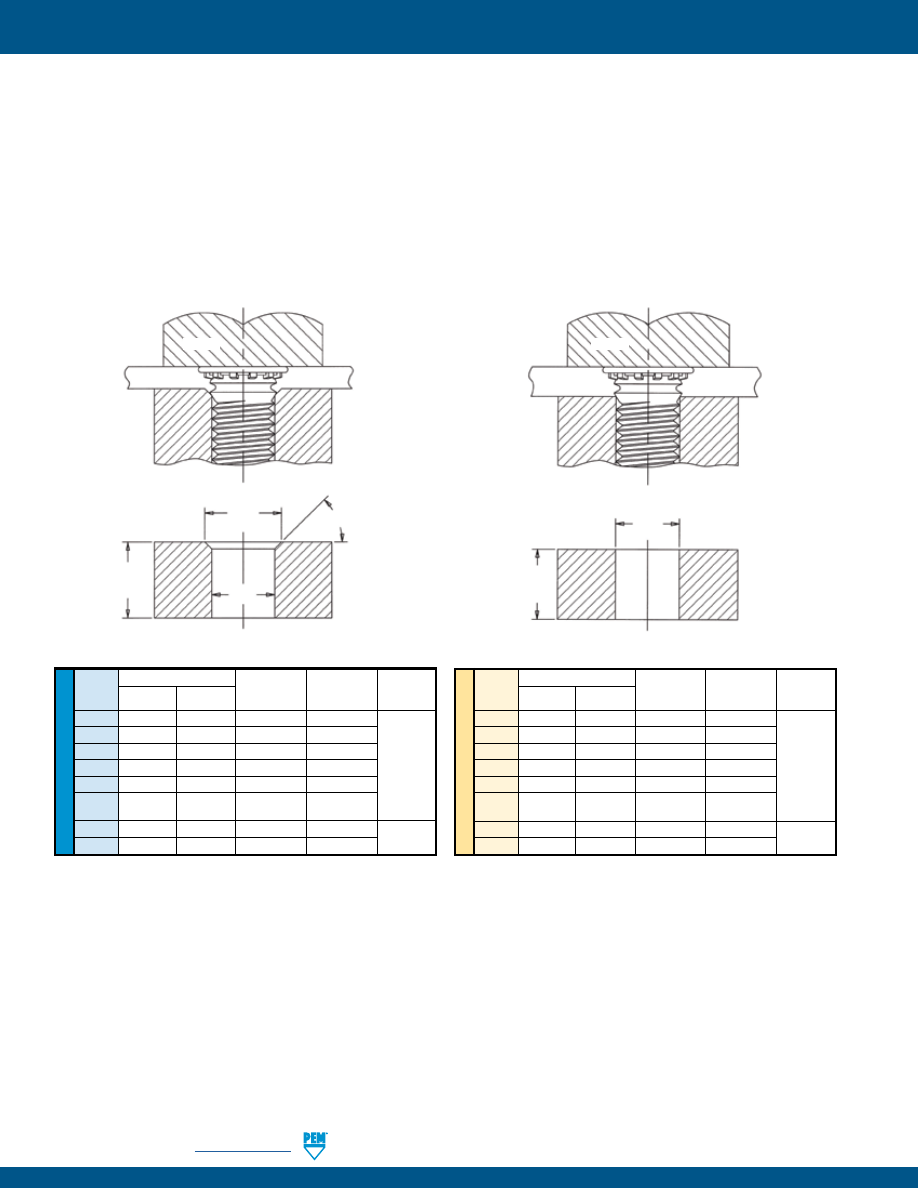

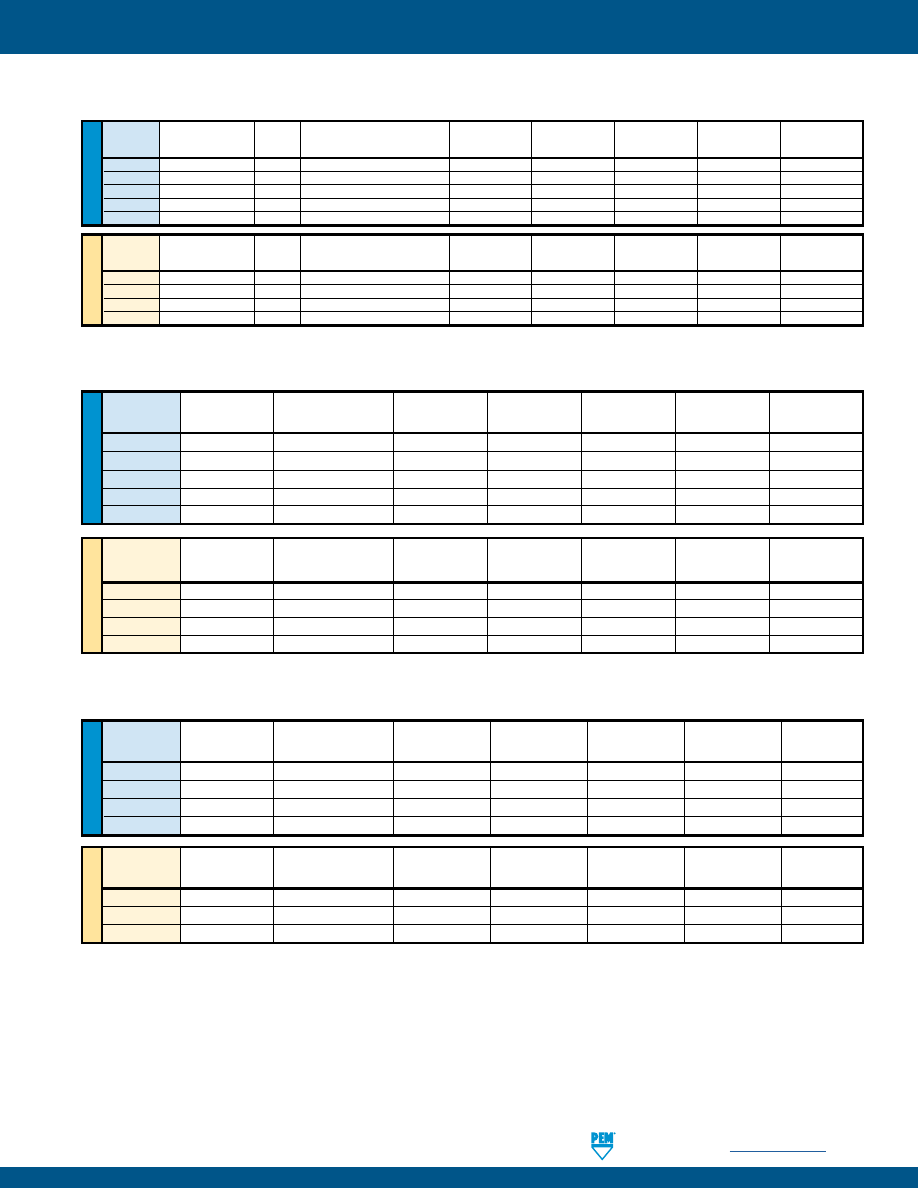

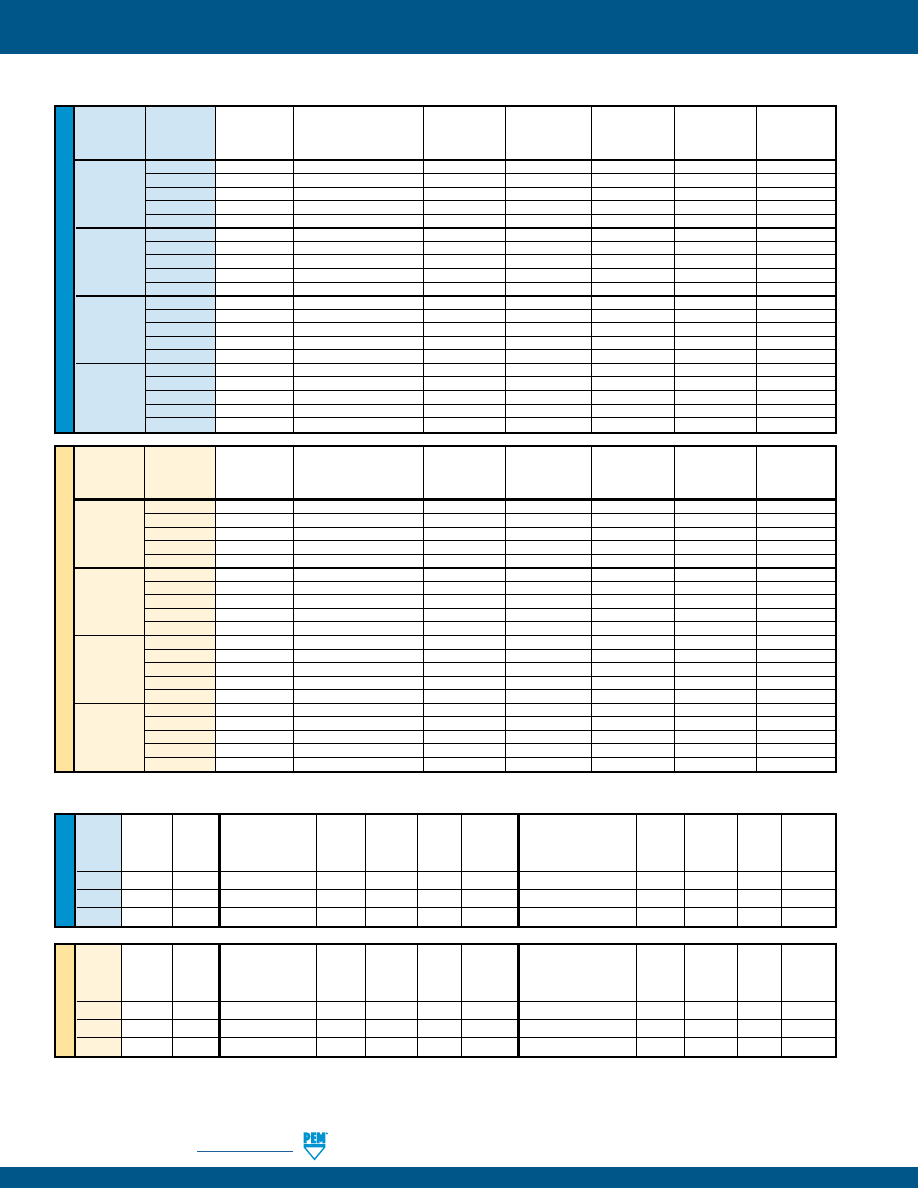

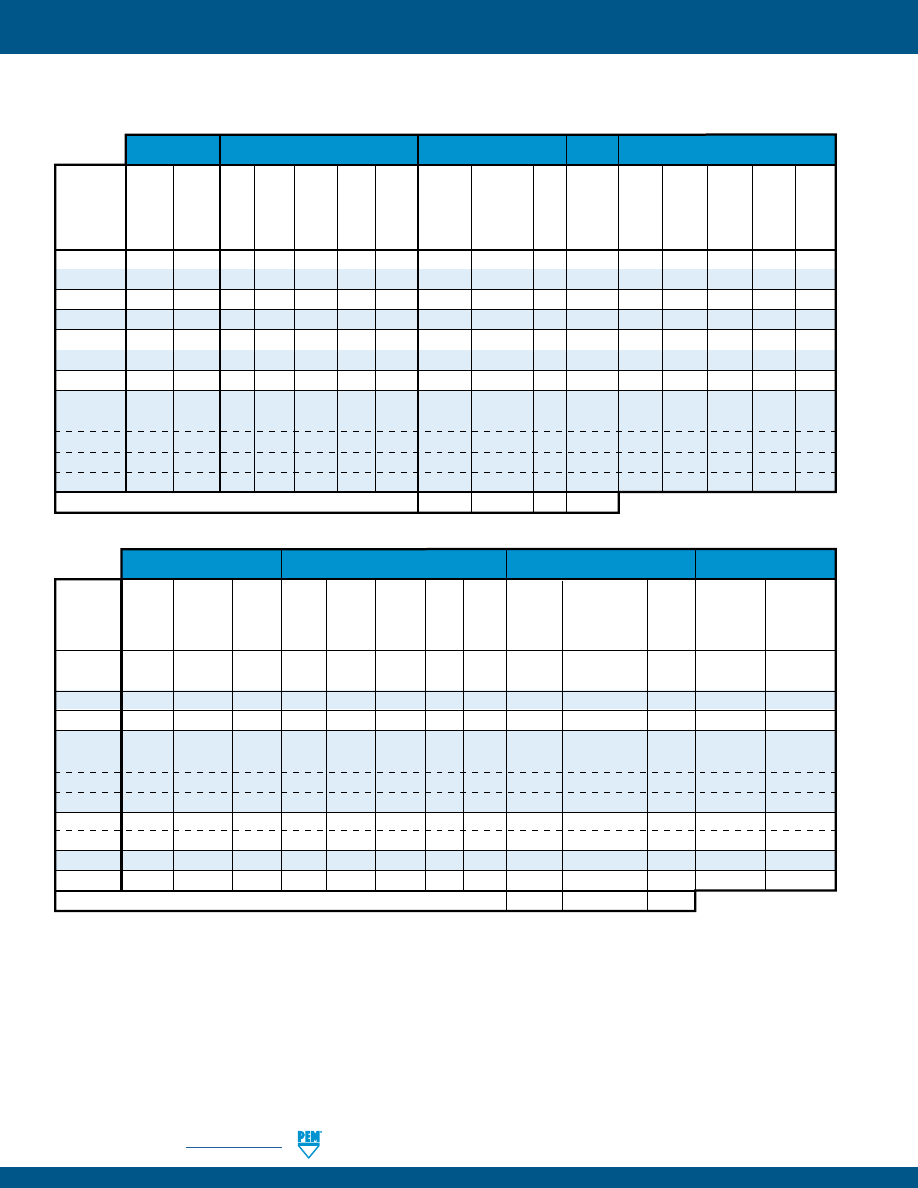

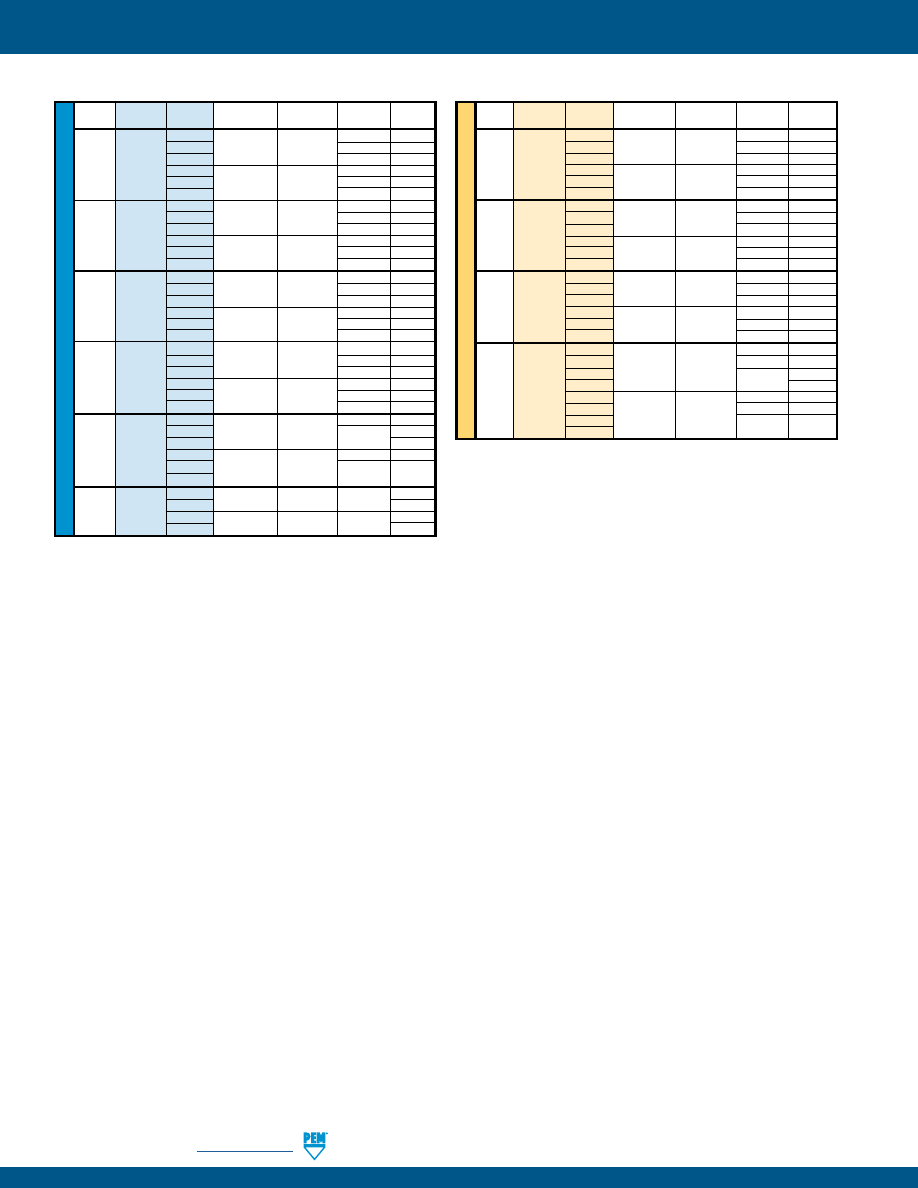

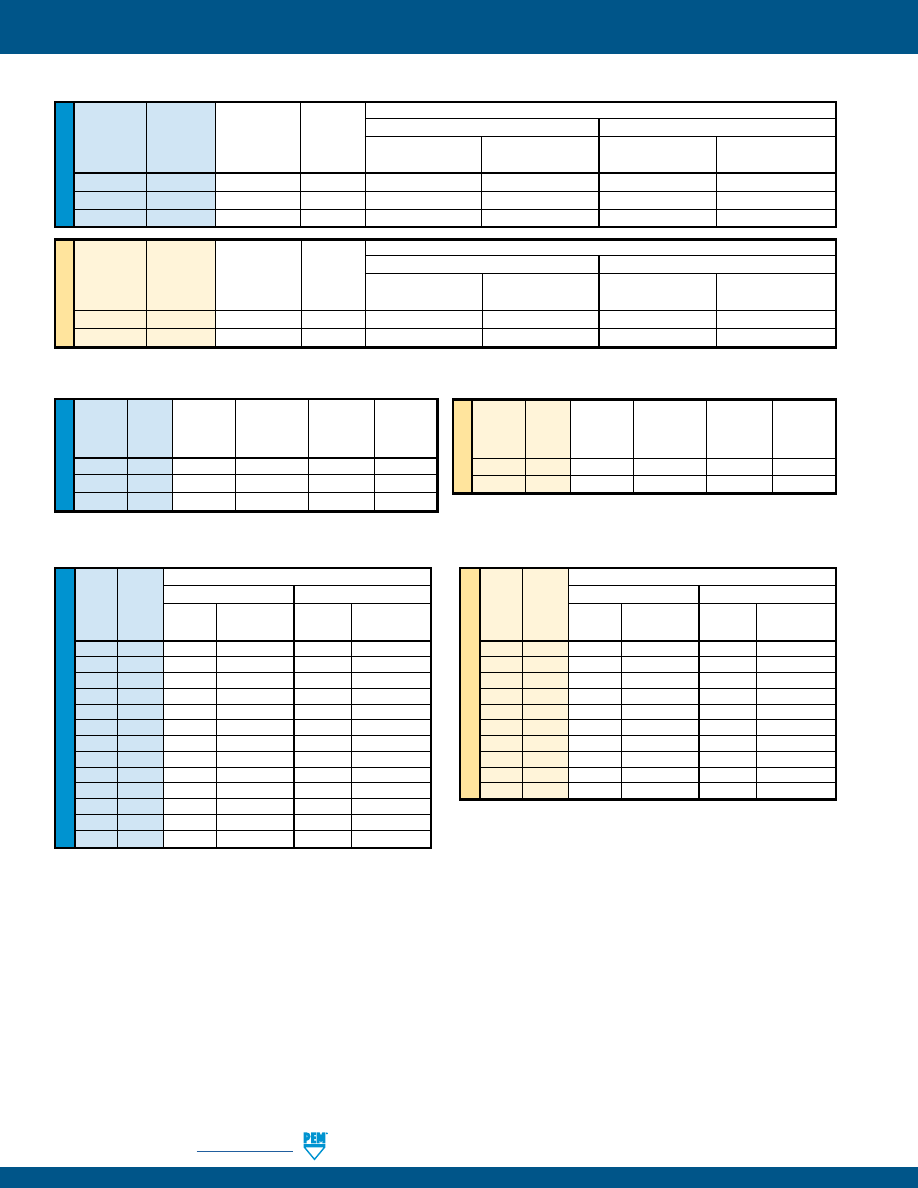

PERFORMANCE DATA

(1)(2)

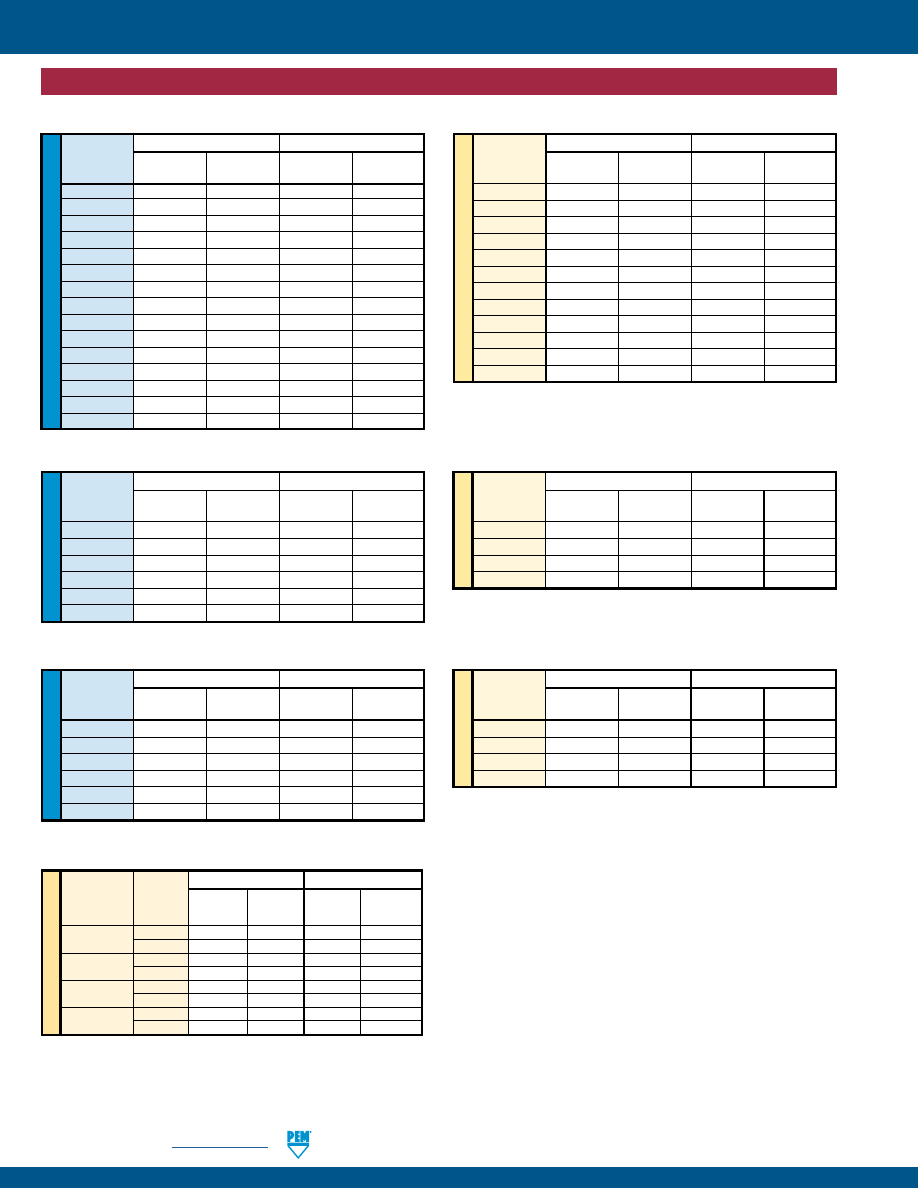

AC/AS/LAC/LAS NUTS

ME

TR

IC

U

NIF

IE

D

Test Sheet Material

5052-H34 Aluminum

Cold-Rolled Steel

Thread Shank Retainer Retainer

Retainer Retainer

Code Code

Installation

Pushout Torque-out Installation

Pushout Torque-out

(lbs.)

(lbs.)

(in. lbs.)

(lbs.)

(lbs.)

(in. lbs.)

440 1 1500 215 65 3000 300 85

2

2000

225

80

150

632 1 2000 240 140 3000 300 150

2

250

150

175

832 1 2000 250 140 3000 300 150

2

265

150

400

200

032 1 2000 300 150 3500 400 150

2

350

175

450

200

0420

2 3000 400 325 5000 500 325

0428

Test Sheet Material

5052-H34 Aluminum

Cold-Rolled Steel

Thread Shank Retainer Retainer

Retainer Retainer

Code Code

Installation

Pushout Torque-out Installation

Pushout Torque-out

(kN)

(N) (N•m) (kN)

(N) (N•m)

M3

1 6.7 956 7.3 13.3 1334 9.6

2

8.9

1000

9

13.3

1334

16.9

M4

1 8.9 1112 15.8 13.3 1334 16.9

2 8.9 1178 16.9 13.3 1779 22.6

M5

1 8.9 1334 16.9 15.6 1779 16.9

2

8.9

1556

19.7

15.6

2001

22.6

M6

2

13.3

1779

36.7

22.2

2224

36.7

Test Sheet Material

300 Series Stainless Steel

Thread Retainer Retainer

Code

Installation

Pushout Torque-out

(lbs.)

(lbs.)

(in. lbs.)

440

9000

200

85

632

10000

200

85

832

12000

200

85

032

13000

250

125

Test Sheet Material

300 Series Stainless Steel

Thread Retainer Retainer

Code

Installation

Pushout Torque-out

(kN)

(N) (N•m)

M3

40

890

9.6

M4

53

890

9.6

M5

57

1100

14.1

A4/LA4

(3)

NUTS

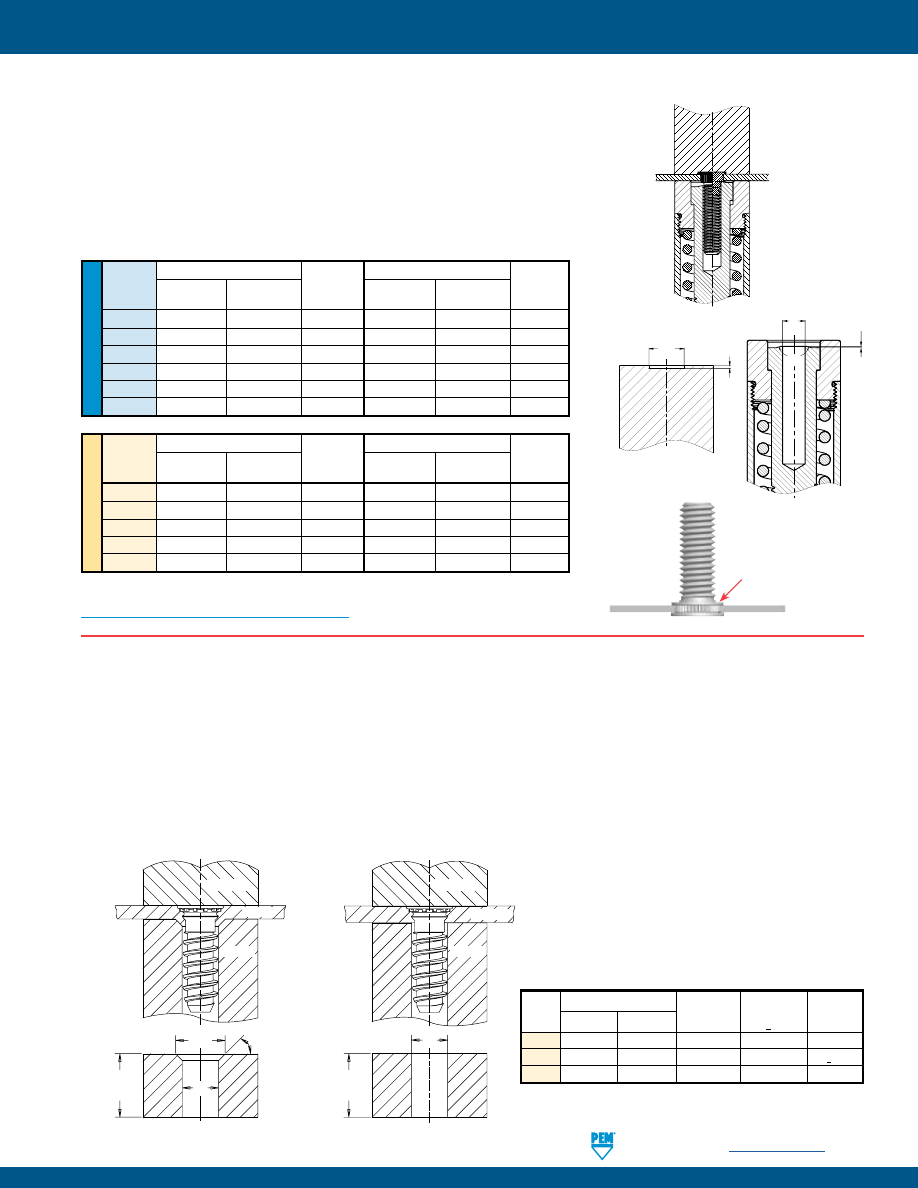

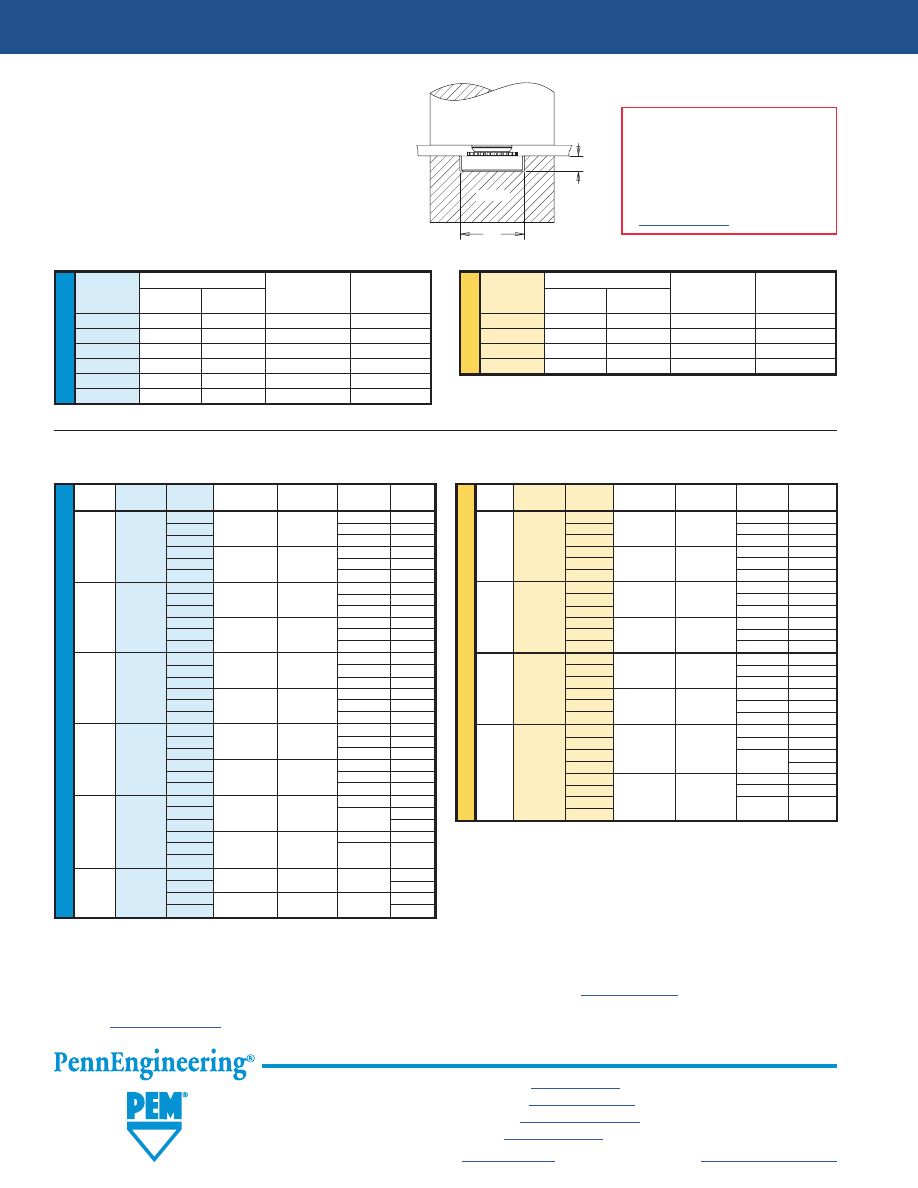

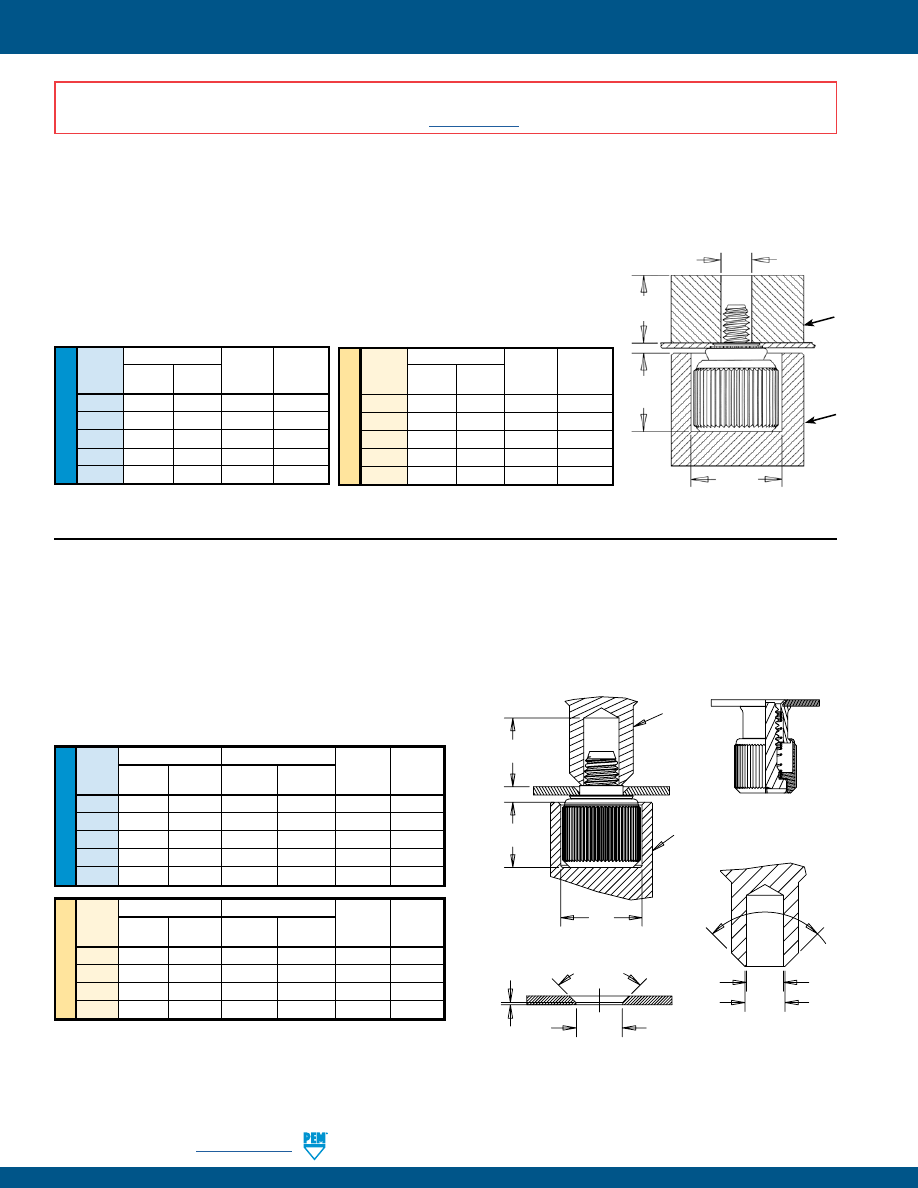

INSTALLATION

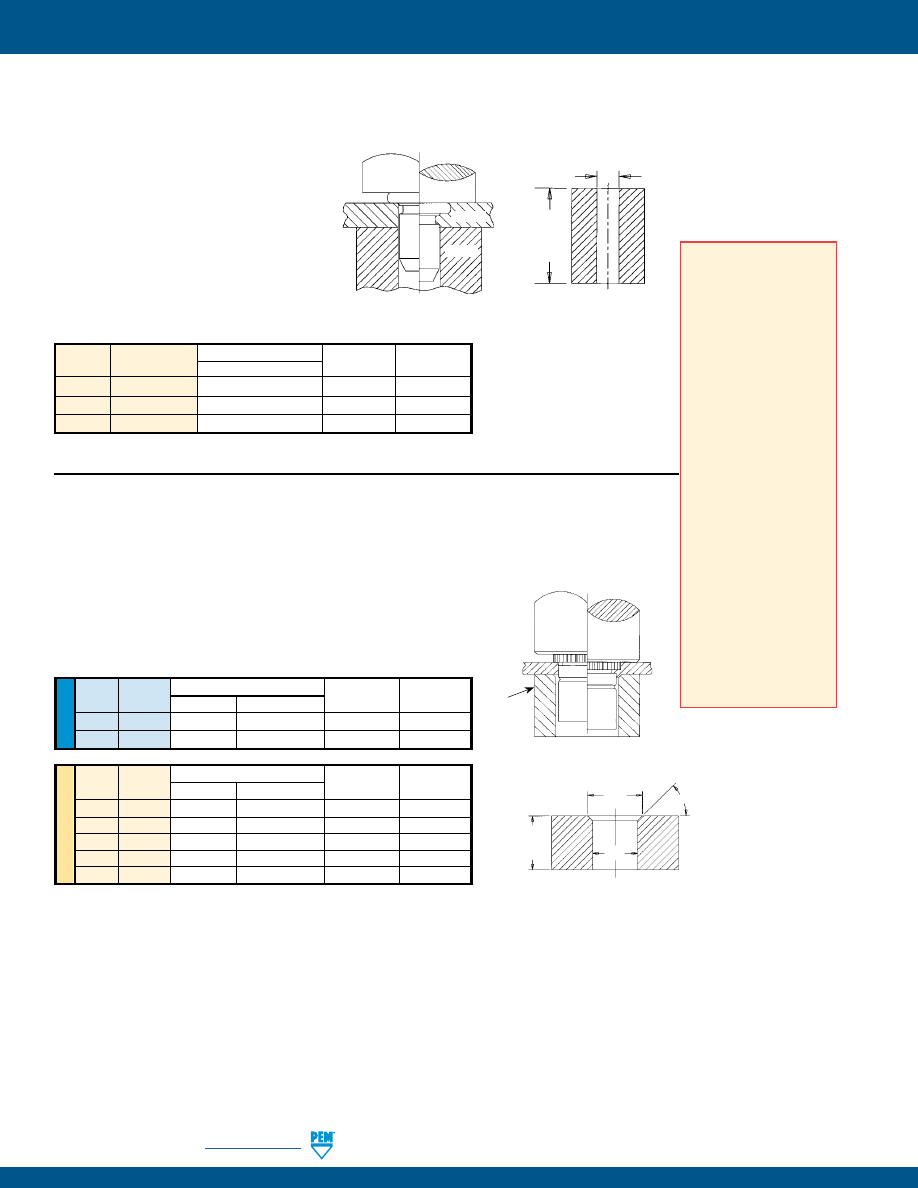

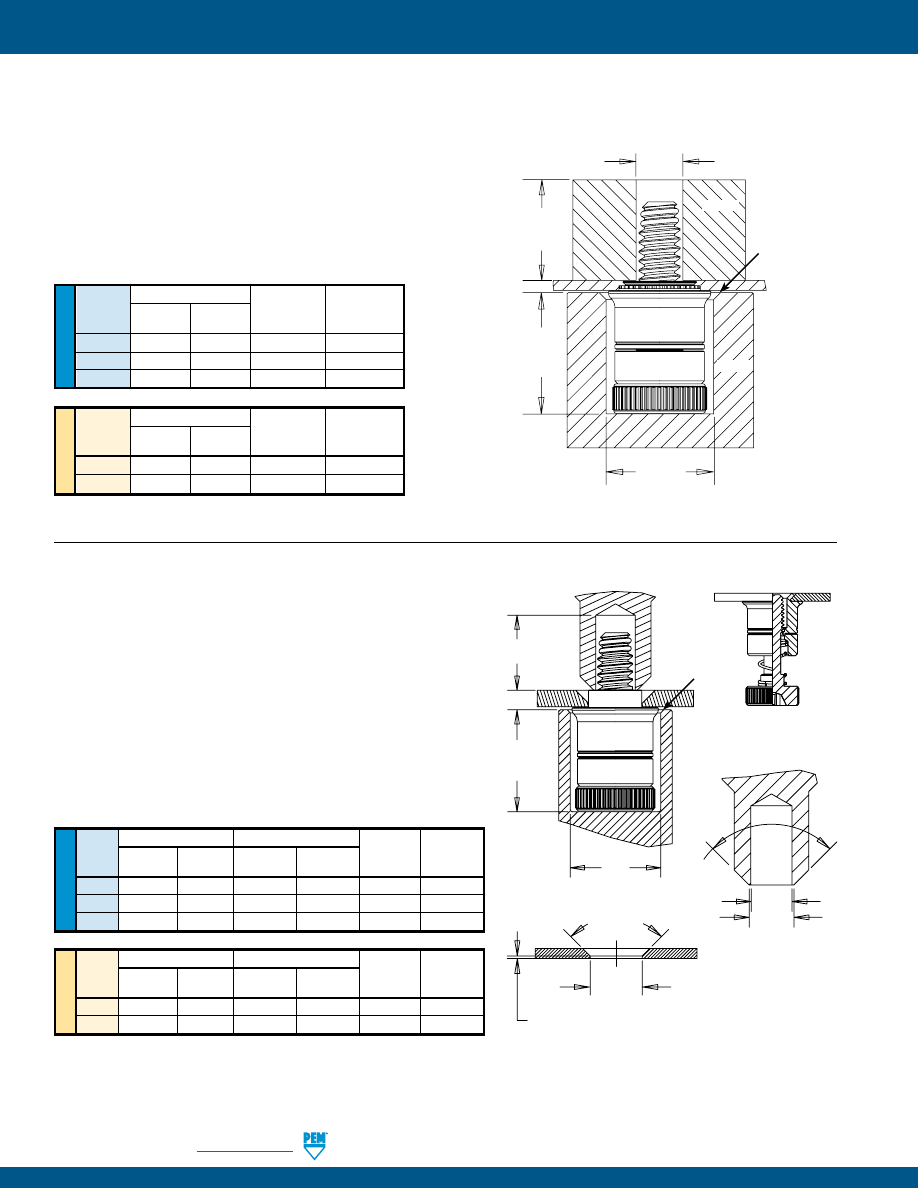

PEMSERTER® Installation Tooling - AC/AS/LAC/LAS/A4/LA4 NUTS

PUNCH

D*

+.002 /+0.05 mm

+.005”/+0.13 mm

E*

+.004” –.000” / +0.1 mm

B

ANVIL

A

* For “D” and “E”,

see page 3.

Counterbore Hole Depth Below Counterbore

Thread A

B

Anvil Part

Punch

Code

±.001

±0.03

±.005

±0.13

Number

Part

440/M3

.054

1.37

.258

6.55

8013889 975200048

632

.054

1.37

.258

6.55

8013890 975200048

832/M4

.054

1.37

.258

6.55

8013891 975200048

032/M5

.071

1.8

.241

6.12

8013892 975200048

0420/M6

.092

2.34

.220

5.59

8021392

8012030

(3) Specifically designed for installation into

stainless steel.

FLOATING SELF-CLINCHING FASTENERS

INSTALLATION NOTES

•

For best results we recommend using a PEMSERTER® press for

installation of PEM self-clinching fasteners. Please check our

website for more information.

•

Visit the Animation Library on our website to view the installation

process

for select products

.

pem-html.html

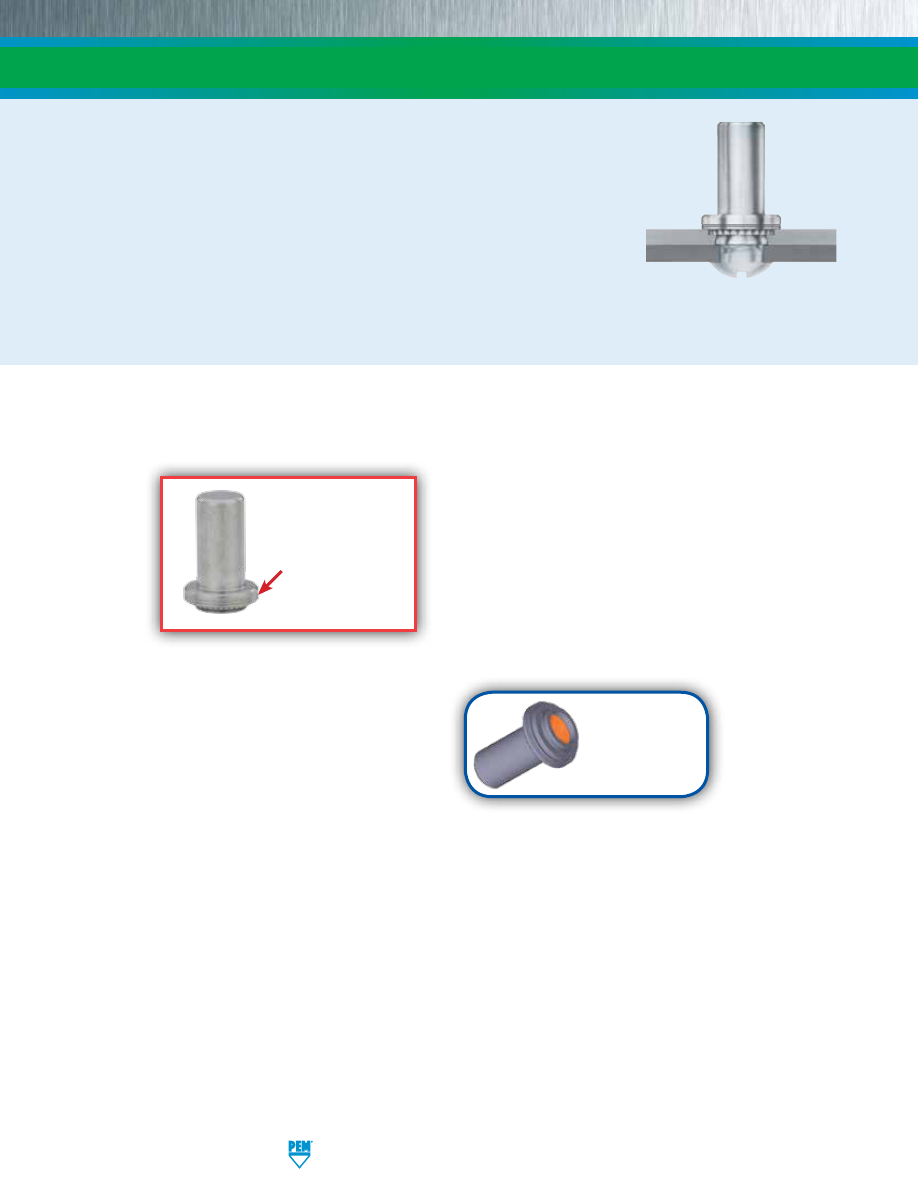

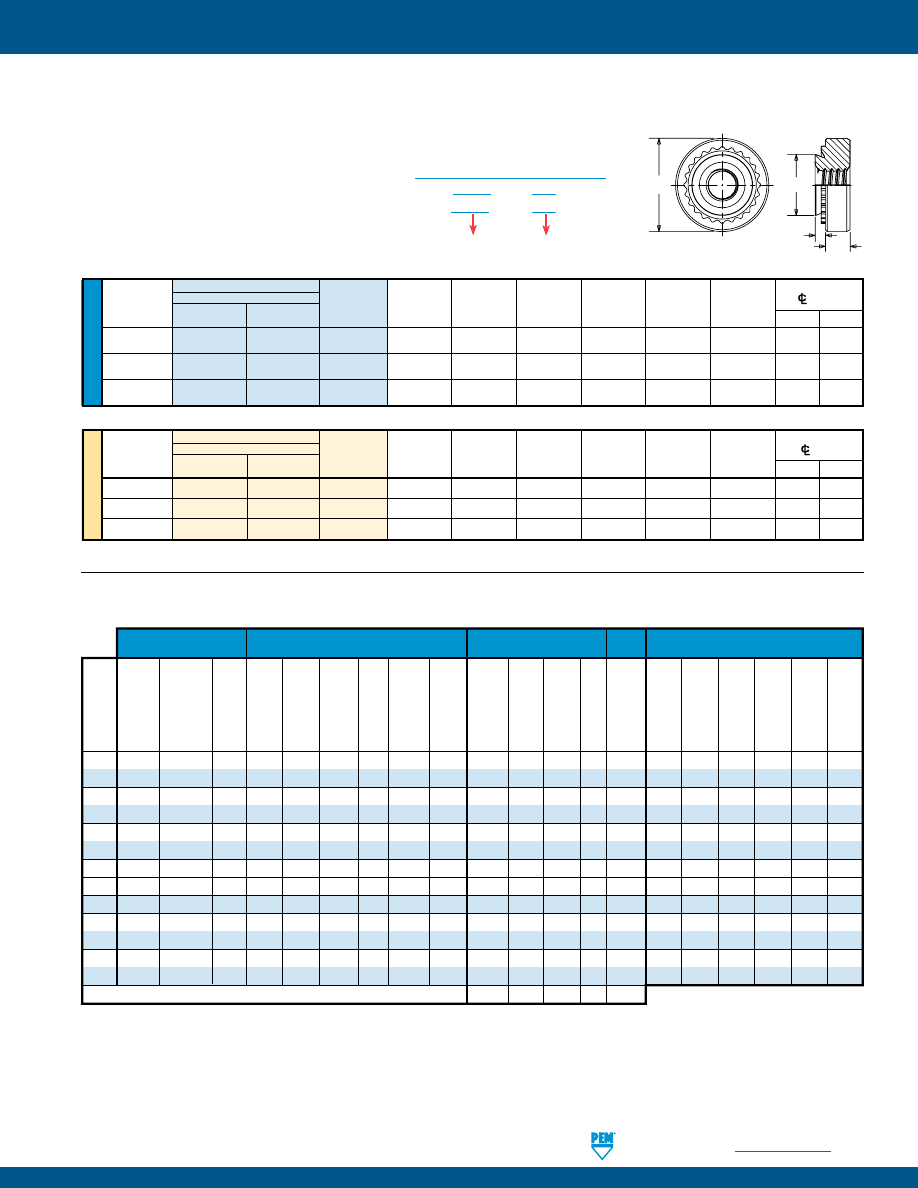

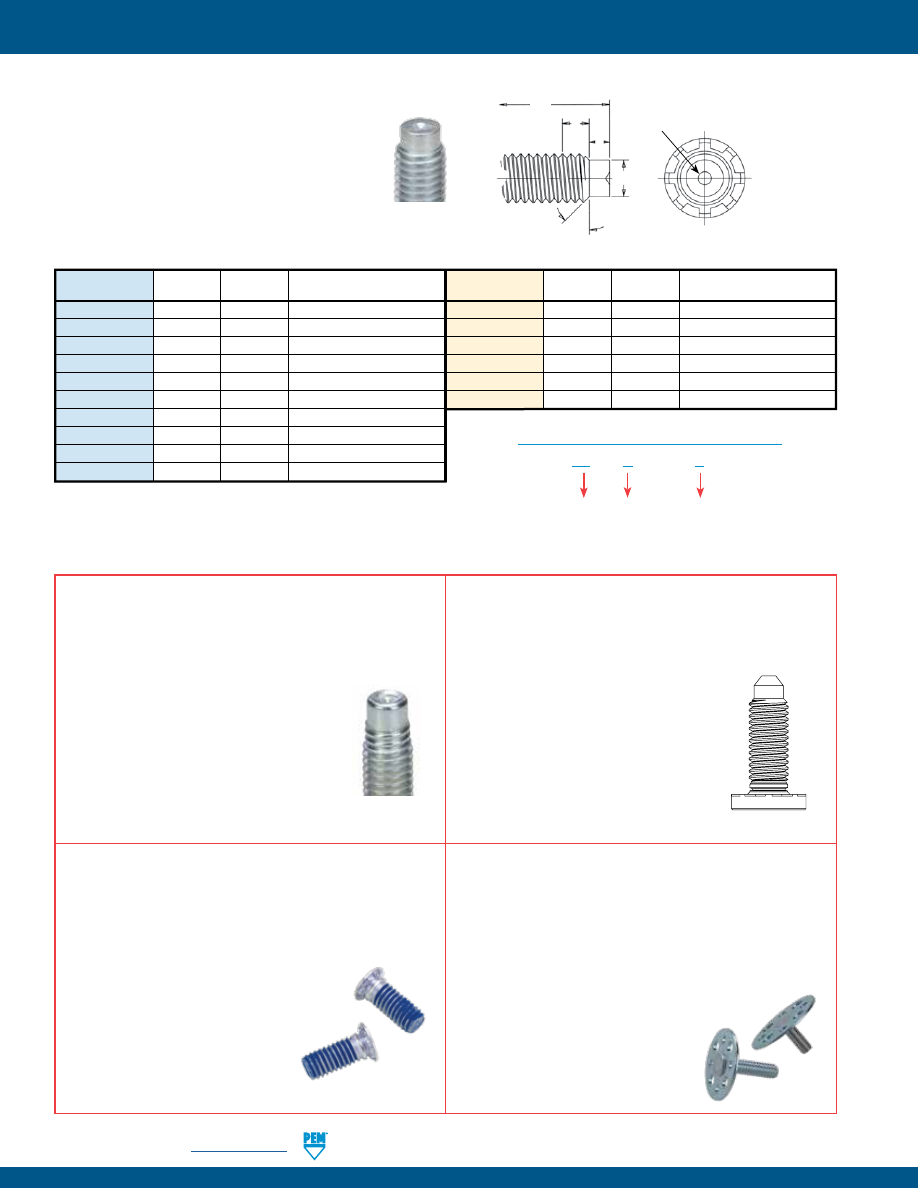

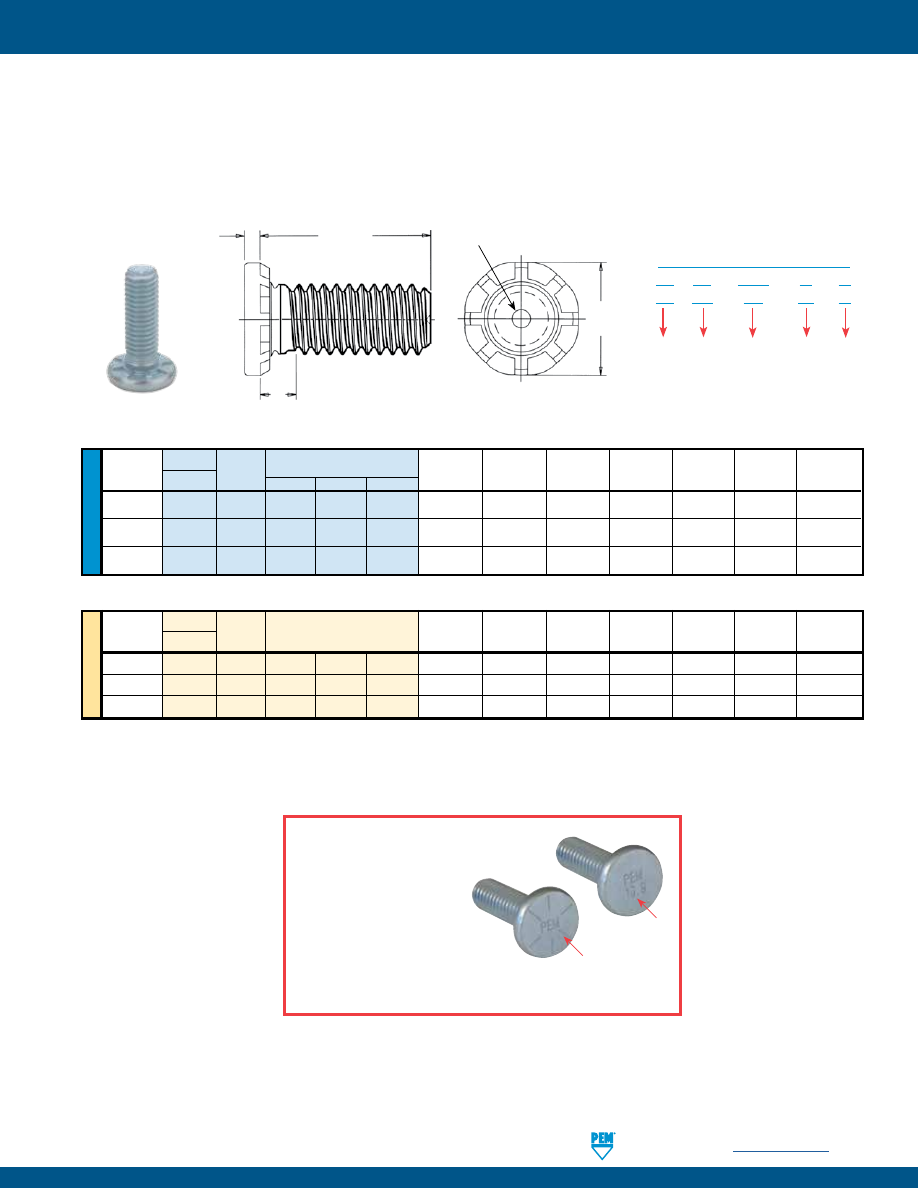

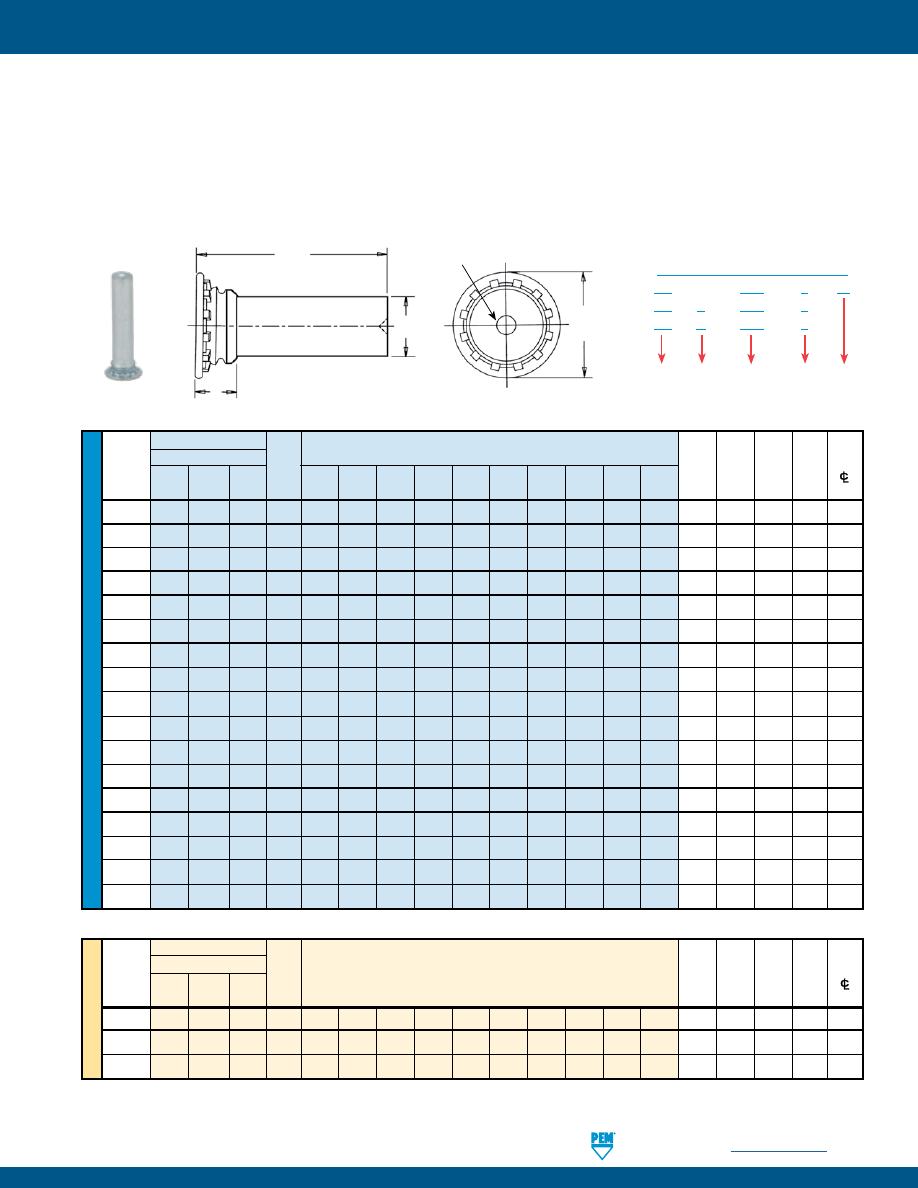

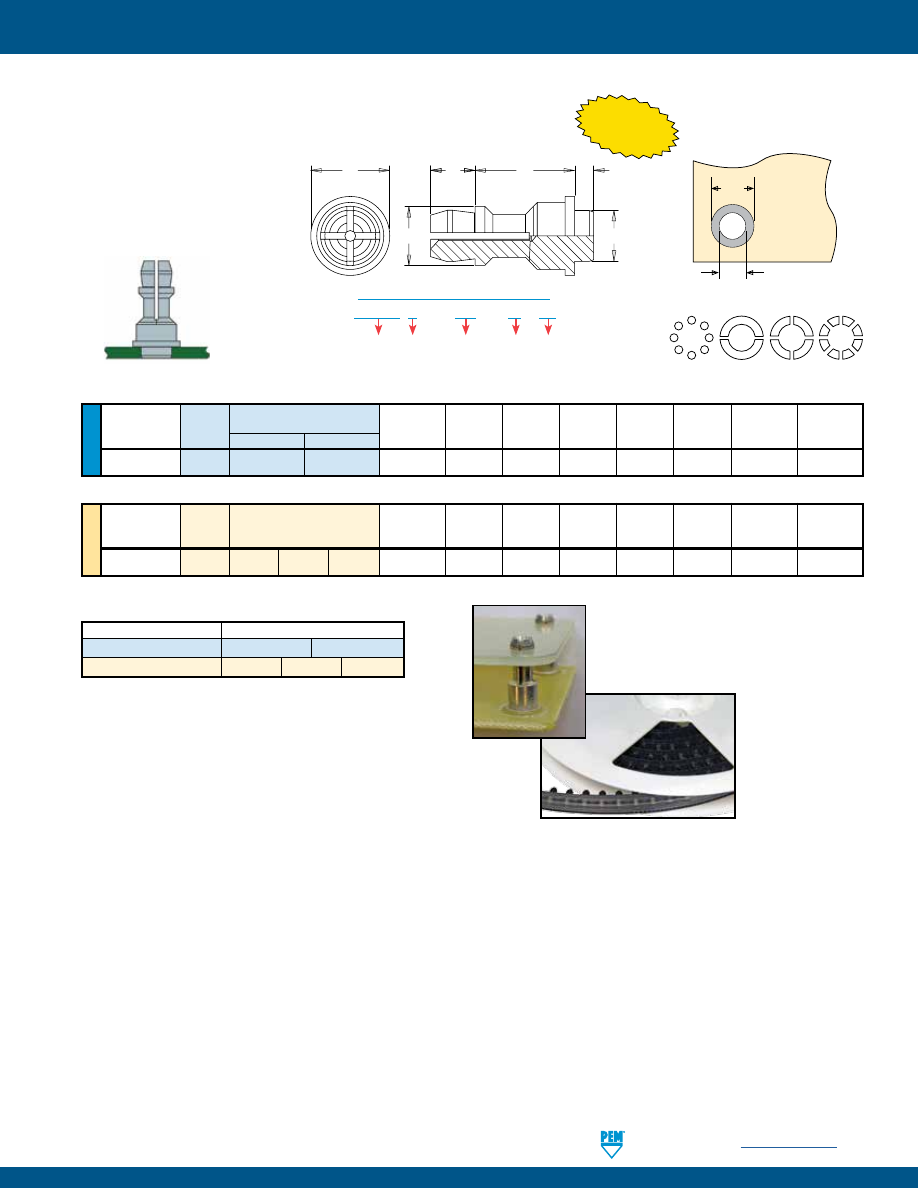

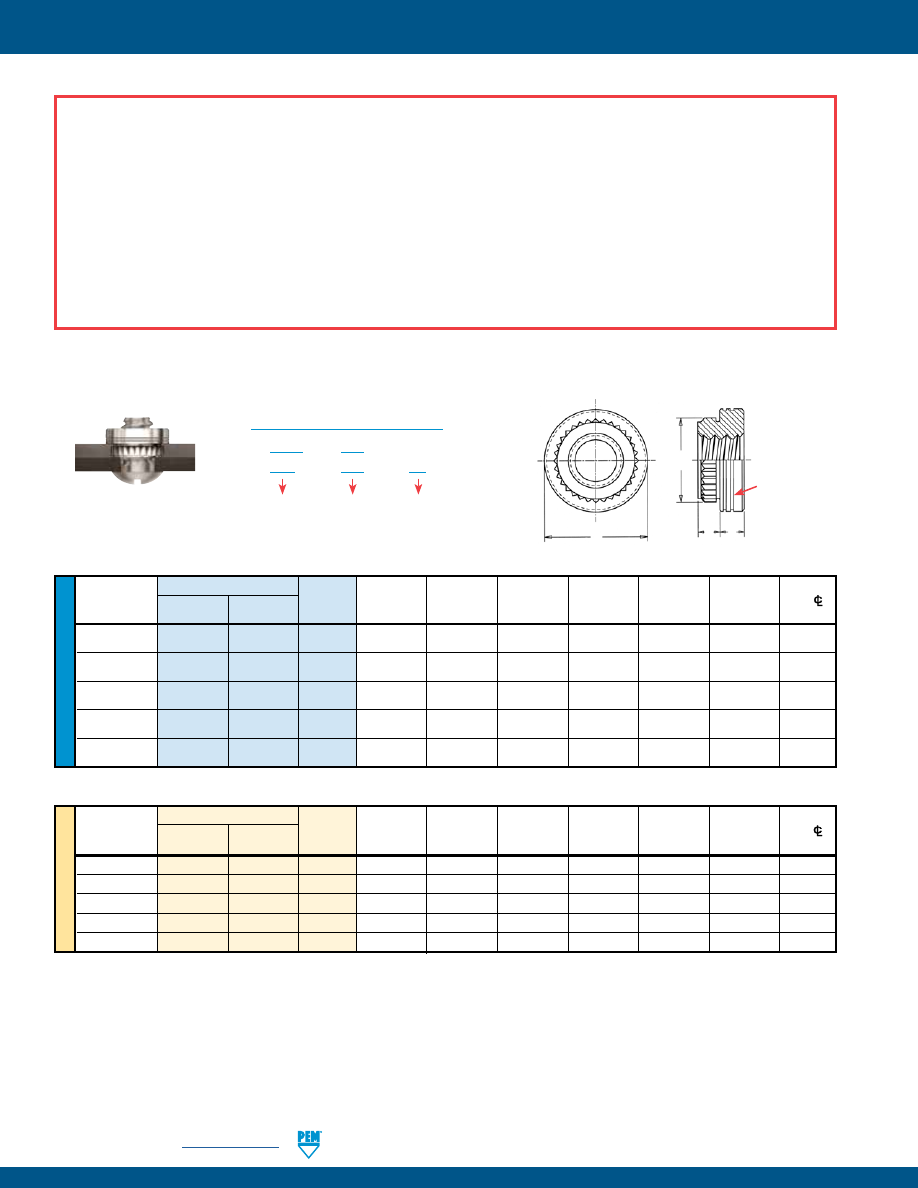

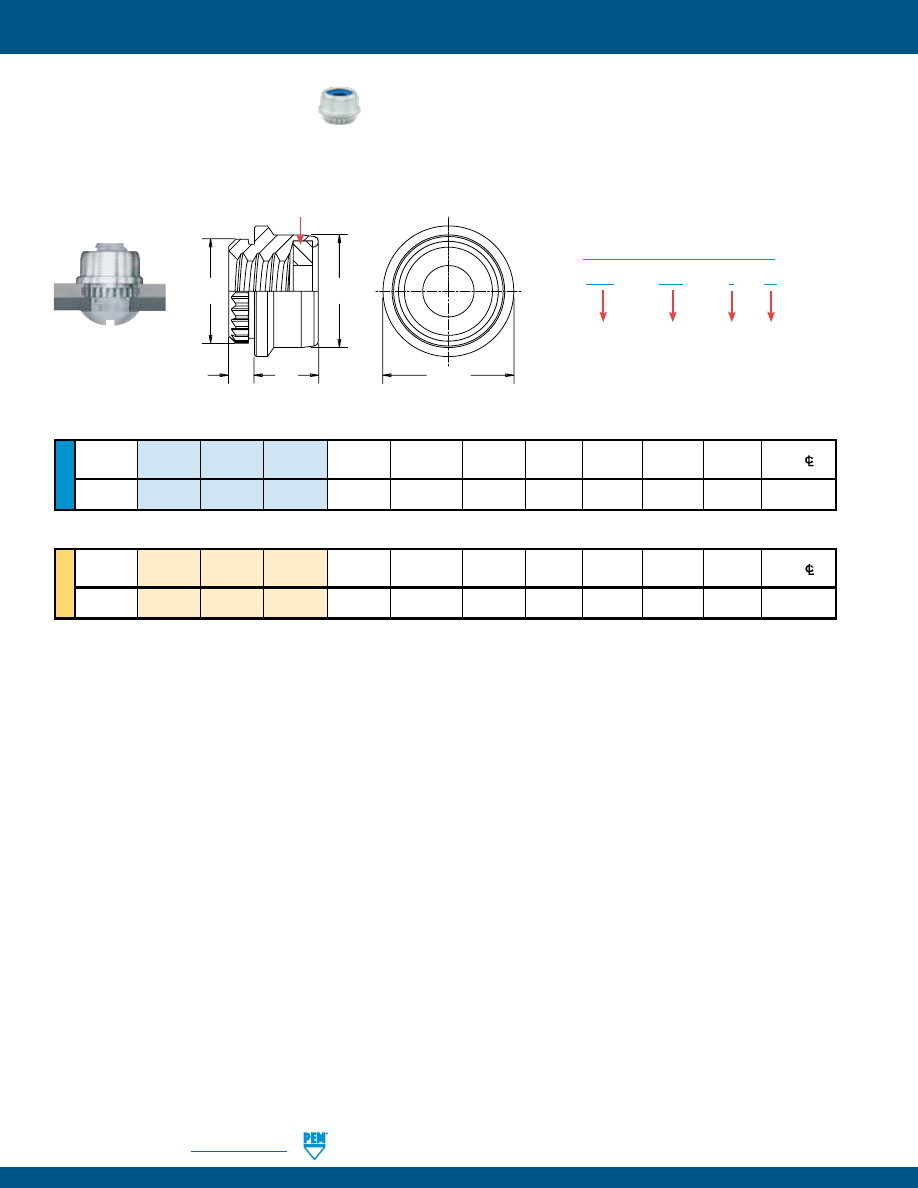

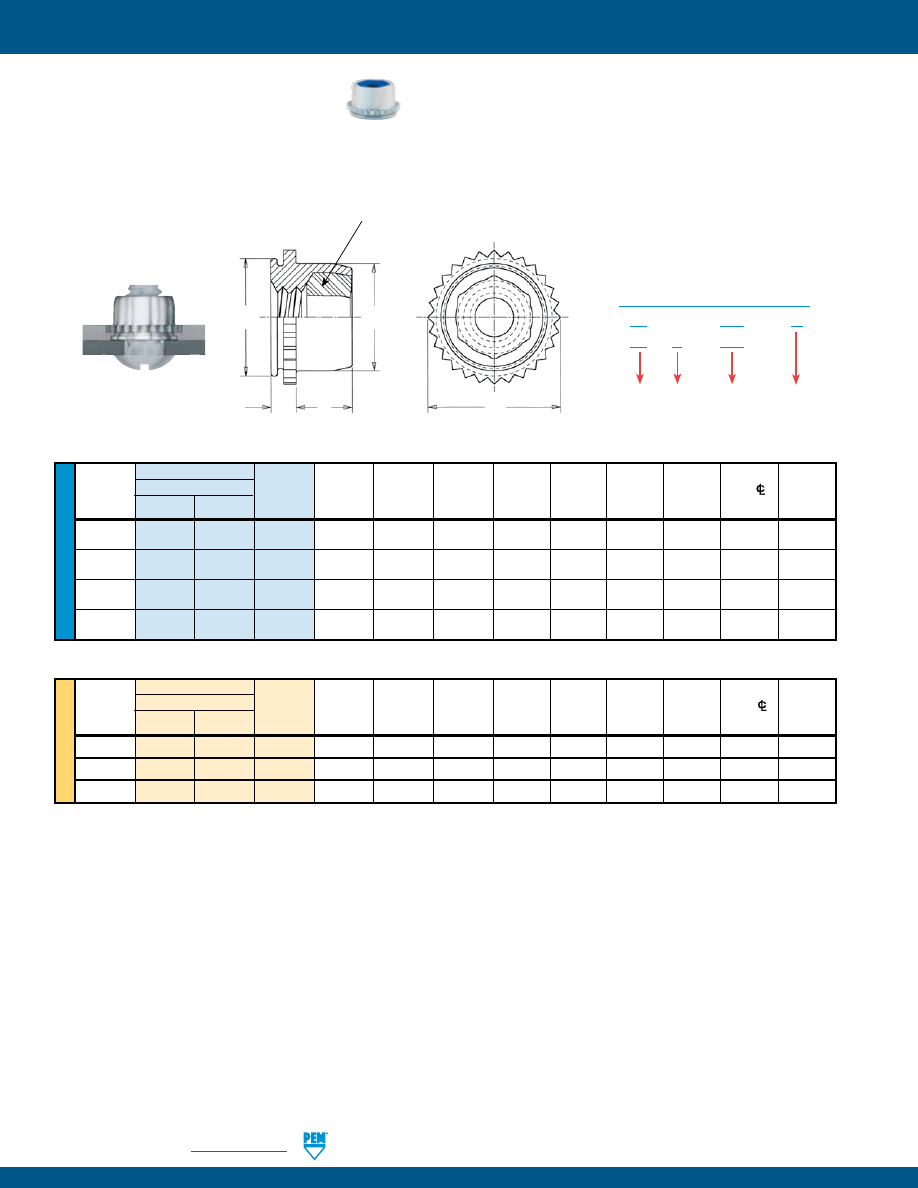

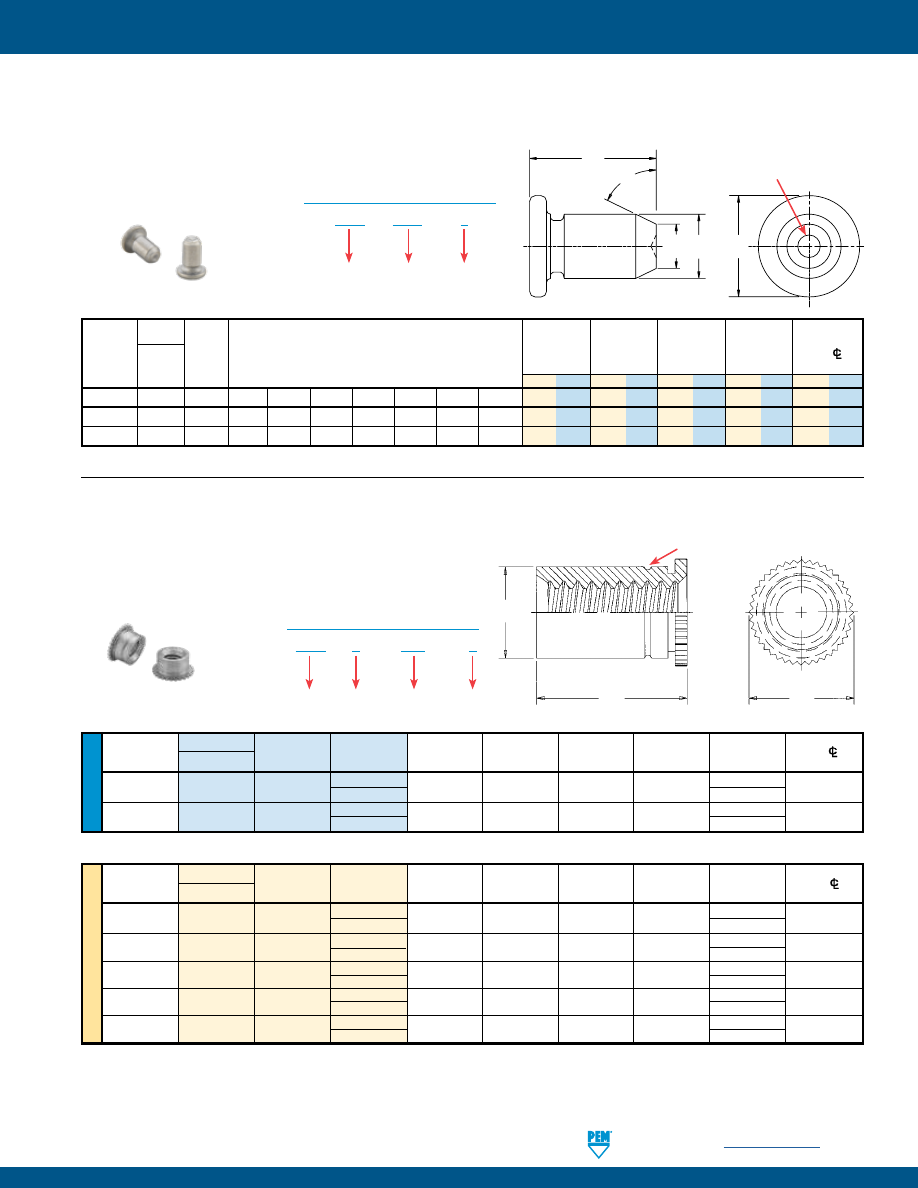

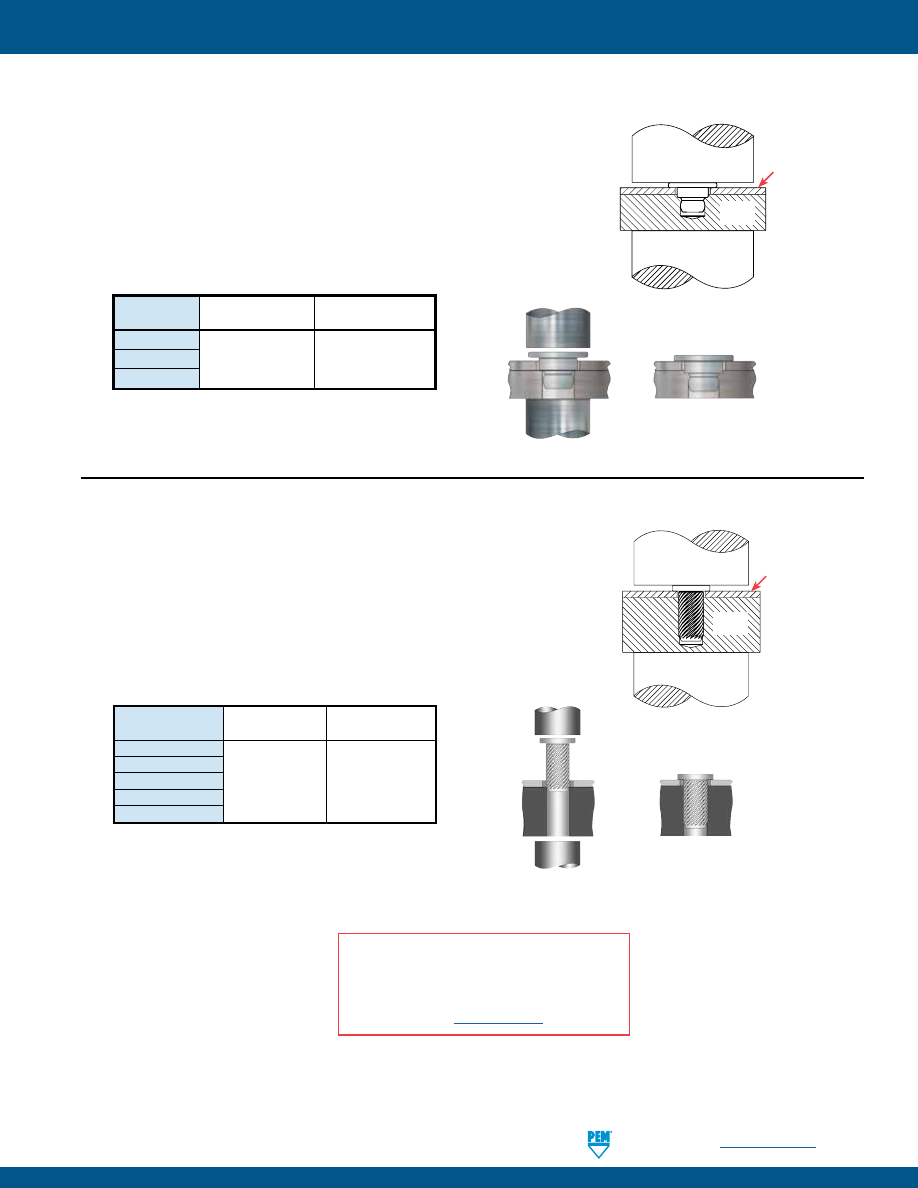

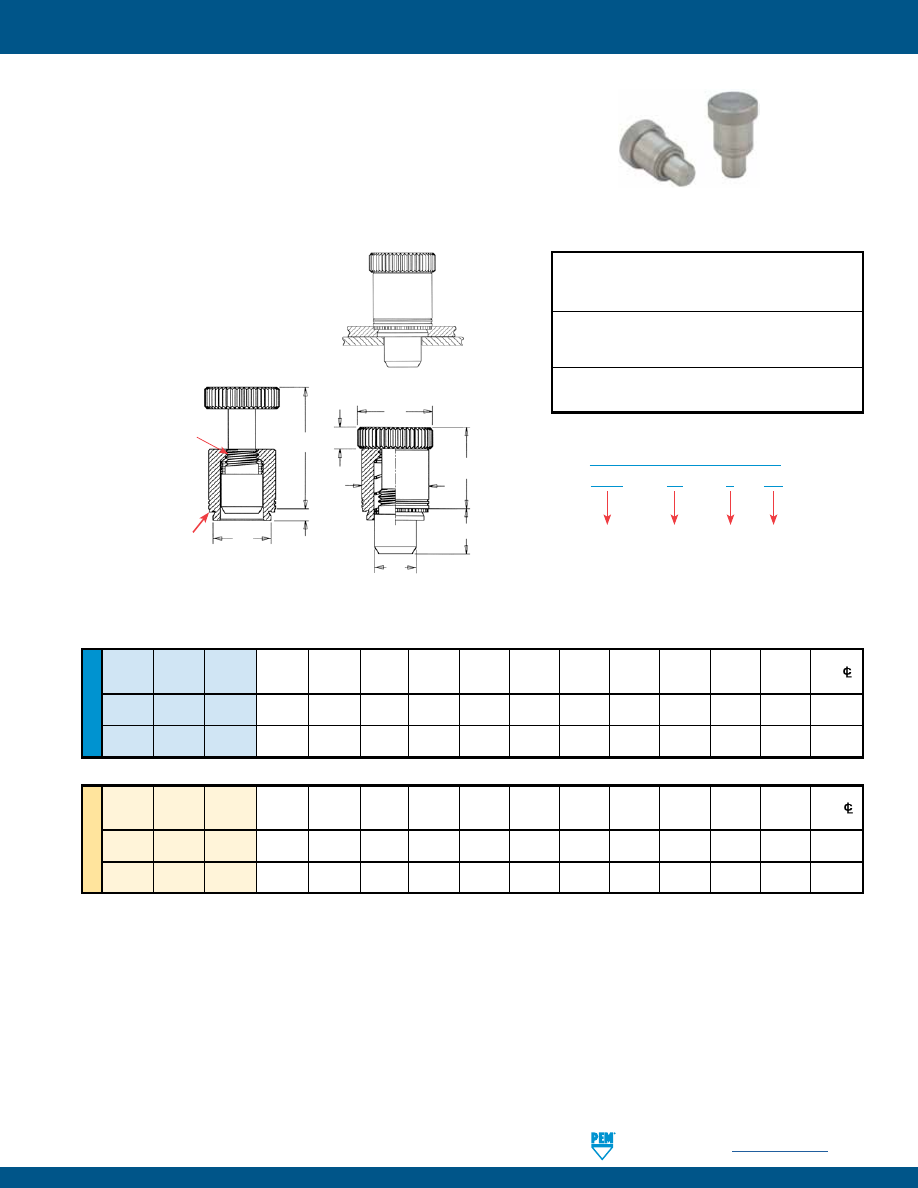

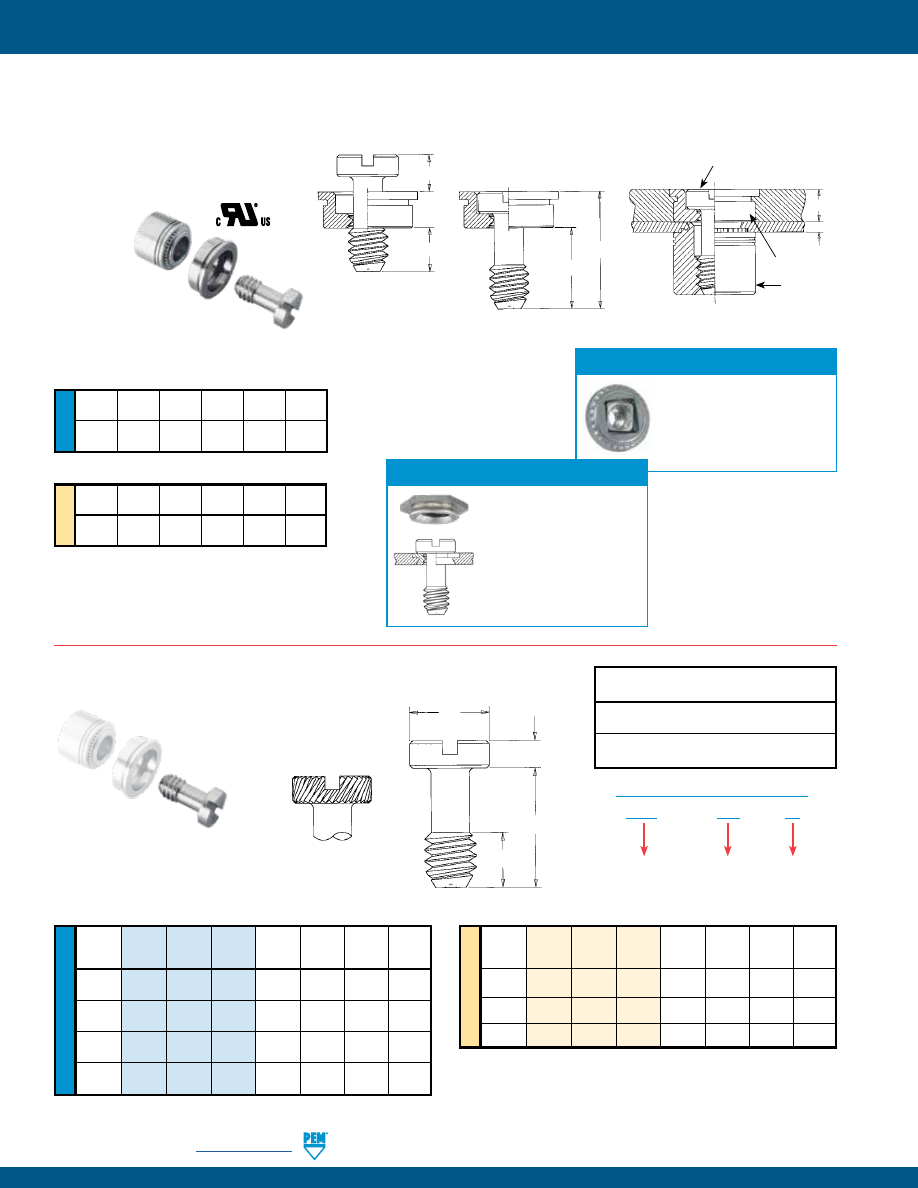

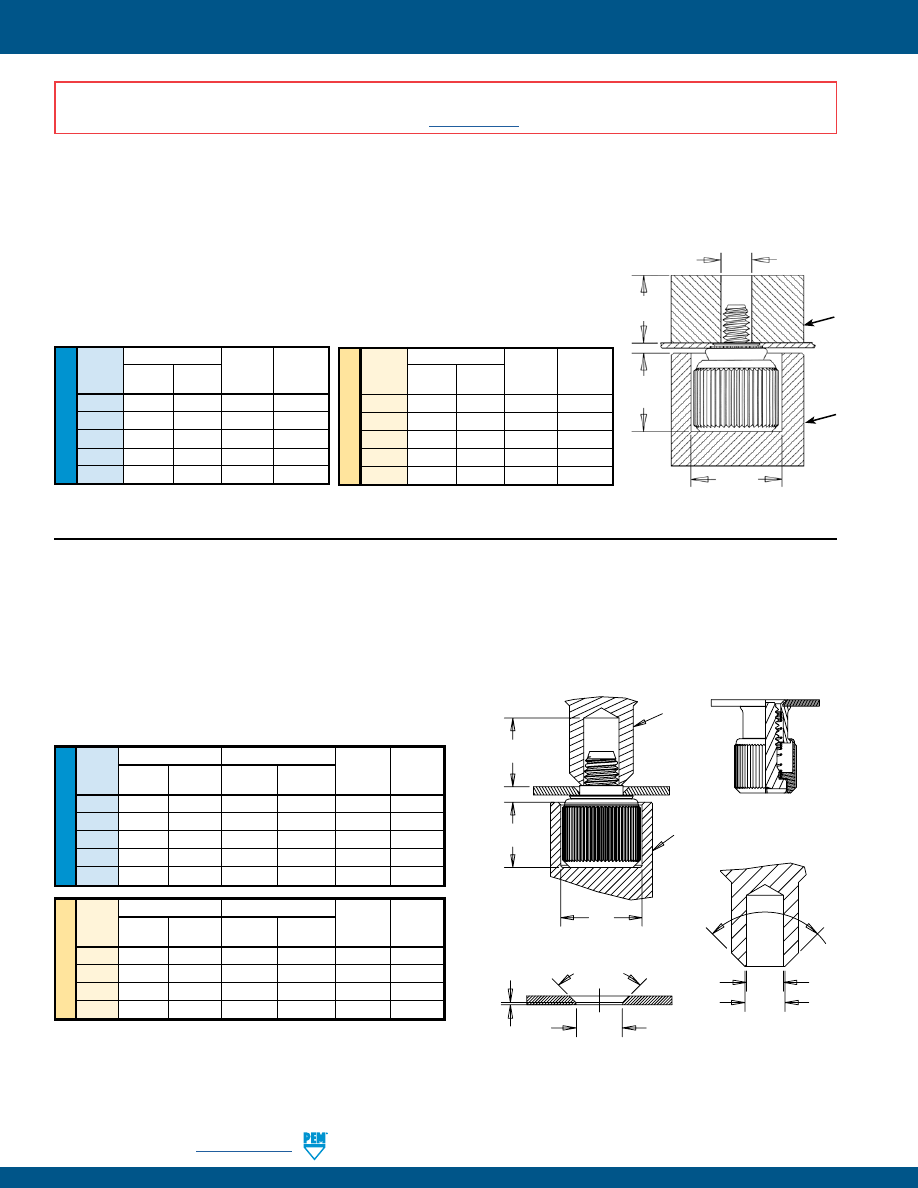

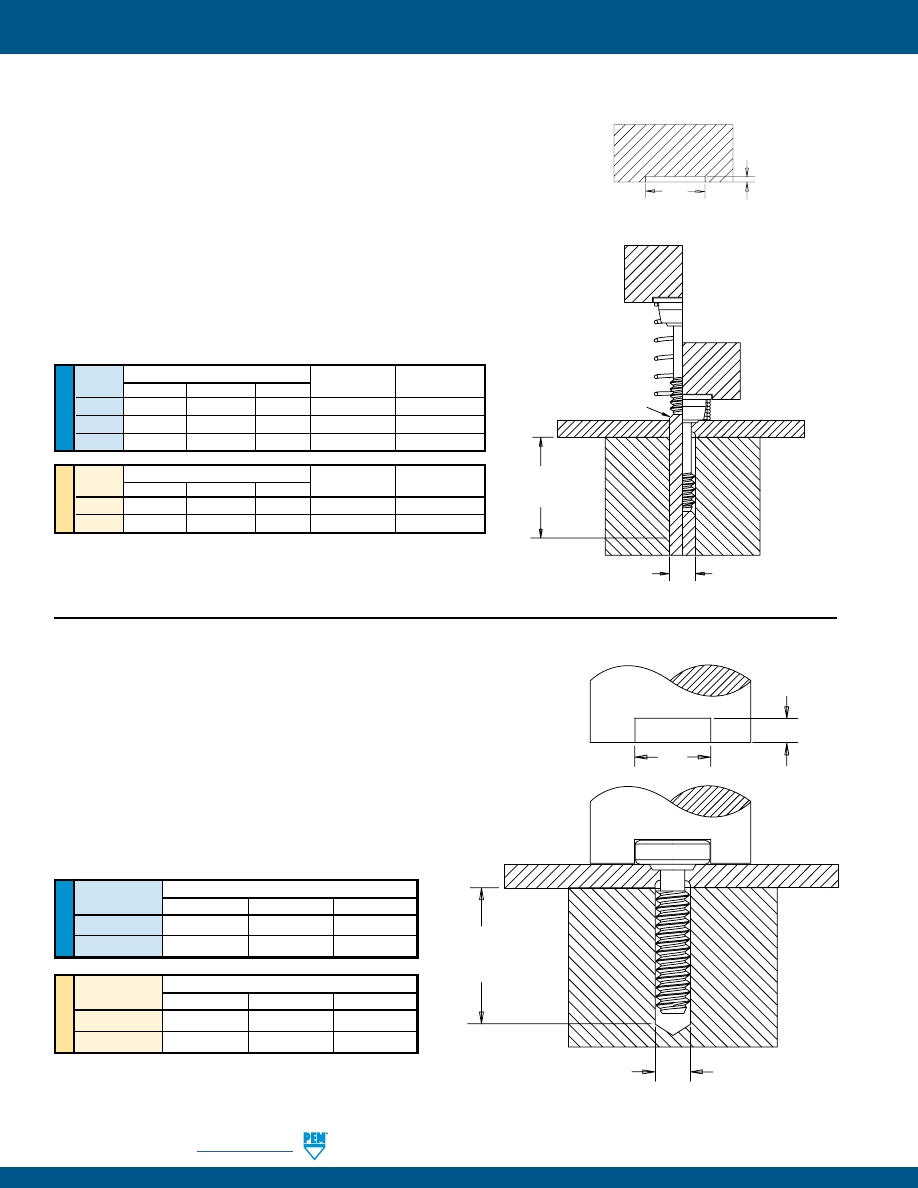

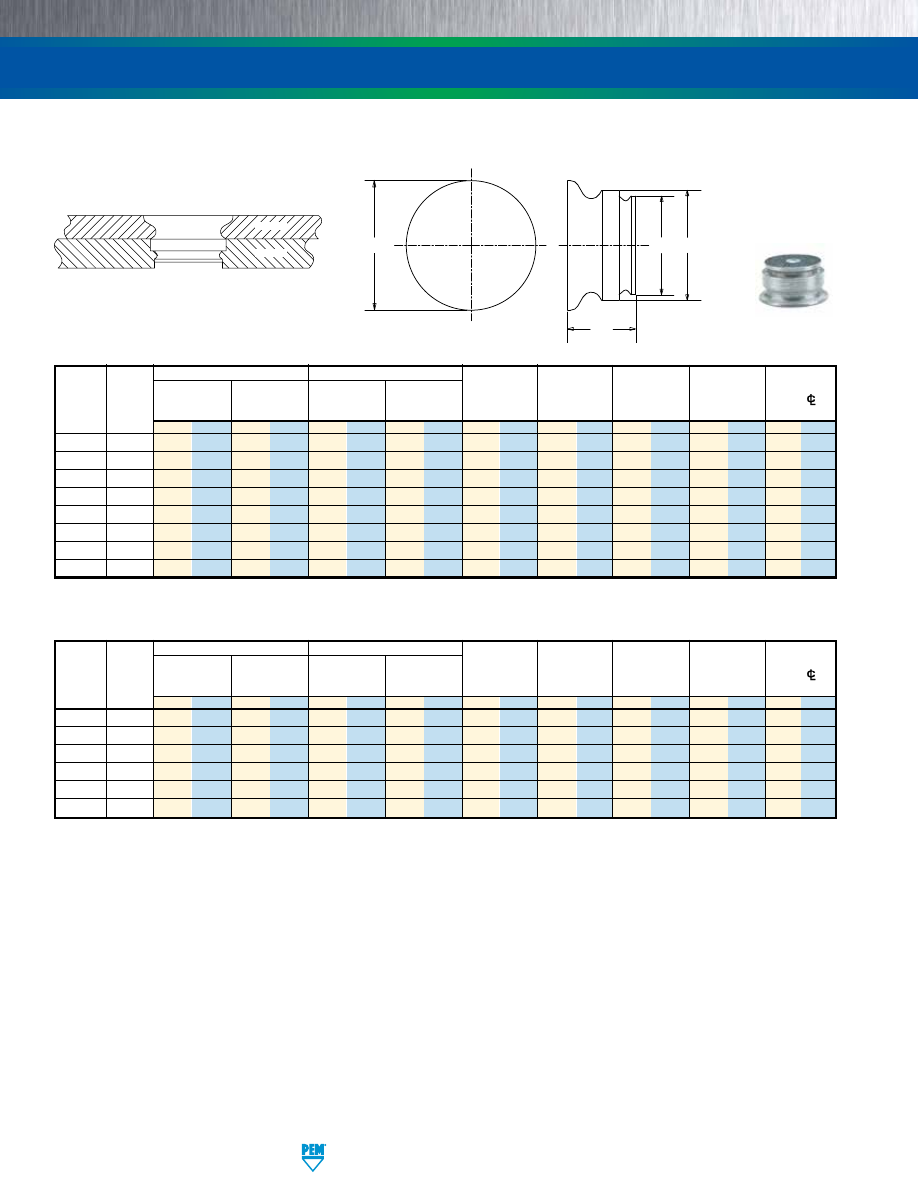

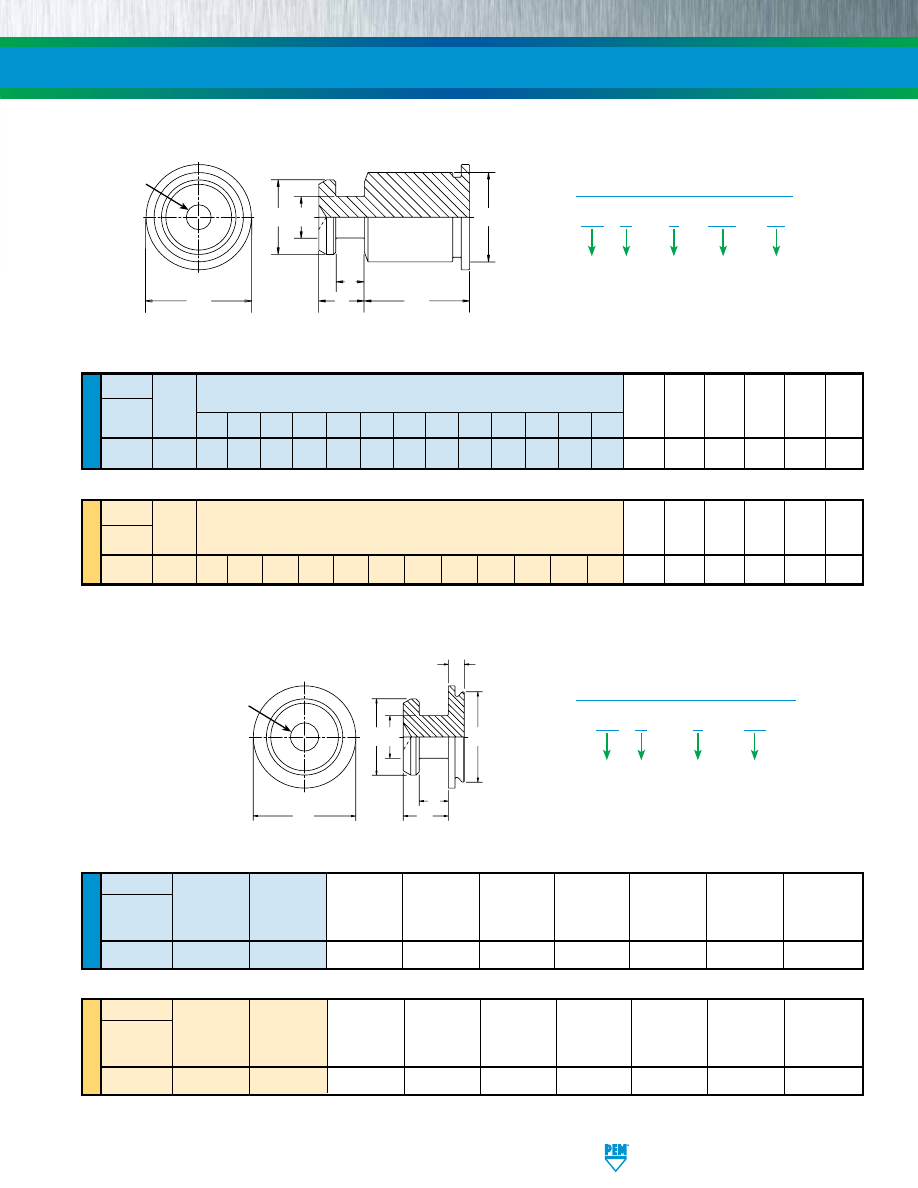

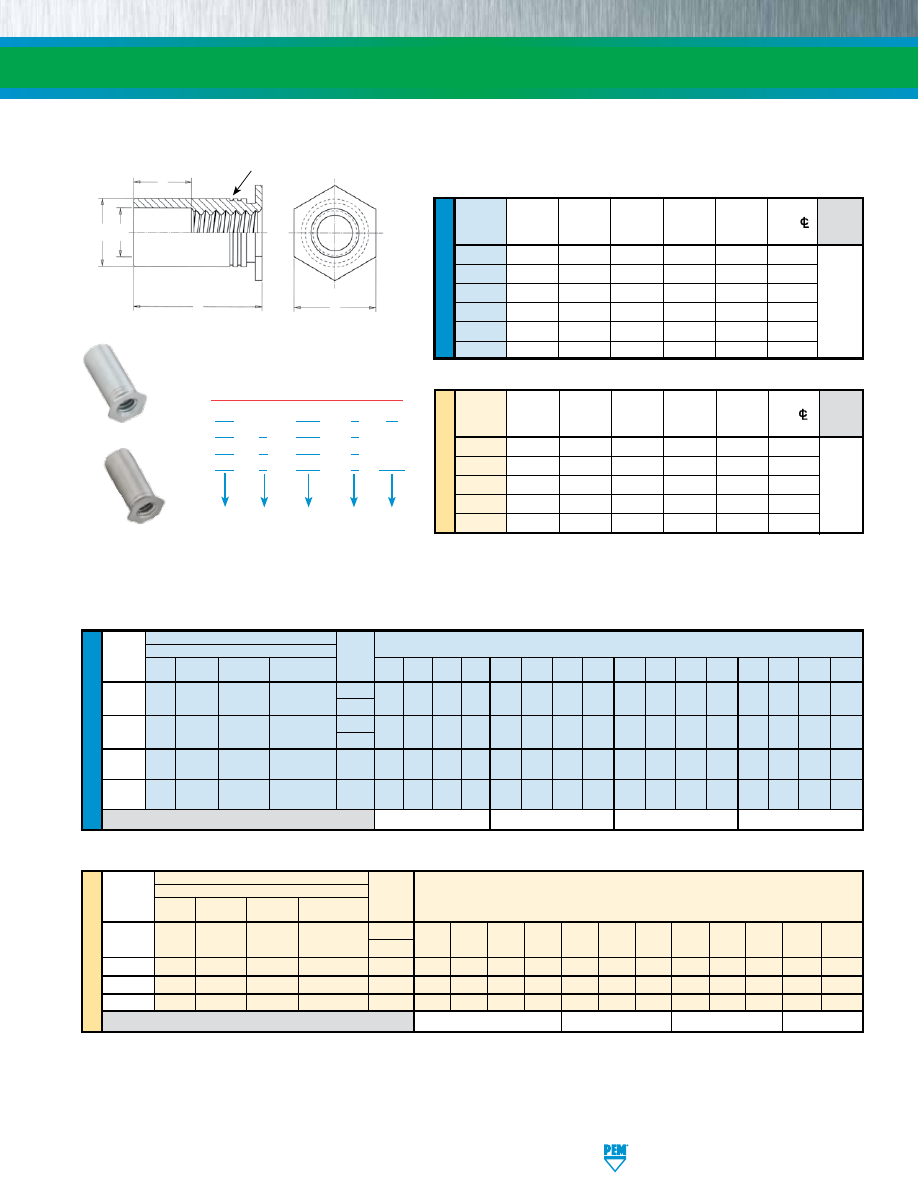

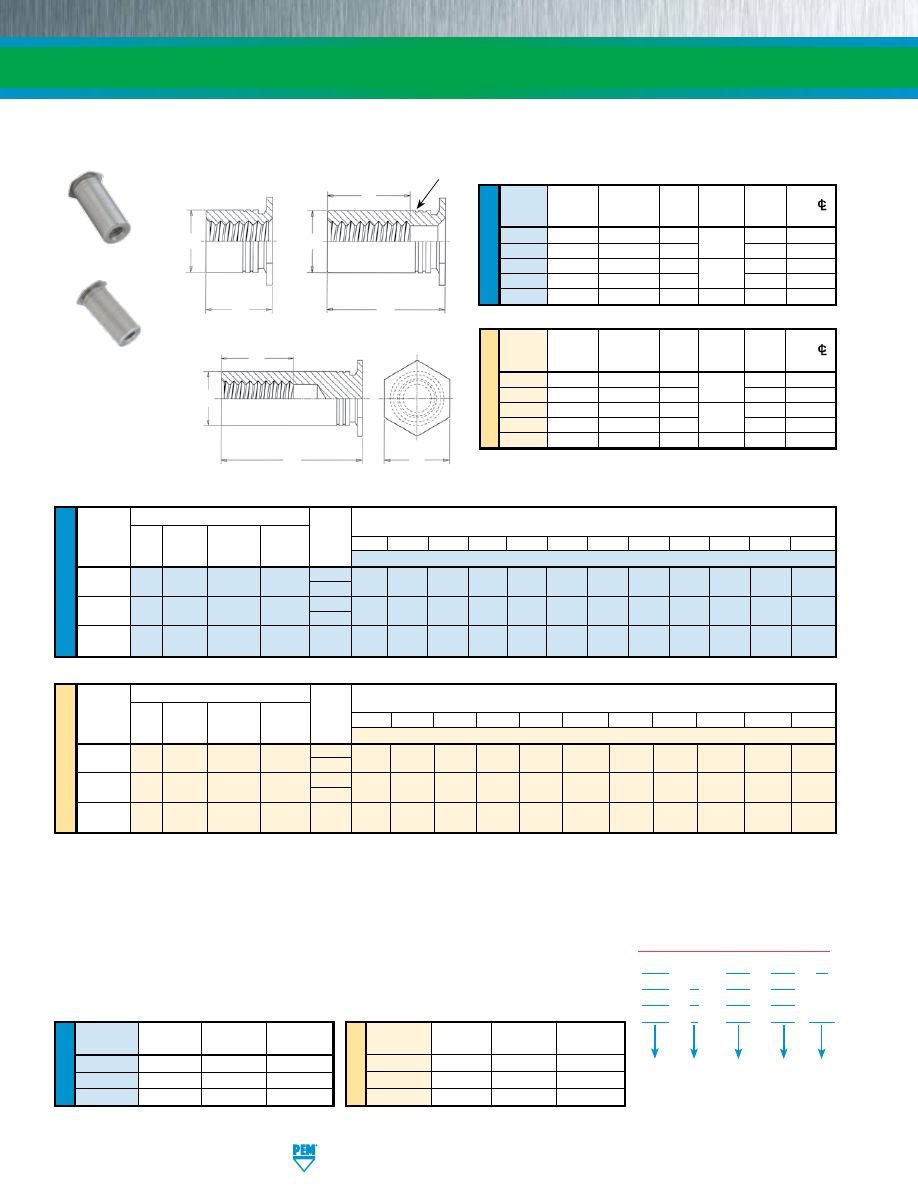

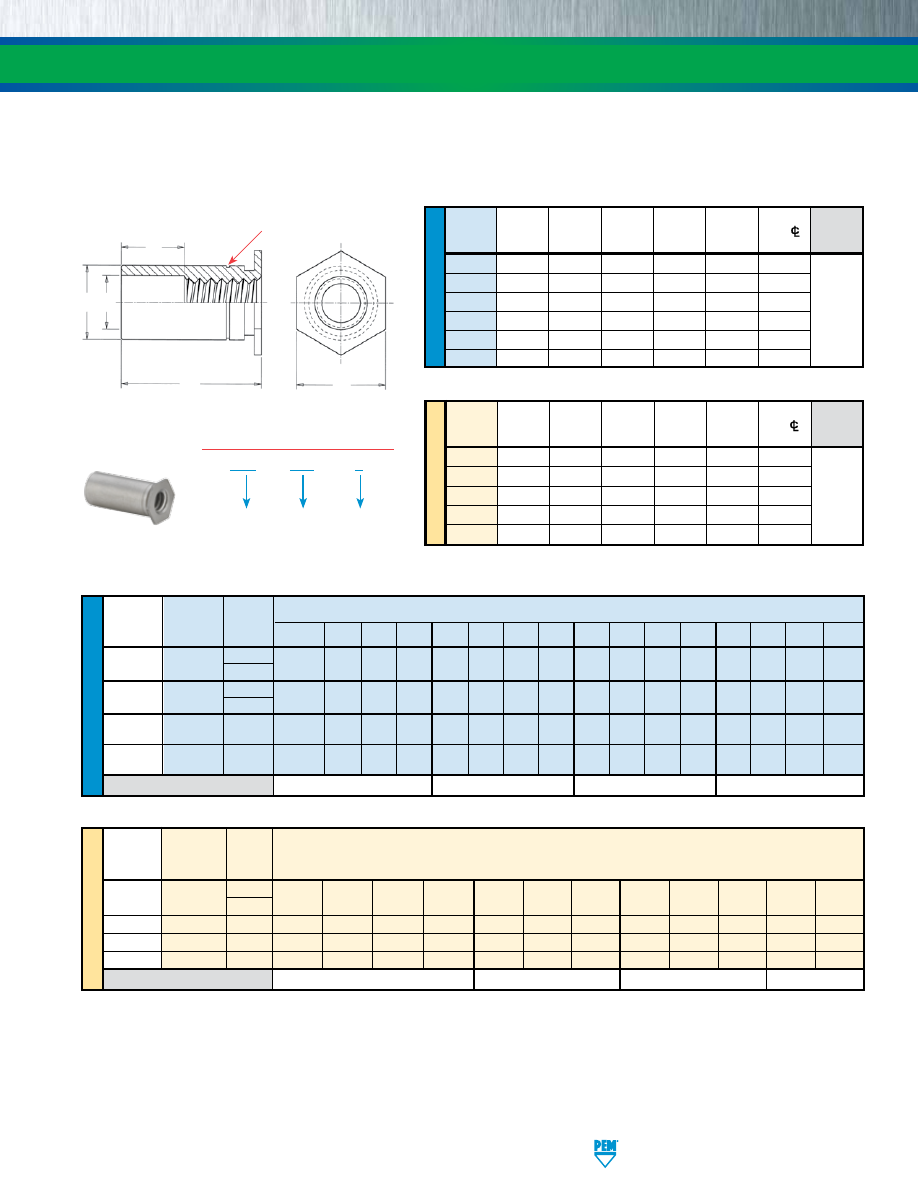

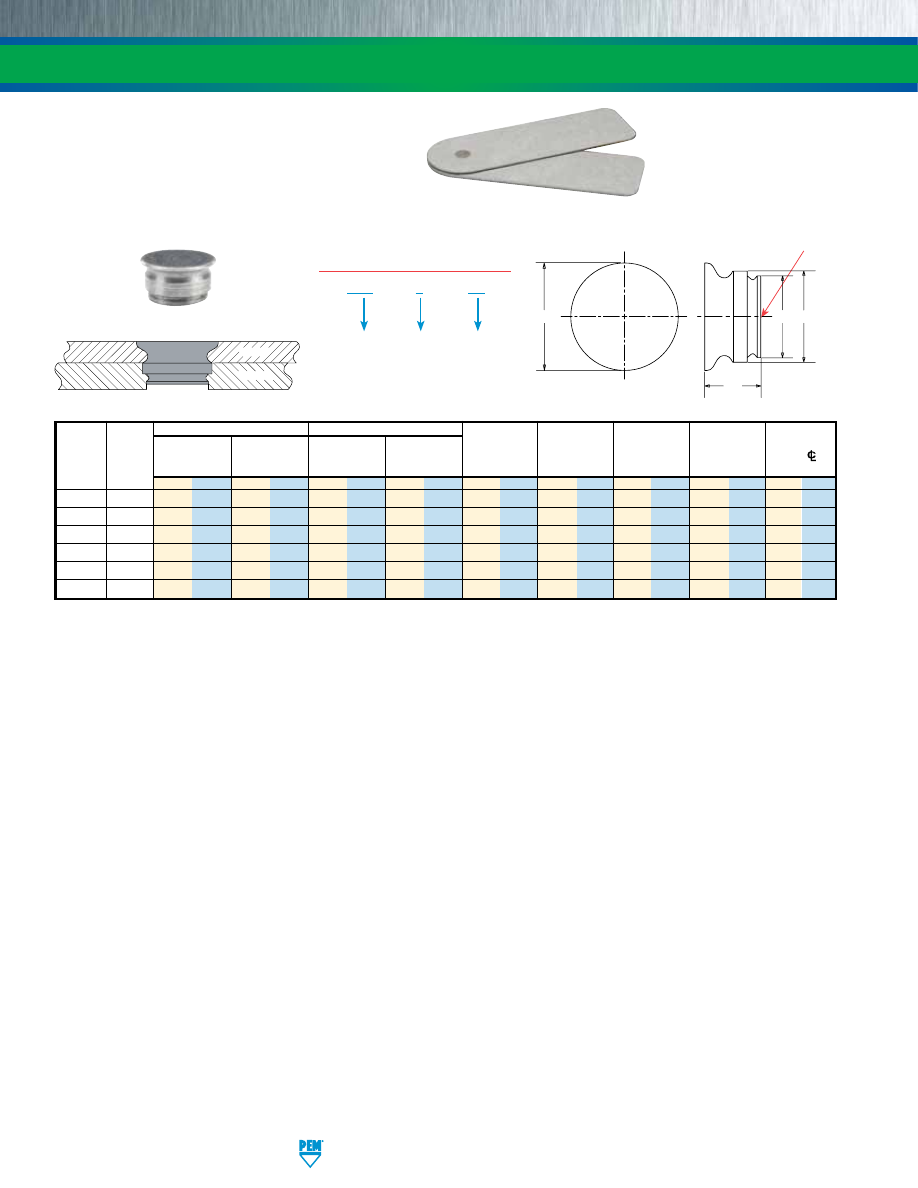

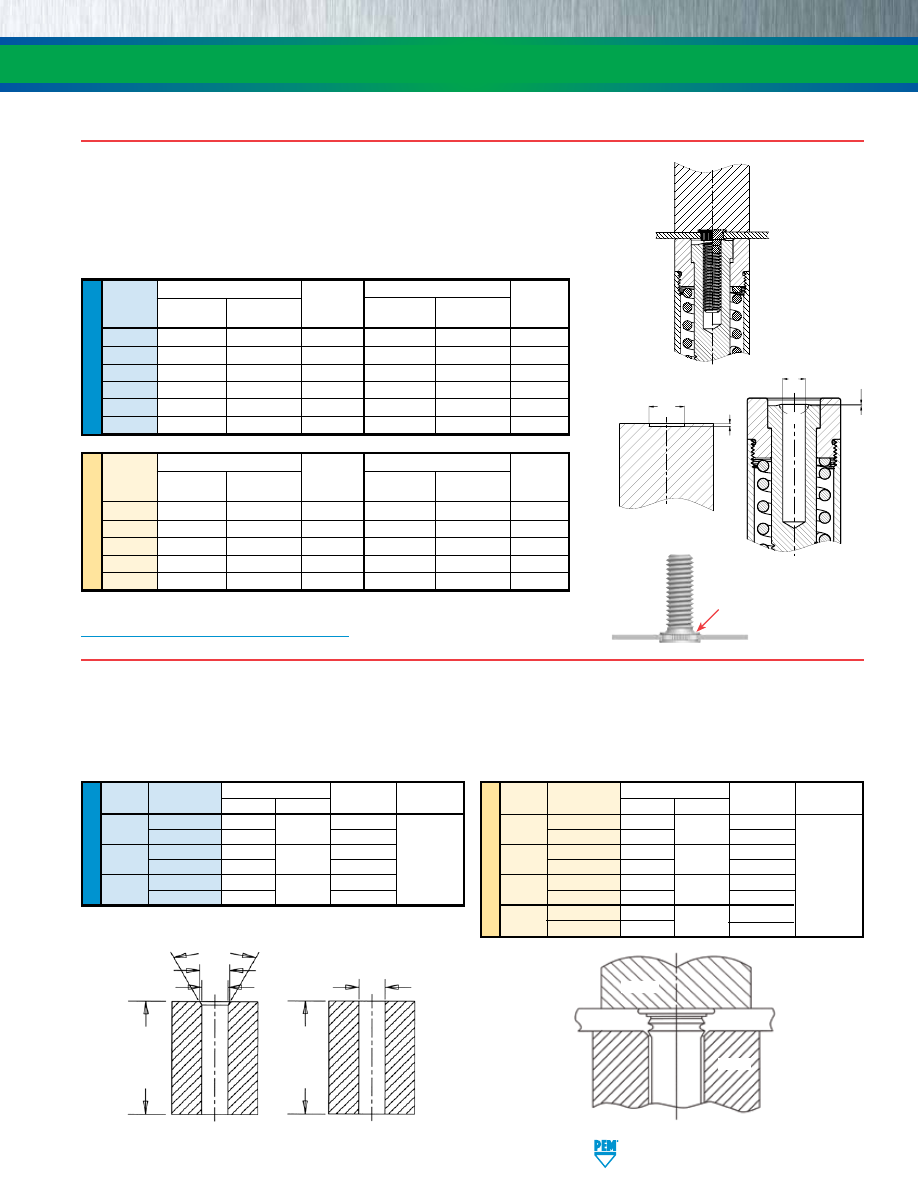

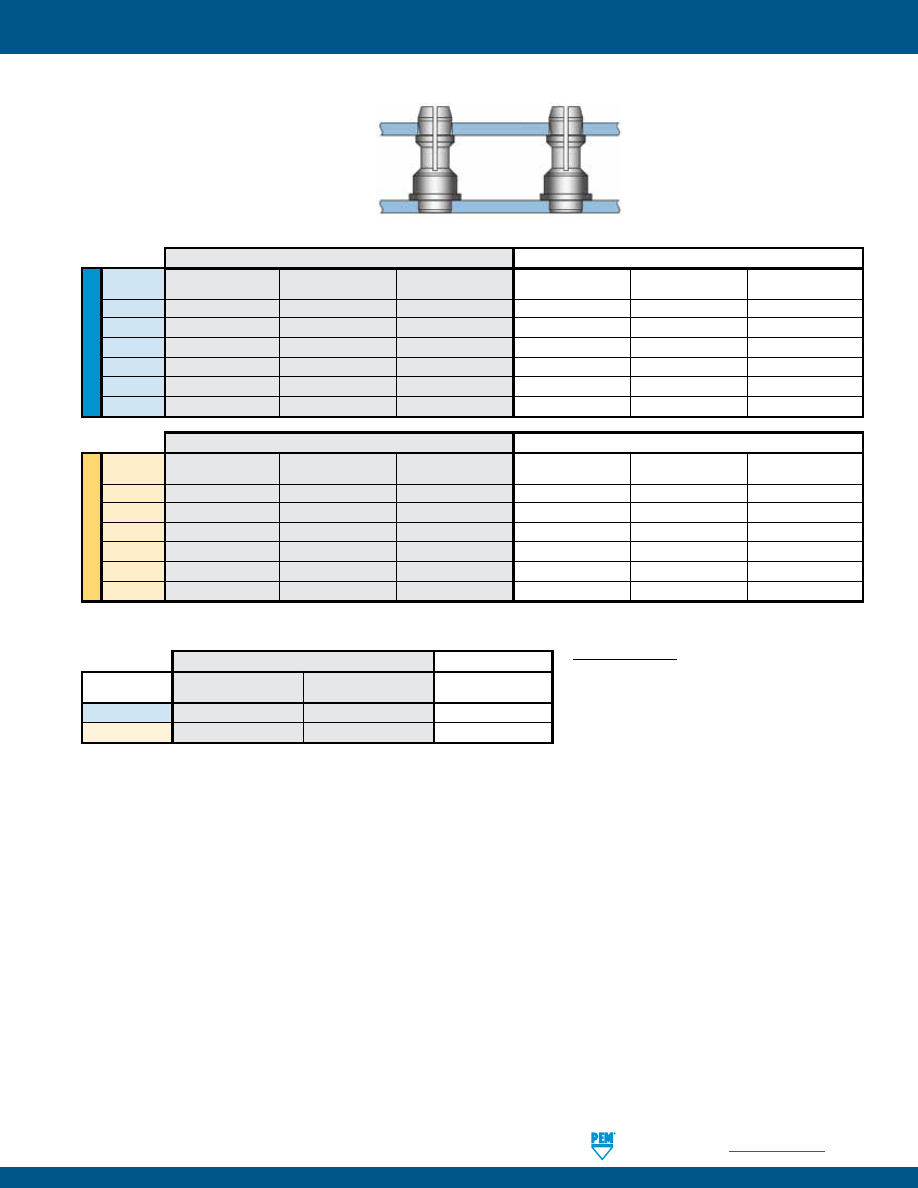

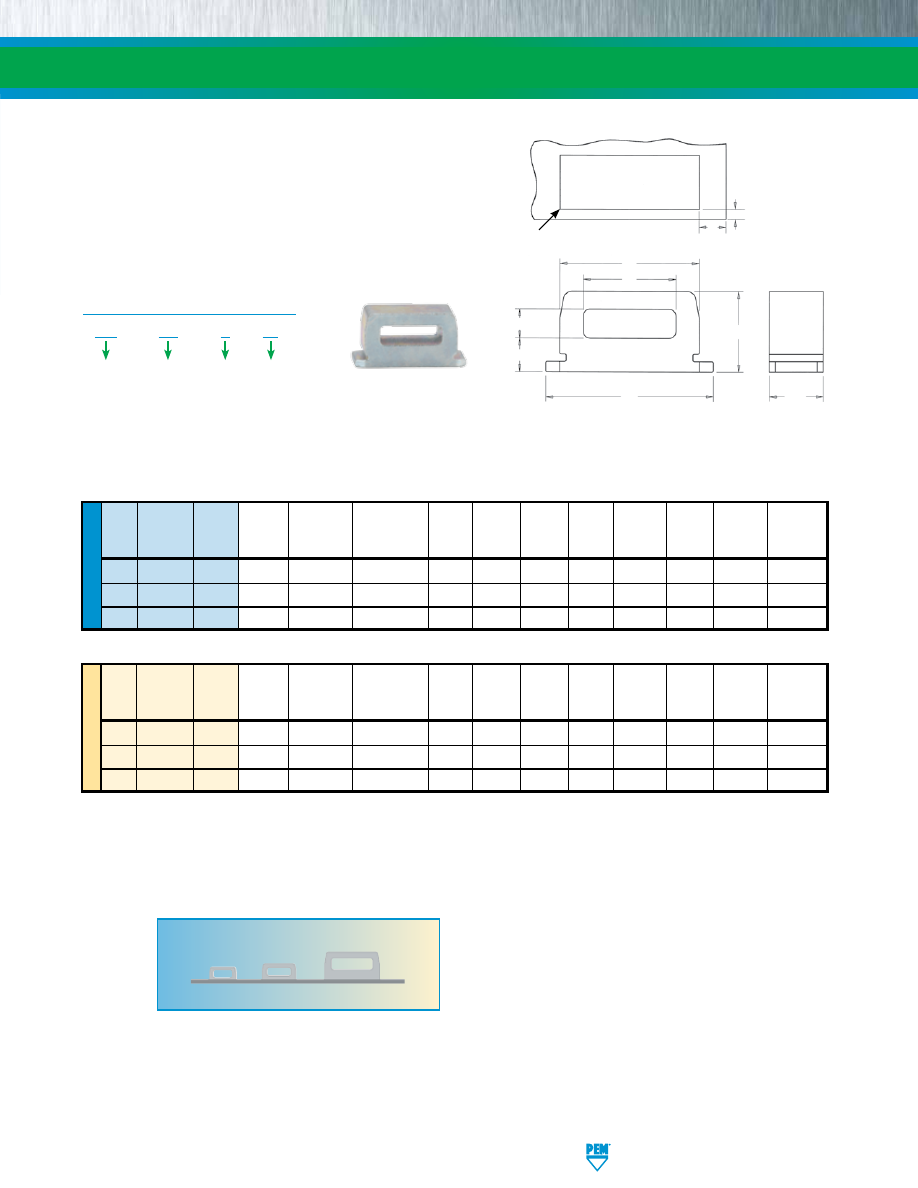

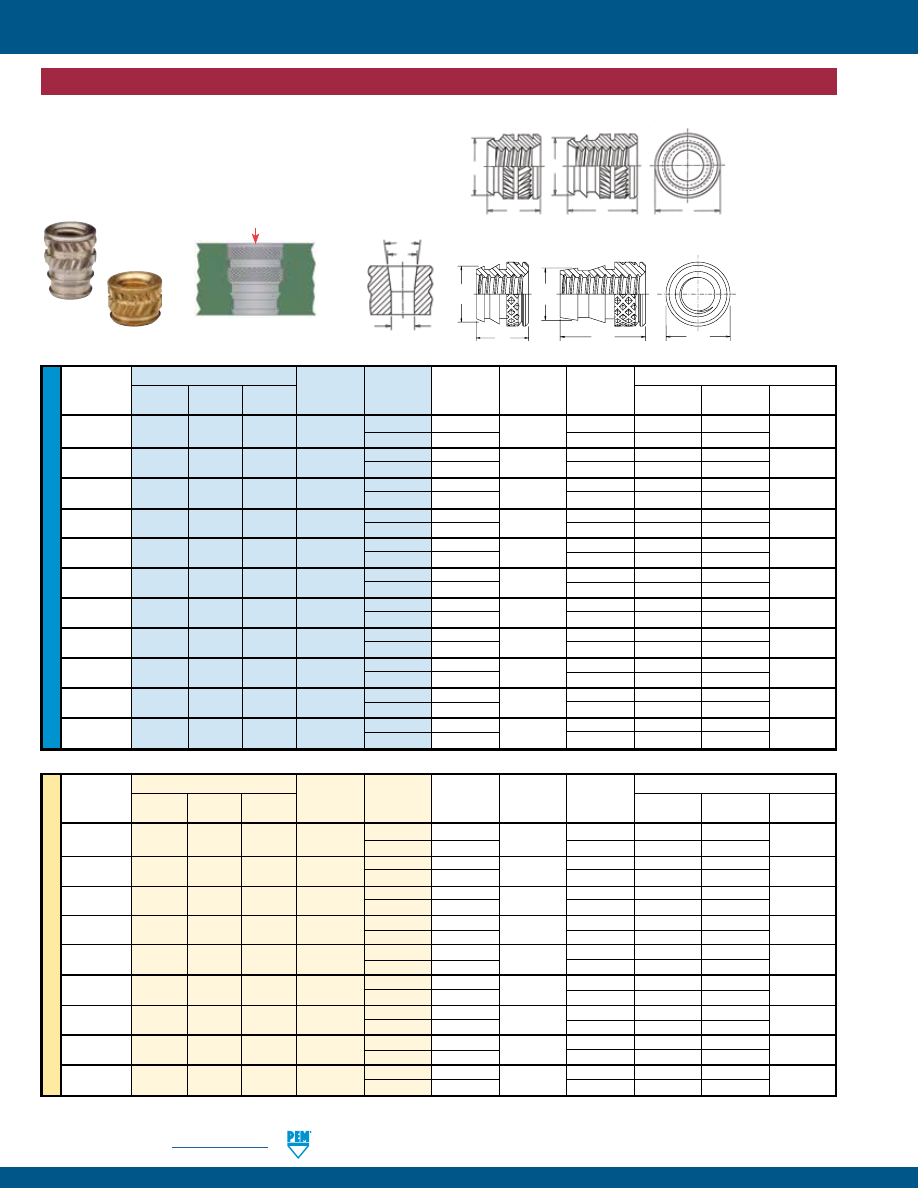

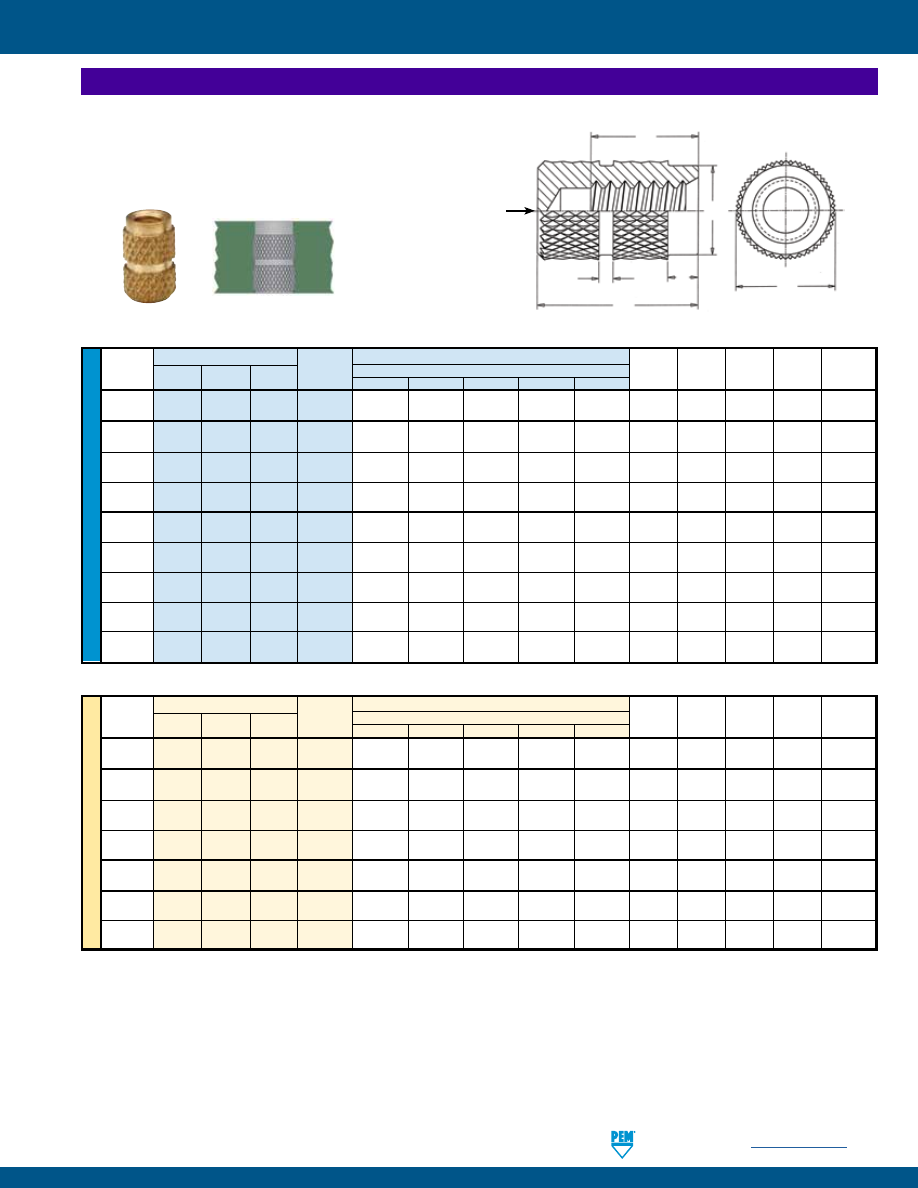

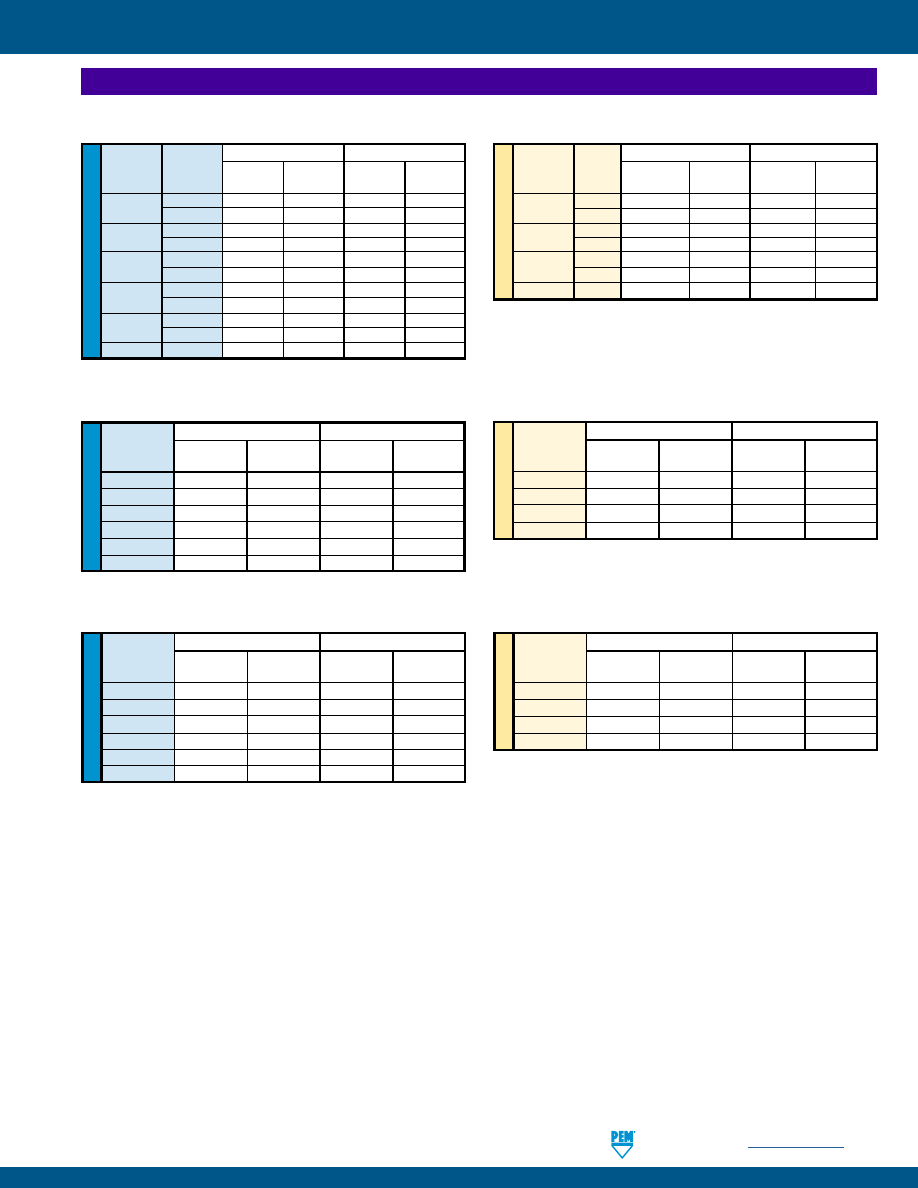

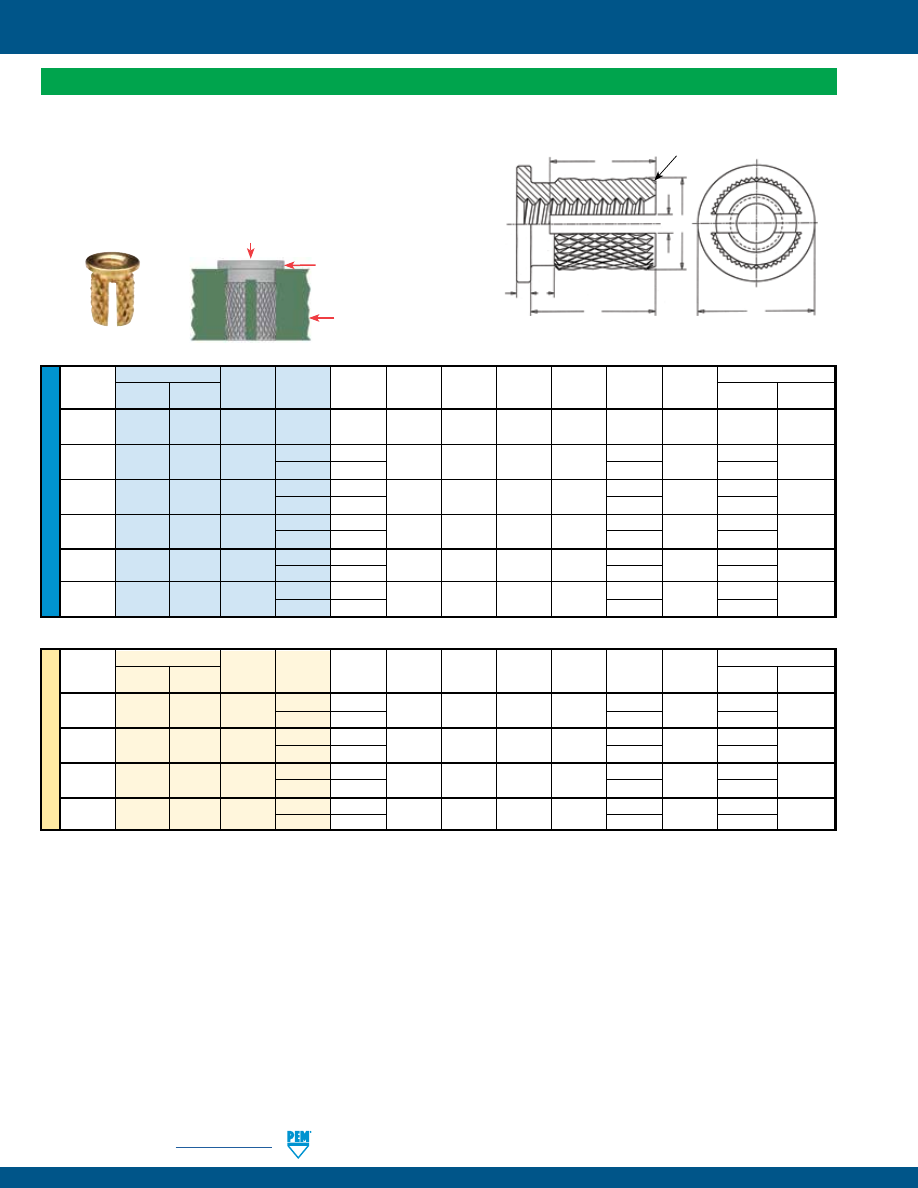

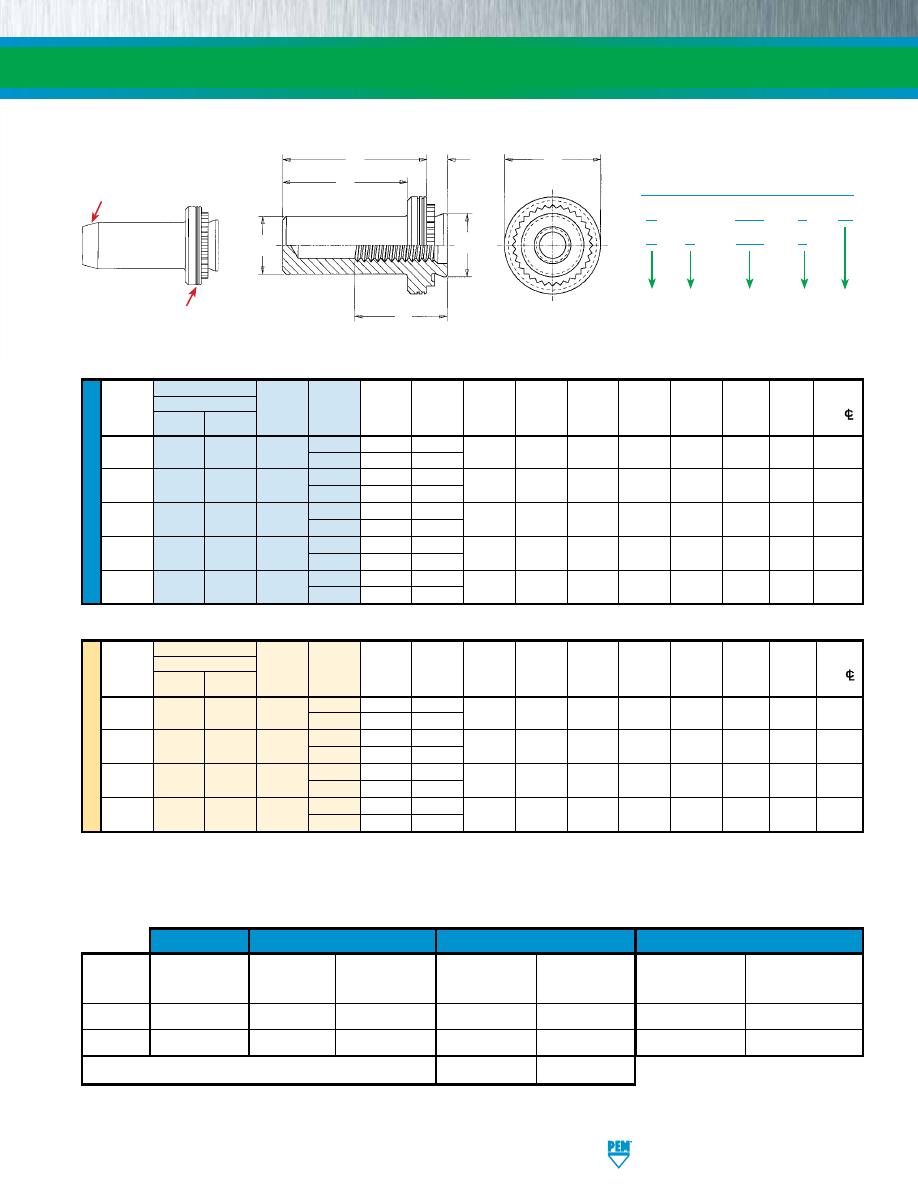

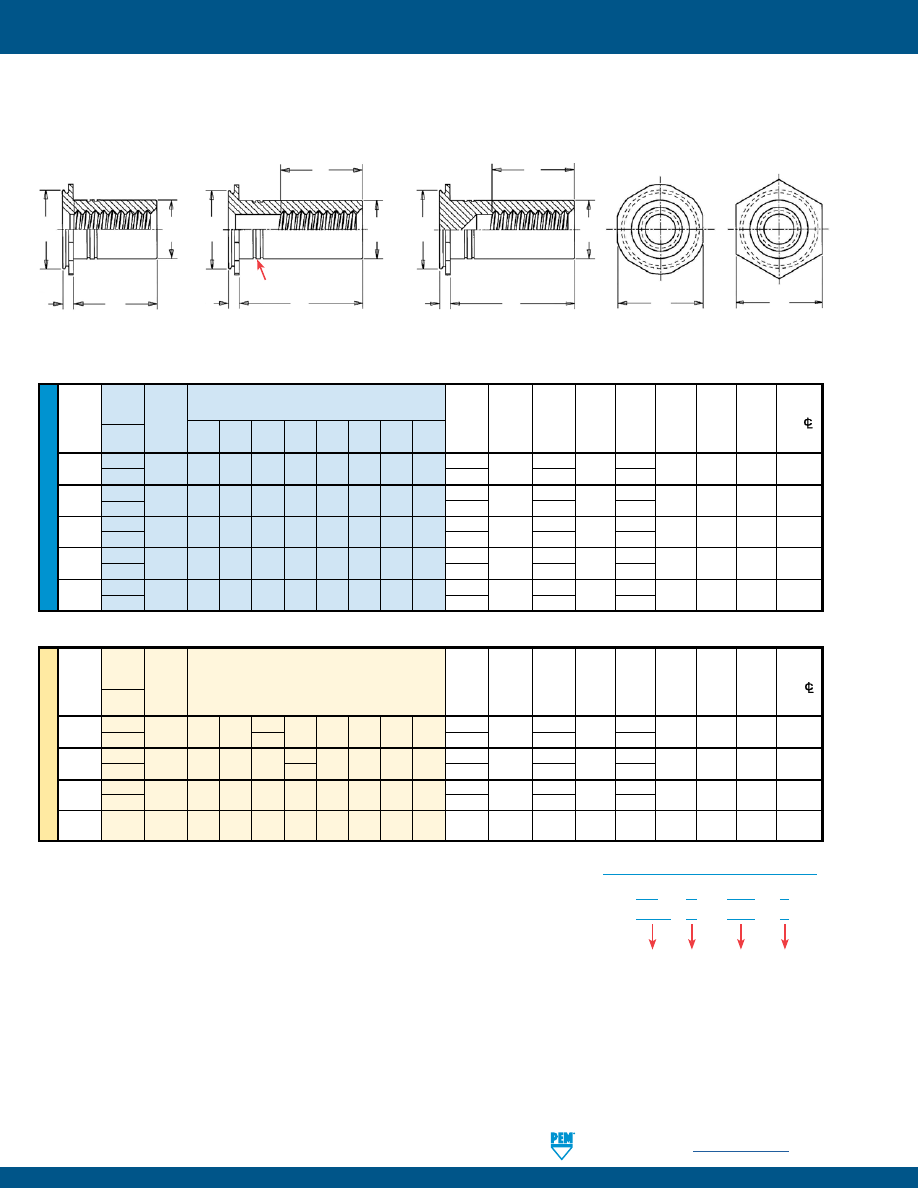

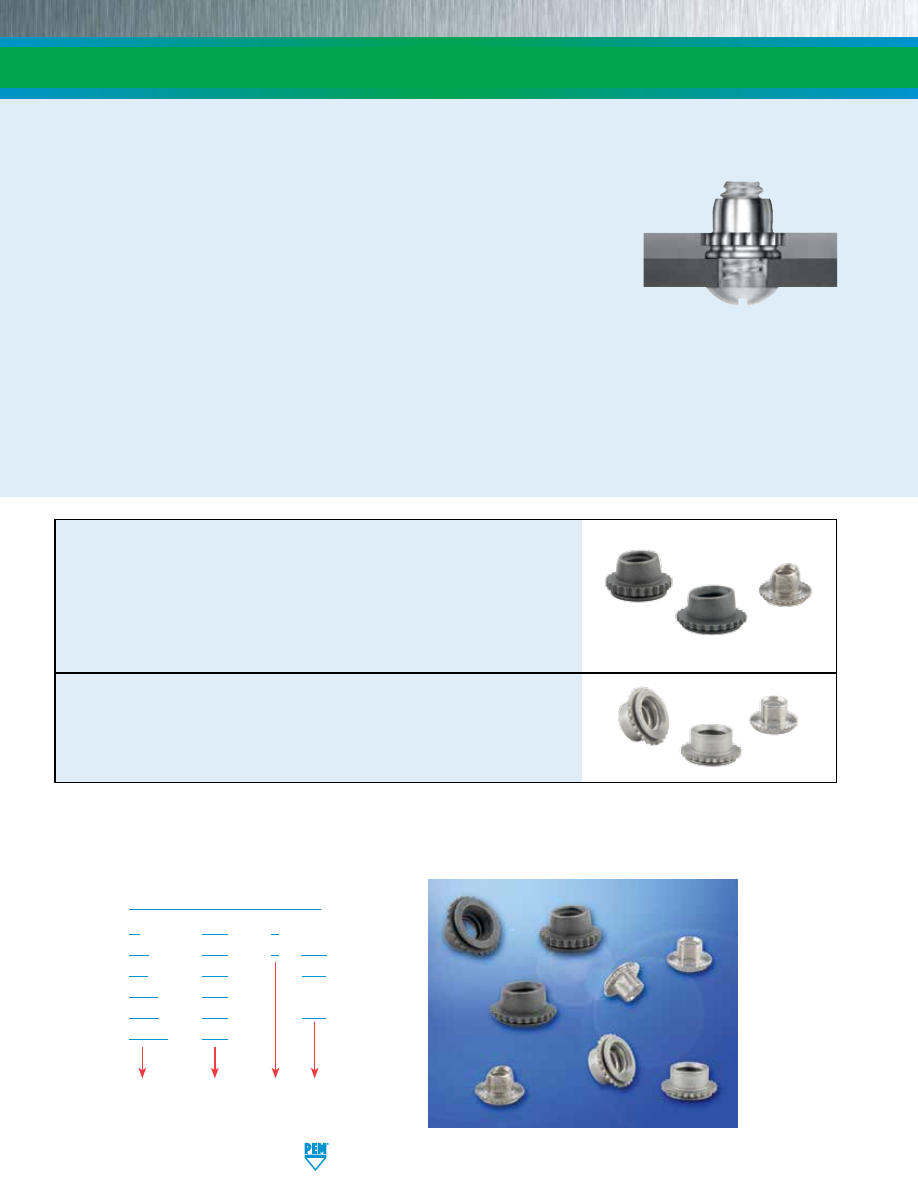

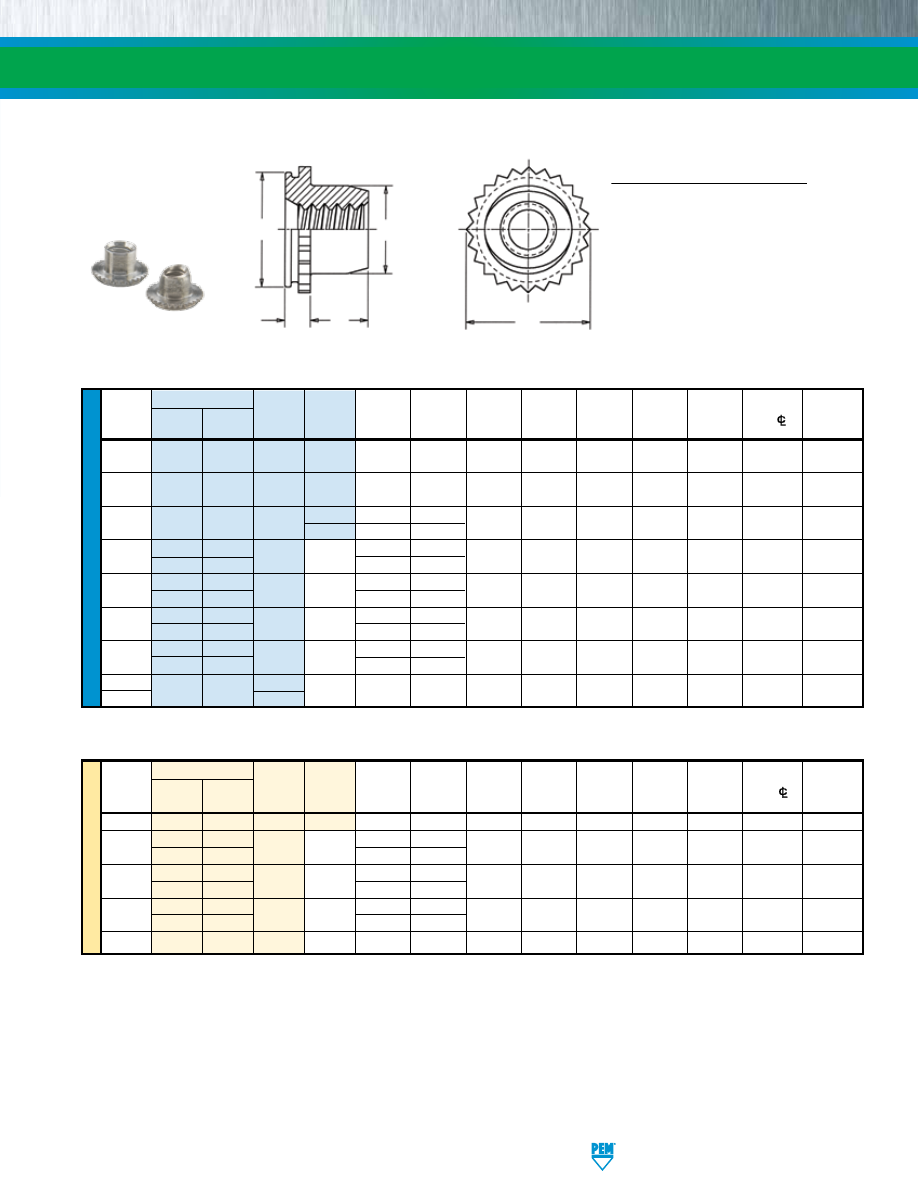

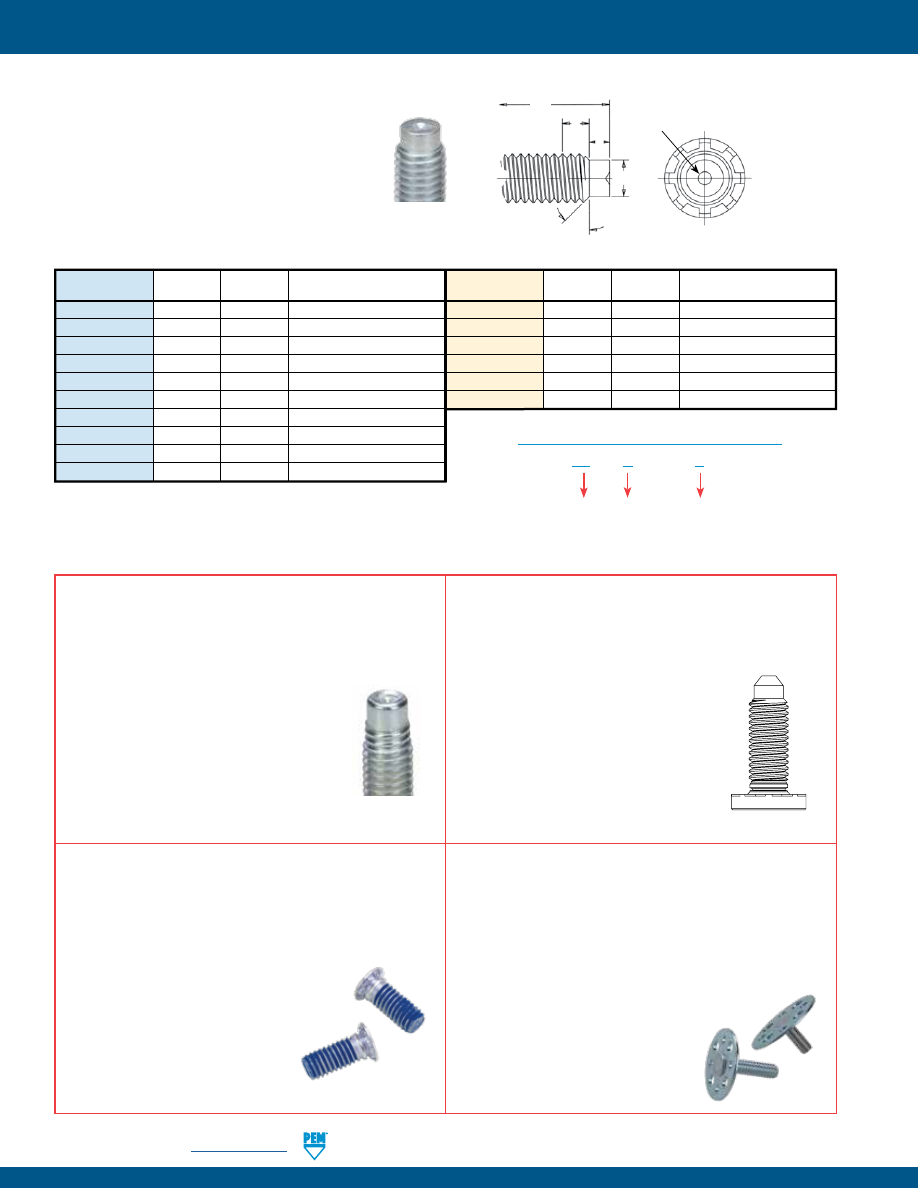

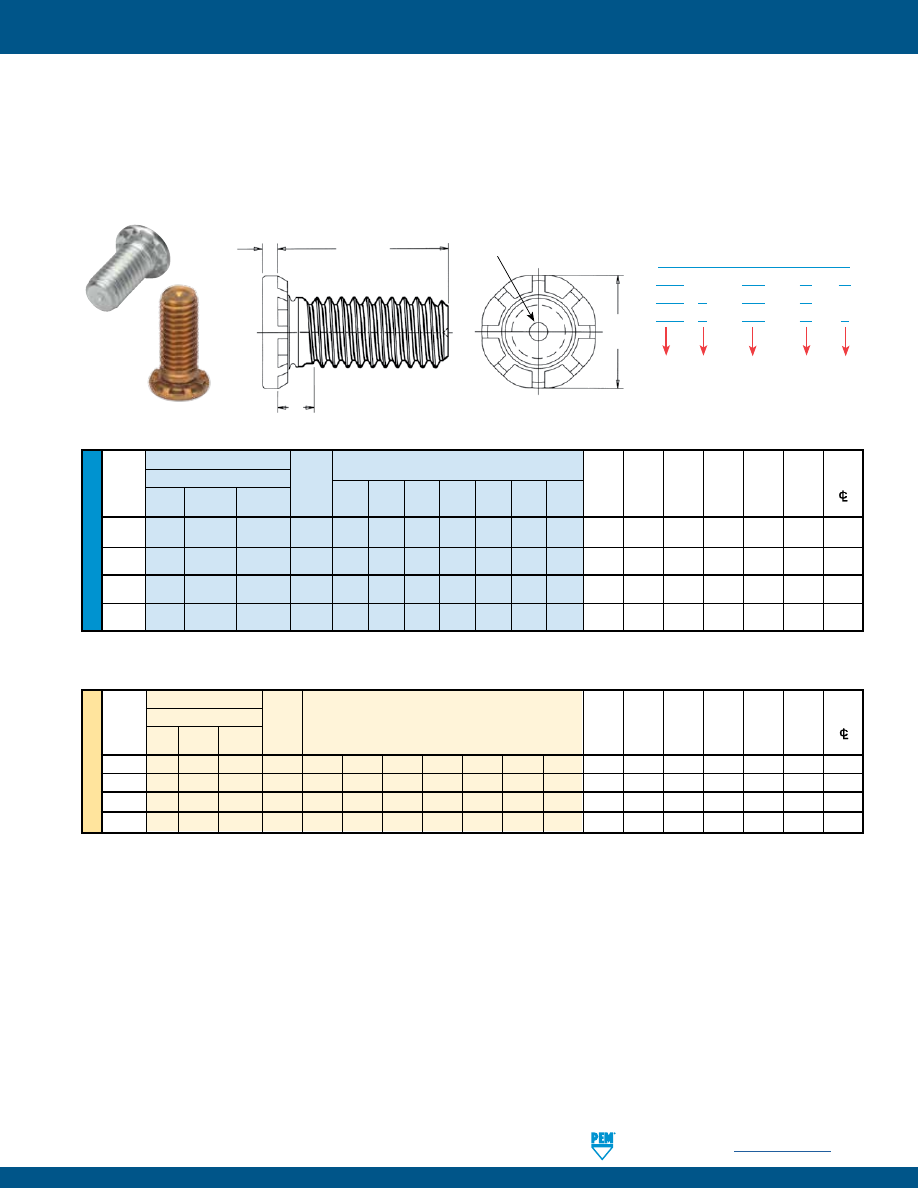

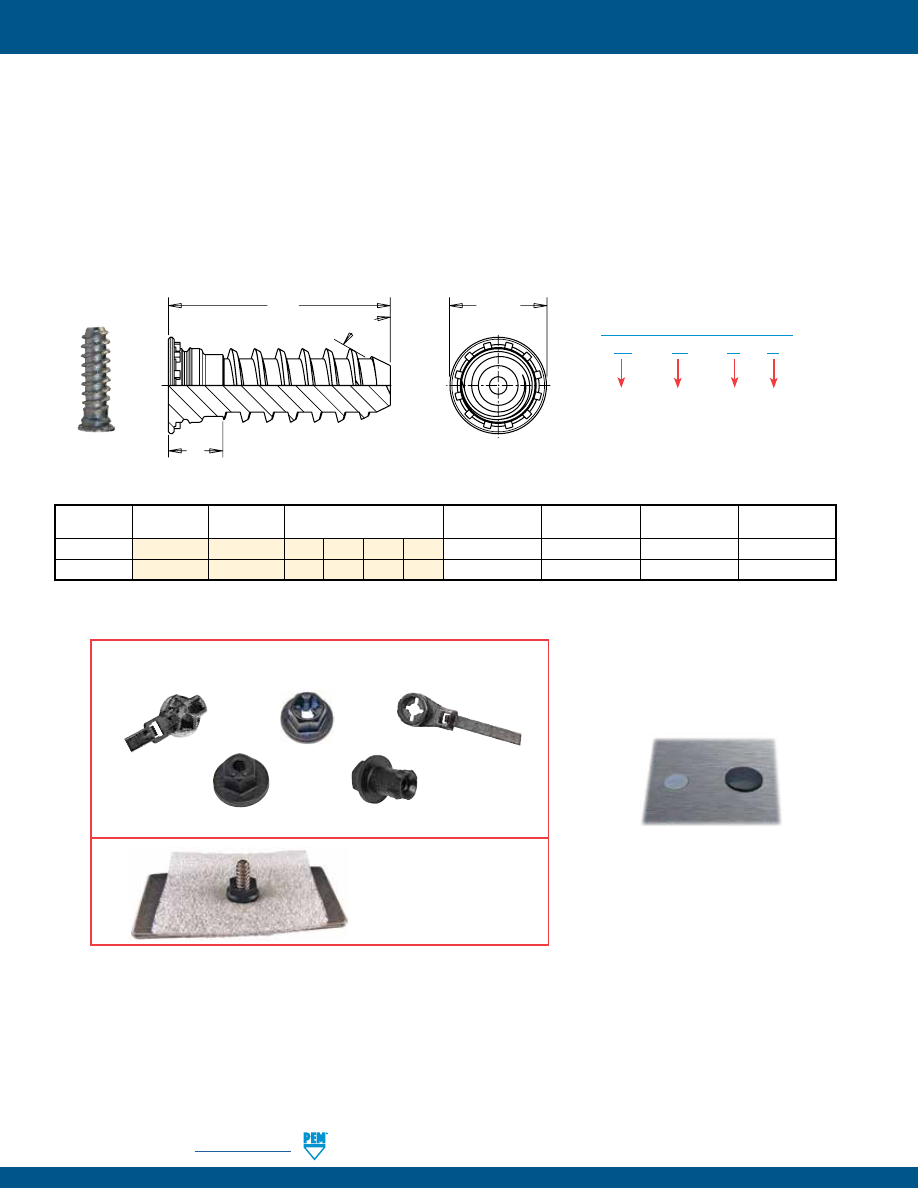

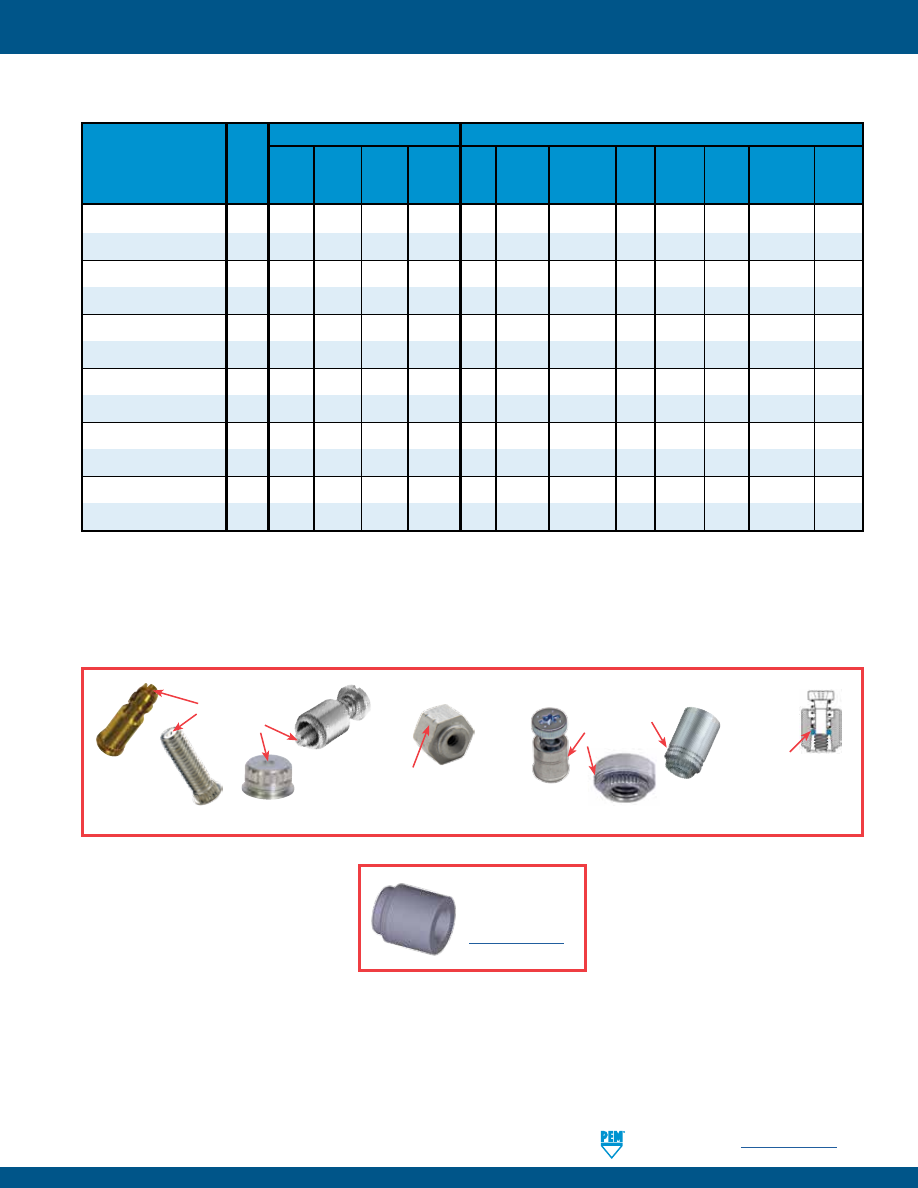

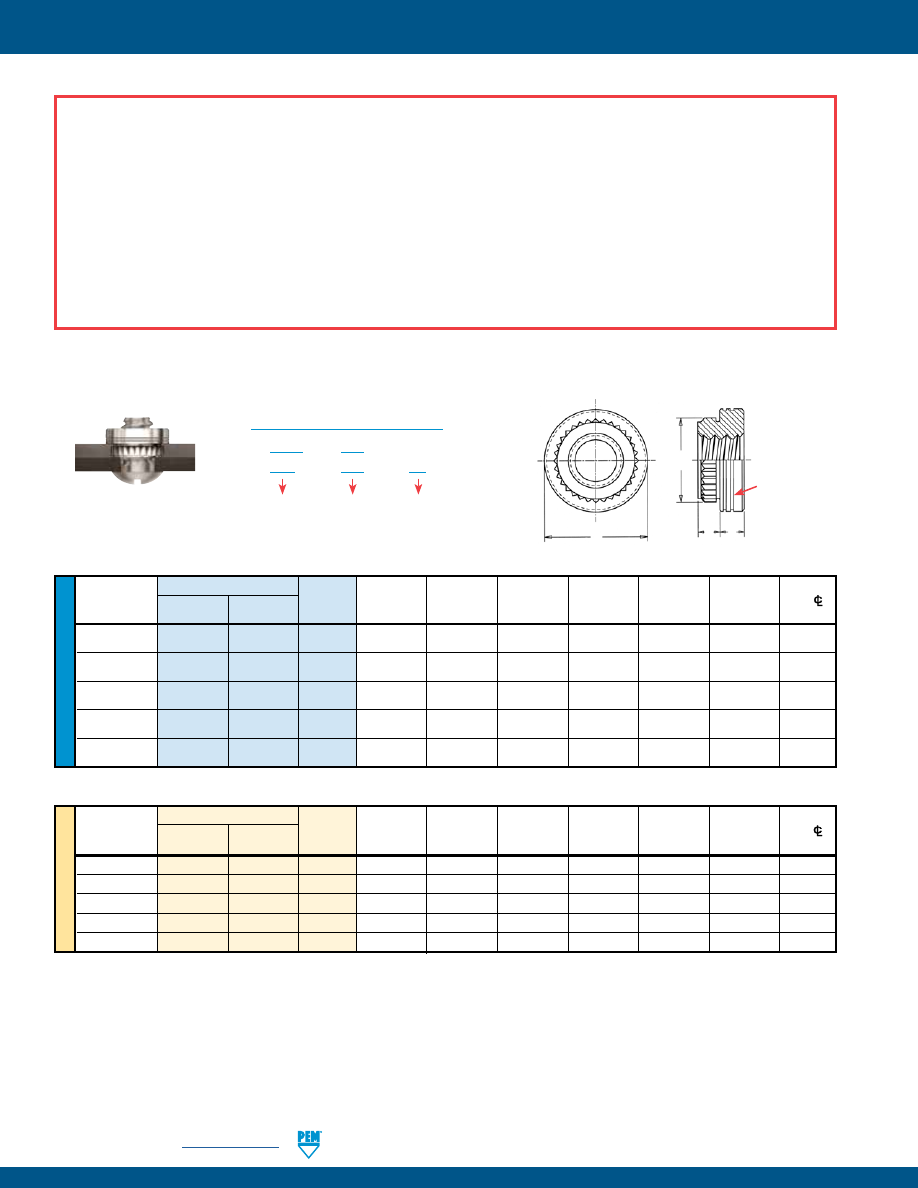

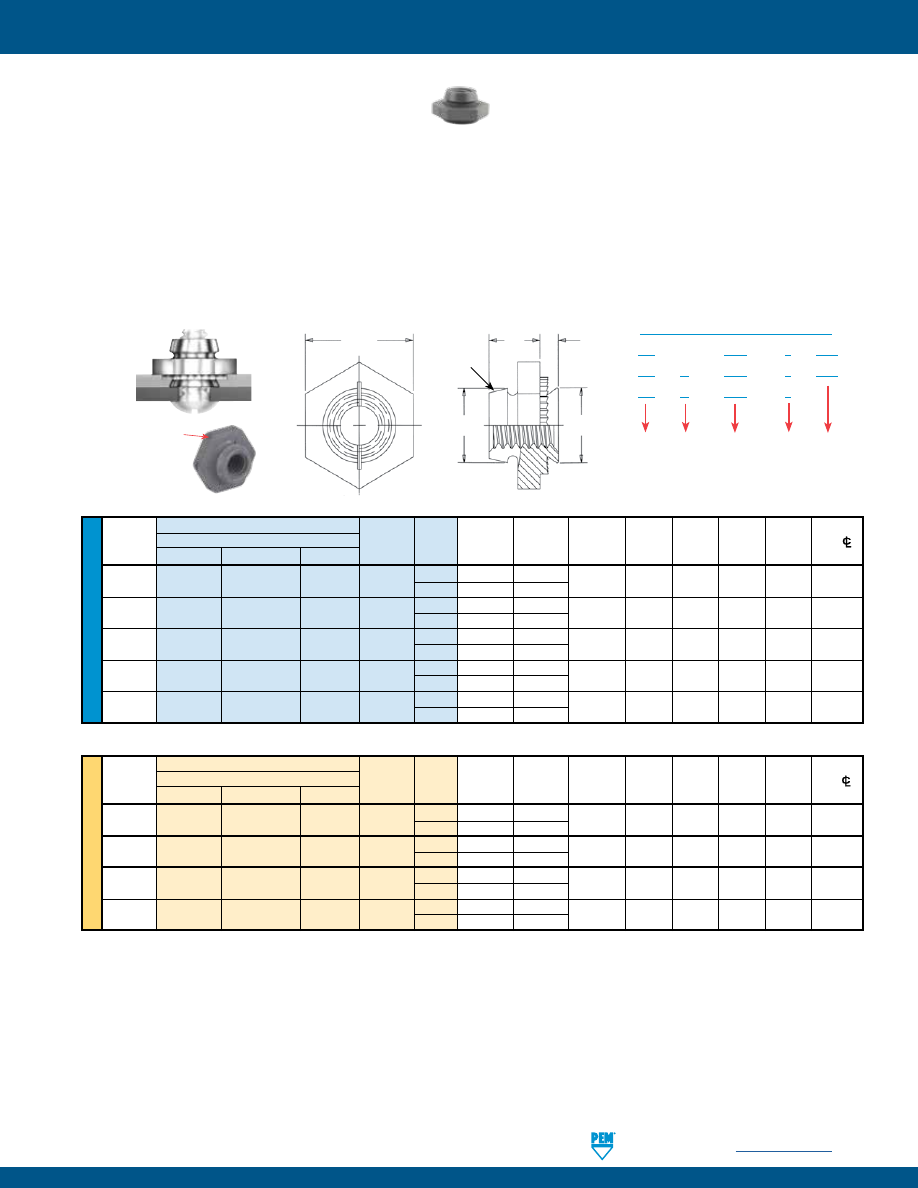

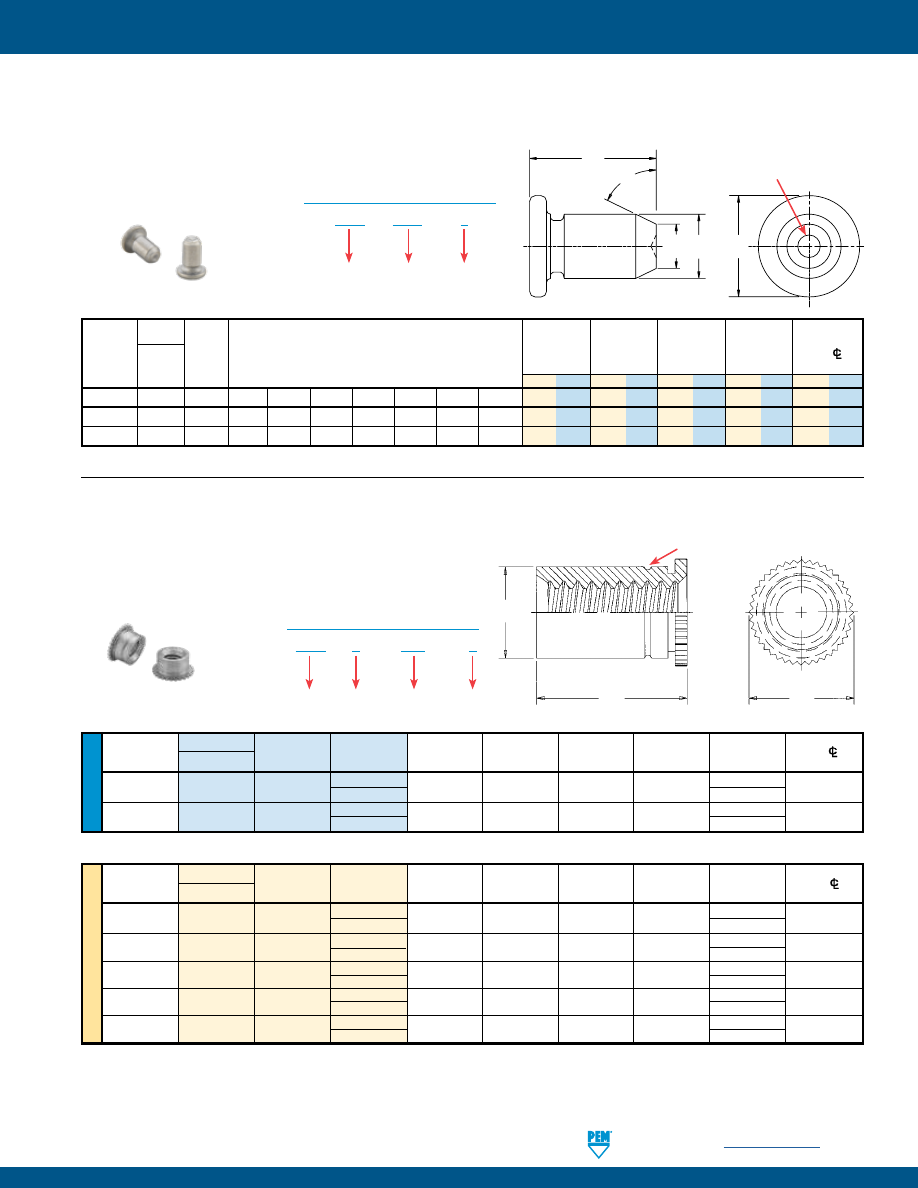

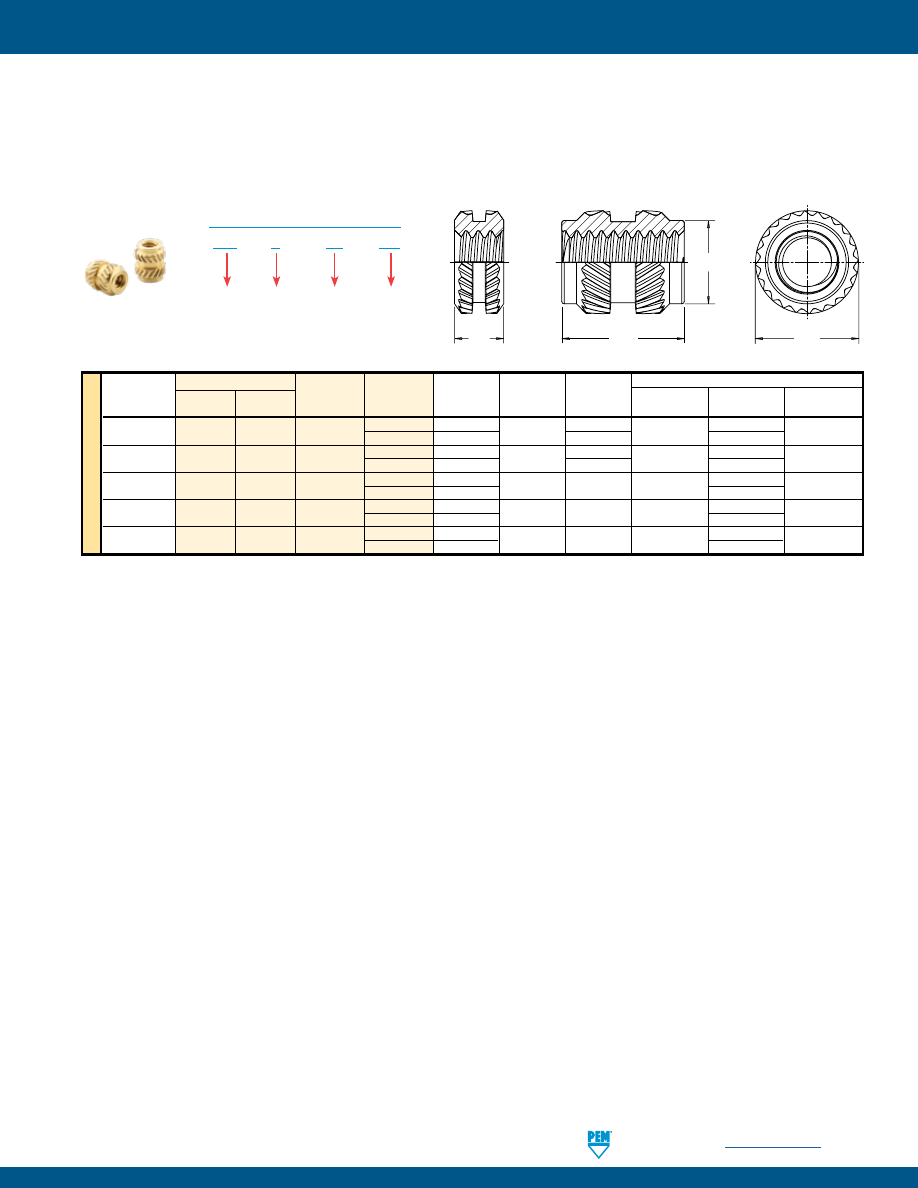

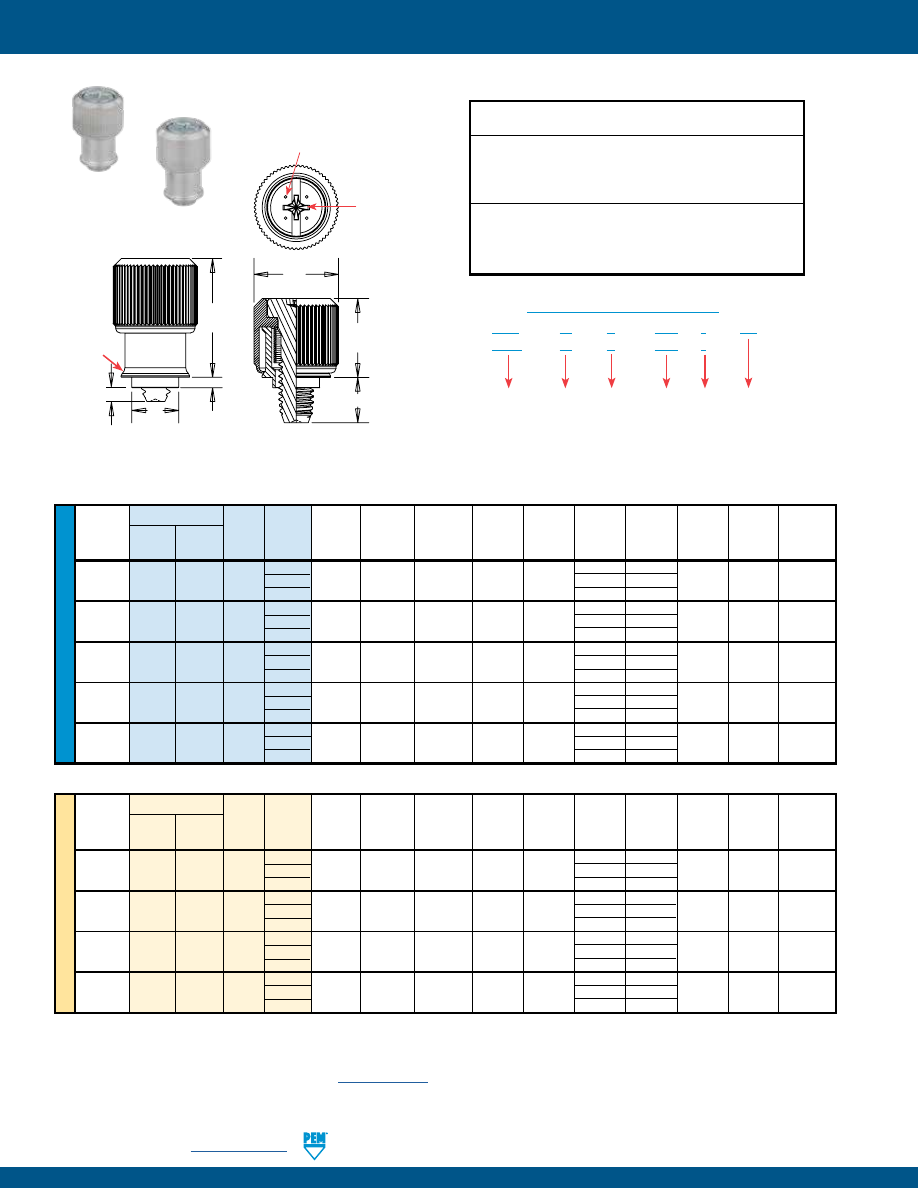

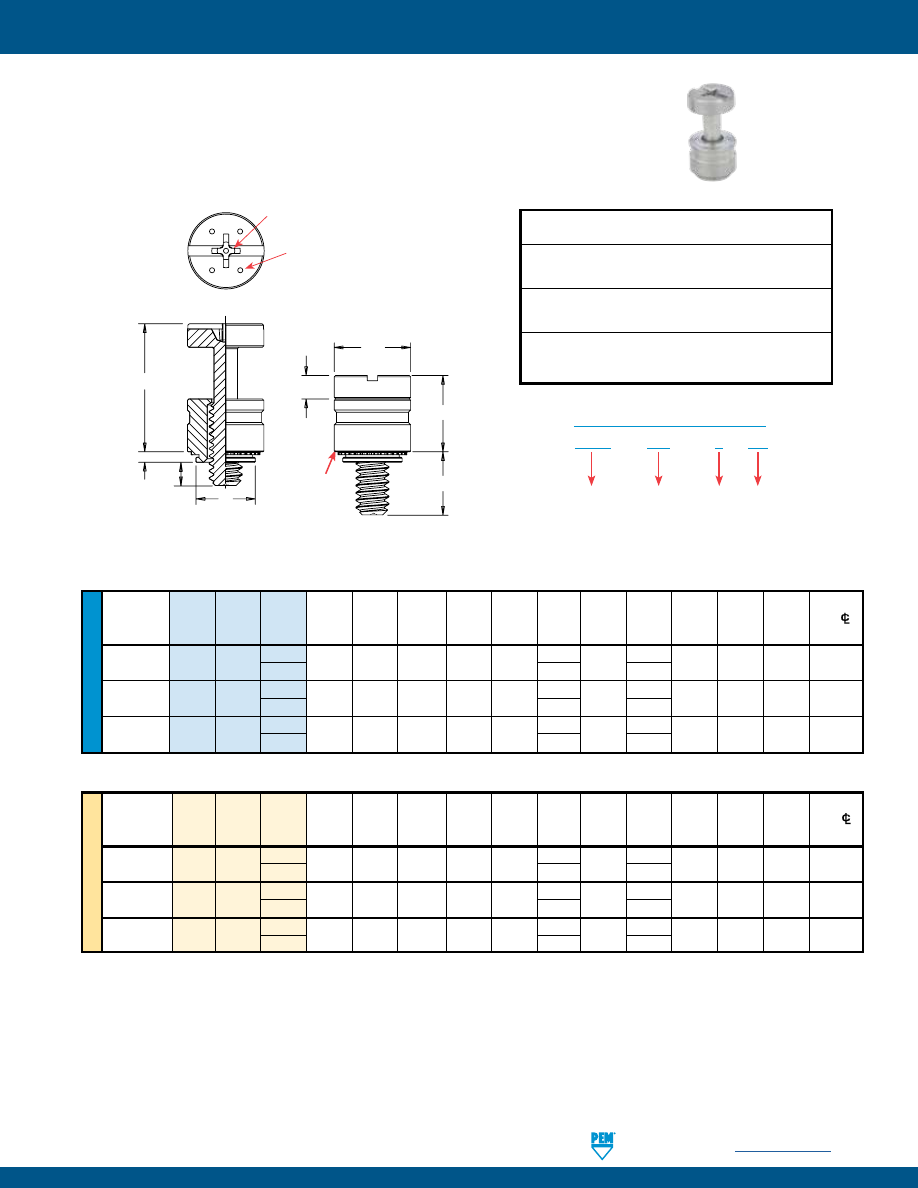

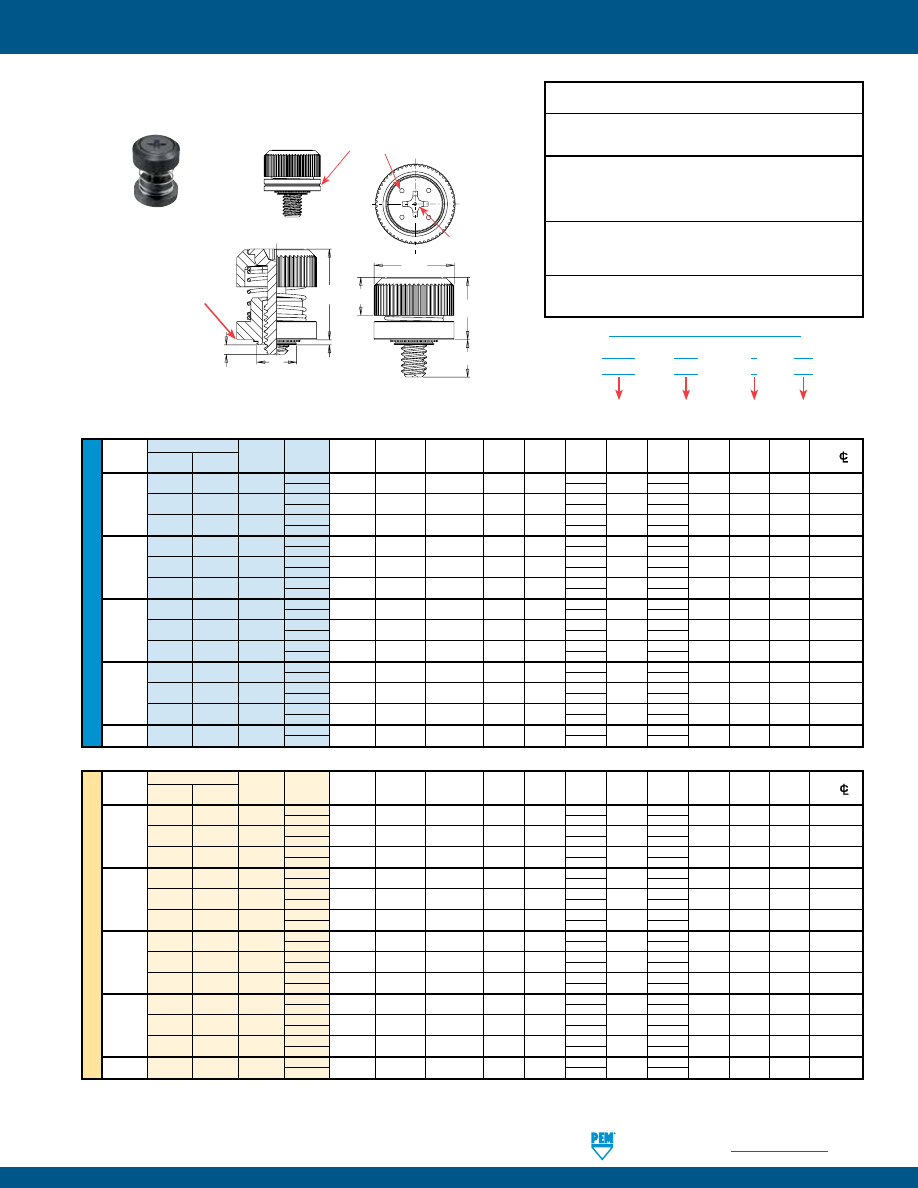

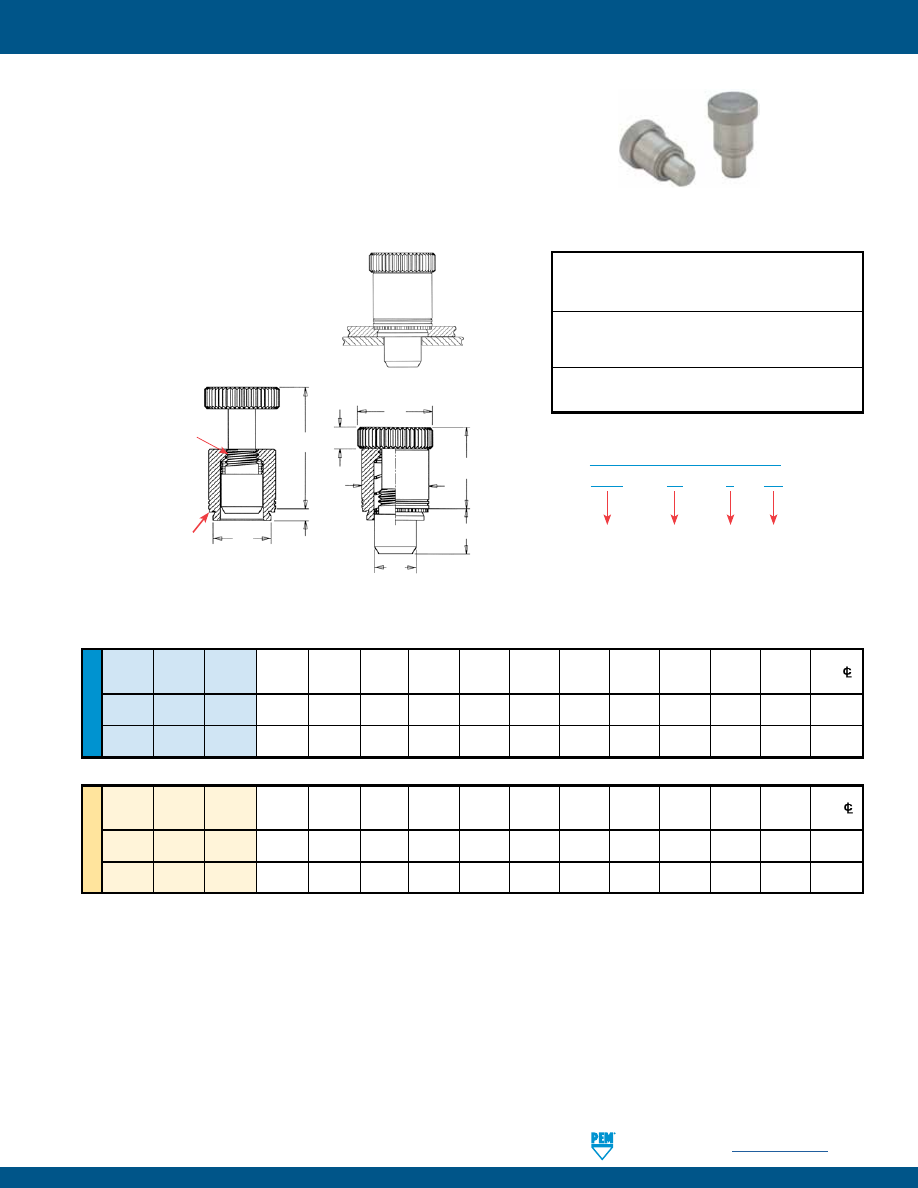

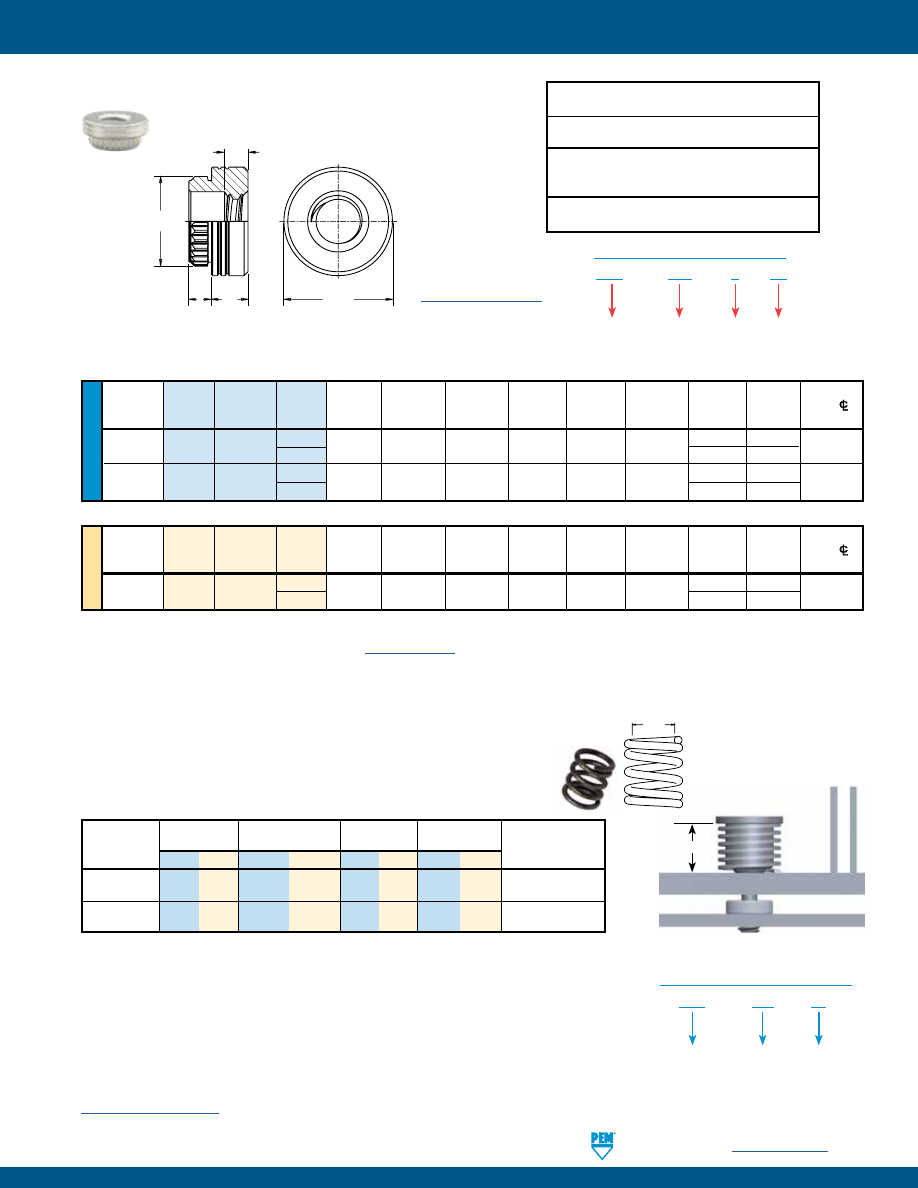

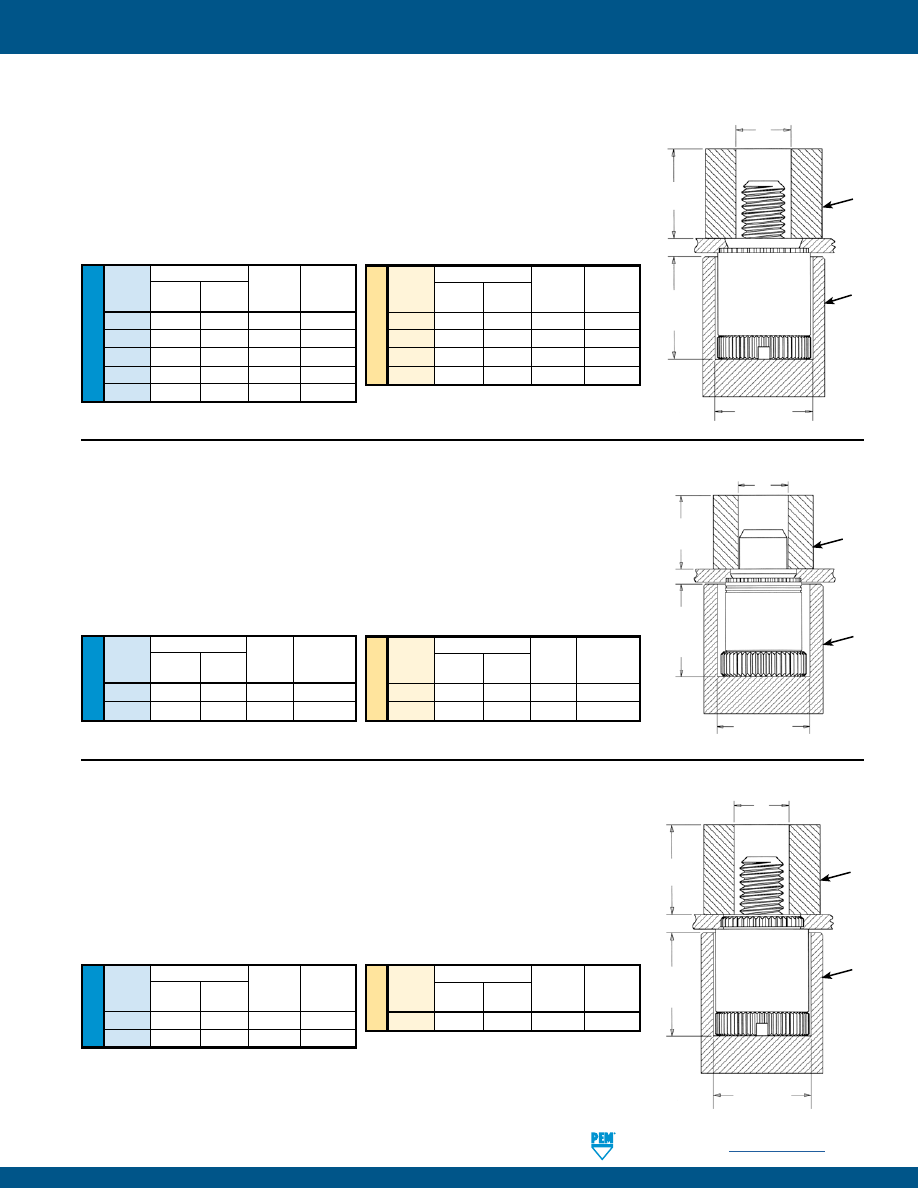

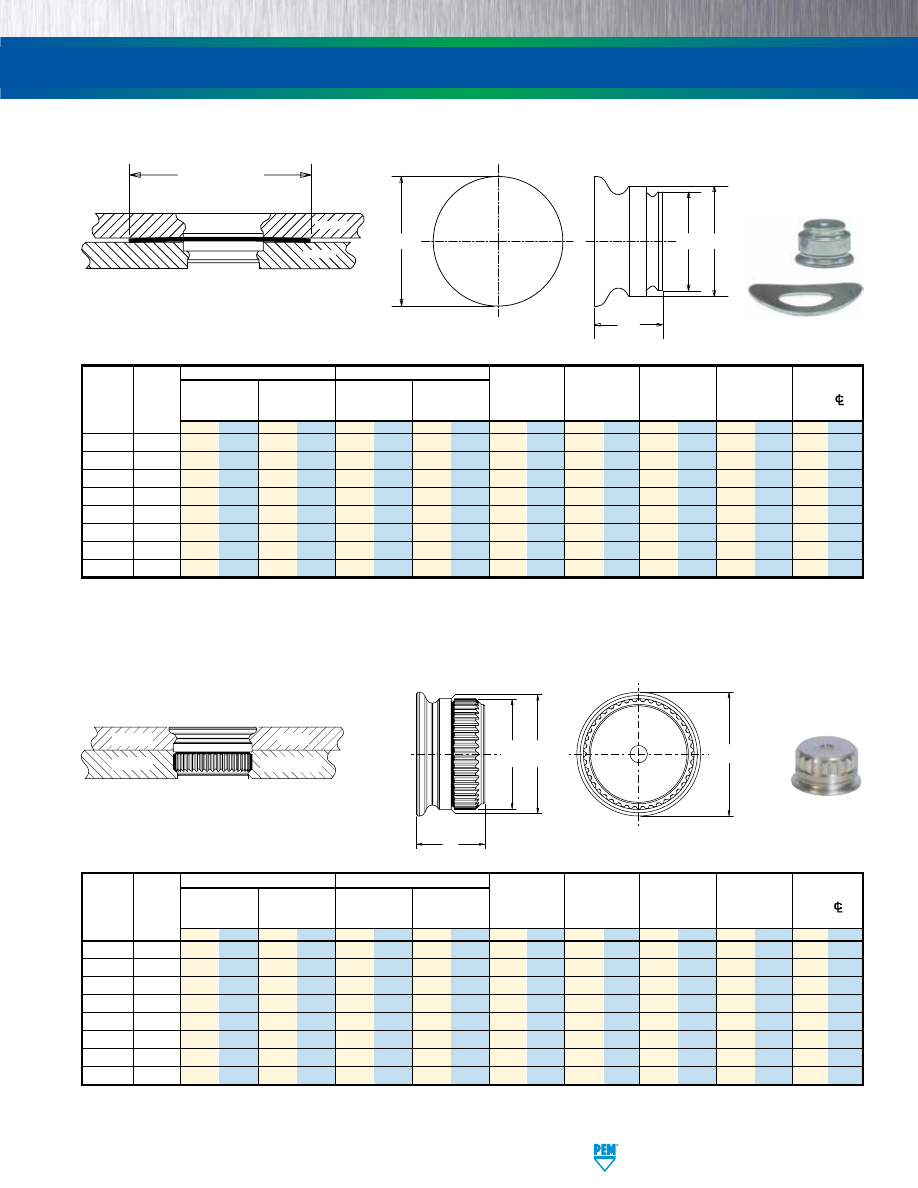

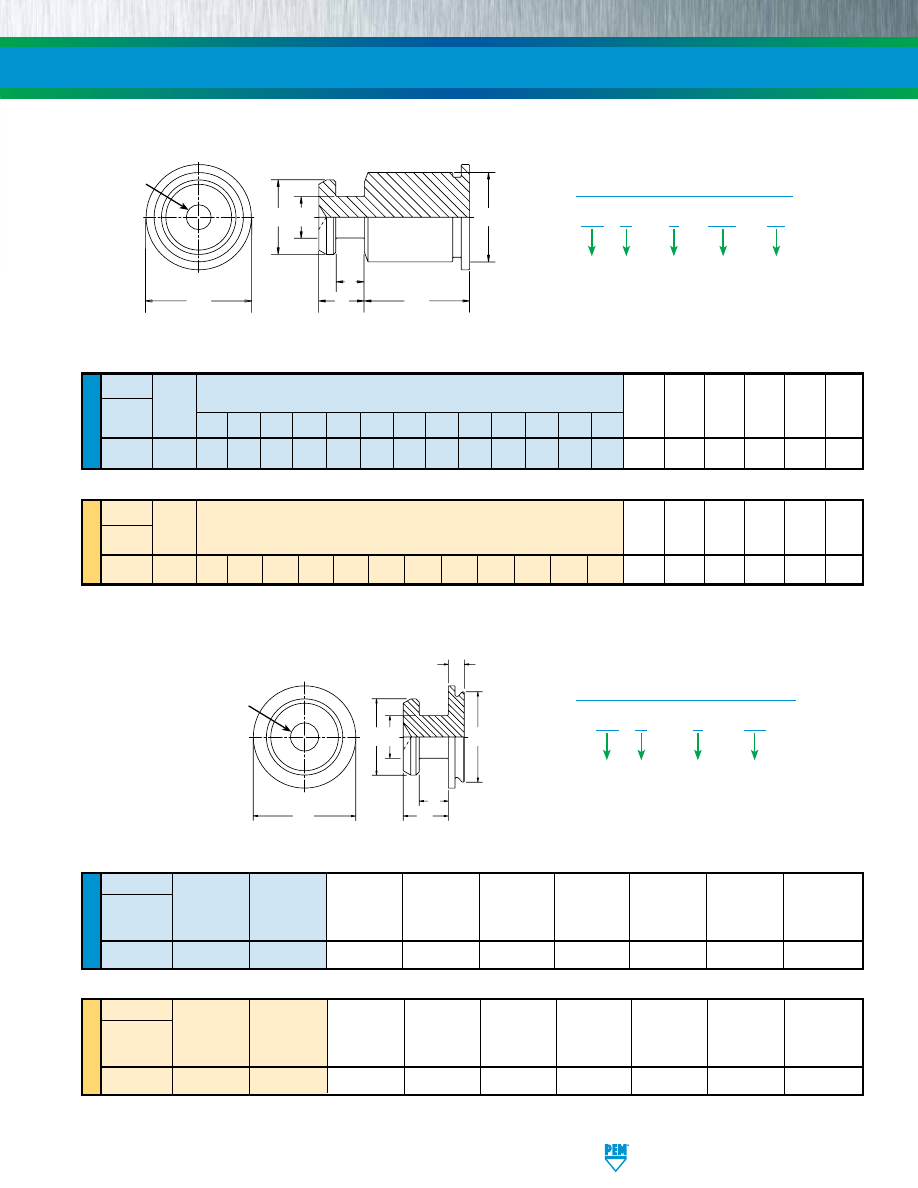

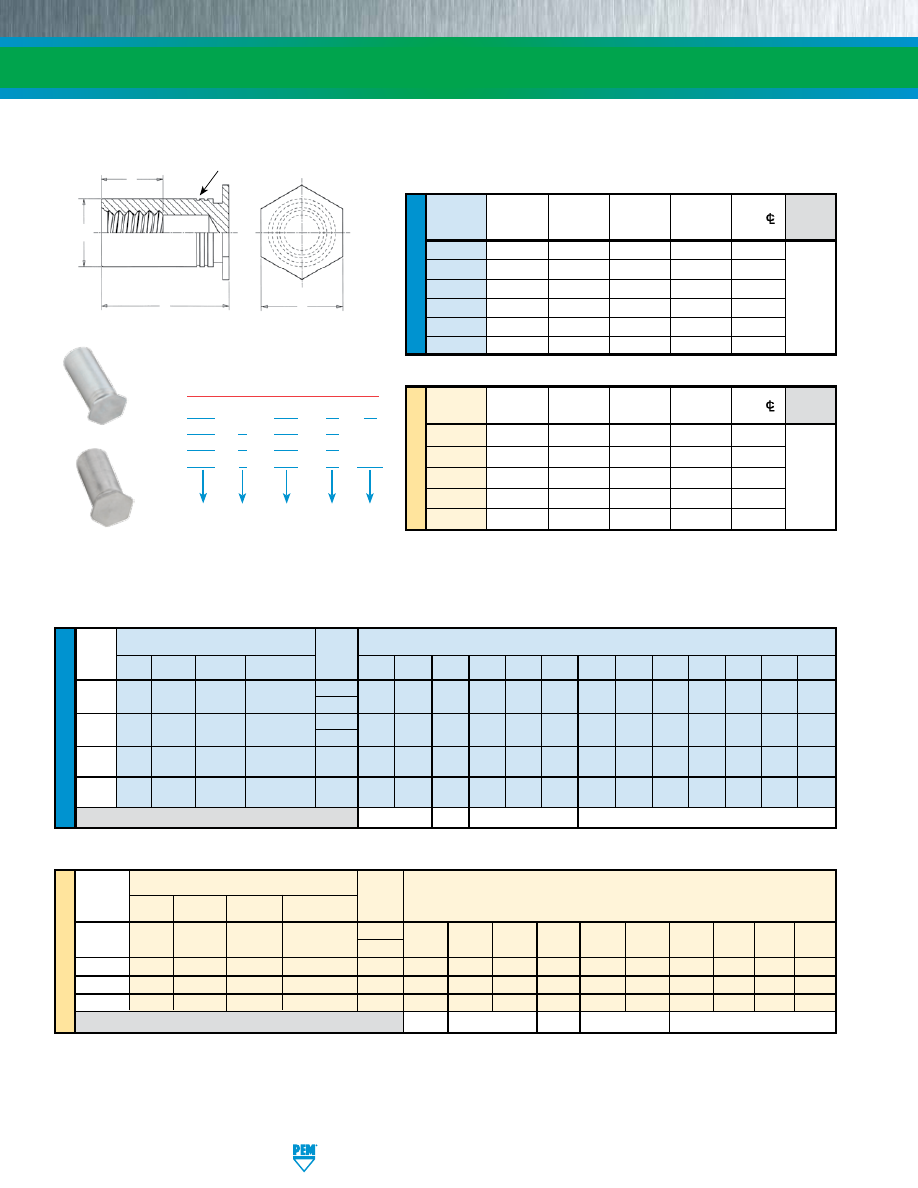

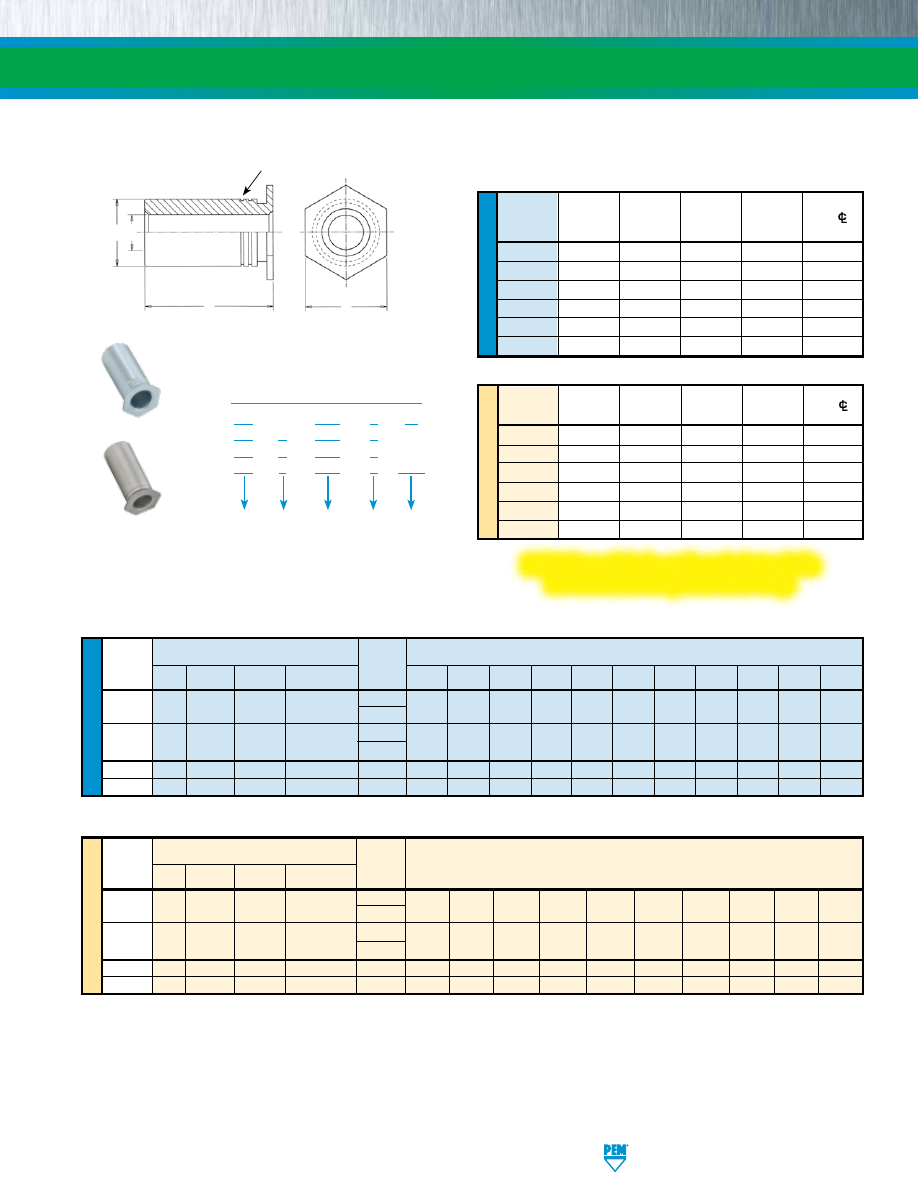

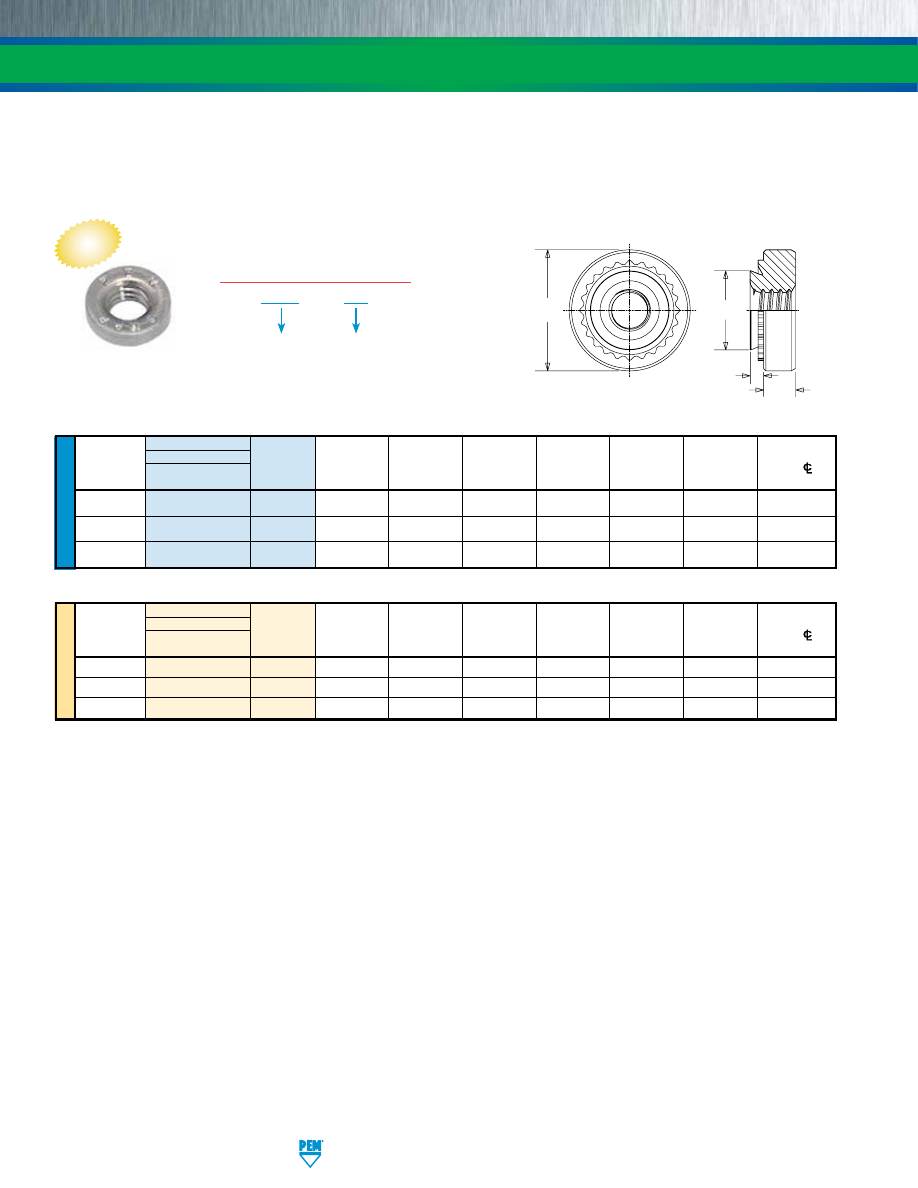

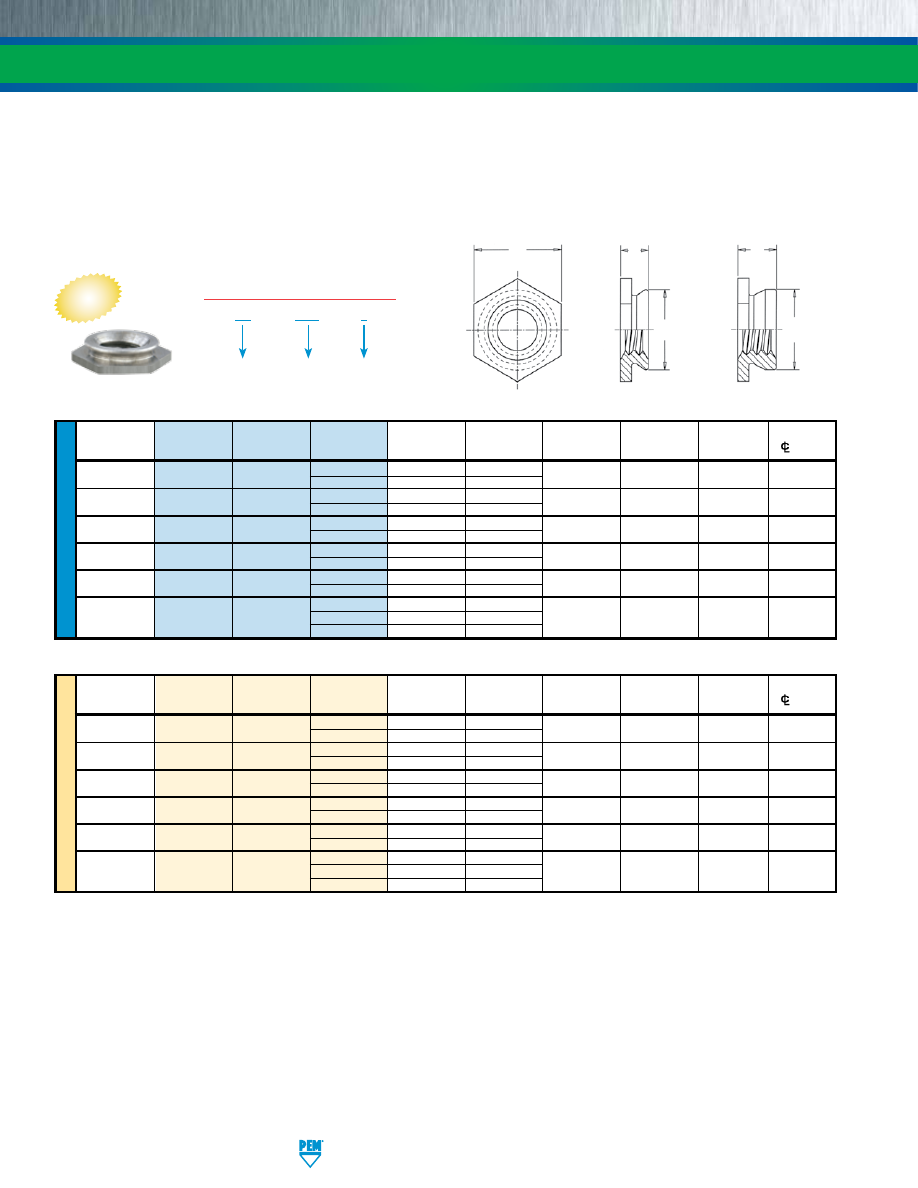

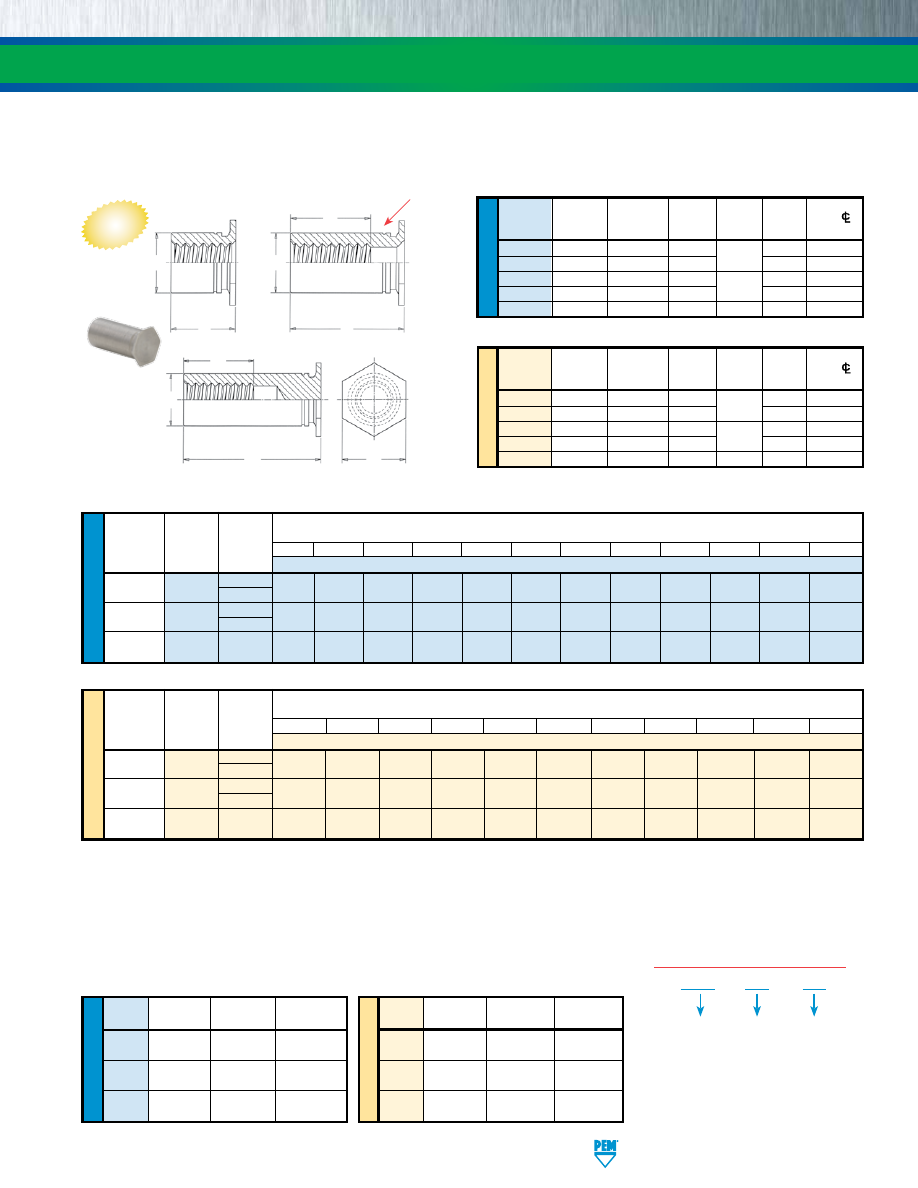

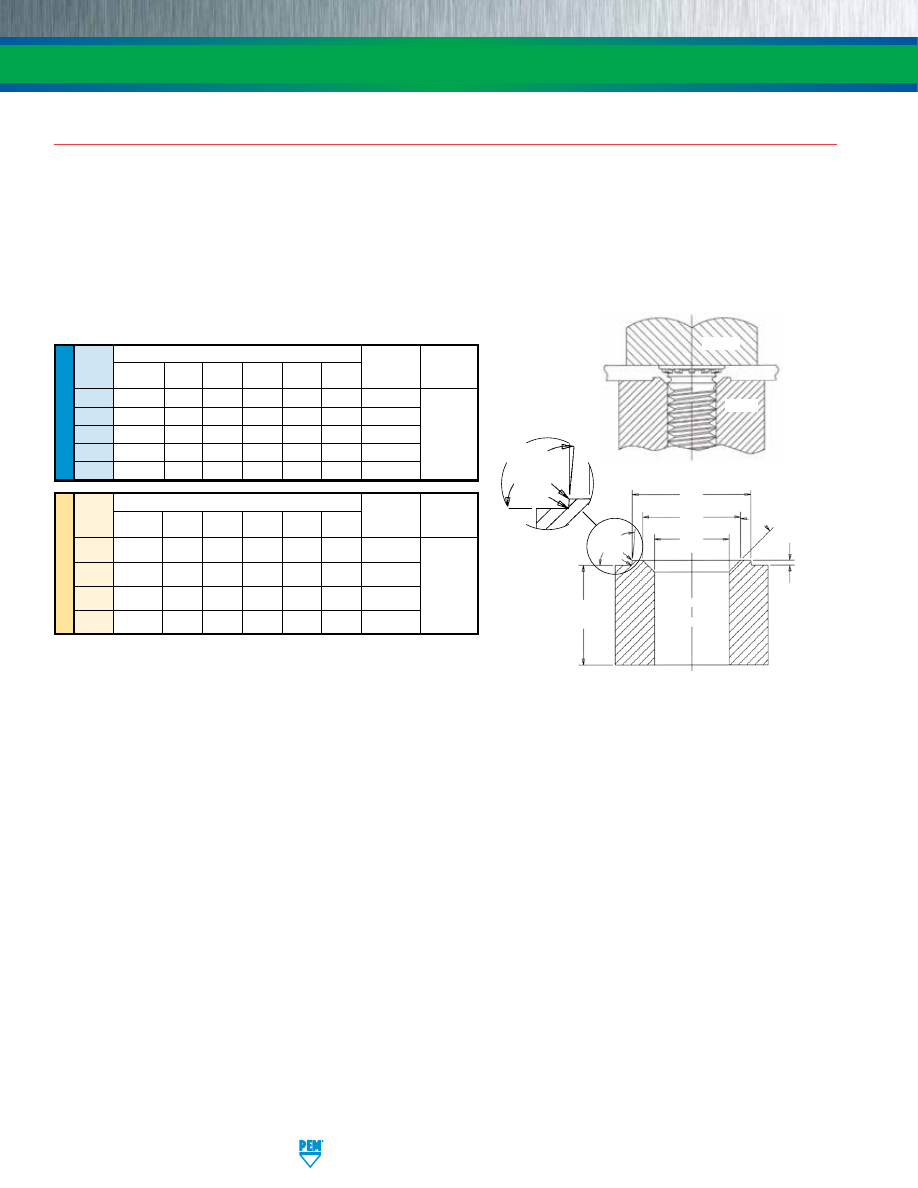

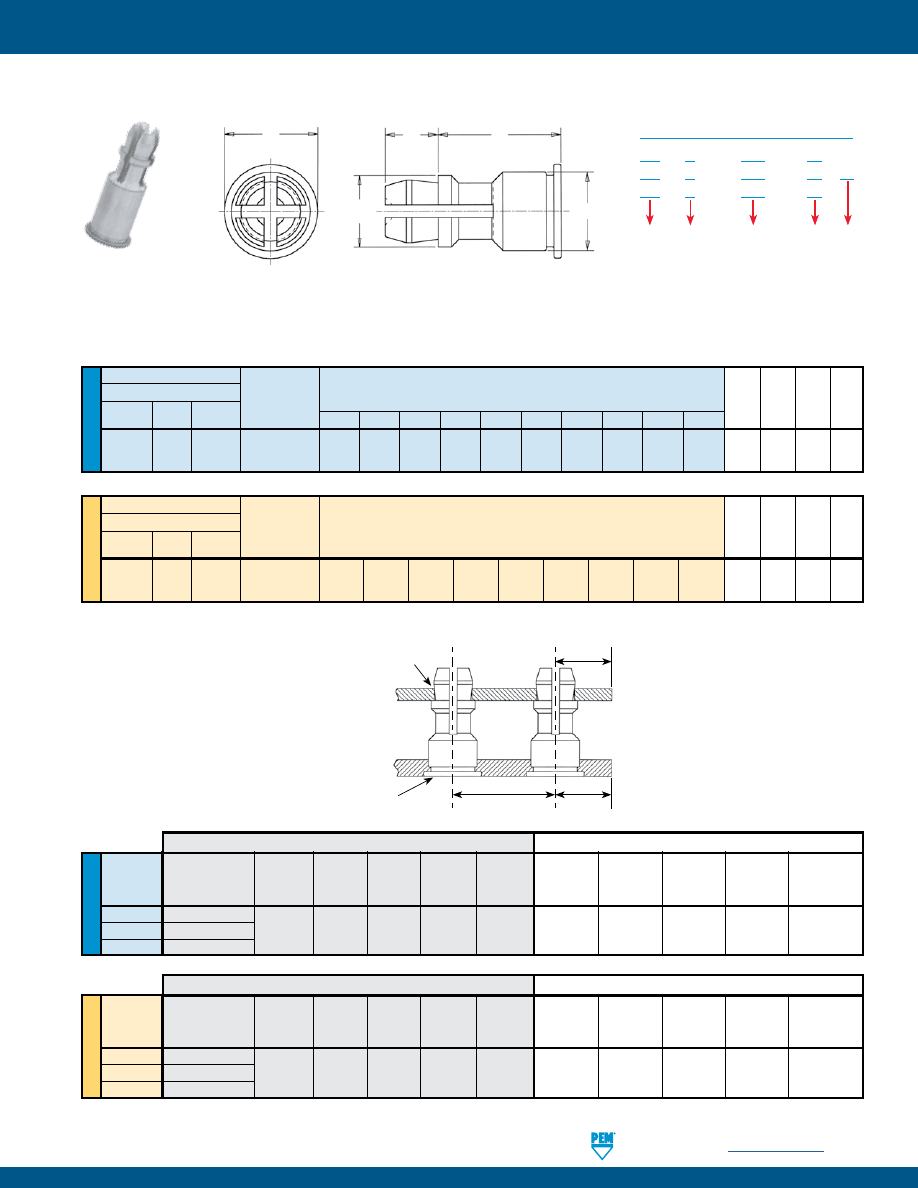

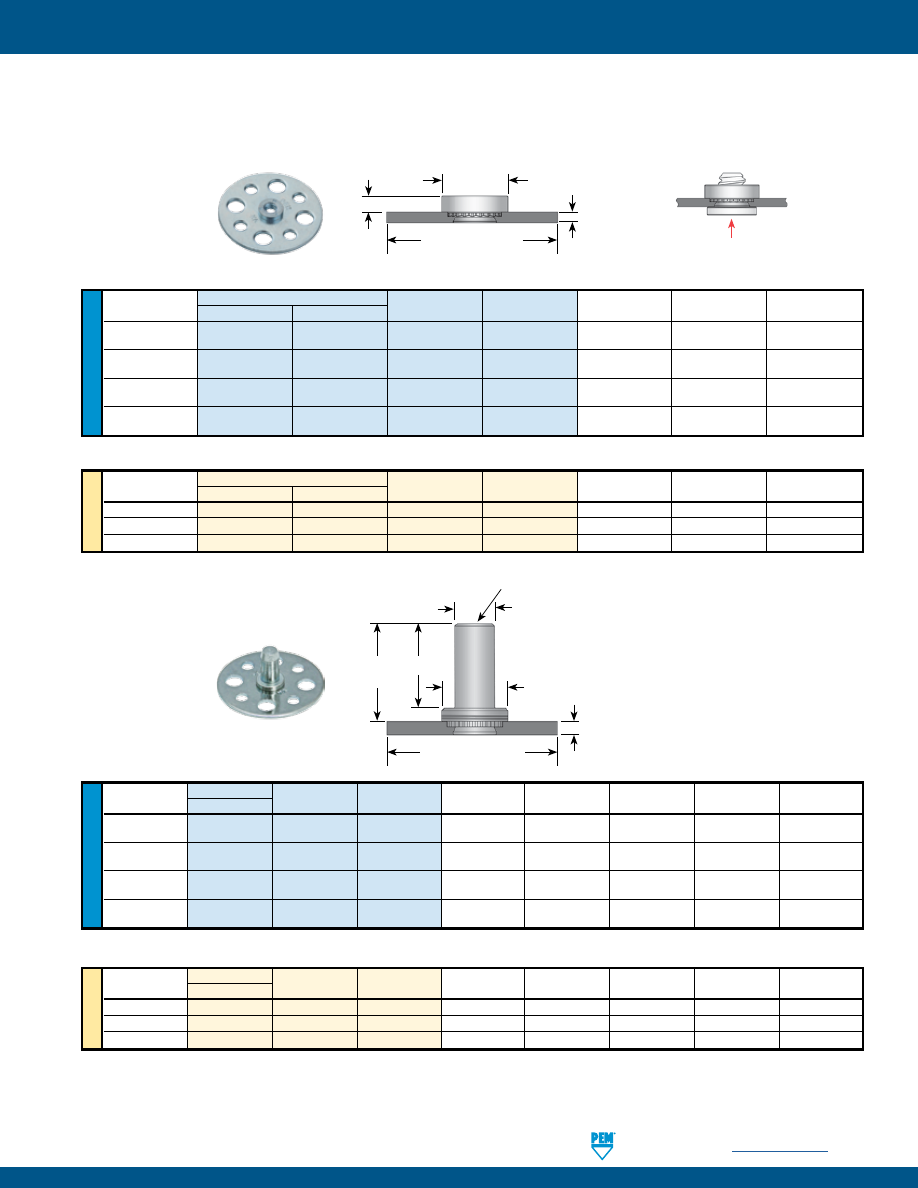

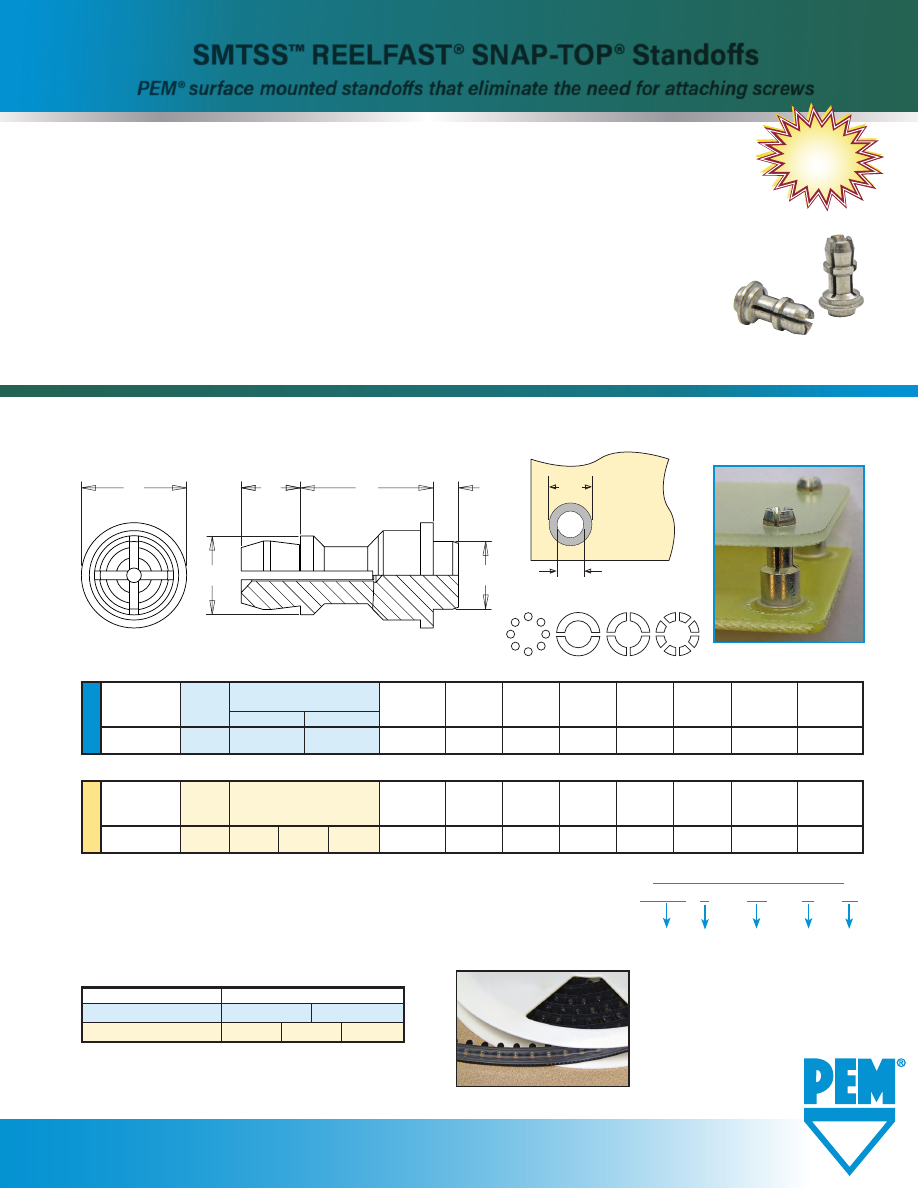

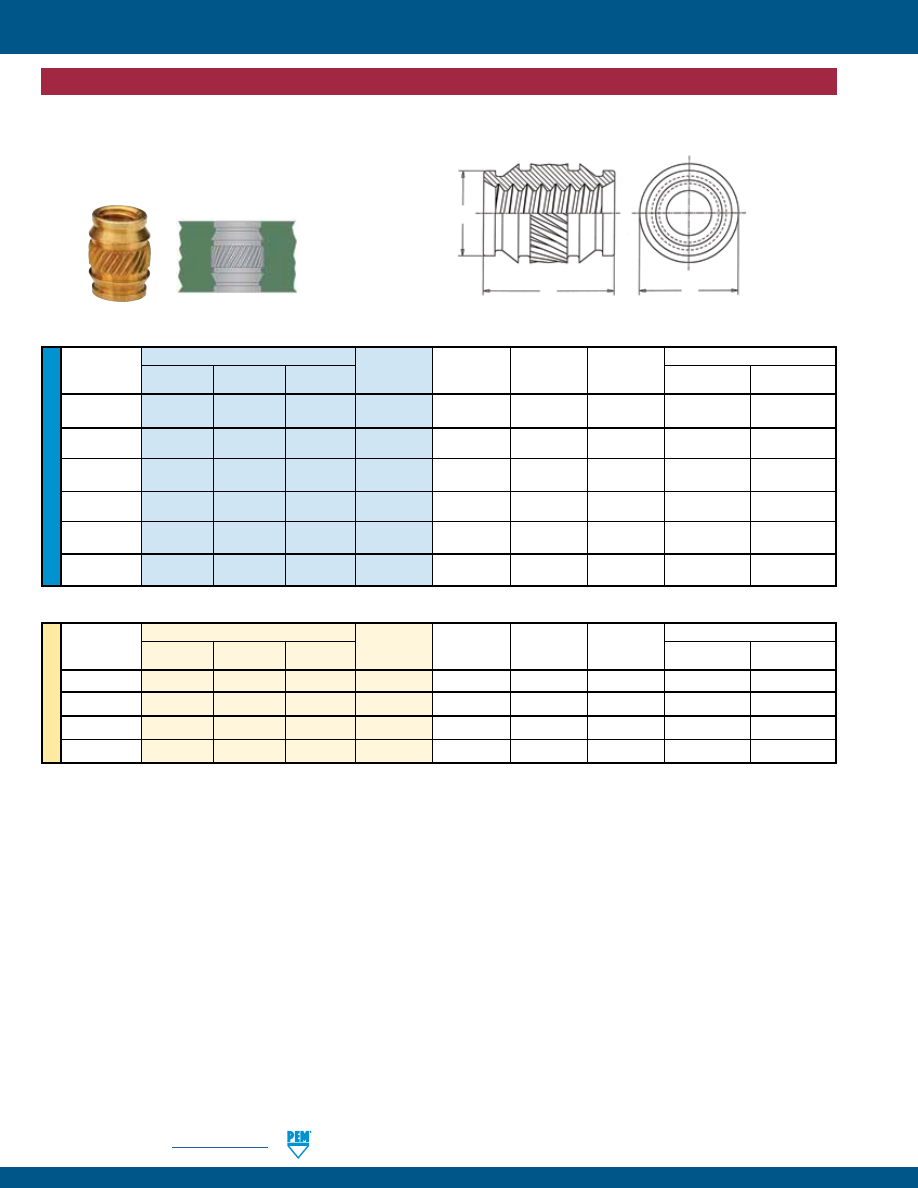

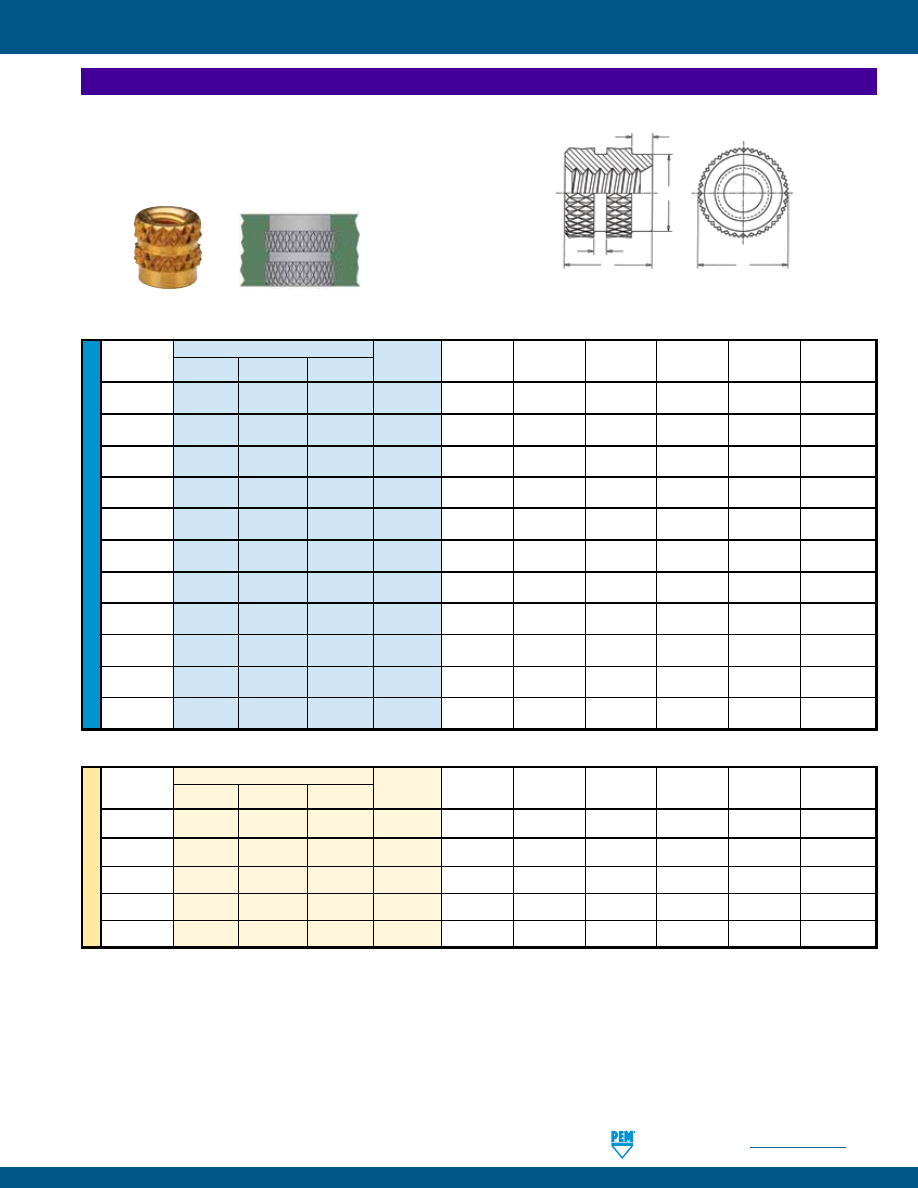

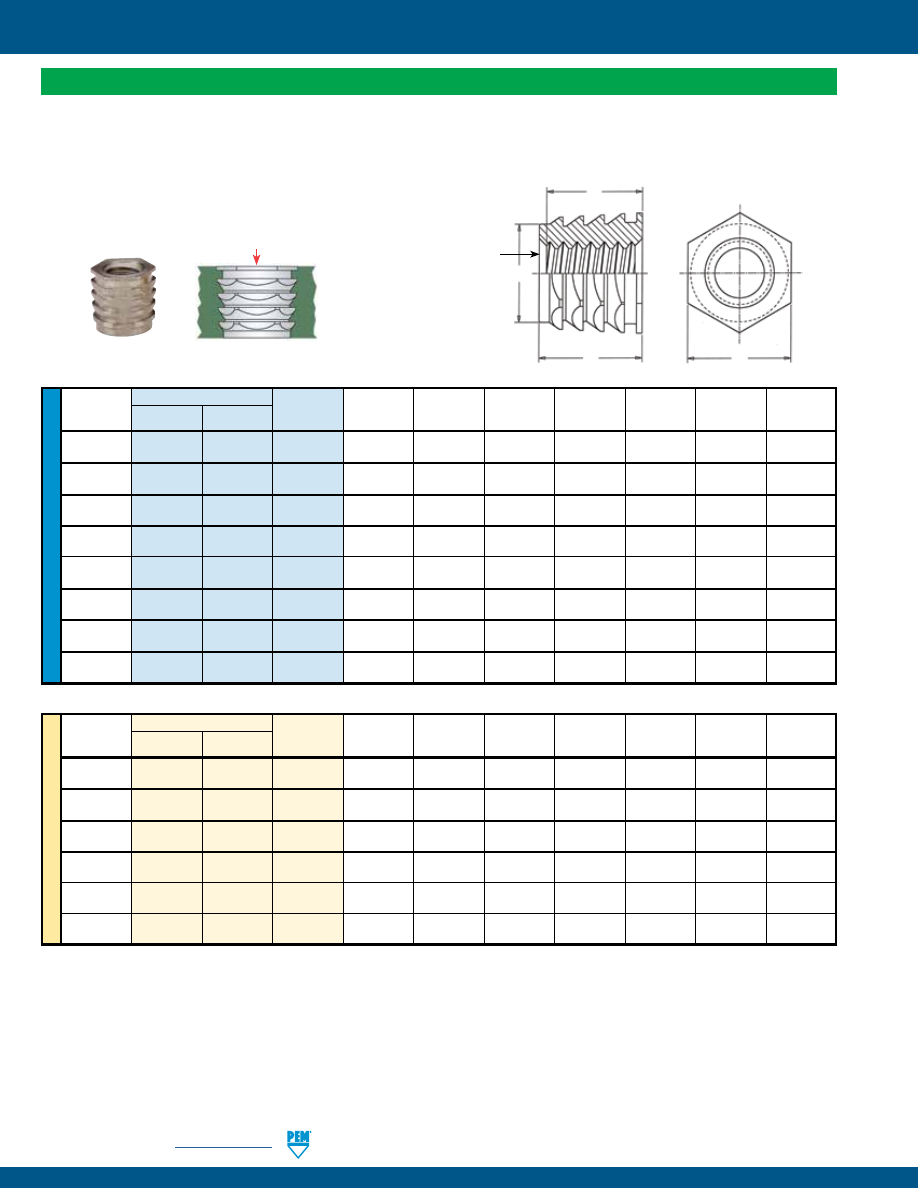

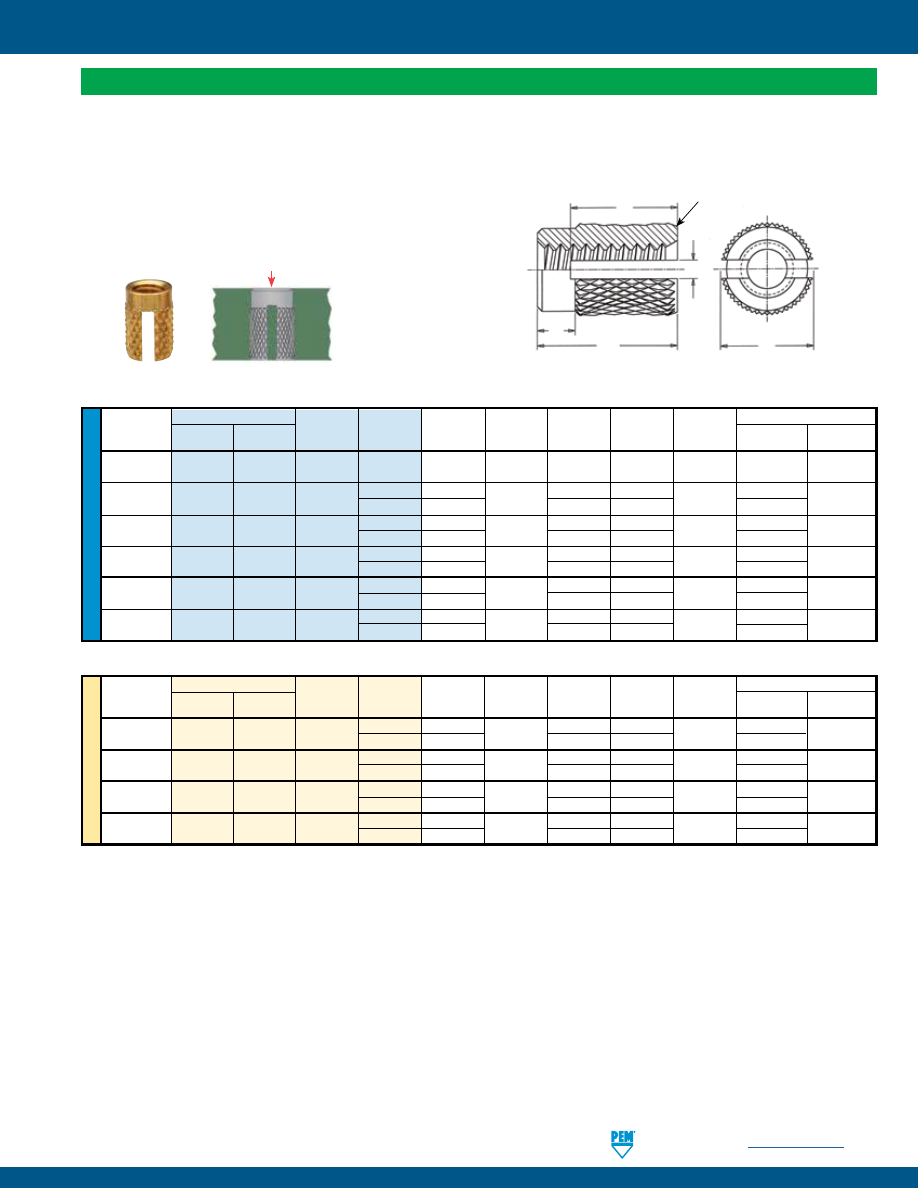

SELF-CLINCHING BLIND FASTENERS

BULLETIN

B

916

pem-html.html

B-2

PennEngineering • www.pemnet.com

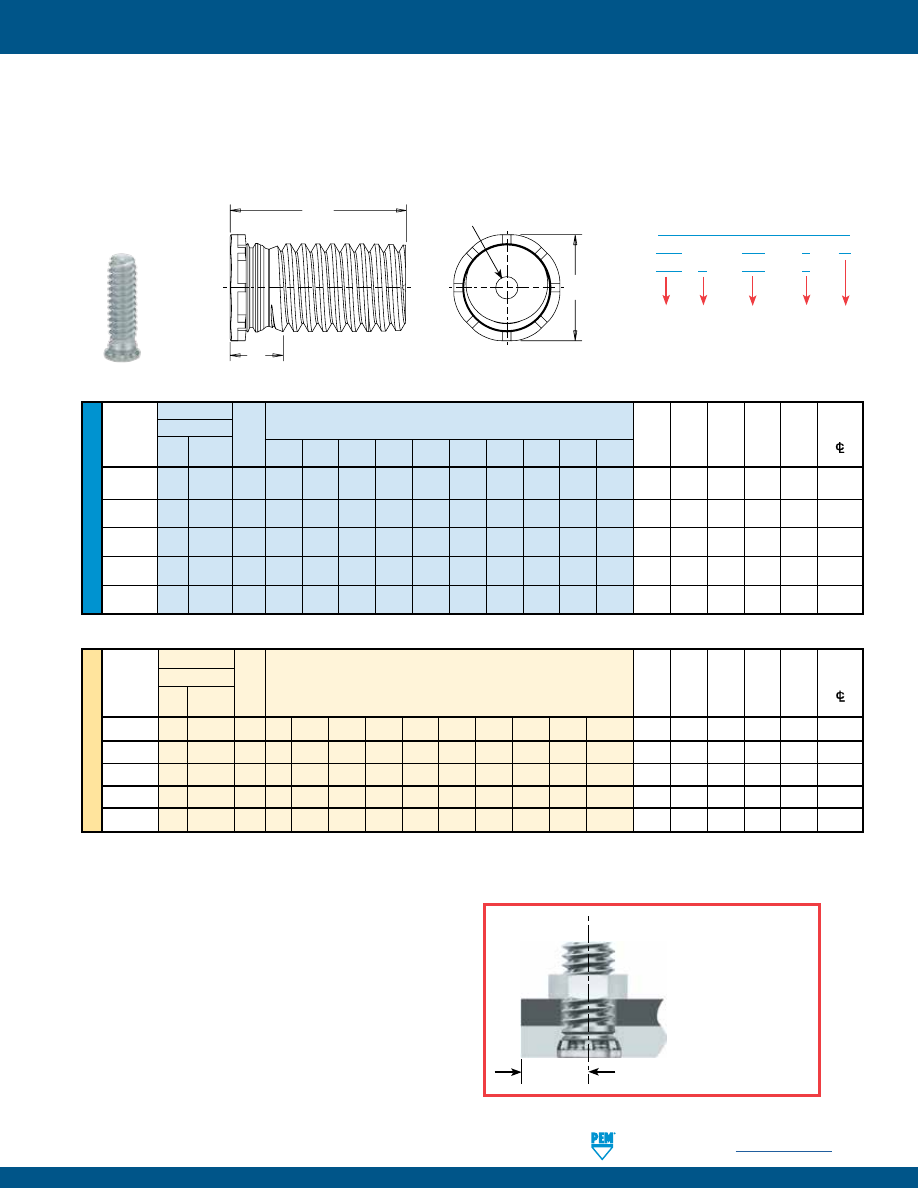

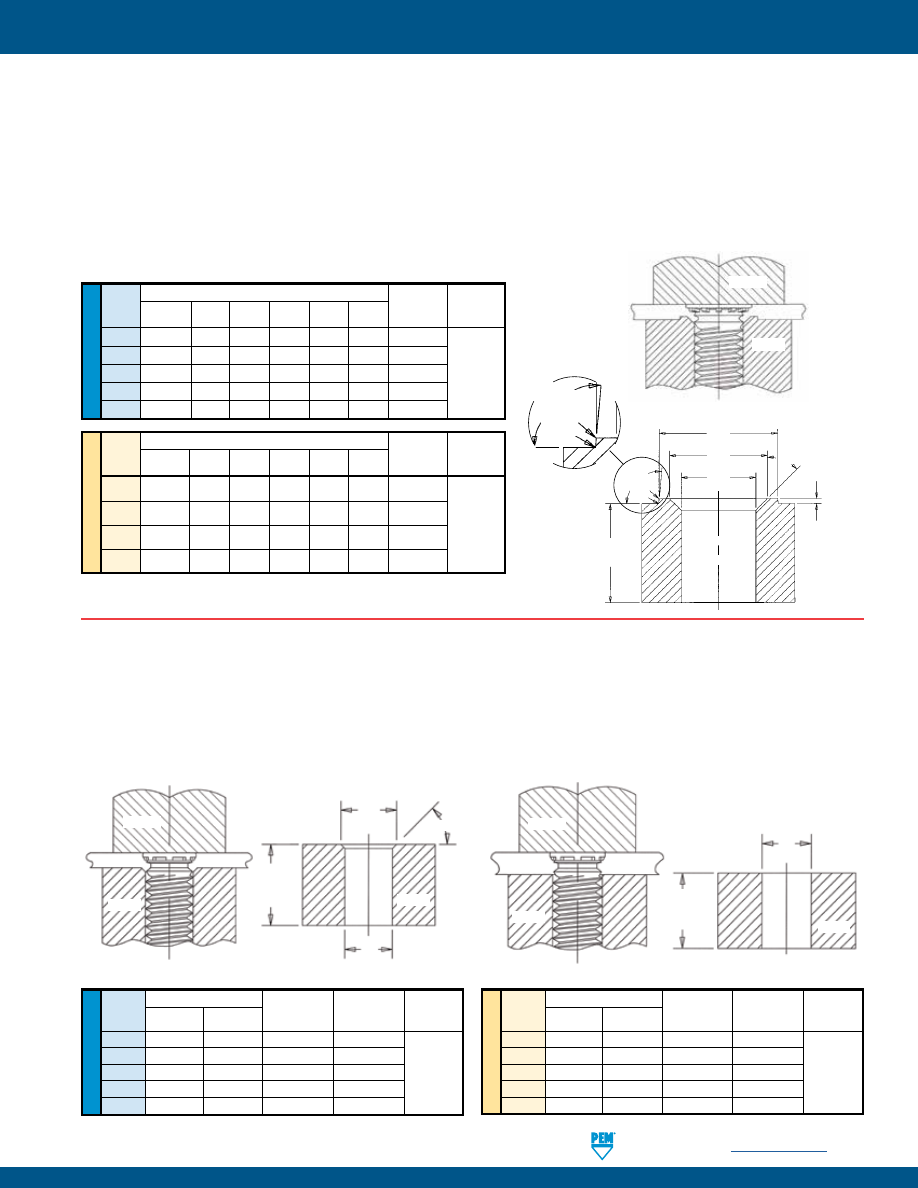

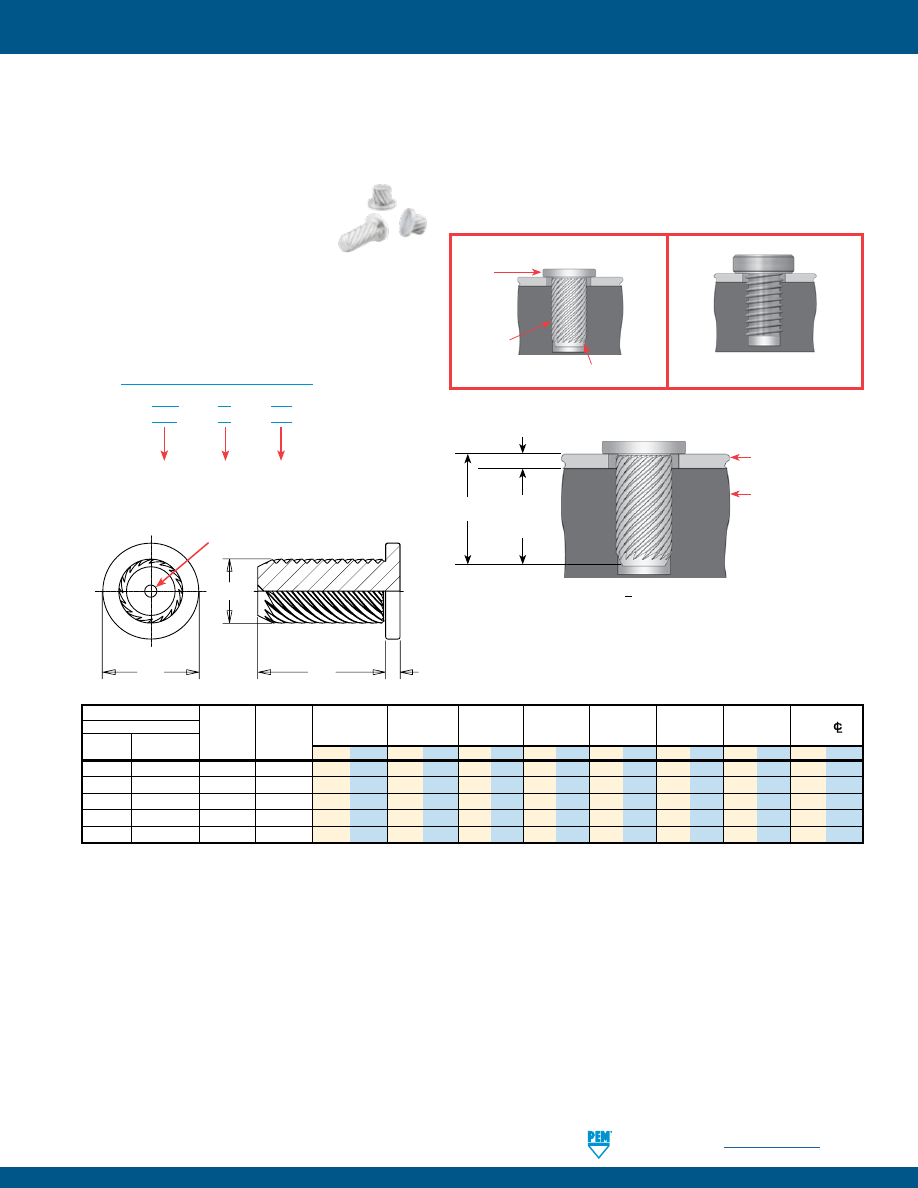

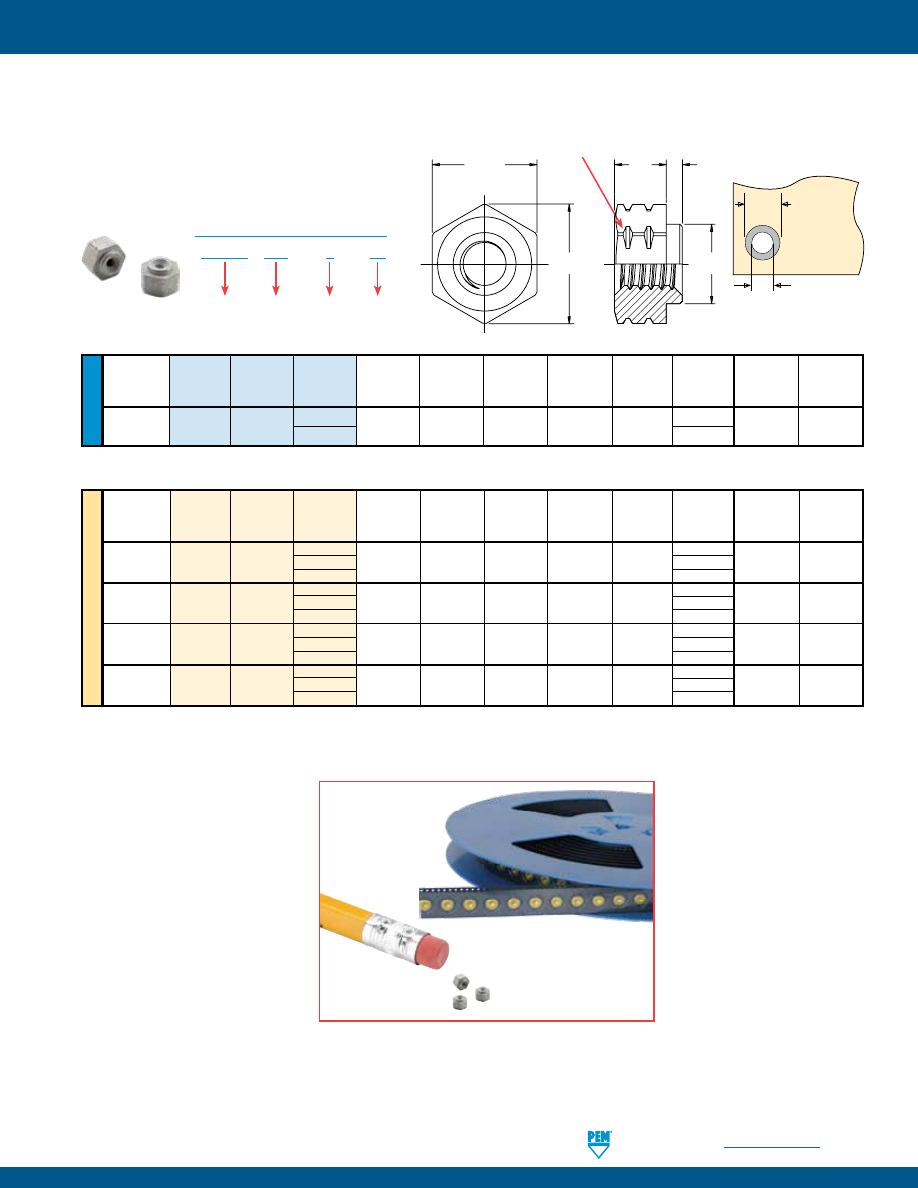

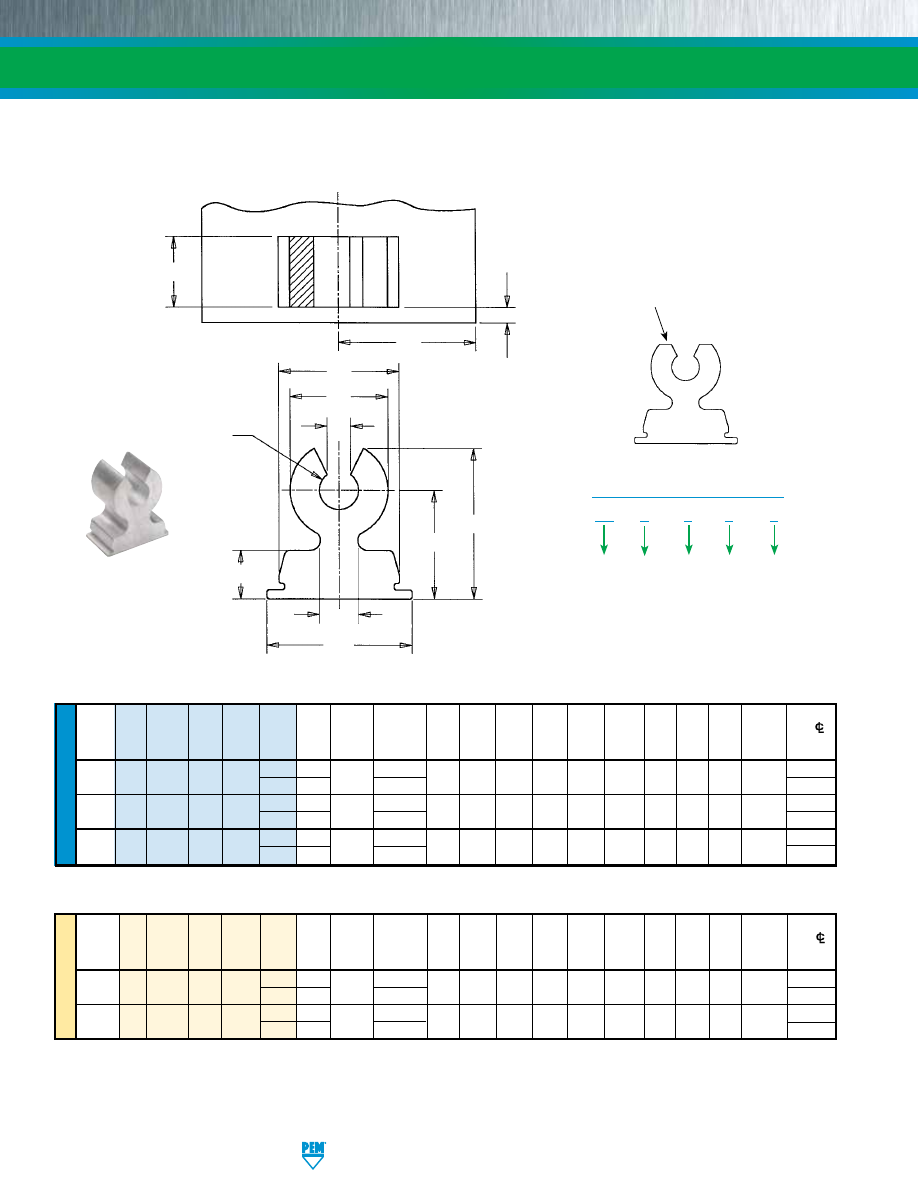

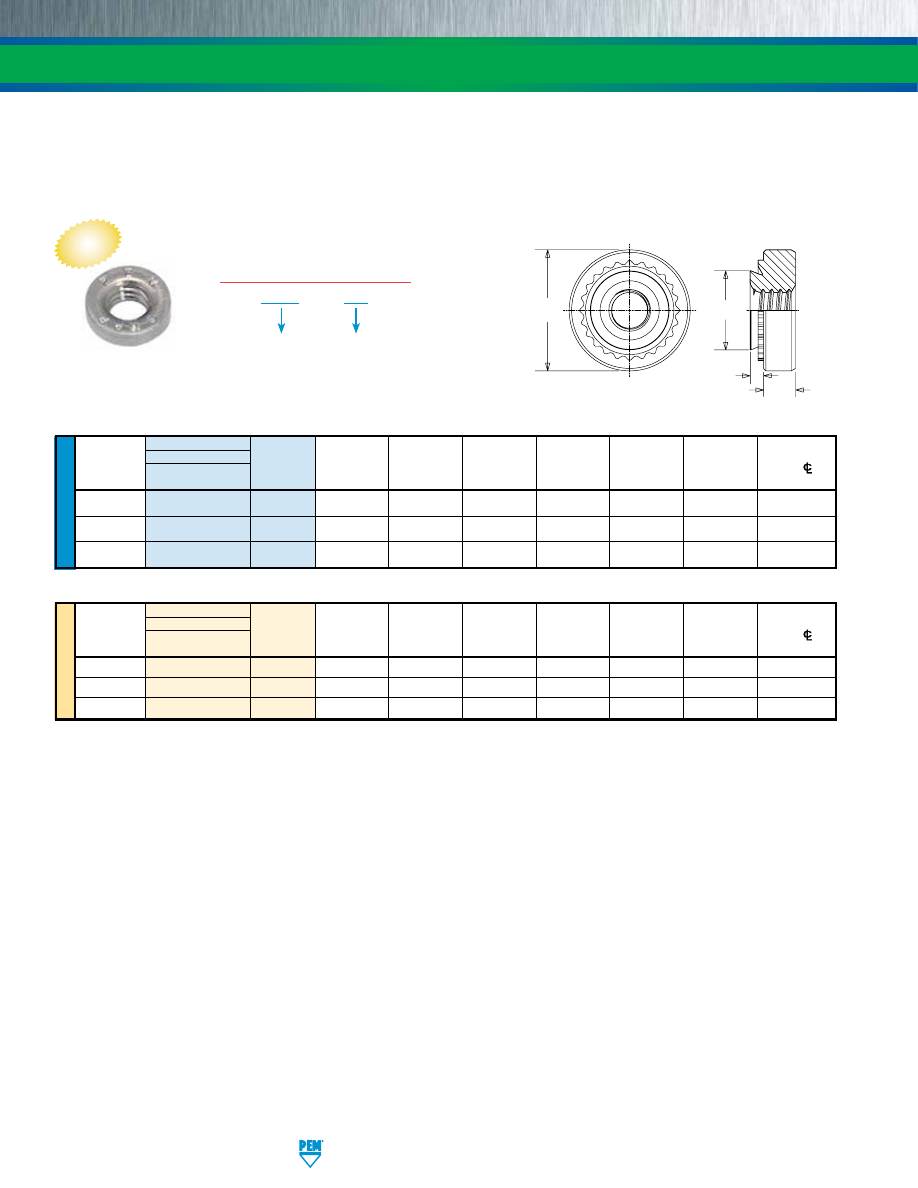

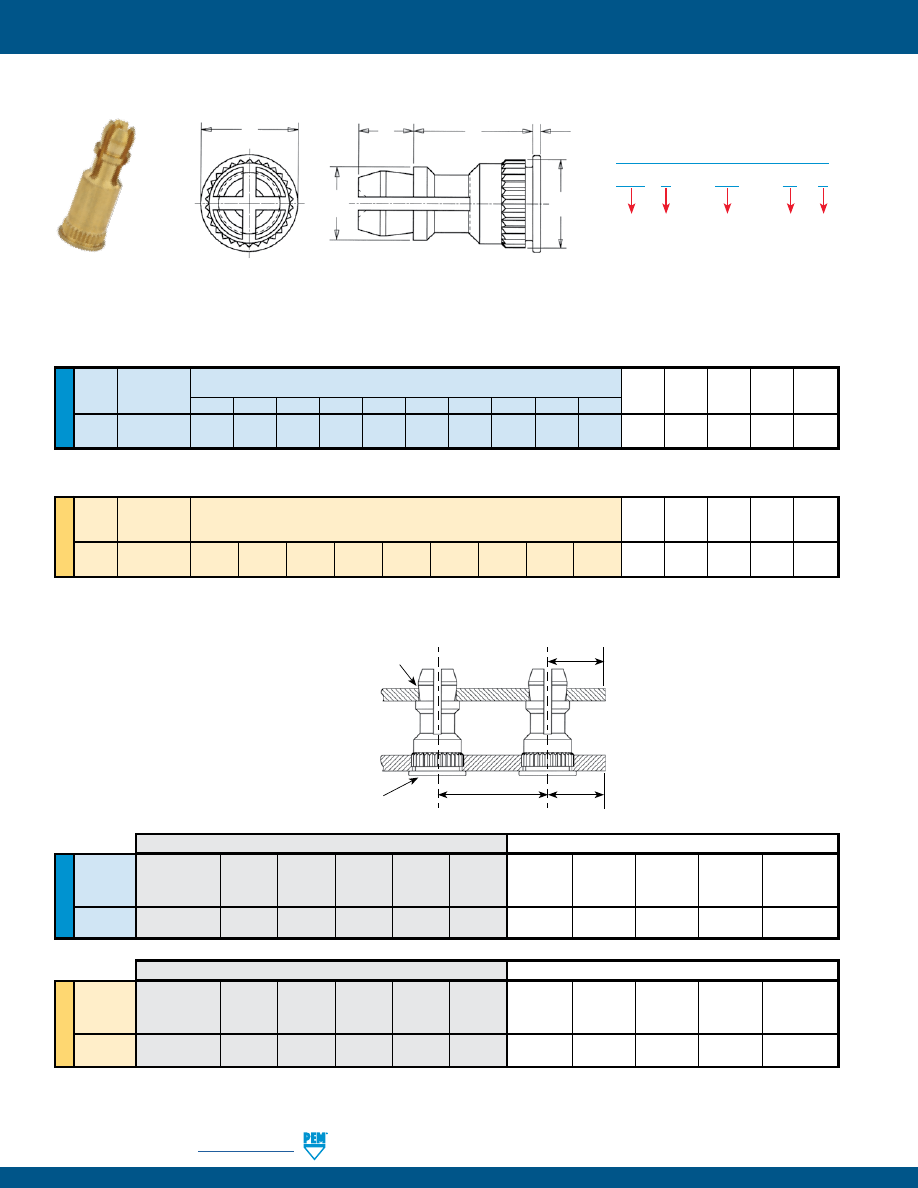

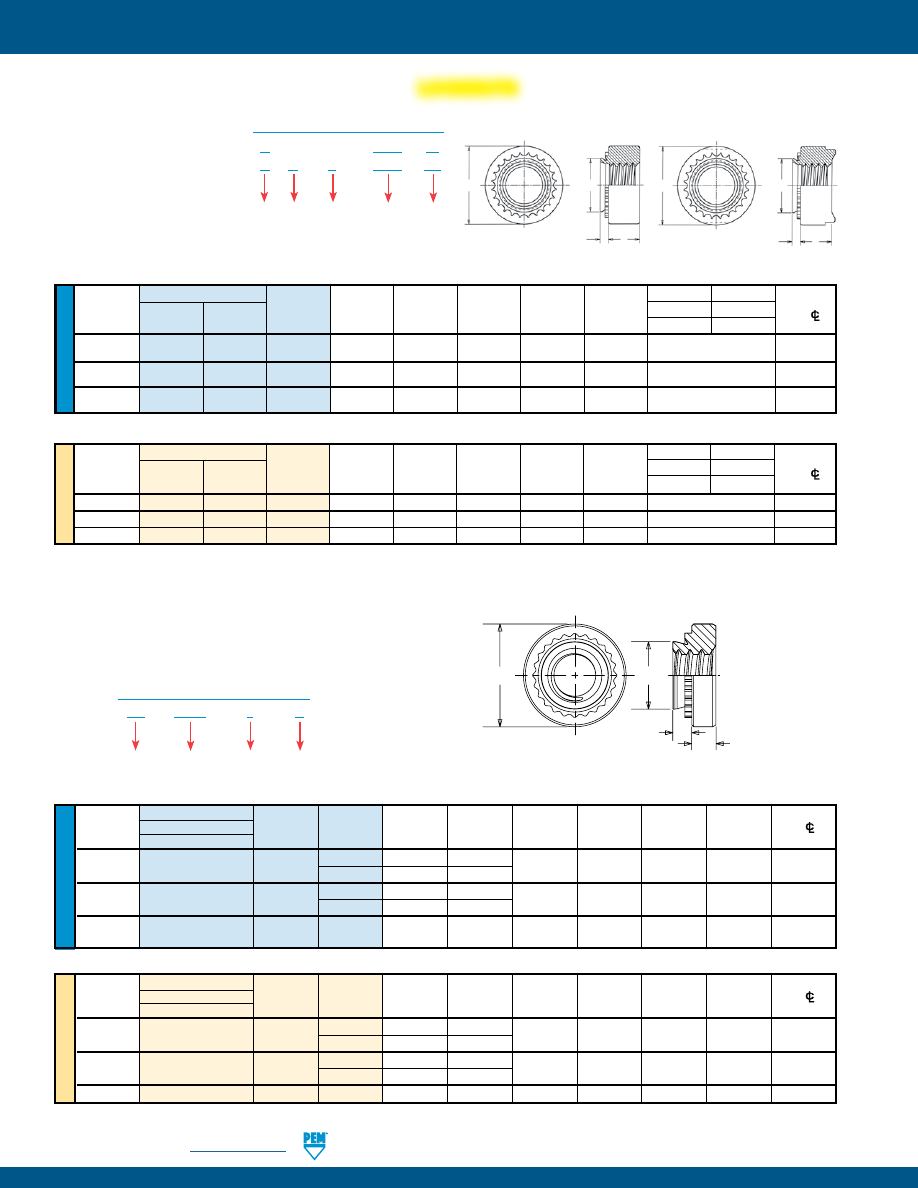

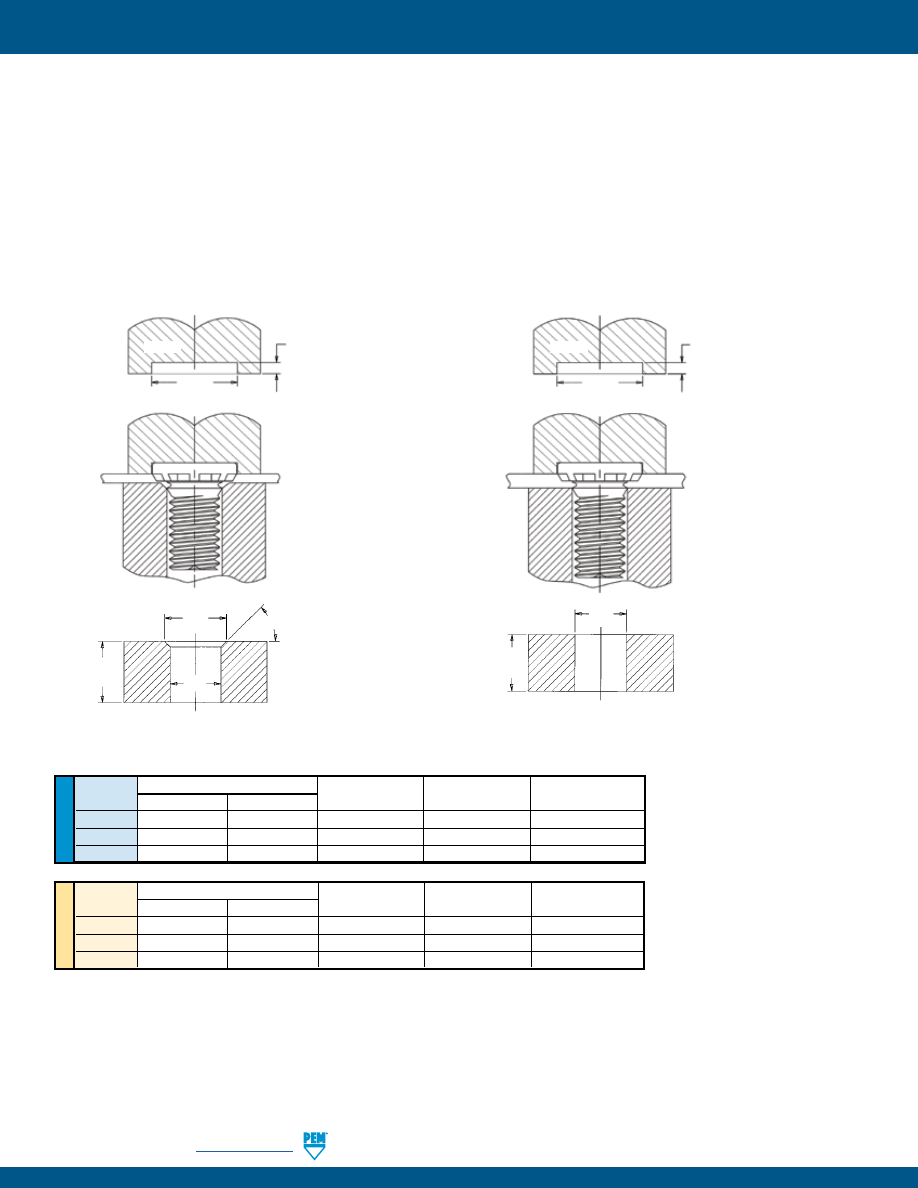

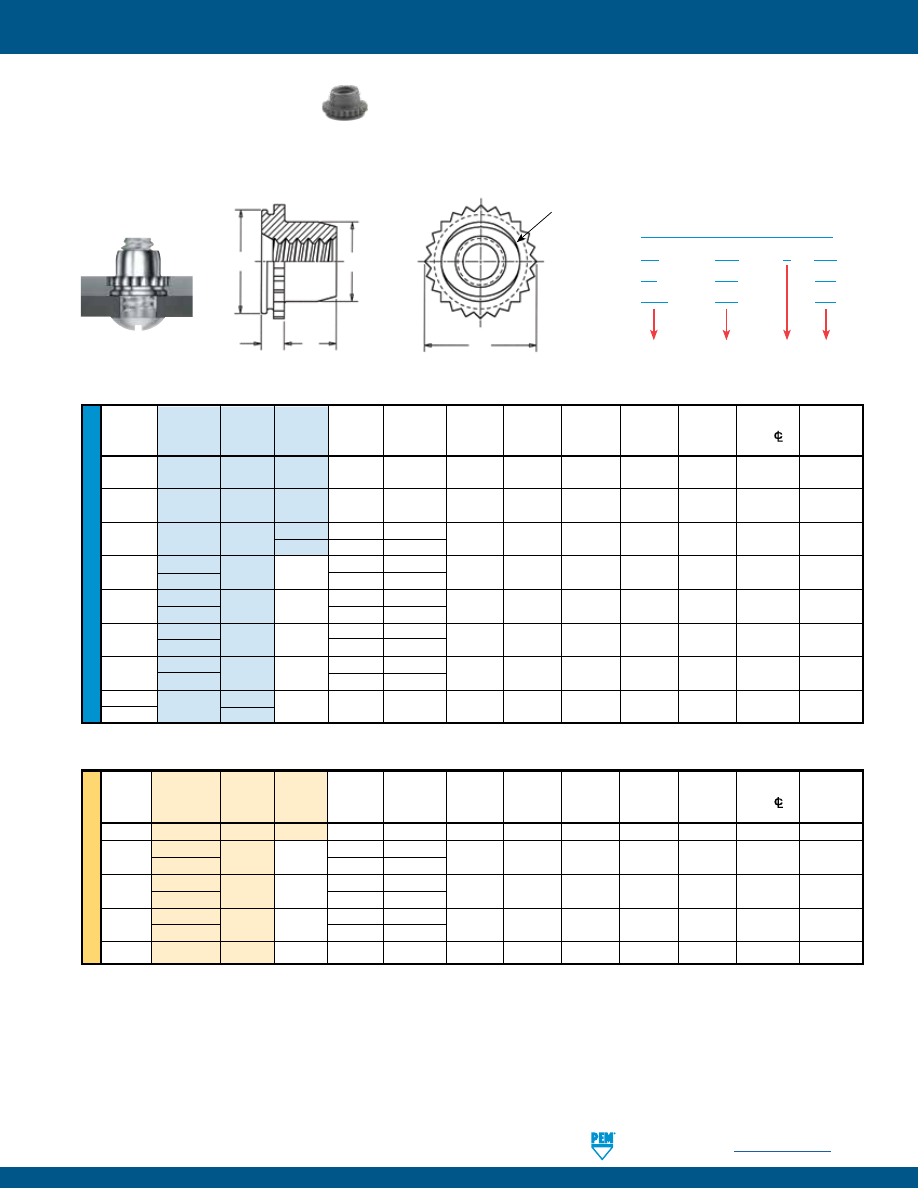

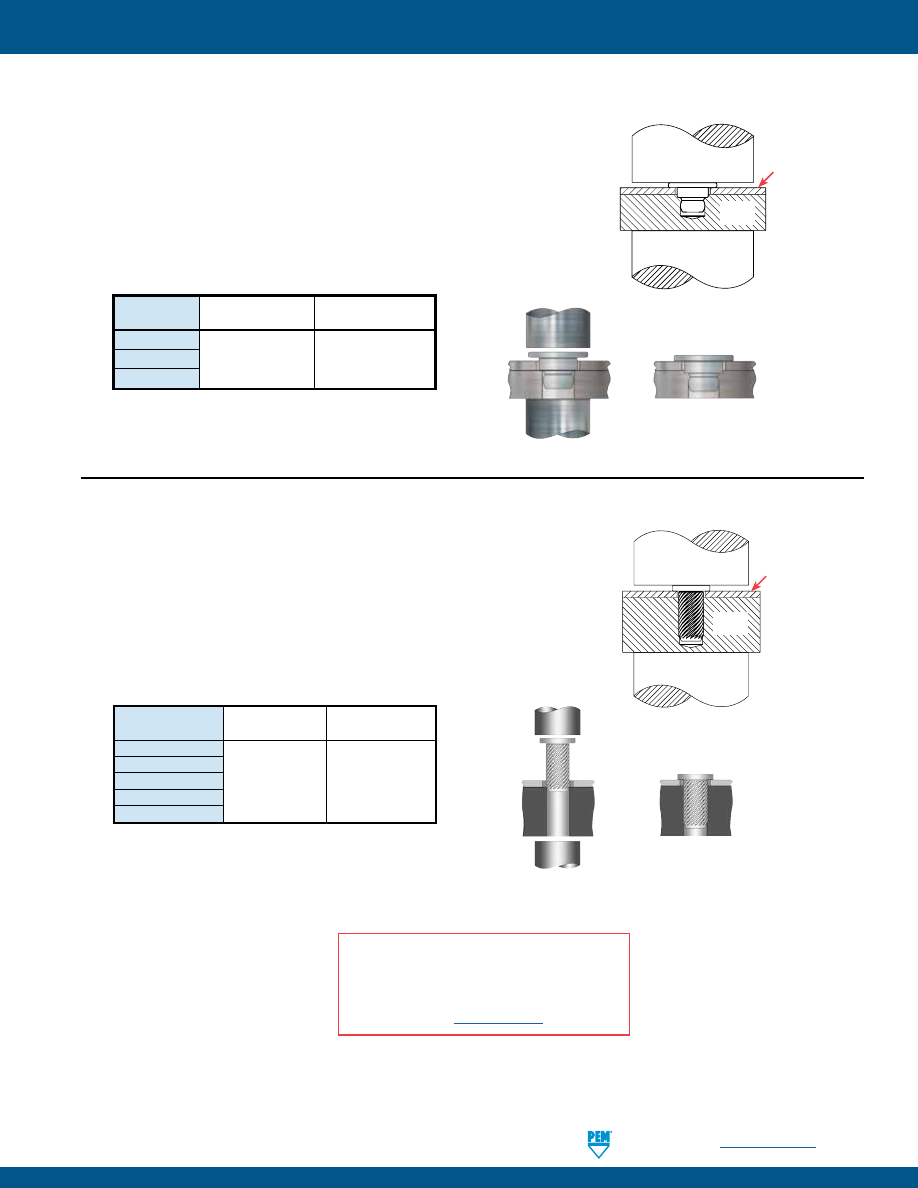

SELF-CLINCHING BLIND FASTENERS

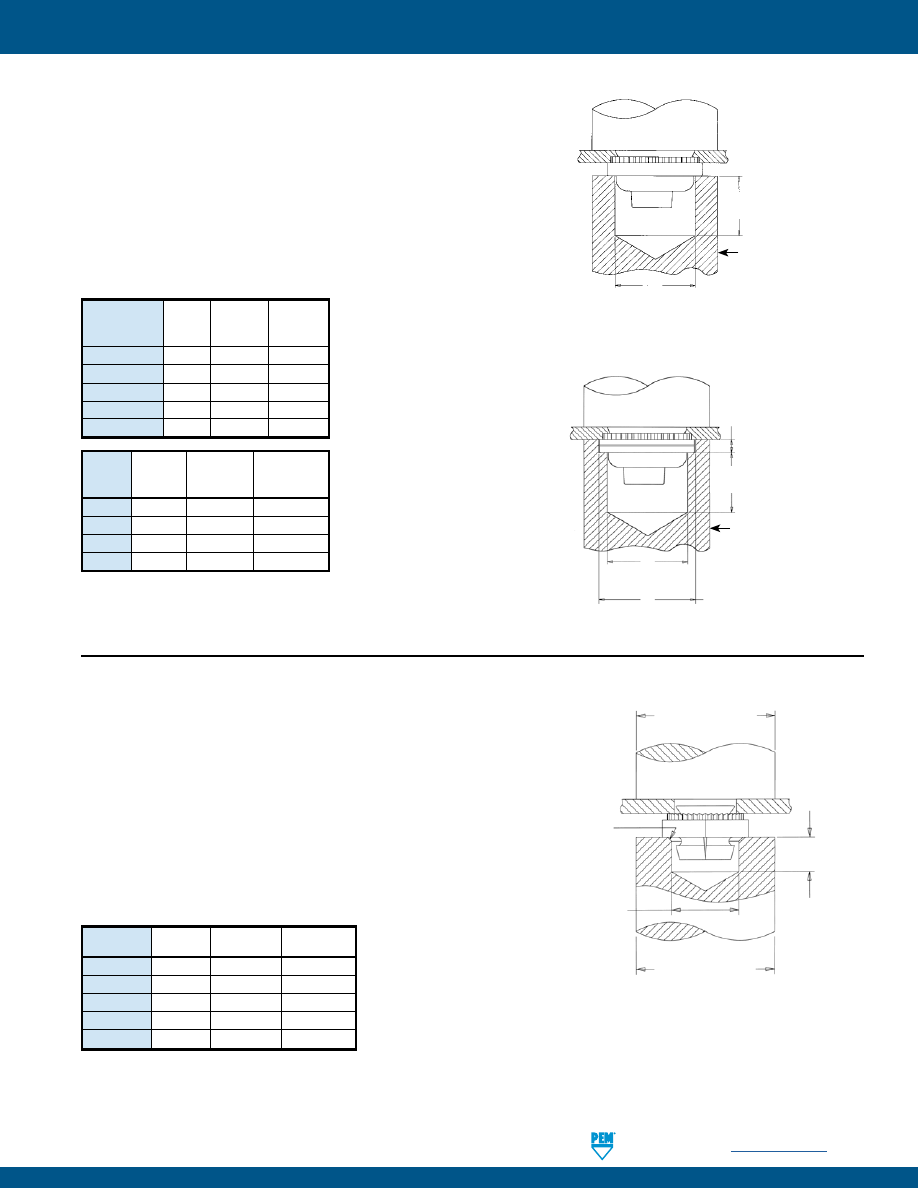

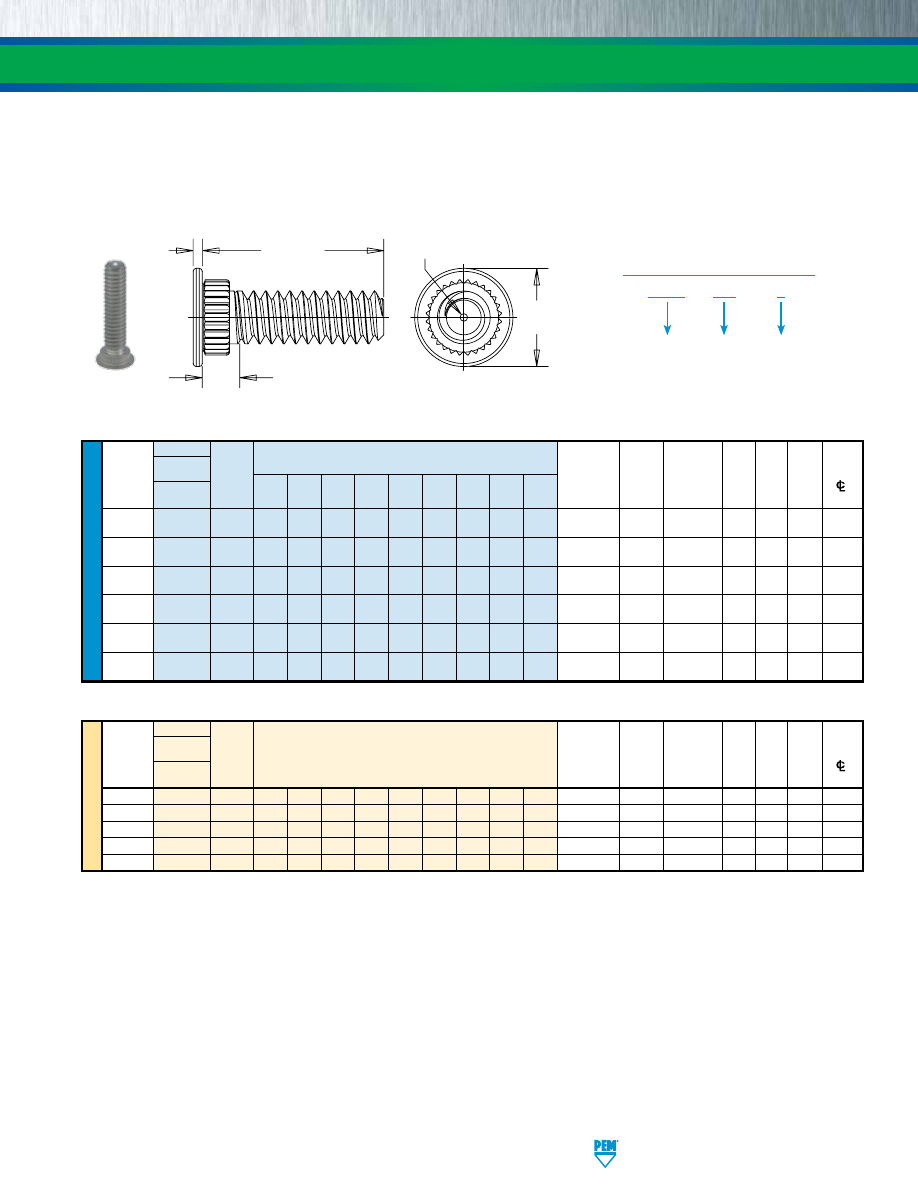

PEM® brand self-clinching blind fasteners provide permanently mounted blind threads in

metal sheets as thin as .040” / 1 mm.

•

Provides barrier to protect threads against foreign matter.

•

Limits screw penetration, protecting internal components from potential damage.

PEM blind fasteners employ the proven PEM self-clinching design and are easily installed into

properly sized holes. Shanks of PEM fasteners act as their own pilots. PEM blind fasteners can be

installed with any standard press applying squeezing forces between parallel surfaces.

PEM self-clinching blind fasteners are available in thread sizes from #4-40 through 1/4-20 / M3 through M6 in carbon or stainless steel.

PEM®

“two groove”

(Registered Trademark)

Fastener drawings

and models are

available at

www.pemnet.com

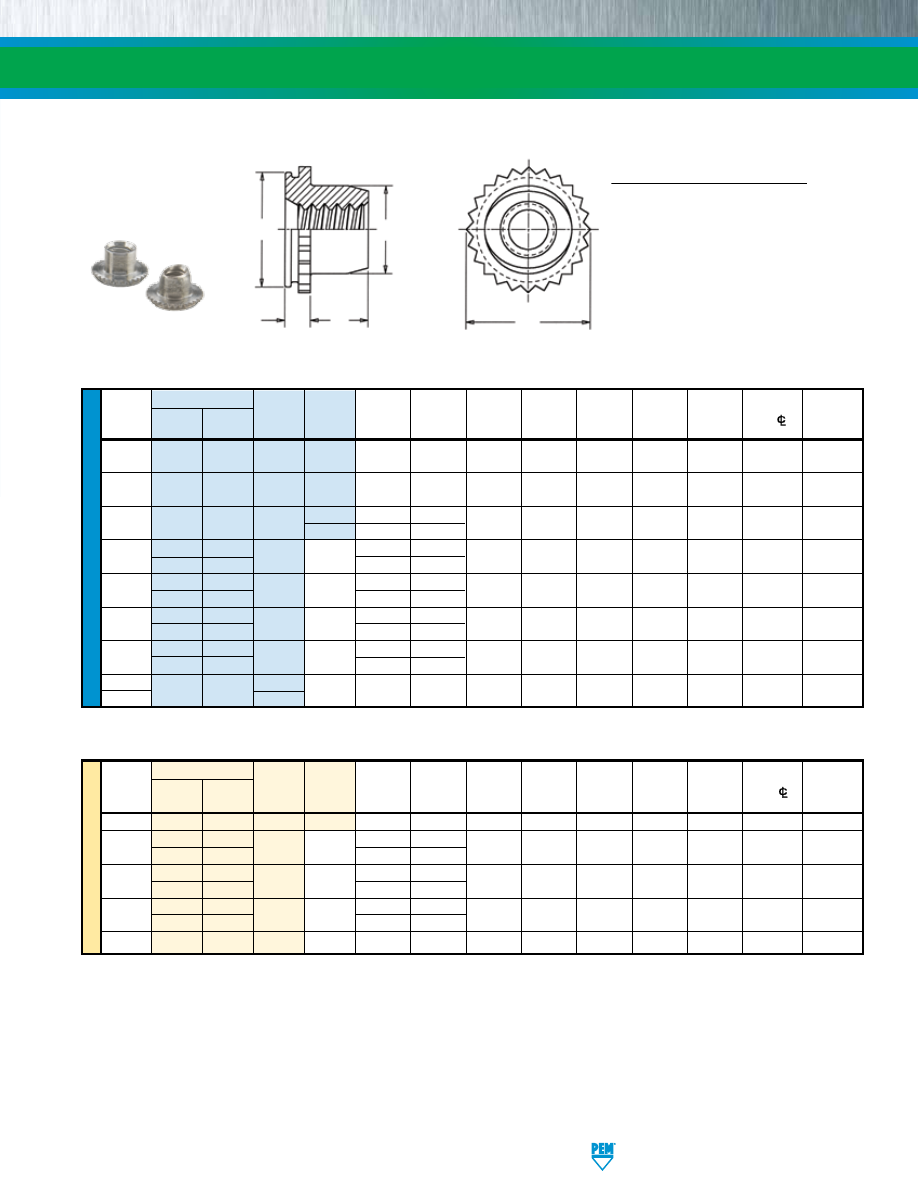

pem-html.html

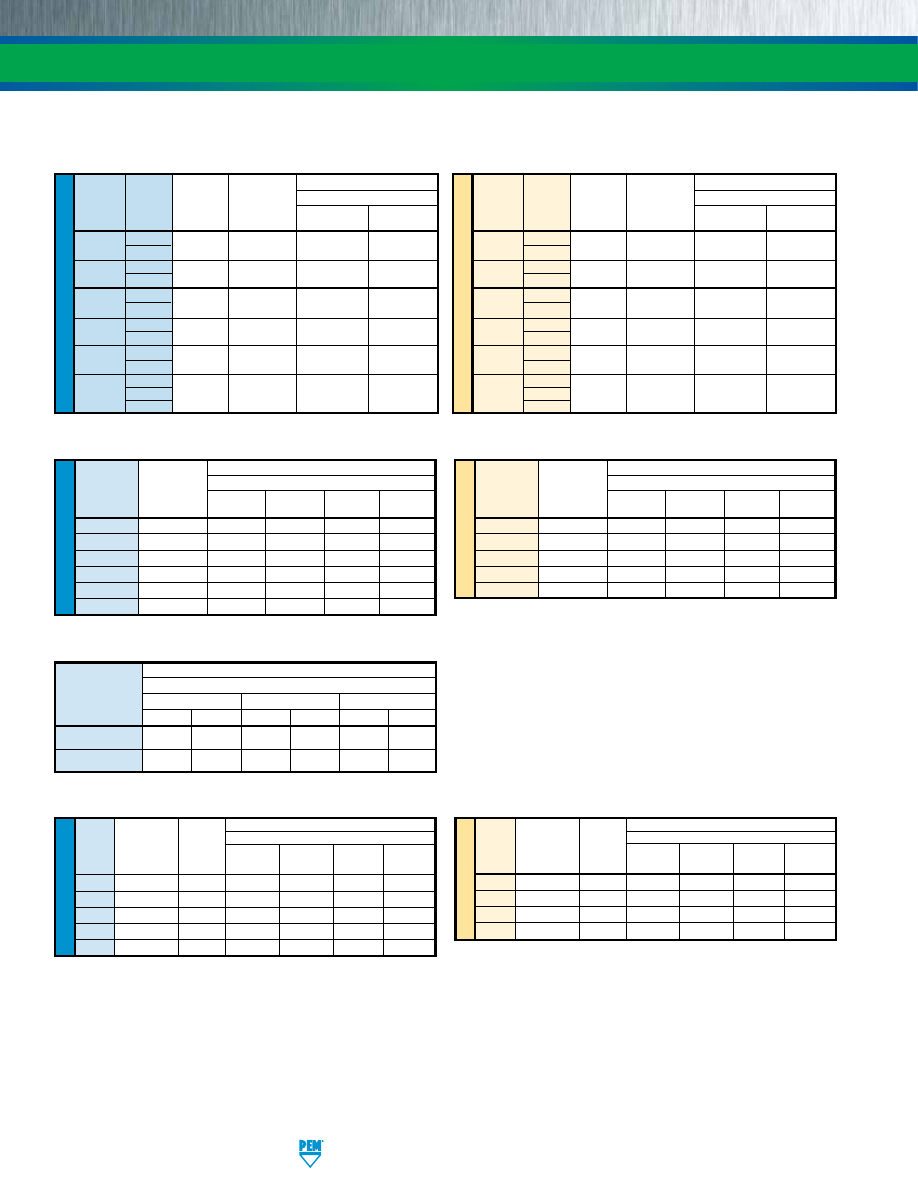

ME

TR

IC

Threads

Fastener Materials

Standard Finishes

For Use in Sheet Hardness: (2)

Internal,

Passivated and/or

HRB 80 /

HRB 70 /

ASME B1.1, 2B /

Hardened

300 Series

Tested Per

Zinc Plated, 5µm,

HB 150

HB 125

Type

ASME B1.13M, 6H

Carbon Steel

Stainless Steel

ASTM A380

Colorless (1)

or less

or less

B

• • • •

BS

• • •

•

Part Number Code For Finishes

None ZI

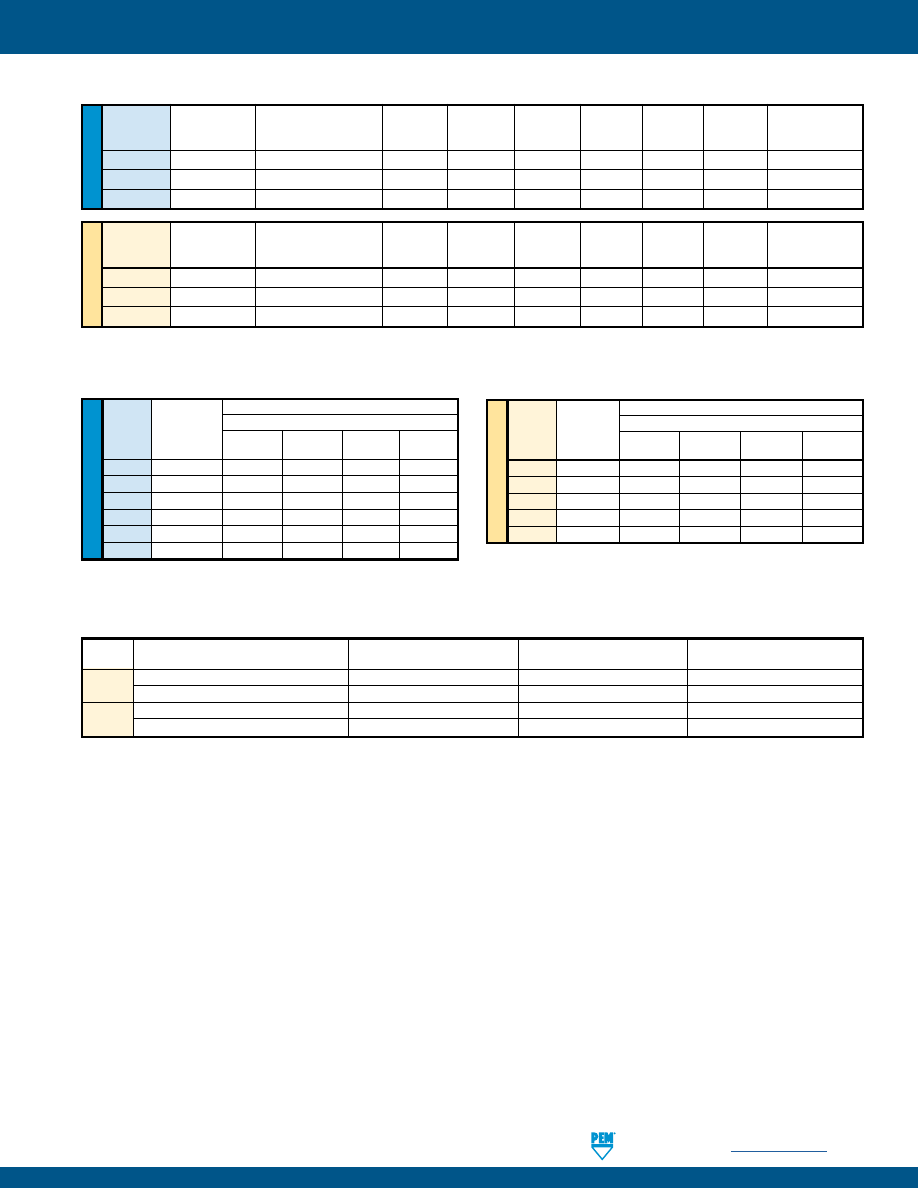

PennEngineering • www.pemnet.com

B-3

U

NIF

IE

D

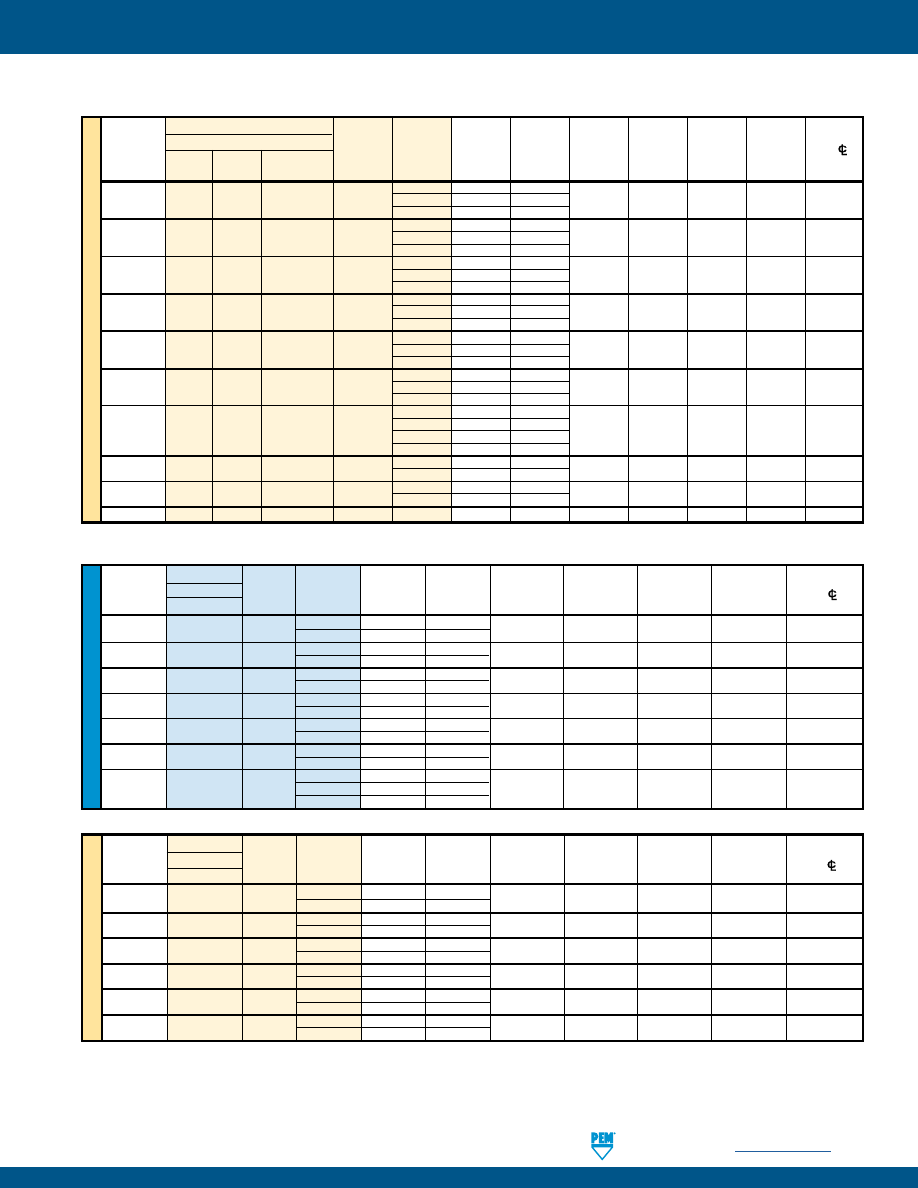

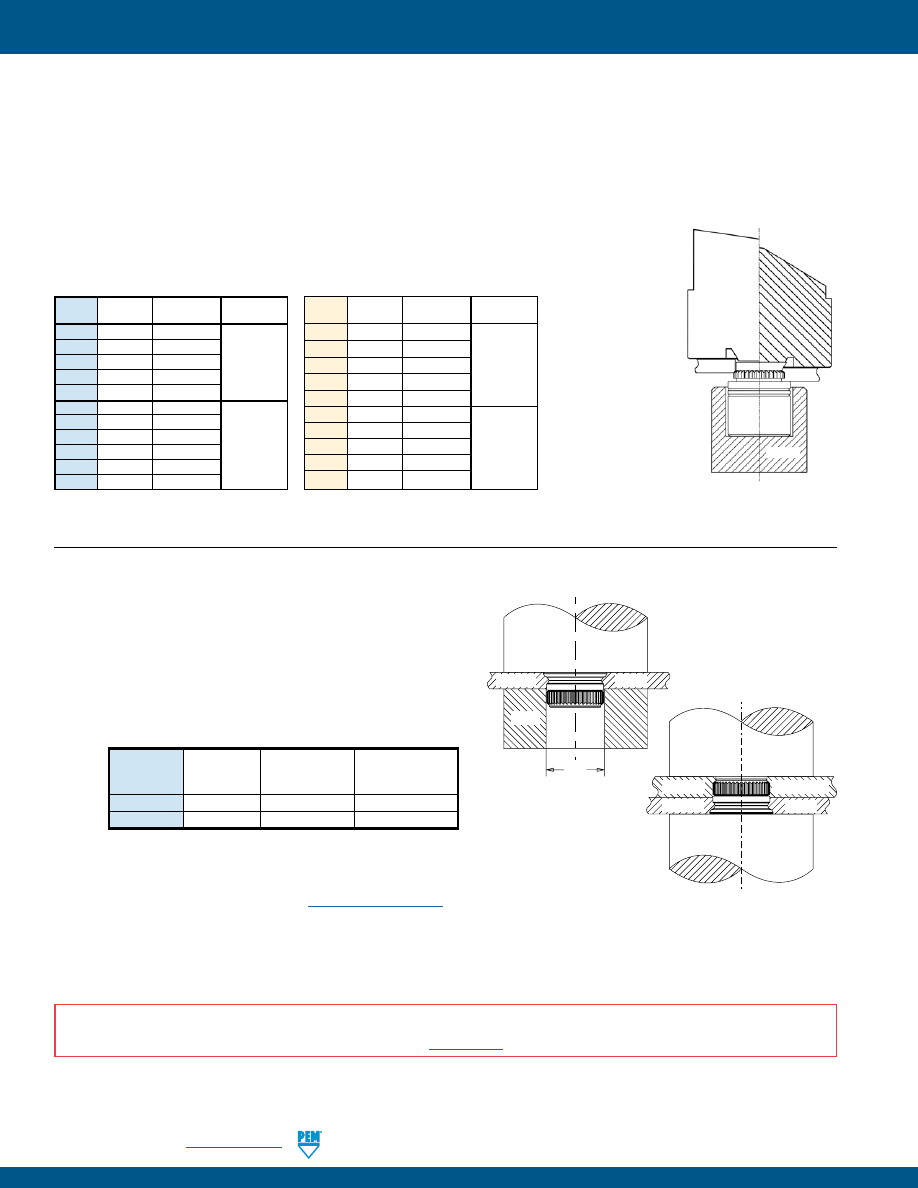

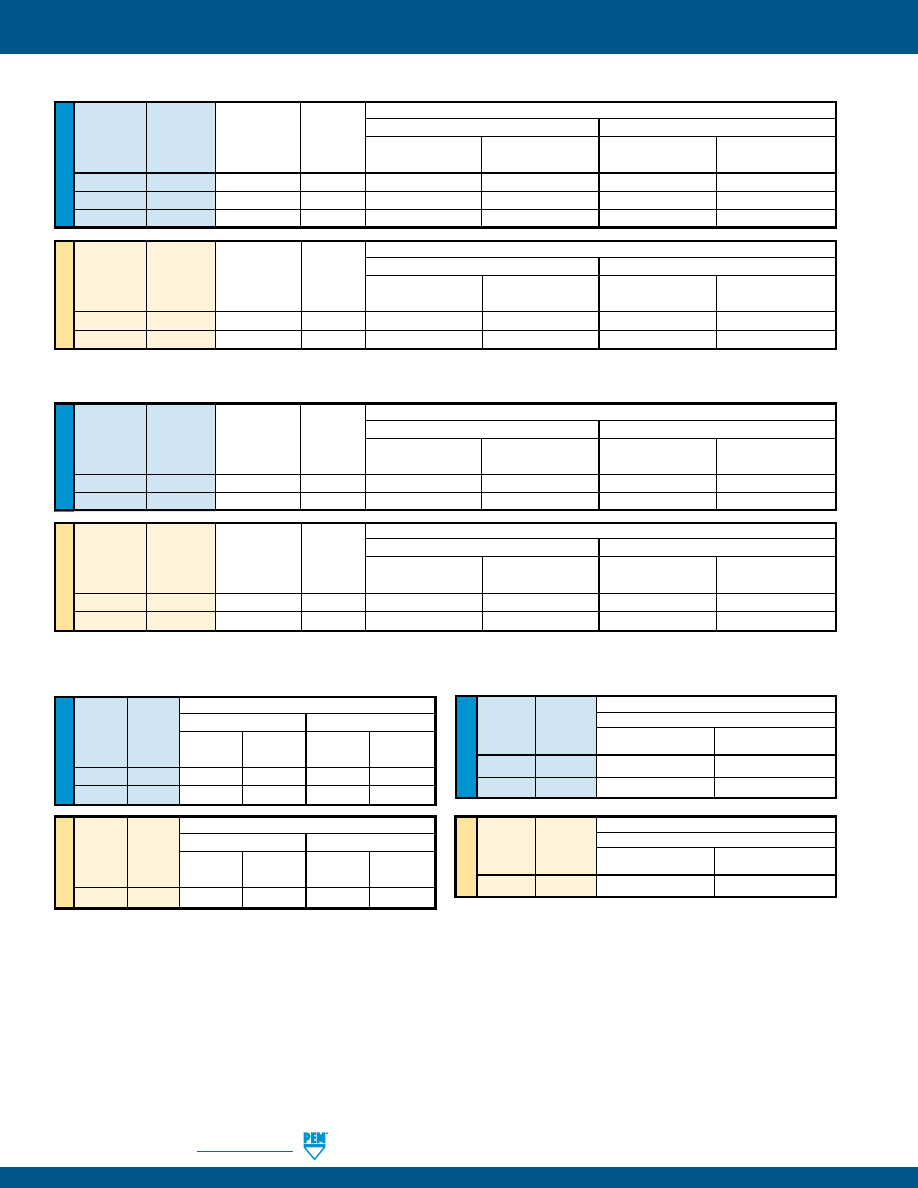

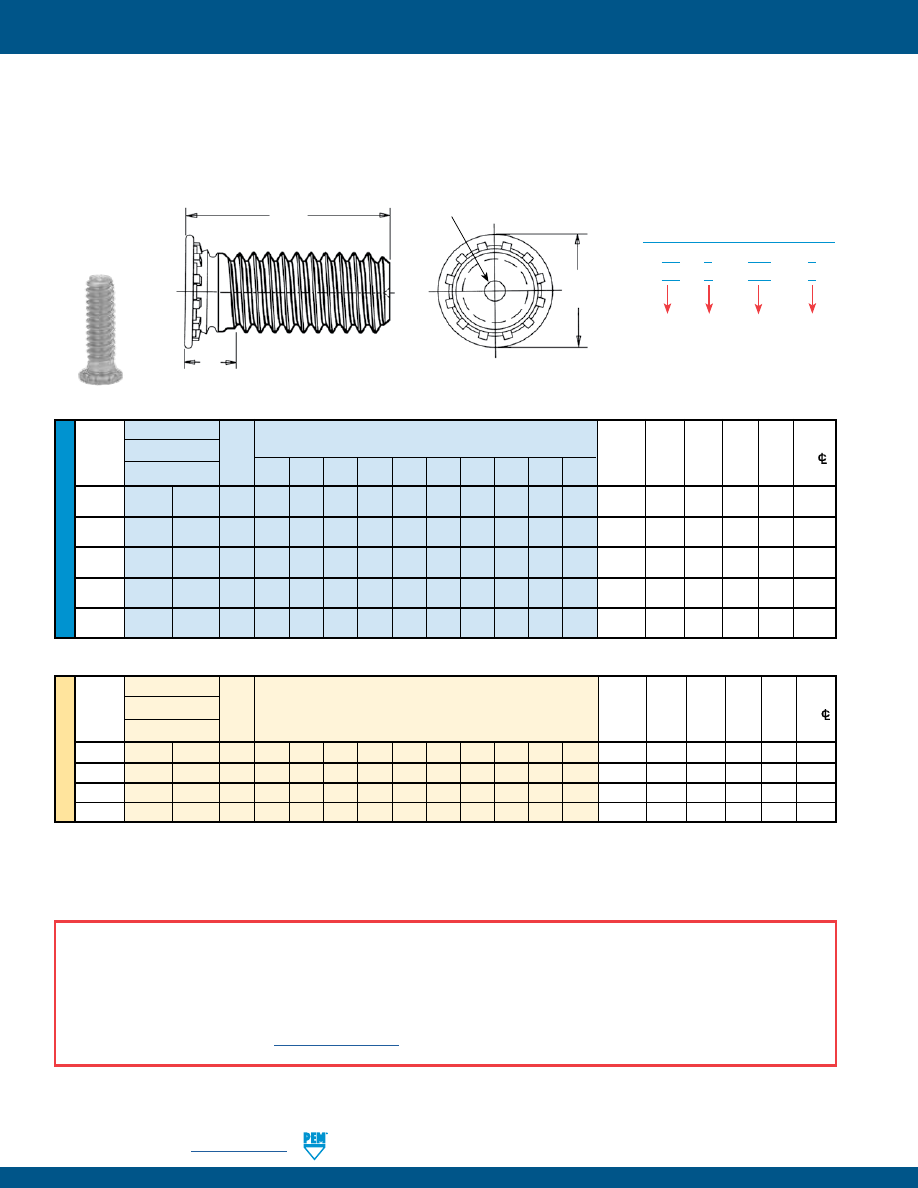

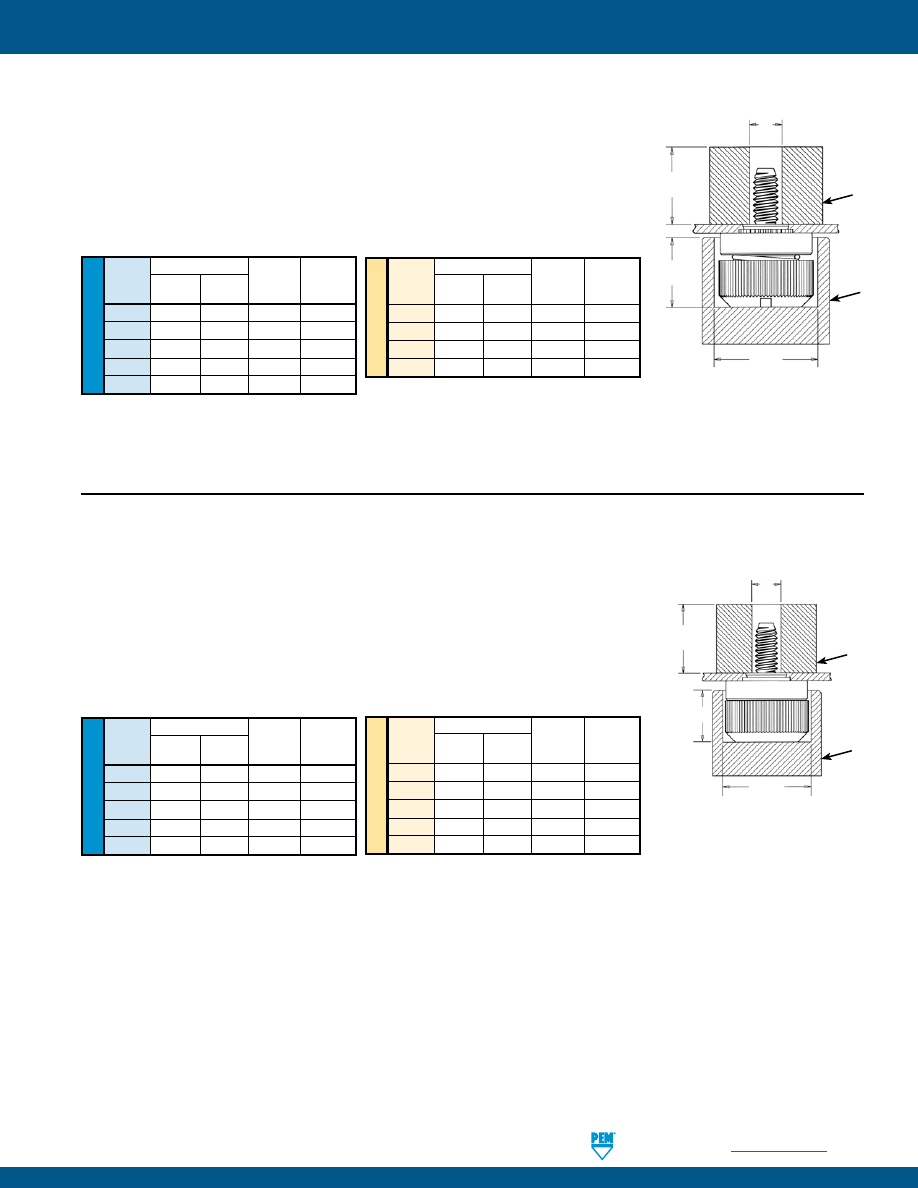

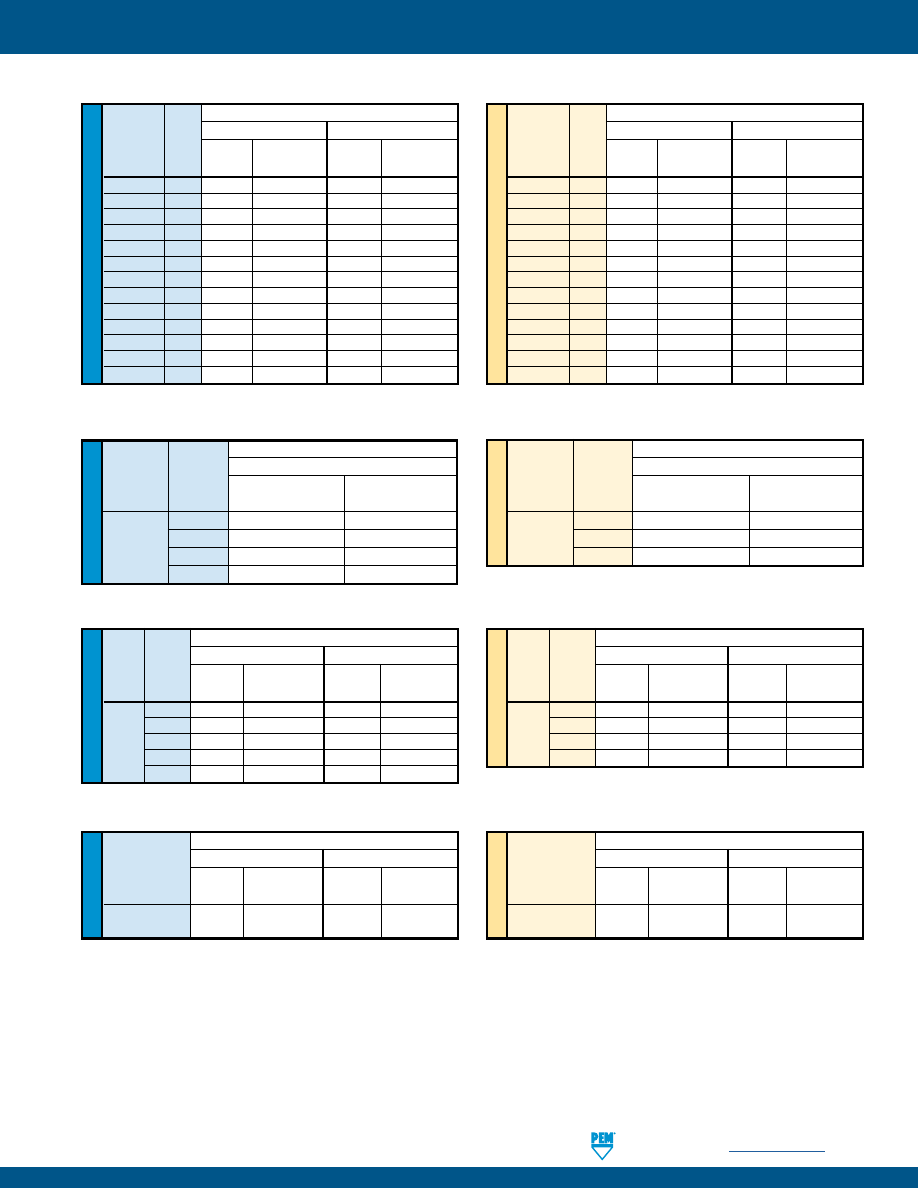

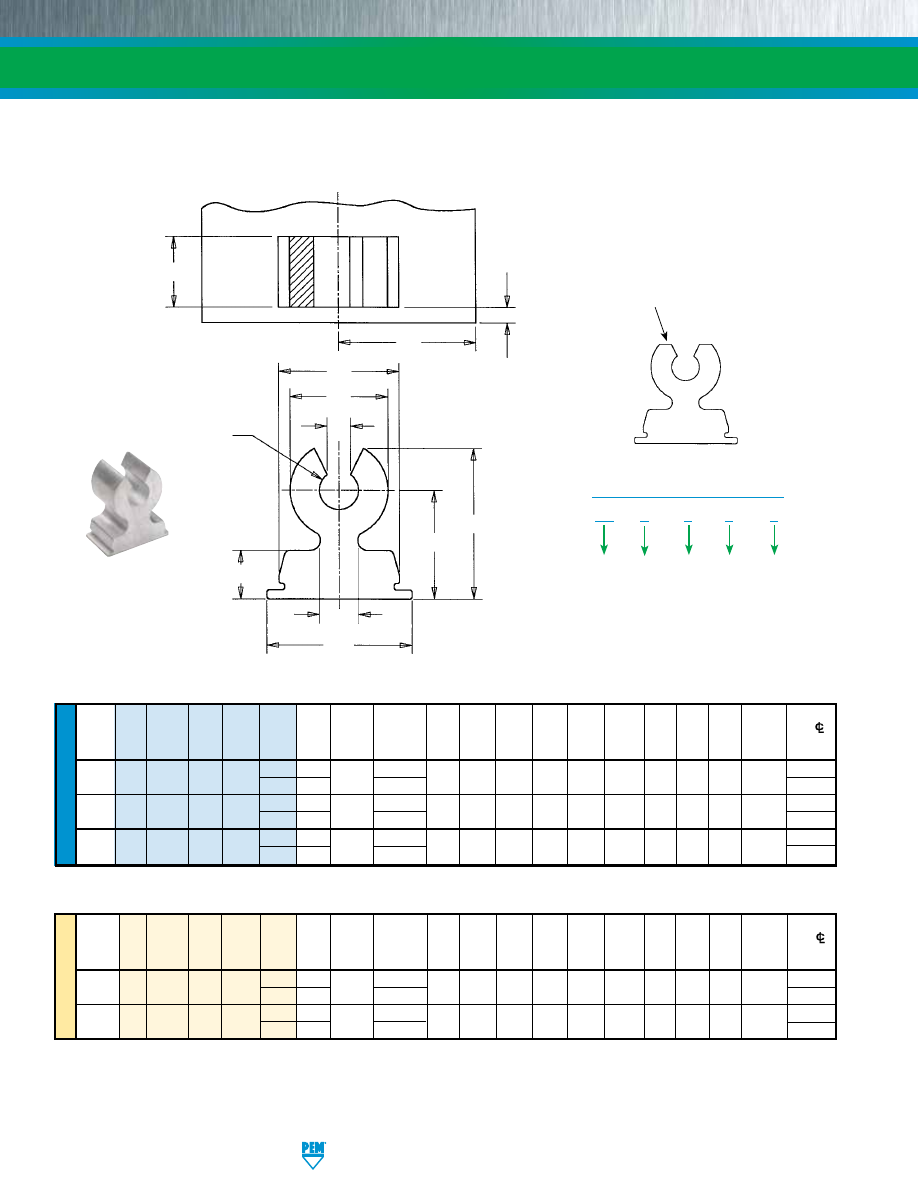

Type

A

Min.

Hole Size

Thread

Fastener Material

Thread Shank (Shank)

Sheet

in Sheet

B

C

E

F

L

T

Min. Dist.

Size

Steel Stainless

Code Code Max. Thickness + .003

Max.

Max.

± .010

Min.

Max.

± .010

Hole

C/L

Steel

-

.000

to

Edge

.112-40

B BS 440

1 .038 .040

.166 .150 .165 .250 .210 .335 .380 .19

(#4-40)

2 .054 .056

.138-32

B BS 632

1 .038 .040

.1875 .169 .187 .280 .230 .335 .380 .22

(#6-32)

2 .054 .056

.164-32

B BS 832

1 .038 .040

.213 .204 .212 .310 .280 .385 .440 .27

(#8-32)

2 .054 .056

.190-32

B BS 032

1 .038 .040

.250 .235 .249 .340 .280 .385 .440 .28

(#10-32)

2 .054 .056

.250-20

B BS 0420

1 .054 .056

.344 .305 .343 .430 .310 .500 .560 .34

(1/4-20)

2 .087 .090

All dimensions are in inches.

Thread Type

A

Min.

Hole Size

Size x Fastener Material Thread Shank (Shank)

Sheet

in Sheet

B

C

E

F

L

T

Min. Dist.

Pitch

Steel

Stainless Code Code Max.

Thickness

+ 0.08

Max.

Max.

± 0.25

Min.

Max.

± 0.25

Hole

C/L

Steel

to

Edge

M3 x 0.5

B

BS

M3

1 0.97 1

4.22 3.84 4.2 6.35 5.3 8.5 9.6 4.8

2

1.38

1.4

M4 x 0.7

B

BS

M4

1 0.97 1

5.41 5.2 5.38 7.95 7.1 9.8 11.2 6.9

2

1.38

1.4

M5 x 0.8

B

BS

M5

1 0.97 1

6.35 6.02 6.33 8.75 7.1 9.8 11.2 7.1

2

1.38

1.4

M6 x 1

B

BS

M6

1 1.38 1.4

8.75 7.8 8.73 11.1 7.8 12.7 14.3 8.6

2

2.21

2.29

All dimensions are in millimeters.

Metric parts are

identified by large

chamfer at blind end.

PEM®

“two groove”

registered trademark.

(1) See PEM Technical Support section of our web site (www.pemnet.com) for related plating standards and specifications.

(2) HRB - Hardness Rockwell “B” Scale. HB - Hardness Brinell.

SELF-CLINCHING BLIND FASTENERS

MATERIAL AND FINISH SPECIFICATIONS

B

S – 832 – 2

Type

Finish

PART NUMBER DESIGNATION

Material

Code

Thread

Size Code

Shank

Code

B – 832 – 2

ZI

T

L

A

E

C

F

Full Thread Depth

B

Clinching profile may vary.

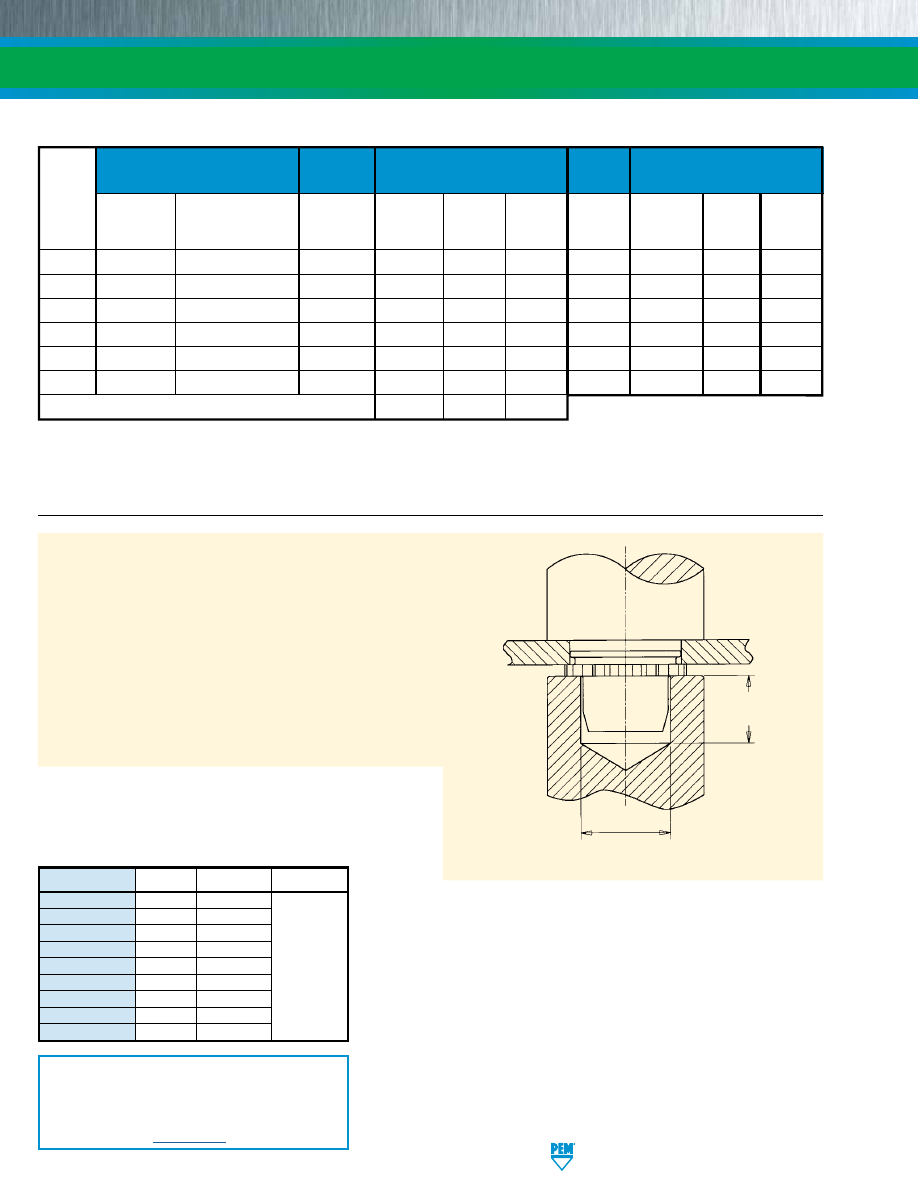

pem-html.html

U

NIF

IE

D

(1) Published installation forces are for general reference. Actual set-up and confirmation of complete installation should be made by observing

proper seating of fastener as described in the installation steps. Other performance values reported are averages when all proper

installation parameters and procedures are followed. Variations in mounting hole size, sheet material, and installation procedure may affect

performance. Performance testing this product in your application is recommended. We will be happy to provide technical assistance and/

or samples for this purpose.

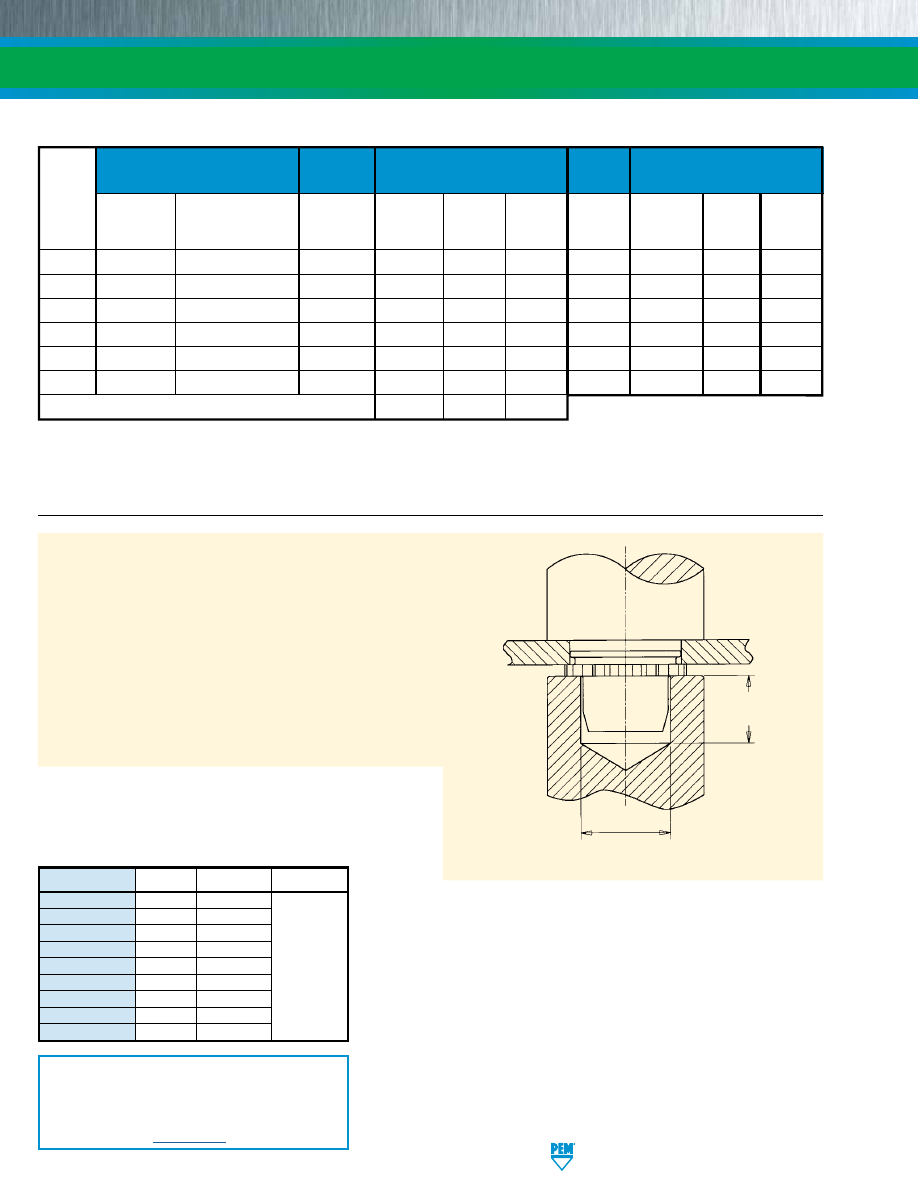

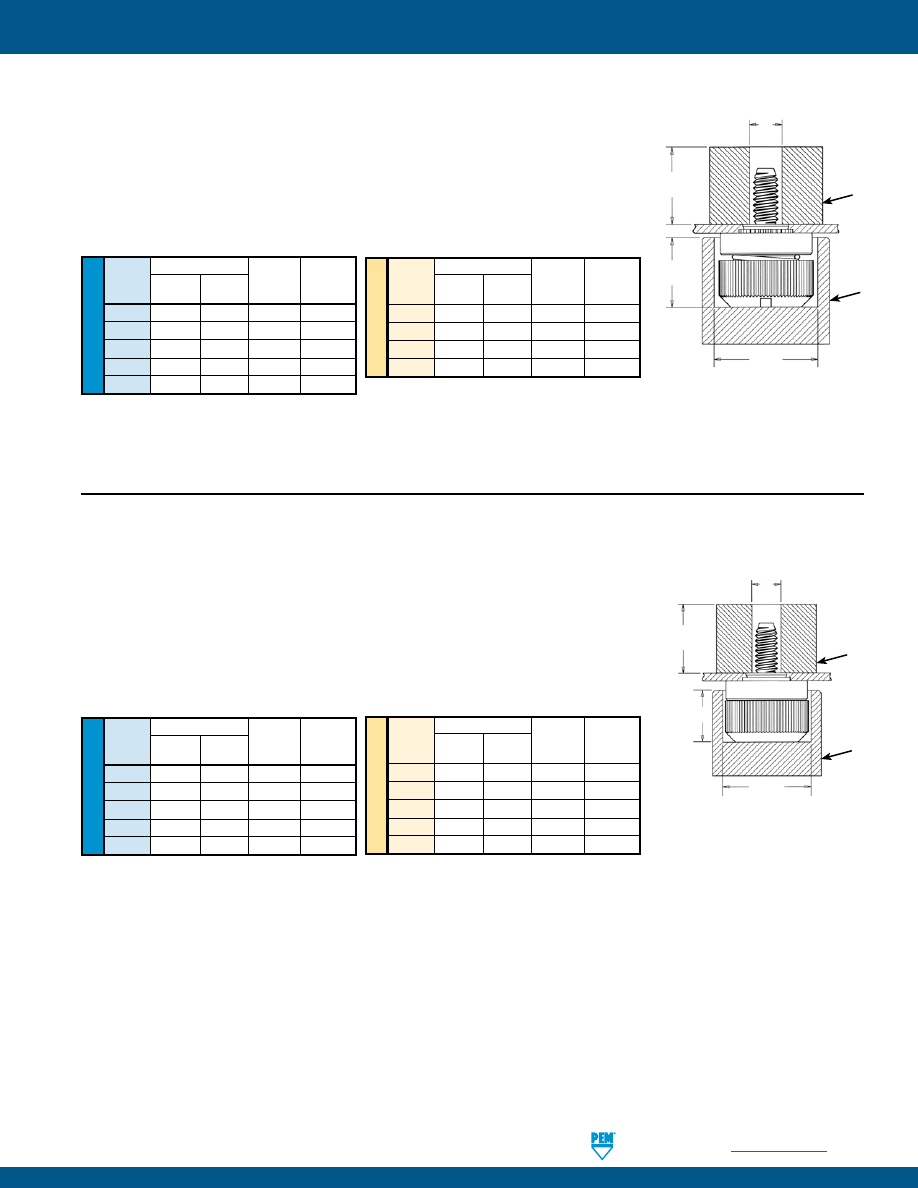

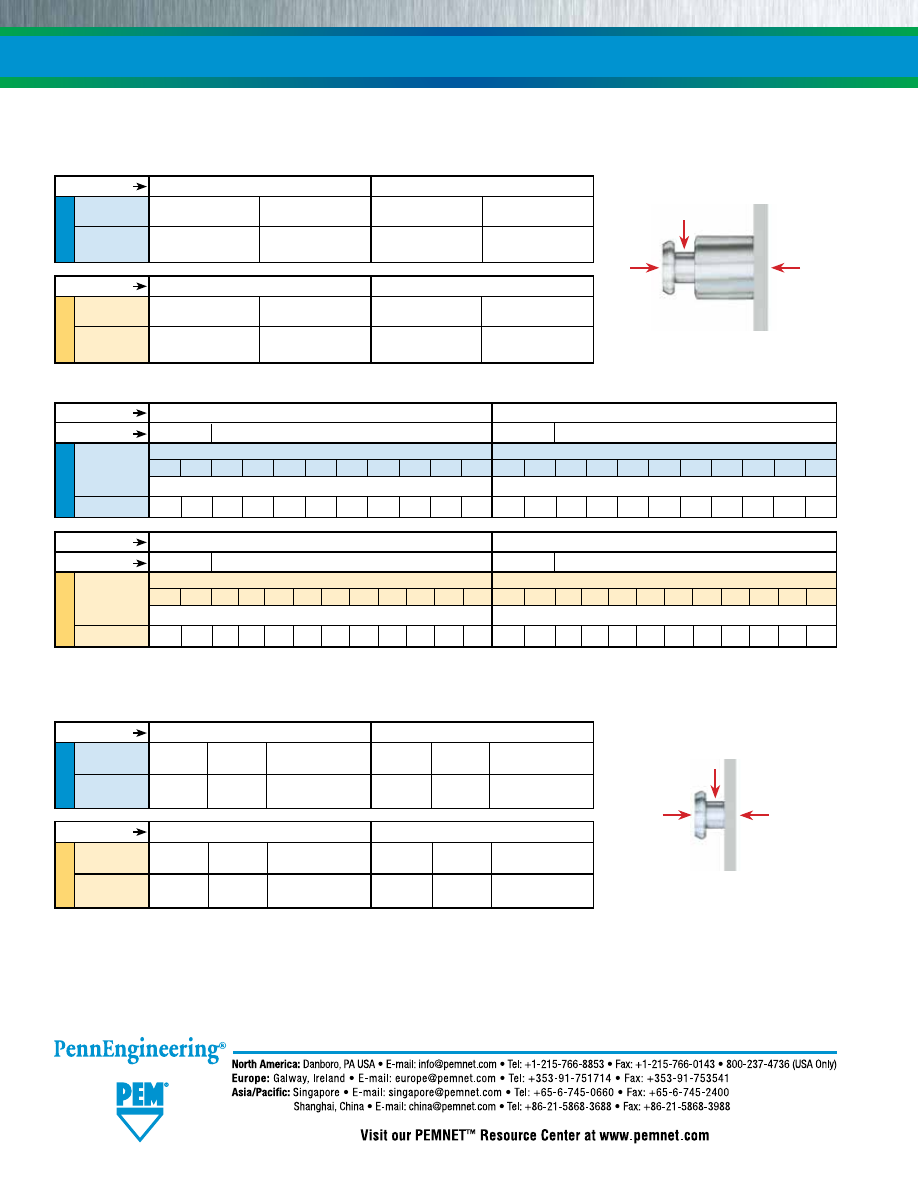

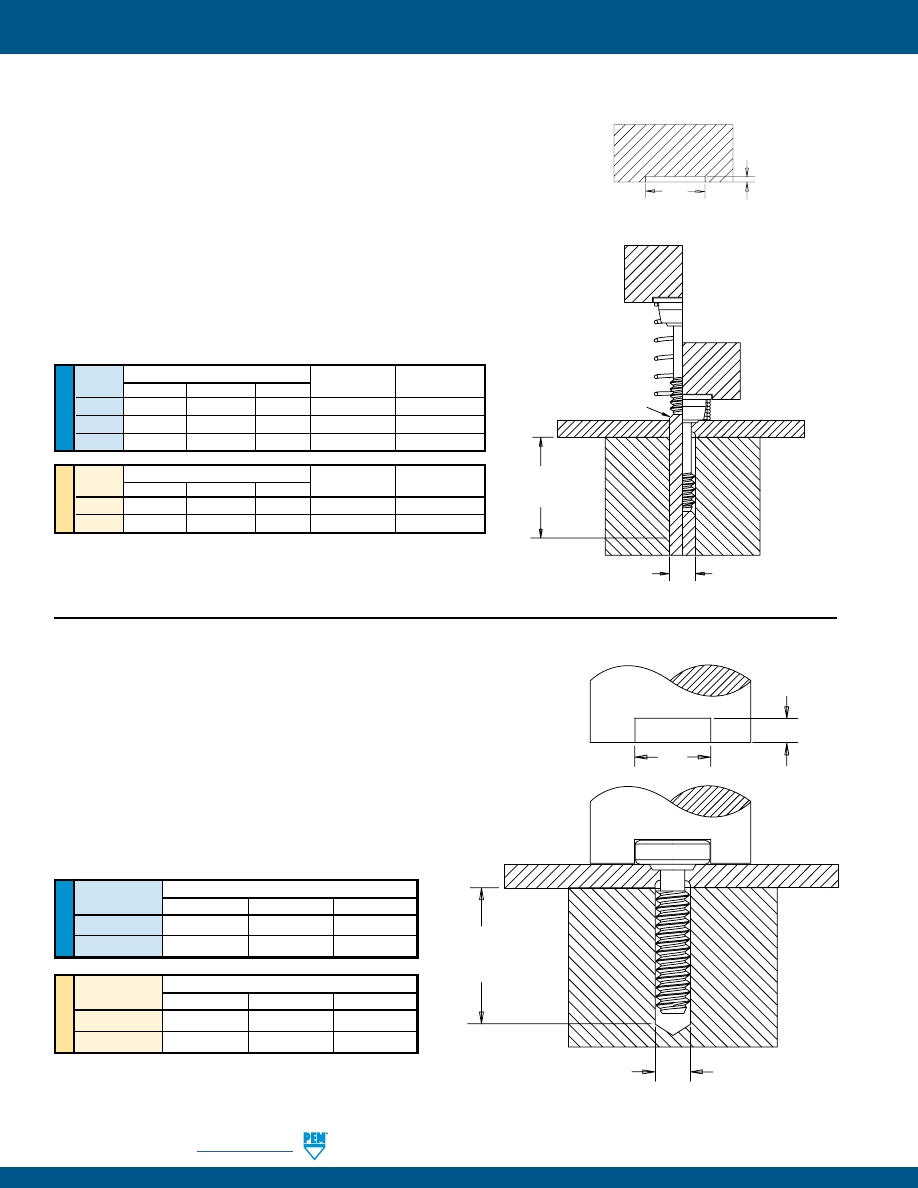

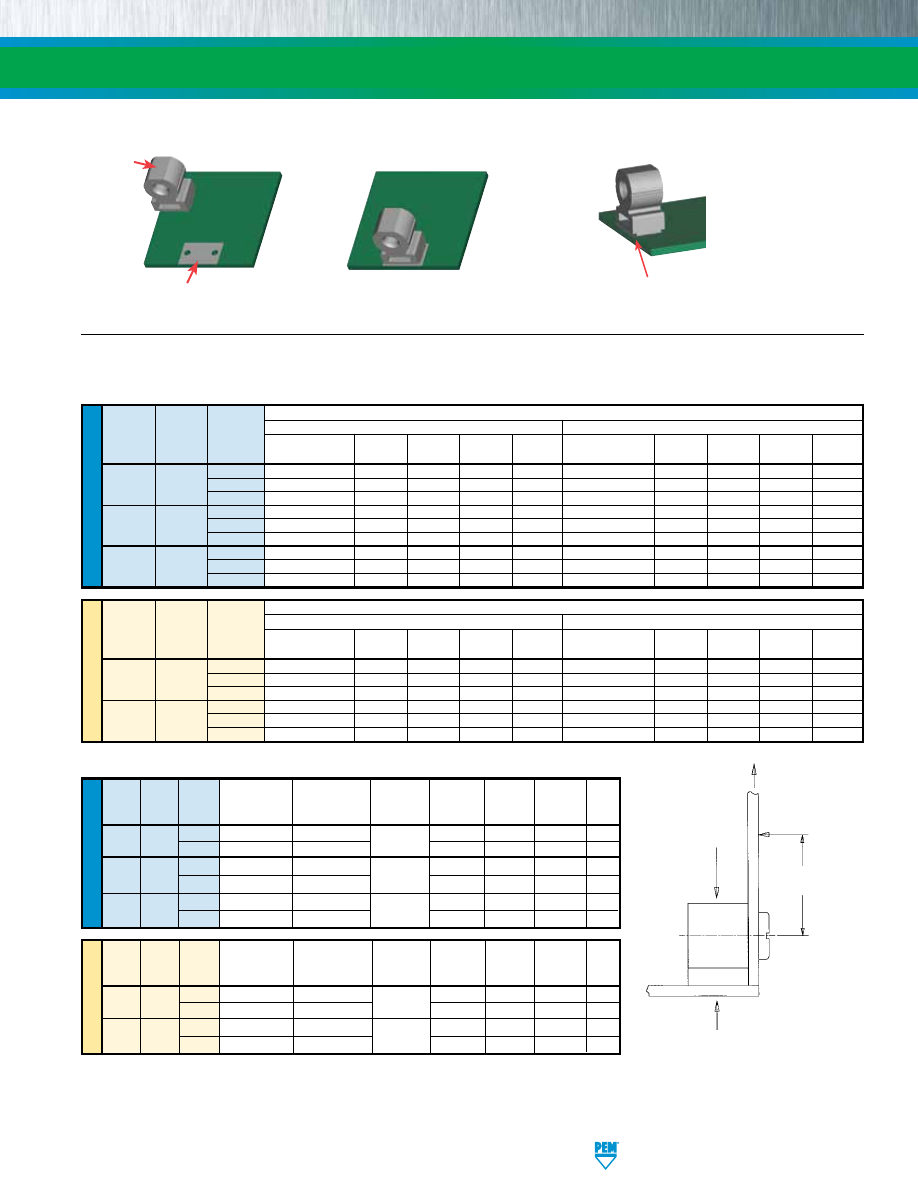

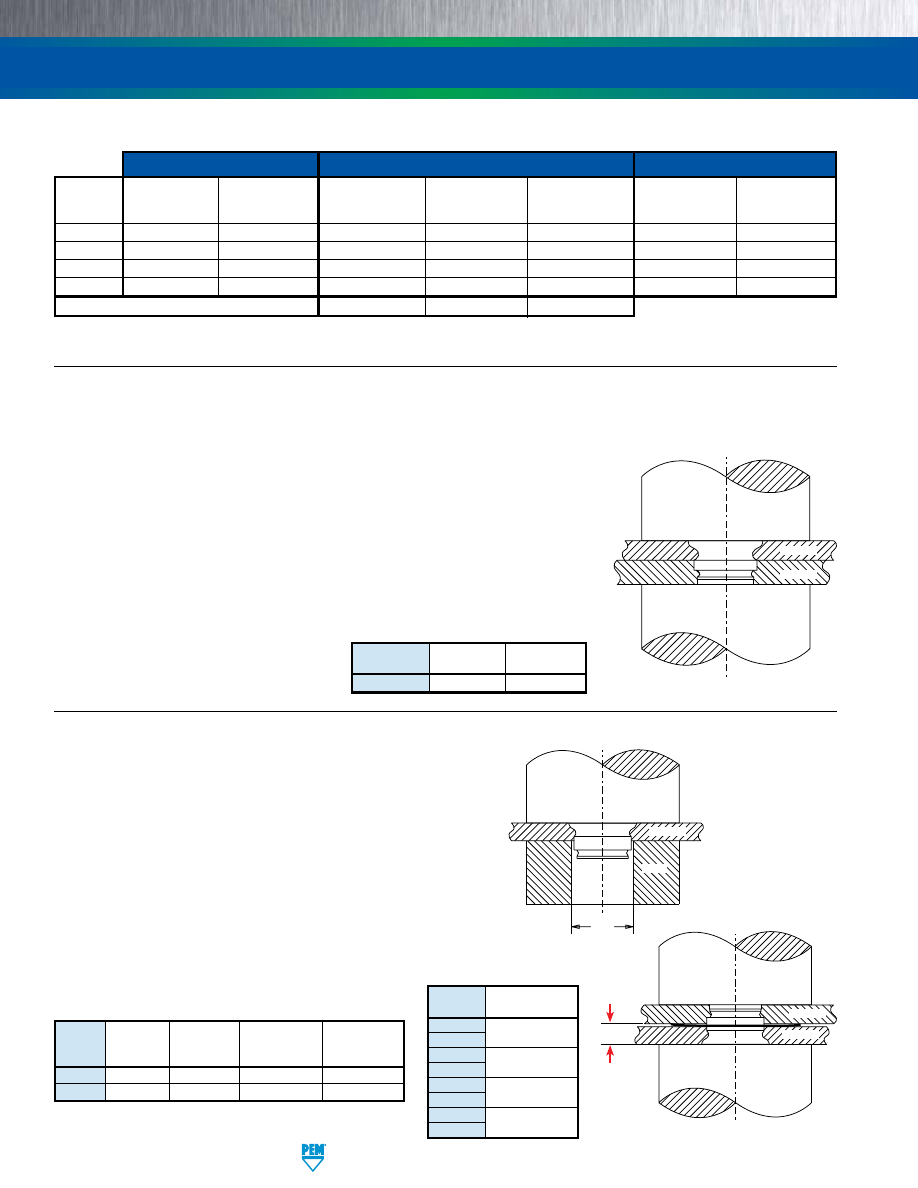

1.

Prepare properly sized mounting hole in the sheet. Do not perform

any secondary operations such as deburring.

2.

Place the barrel of the fastener into the anvil hole and place the

mounting hole (preferably the punch side) over the shank of the

fastener.

3.

With the installation punch and anvil surfaces parallel, apply

squeezing force until the flange contacts the mounting sheet. The

sketch at the right indicates suggested tooling for applying these

forces.

INSTALLATION NOTES

•

For best results we recommend using a PEMSERTER®

press for installation of PEM Types B and BS fasteners.

Please check our website for more information.

•

Visit the Animation Library on our website to view the

installation process

for this product

.

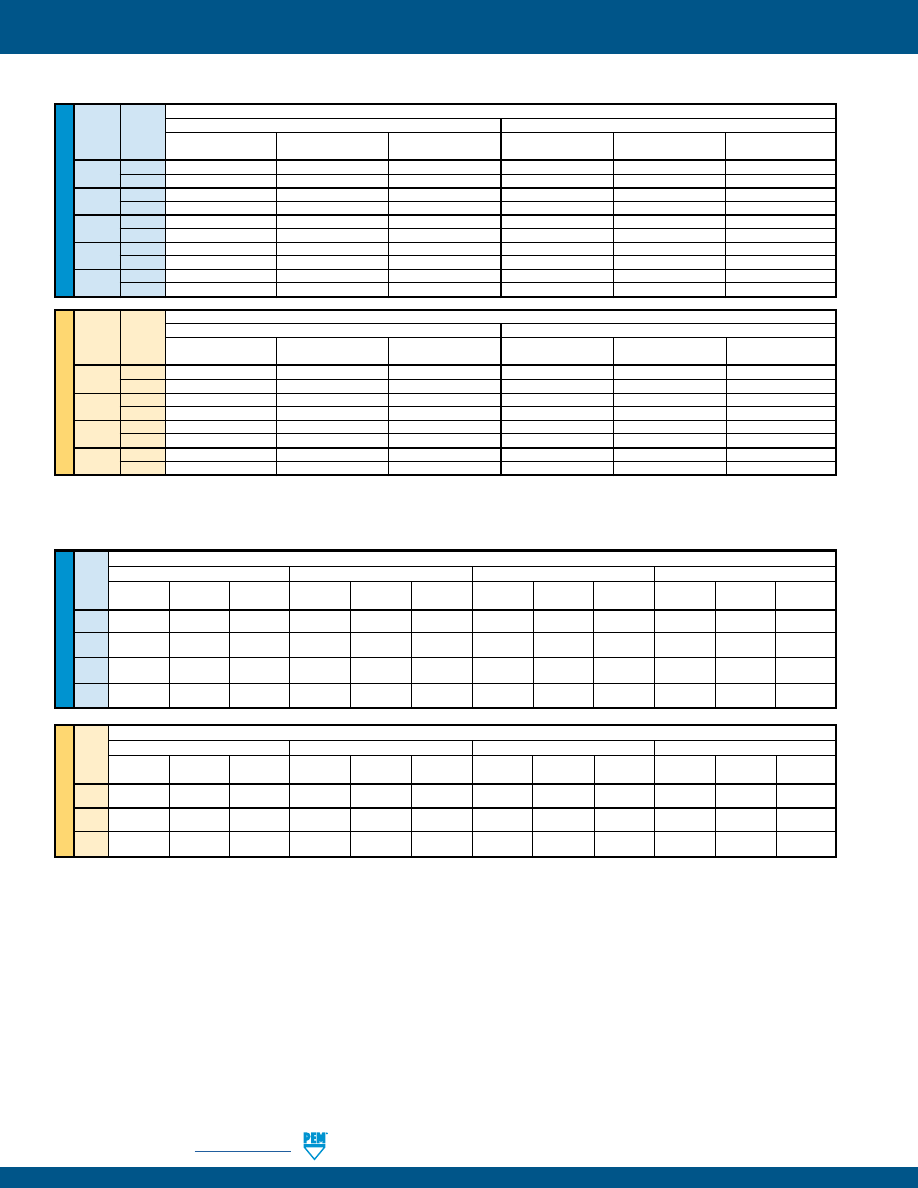

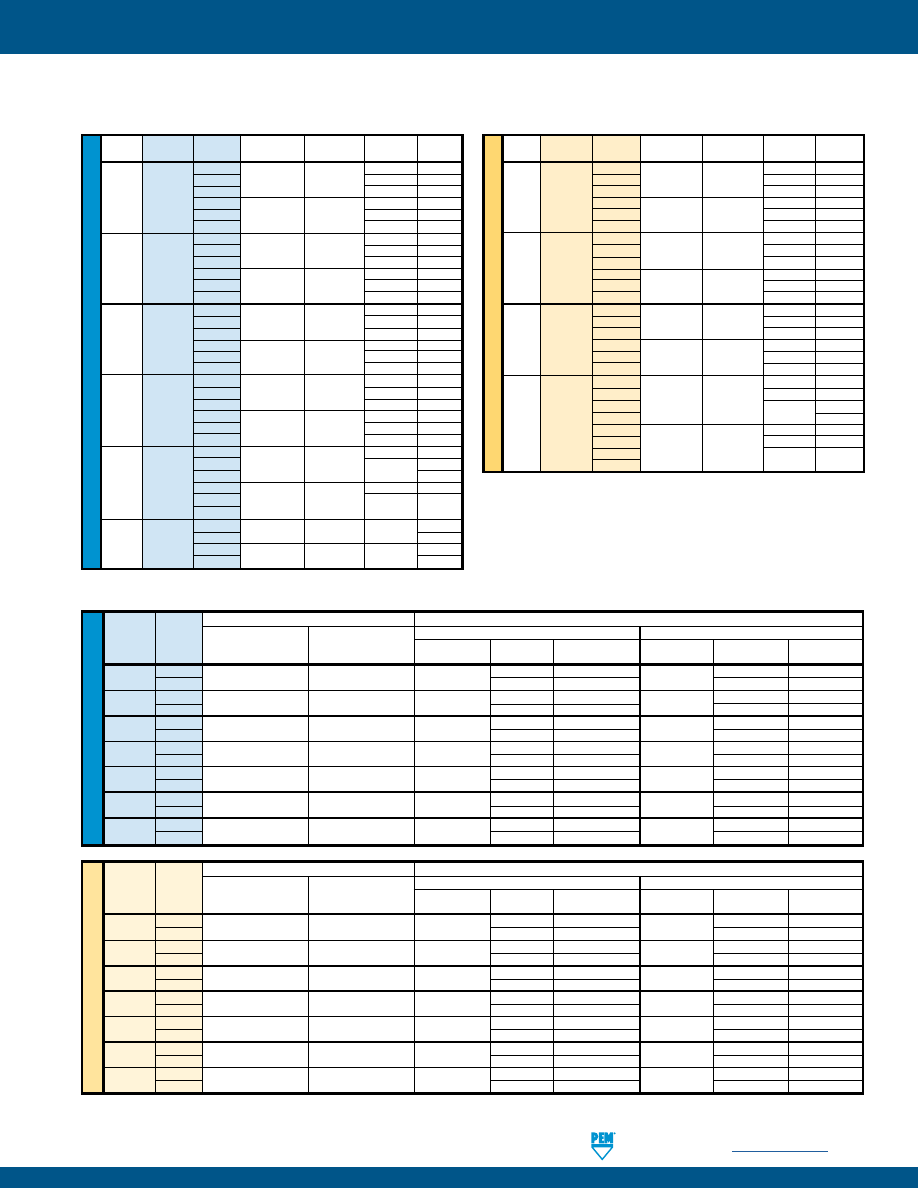

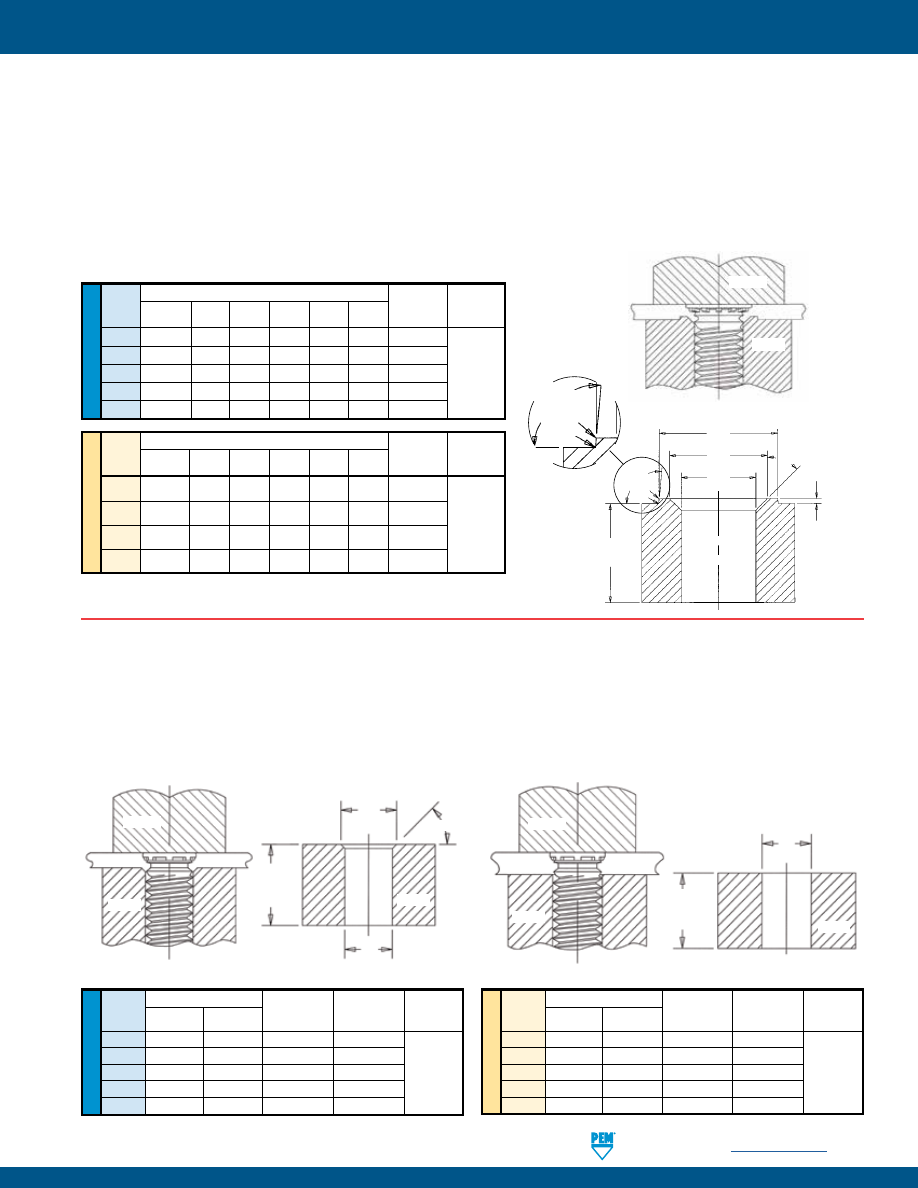

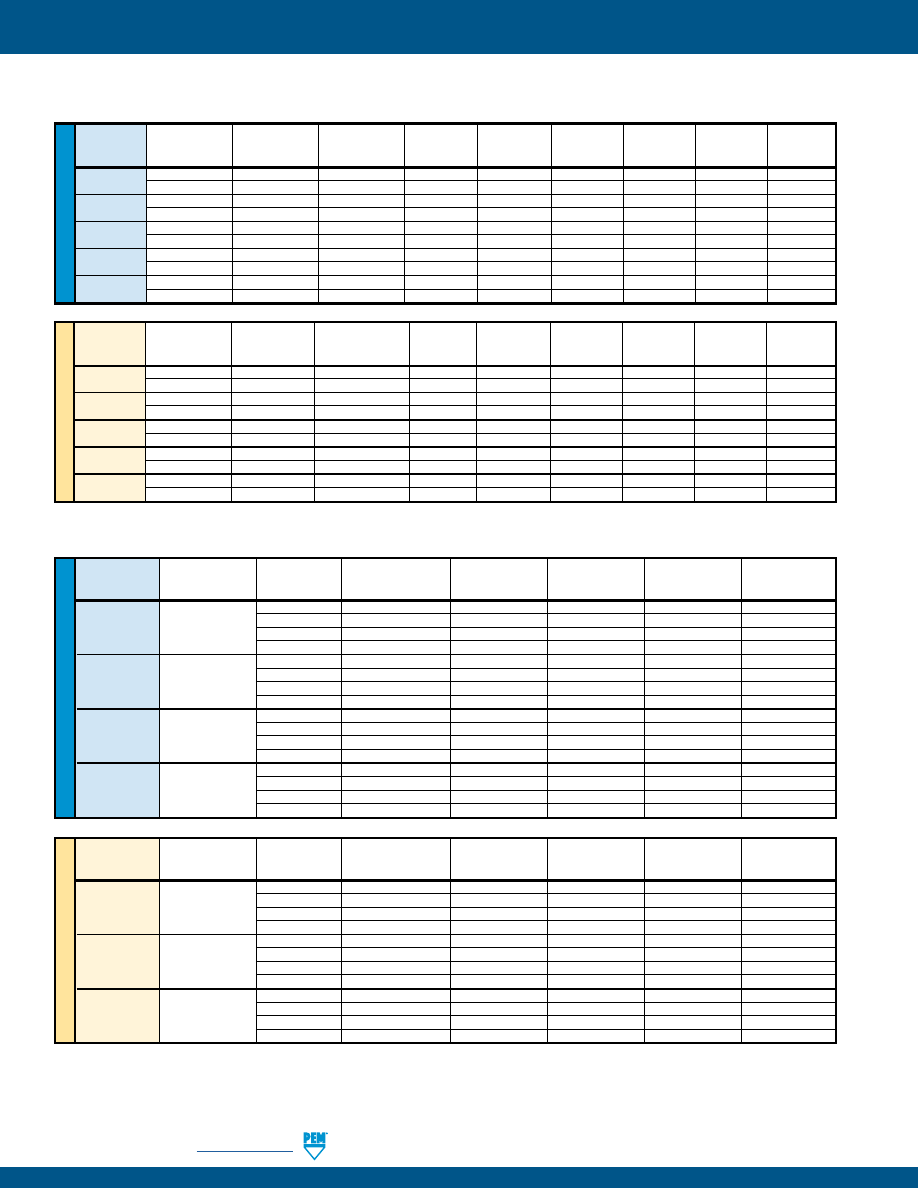

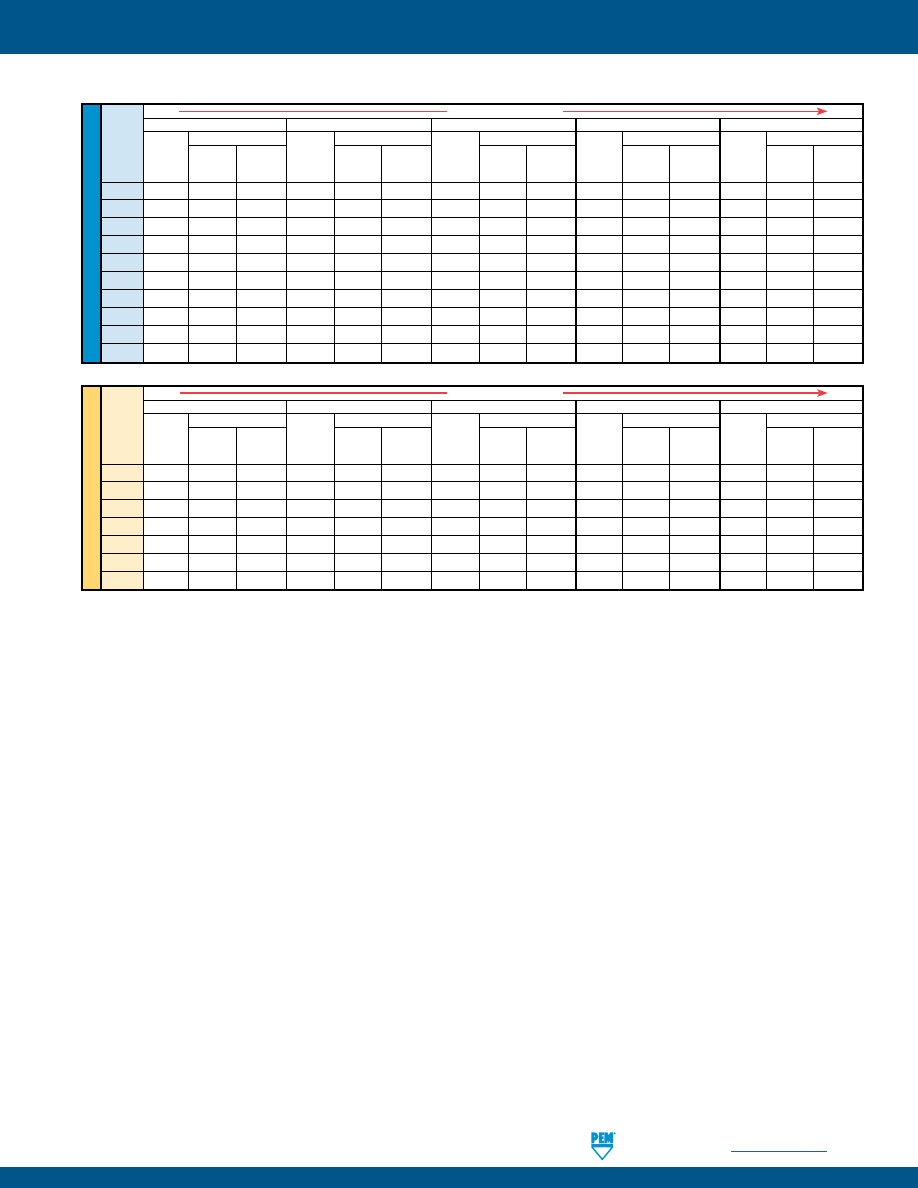

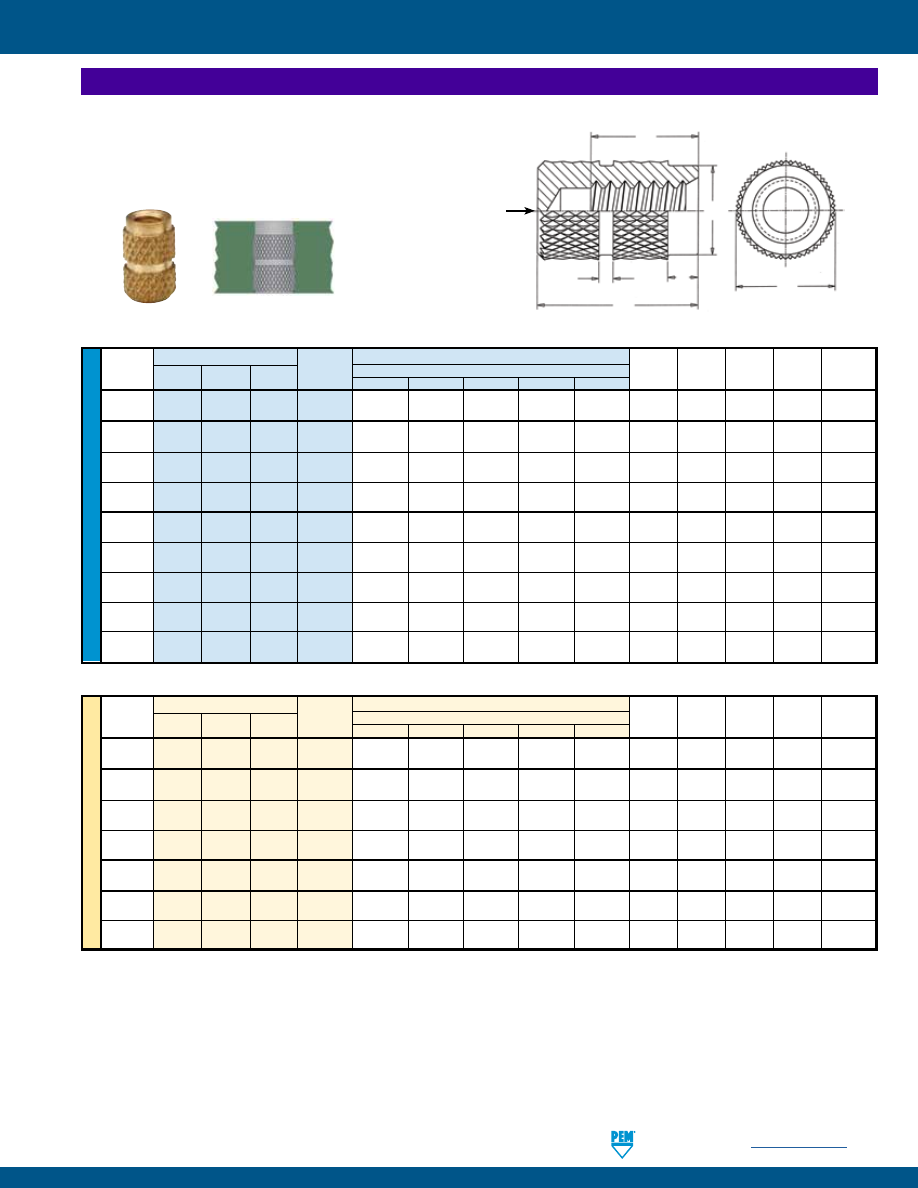

Test Sheet Material

Thread Shank Sheet

5052-H34 Aluminum

Cold-Rolled Steel

Code Code Thick- Install- Torque-

Install- Torque-

ness ation Pushout out ation Pushout out

(in.) (lbs.) (lbs.) (in.

lbs.) (lbs.) (lbs.) (in.

lbs.)

440

1 .040 1600 90 10 2500 125 13

2 .056 2000 170

13 3500 230

18

632

1 .040 1800 95 17 3000 130 18

2 .056 2800 190

22 4000 260

28

832

1 .040 2000 105 23 3500 135 30

2 .056 3000 220

35 5000 285

45

032

1 .040 2100 110 32 4000 140 35

2 .056 3500 190

50 5000 250

60

0420

1 .056

4000 315 90 6000 400 105

2 .090

B-4

SELF-CLINCHING BLIND FASTENERS

PERFORMANCE DATA

(1)

INSTALLATION

B

+ .006” / 0.15 mm

+ .003” / 0.08 mm

L*

+.06” / 1.5 mm

MIN.

.010” / 0.25 mm

x 45˚ Nom.

Chamfer on anvil

PUNCH

ANVIL

* For “L”,

see page 3.

ME

TR

IC

Test Sheet Material

Thread Shank Sheet

5052-H34 Aluminum

Cold-Rolled Steel

Code Code Thick- Install- Torque-

Install- Torque-

ness ation Pushout out ation Pushout out

(mm) (kN) (N) (N•m) (kN) (N) (N•m)

M3

1 1 7.1 400 1.15 11.1 550 1.5

2 1.4

9

750 1.47

14 1010 2.05

M4

1 1 8.9 470 2.6 15.6 600 3.4

2 1.4 12.5 970

4

20 1250 5.1

M5

1 1 9.3 480 3.6 17.8 620 4

2 1.4 14

845

5.7

25

1112

6.8

M6

1 1.4

17.8 1400 10.2 25.7 1760 11.9

2 2.3

Anvil

Punch

Type Thread

Part Part

Code

Number Number

B/BS 440/M3 975200001 975200048

B/BS

632 975200002 975200048

B/BS 832/M4 975200003 975200048

B/BS 032/M5 975200004 975200048

B/BS 0420/M6 975200005 975200048

PEMSERTER® Installation Tooling

Technical support e-mail: techsupport@pemnet.com

All PEM® products meet our stringent quality standards. If you require additional industry or other specific quality certifications, special procedures and/or part

numbers are required. Please contact your local sales office or representative for further information.

Regulatory compliance information is available in Technical Support section of our website. Specifications subject to change without notice. See our website for the

most current version of this bulletin.

© 2016 PennEngineering.

pem-html.html

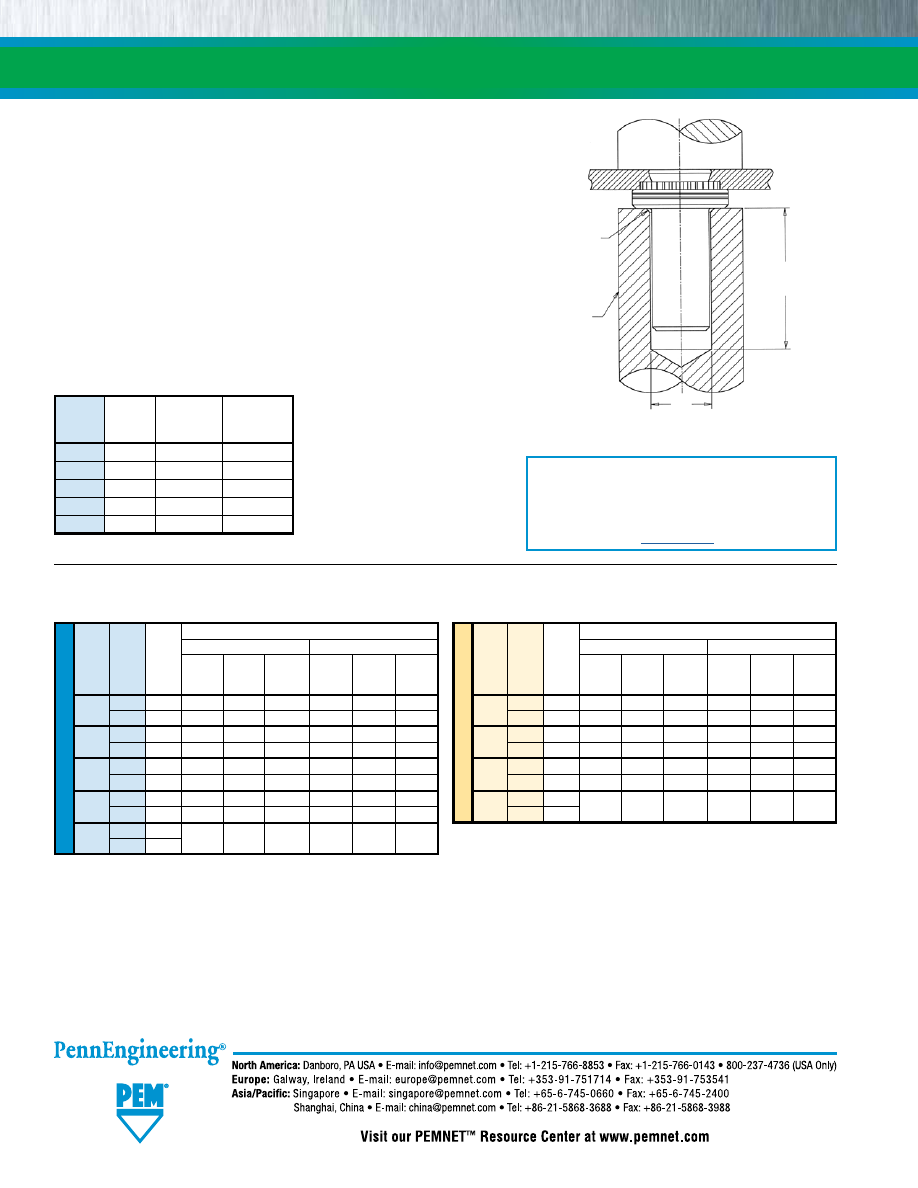

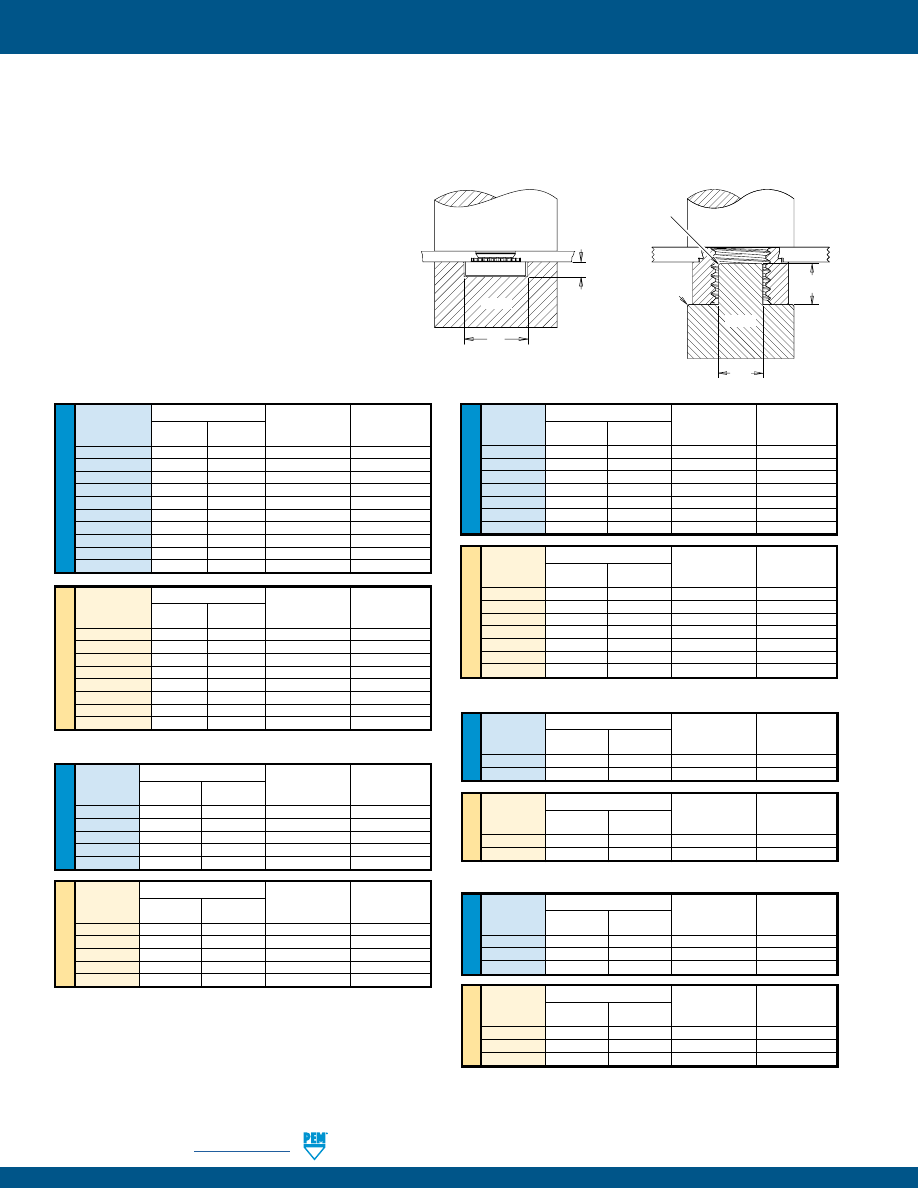

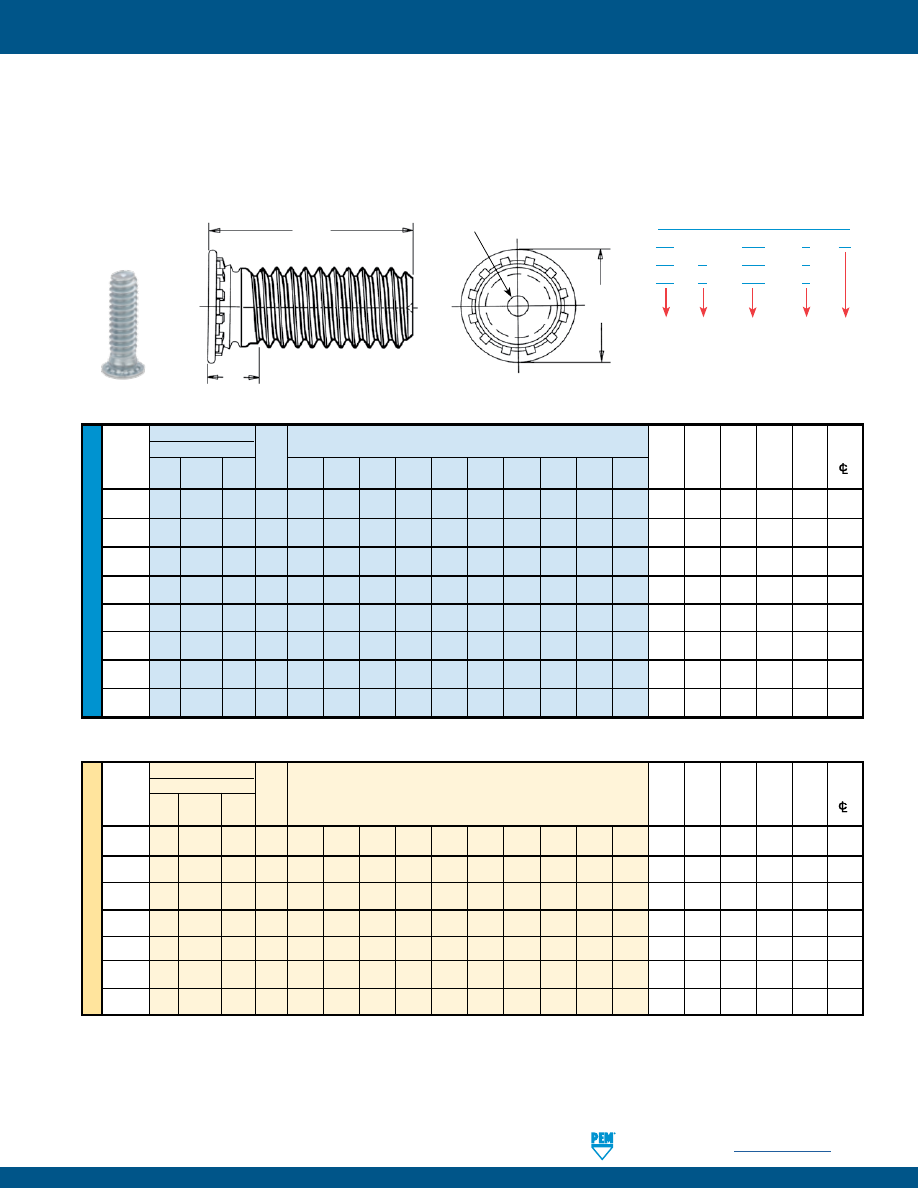

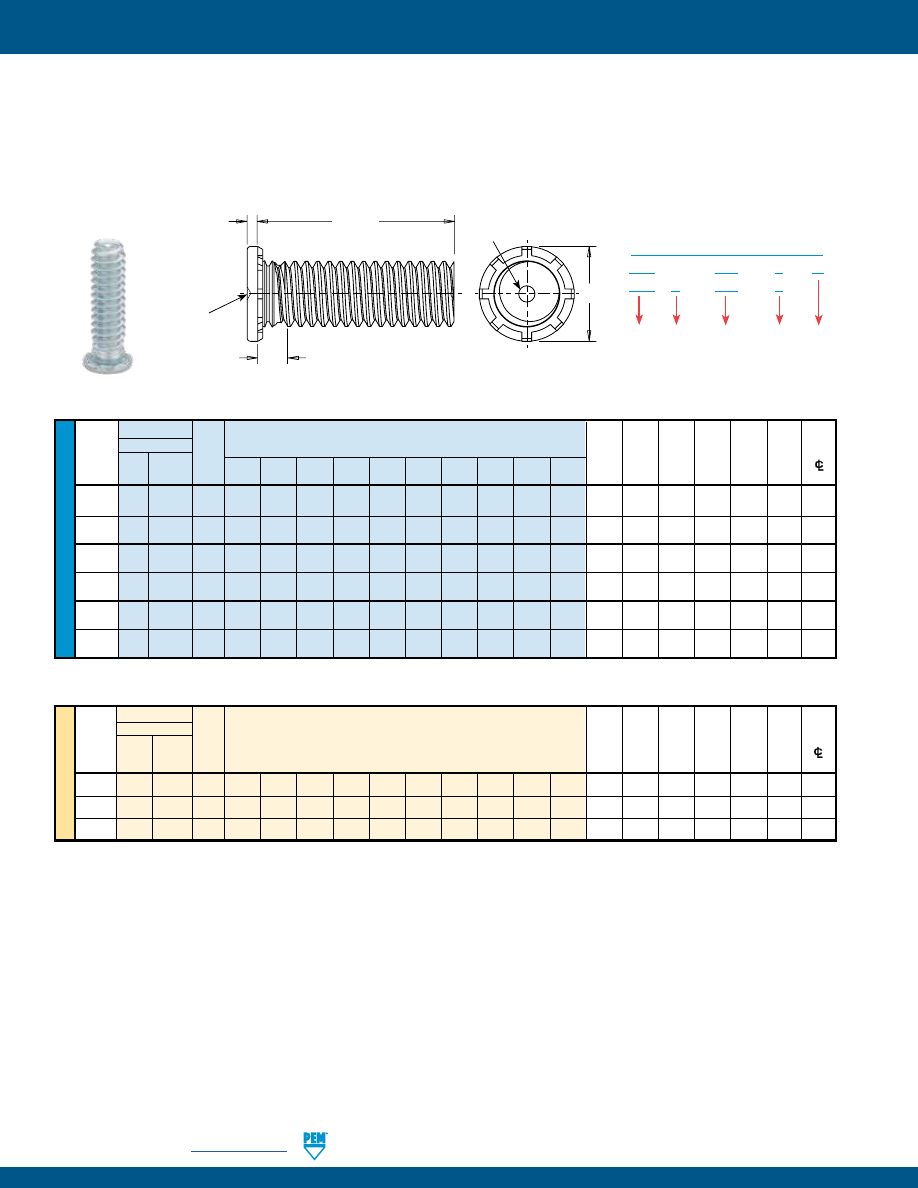

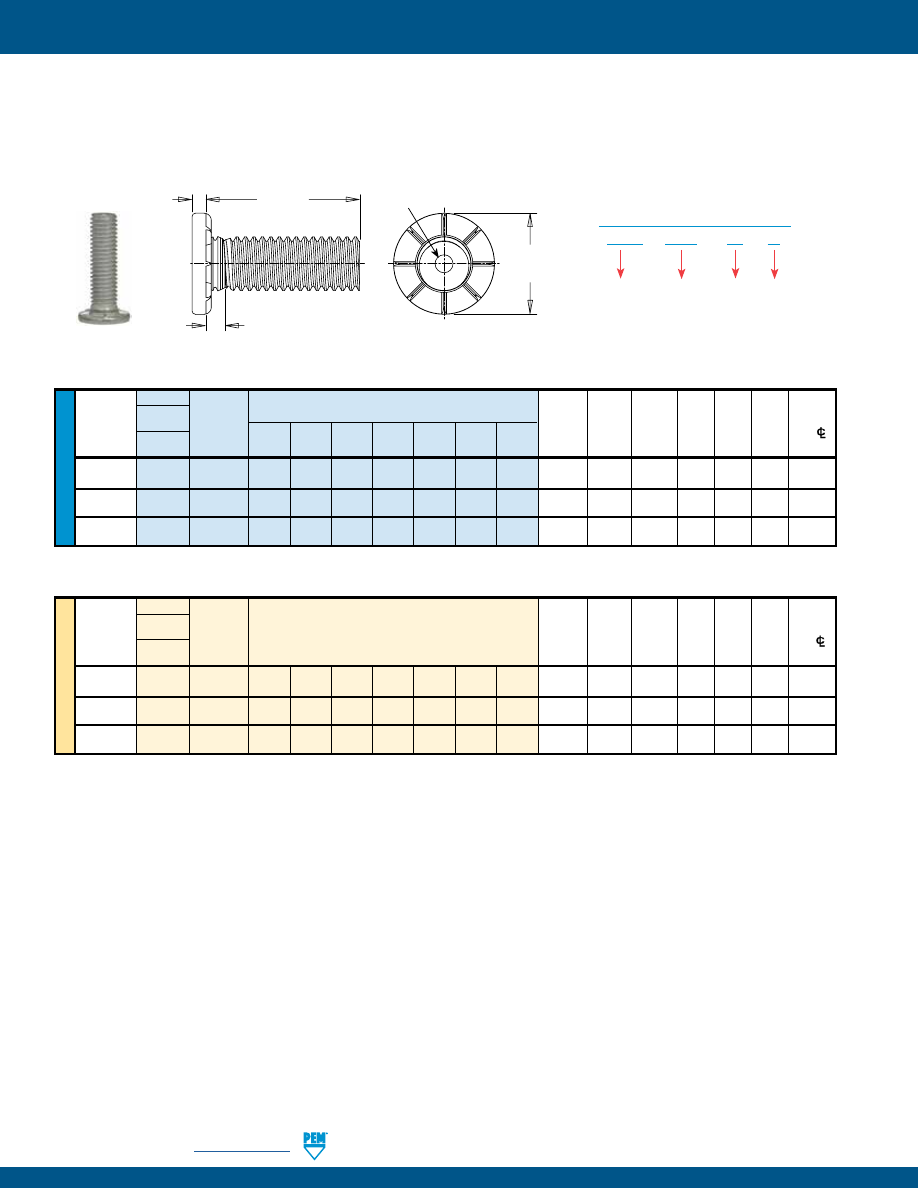

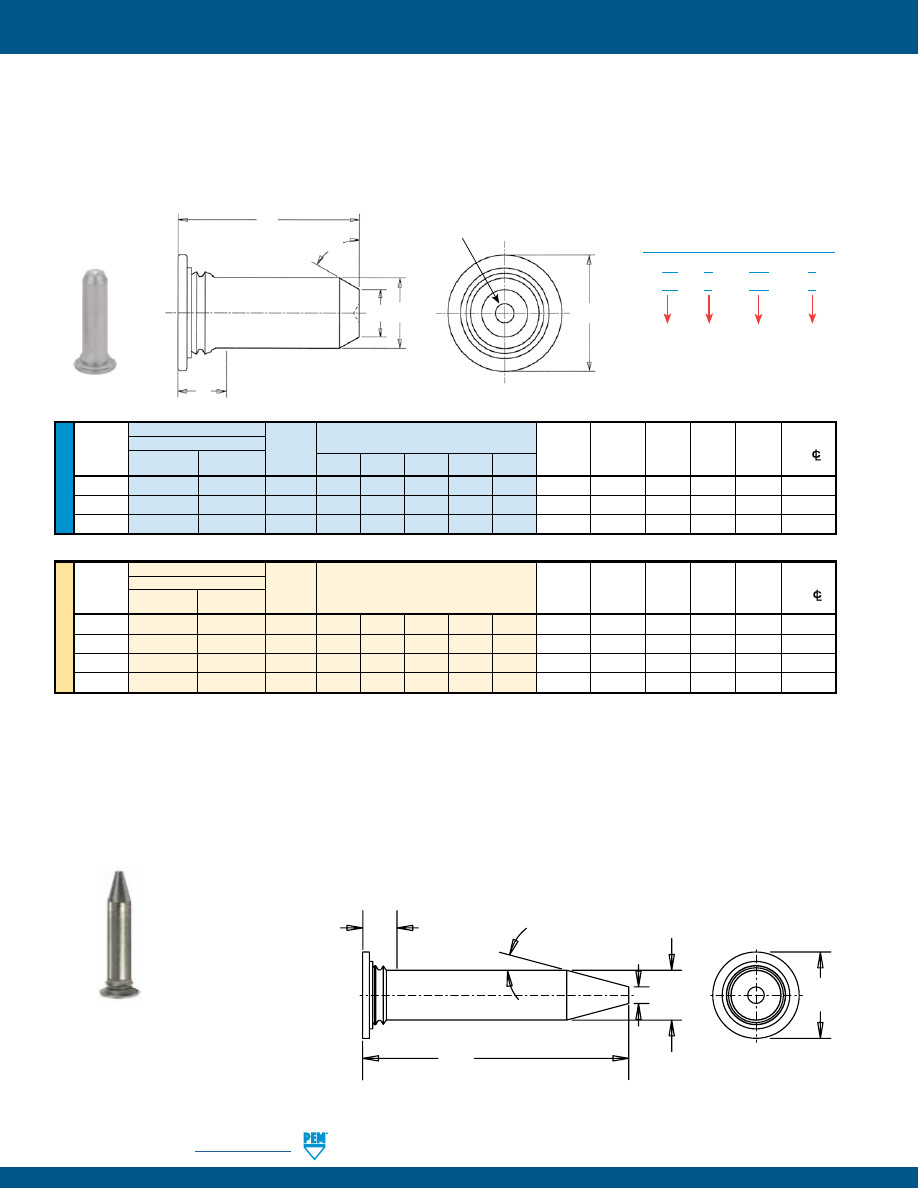

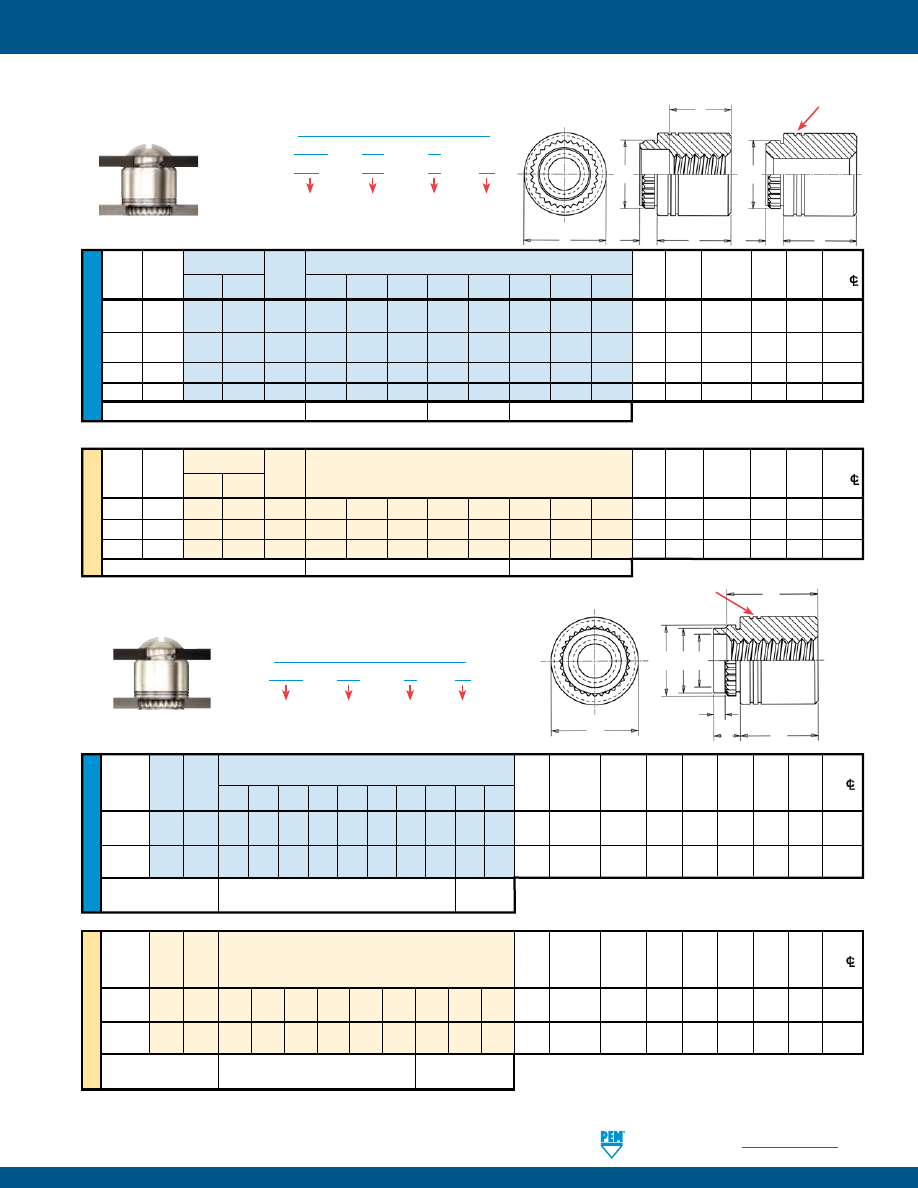

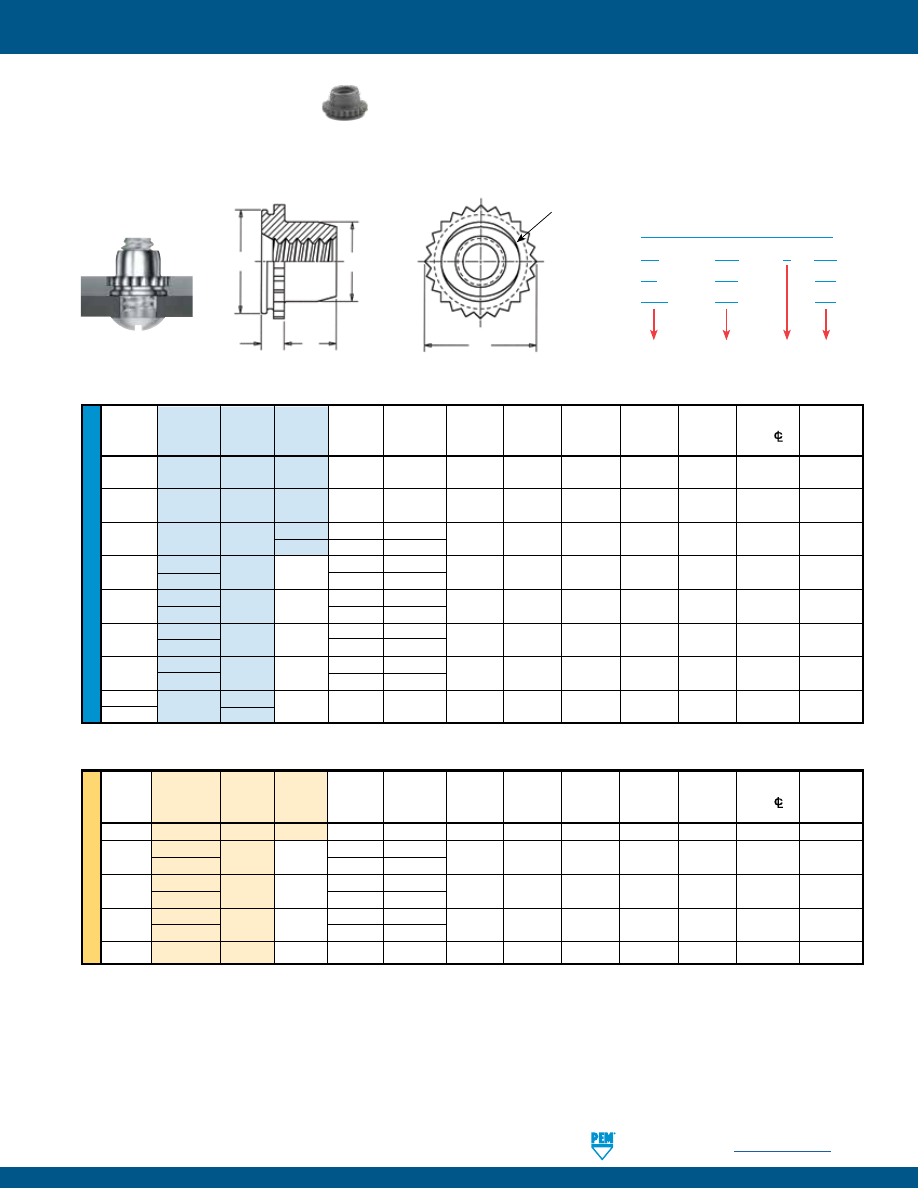

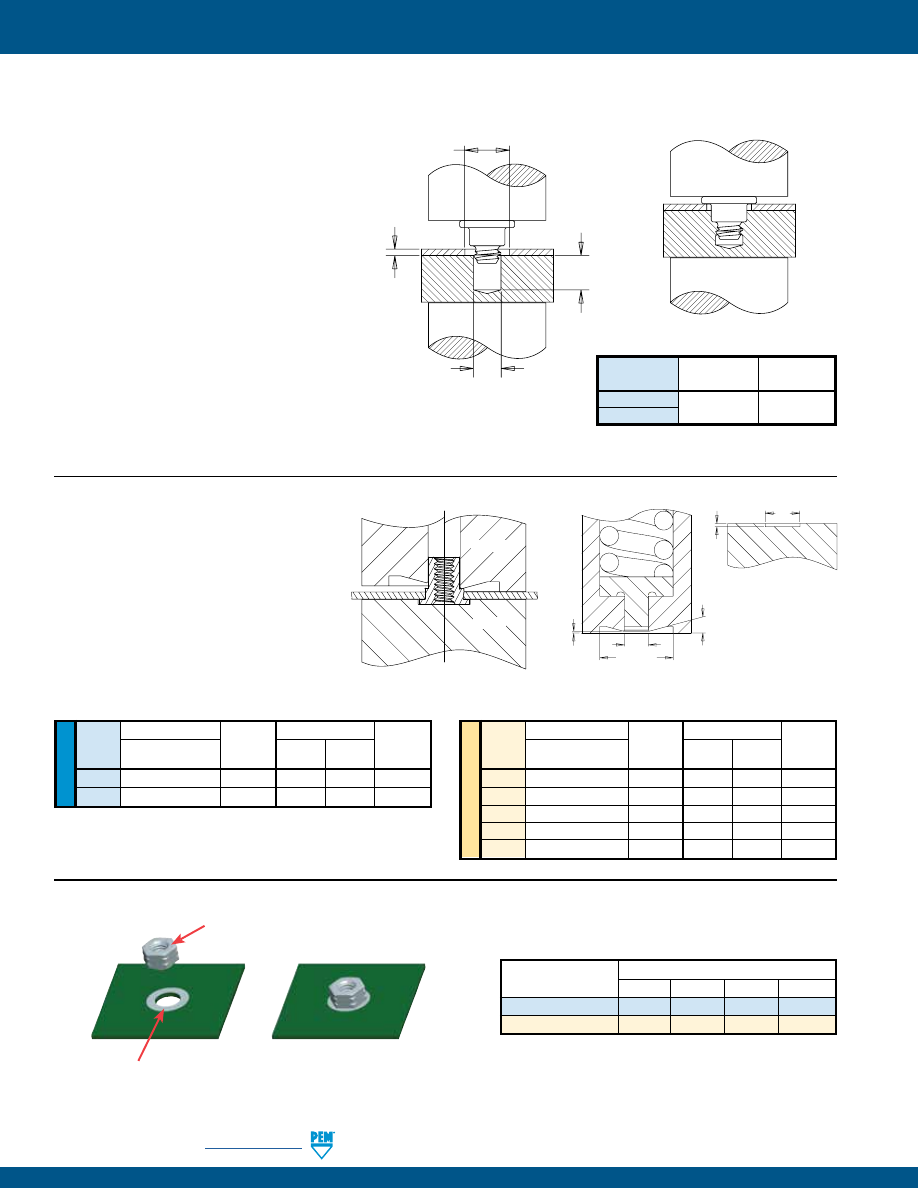

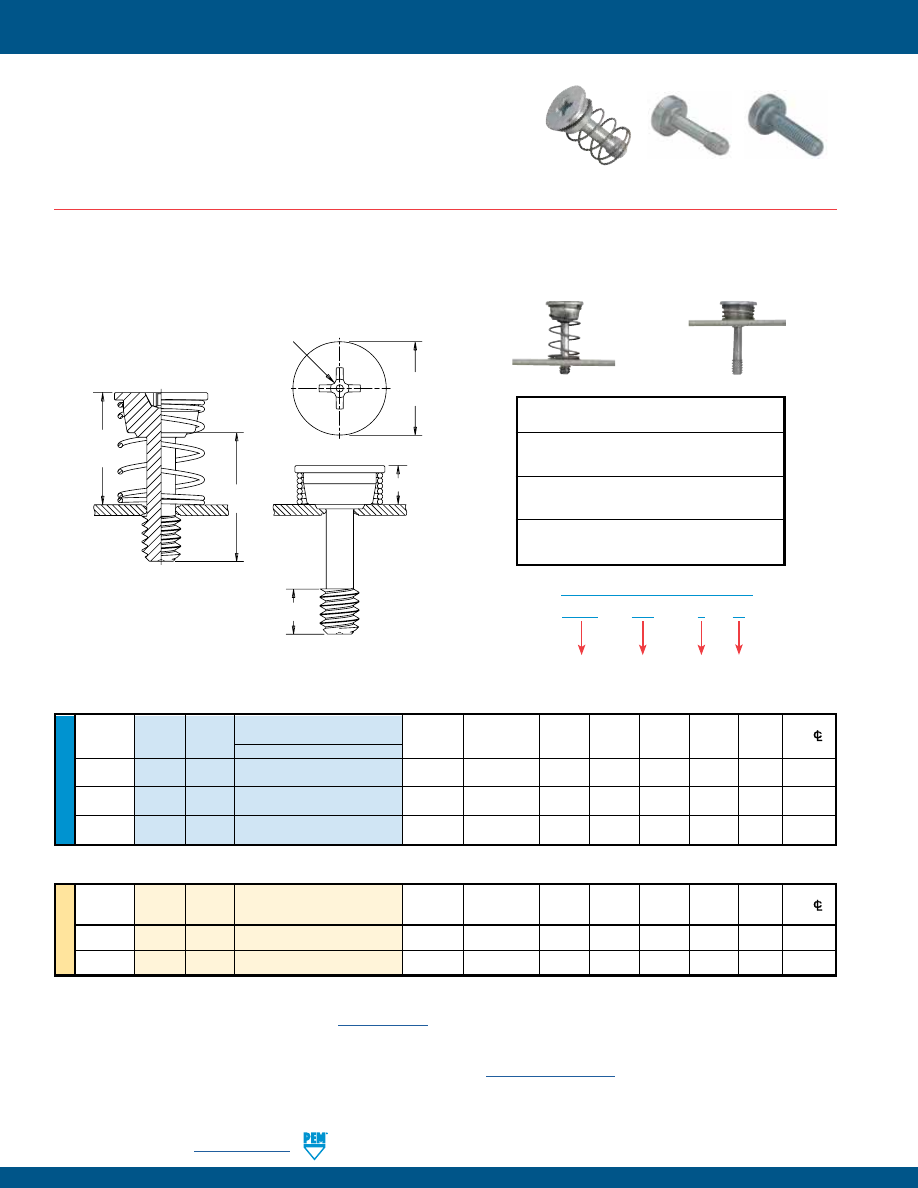

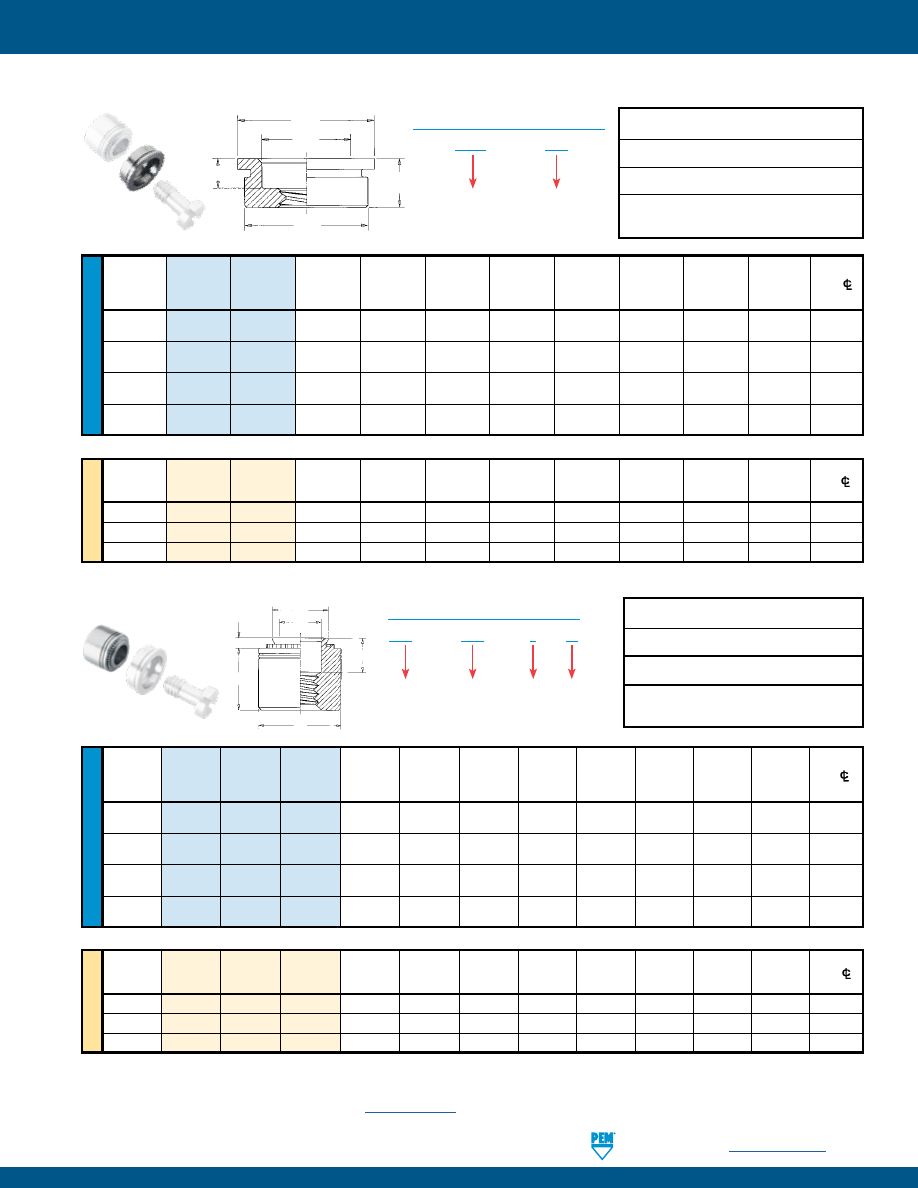

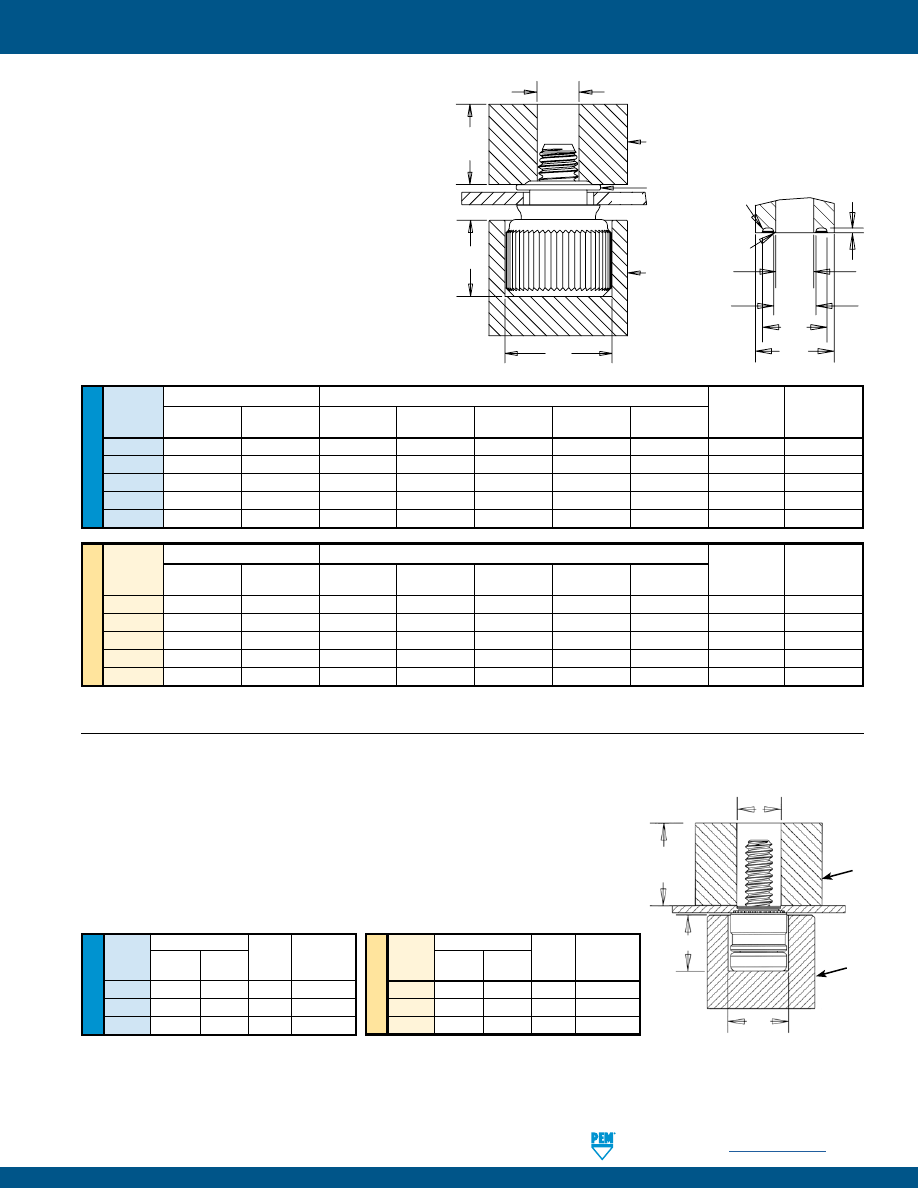

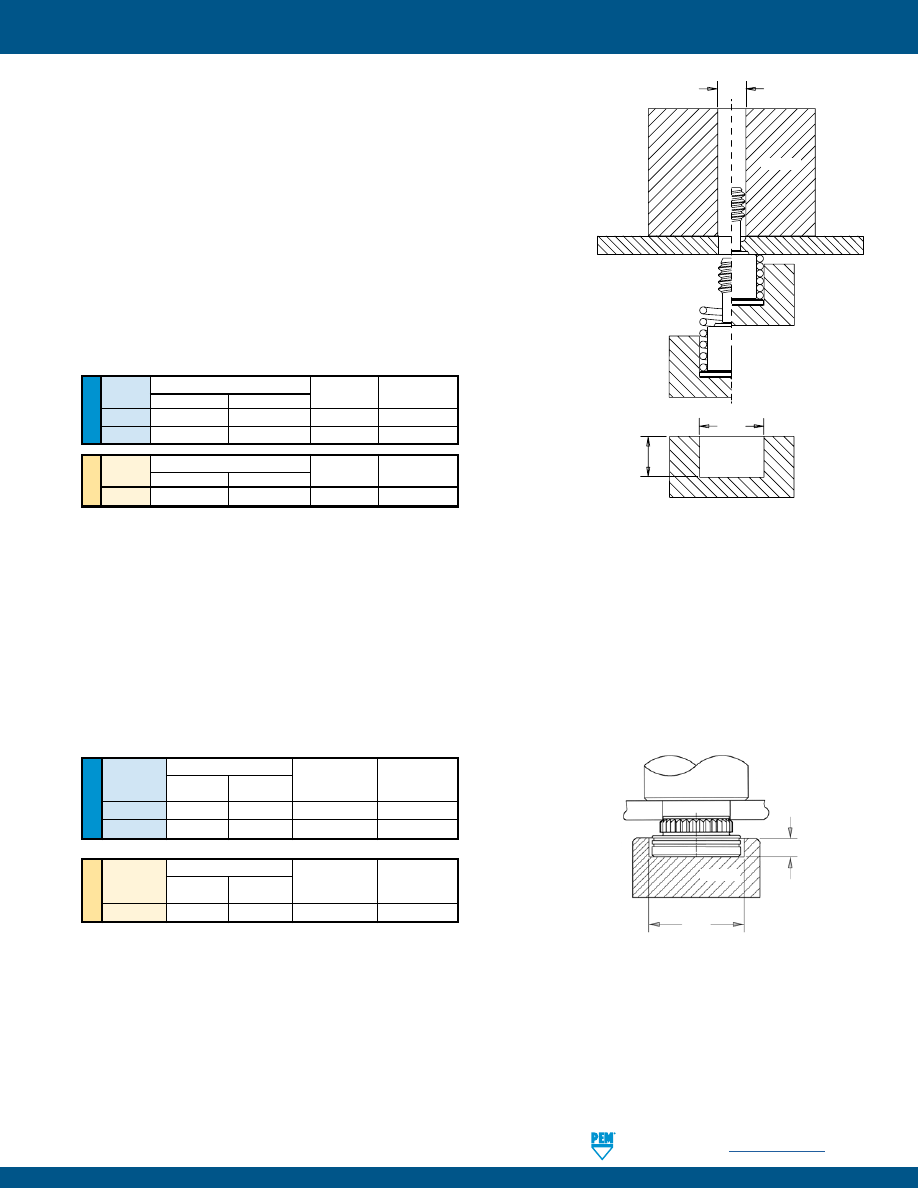

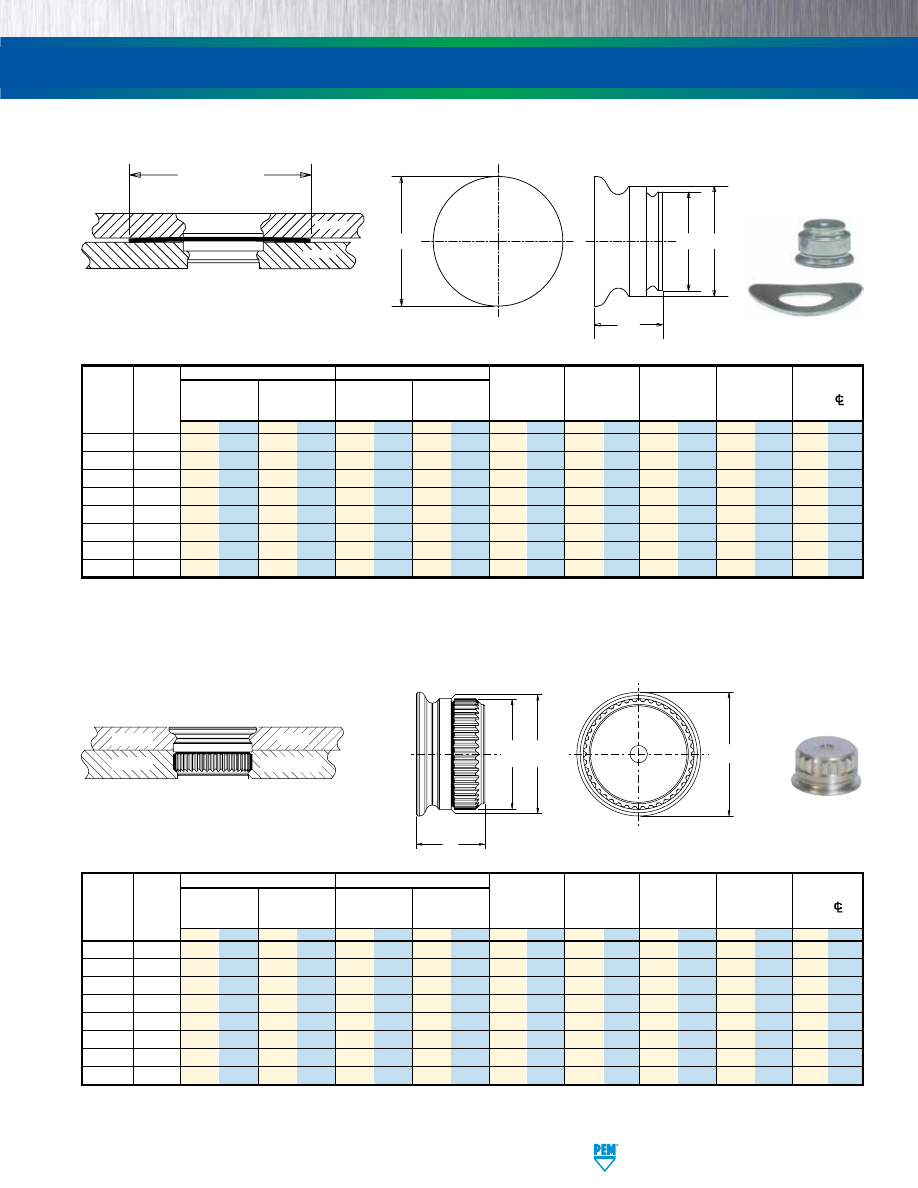

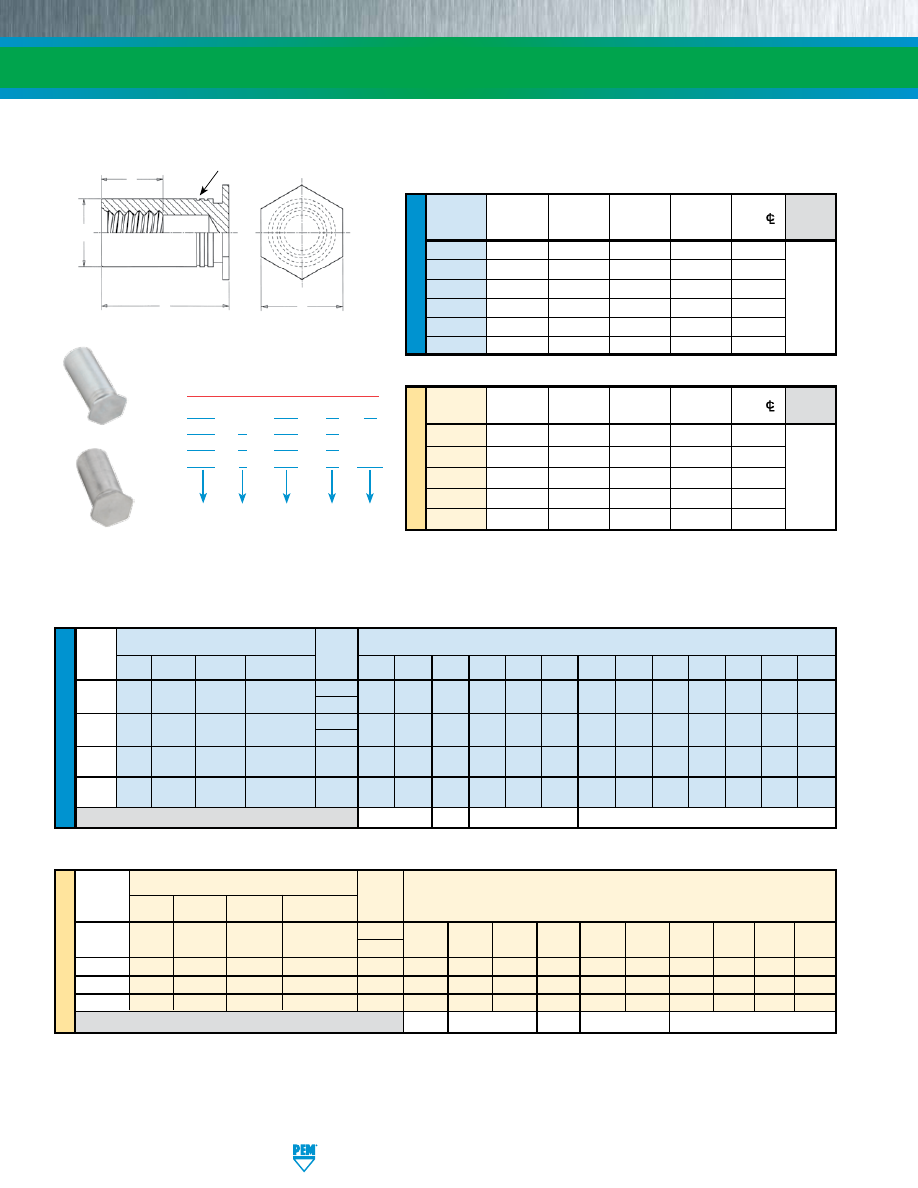

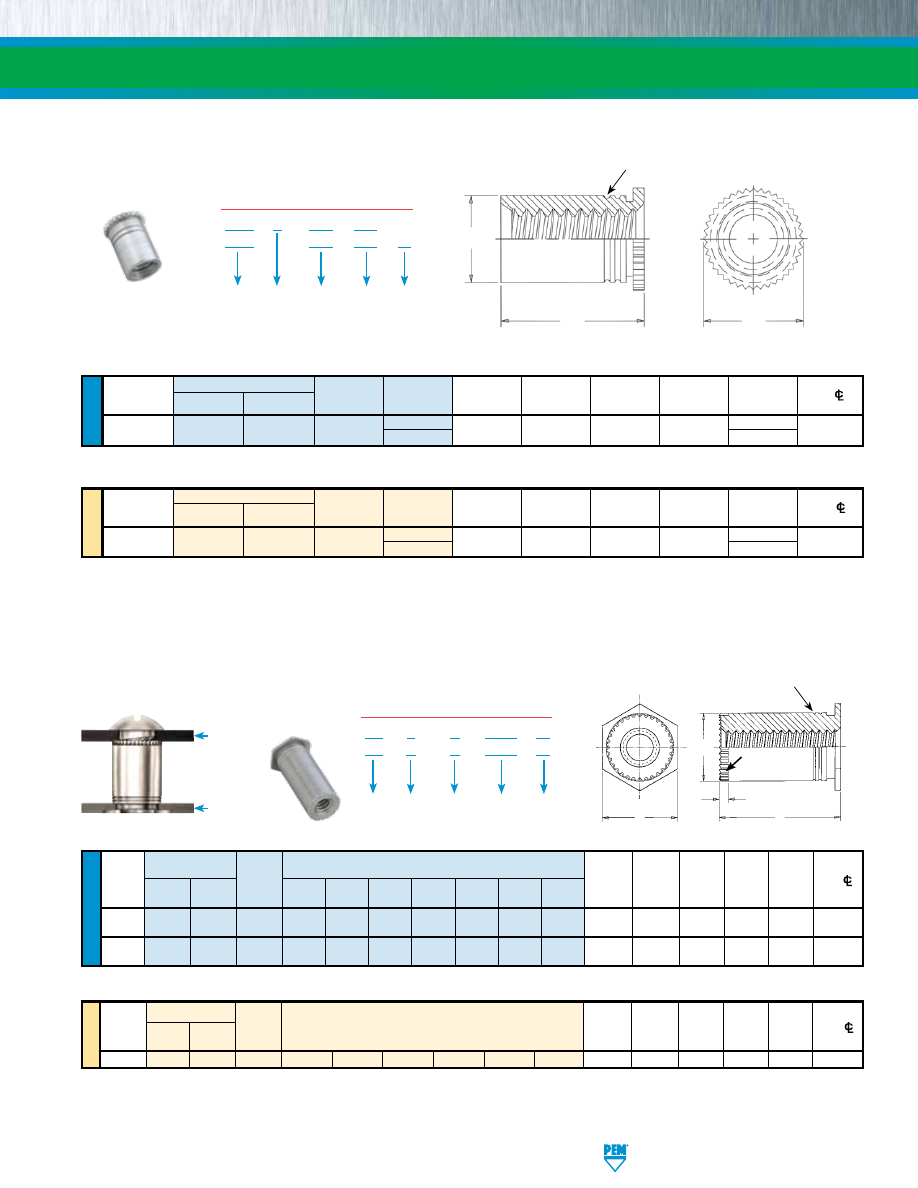

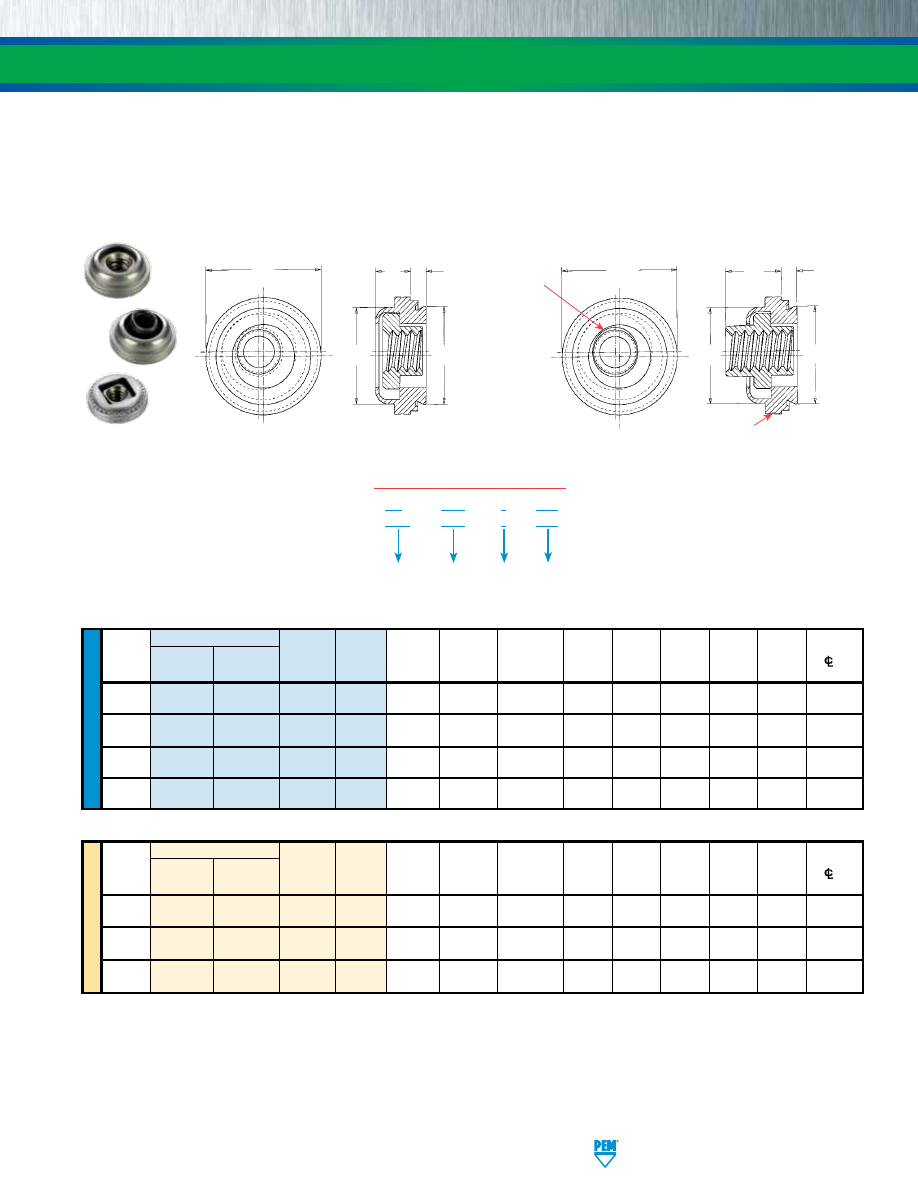

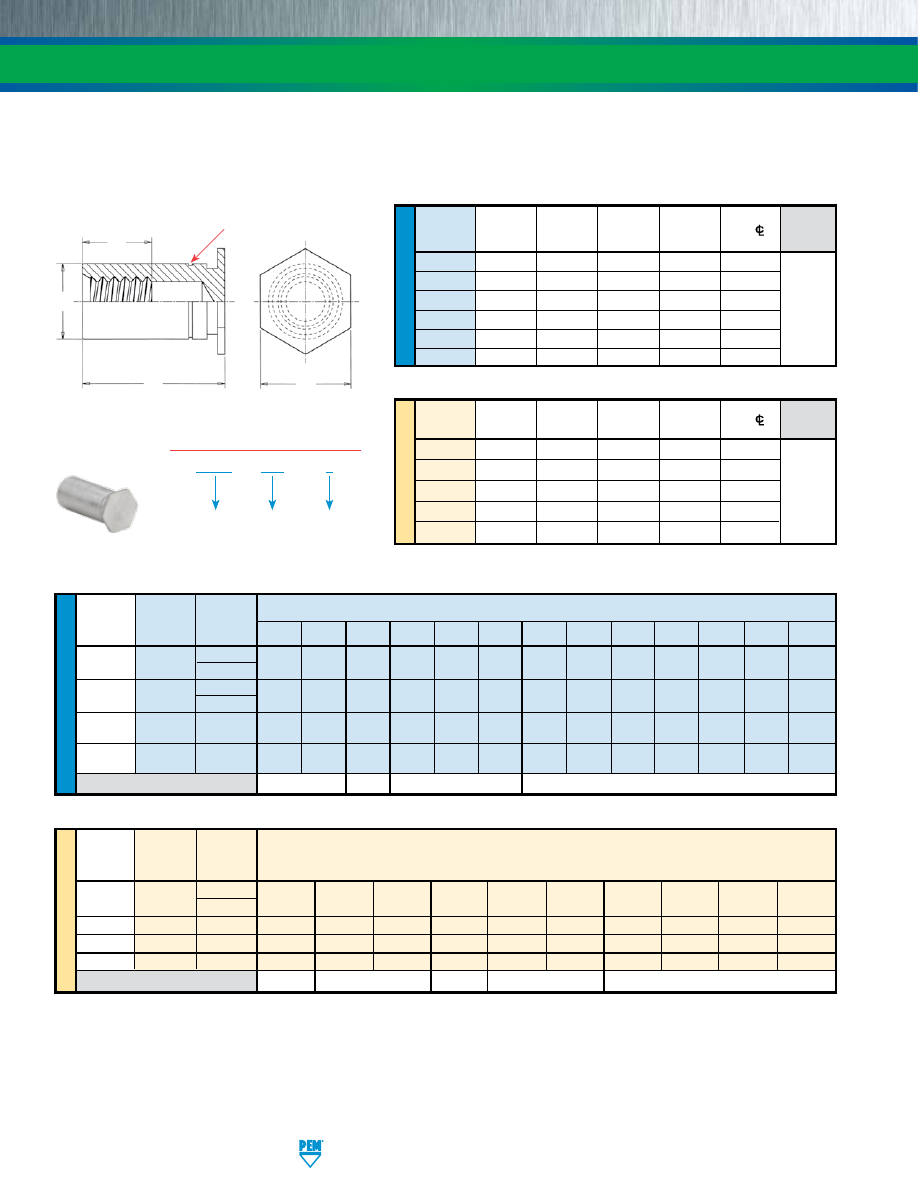

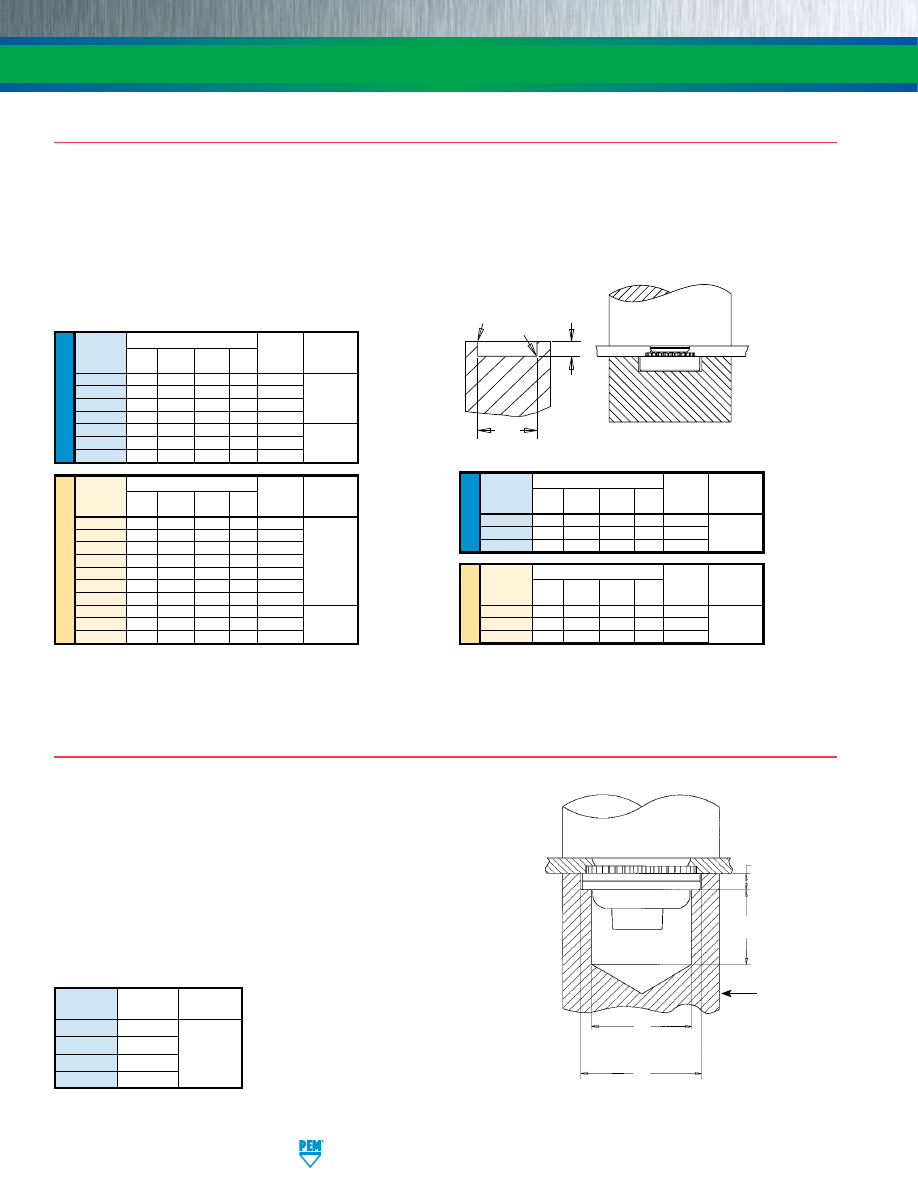

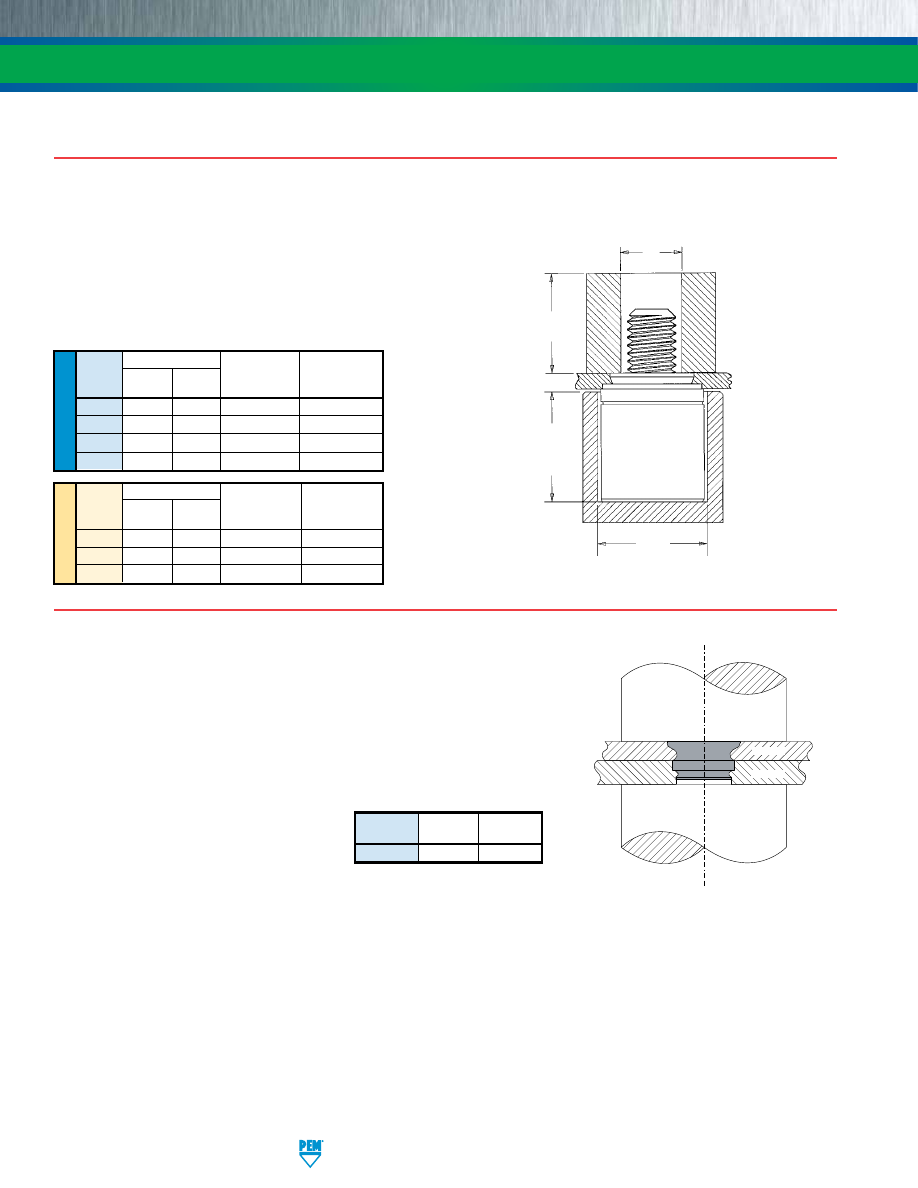

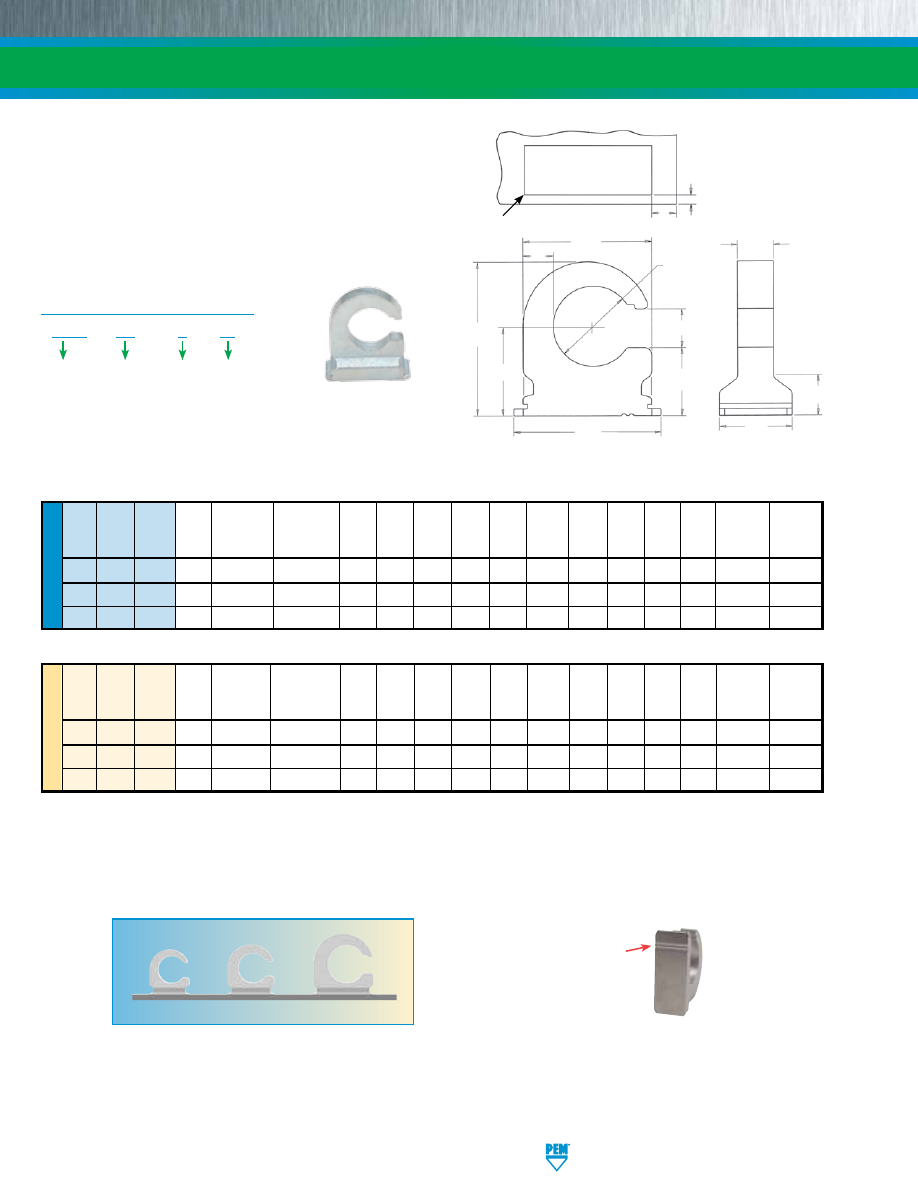

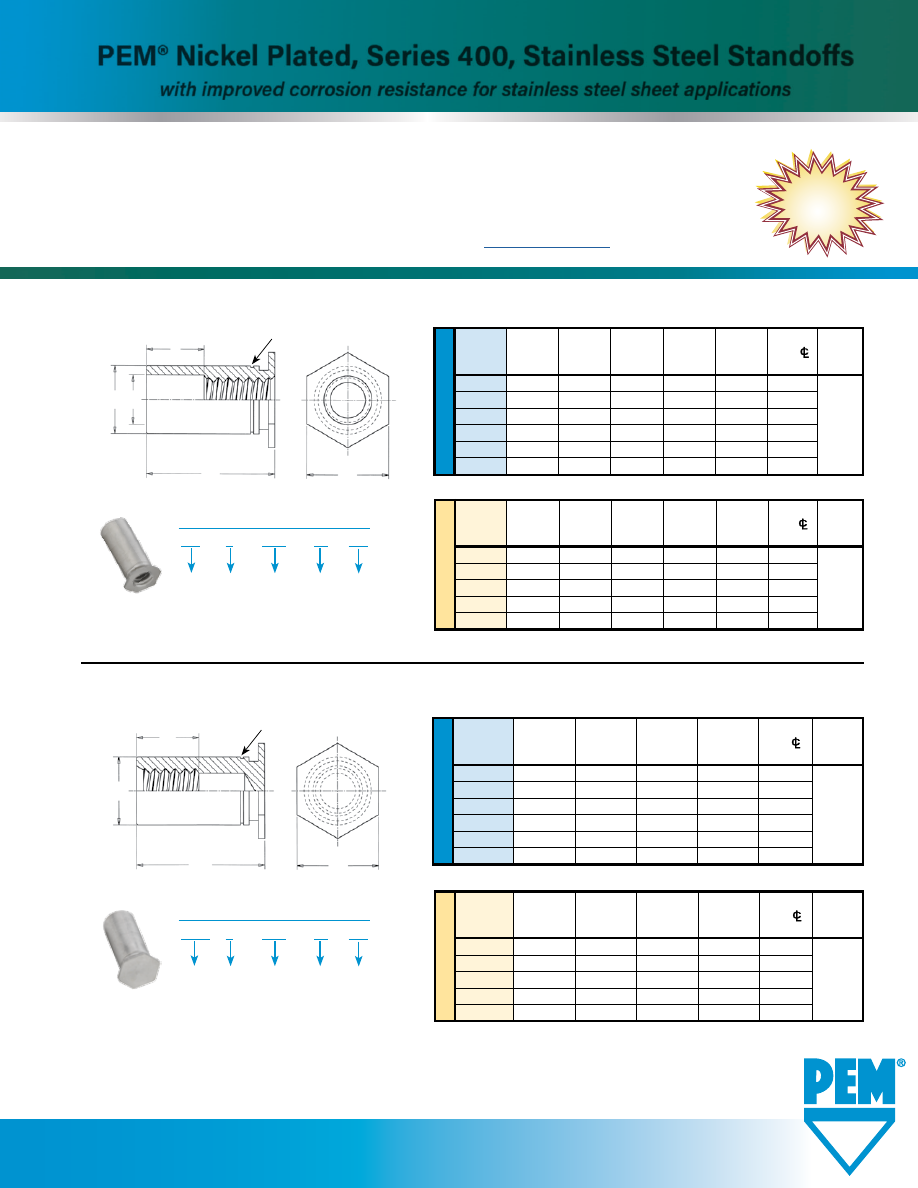

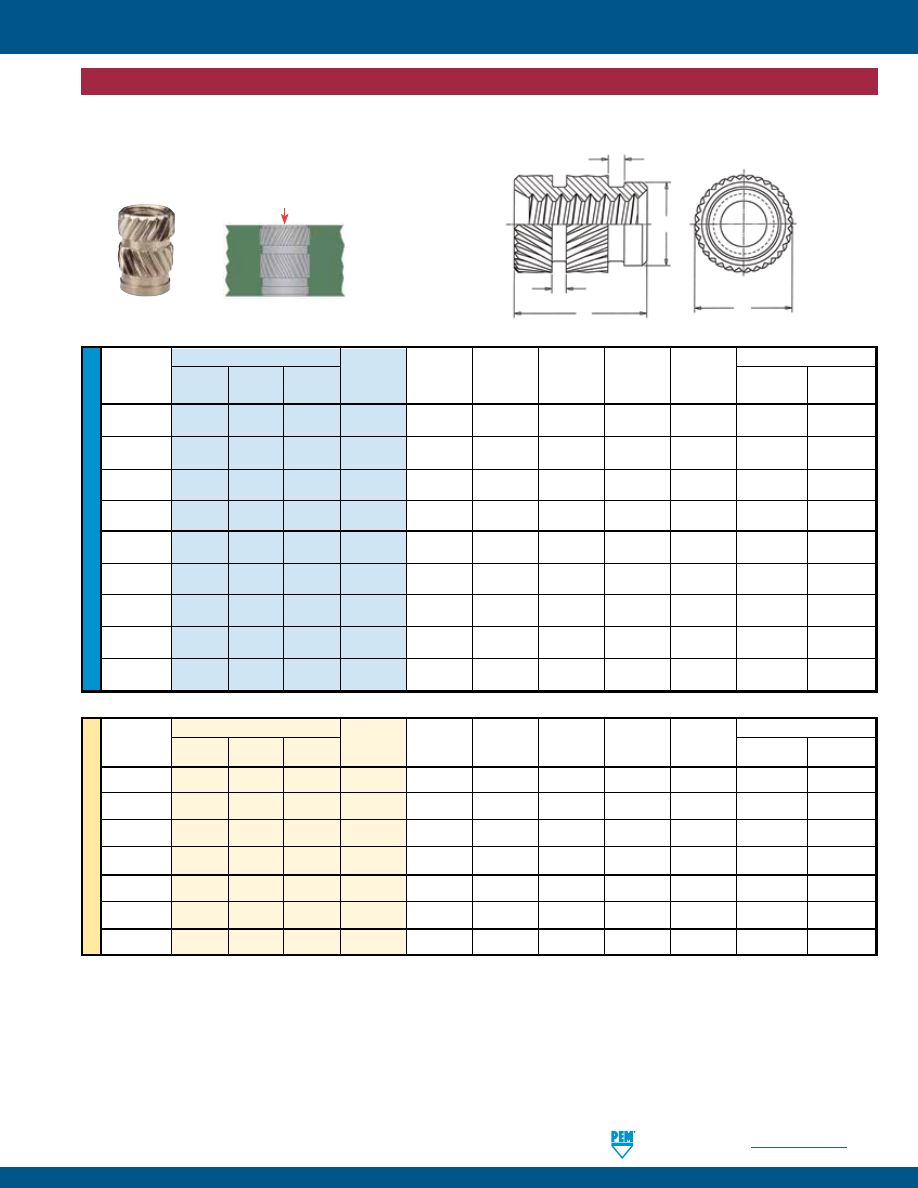

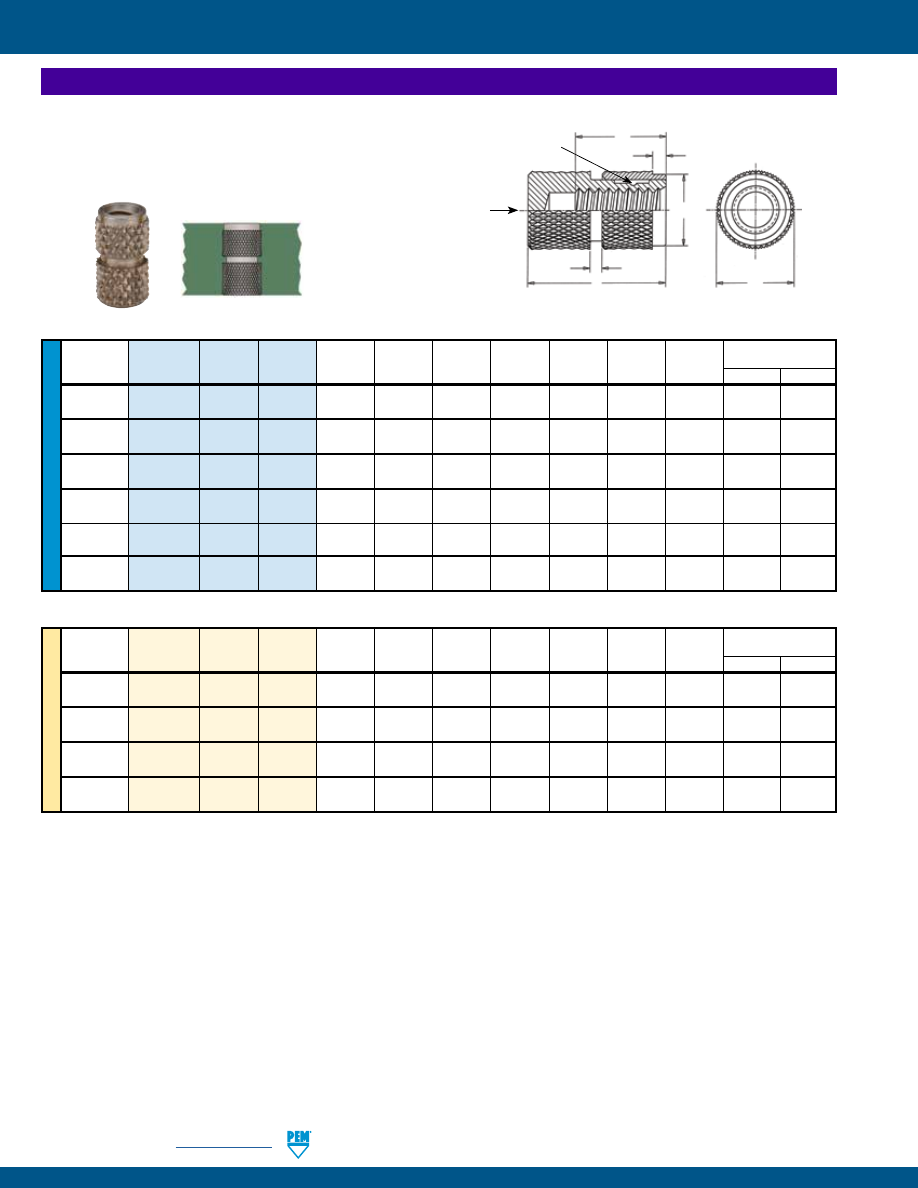

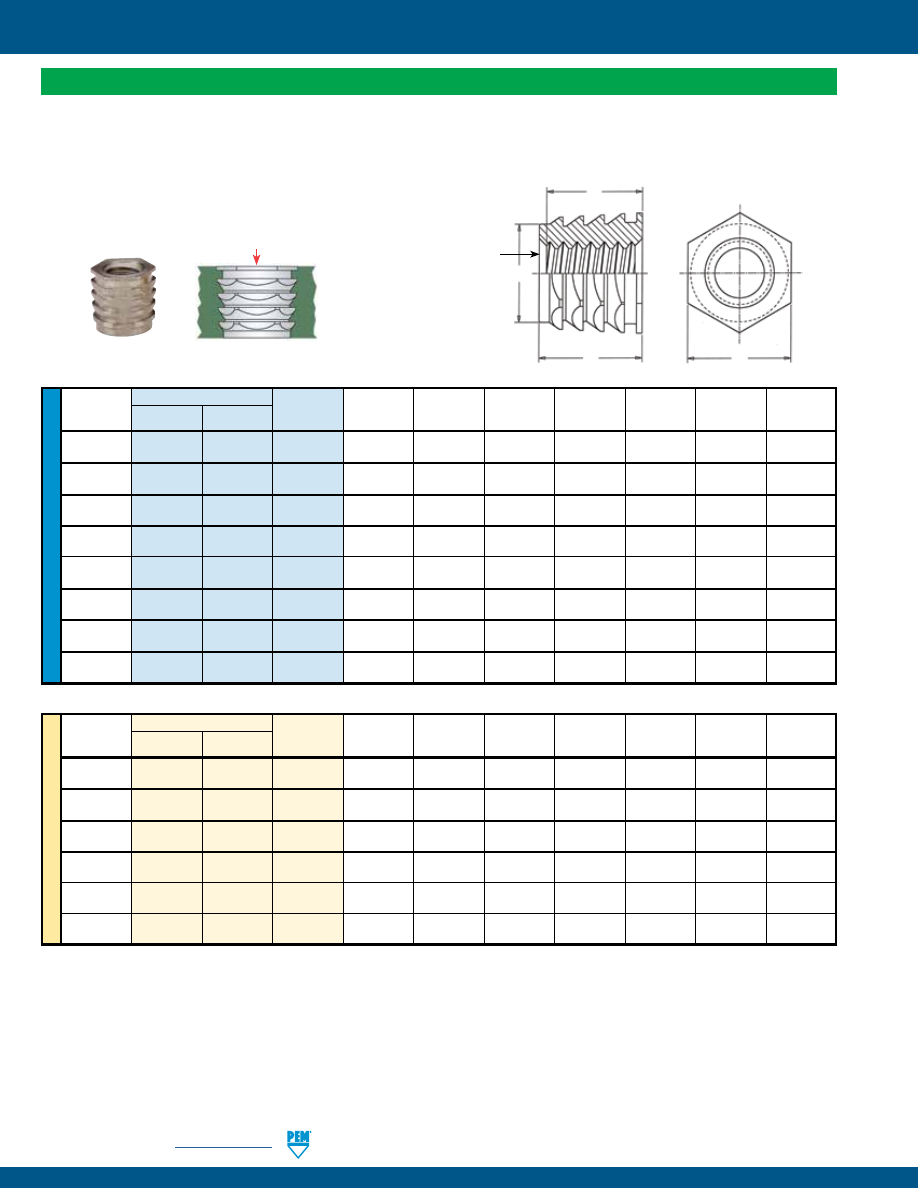

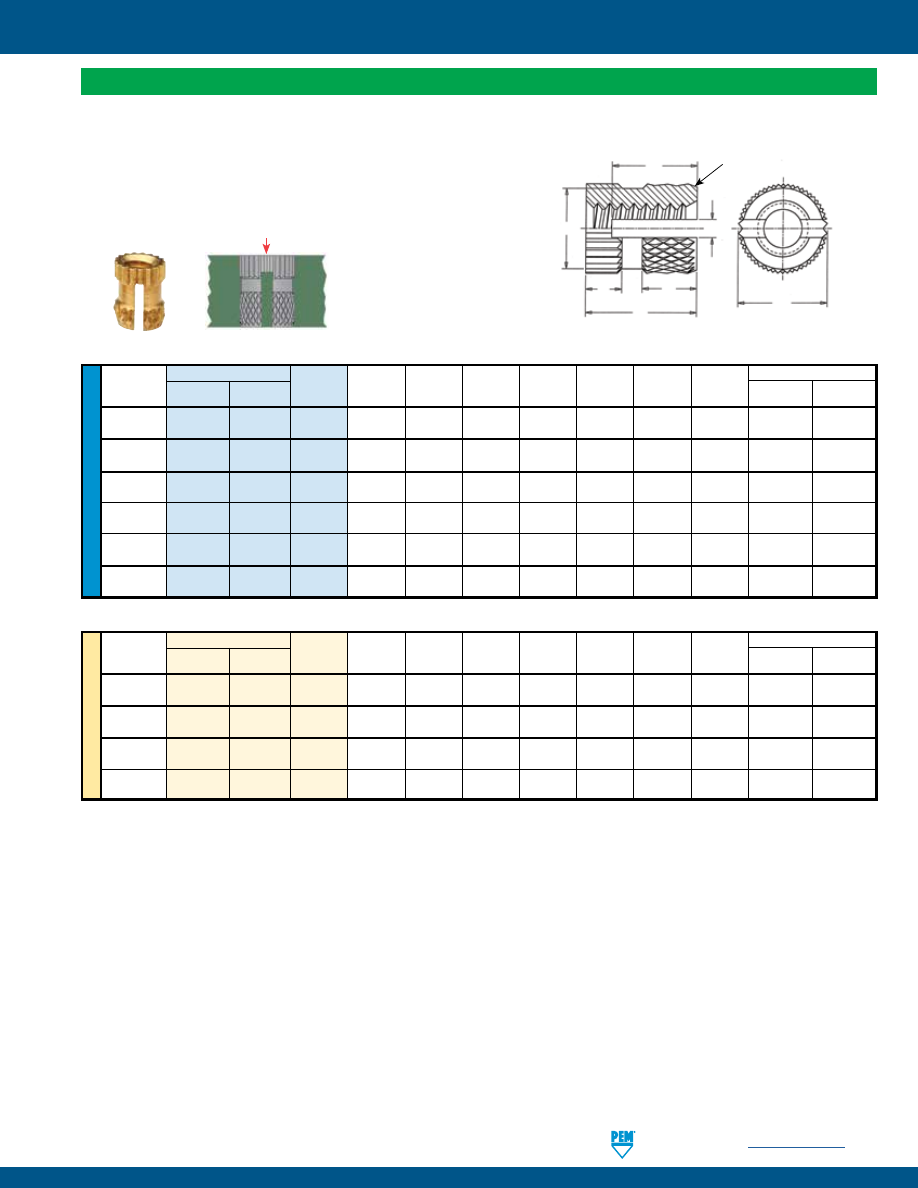

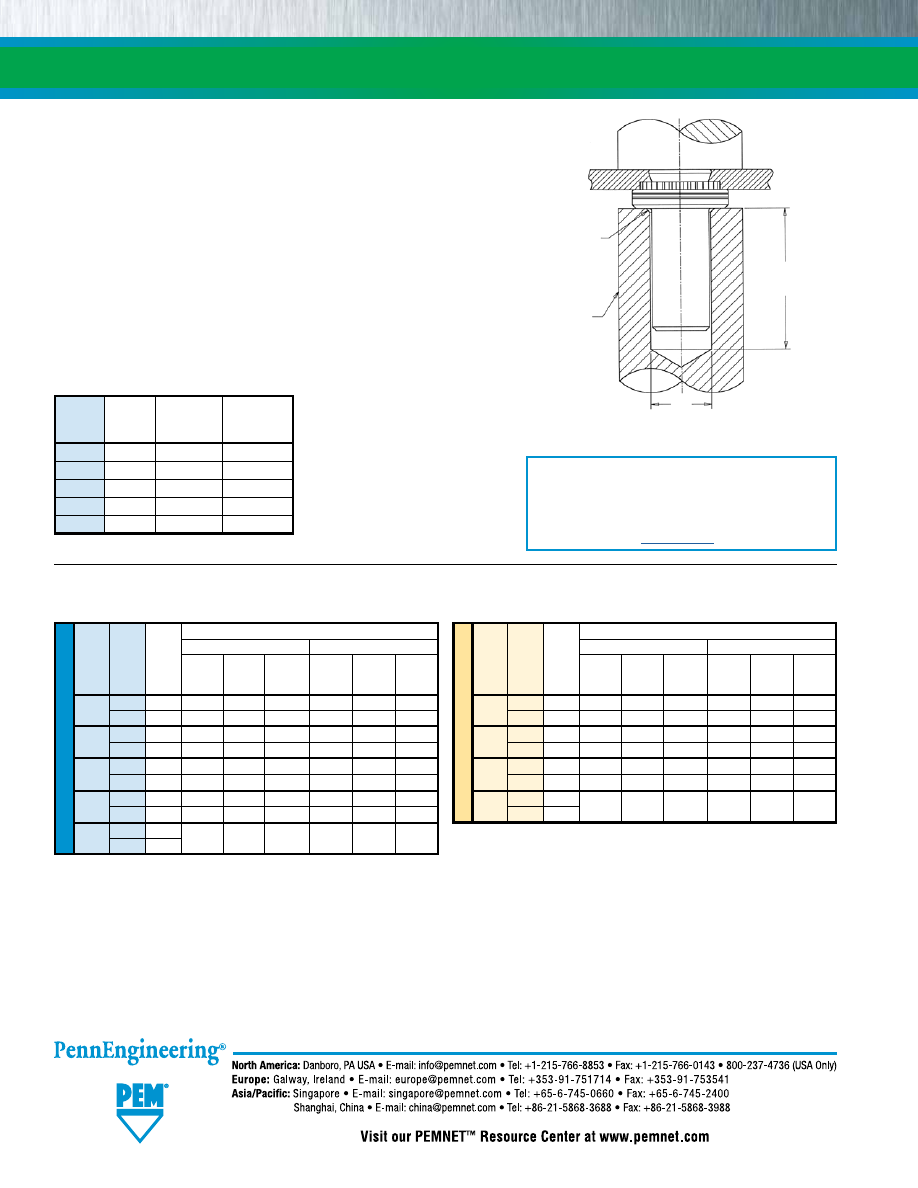

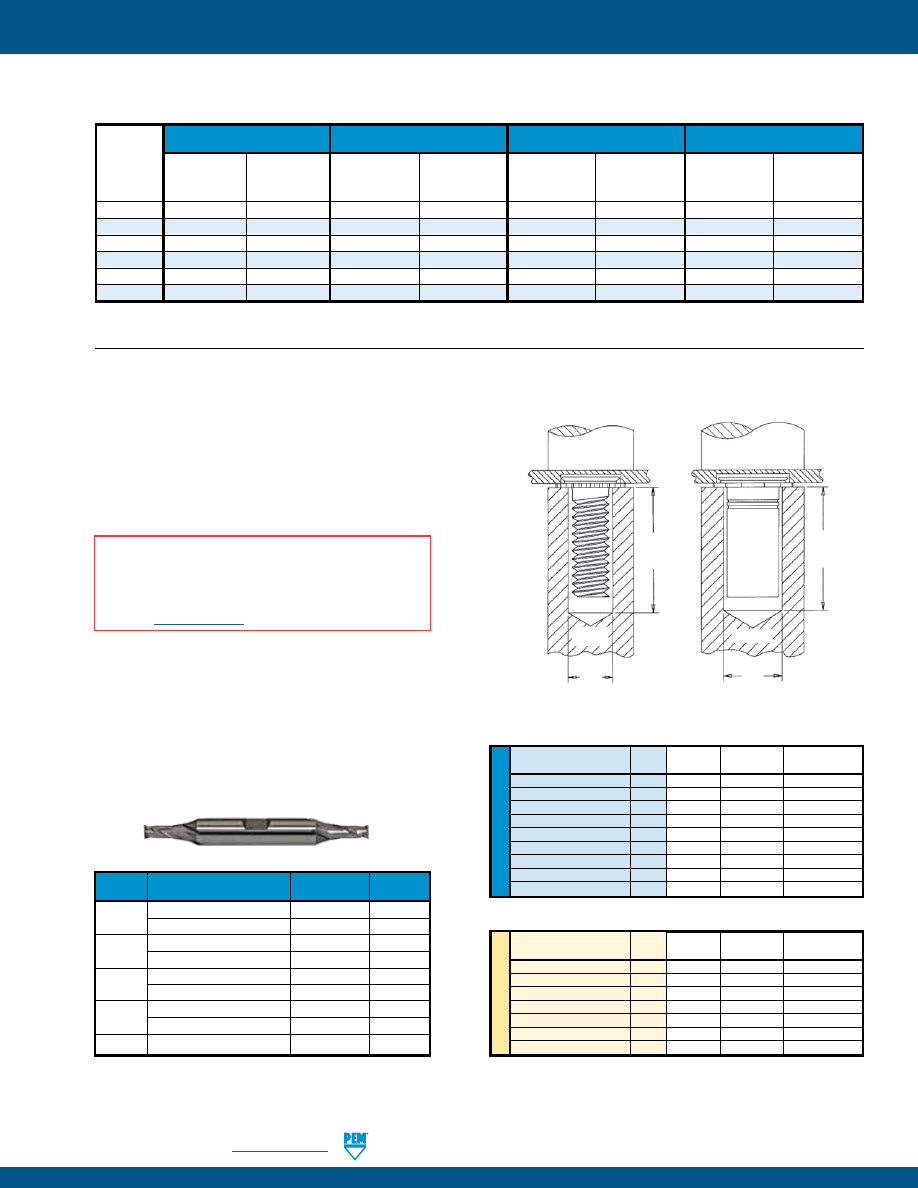

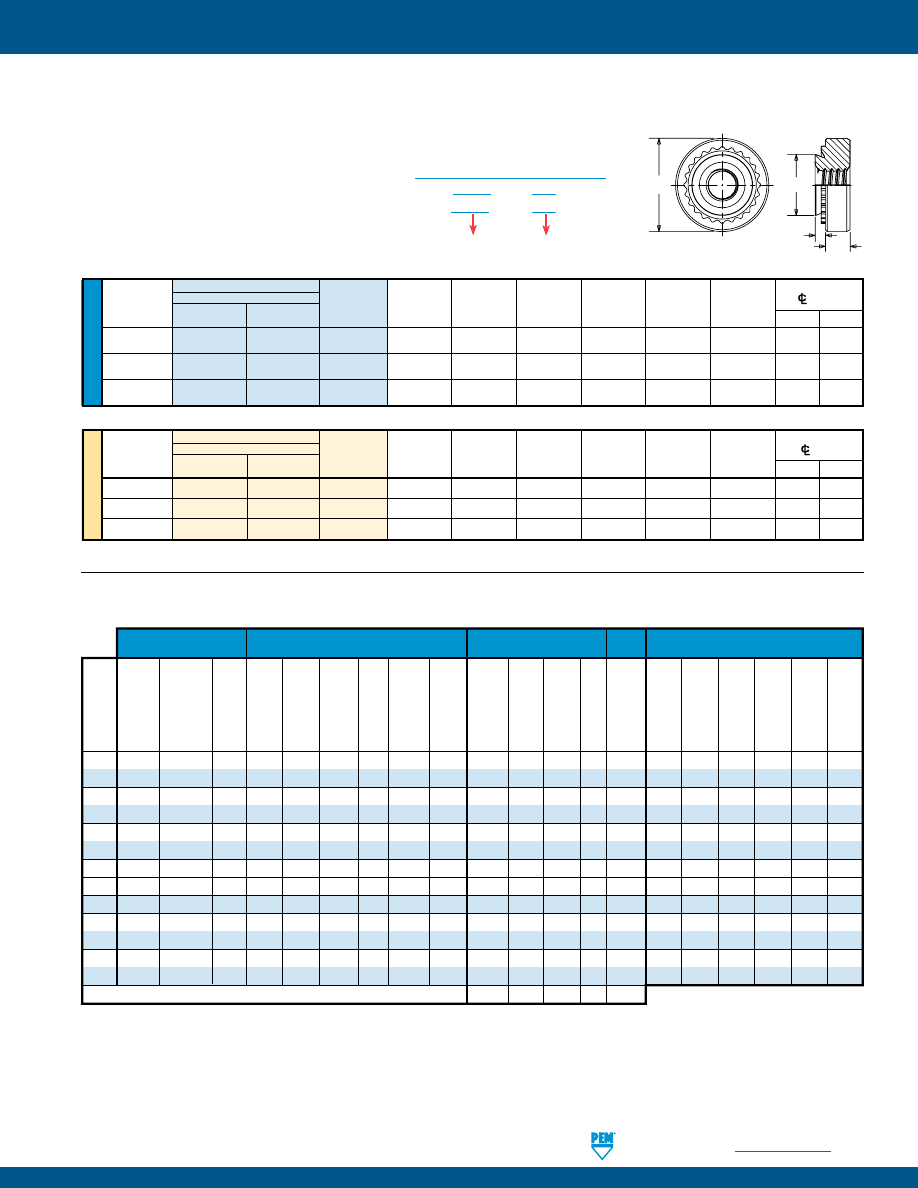

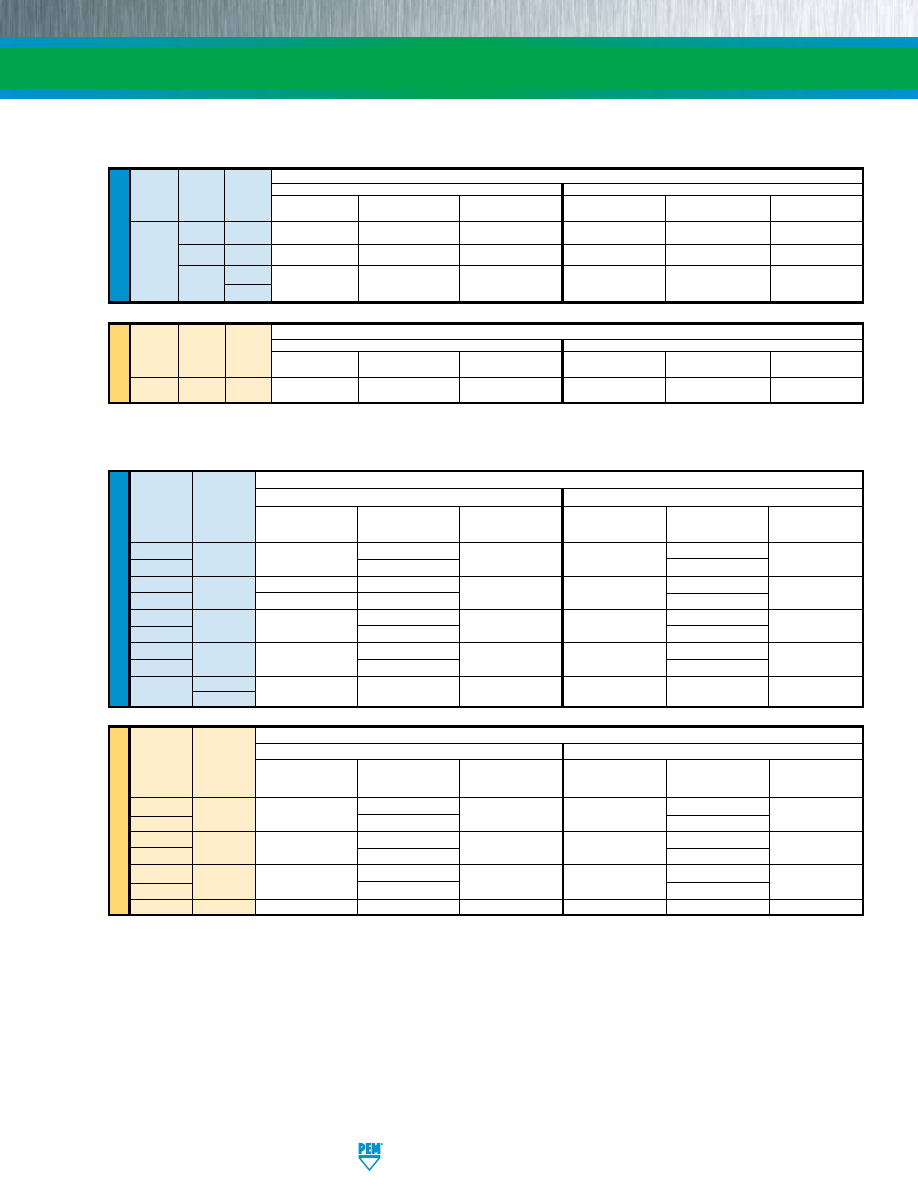

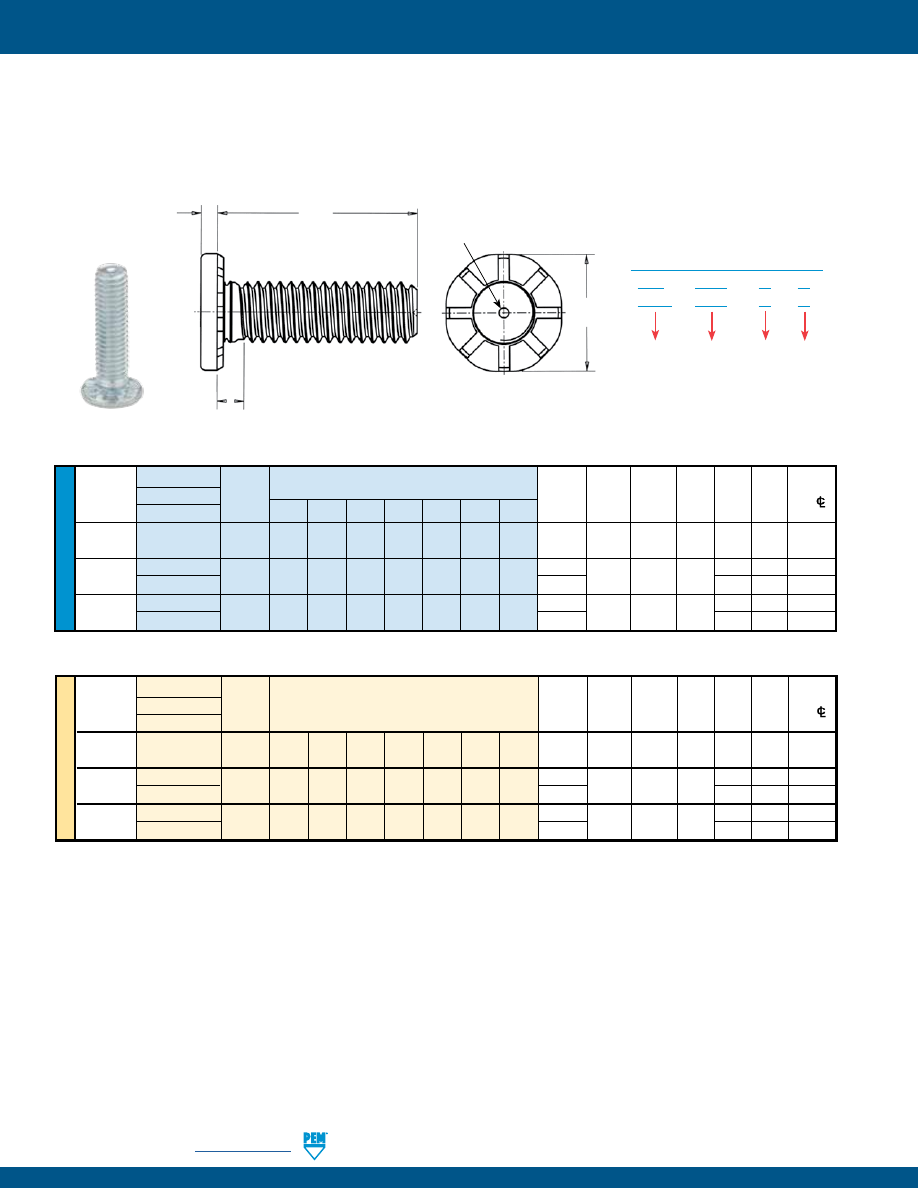

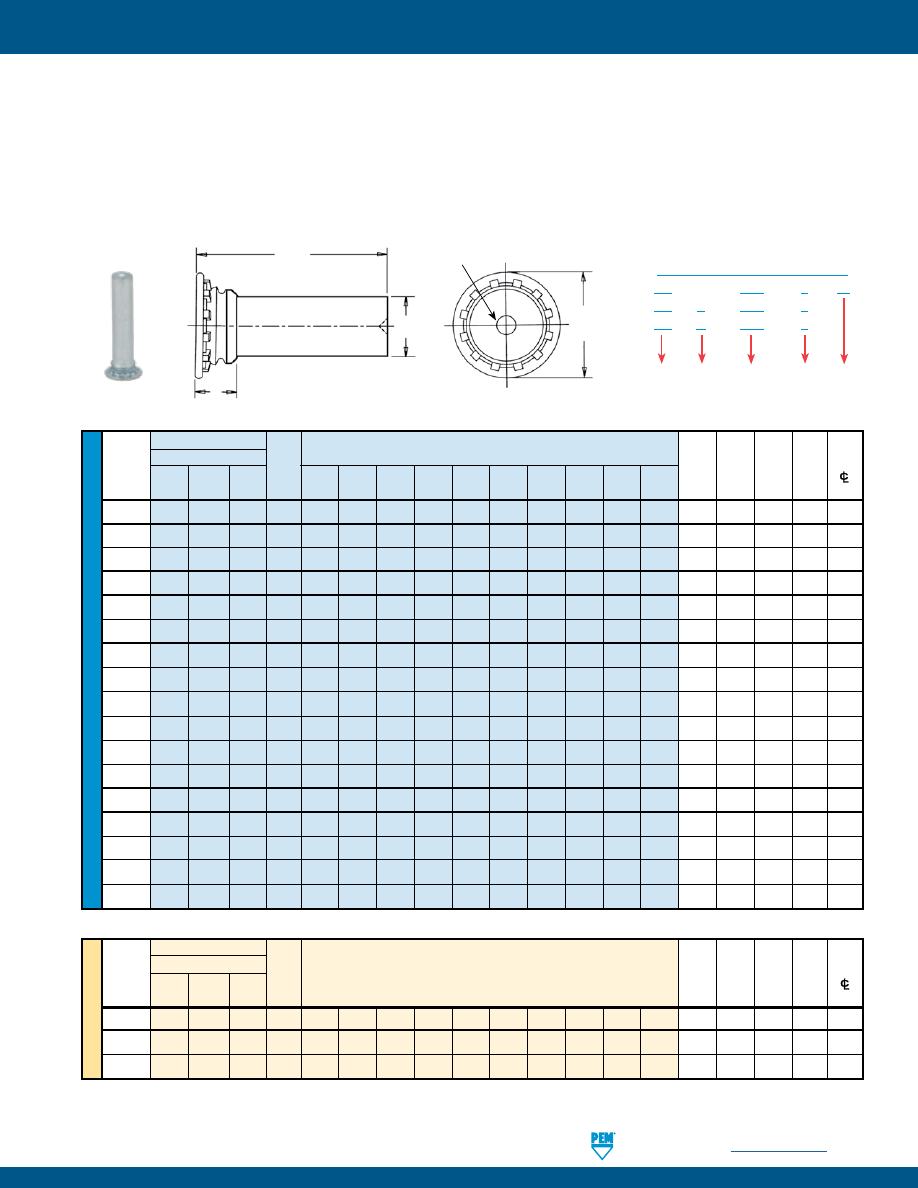

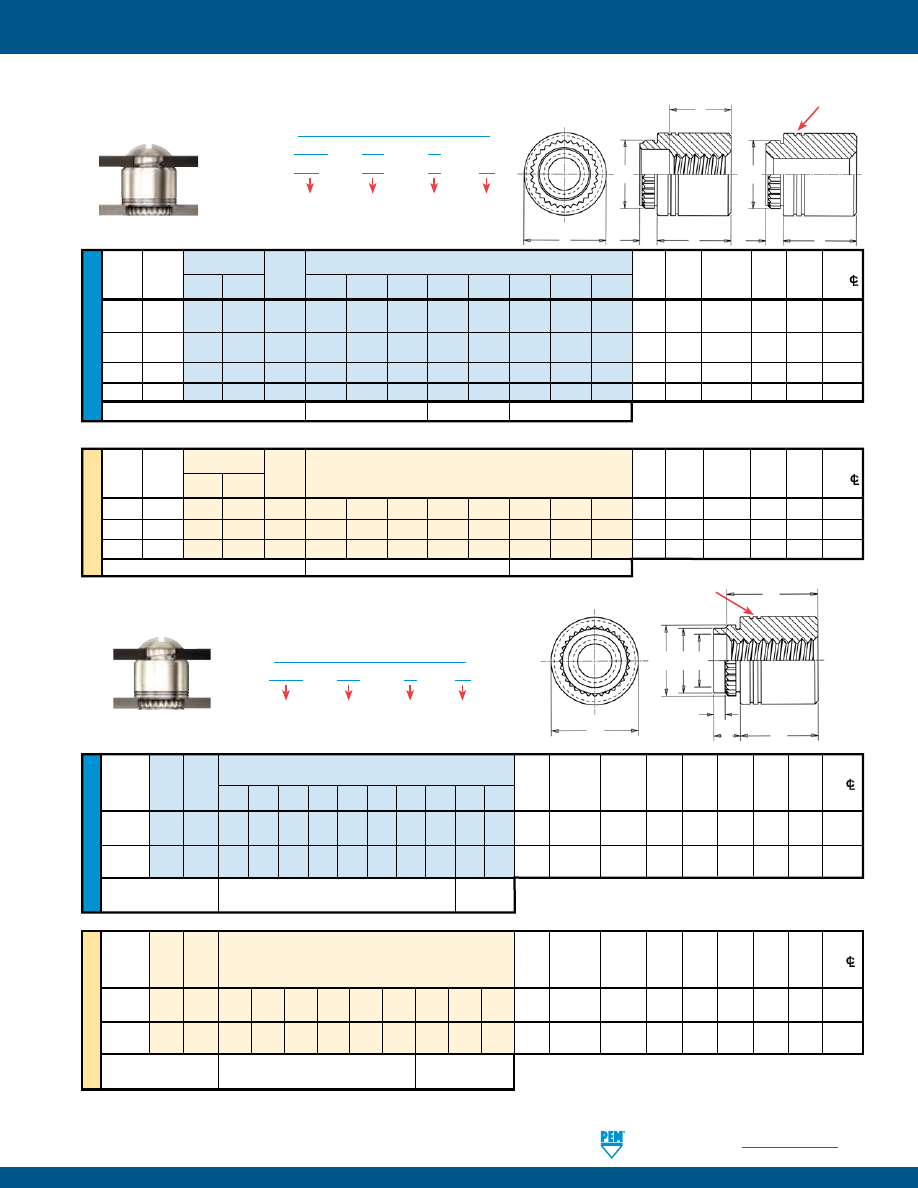

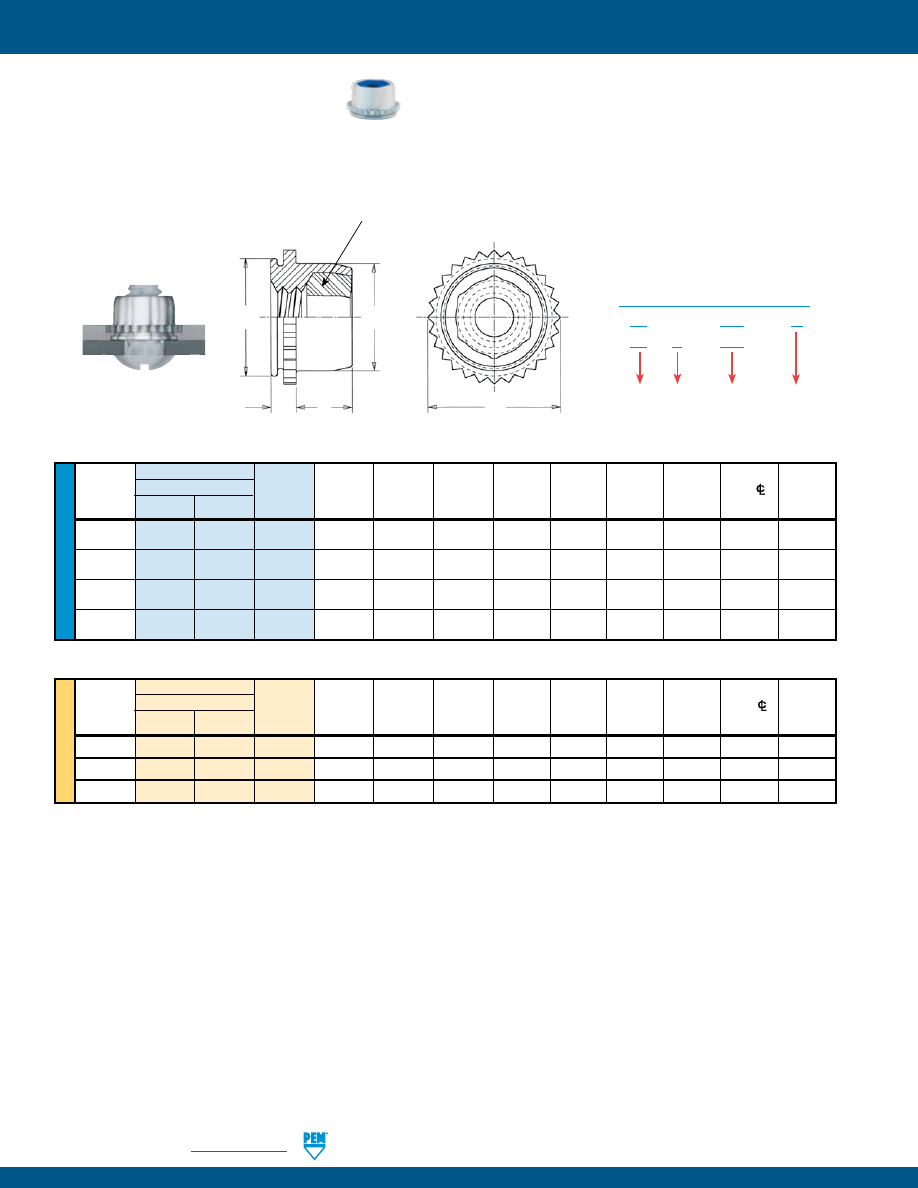

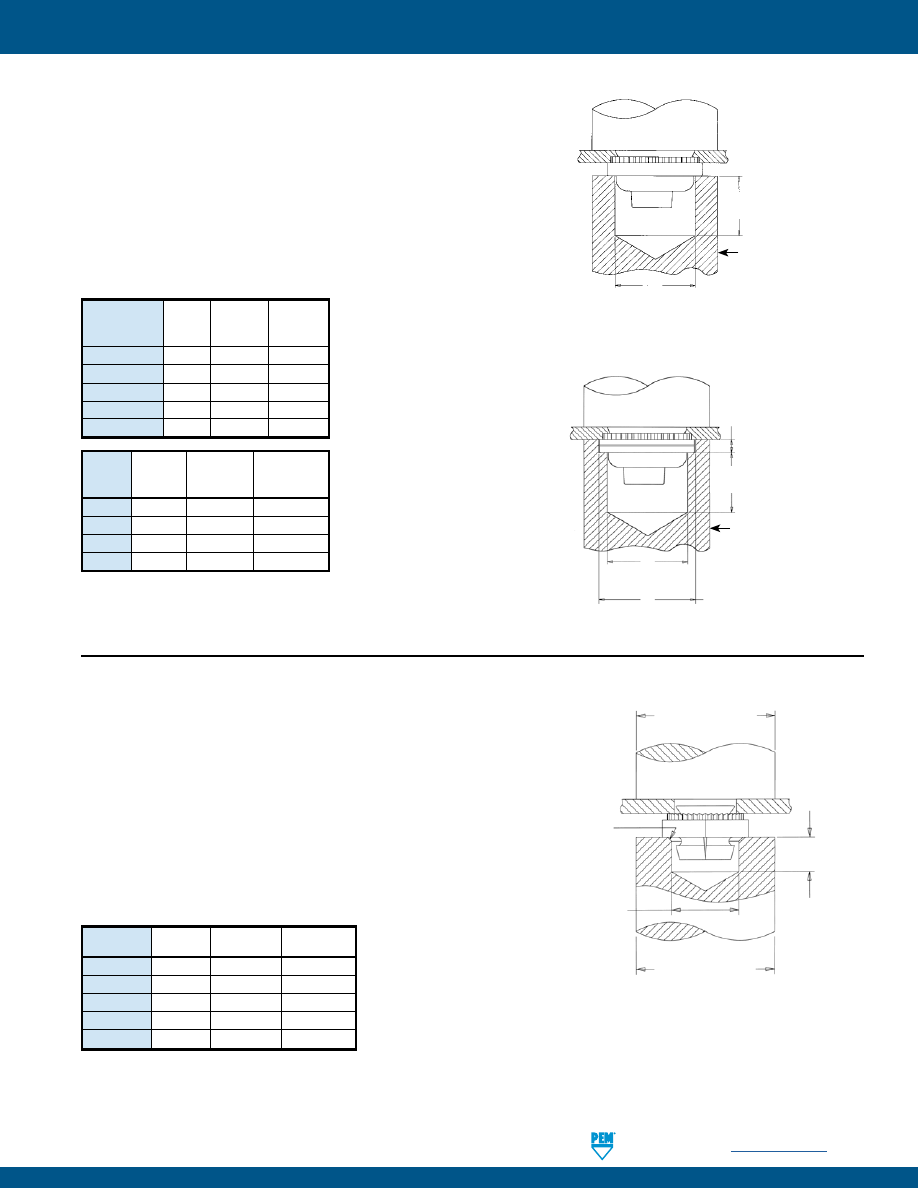

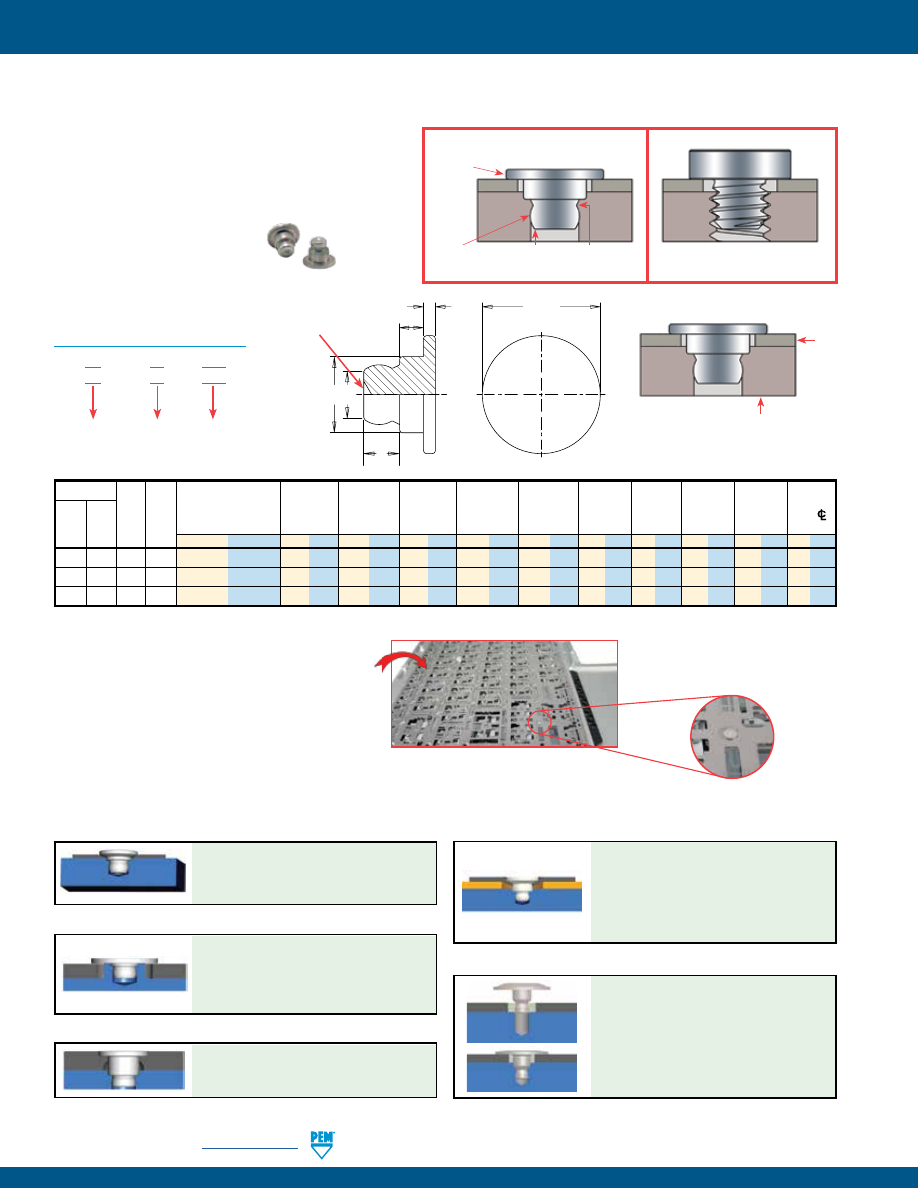

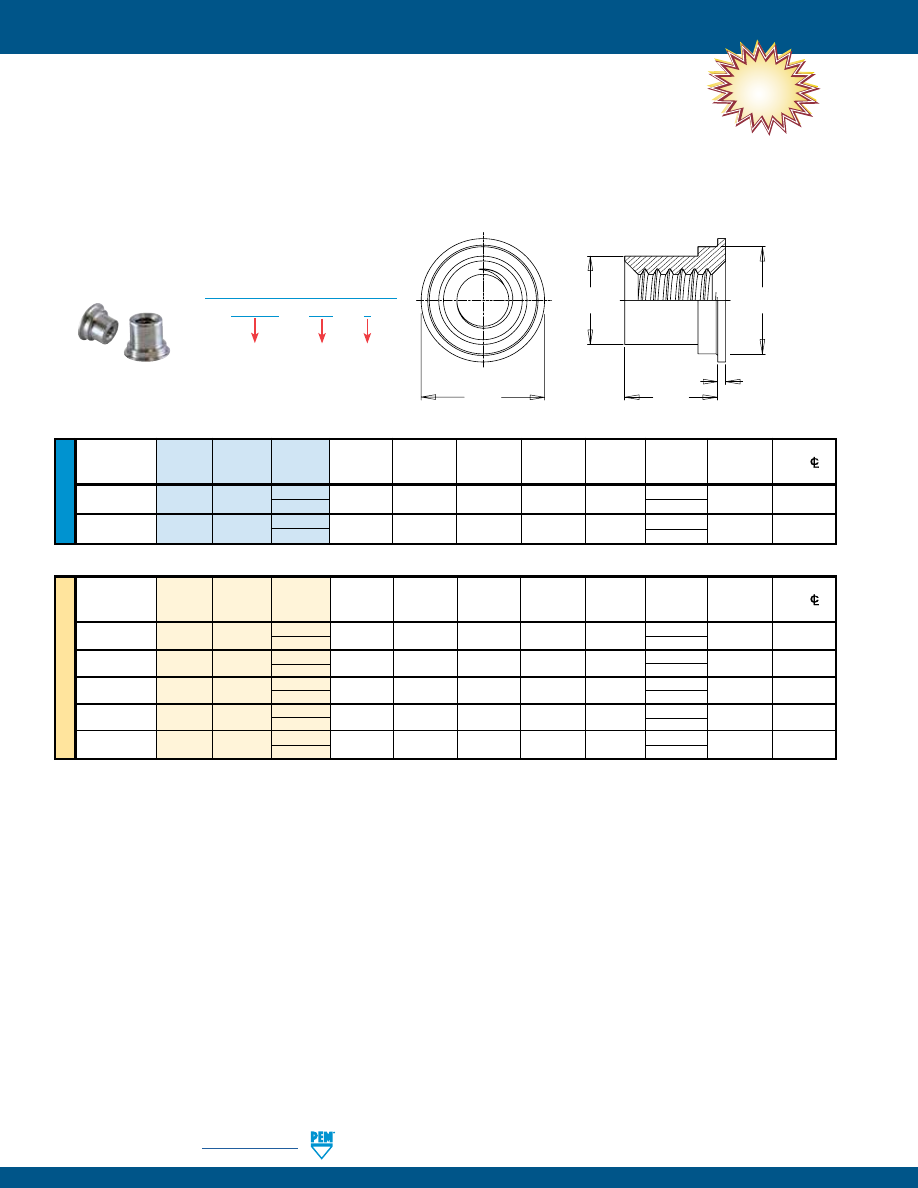

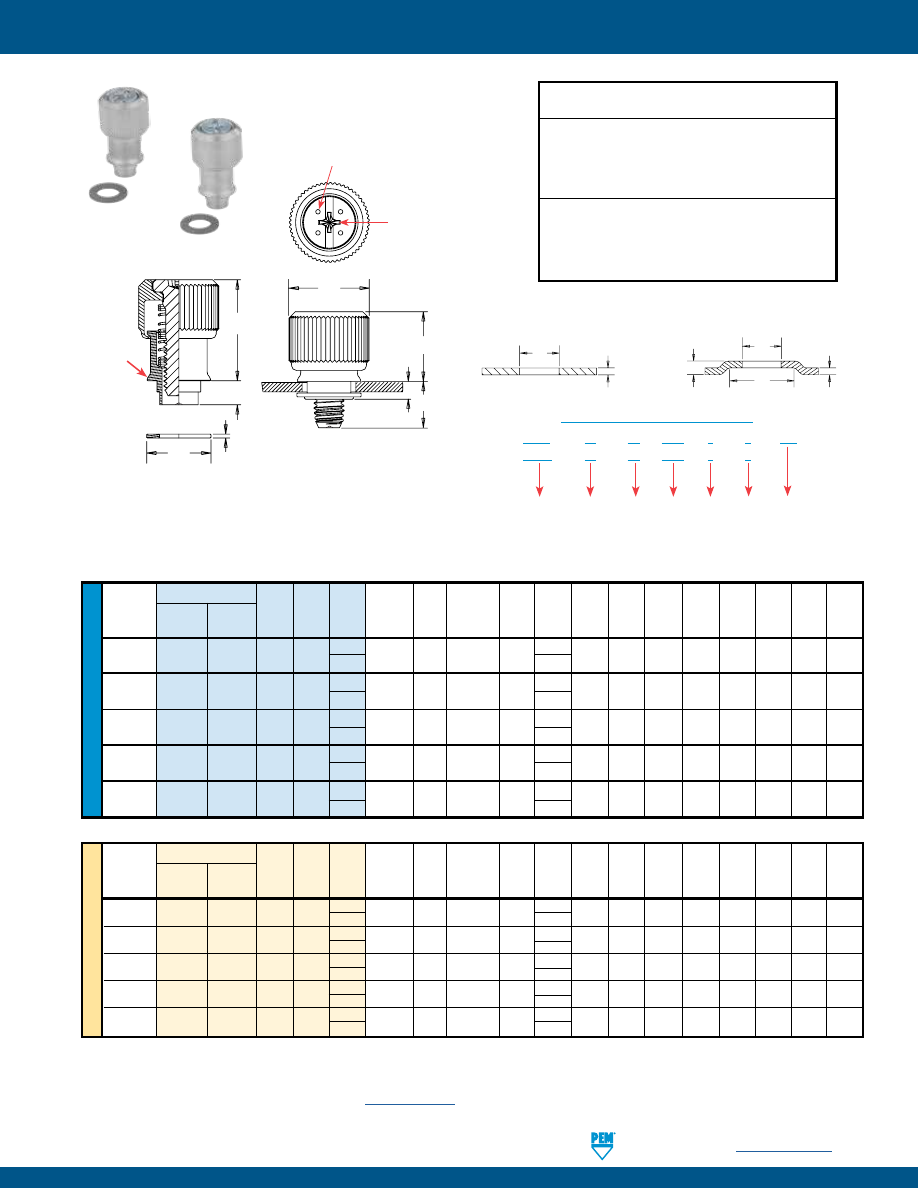

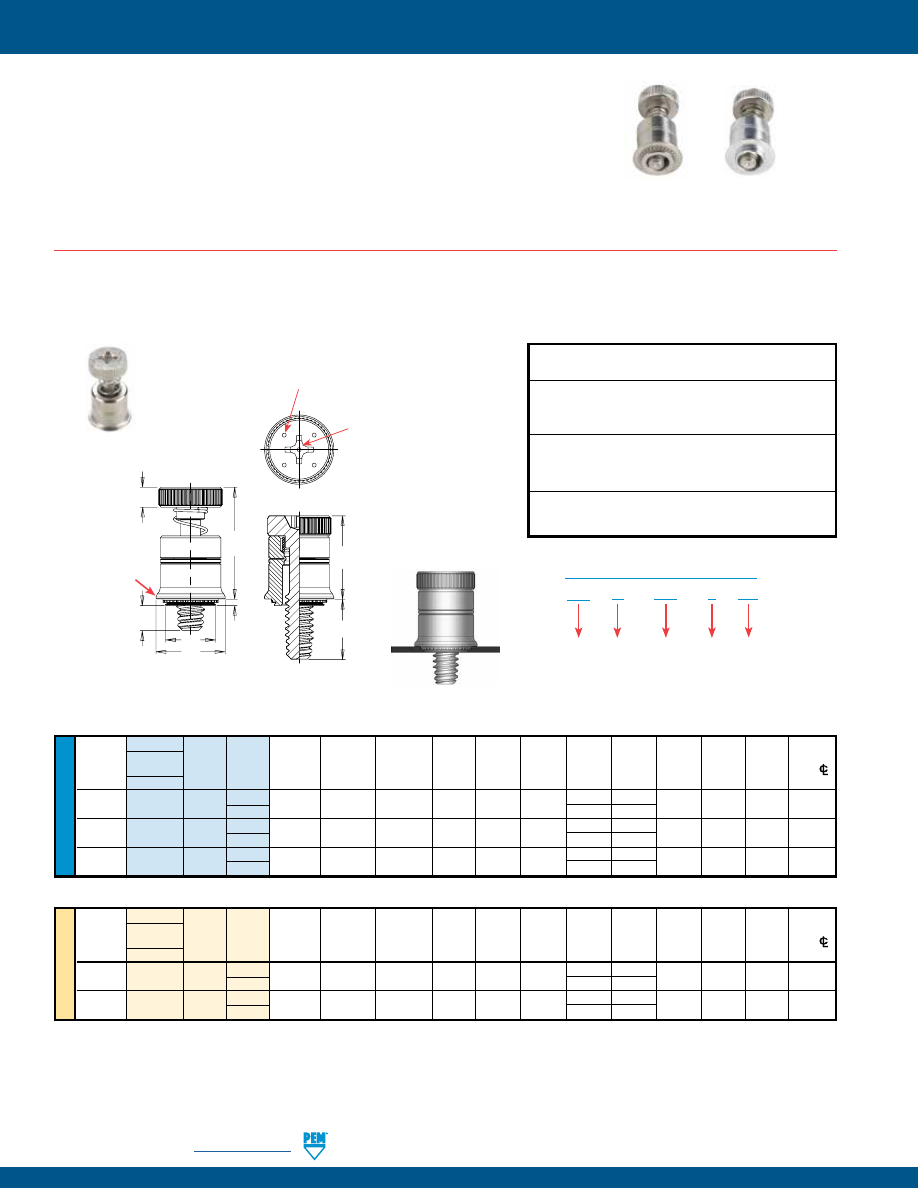

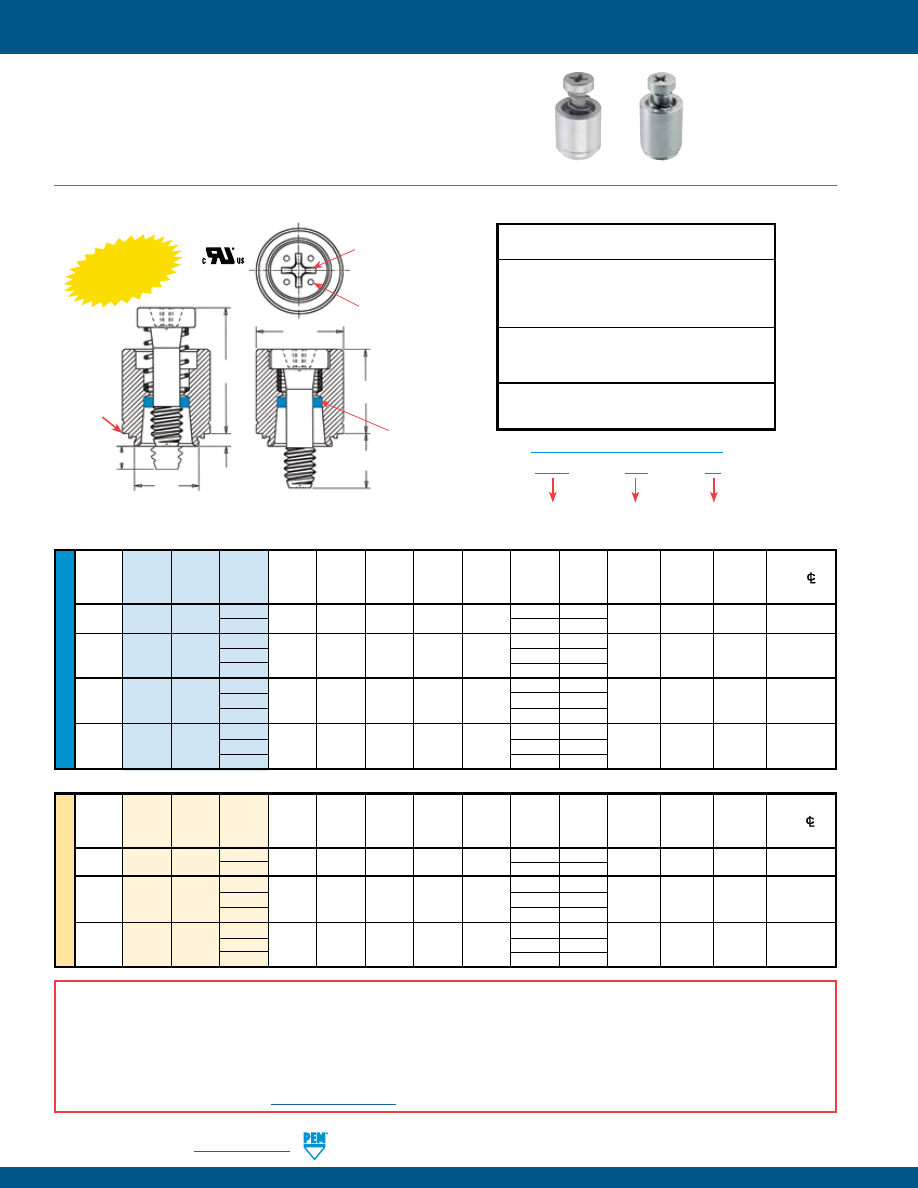

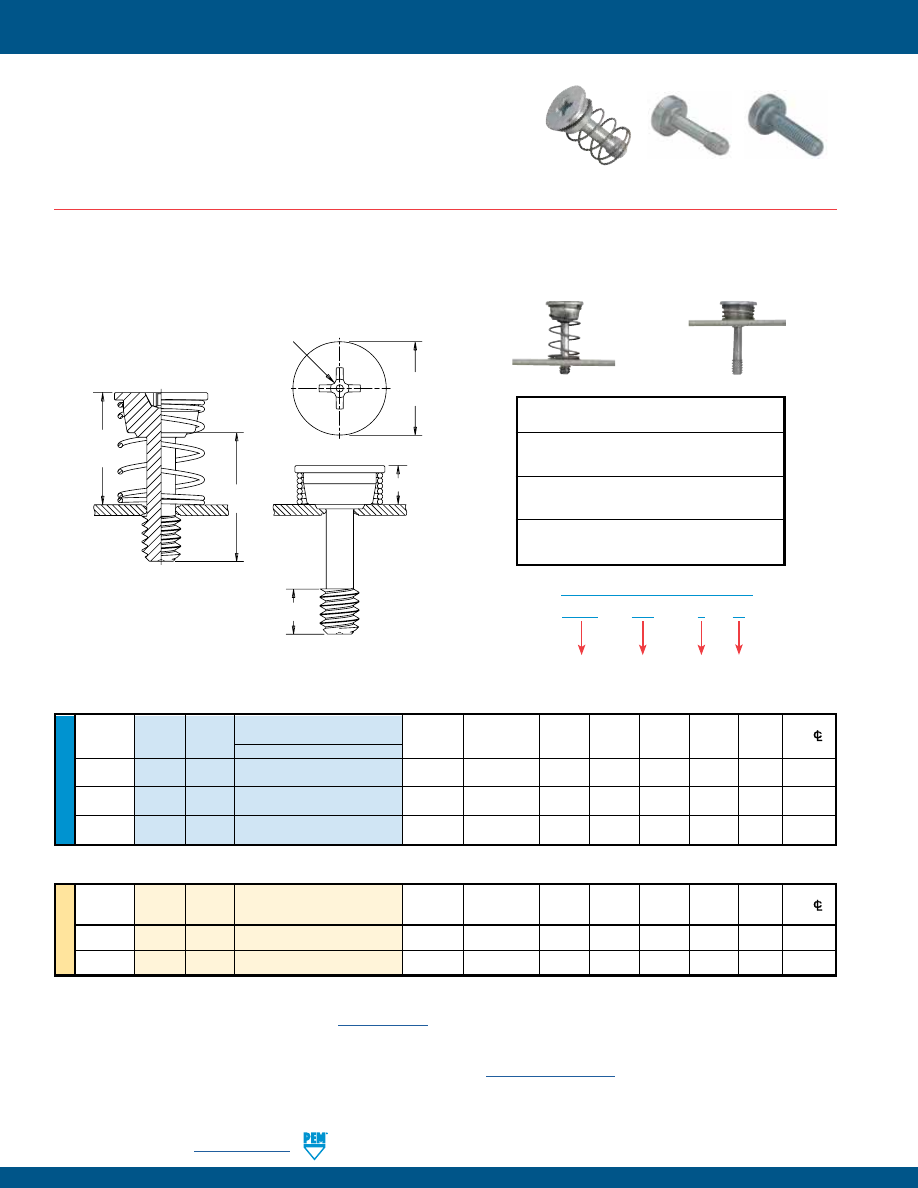

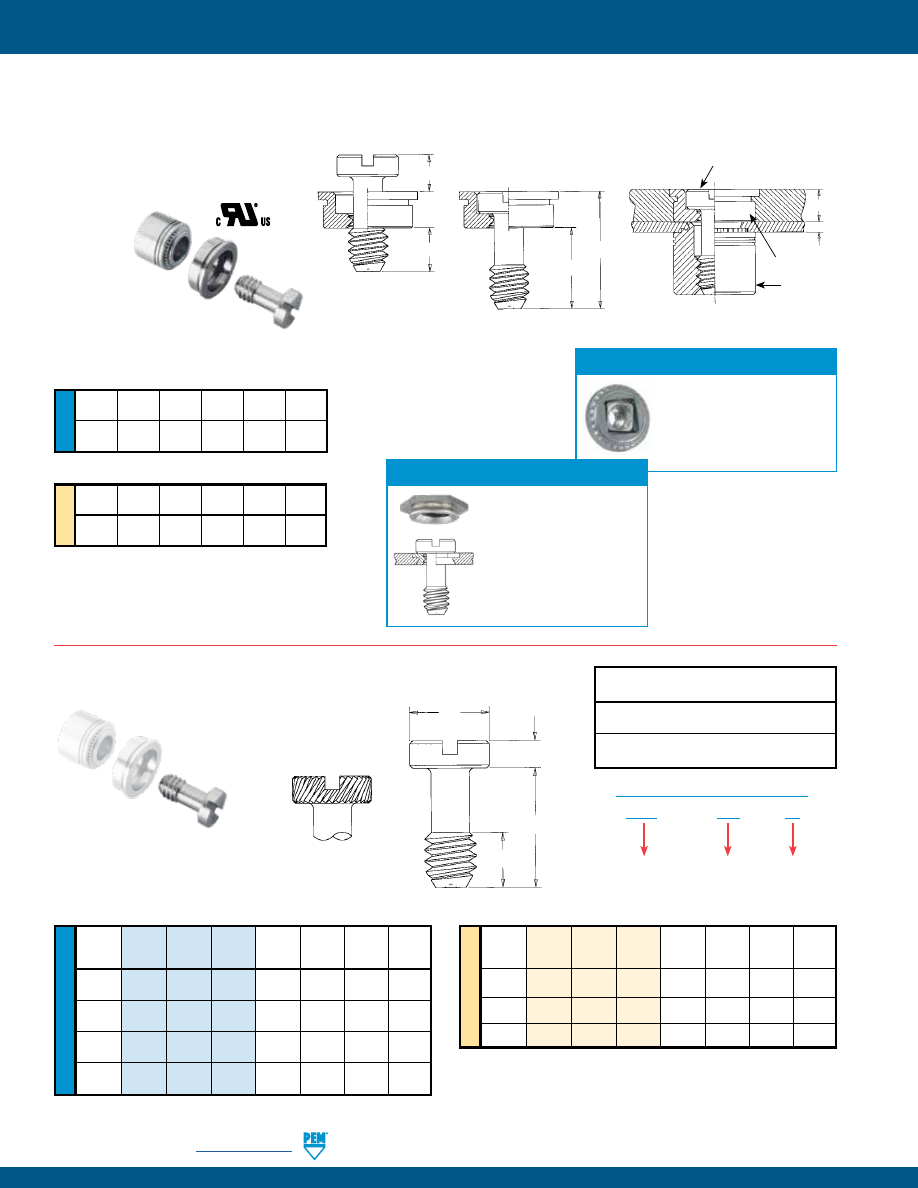

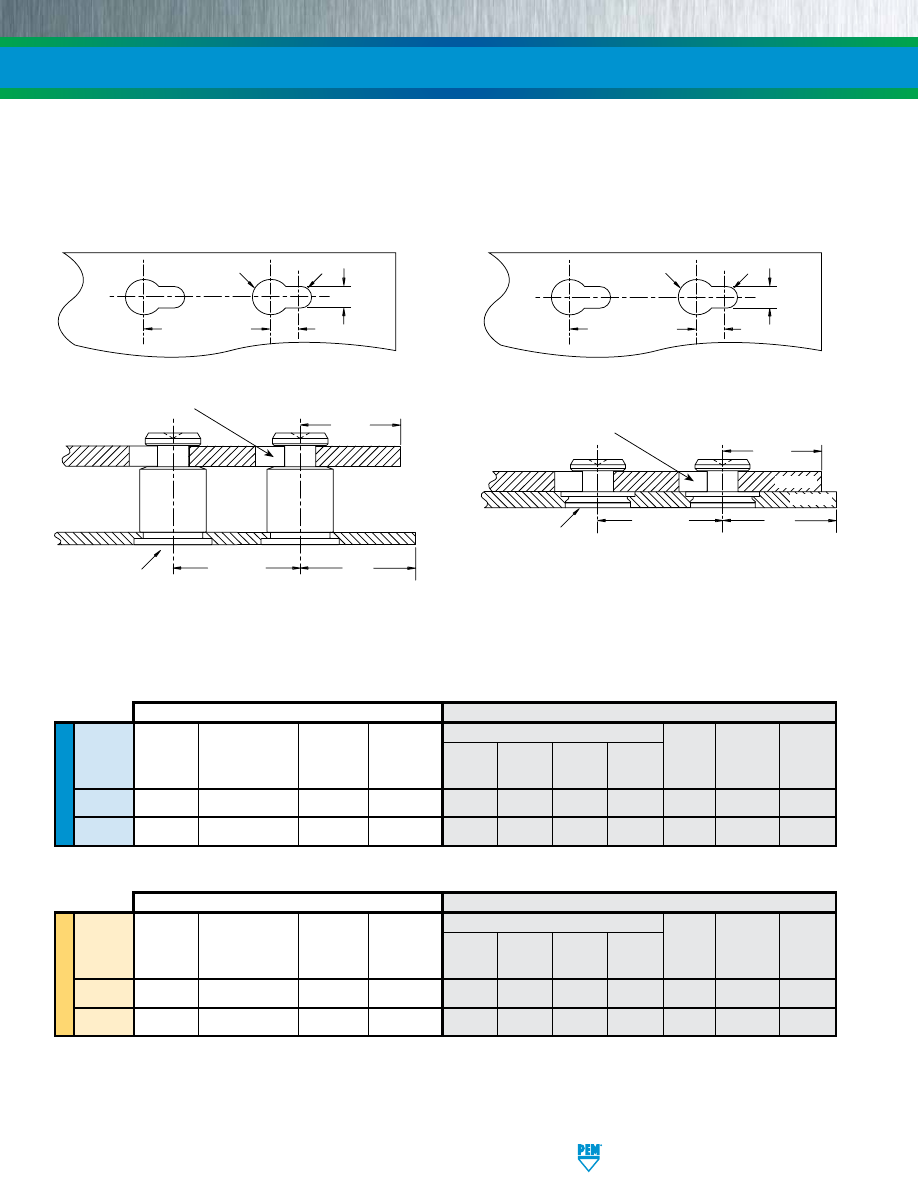

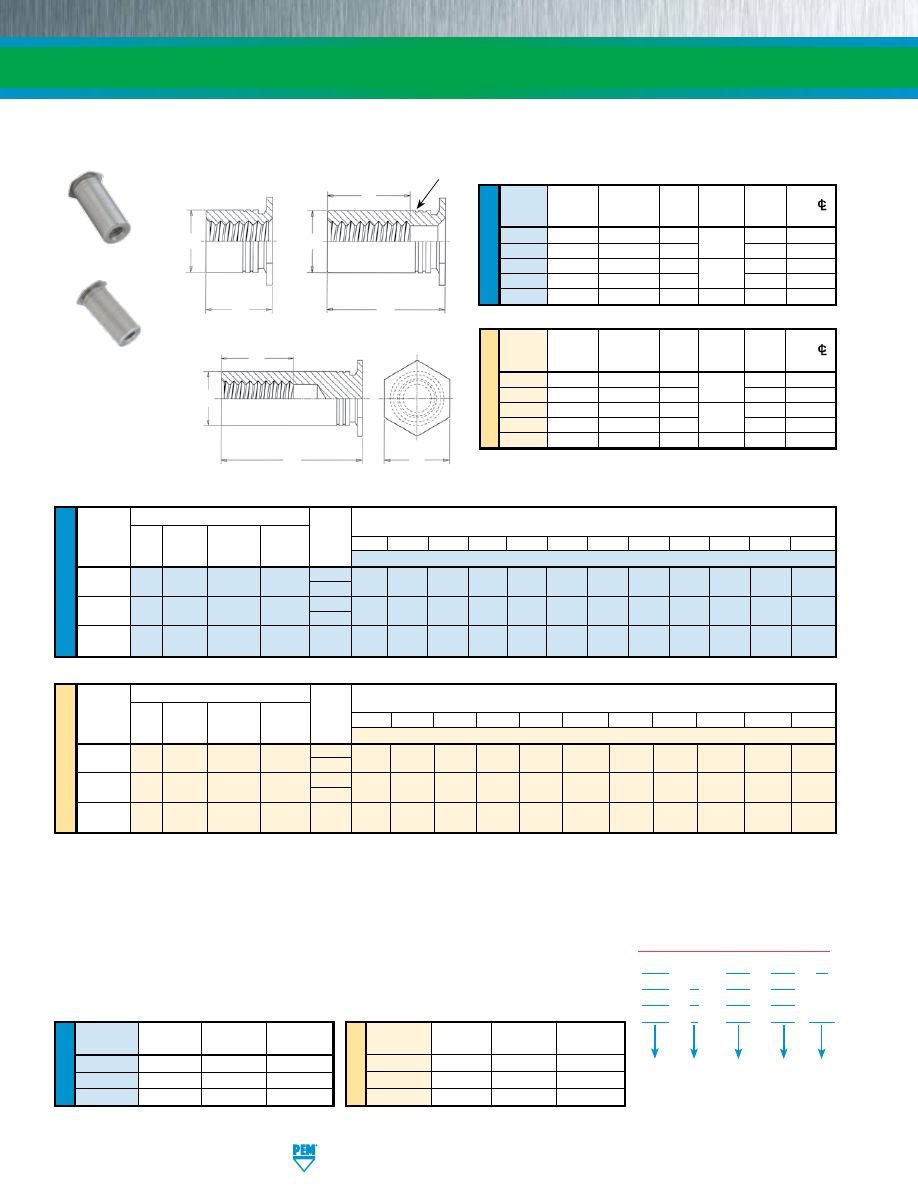

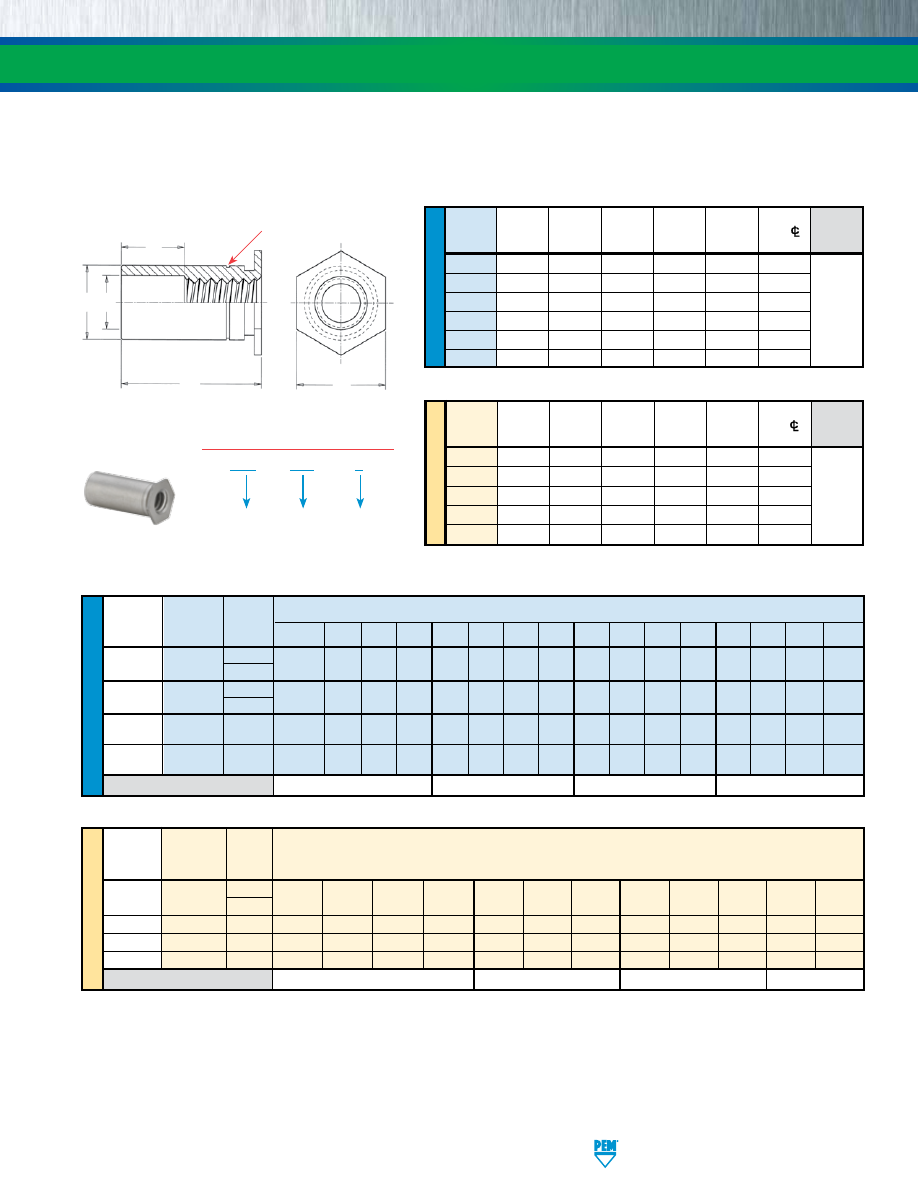

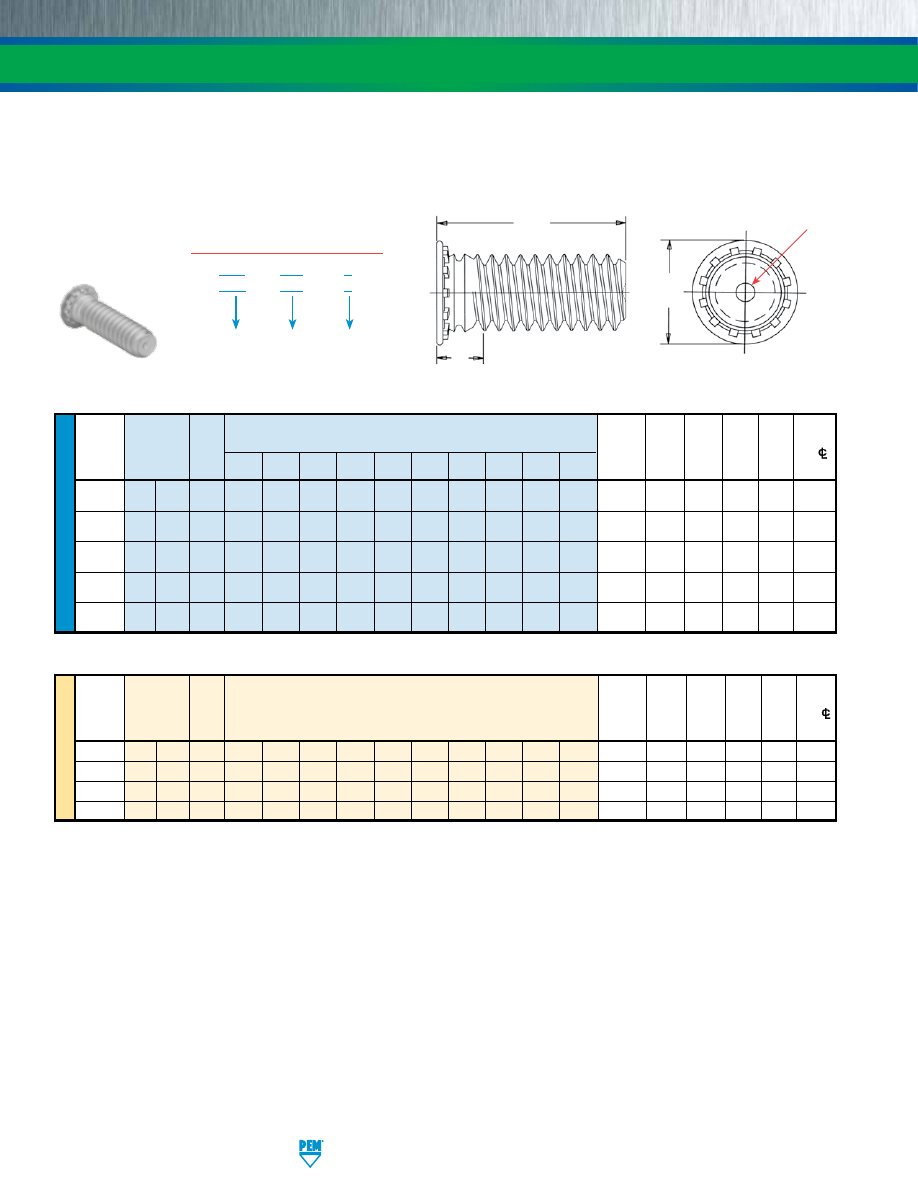

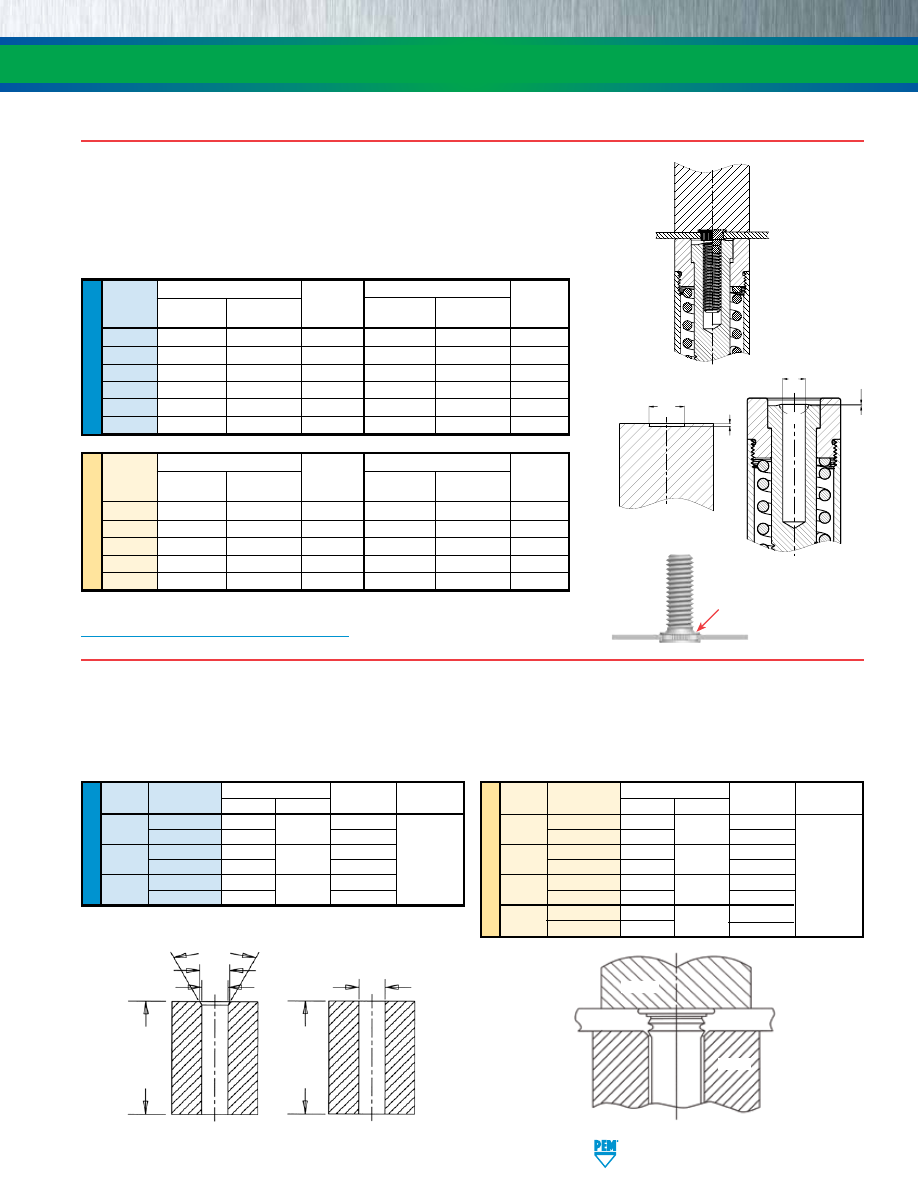

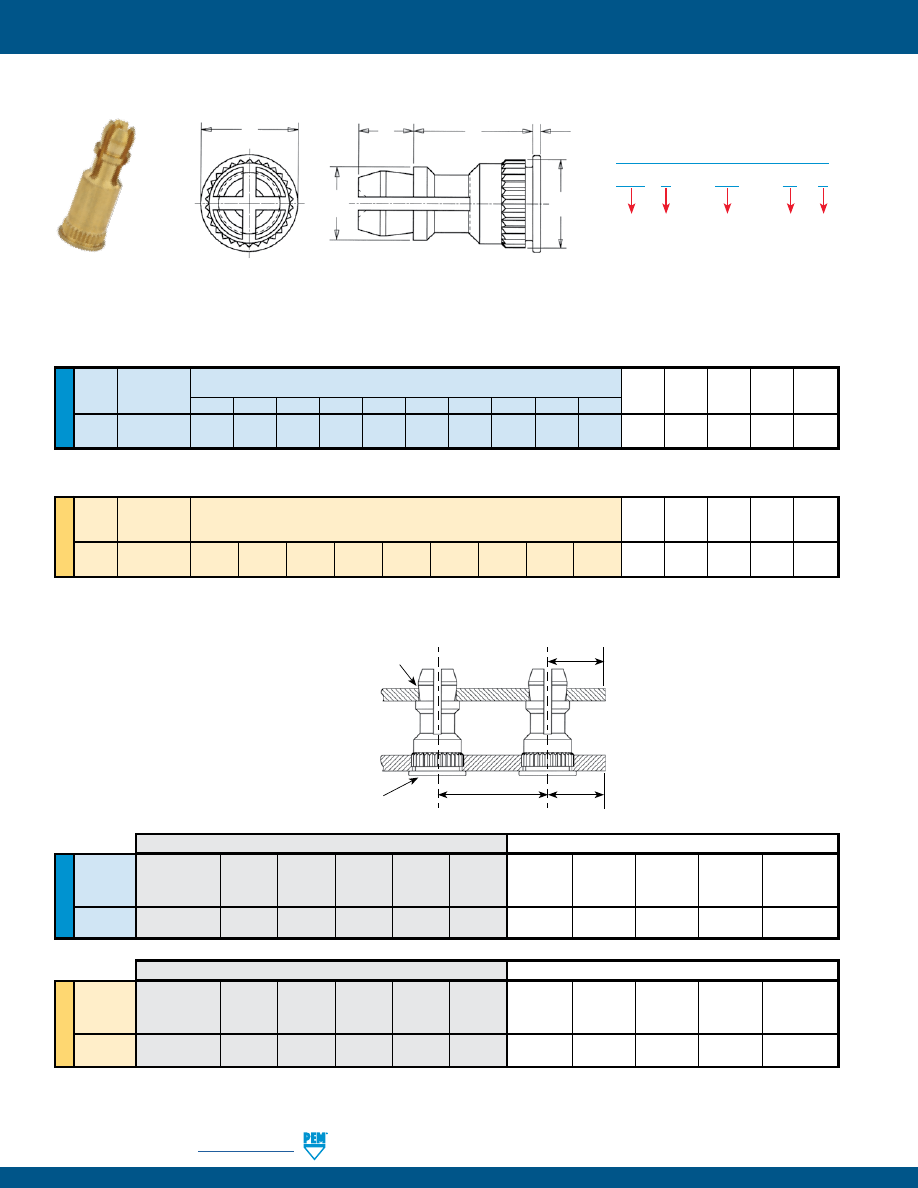

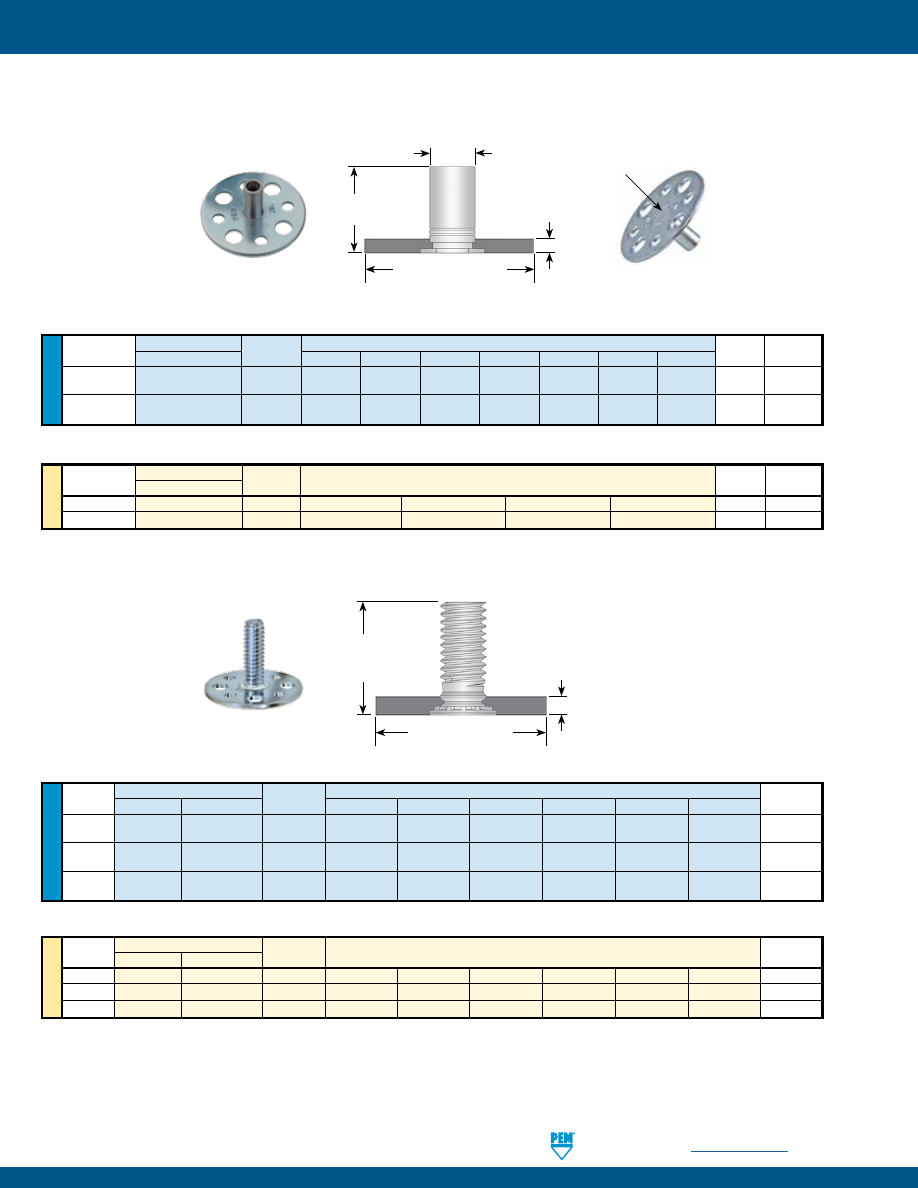

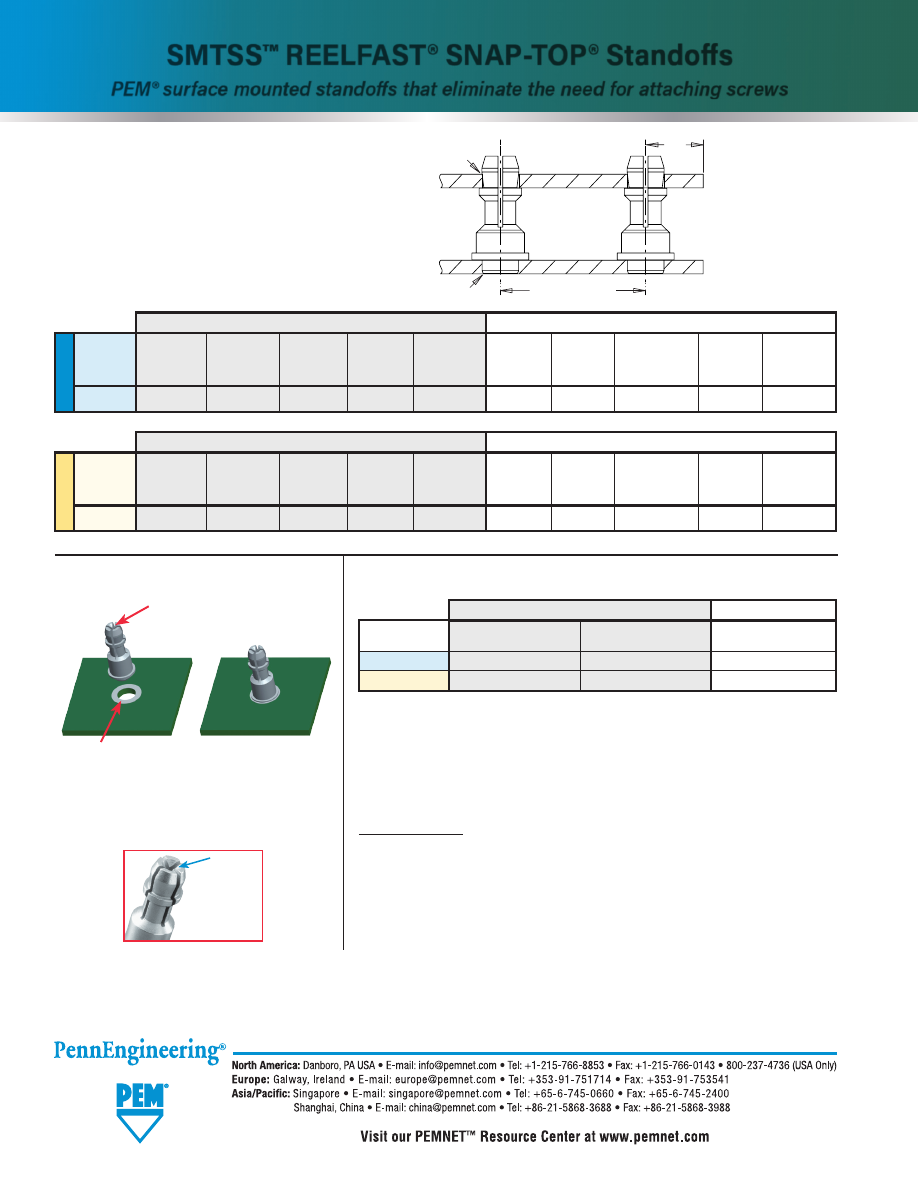

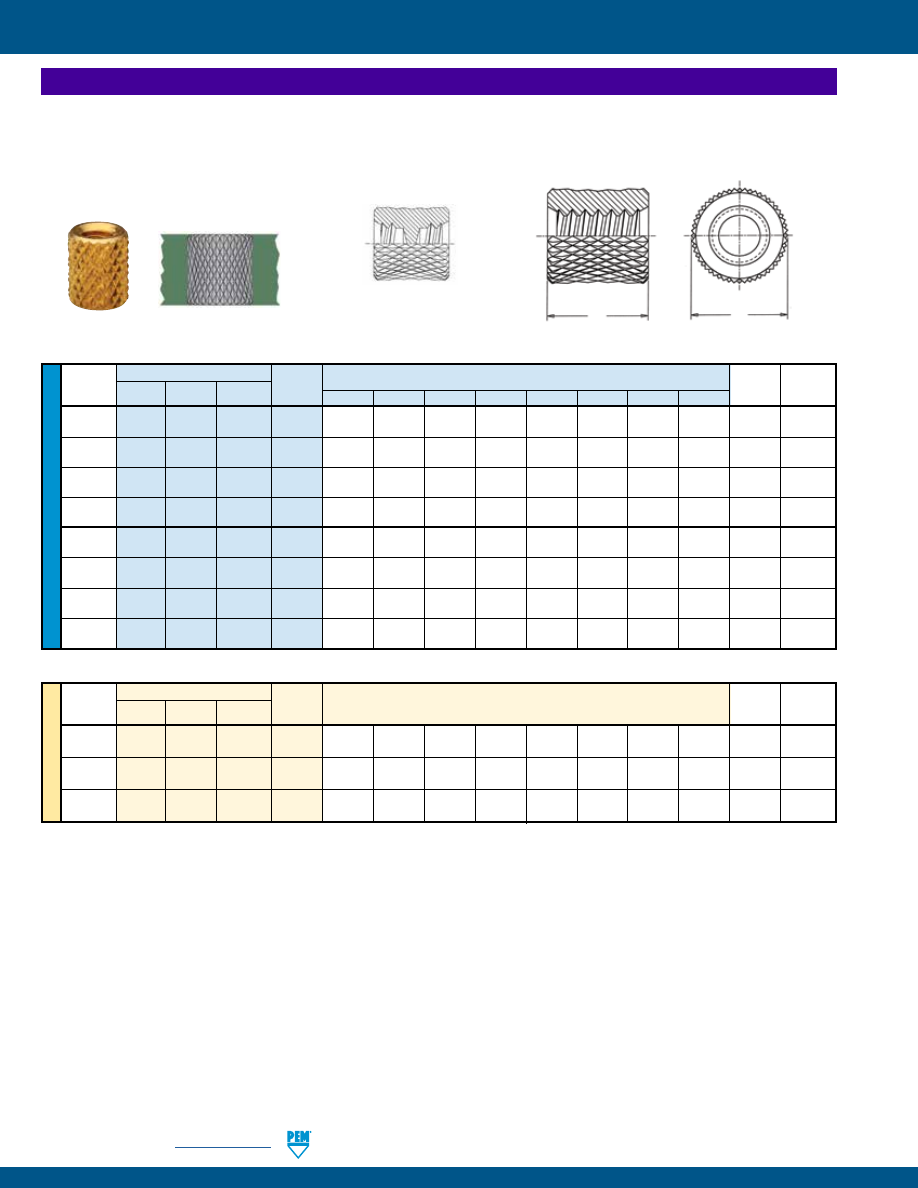

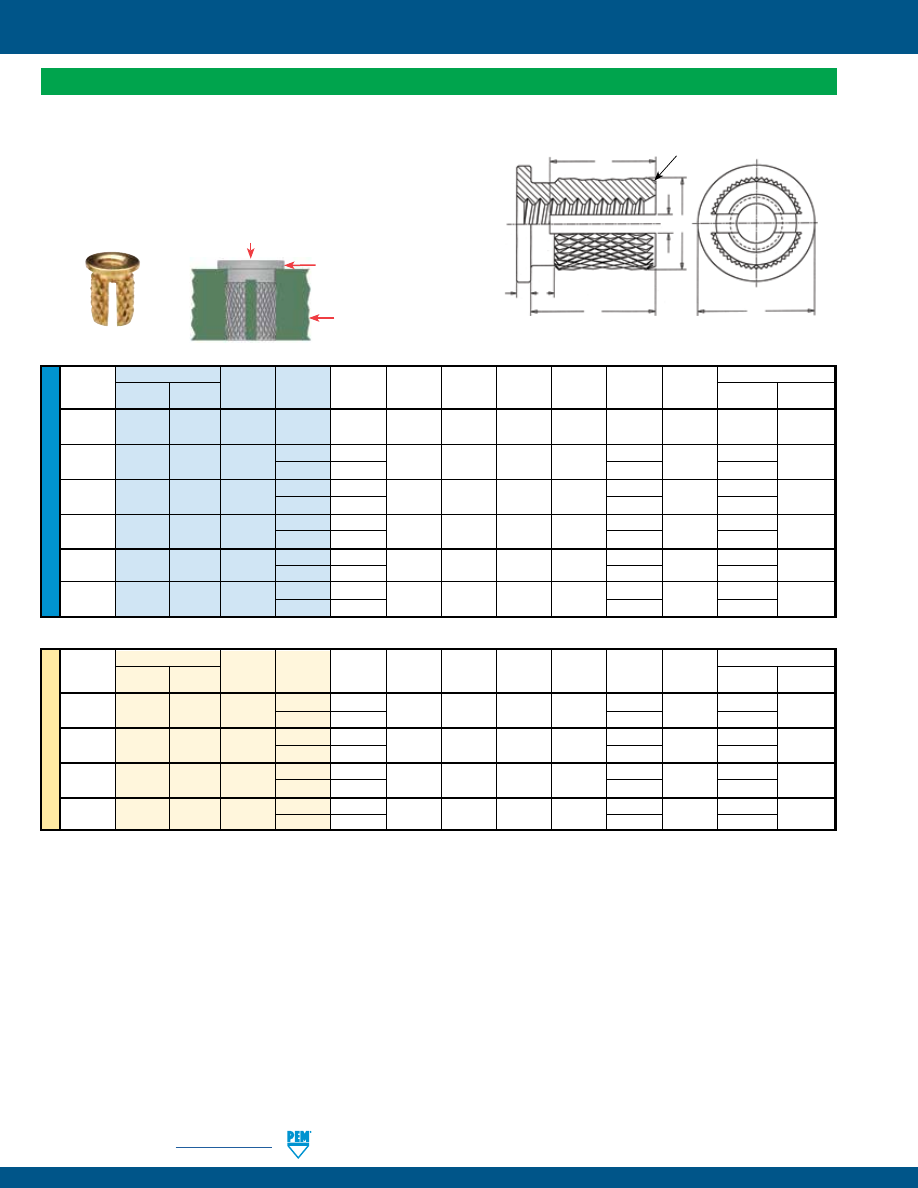

CH

™

CONCEALED-HEAD

SELF-CLINCHING

STUDS AND STANDOFFS

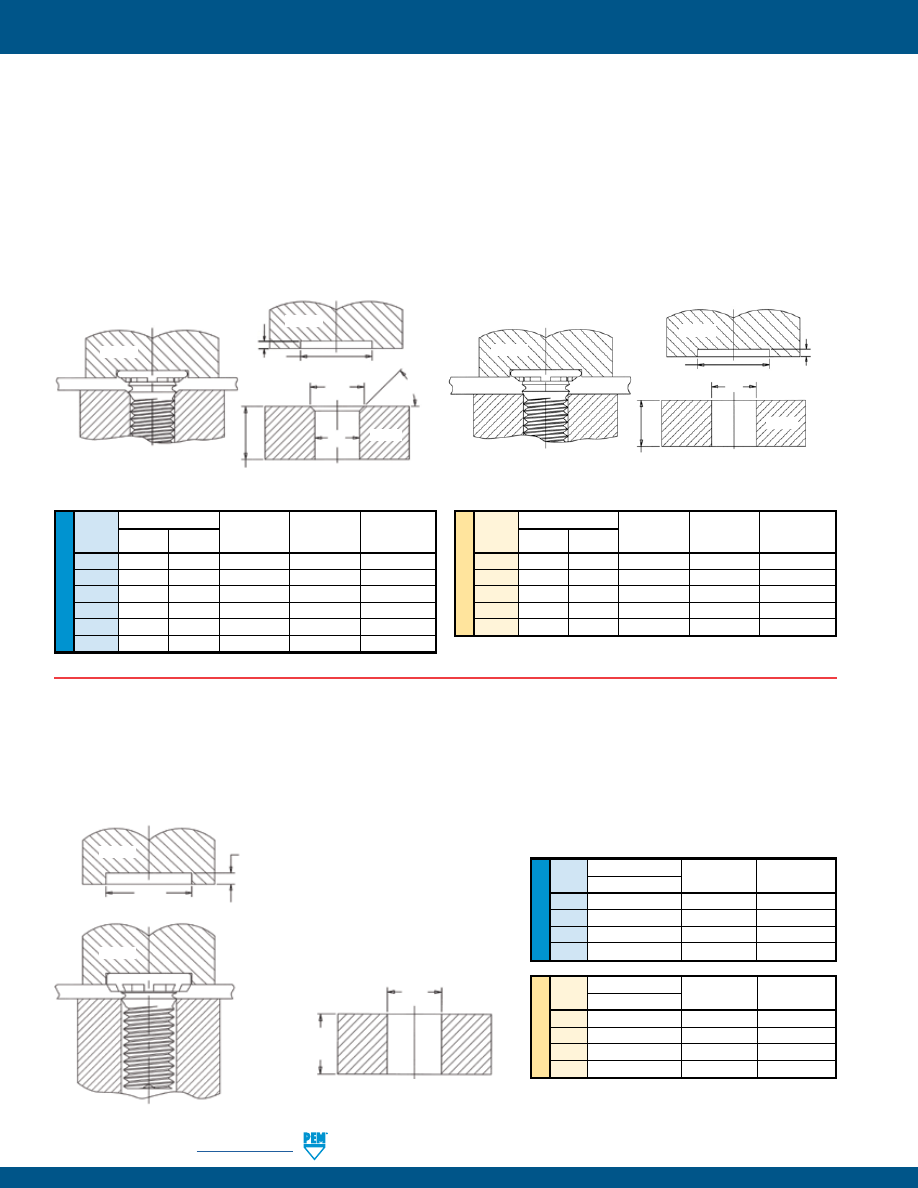

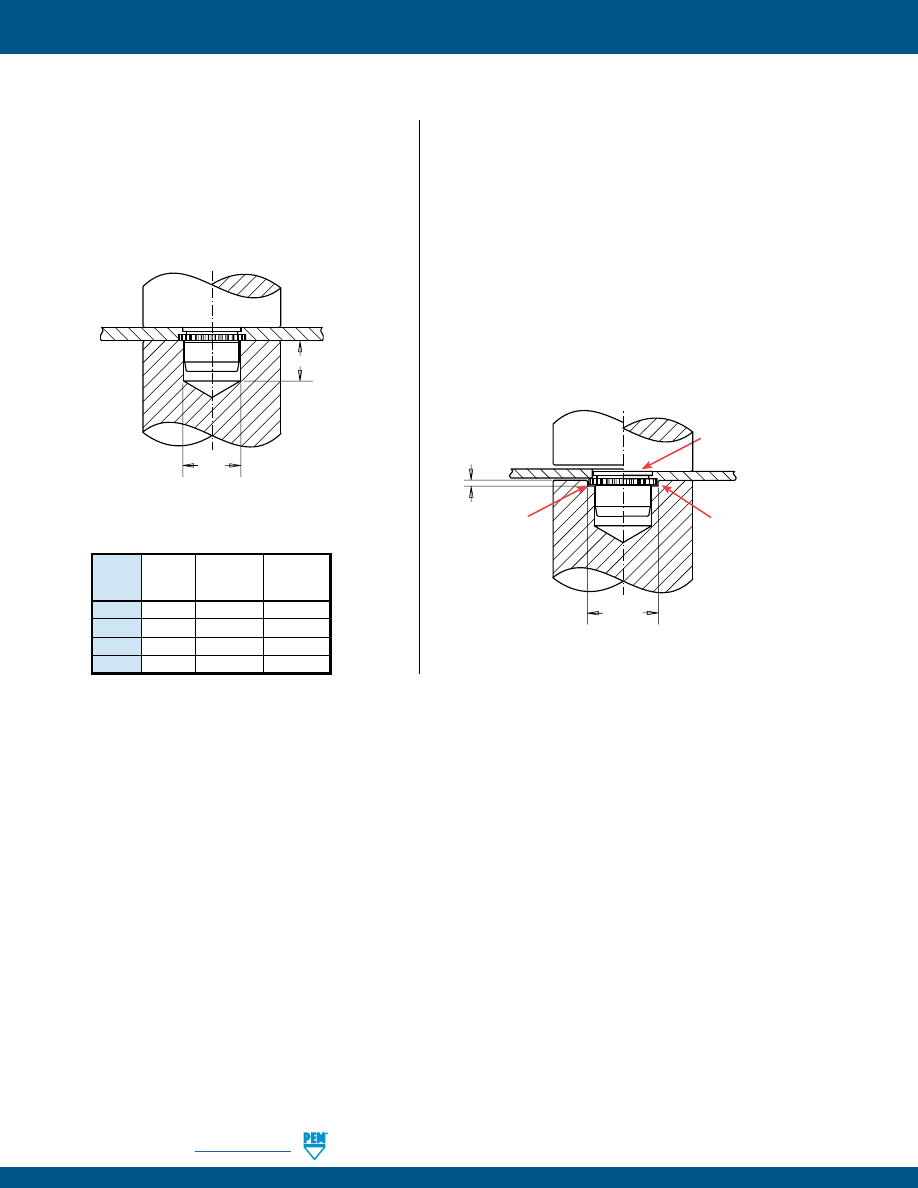

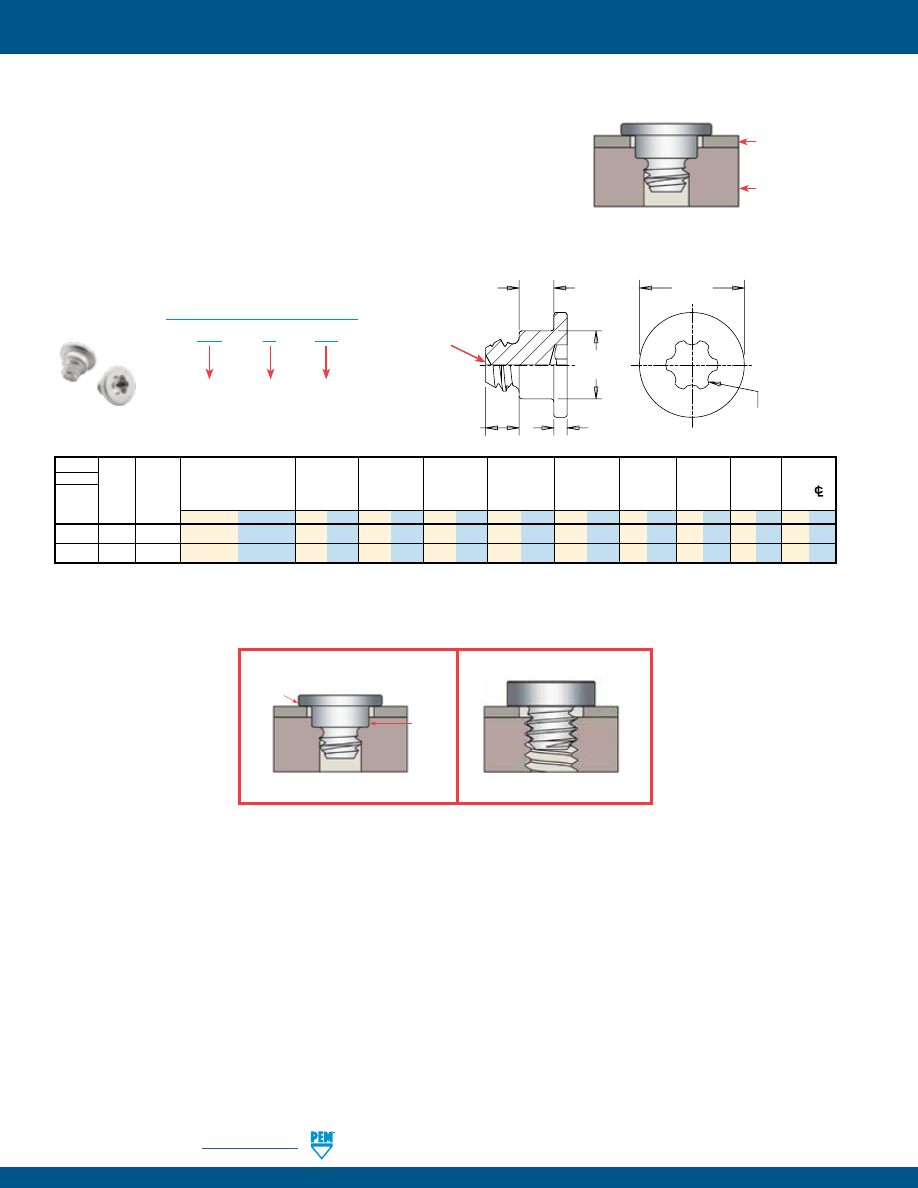

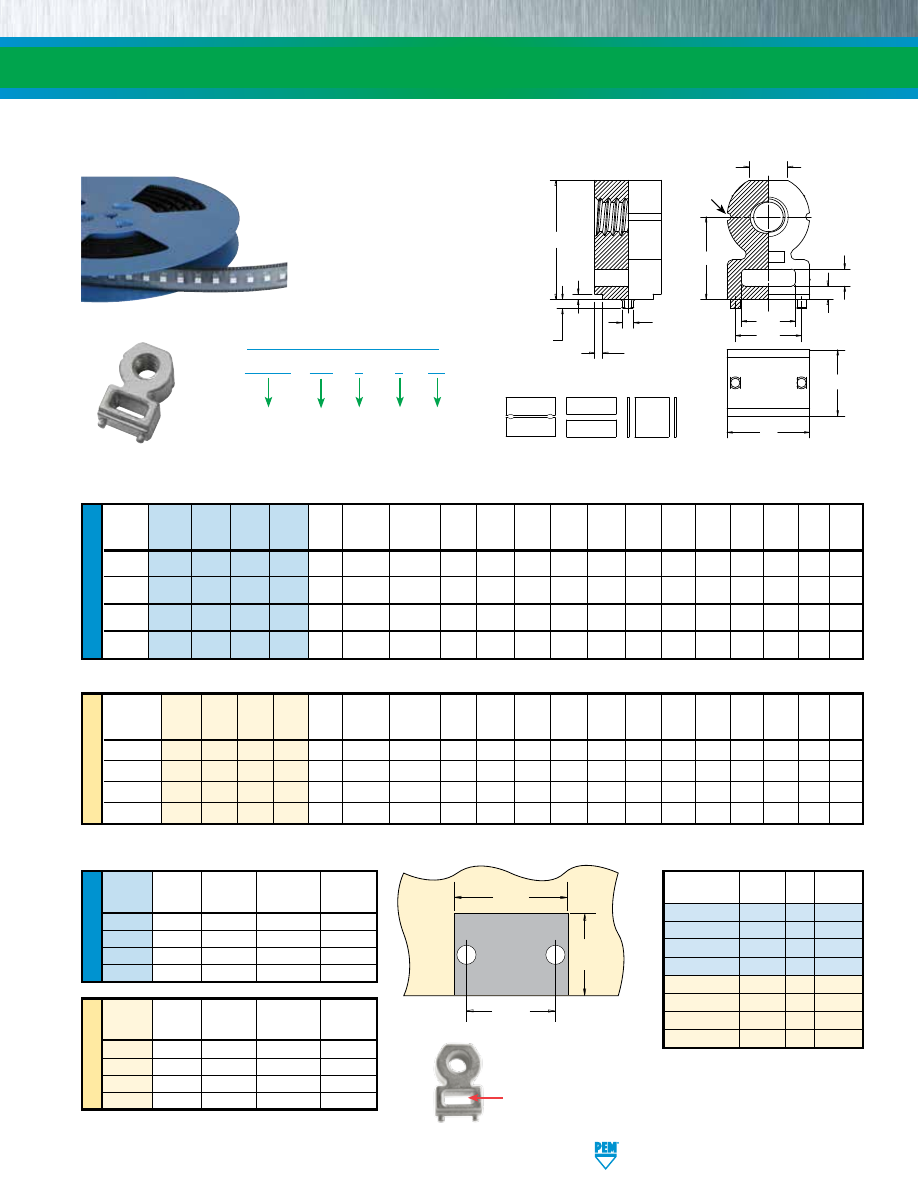

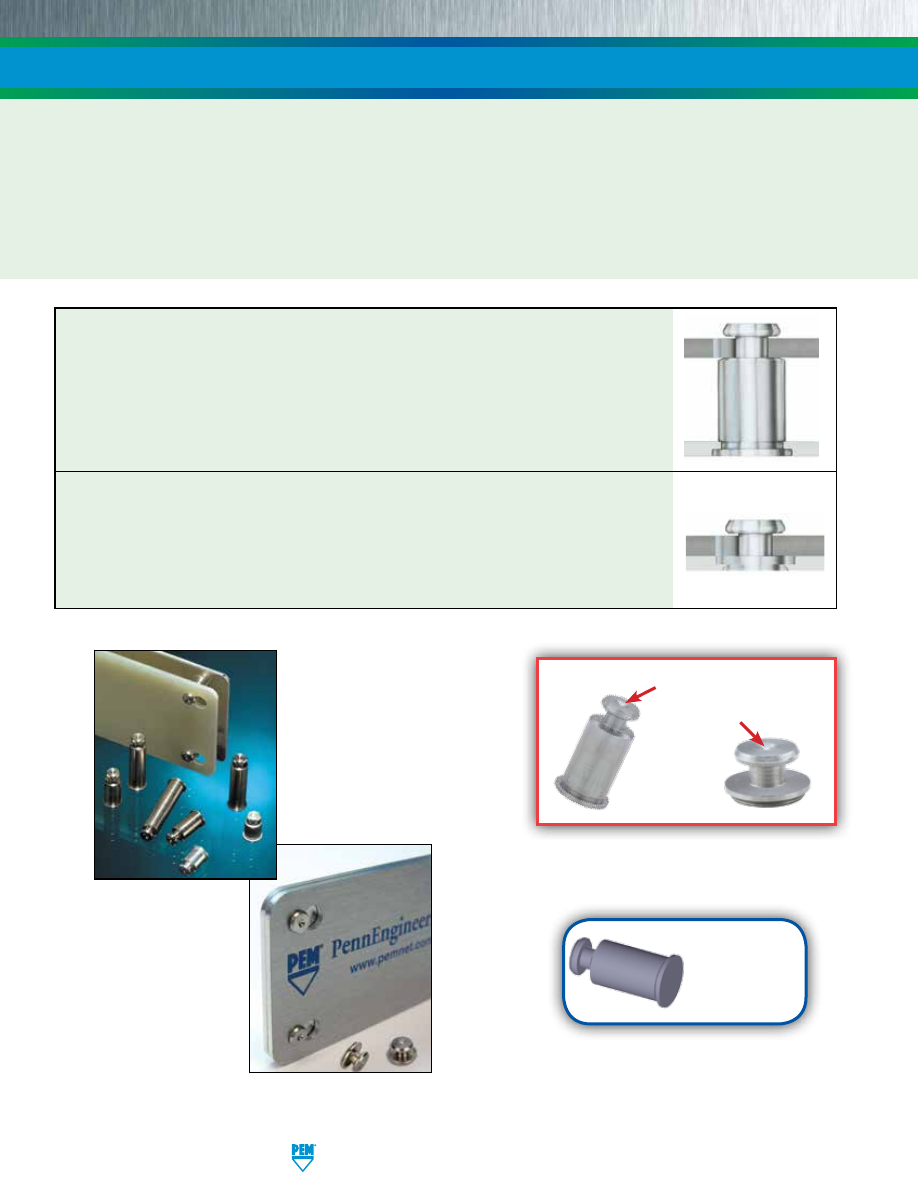

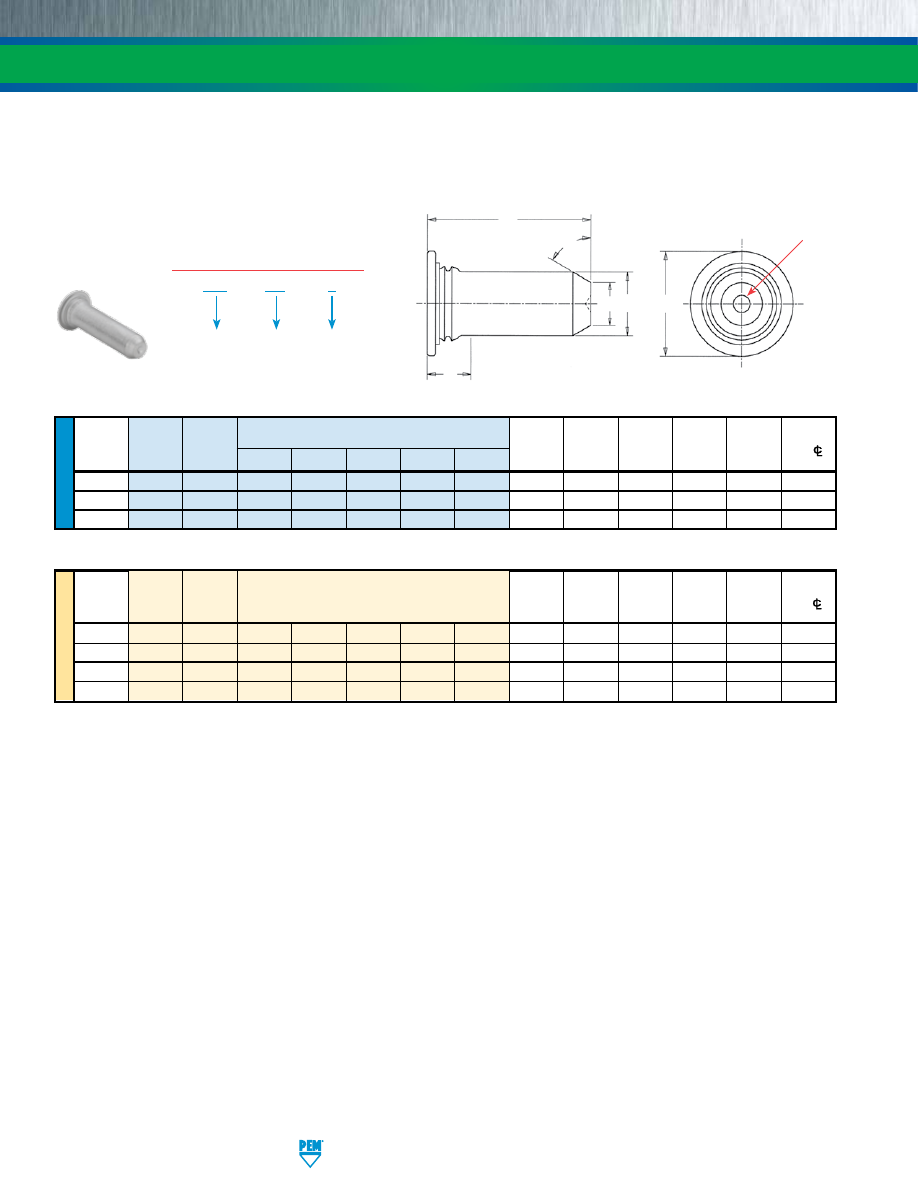

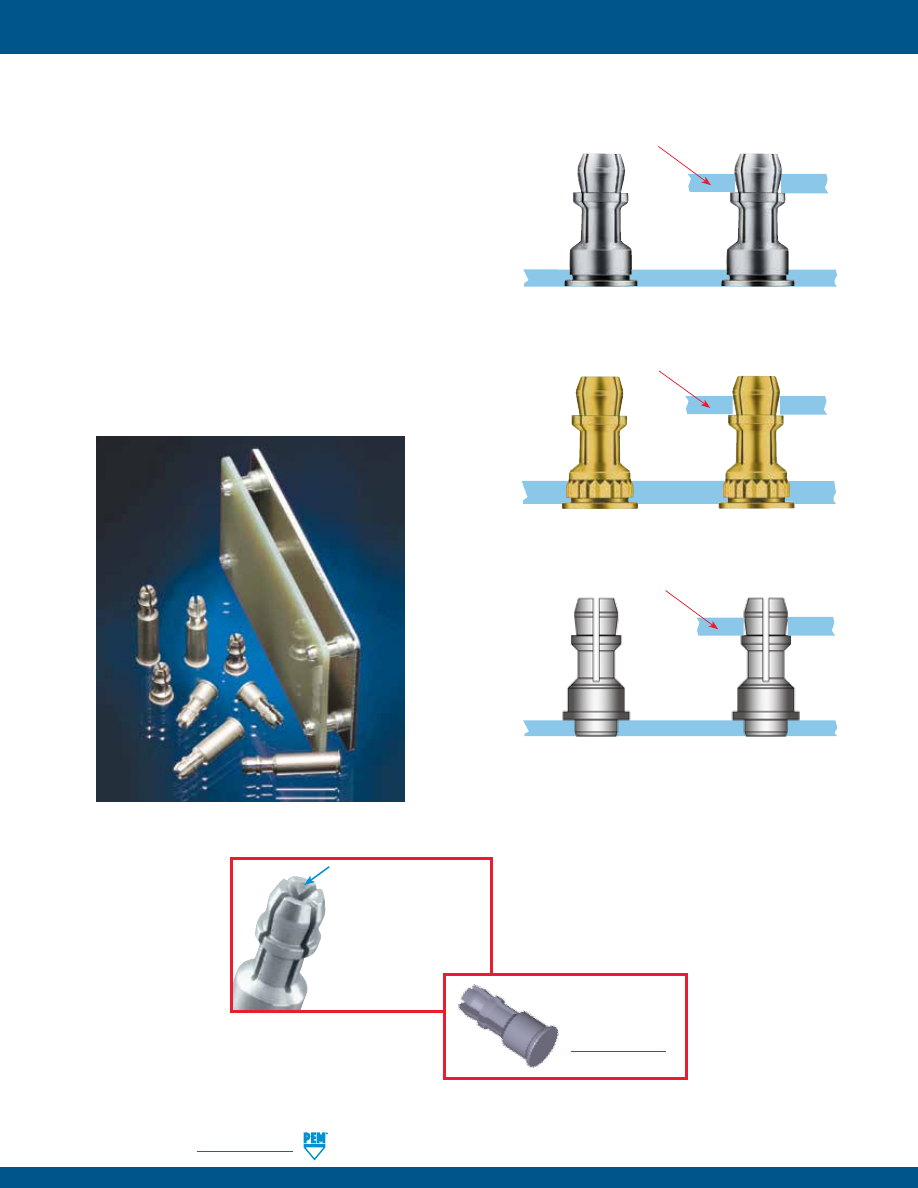

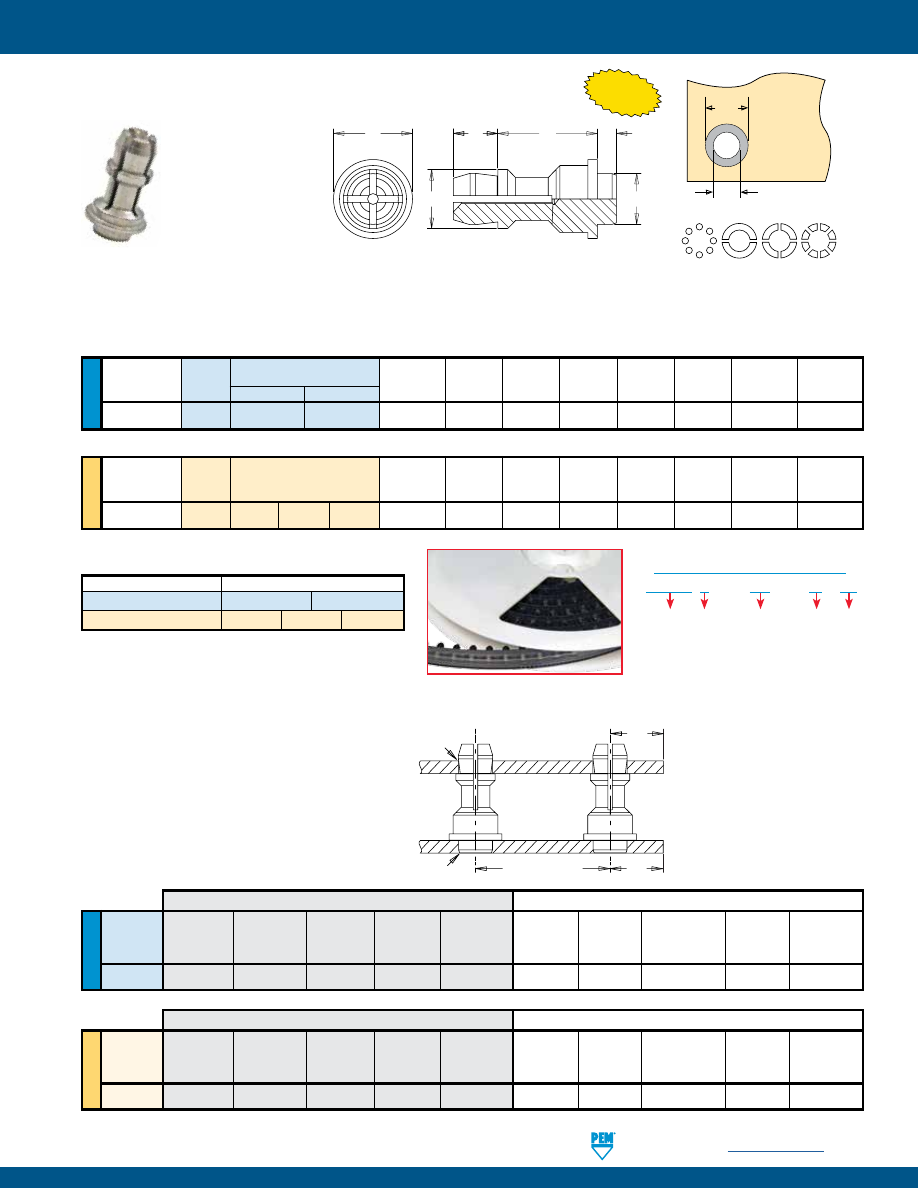

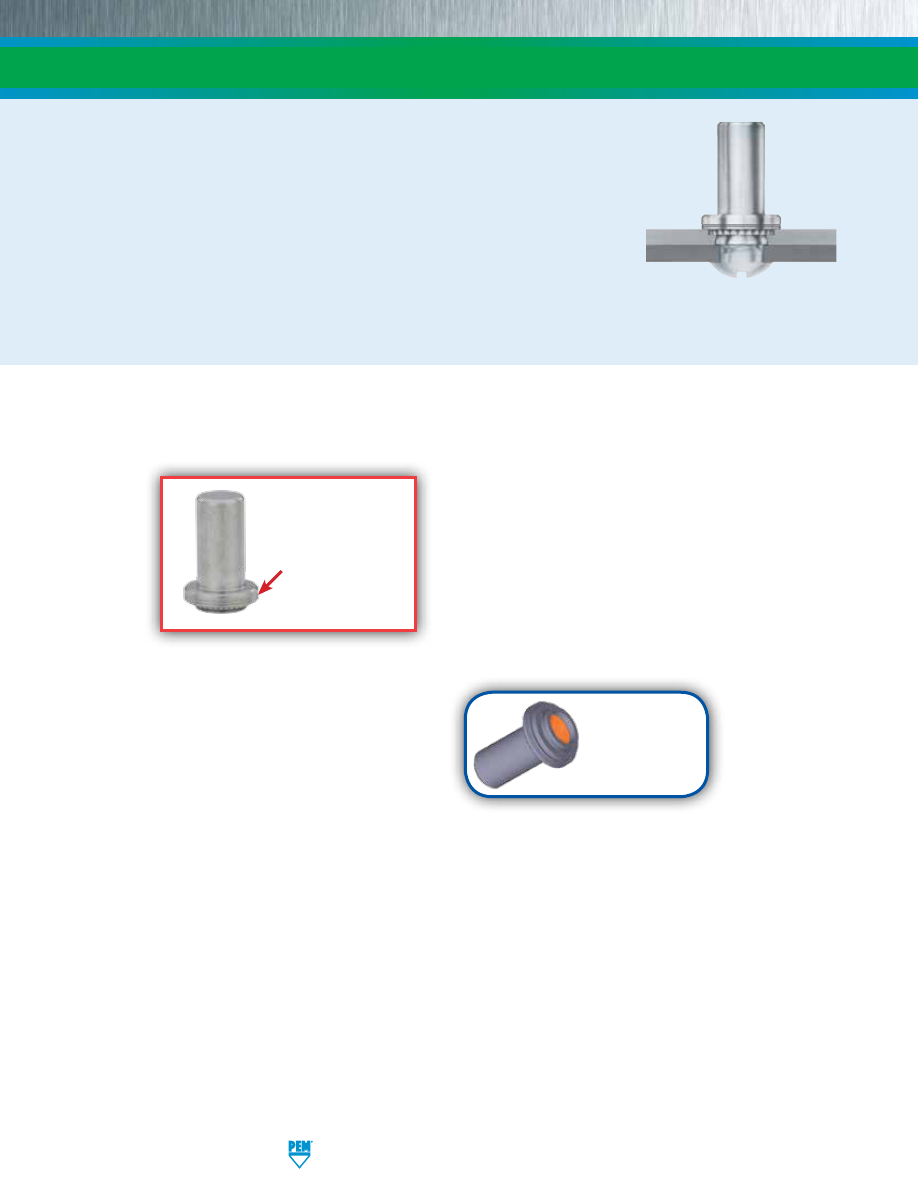

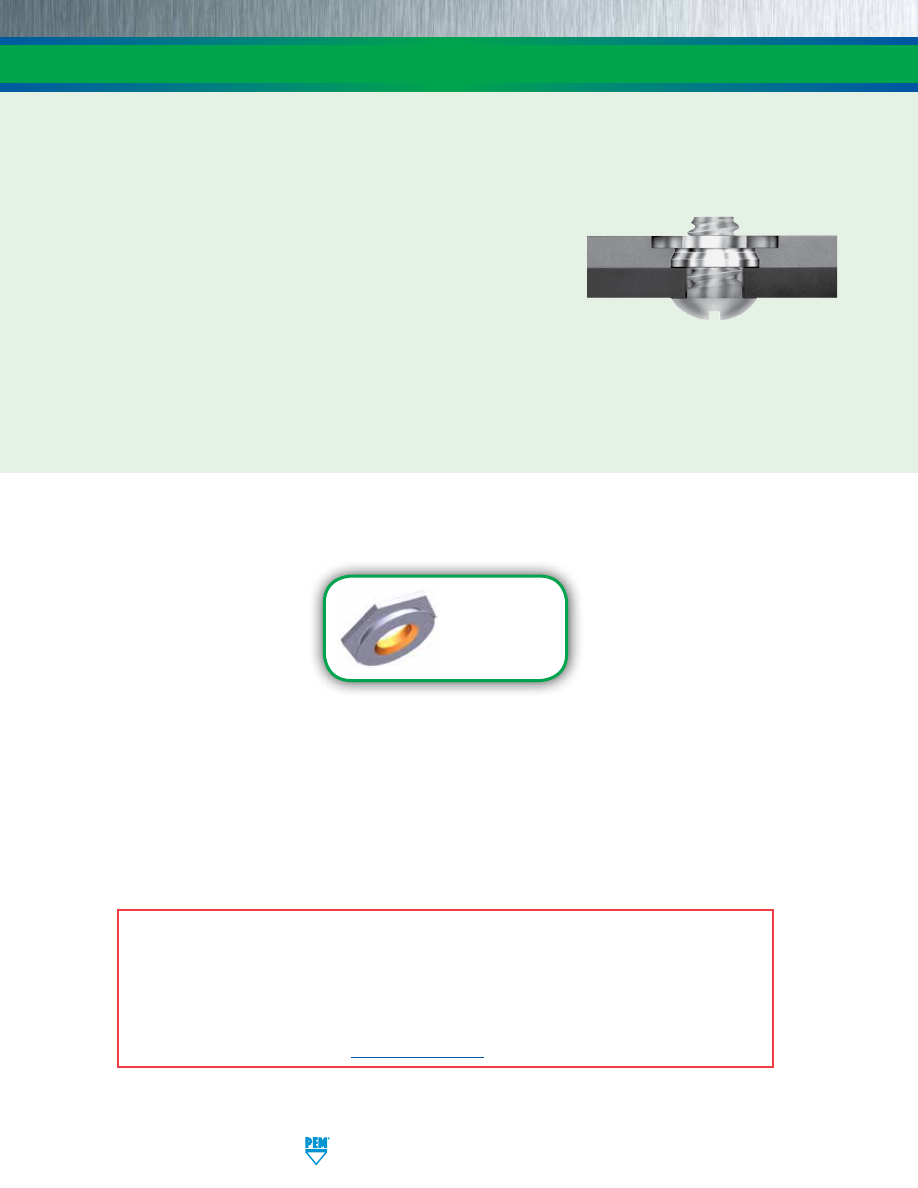

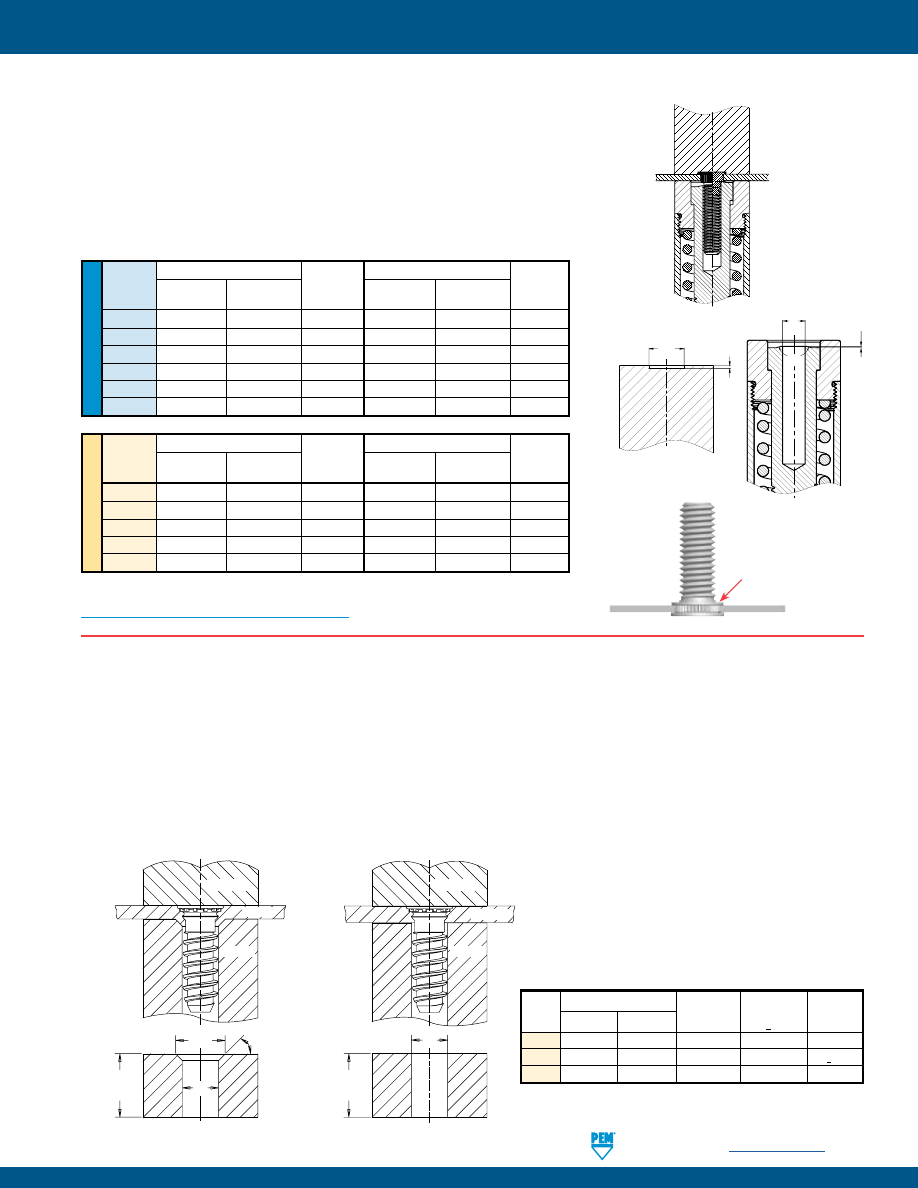

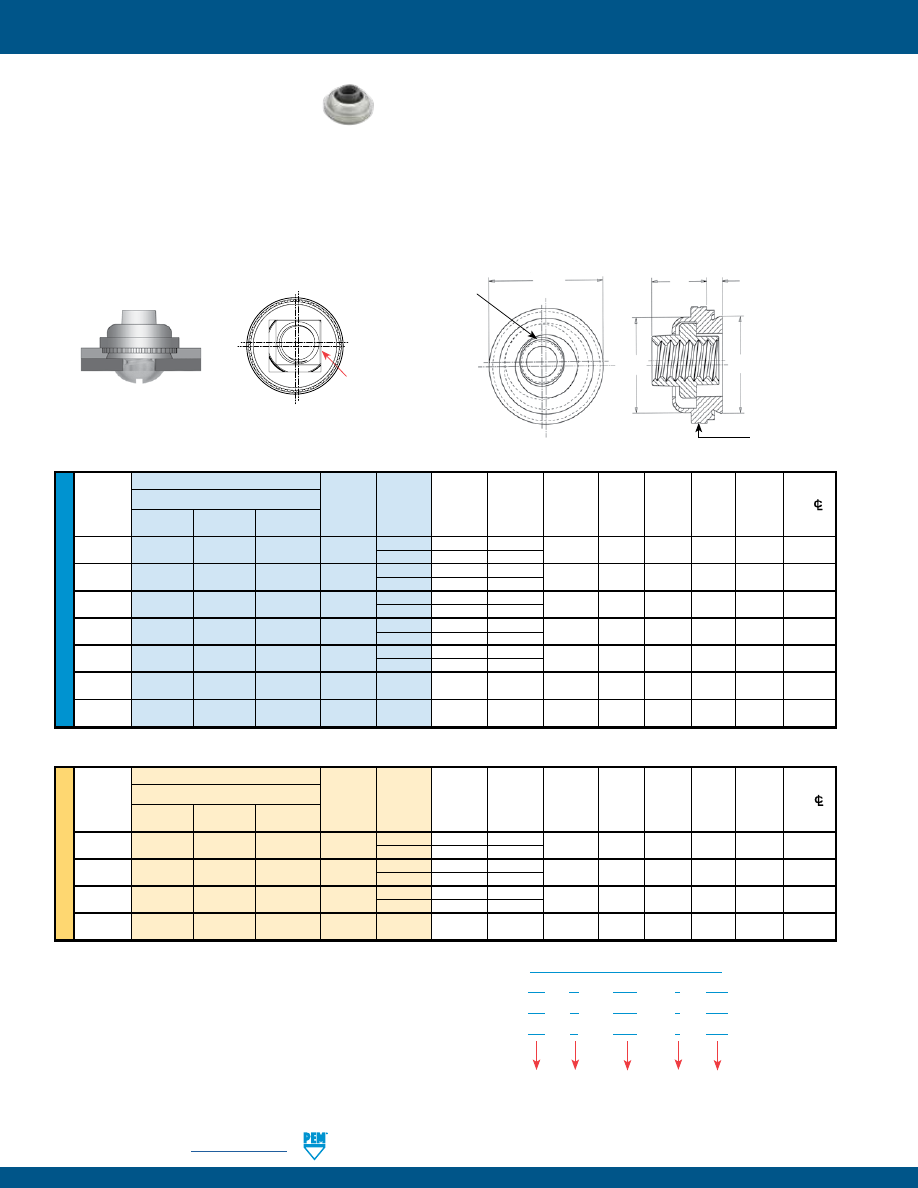

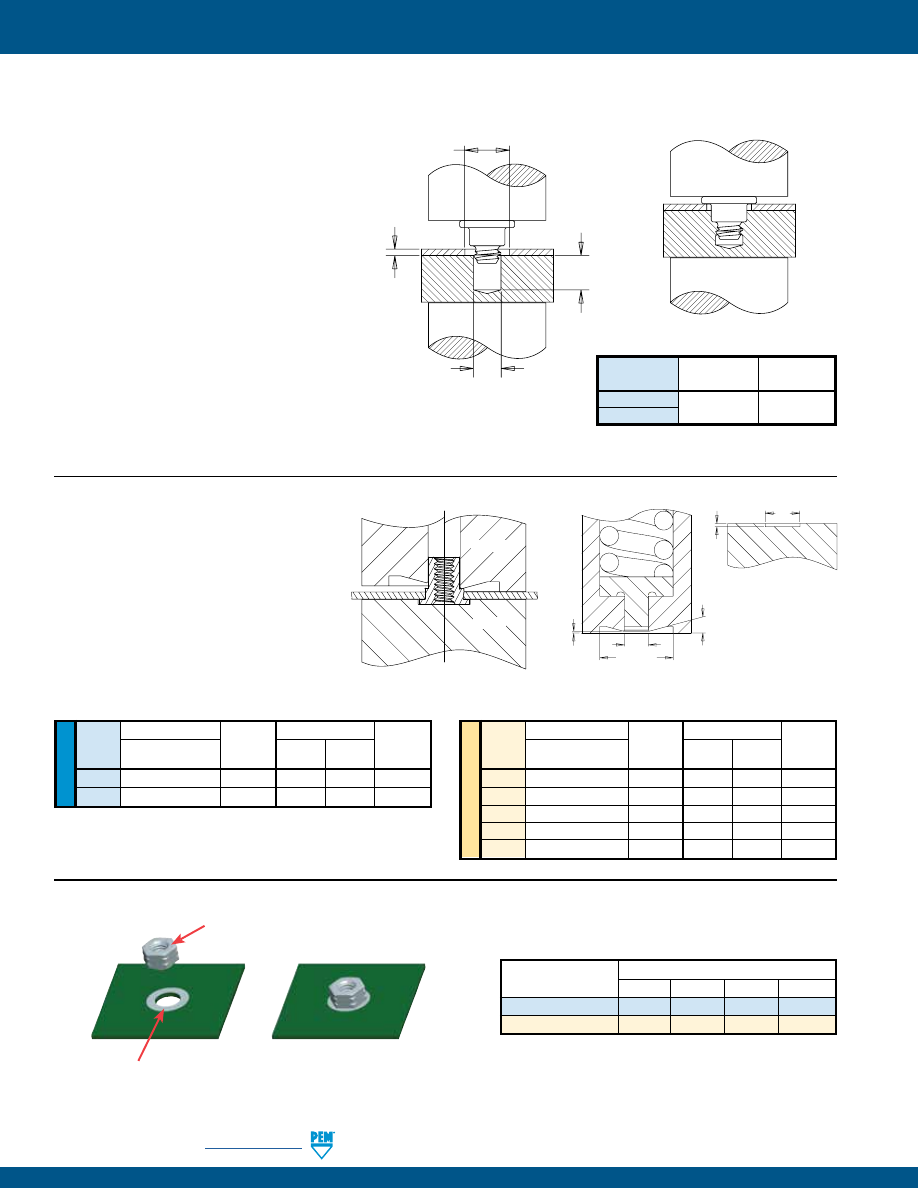

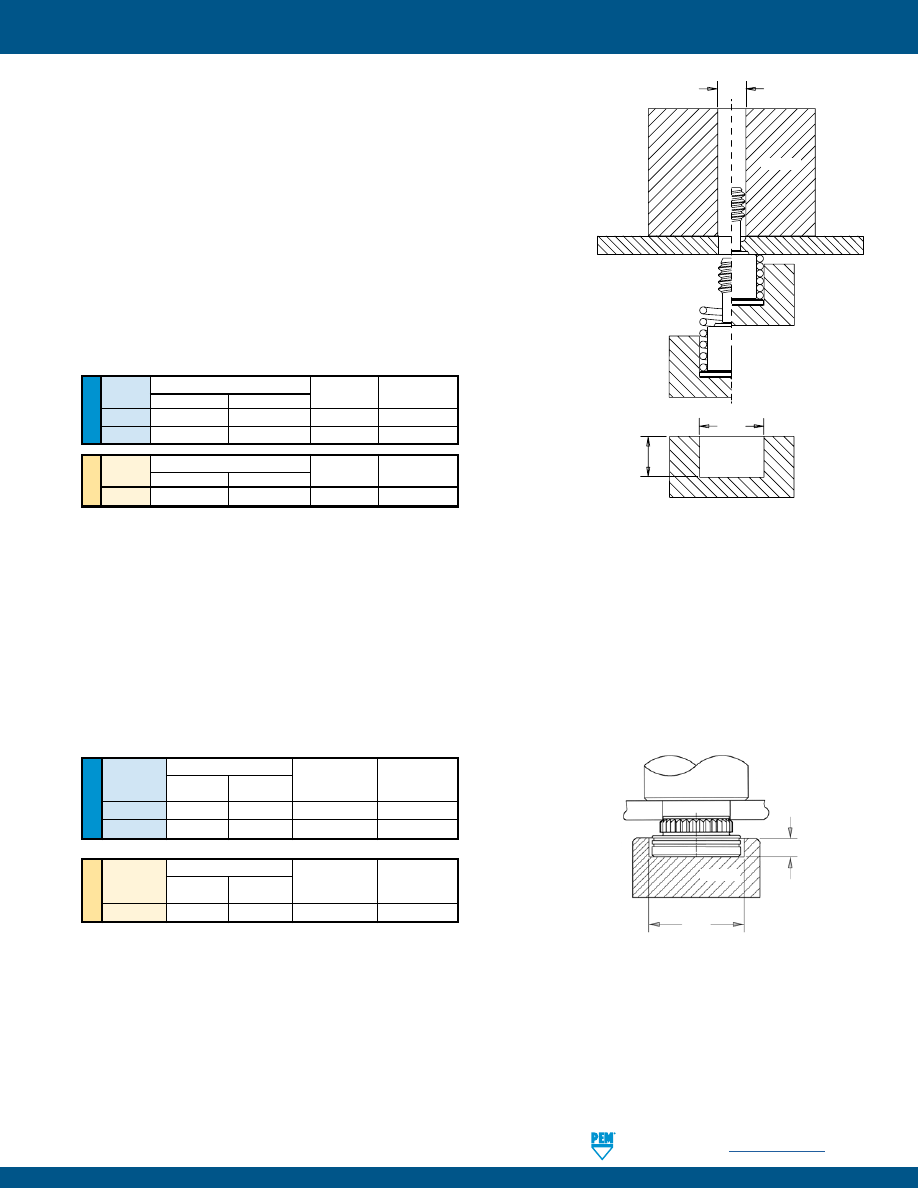

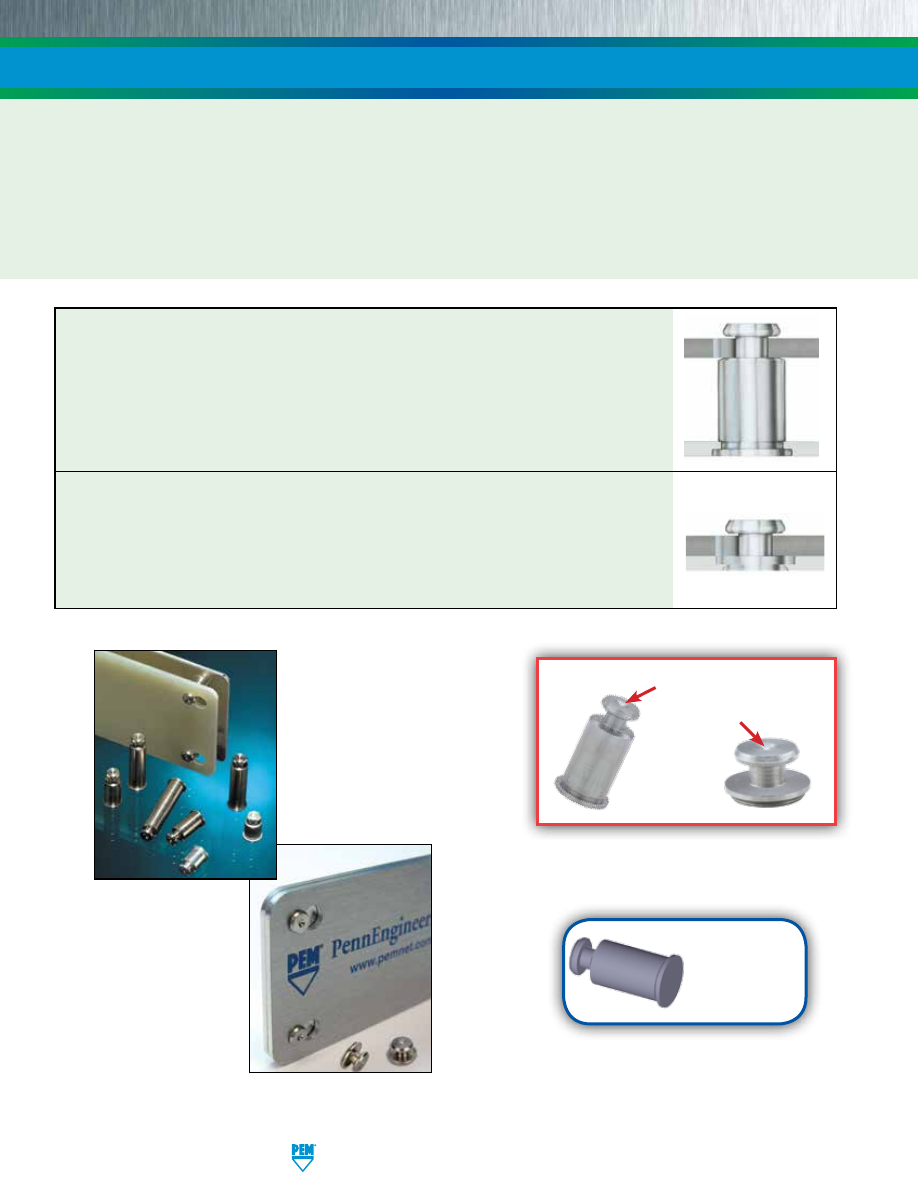

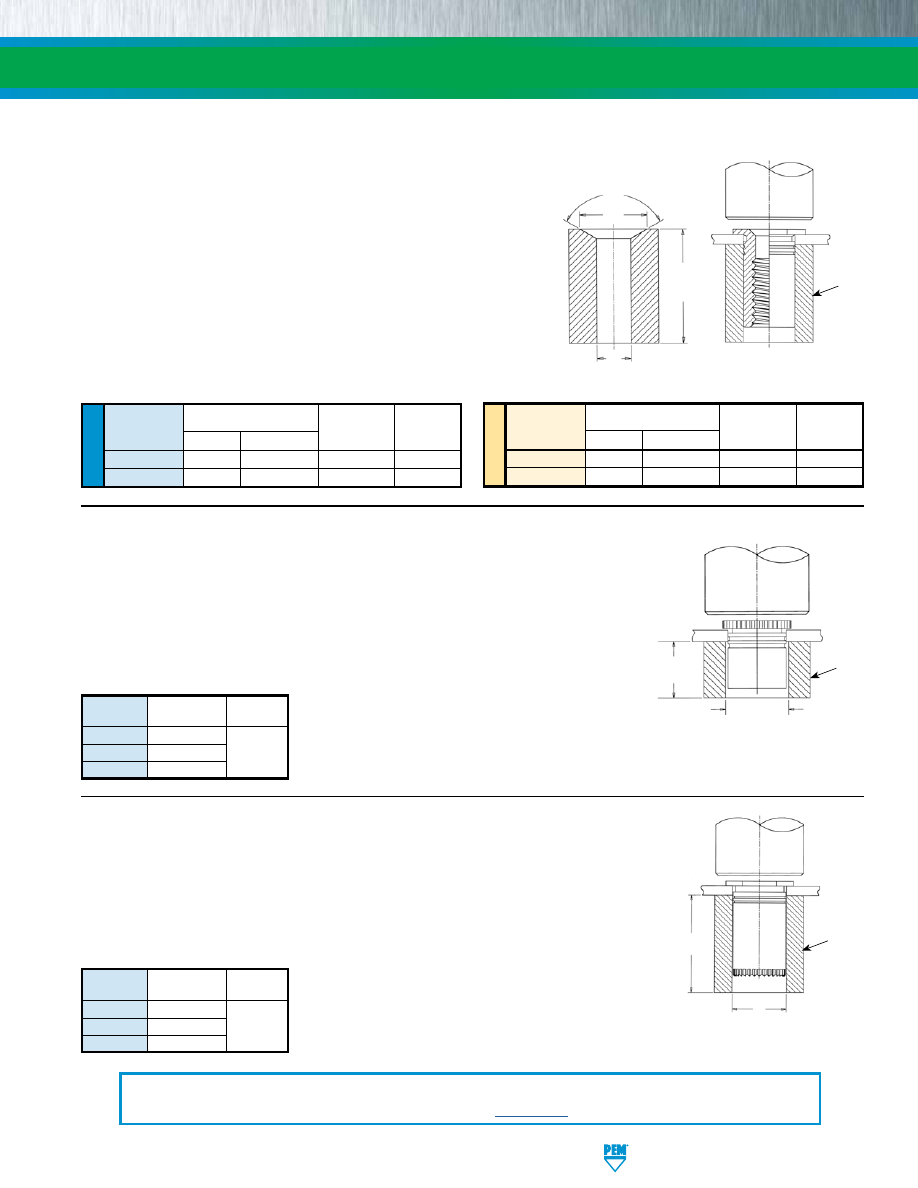

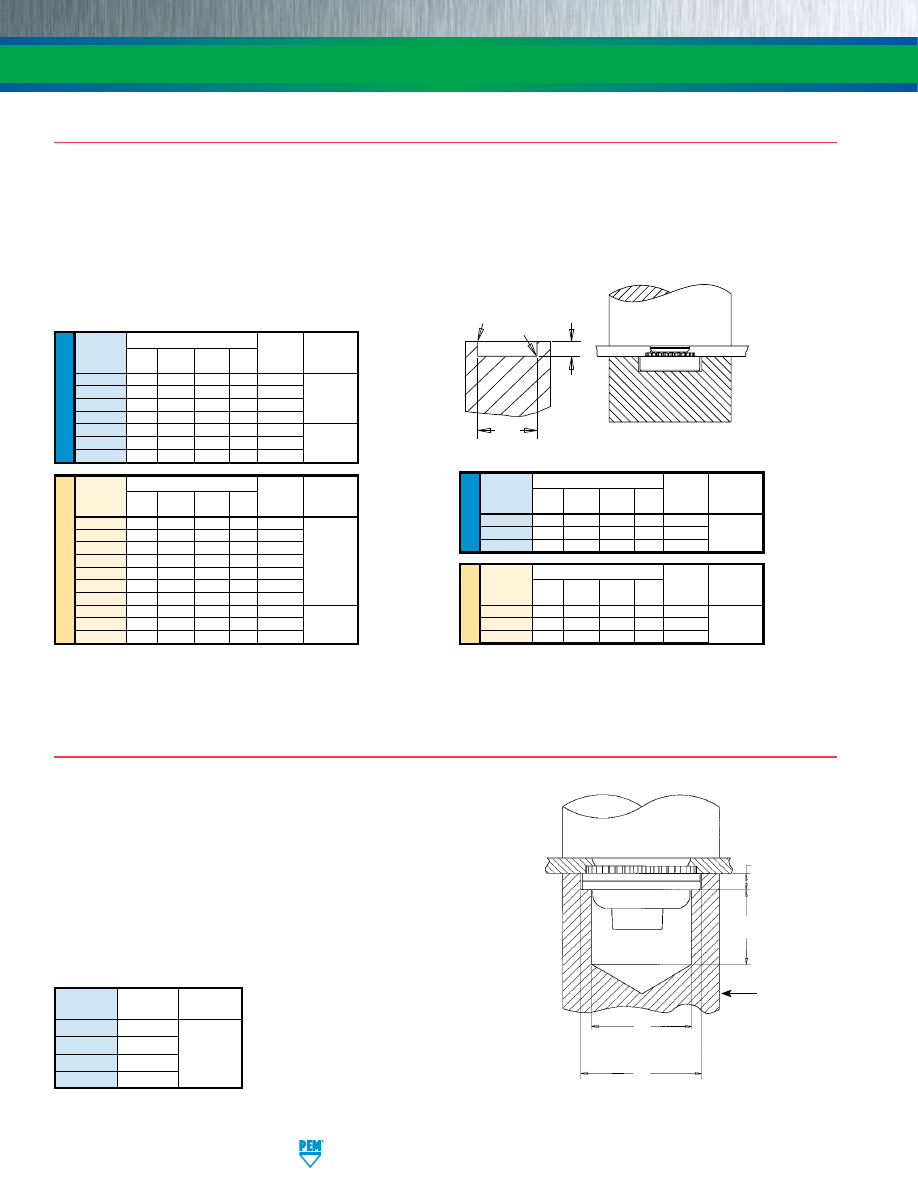

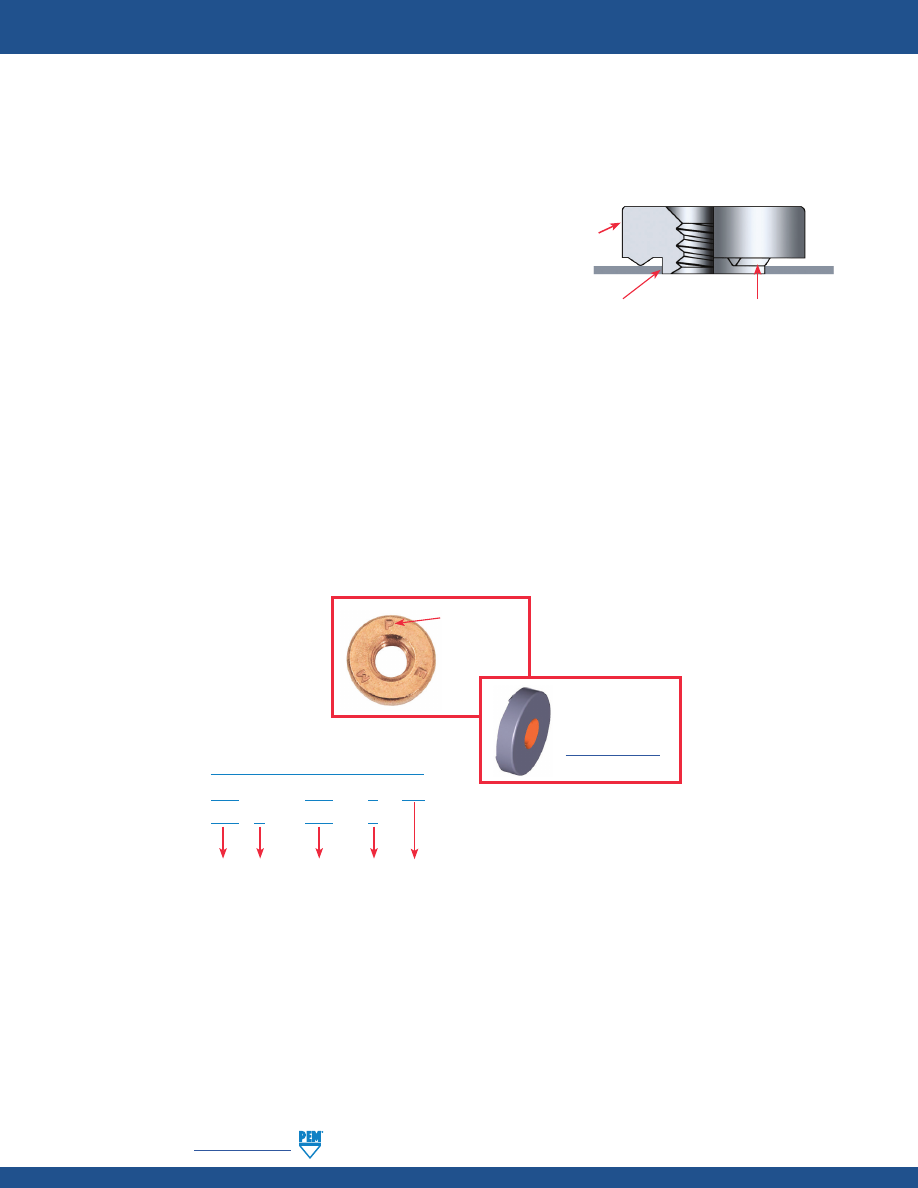

PEM® concealed-head self-clinching

studs and standoffs install permanently

and promote smooth designs.

Bulletin CH-1217

pem-html.html

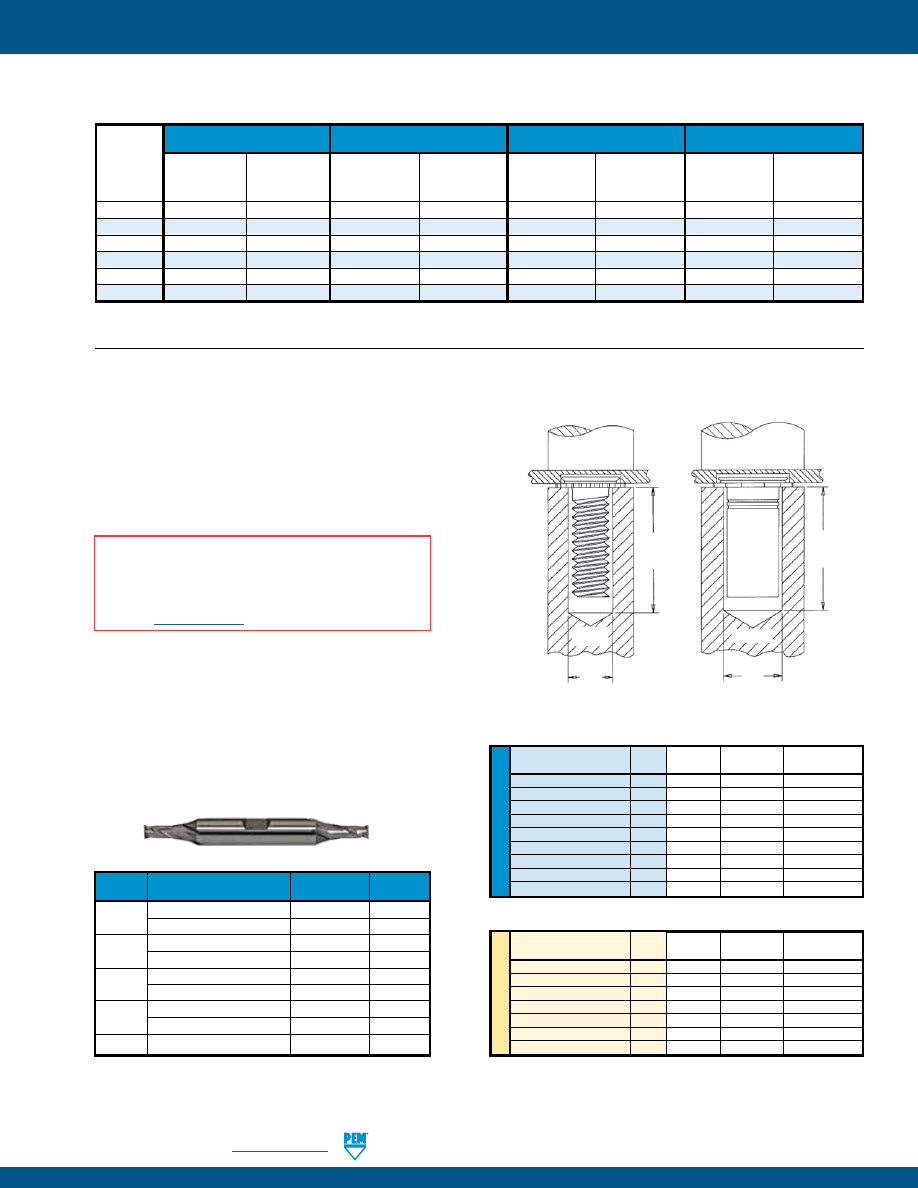

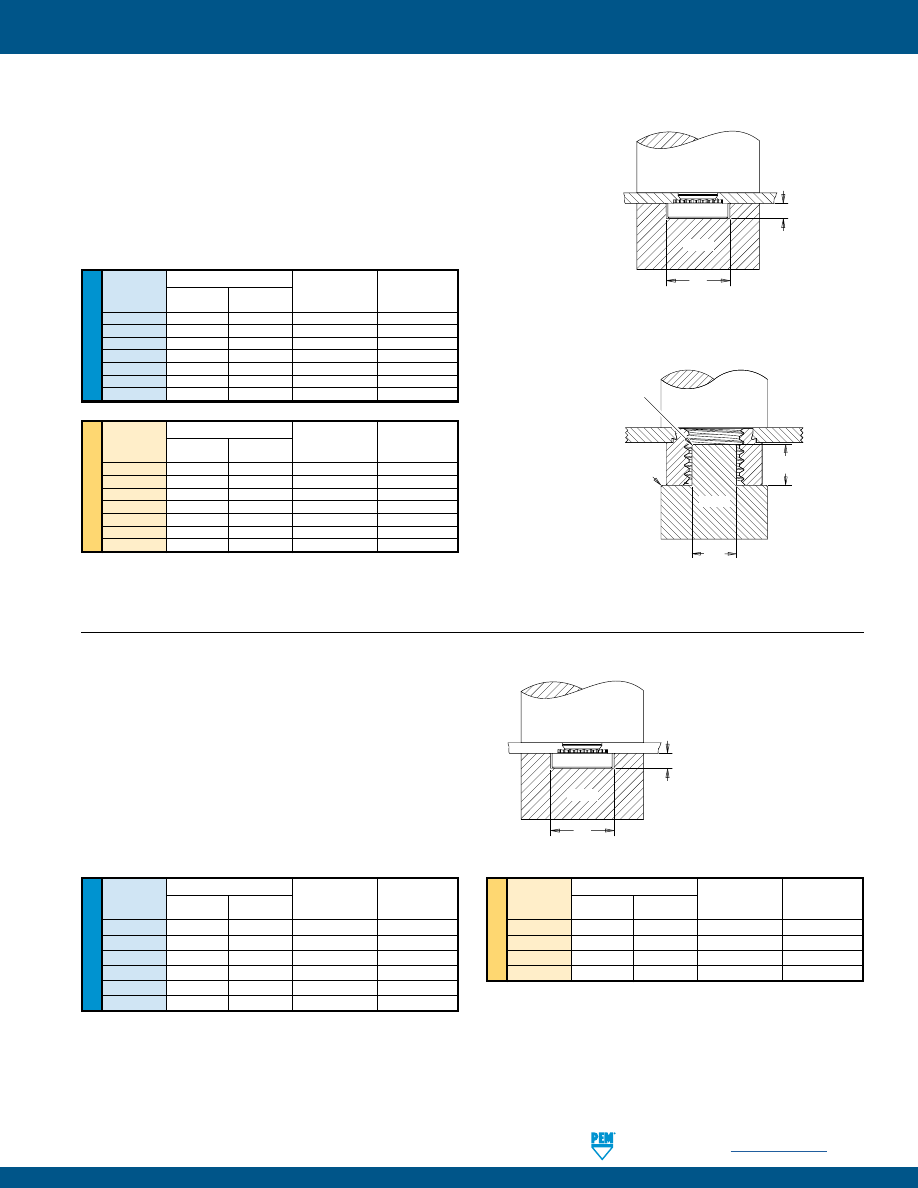

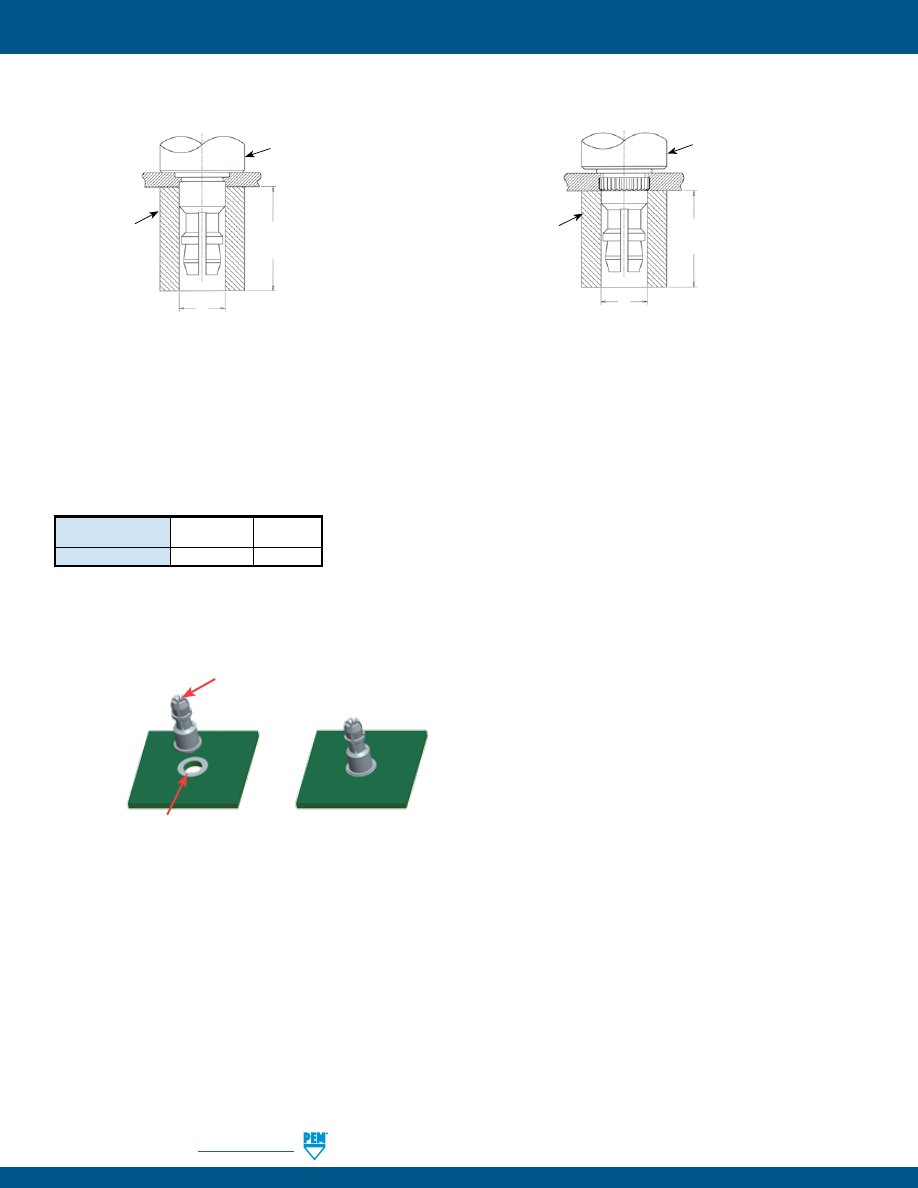

Concealed-head self-clinching studs and standoffs install permanently and

promote smooth designs:

•

Install permanently in steel or aluminum sheets as thin as .062” / 1.6 mm to provide strong

and reusable threads for mating hardware in a wide range of assembly applications.

•

Allow the side of the sheet opposite installation to remain smooth and unmarred.

•

One side installation additionally serves to satisfy strict ingress protection (IP)

requirements where the sheet must remain completely sealed from air, liquid, dust,

gases or other potentially infiltrating elements.

•

Only require a blind milled hole to the recommended size and minimum depth.

•

Install using a PEMSERTER® press or other standard press.

•

CFHC™ studs can be ordered to NAS63540/4 specifications.

(1)

Concealed-head Stud

Concealed-head Standoff

Back side of sheet

remains smooth

(1) To meet national aerospace standards and to obtain testing documentation, Type CFHC studs must be

ordered using appropriate NAS63540/4 part number. Check our web site for a complete Military Specification

and National Aerospace Standards Reference Guide (Bulletin NASM).

CONCEALED-HEAD SELF-CLINCHING STUDS AND STANDOFFS

CH-2

PennEngineering •

www.pemnet.com

pem-html.html

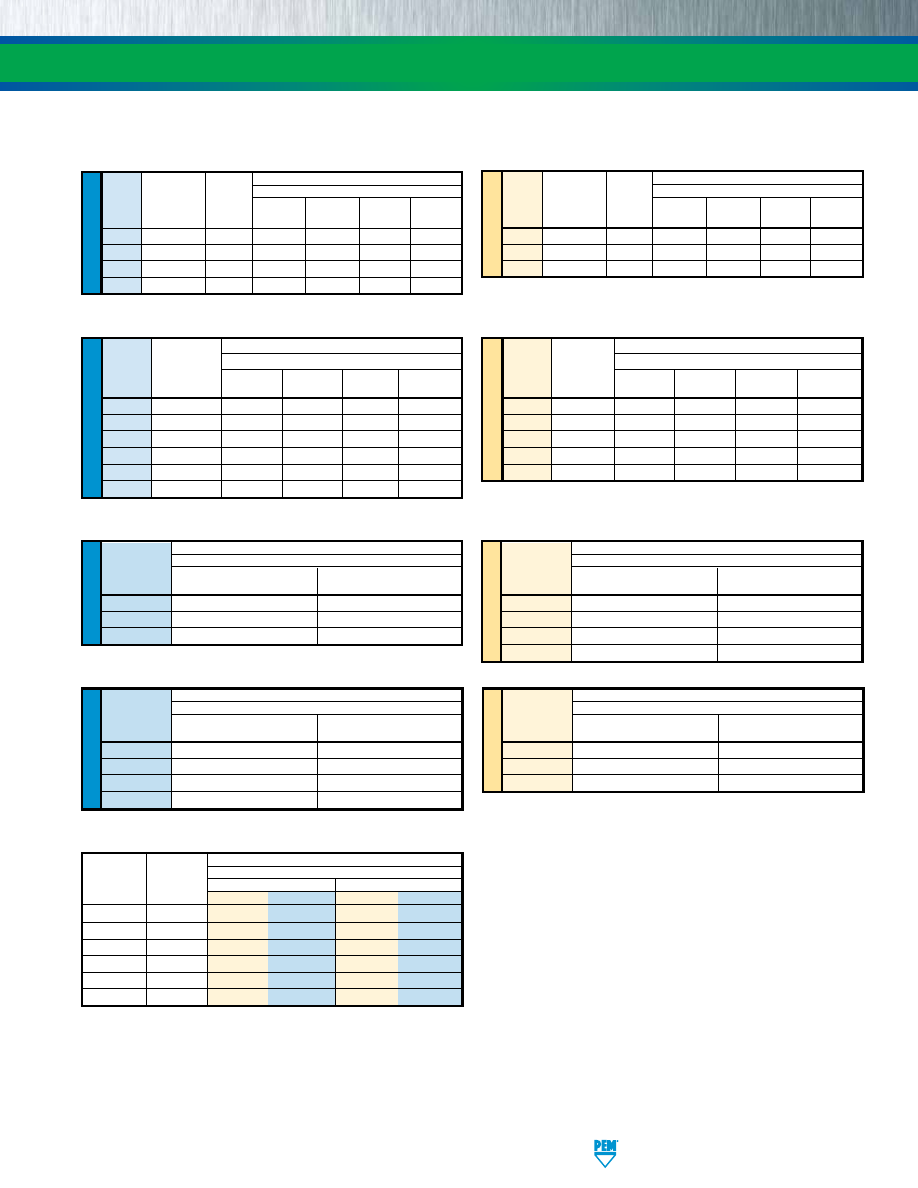

ME

TR

IC

U

NIF

IE

D

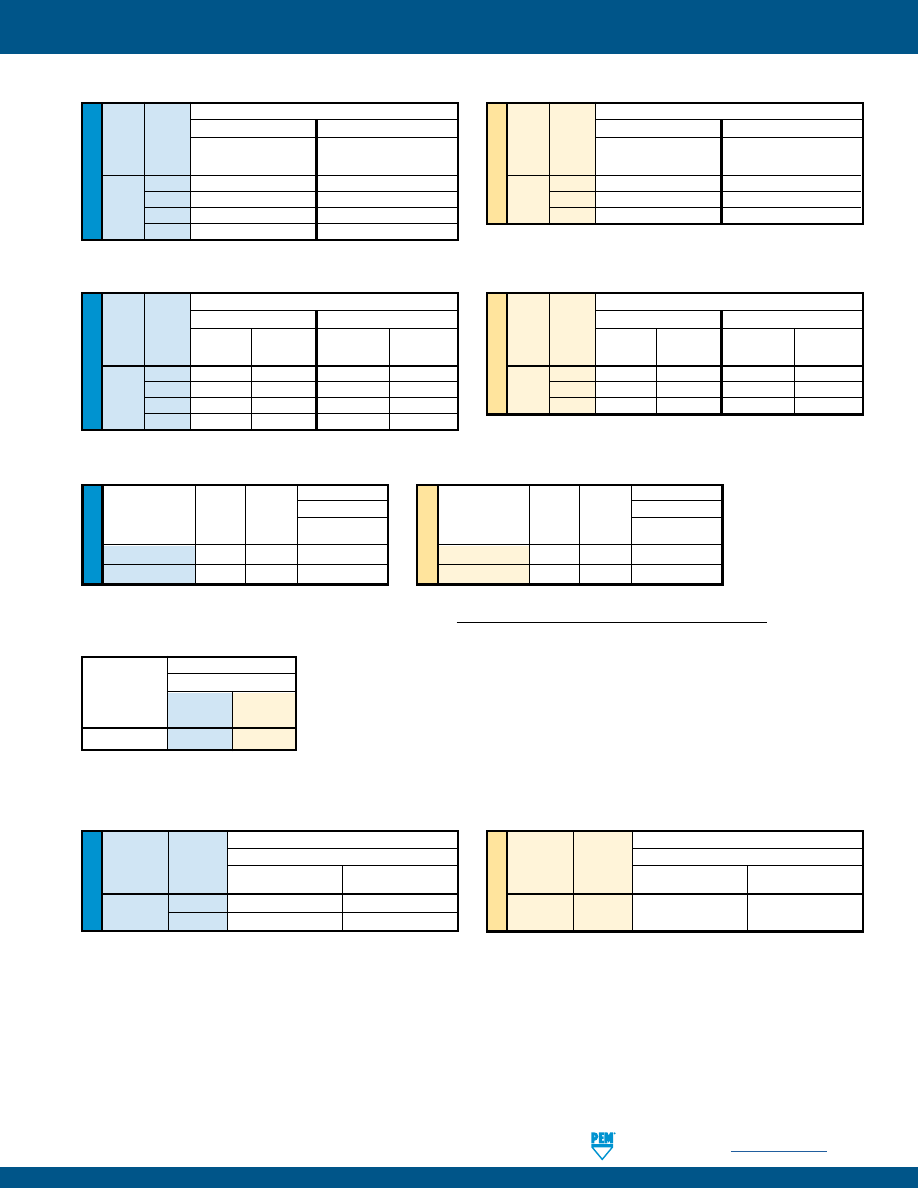

Type

Length Code “L” ±.015

Blind Min.

(Length code is in 16ths of an inch)

Min. Mounting Depth

Max.

Thread Thread

Sheet Hole Dia. of Blind

A

E

C

Min. Dist. Hole In

Size

Aluminum Stainless

Code

.250 .375 .500 .625 .750 1.00

Thick- +.003 Hole (Shank) ±.010

Max. Hole

CL

Attached

Steel

ness -.000 (1) Max. To Edge

Parts

.112-40 CHA CHC

440 4 6 8 10 12 —

.062

.172

.043 .041

.205 .171 .156 .135

(#4-40)

CFHA

CFHC

.093

.075

.071

.138-32 CHA CHC

632 4 6 8 10 12 16

.062

.213

.043 .041

.250 .212 .188 .160

(#6-32)

CFHA

CFHC

.093

.075

.071

.164-32 CHA

CHC

832 4 6 8 10 12 16

.062

.290

.043 .041

.328 .289 .219 .185

(#8-32)

CFHA

CFHC

.093

.075

.071

.190-32 CHA CHC

032 — 6 8 10 12 16

.062

.312

.043 .041

.350 .311 .250 .210

(#10-32)

CFHA

CFHC

.093

.075

.071

Type

Blind Min.

Thread

Length Code “L” ±0.4

Min.

Mounting Depth

Max.

Size

x Thread

(Length code is in millimeters)

Sheet

Hole Dia. of Blind

A

E

C

Min. Dist. Hole In

Pitch

Aluminum Stainless

Code

Thick-

+0.08 Hole

(Shank) ±0.25 Max. Hole

CL

Attached

Steel

ness (1) Max. To Edge Parts

M3 x 0.5

CHA CHC

M3 6 8 10 12 16 20 —

1.6

4.37

1.1 1.04

5.21 4.35 4 3.6

CFHA

CFHC 2.4 1.91

1.8

M4 x 0.7

CHA CHC

M4 6 8 10 12 16 20 25

1.6

7.37

1.1 1.04

8.33 7.35 5.6 4.6

CFHA

CFHC 2.4 1.91

1.8

M5 x 0.8

CHA CHC

M5 — — 10 12 16 20 25

1.6

7.93

1.1 1.04

8.89 7.9 6.4 5.6

CFHA

CFHC 2.4 1.91

1.8

(1) Blind holes may be deeper than minimums except where sheet material is at or near minimum thickness. Fasteners should always be installed so the

flange is flush with the surface of the sheet.

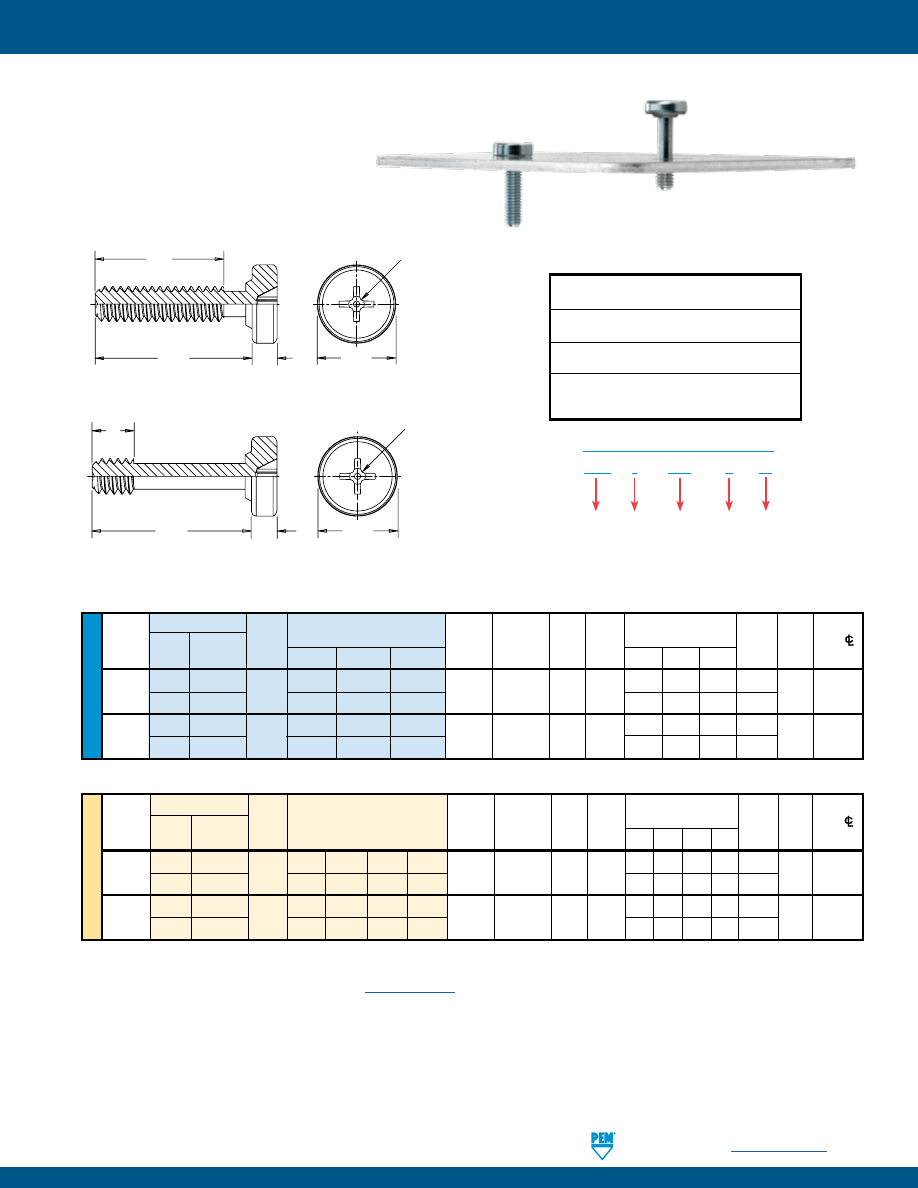

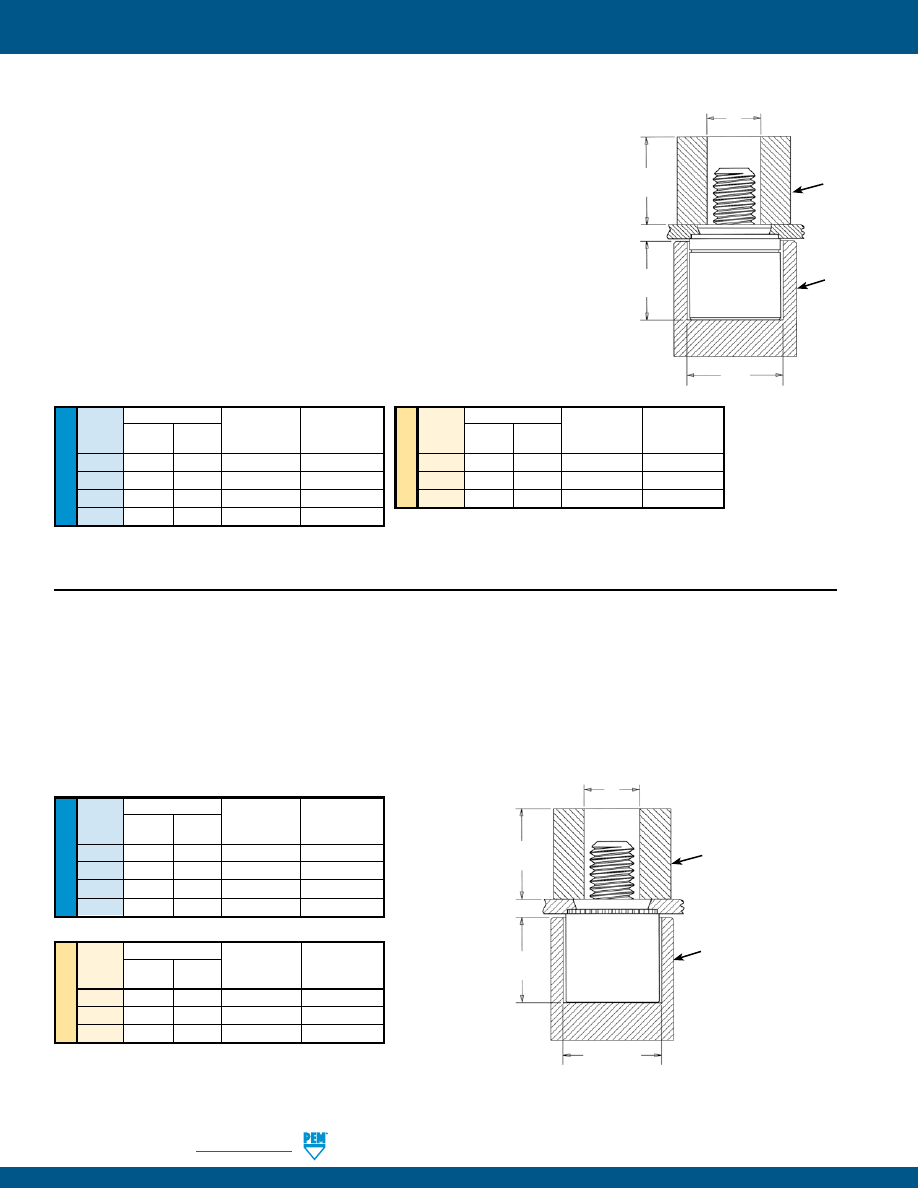

CHA™, CFHA™, CHC™ AND CFHC™ ALUMINUM AND STAINLESS STEEL STUDS

CH

A – 632 – 6

CFH A – 632 – 6

CH

C – 632 – 6

CFH C – 632 – 6

Type

PART NUMBER DESIGNATION

Material

Length

Code

Thread

Code

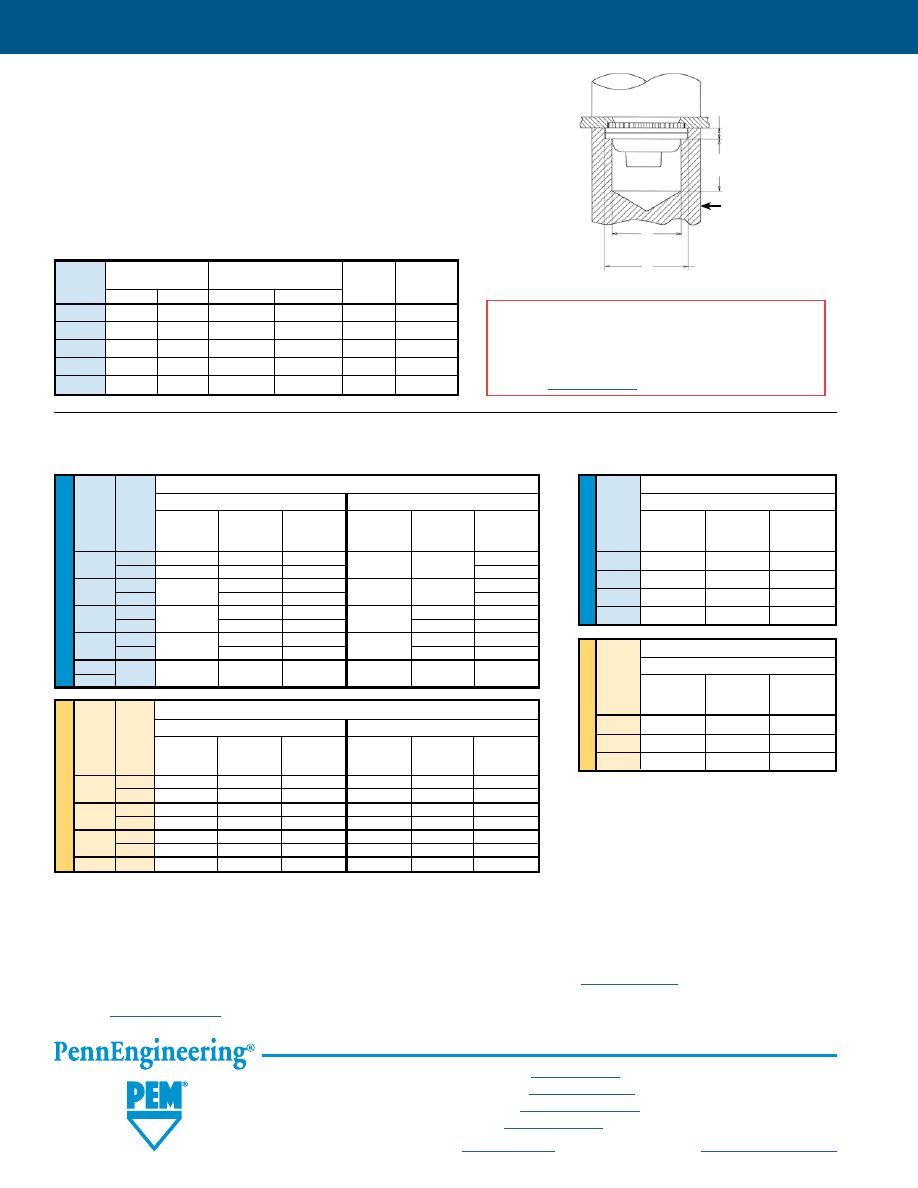

L

E

A

C

.062” / 1.6 mm Max.

Dimple (Registered

Trademark)

Clinching profile may vary.

All dimensions are in inches.

All dimensions are in millimeters.

CONCEALED-HEAD SELF-CLINCHING STUDS AND STANDOFFS

PennEngineering •

www.pemnet.com

CH-3

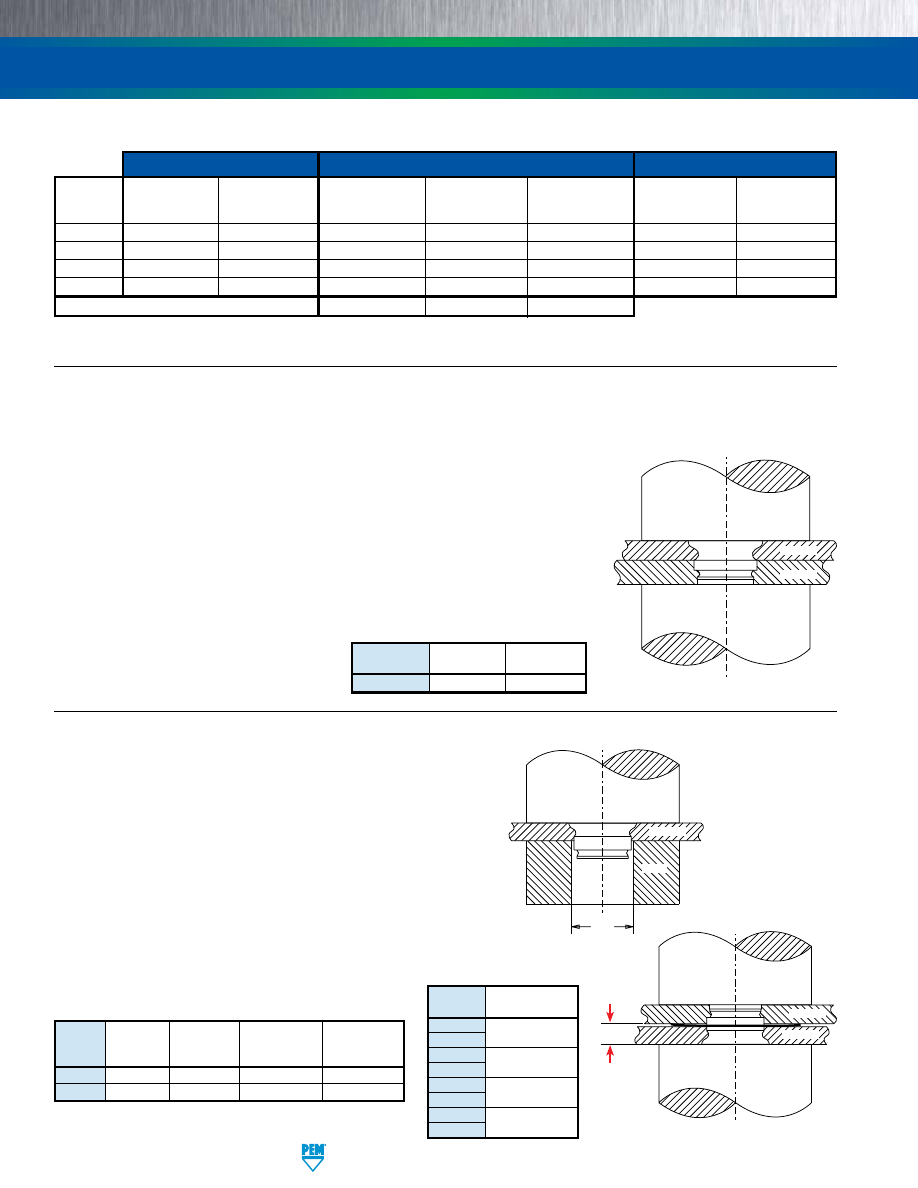

pem-html.html

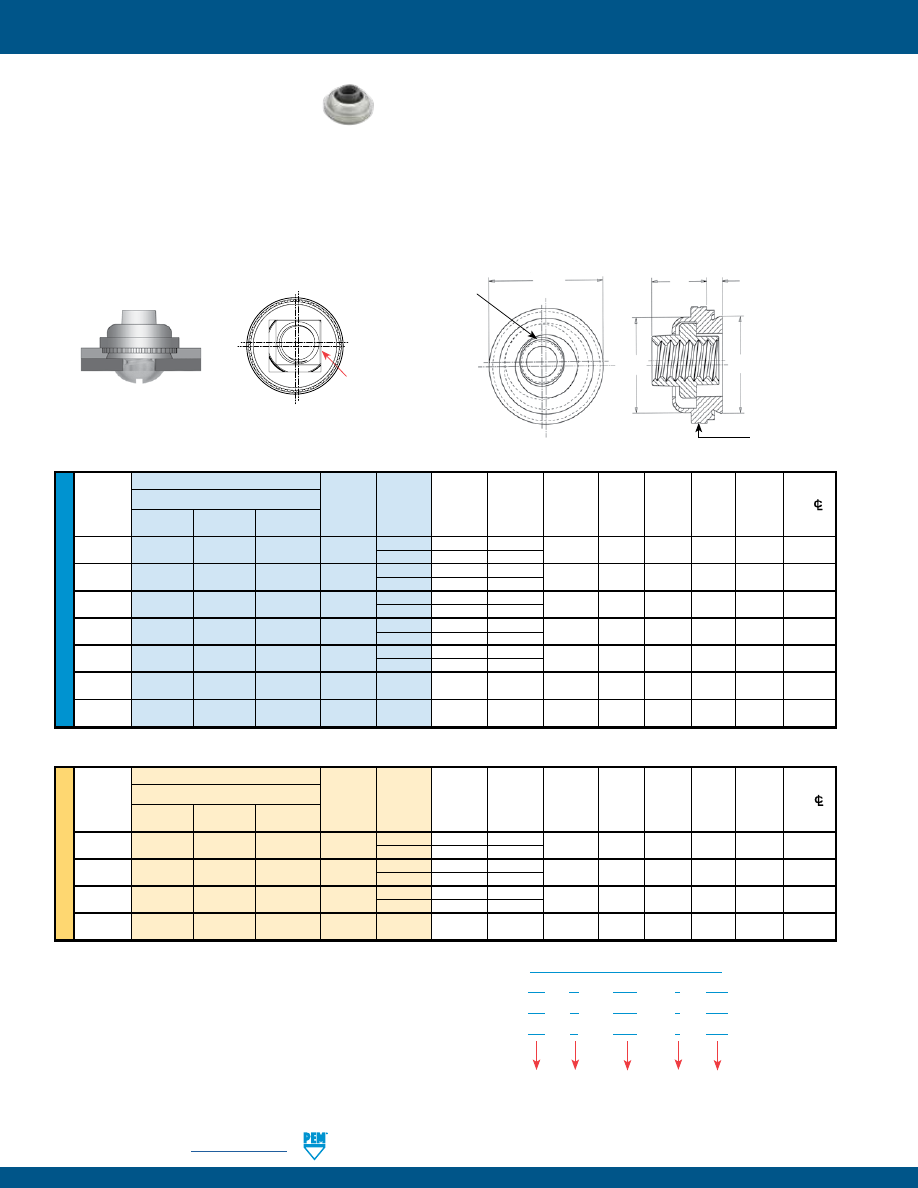

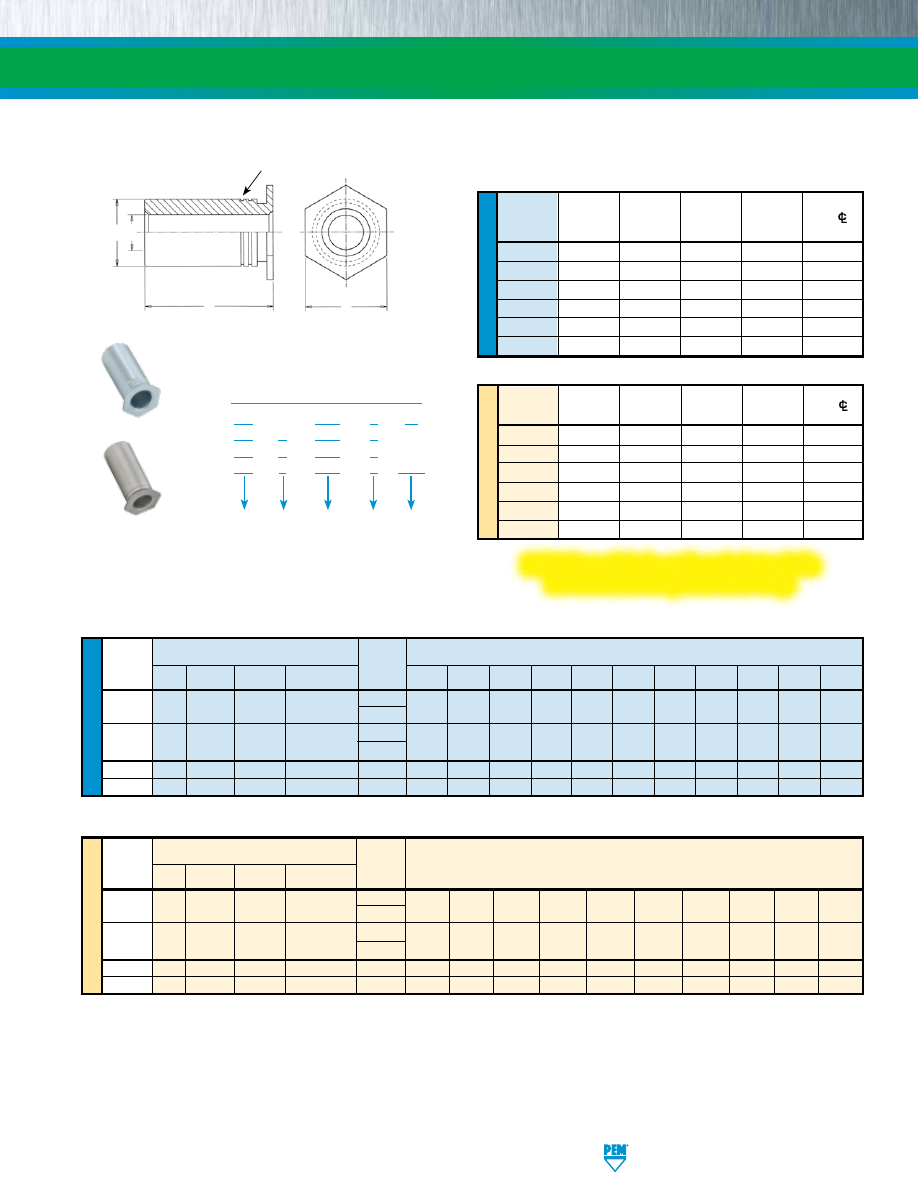

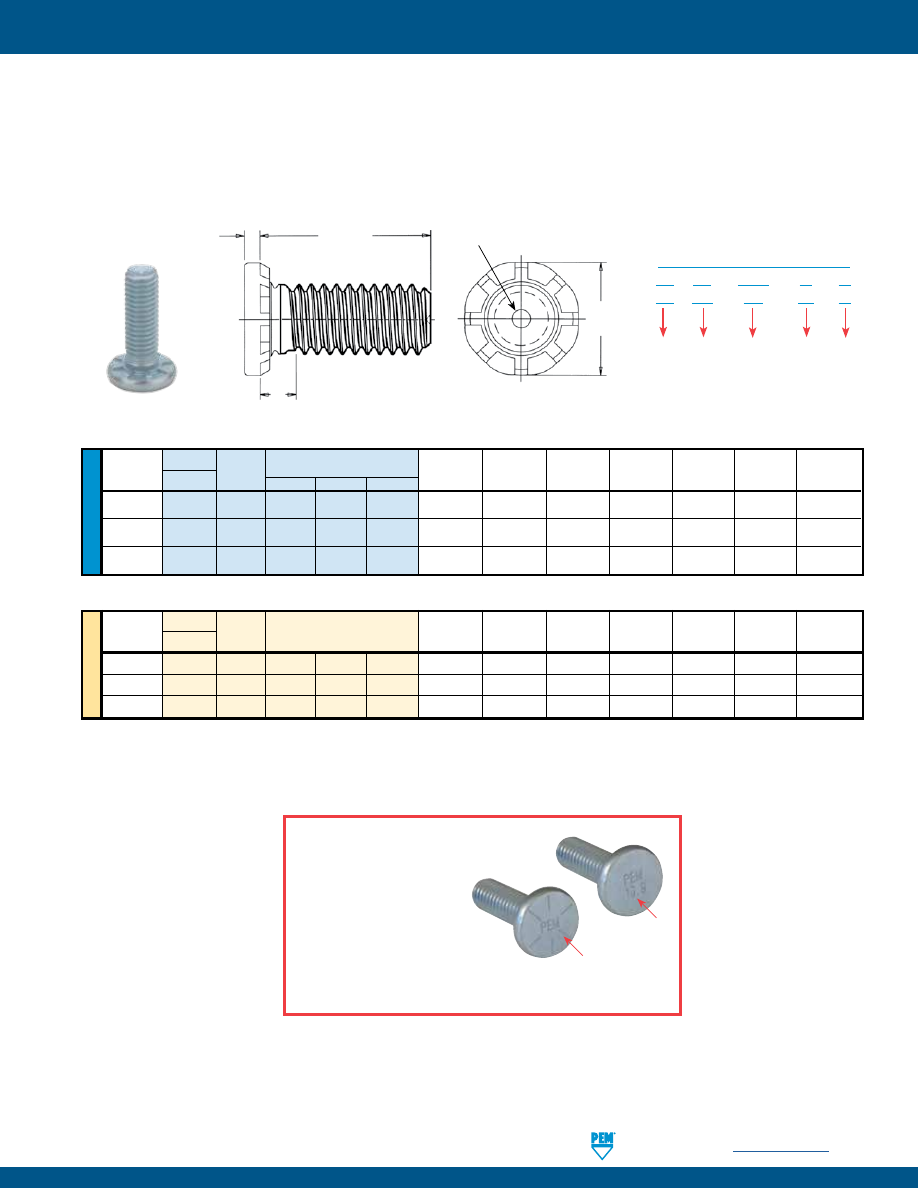

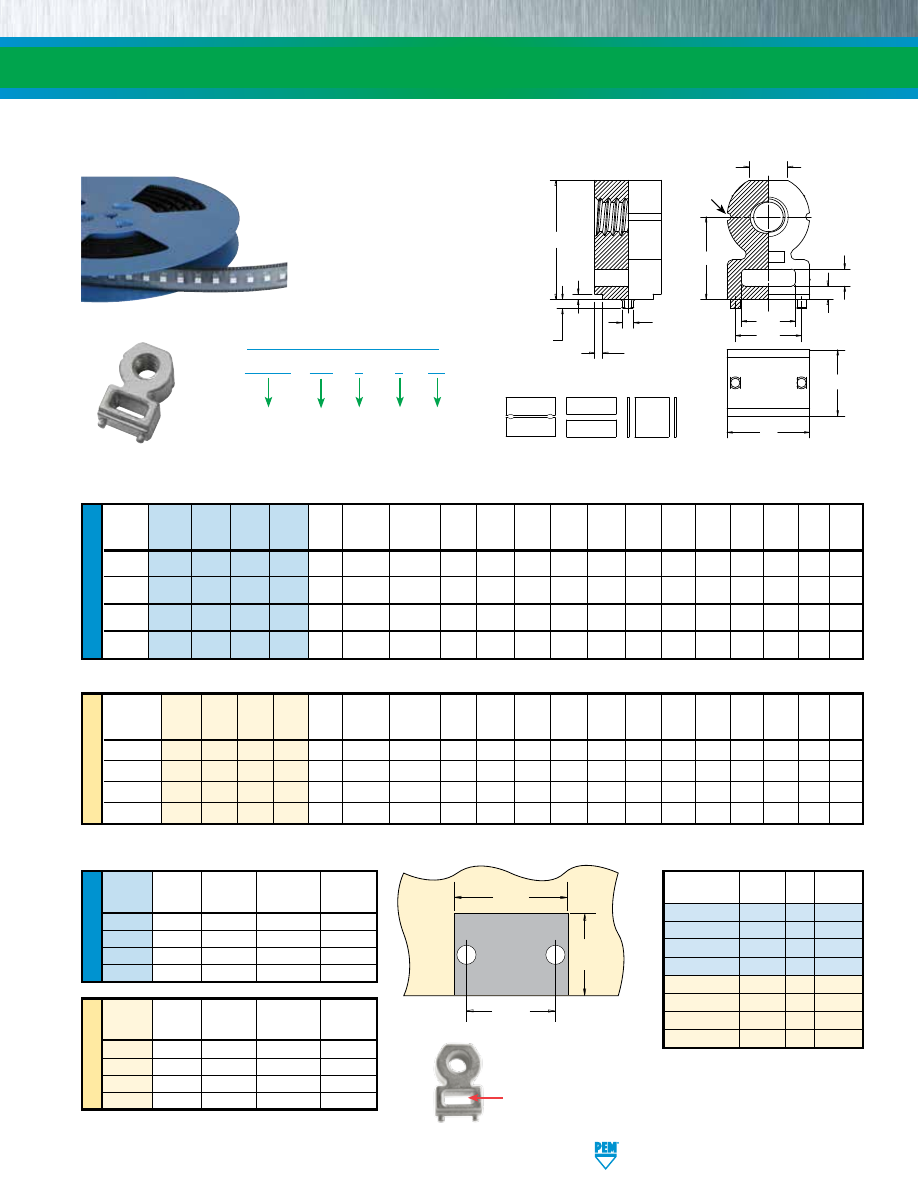

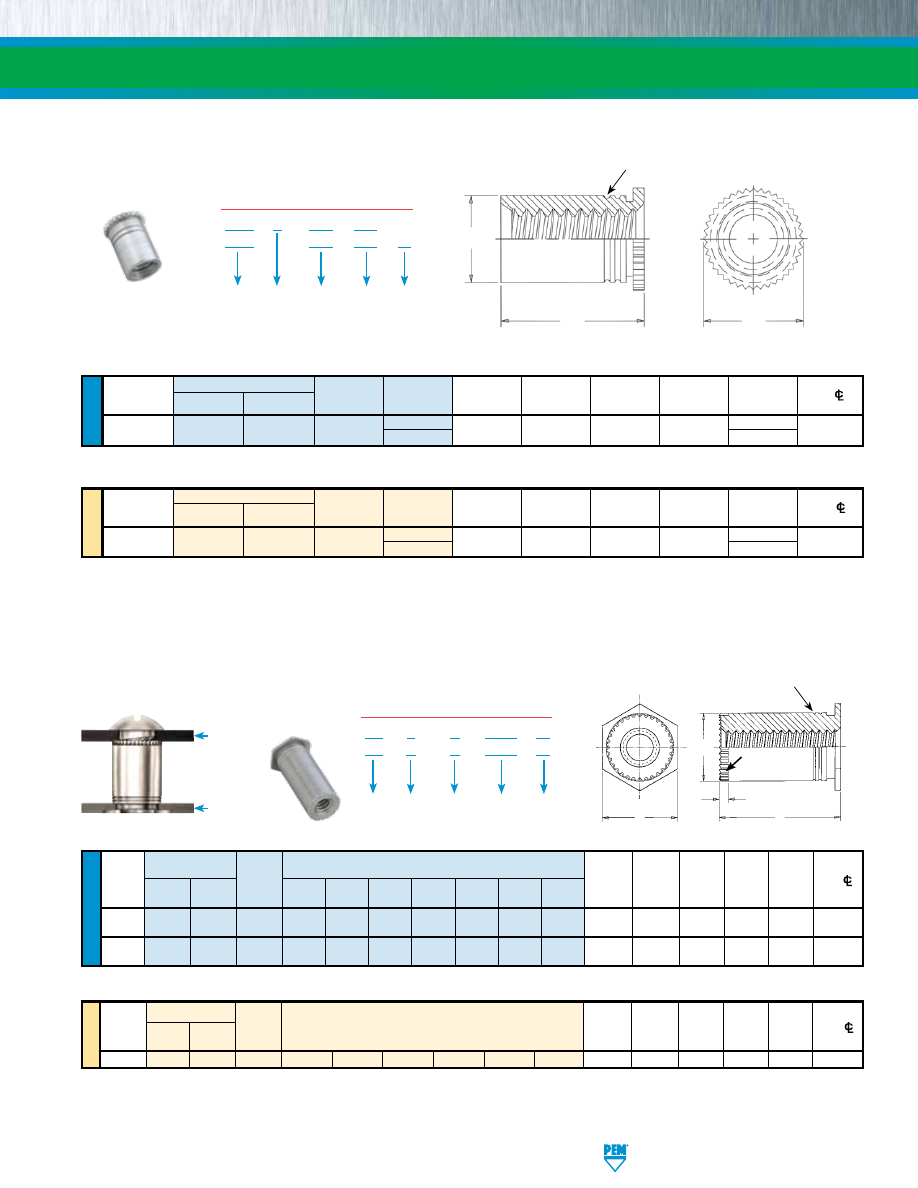

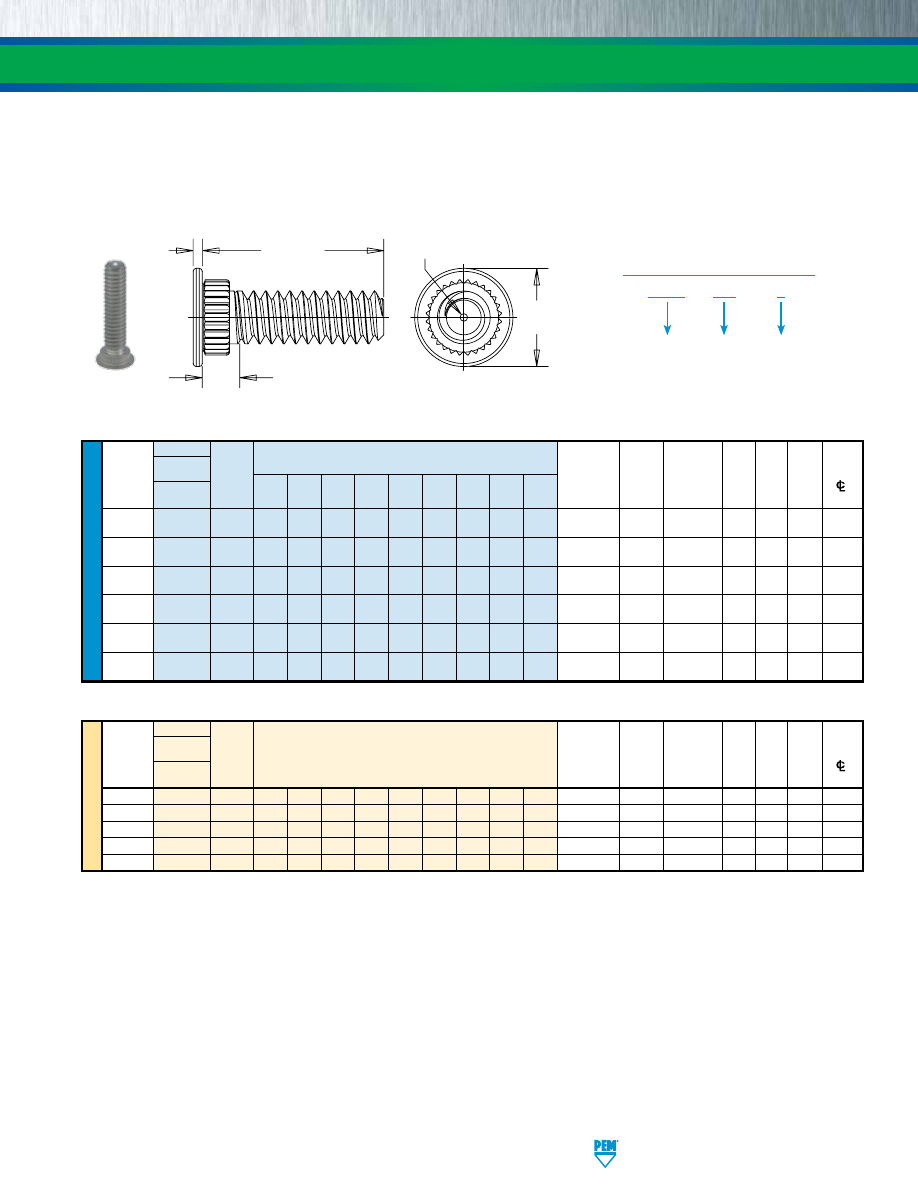

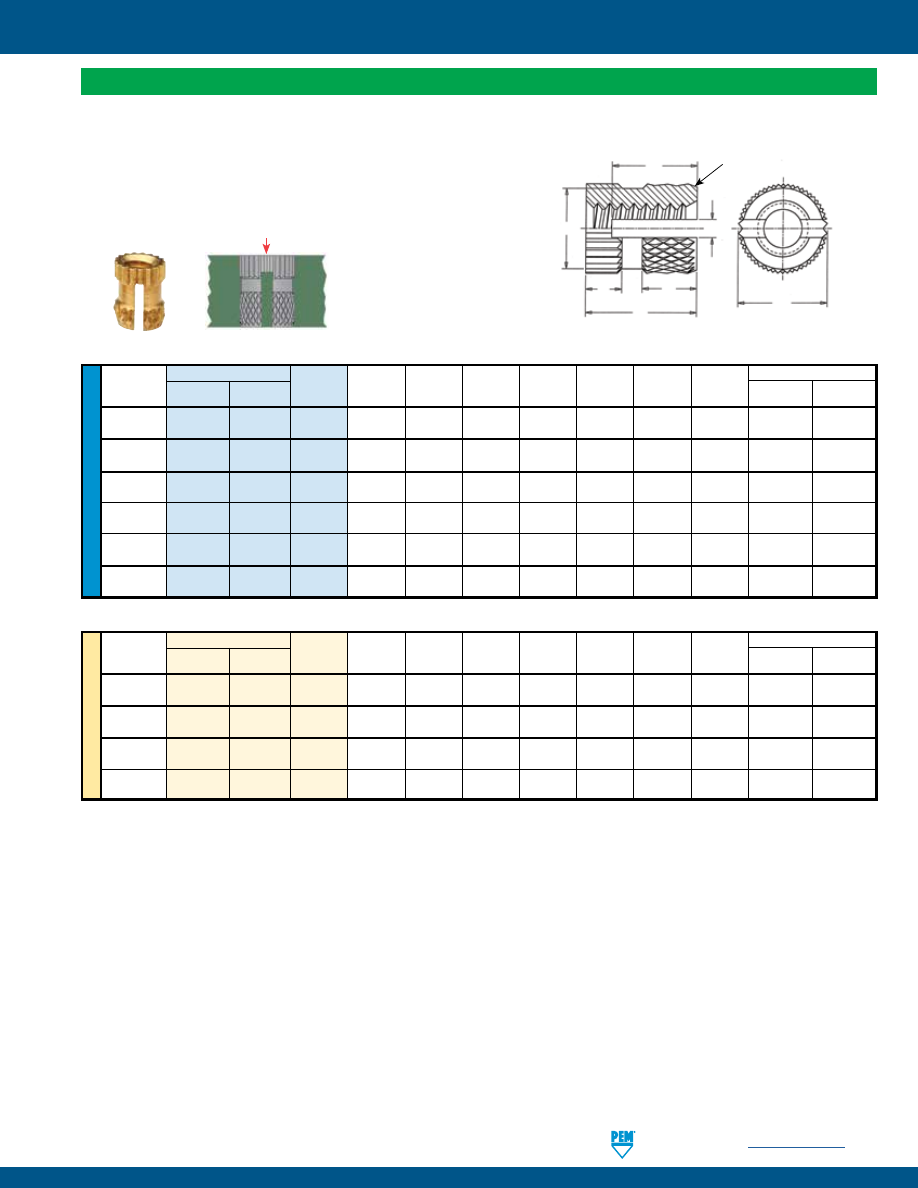

ME

TR

IC

U

NIF

IE

D

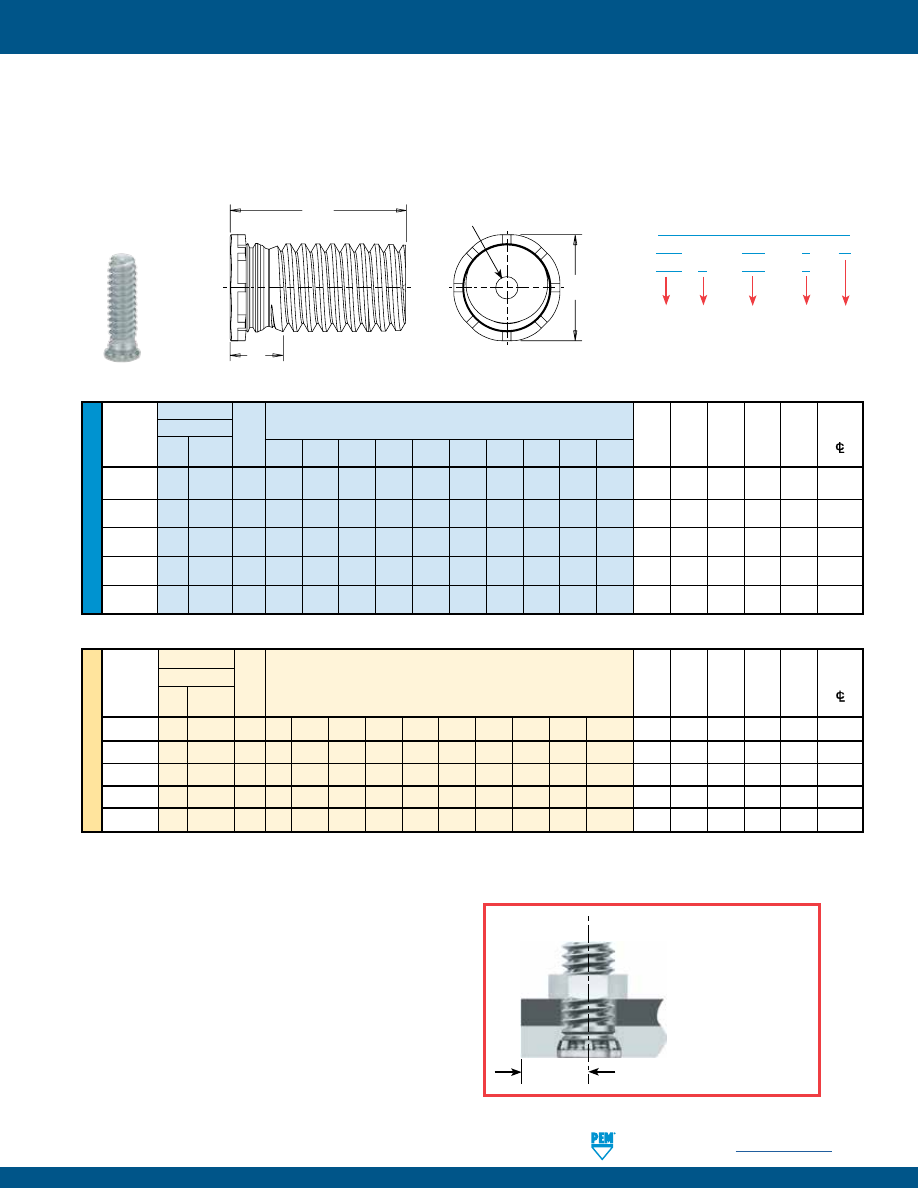

Min.

Type Min.

Blind Depth Min.

Min.

Thread Thread Sheet

Mounting of Depth

A

B C H Dist.

Size Code Thick-

Hole Dia. Blind Full (Shank) Max. Max. Nom. Hole

C/L

Stainless ness

+.003 Hole Thread Max.

(5)

To Edge

Steel

.187 .250 .312 .375 .500 .625 .750 1.00

-.000 (4) F

.112-40 CSS

440 3

(1)

4

(2)

5

(2)

6

(2)

8

(3)

10

(3)

12

(3)

16

(3)

.062

.213

.043

.188

.041

.165 .212 .250 .188

(#4-40)

CSOS .093 .075 .072

.138-32 CSS

632 3

(1)

4

(1)

5

(2)

6

(2)

8

(3)

10

(3)

12

(3)

16

(3)

.062

.290

.043

.250

.041

.213 .289 .312 .219

(#6-32)

CSOS .093 .075 .072

.164-32 CSS

832 3

(1)

4

(1)

5

(2)

6

(2)

8

(3)

10

(3)

12

(3)

16

(3)

.062

.312

.043

.250

.041

.245 .311 .344 .250

(#8-32)

CSOS .093 .075 .072

.190-32 CSS

032 3

(1)

4

(1)

5

(1)

6

(1)

8

(2)

10

(3)

12

(3)

16

(3)

.062

.344

.043

.375

.041

.290 .343 .375 .281

(#10-32)

CSOS .093 .075 .072

.250-20 CSS

0420 3

(1)

4

(1)

5

(1)

6

(1)

8

(2)

10

(2)

12

(3)

16

(3)

.062

.390

.043

.375

.041

.354 .389 .438 .375

(1/4-20)

CSOS .093 .075 .072

Min.

Type Min. Blind Depth Min.

Min.

Thread Thread Sheet

Mounting of Depth

A

B C H Dist.

Size x Code Thick- Hole Blind Full (Shank) Max. Max. Nom. Hole

C/L

Pitch Stainless ness

Diameter Hole Thread Max.

(5)

To Edge

Steel

+0.08 (4) F

M3 x 0.5

CSS

M3 4

(1)

6

(1)

8

(2)

10

(3)

12

(3)

16

(3)

20

(3)

25

(3)

1.6

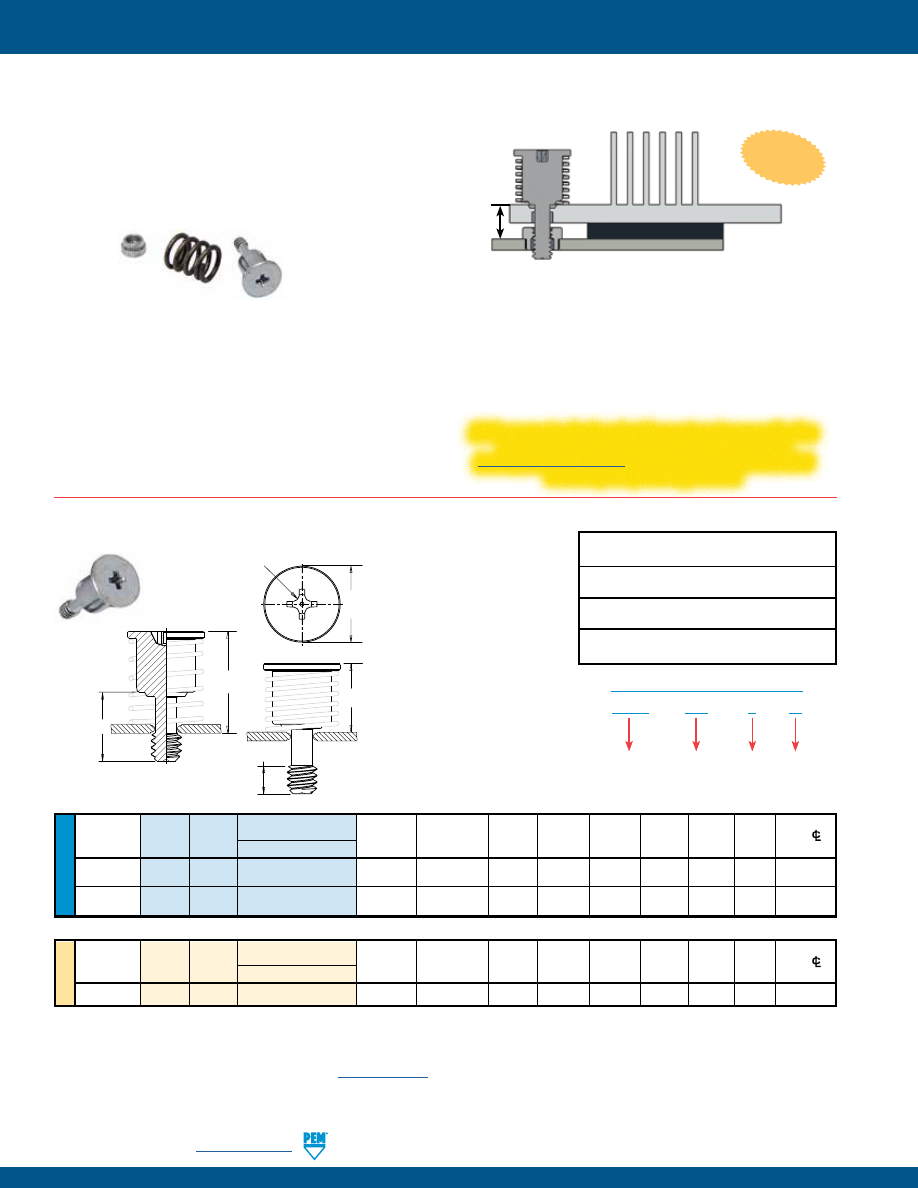

5.41

1.1

5

1.04

4.2 5.39 6.35 4.8

CSOS

8

(3)

2.4 1.91 1.83

M4 x 0.7

CSS

M4 4

(1)

6

(1)

8

(2)

10

(2)

12

(3)

16

(3)

20

(3)

25

(3)

1.6

7.92

1.1

6.5

1.04

6.23 7.9 8.74 6.4

CSOS 10

(3)

2.4 1.91 1.83

M5 x 0.8

CSS

M5 4

(1)

6

(1)

8

(1)

10

(2)

12

(2)

16

(3)

20

(3)

25

(3)

1.6

8.74

1.1

9.6

1.04

7.37 8.72 9.53 7.2

CSOS 2.4 1.91 1.83

M6 x 1

CSOS

M6 4

(1)

6

(1)

8

(1)

10

(2)

12

(2)

16

(3)

20

(3)

25

(3)

2.4 9.9 1.91 9.6 1.83 9 9.89 11.11 9.5

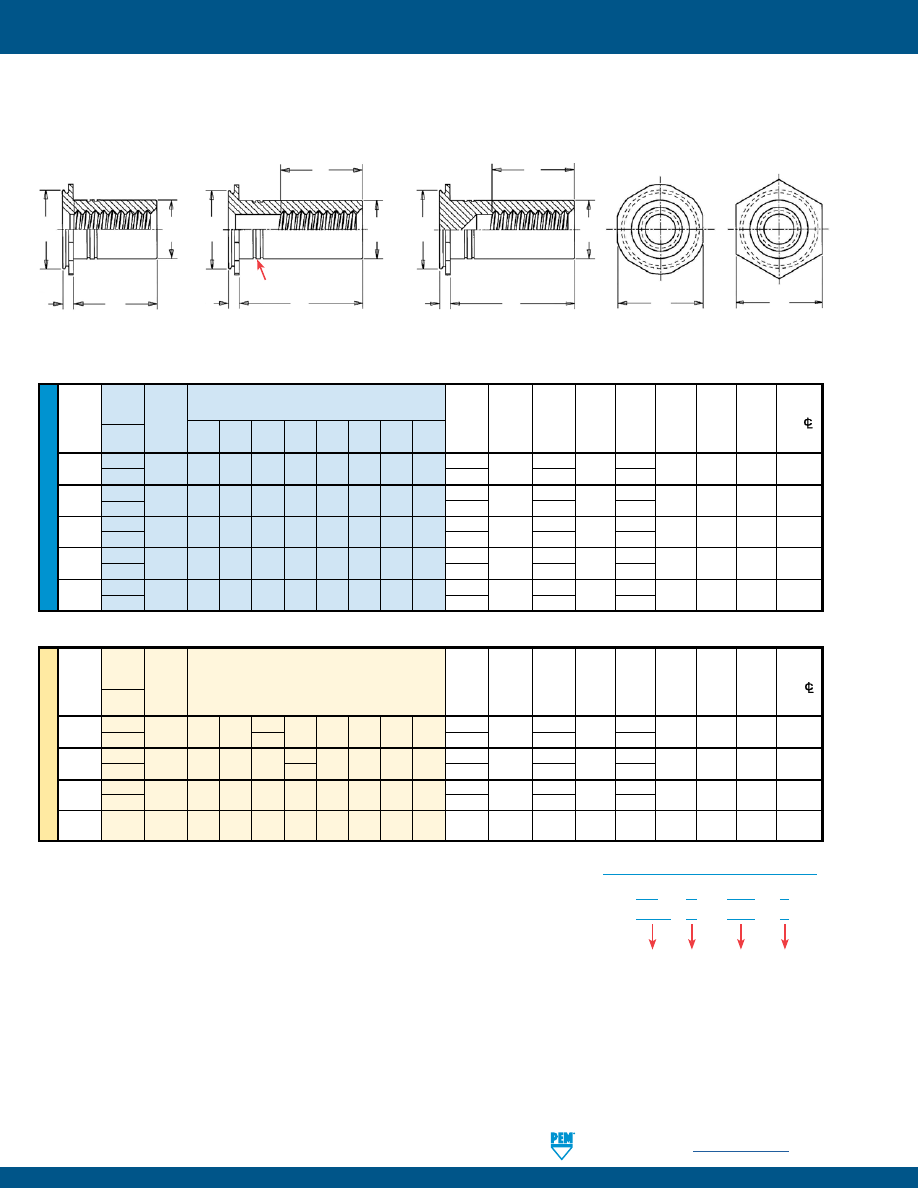

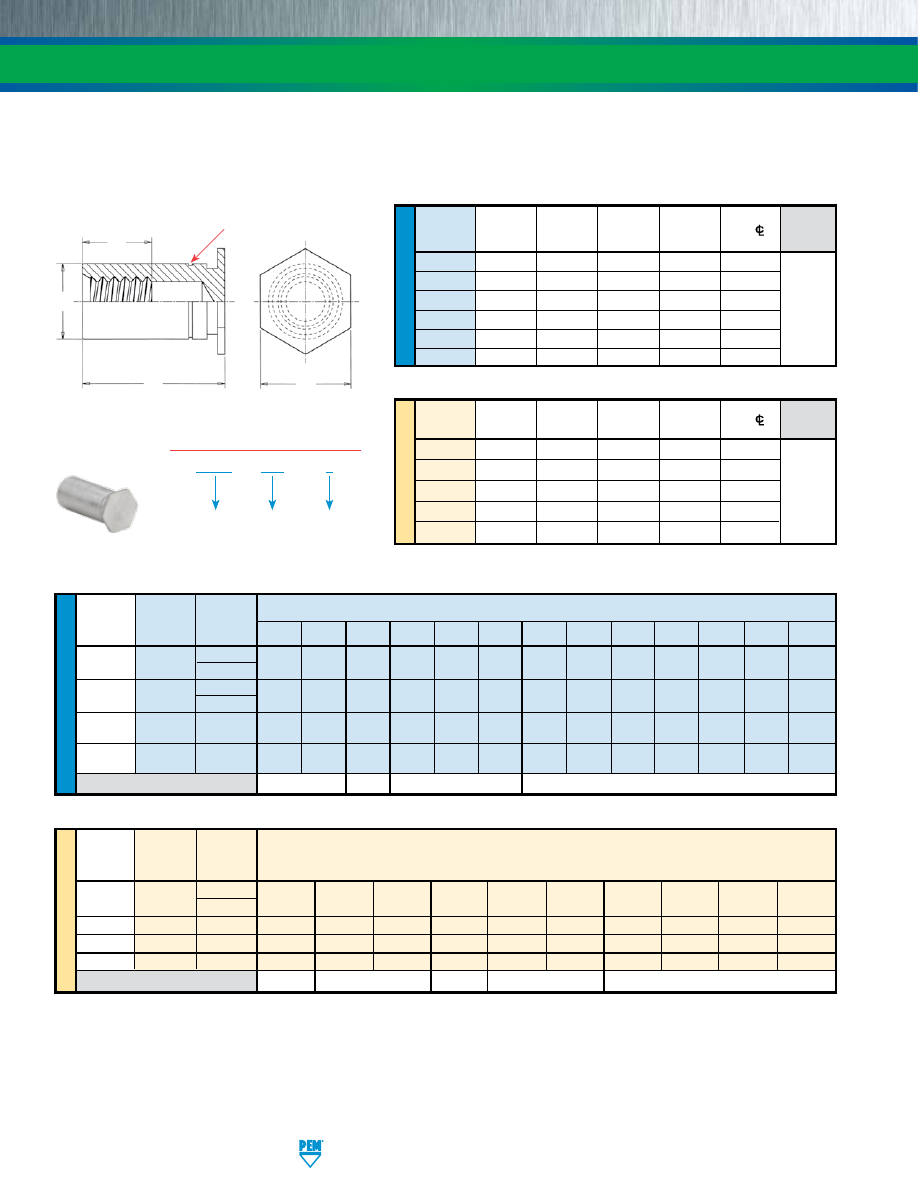

(1)

Style #1. Minimum thread length is equal to barrel length “L”. Screw might not pass

through shank end. Screws with lengths exceeding “L” should not be used or they may

cause “jacking-out” of standoff from the sheet.

(2)

Style #2. Screw might not pass through unthreaded end. Screws with lengths

exceeding “L” should not be used or they may cause “jacking-out” of standoff from the

sheet.

(3)

Style #3. Blind.

(4) Blind mounting holes may be deeper than minimums except where sheet material is at or

near minimum thickness. Fasteners should always be installed so the flange is flush with

the surface of the sheet.

(5) If standoff is used as a bushing, the hole in attached part must not exceed “B” plus .020”

/ 0.51 mm.

Length Code “L” +.002 –.005

(Length code is in 16ths of an inch)

Length Code “L” +0.05 –0.13

(Length code is in millimeters)

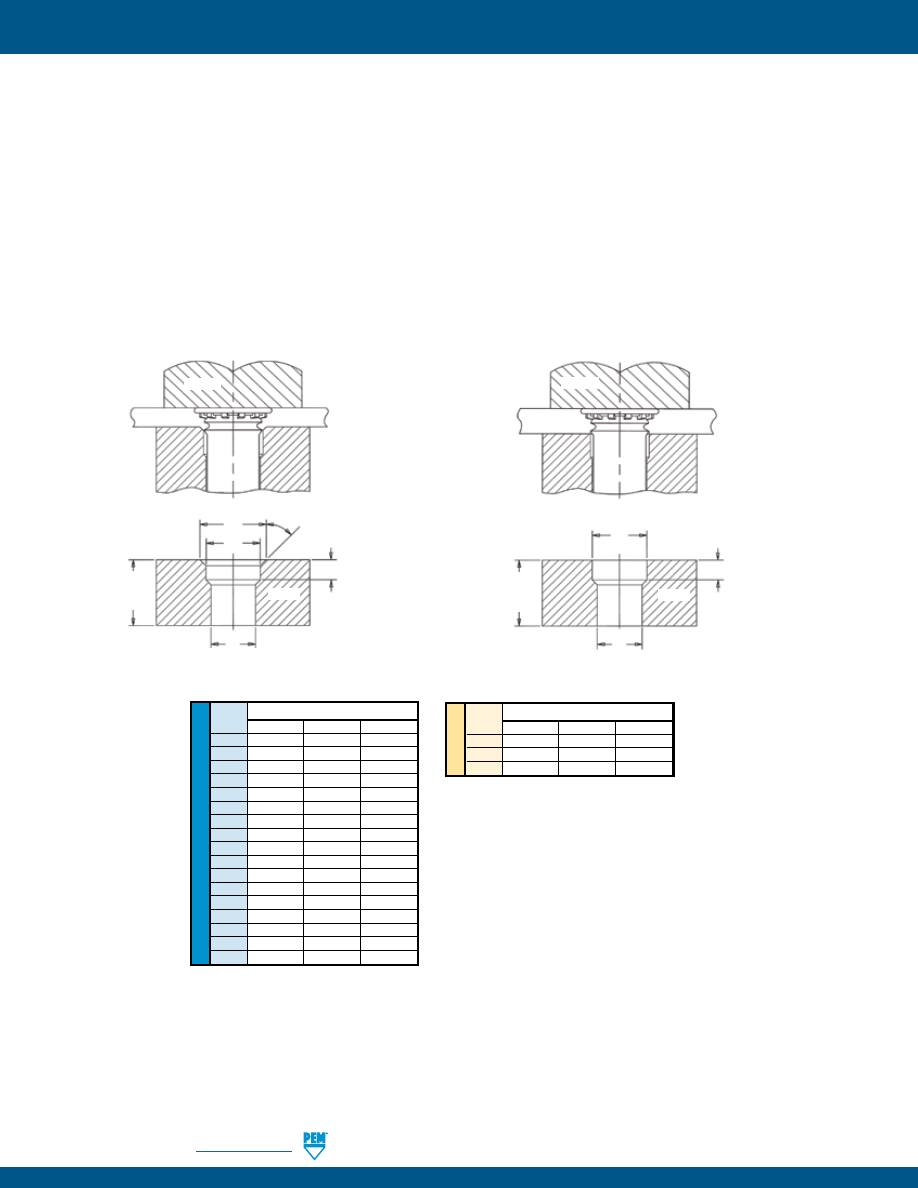

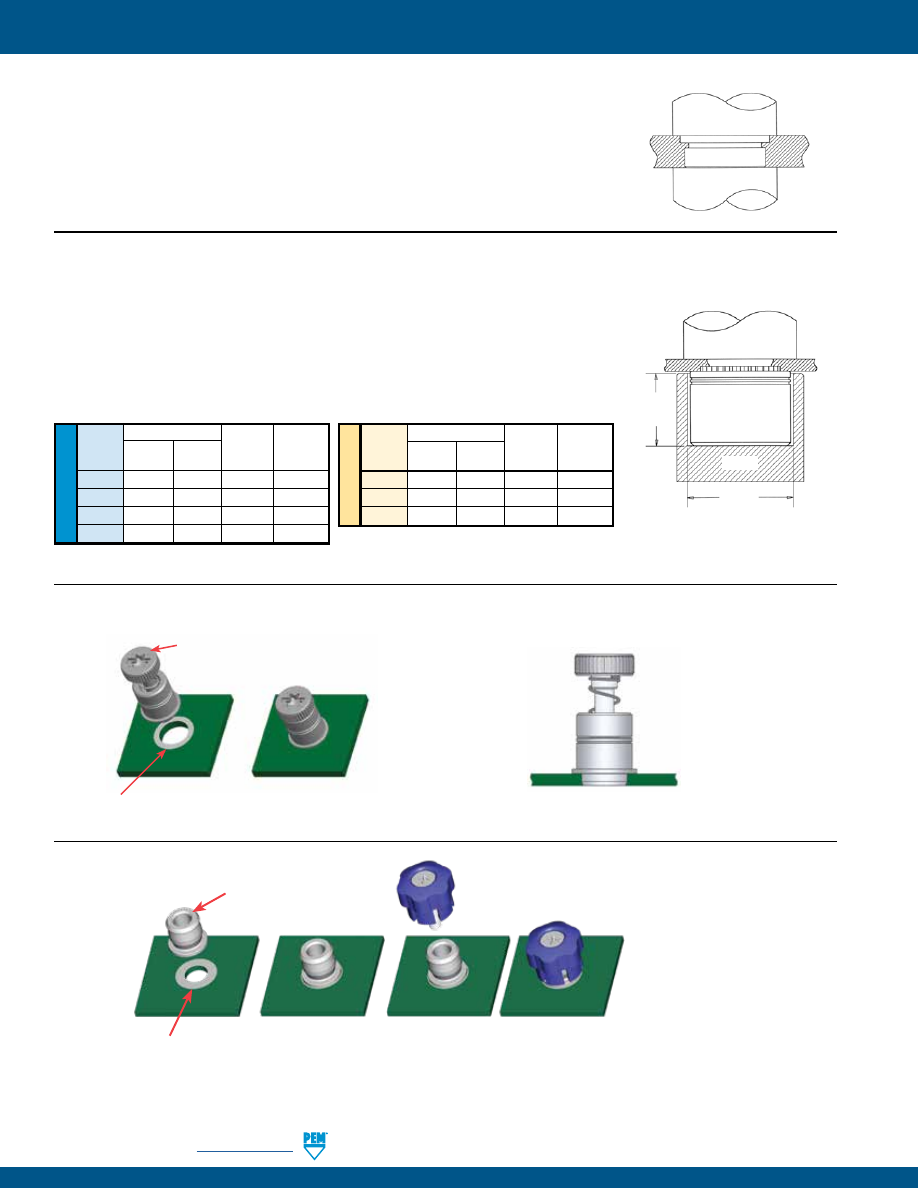

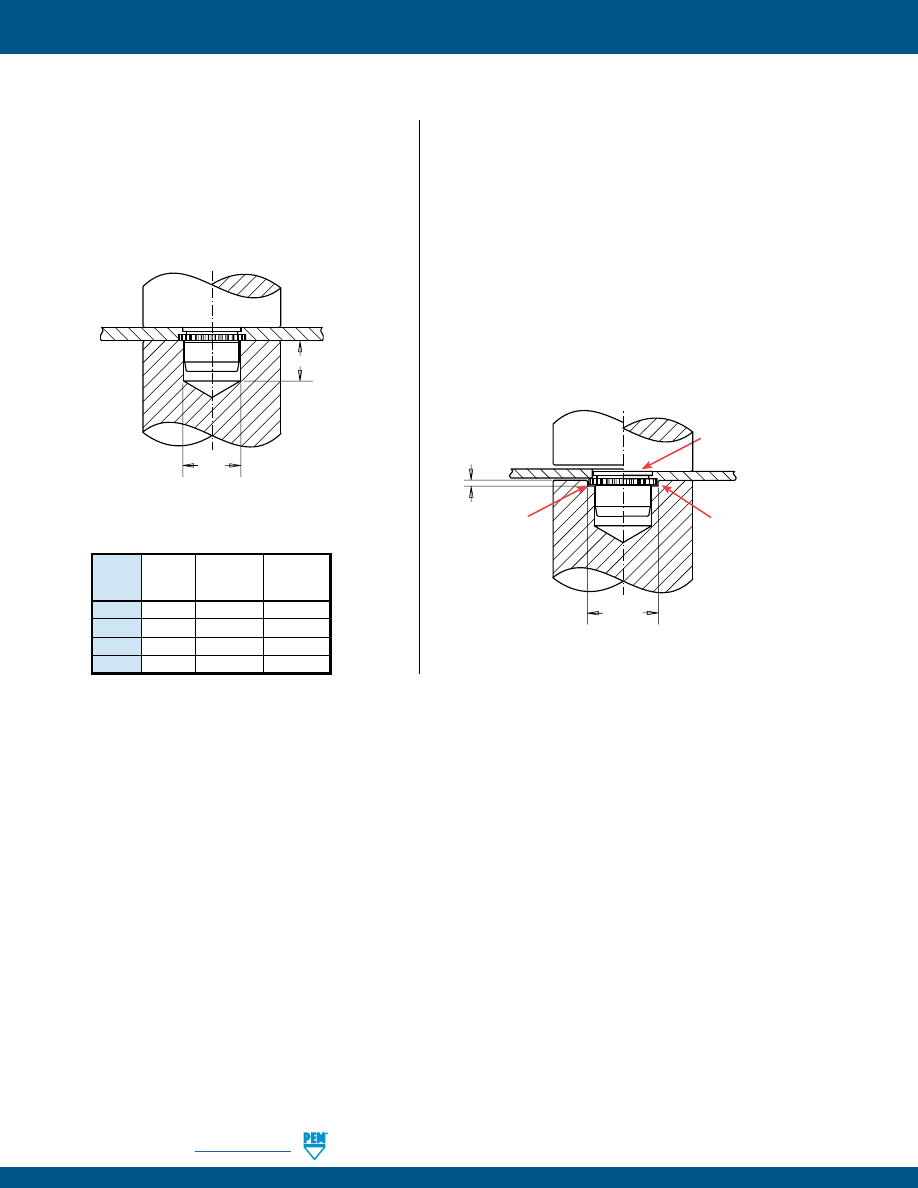

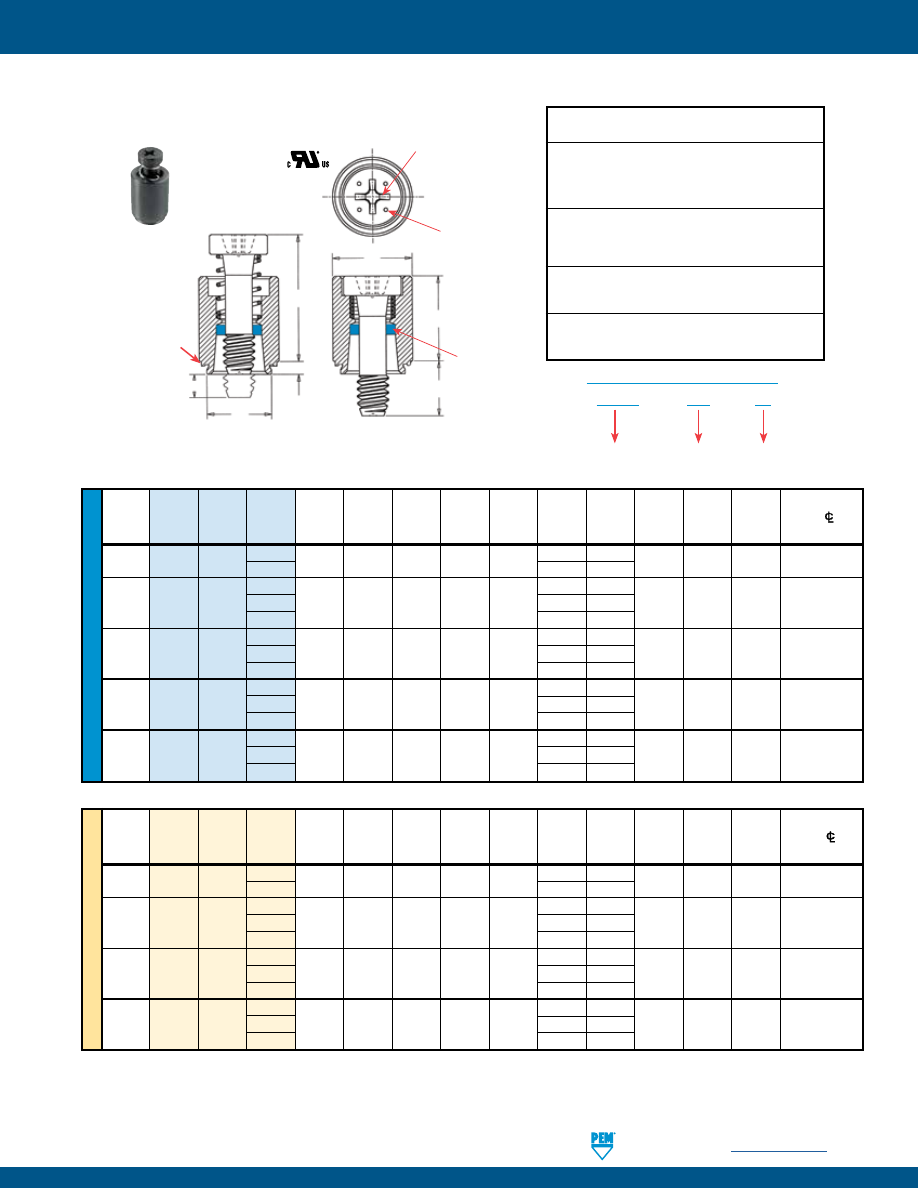

CSS™ AND CSOS™ STAINLESS STEEL STANDOFFS

CS

S – 632 – 6

CSO S – 632 – 6

Type

PART NUMBER DESIGNATION

Material

Length

Code

Thread

Code

L

H

TYPE CSS

TYPE CSOS

H

C

F

B

A

Style #2

Style #3

C

F

B

L

A

Style #1

C

B

L

A

Two Groove

(Registered Trademark)

Clinching profile may vary.

All dimensions are in inches.

All dimensions are in millimeters.

CONCEALED-HEAD SELF-CLINCHING STUDS AND STANDOFFS

PennEngineering •

www.pemnet.com

CH-4

pem-html.html

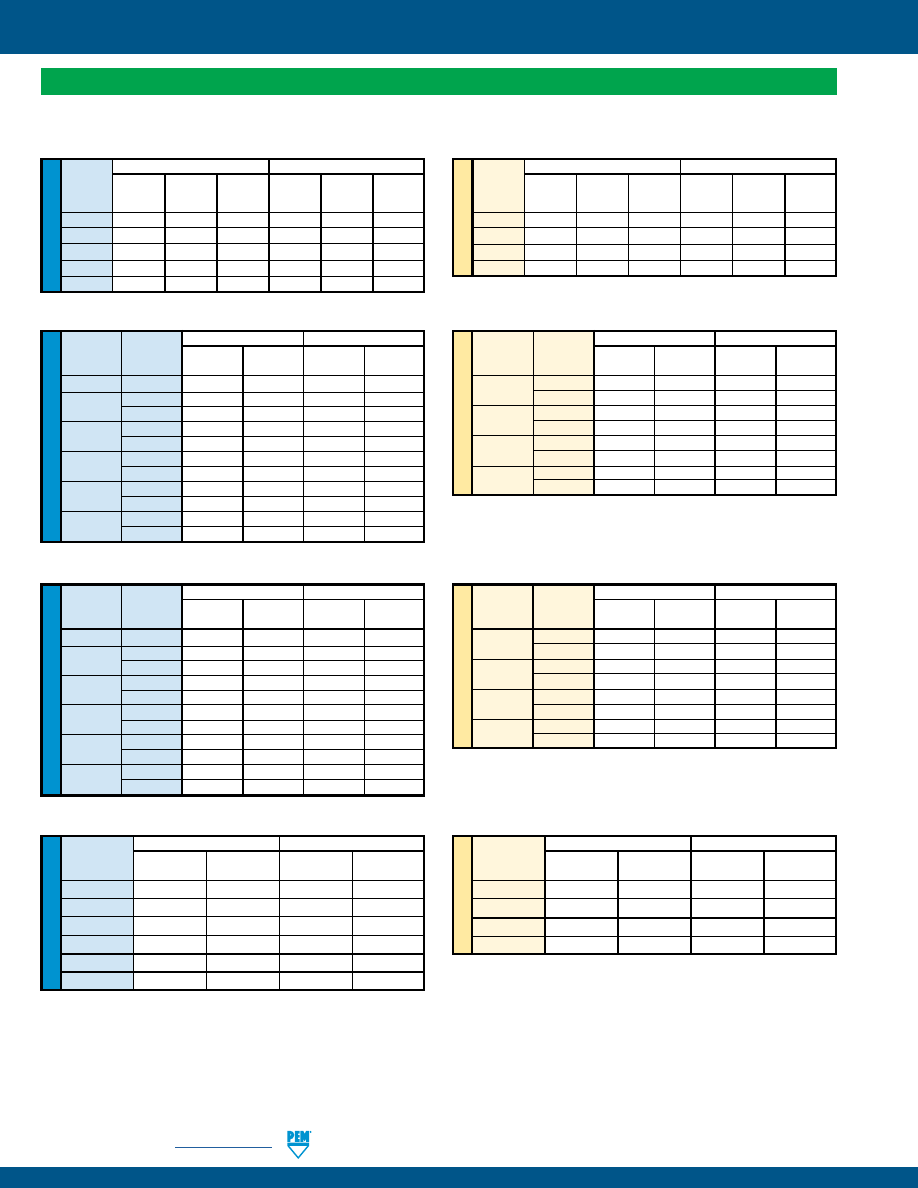

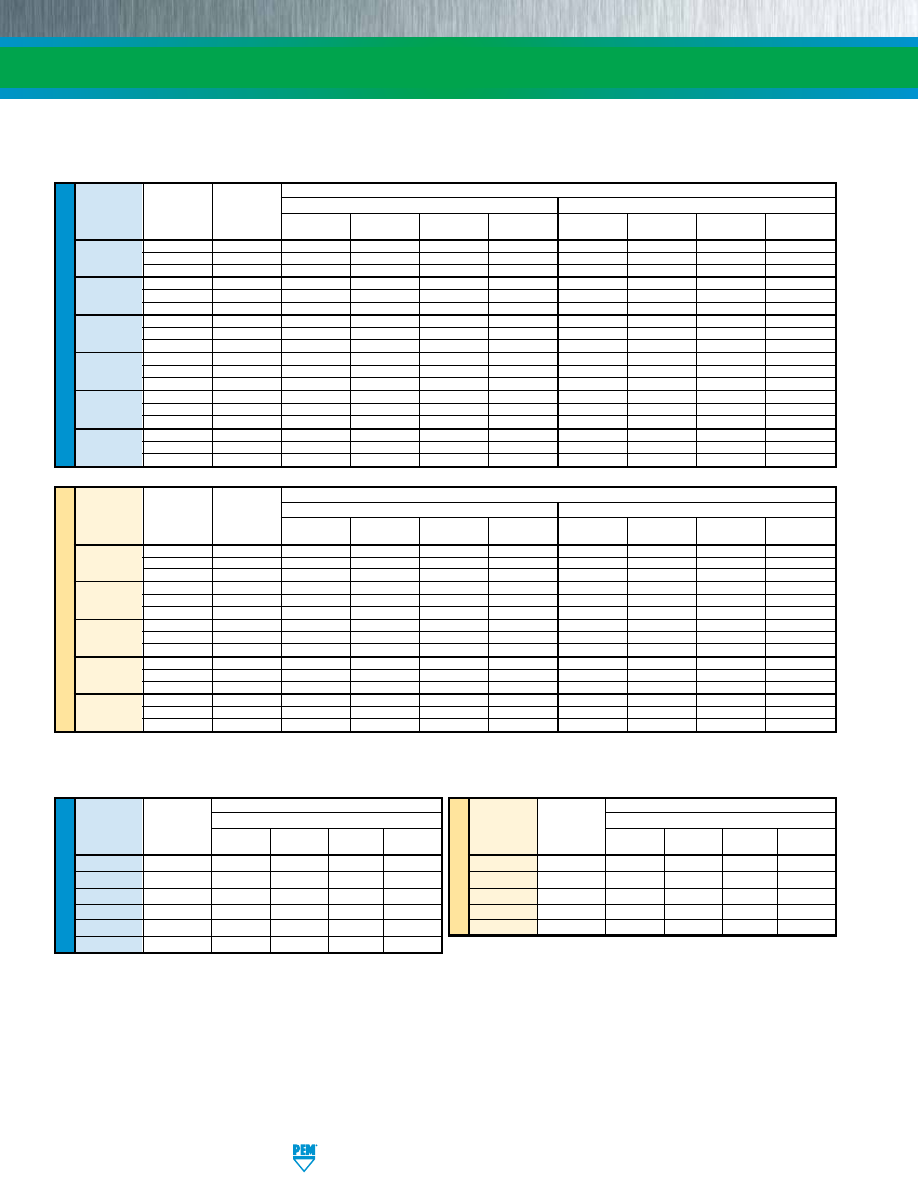

Threads

Fastener Materials

Finish

For Use In Sheet Hardness (1)

Passivated

Type

External, Internal,

300

Series

and/or

HRB 70 /

HRB 50 /

ASME B1.1 2A / ASME B1.1 2B /

Aluminum

Stainless Steel

No Finish

tested per

HB 125

HB 89

ASME B1.13M, 6g ASME B1.13M, 6H

ASTM

A380 or Less

or Less

CHA

•

•

•

•

CFHA

•

•

•

•

CHC

•

•

•

•

CFHC

•

•

•

•

CSS

•

•

•

•

CSOS

•

•

•

•

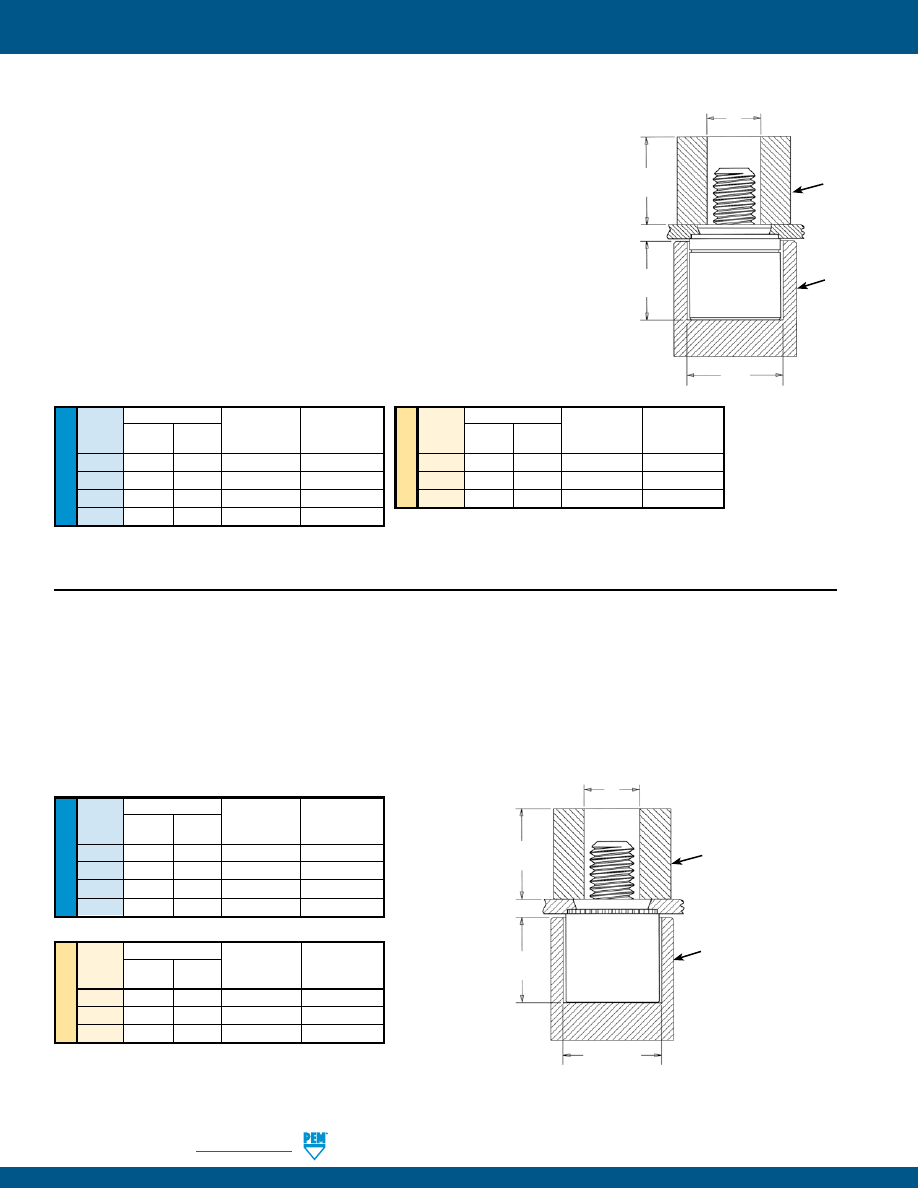

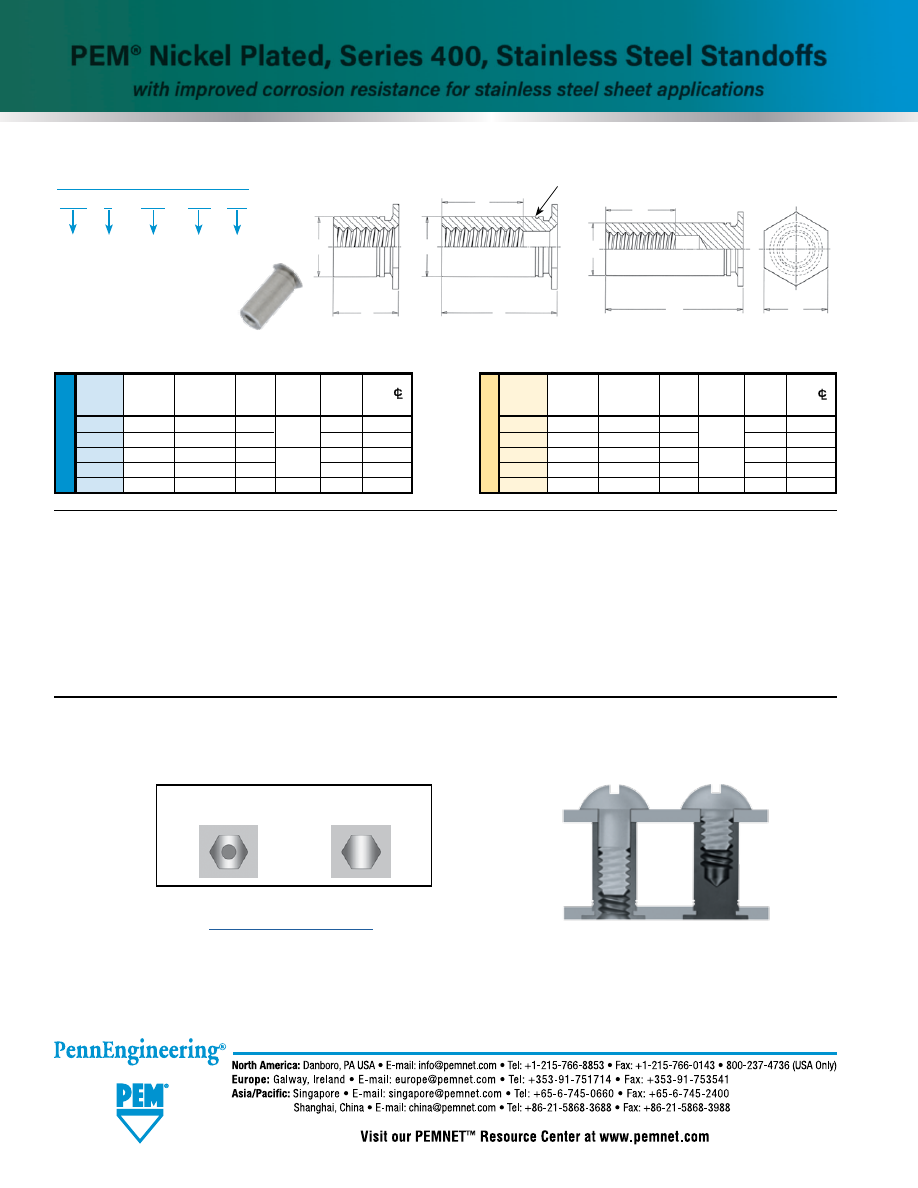

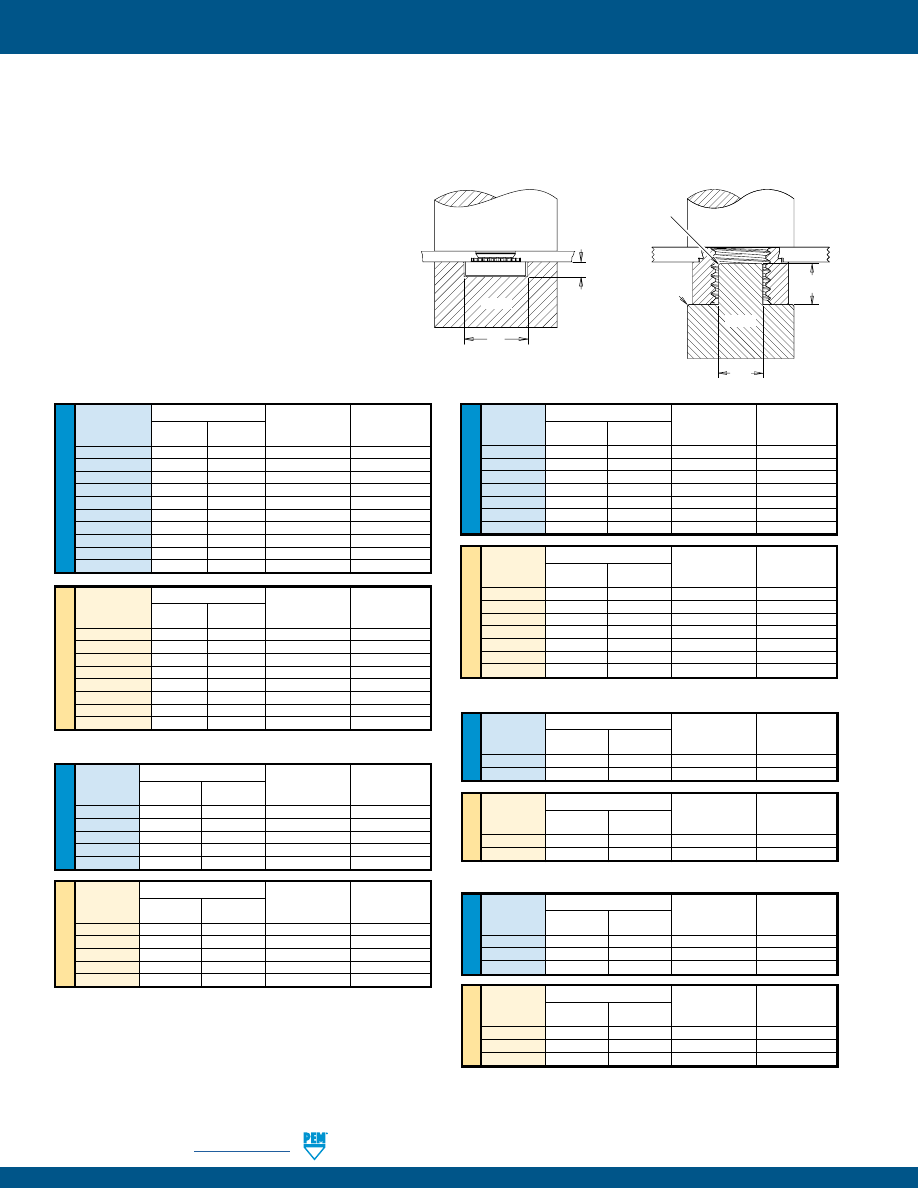

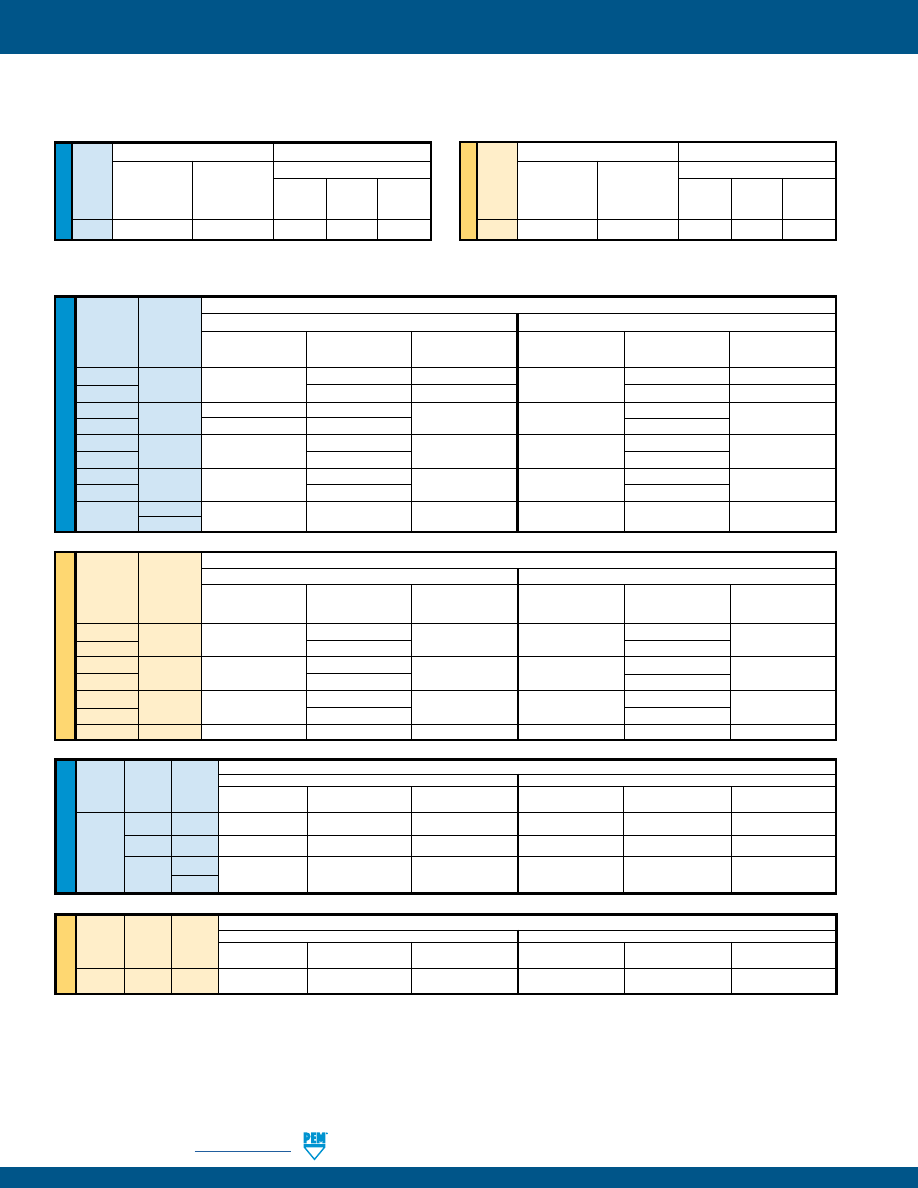

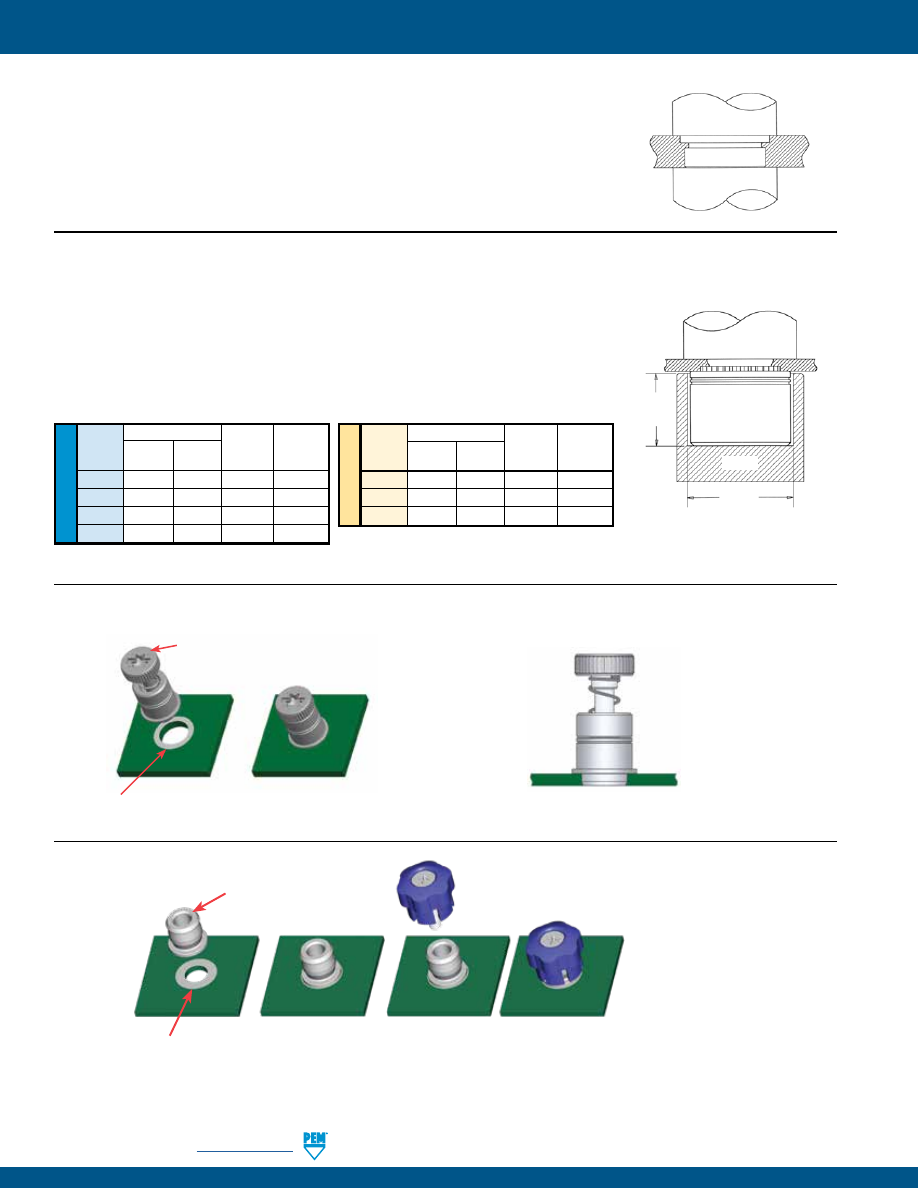

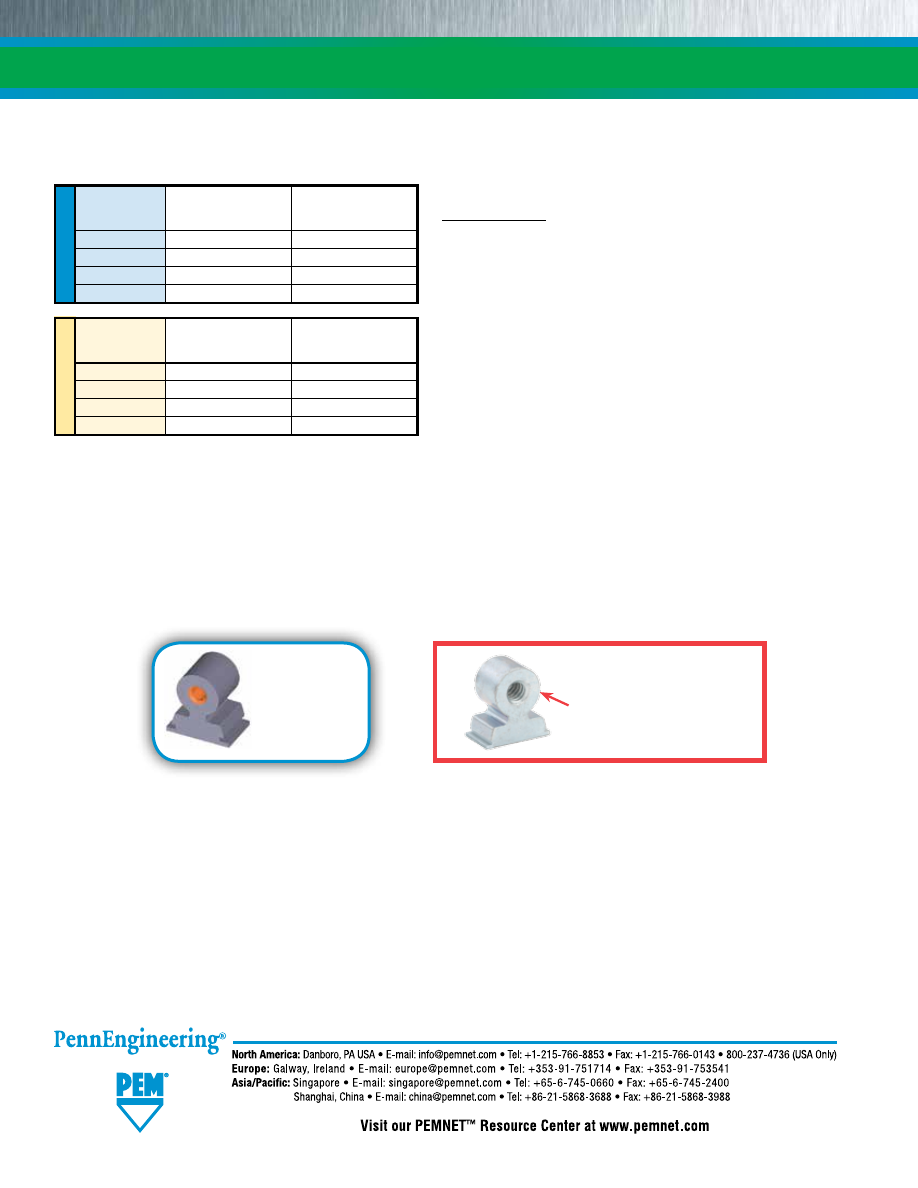

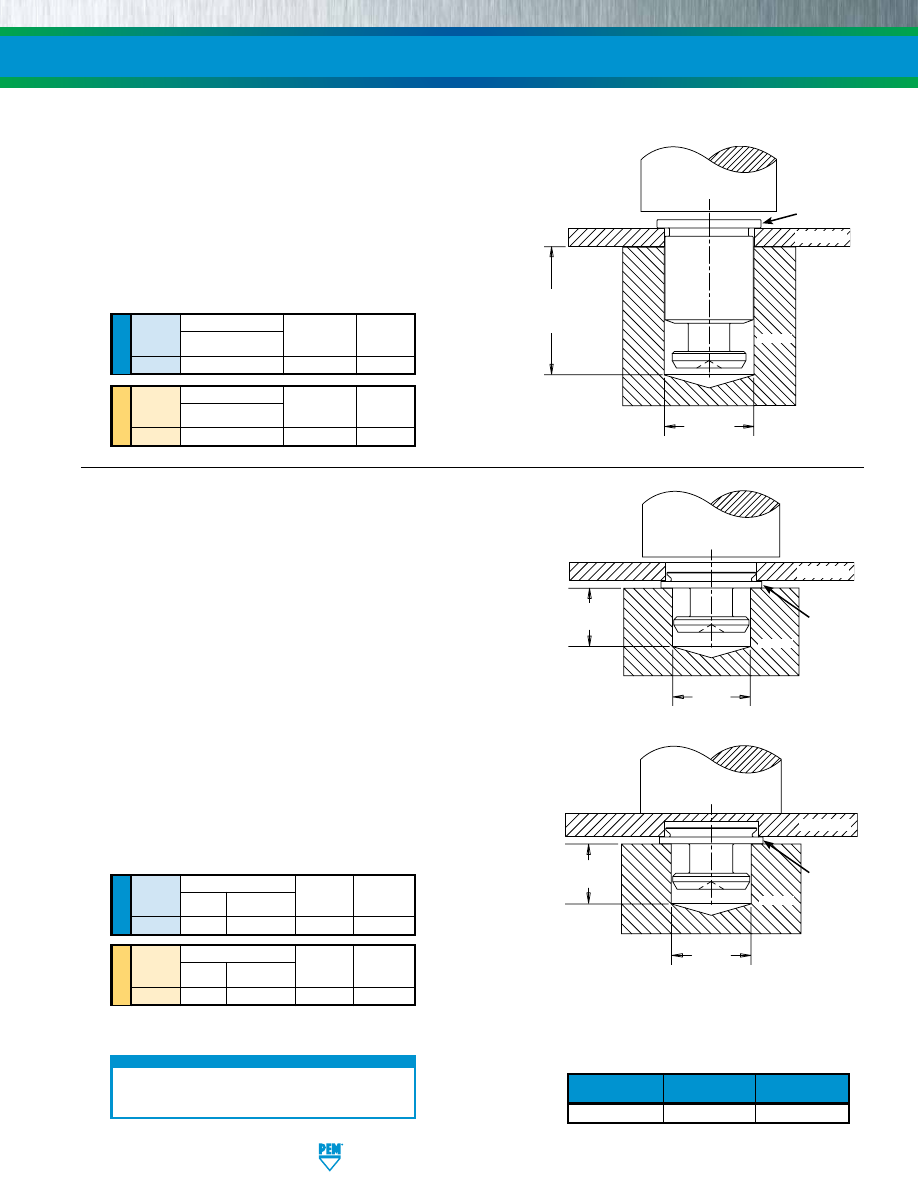

1.

Mill a round blind hole to the correct minimum depth.*

2.

Place fastener into anvil hole.

3.

Place the mounting hole over the shank of the fastener.

4.

With punch and anvil surfaces parallel, apply squeezing

force until the flange is flush with the mounting sheet.

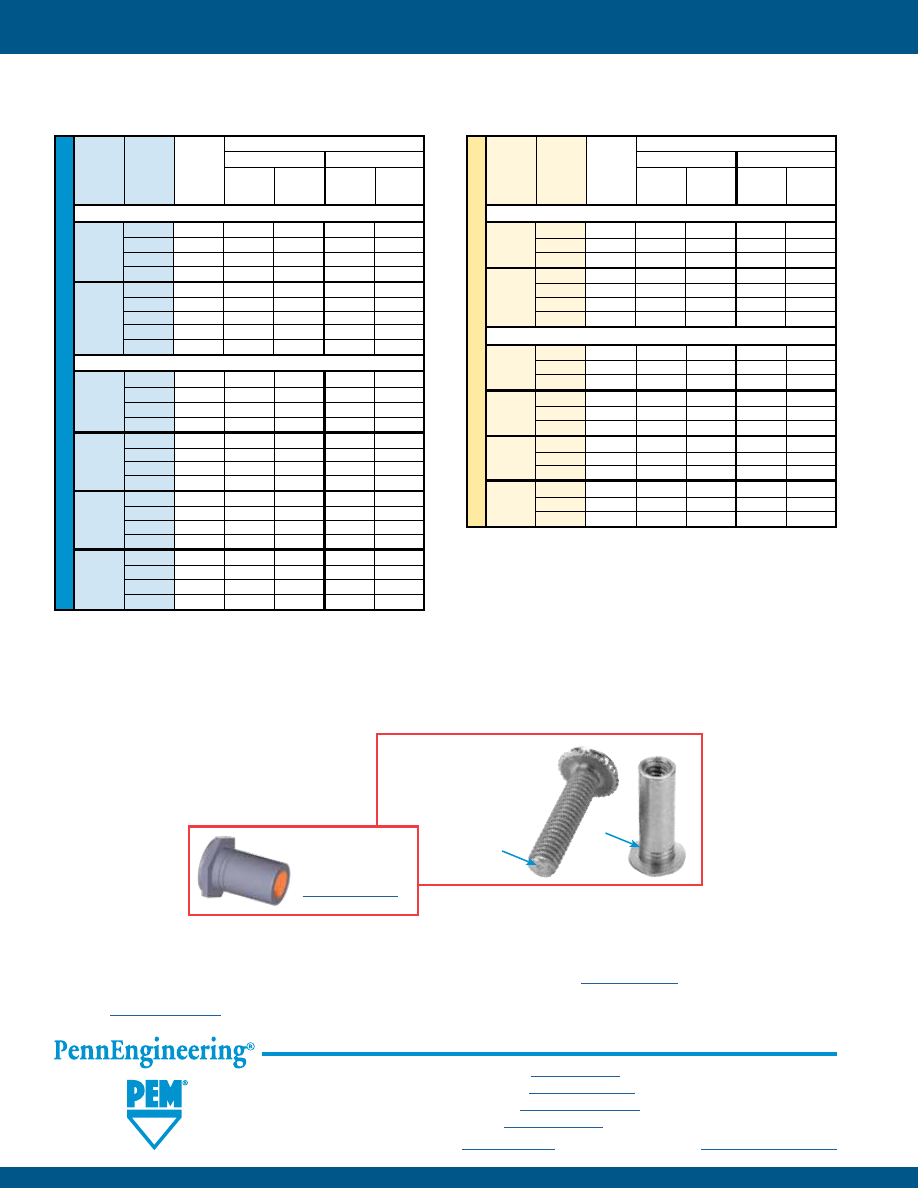

* End mills available from PennEngineering. See chart below.

CFHA, CFHC, CHC, CHA

Concealed-head studs

CSOS, CSS

Concealed-head standoffs

D

D

PUNCH

PUNCH

ANVIL

ANVIL

L + .250”/

6.35 mm

L + .250”/

6.35 mm

All dimensions are in inches.

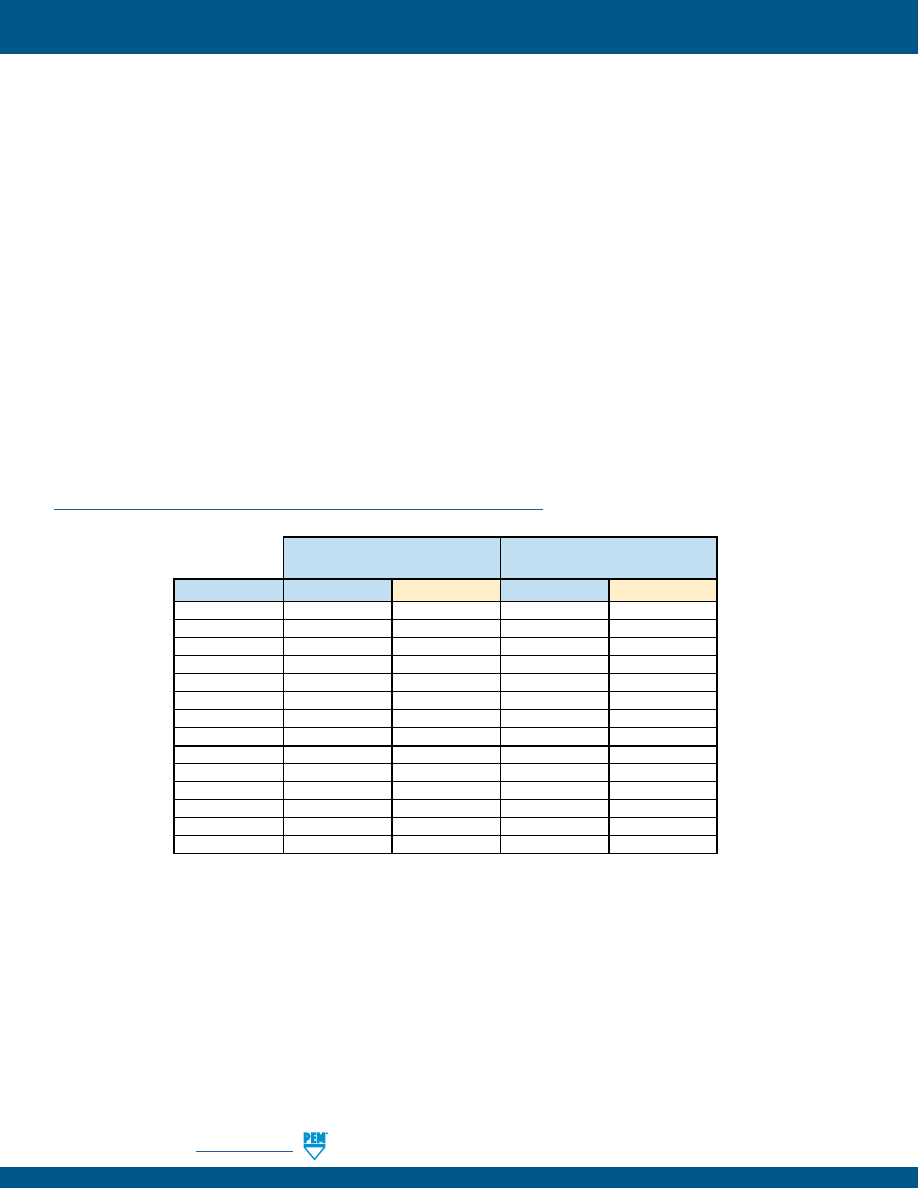

Thread

Fastener Type

Required Size

PEM

Code

End Mill

Part No.

440, M3

CFHC, CHC, CFHA, CHA Studs

.172”

CHM-172

CSOS, CSS Standoffs

.213”

CHM-213

632

CFHC, CHC, CFHA, CHA Studs

.213”

CHM-213

CSOS, CSS Standoffs

.290”

CHM-290

832, M4

CFHC, CHC, CFHA, CHA Studs

.290”

CHM-290

CSOS, CSS Standoffs

.312”

CHM-312

032, M5

CFHC, CHC, CFHA, CHA Studs

.312”

CHM-312

CSOS, CSS Standoffs

.344”

CHM-344

0420, M6

CSOS Standoffs

.390”

CHM-390

All dimensions are in millimeters.

END MILL INFORMATION

Double-ended, two-flute H.S.S. center-cutting end mills

are available from stock.

PennEngineering does not manufacture center-cutting

end mills, but we do keep a supply in stock for your

convenience.

(1) HRB - Hardness Rockwell “B” Scale. HB - Hardness Brinell.

PEMSERTER® Installation Tooling

MATERIAL AND FINISH SPECIFICATIONS

INSTALLATION

U

NIF

IE

D

Type

Thread

D

Punch Anvil

Code +.003 –.000 Part Number

Part Number

CHA / CHC / CFHA / CFHC

440

.127

975200048

970200006300

CHA / CHC / CFHA / CFHC

632

.139

975200048

970200007300

CHA / CHC / CFHA / CFHC

832

.179

975200048

970200008300

CHA / CHC / CFHA / CFHC

032

.205

975200048

970200009300

CSS / CSOS

440

.170

975200048

970200014300

CSS / CSOS

632

.218

975200048

970200015300

CSS / CSOS

832

.250

975200048

970200016300

CSS / CSOS

032

.295

975200048

970200017300

CSS / CSOS

0420

.358

975200048

970200018300

ME

TR

IC

Type

Thread

D

Punch Anvil

Code

+0.08

Part Number

Part Number

CHA / CHC / CFHA / CFHC

M3

3.4

975200048

970200229300

CHA / CHC / CFHA / CFHC

M4

4.4

975200048

970200019300

CHA / CHC / CFHA / CFHC

M5

5.4

975200048

970200020300

CSS / CSOS

M3

4.33

975200048

970200014300

CSS / CSOS

M4

6.36

975200048

970200016300

CSS / CSOS

M5

7.5

975200048

970200017300

CSS / CSOS

M6

9.13

975200048

970200018300

CONCEALED-HEAD SELF-CLINCHING STUDS AND STANDOFFS

CH-5

PennEngineering •

www.pemnet.com

INSTALLATION NOTES

•

For best results we recommend using a PEMSERTER® press for

installation of PEM self-clinching fasteners. Please check our

website for more information.

•

Visit the Animation Library on our website to view the installation

process

for select products

.

pem-html.html

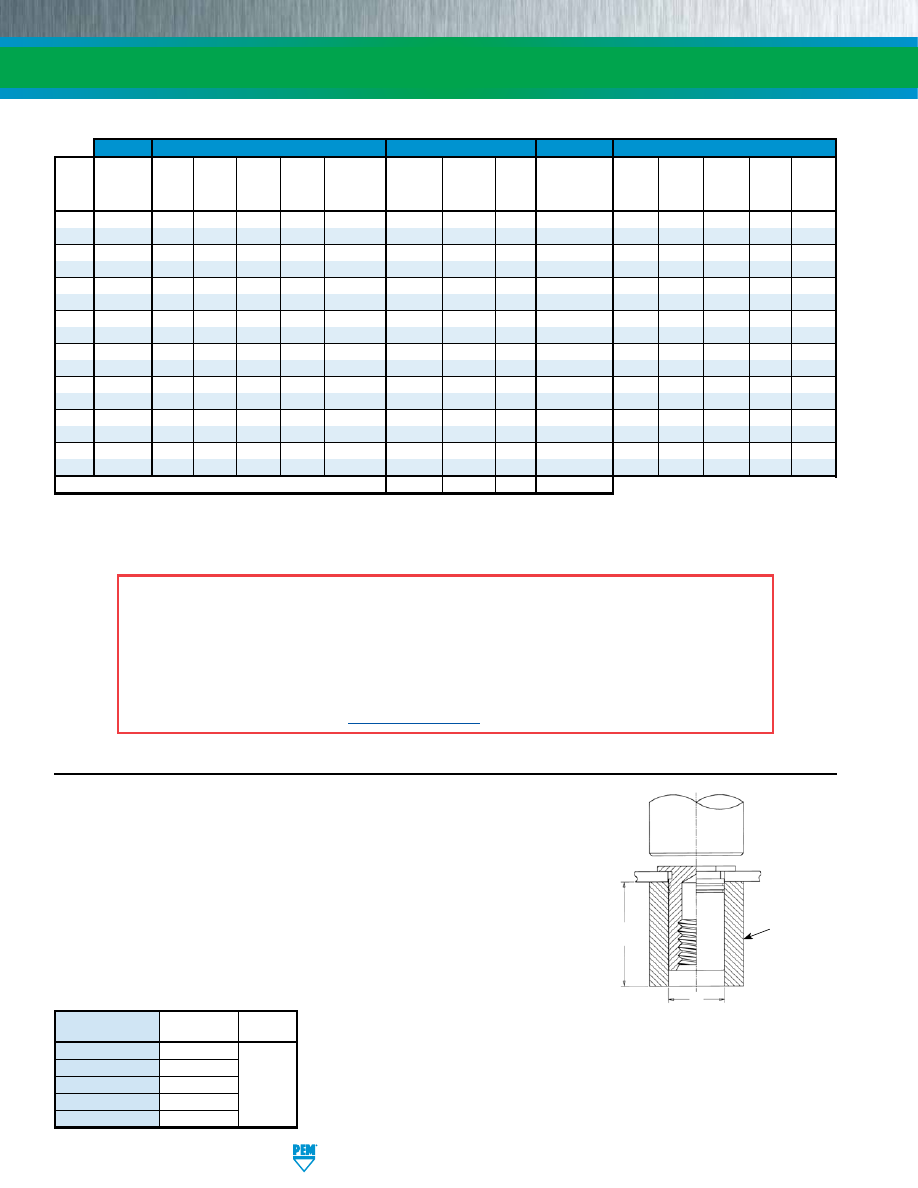

ME

TR

IC

U

NIF

IE

D

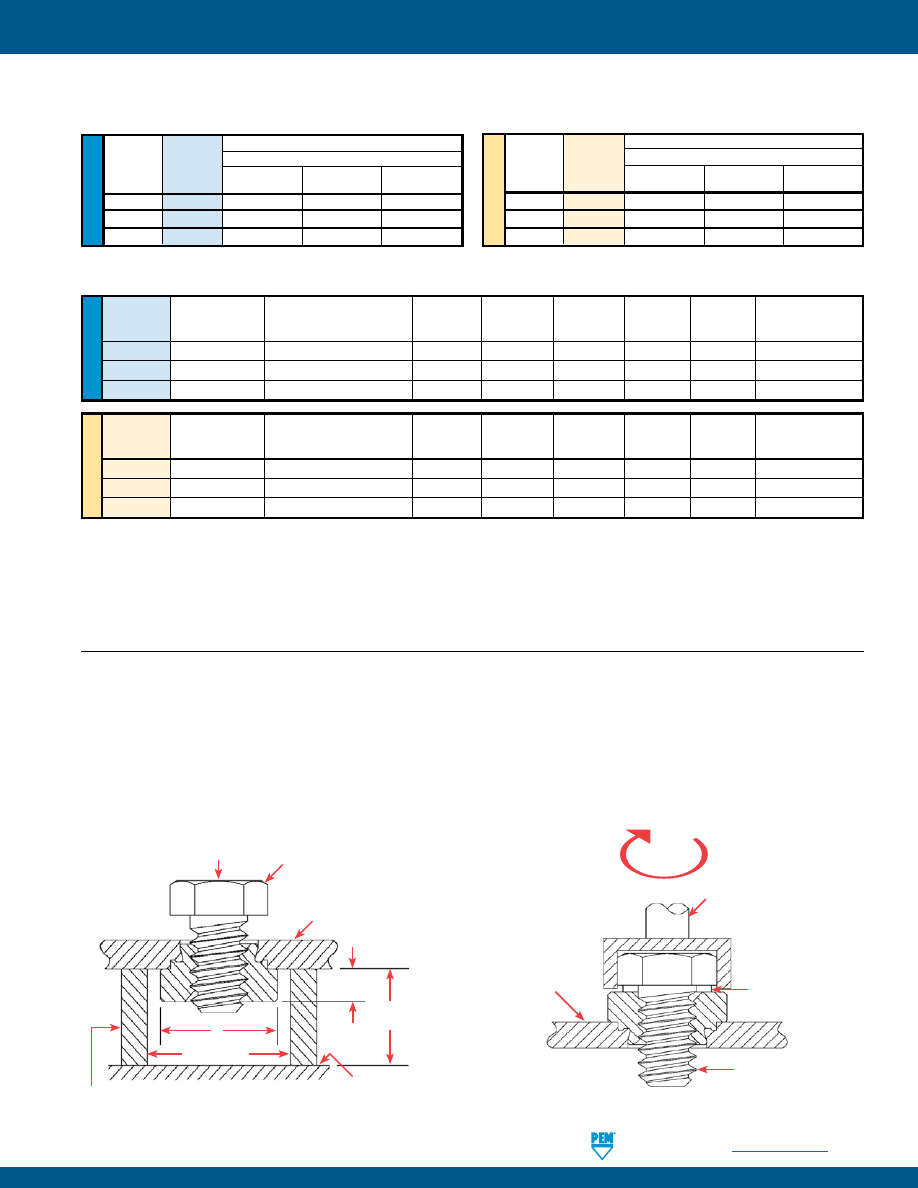

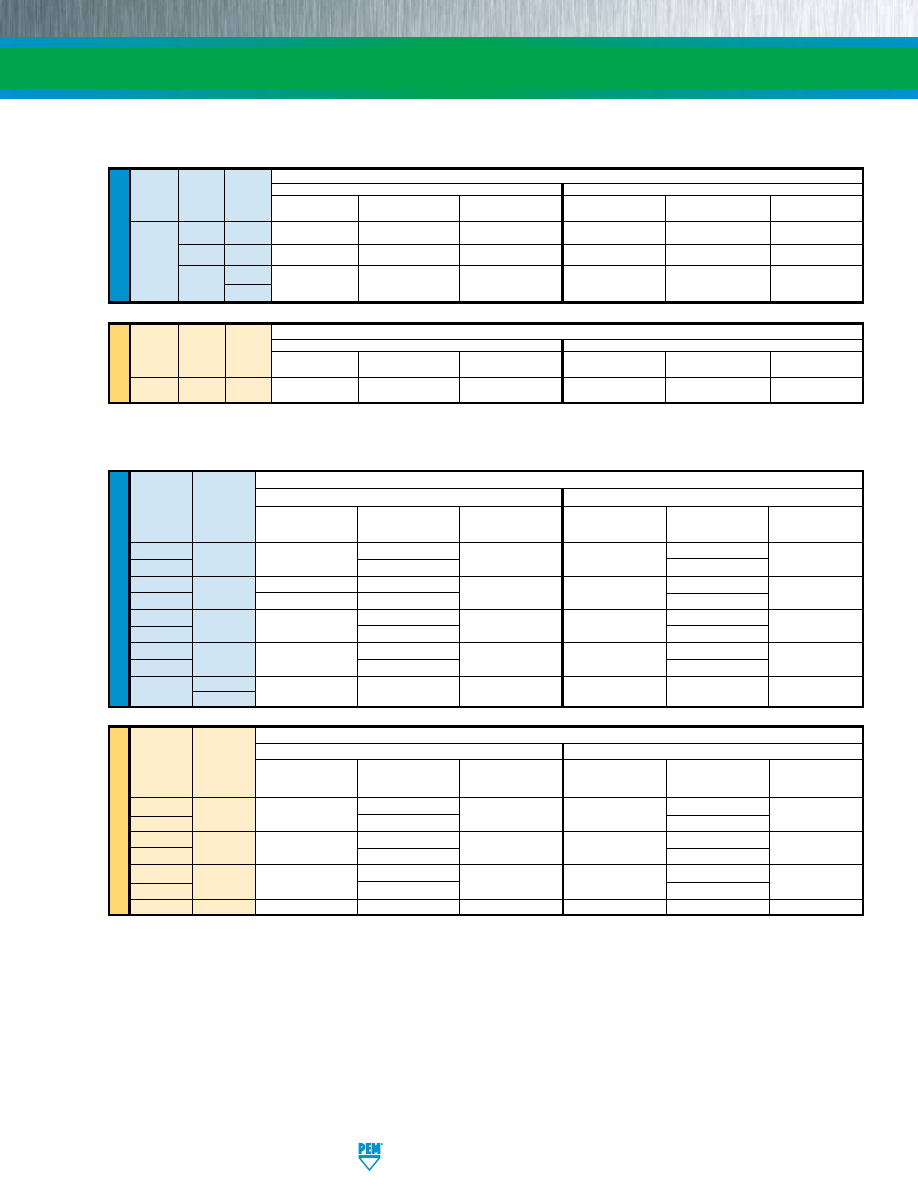

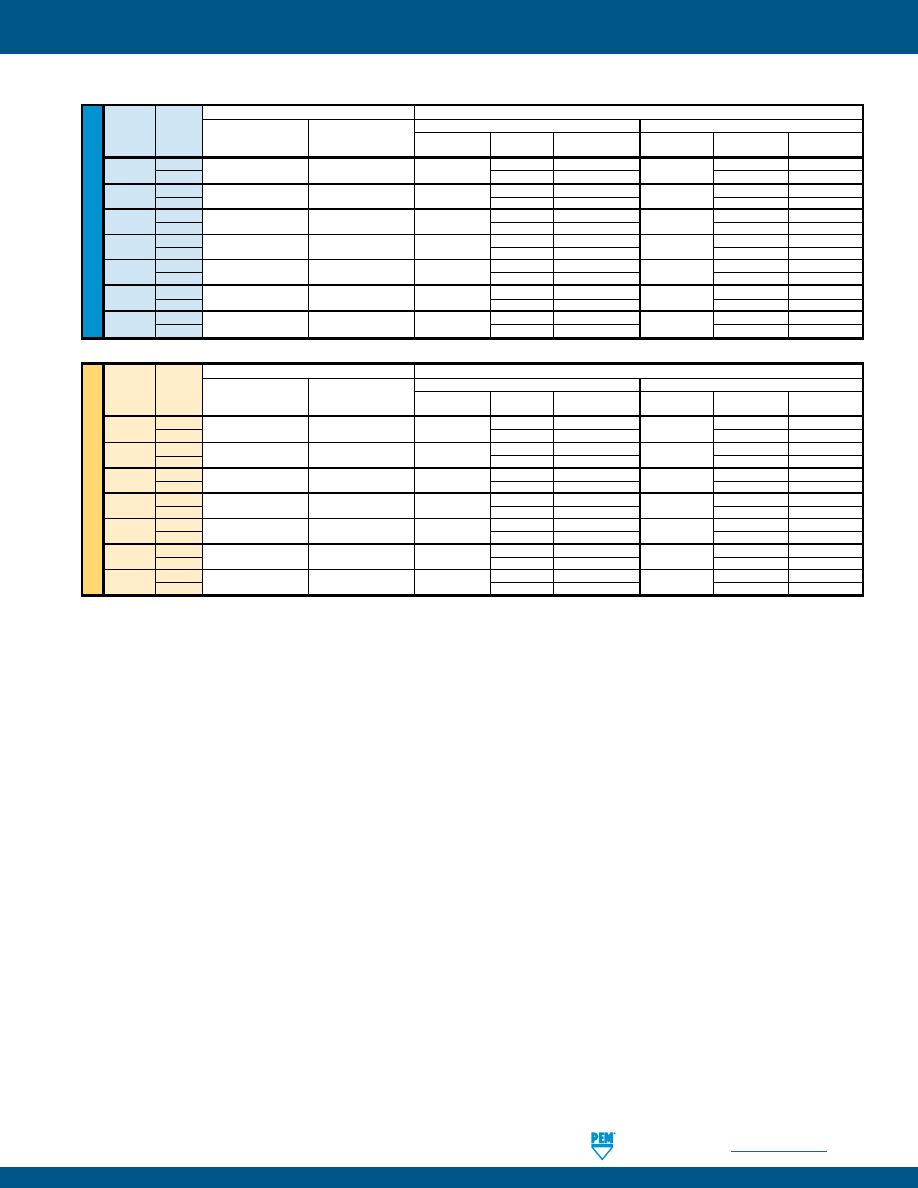

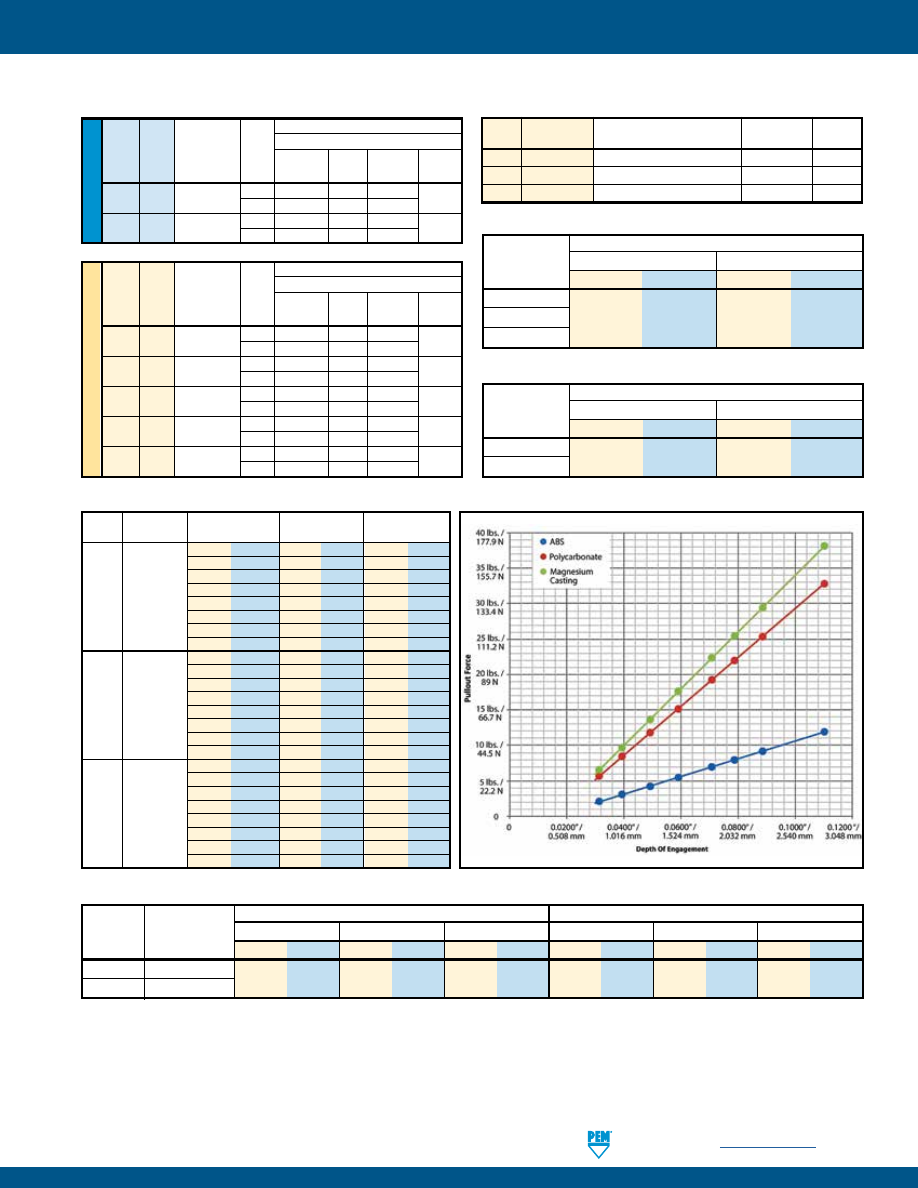

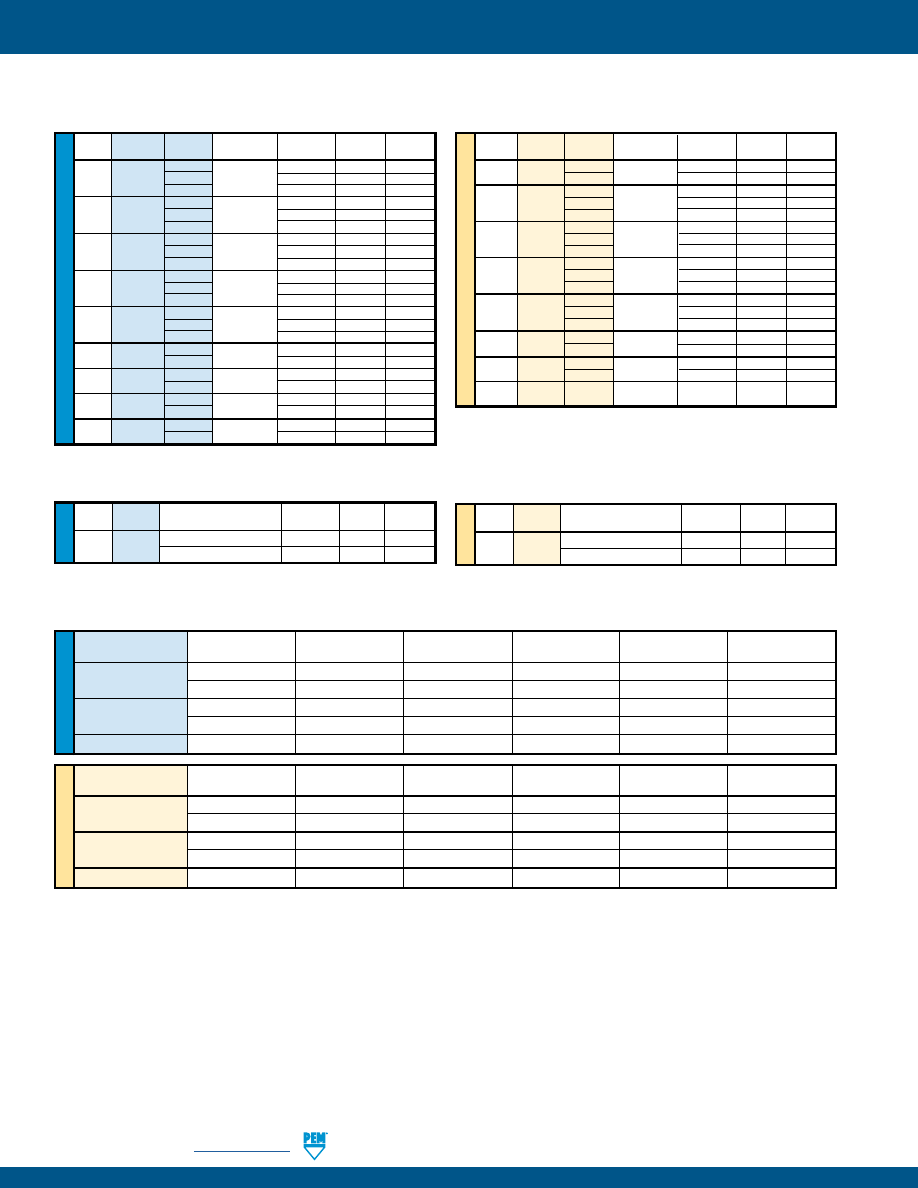

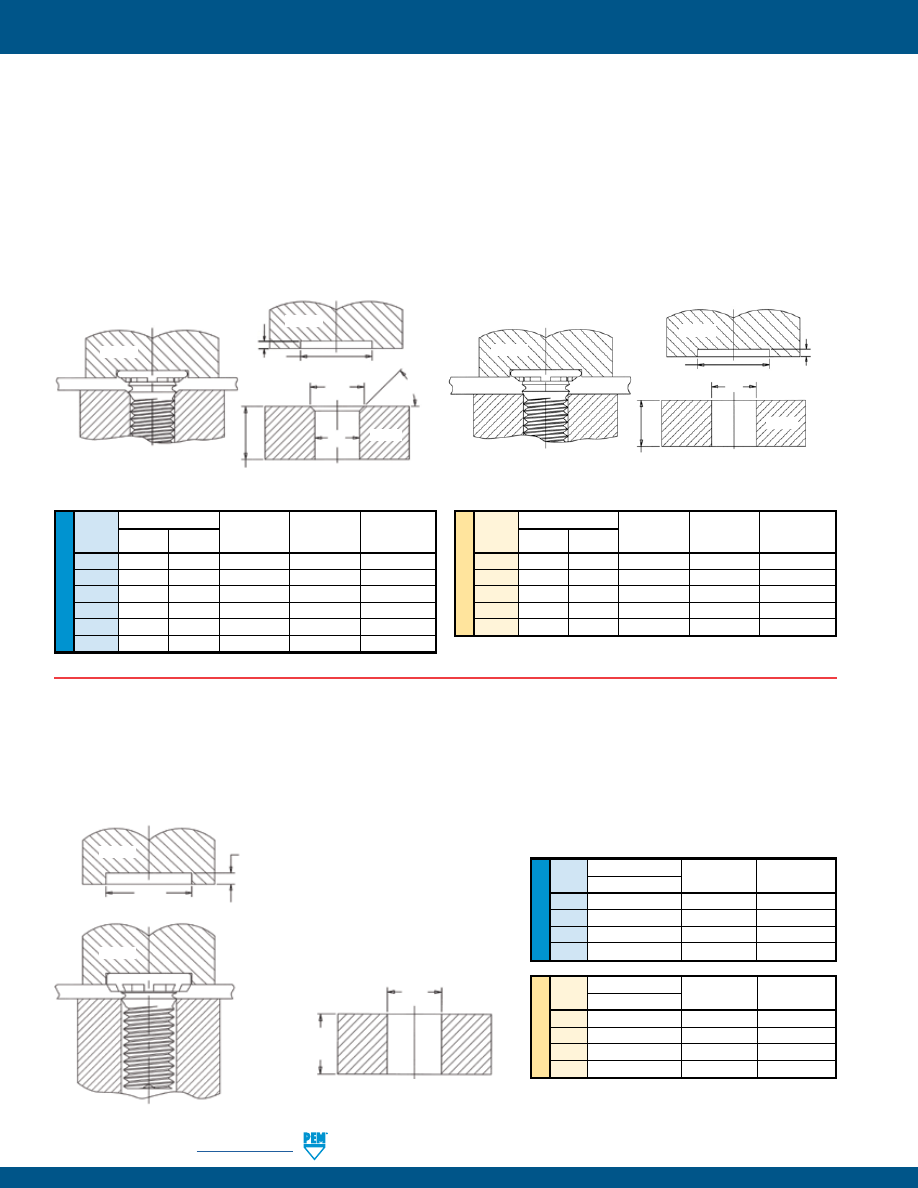

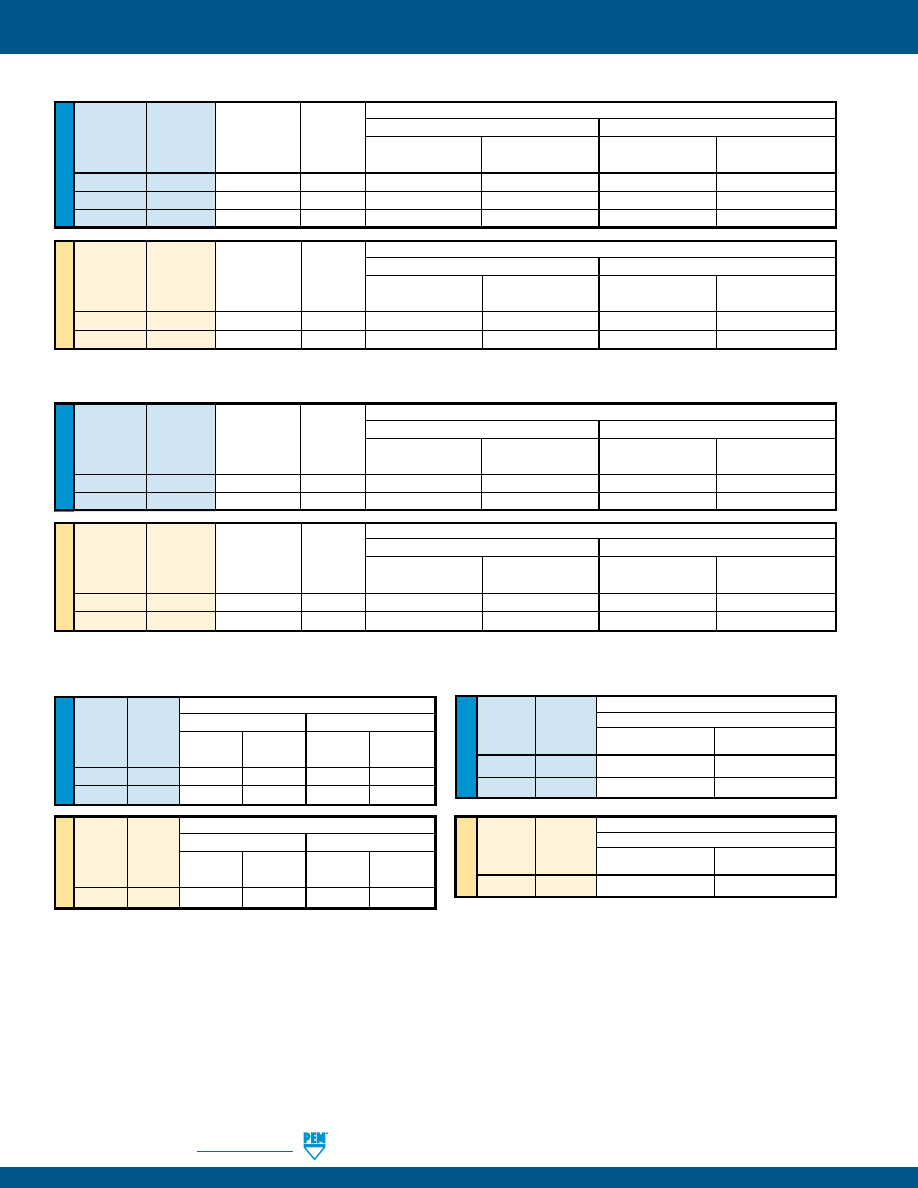

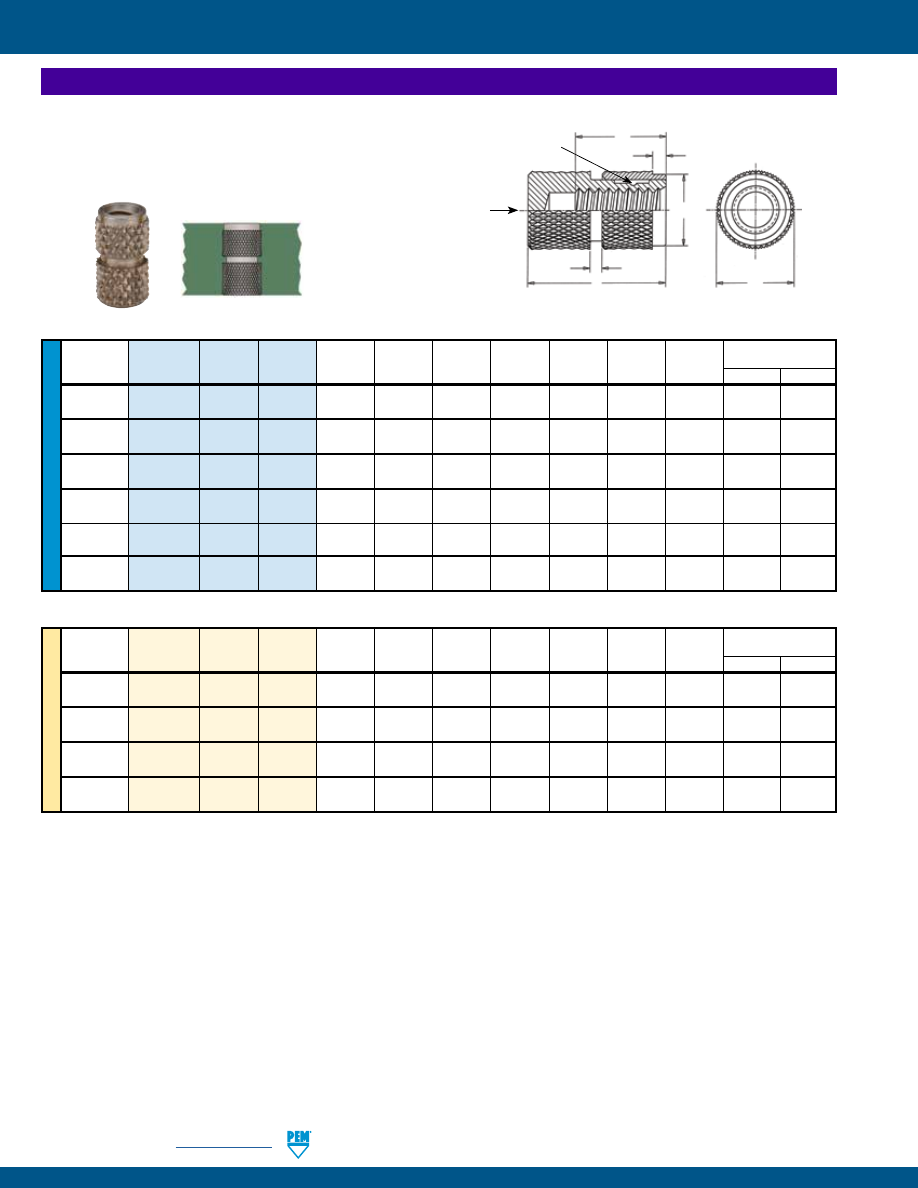

Test Sheet Material

Max.

Cold-rolled Steel

5052-H34 Aluminum

Thread Tightening

Type Code

Torque

Ref.

Installation Pullout Installation Pullout

(in. lbs.)

(lbs.) (lbs.) (lbs.) (lbs.)

Concealed-head Standoffs

440 4.75 4,000 300 2,800 200

632 8.75 4,500 350 3,000 240

CSS

832 18 4,800 400 4,000 270

032 32 5,500 450 5,000 290

440 4.75 4,300 330 2,900 220

632 8.75 5,000 360 3,200 240

CSOS 832 18 5,300 440 4,000 300

032 32 6,000 600 5,000 400

0420 64 6,500 650 5,500 430

Concealed-head Studs

440 4.75 1,800 240 1,400 130

632 8.75 2,500 260 1,800 160

CHC

832 18 4,000 270 2,800 180

032 32 5,000 290 4,000 210

440 4.75 2,000 240 1,500 200

632 8.75 2,700 350 2,500 260

CFHC

832 18 3,300 440 3,000 310

032 32 4,000 680 3,500 360

440 2.85 (2) (2) 1,400 125

632 5.4 (2) (2) 1,800 135

CHA

832 10.8 (2) (2) 2,800 145

032 19.2 (2) (2) 4,000 170

440 2.85 (2) (2) 1,500 190

632 5.4 (2) (2) 2,500 220

CFHA

832 10.8 (2) (2) 3,000 240

032 19.2 (2) (2) 3,500 300

Test Sheet Material

Max.

Cold-rolled steel

5052-H34 Aluminum

Thread Tightening

Type Code

Torque

Ref.

Installation Pullout Installation Pullout

(N•m)

(kN) (N) (kN) (N)

Concealed-head Standoffs

M3 0.55 17.8 1330 12.5 890

CSS M4 2 21.3 1775 17.8 1200

M5 3.6 24.5 2000 22.2 1290

M3 .55 19.2 1465 12.9 975

CSOS

M4 2 23.6 1955 17.8 1335

M5 3.6 26.7 2665 22.2 1775

M6 7.2 28.9 2860 24.4 1915

Concealed-head Studs

M3 0.55 8 1065 6.2 575

CHC M4 2 17.8 1200 12.5 800

M5 3.6 22.2 1290 17.8 930

M3 0.55 8.9 1065 6.7 890

CFHC M4 2 14.7 1955 13.3 1375

M5 3.6 17.8 3020 15.6 1600

M3 0.3 (2) (2) 6.2 555

CHA M4 1.2 (2) (2) 12.5 645

M5 2.16 (2) (2) 17.8 755

M3 0.3 (2) (2) 6.7 845

CFHA M4 1.2 (2) (2) 13.3 1065

M5 2.16 (2) (2) 15.6 1330

(1) Published installation forces are for general reference. Actual set-up and confirmation of complete installation should be made by observing

proper seating of fastener as described in the installation steps. Other performance values reported are averages when all proper

installation parameters and procedures are followed. Variations in mounting hole size, sheet material, and installation procedure may affect

performance. Performance testing this product in your application is recommended. We will be happy to provide technical assistance and/

or samples for this purpose.

(2) Not recommended.

PERFORMANCE DATA

(1)

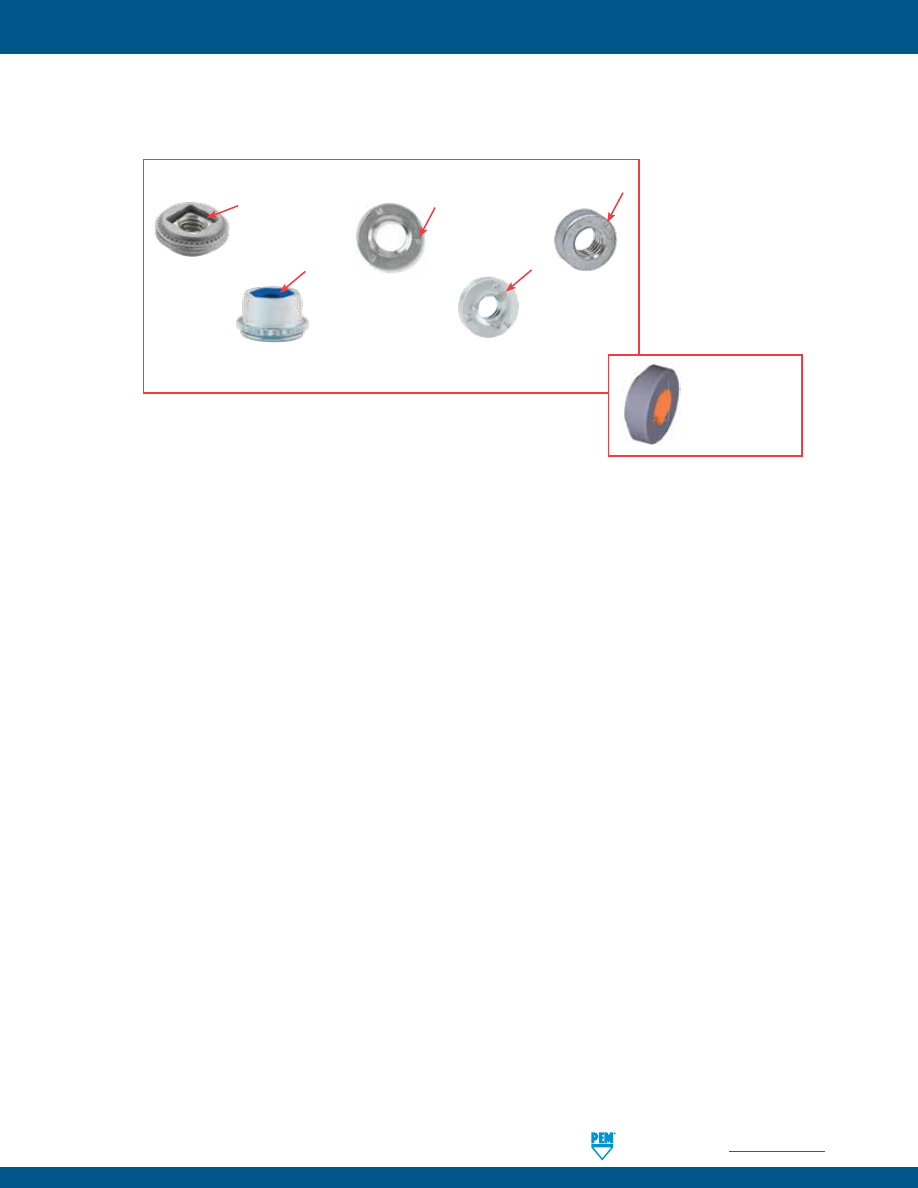

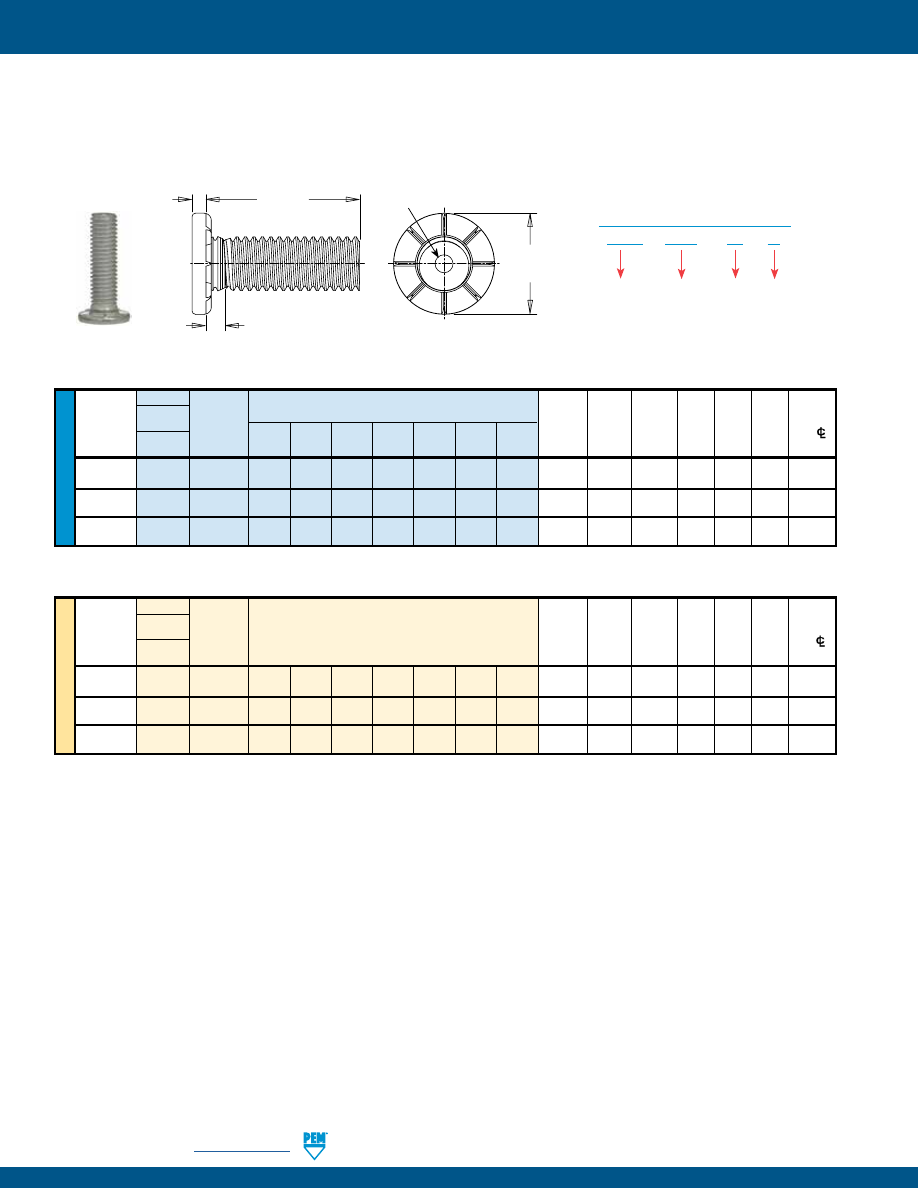

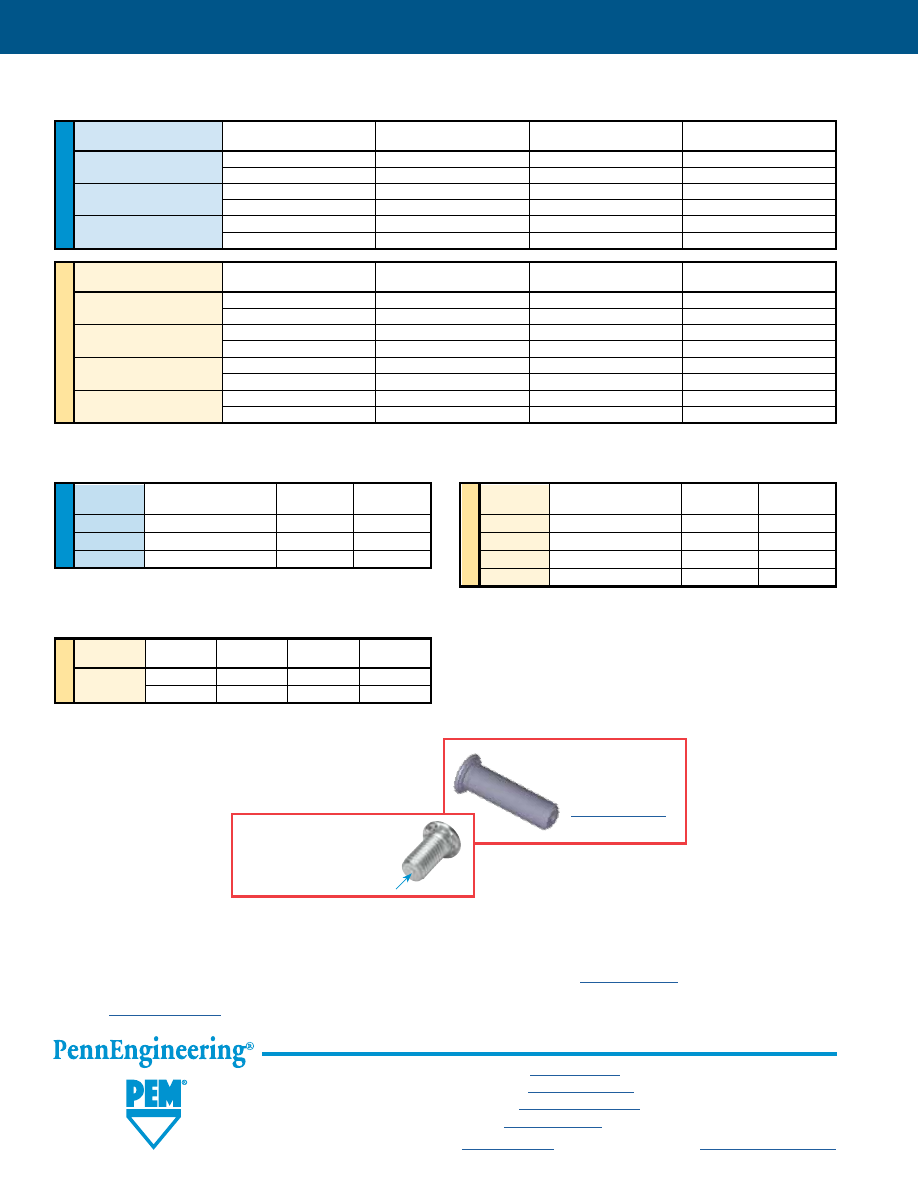

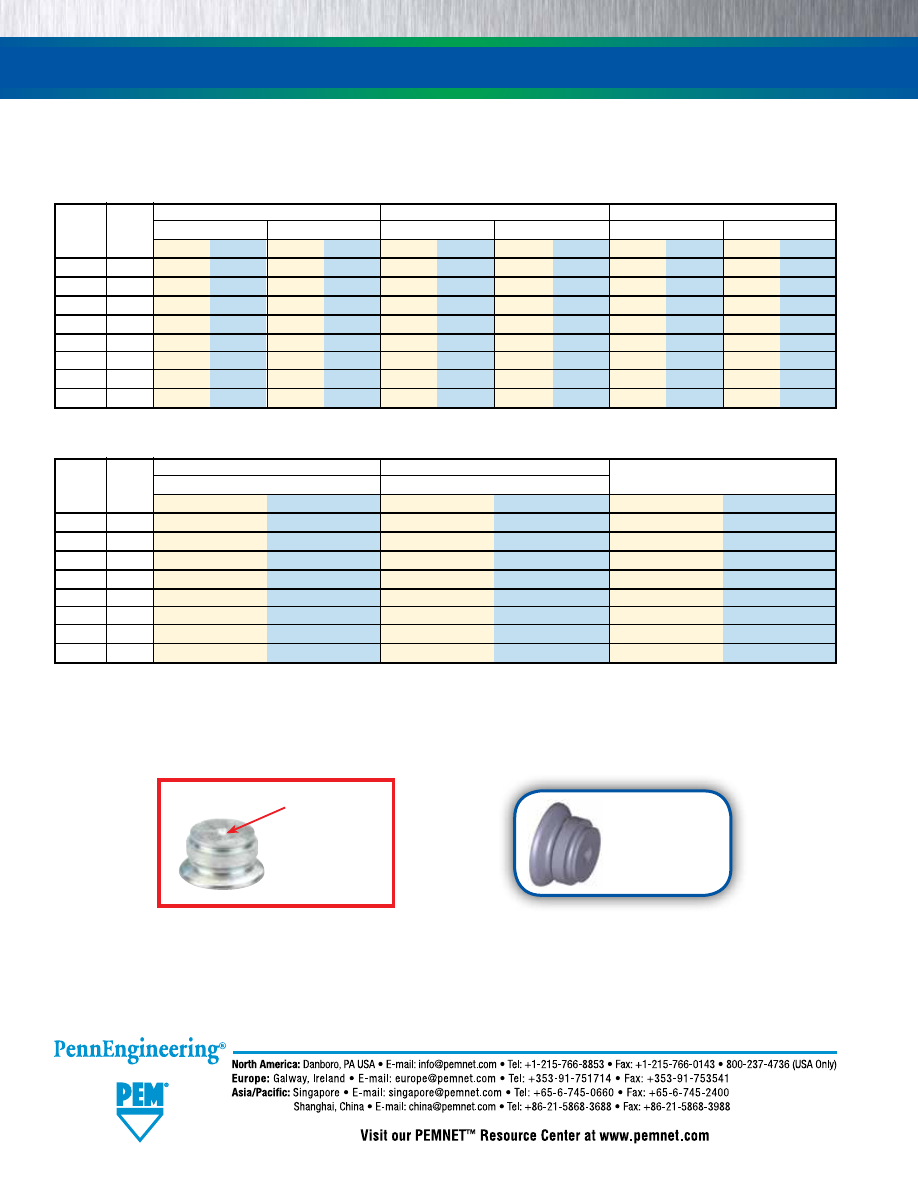

Look for the PEM® dimple

trademark on studs and

the PEM® “two groove”

trademark on standoffs.

CONCEALED-HEAD SELF-CLINCHING STUDS AND STANDOFFS

All PEM® products meet our stringent quality standards. If you require additional industry or other specific

quality certifications

, special procedures and/or part

numbers are required. Please contact your local sales office or representative for further information.

Regulatory

compliance information

is available in Technical Support section of our website. Specifications subject to change without notice. See our website for the

most current version of this bulletin.

North America:

Danboro, Pennsylvania USA

•

E-mail:

info@pemnet.com

•

Tel: +1-215-766-8853

•

800-237-4736 (USA)

Europe:

Galway, Ireland

•

E-mail:

europe@pemnet.com

•

Tel: +353-91-751714

Asia/Pacific:

Singapore

•

E-mail:

singapore@pemnet.com

•

Tel: +65-6-745-0660

Shanghai, China

•

E-mail:

china@pemnet.com

•

Tel: +86-21-5868-3688

Visit our PEMNET™ Resource Center at

www.pemnet.com

•

Technical support e-mail:

techsupport@pemnet.com

CH-6

Fastener drawings

and models

are available at

www.pemnet.com

pem-html.html

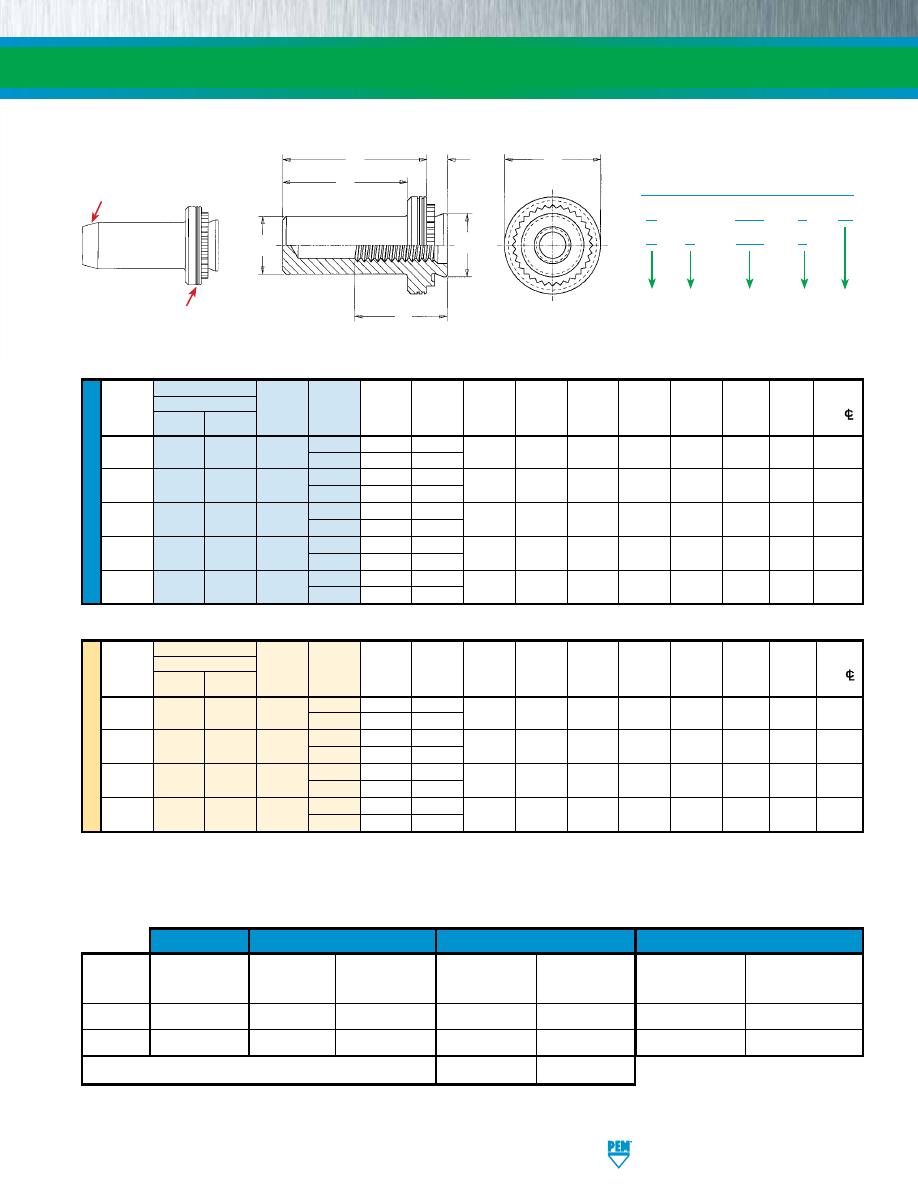

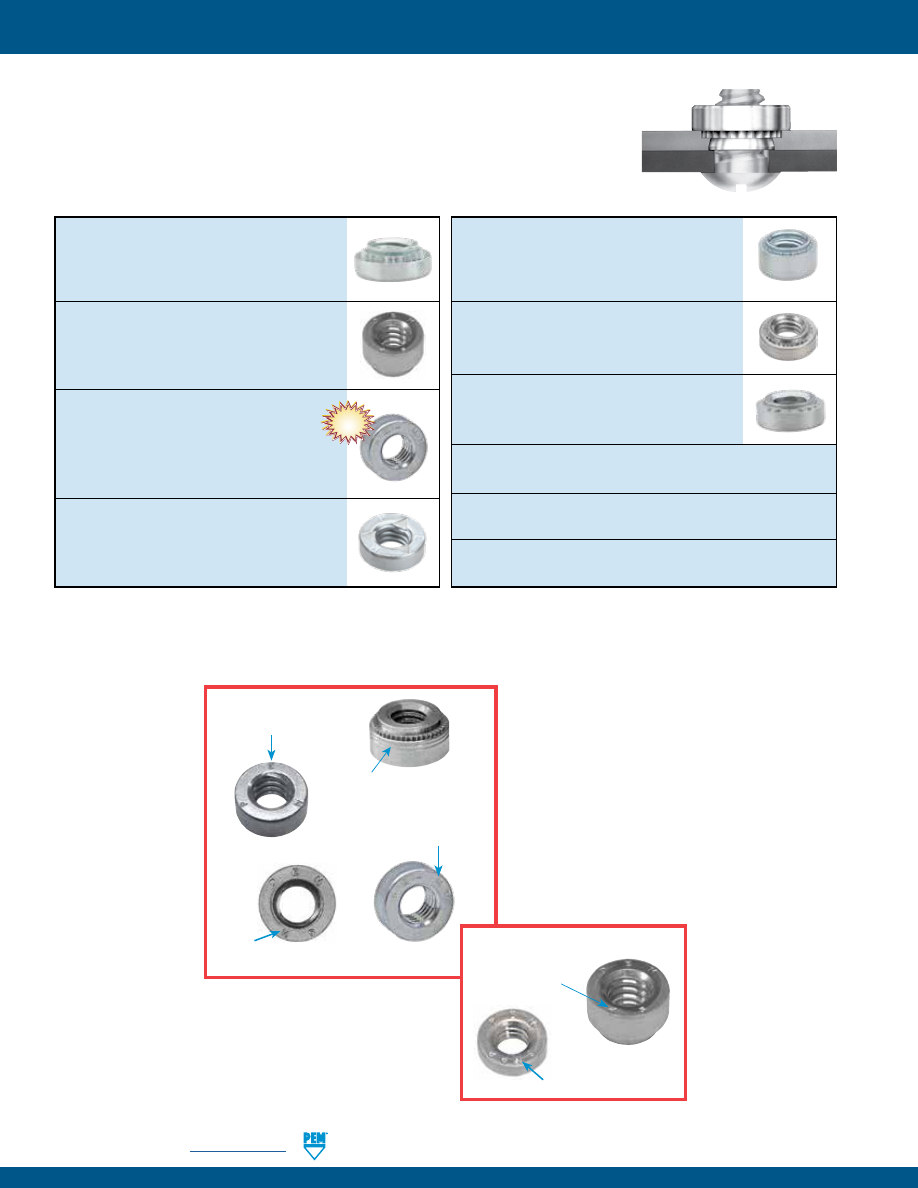

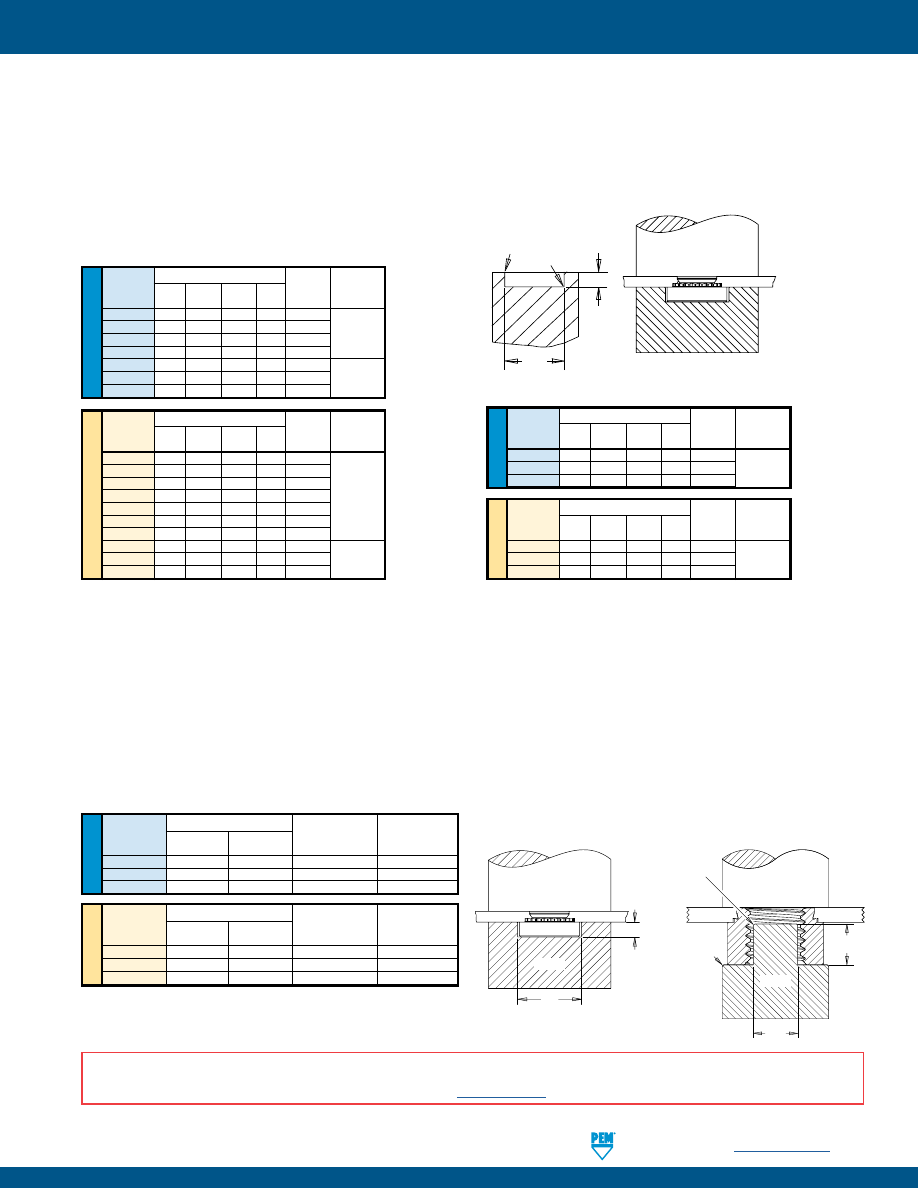

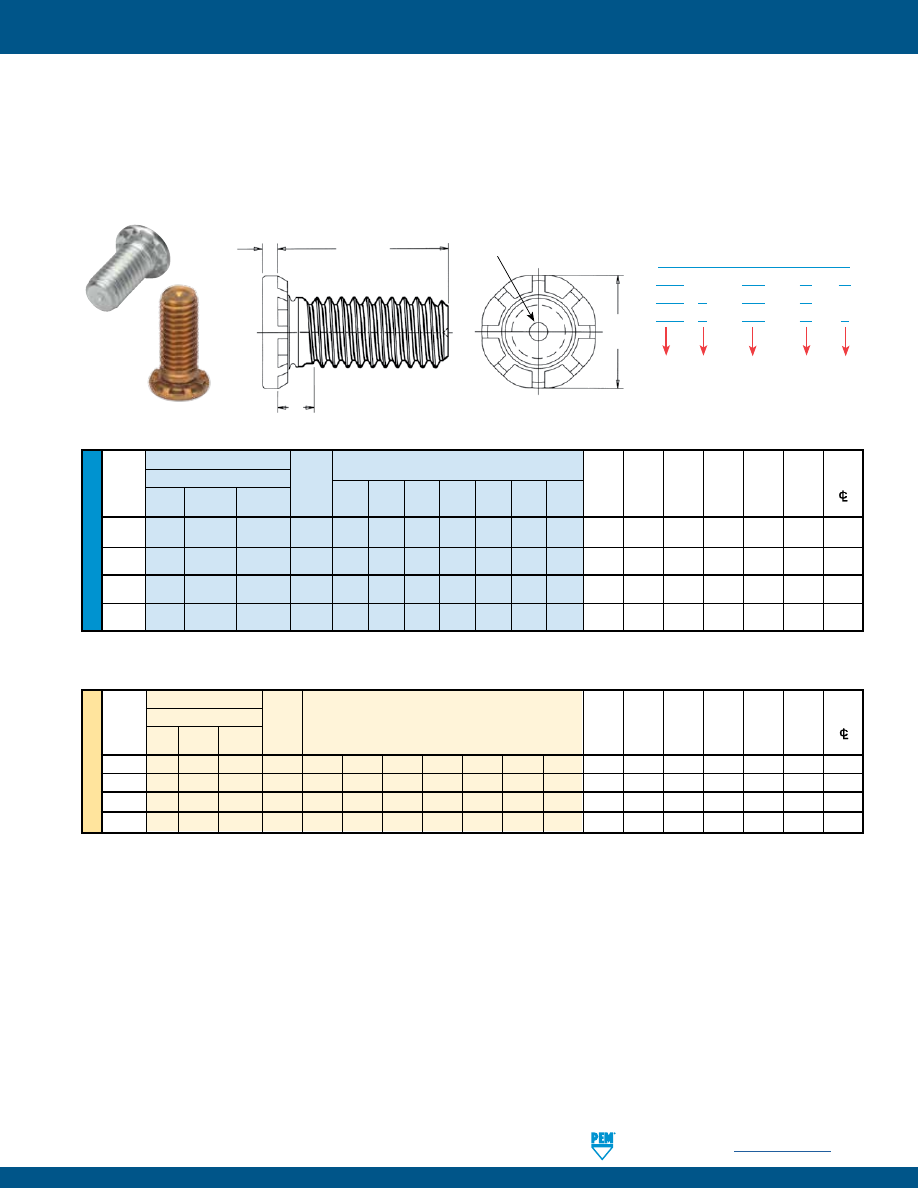

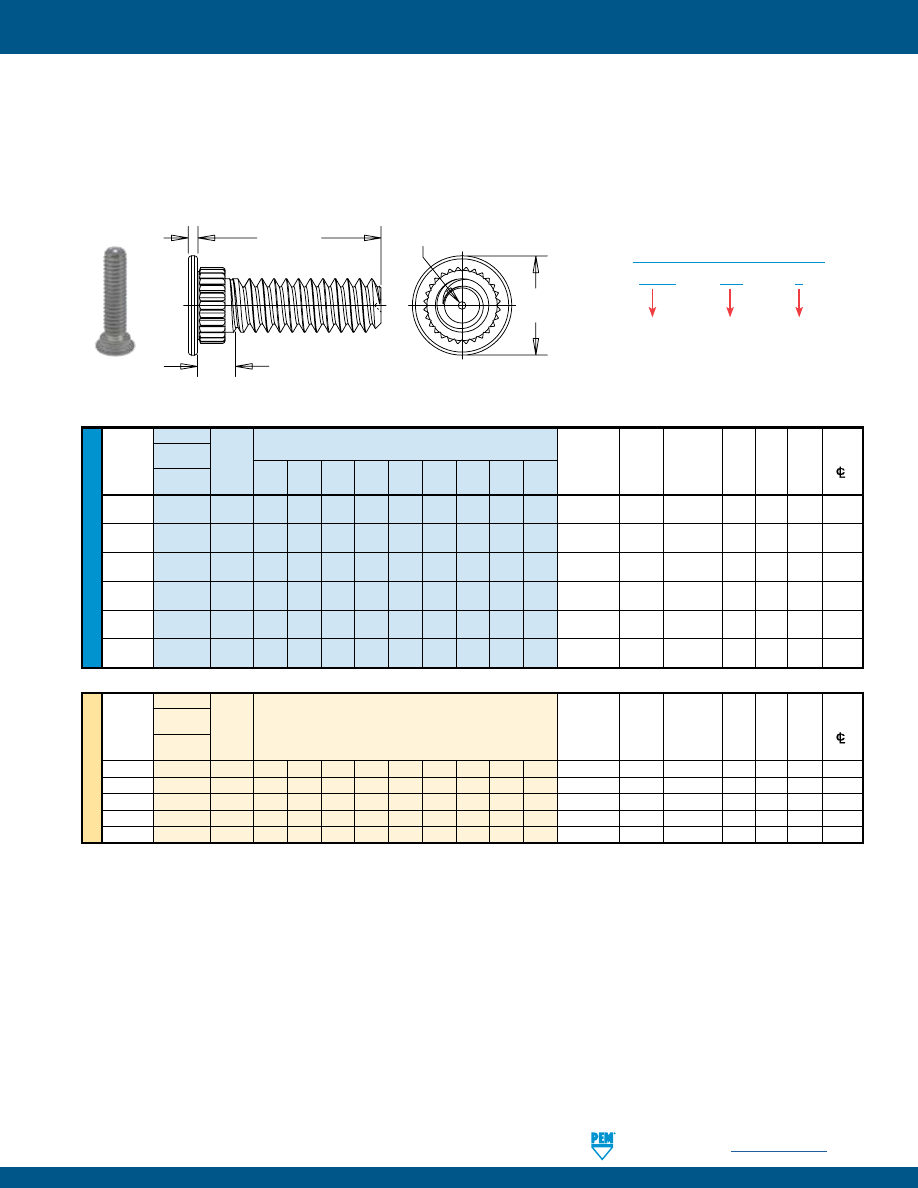

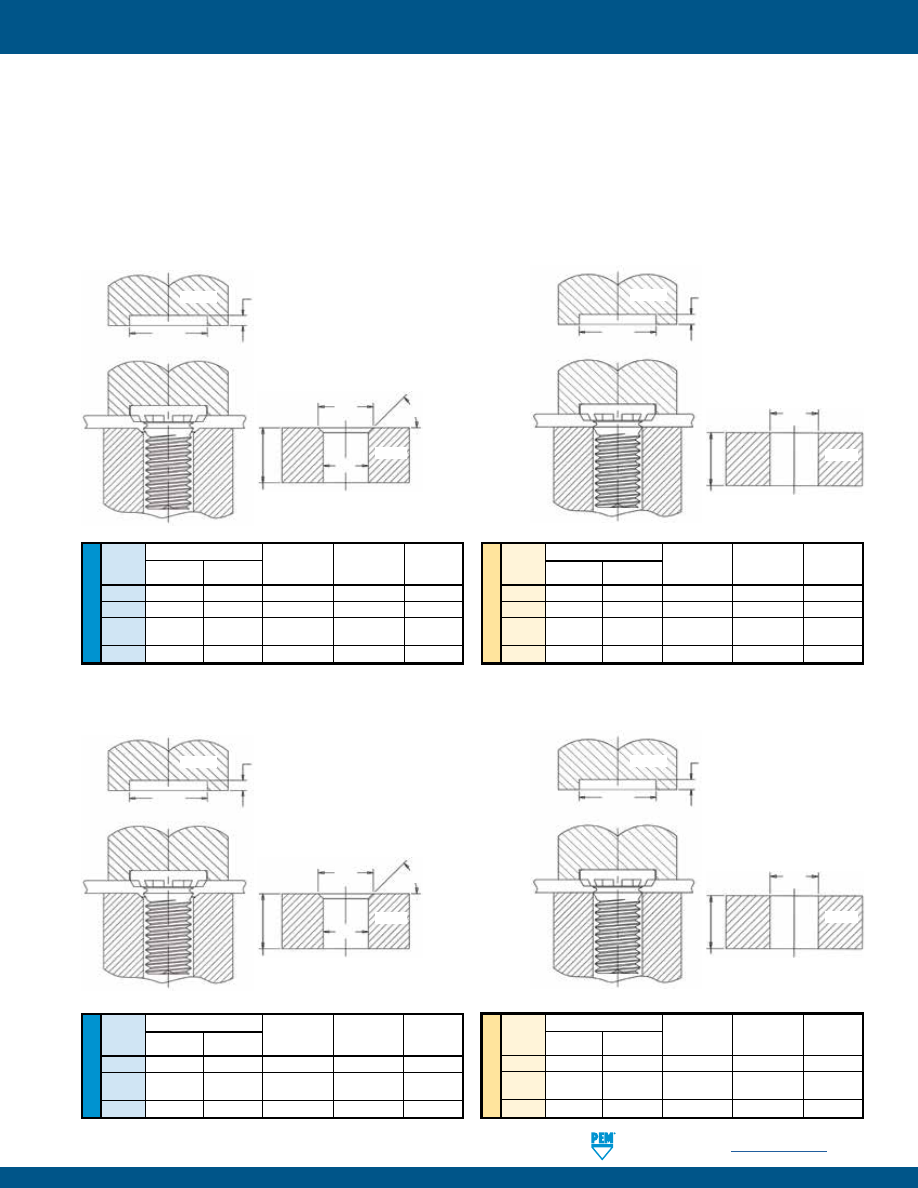

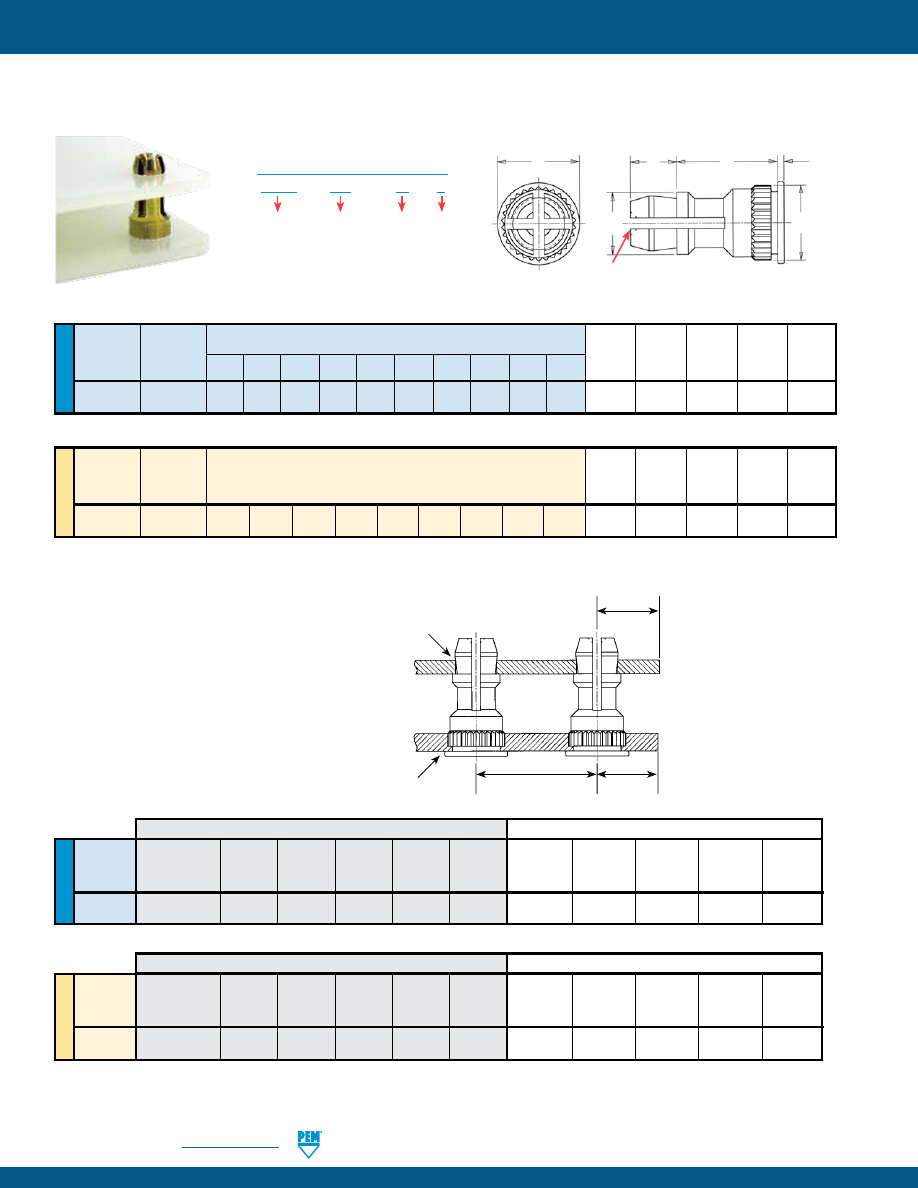

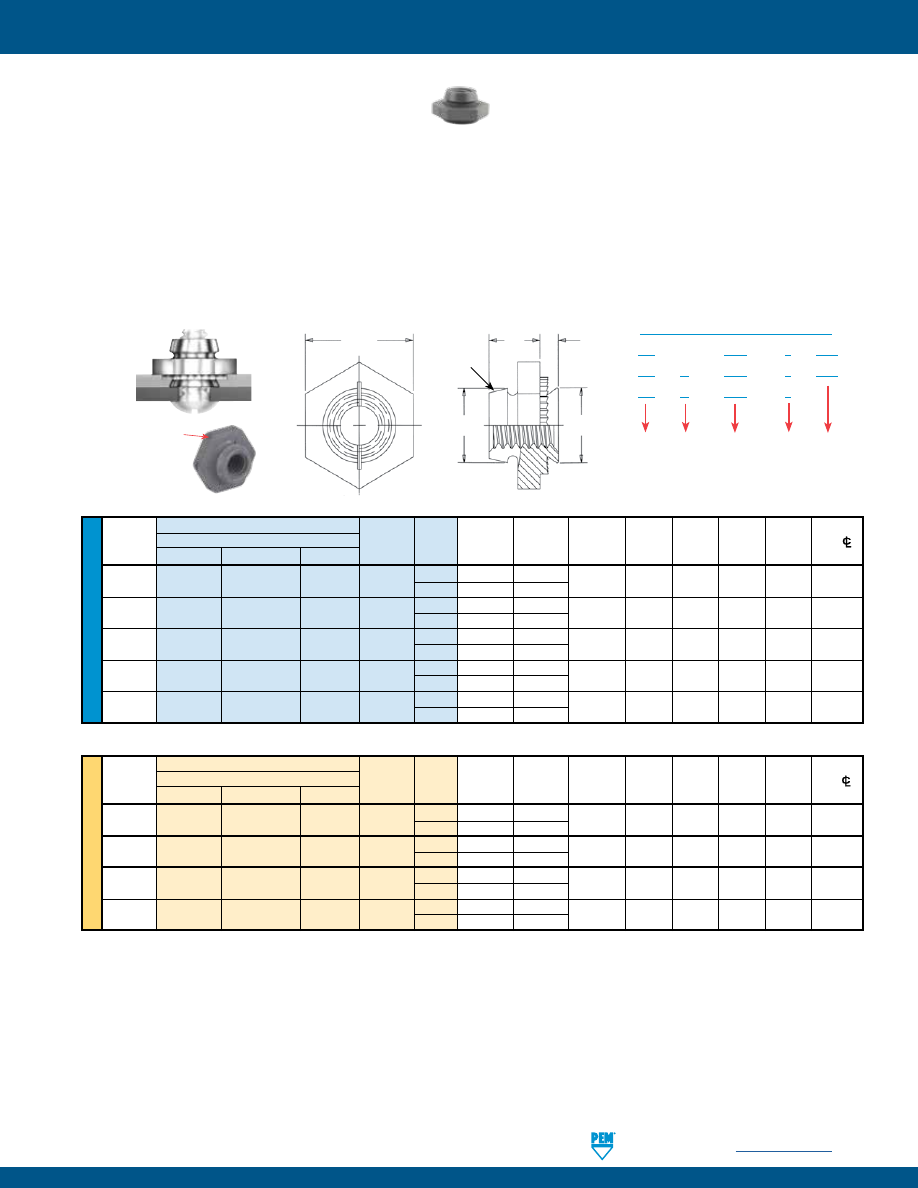

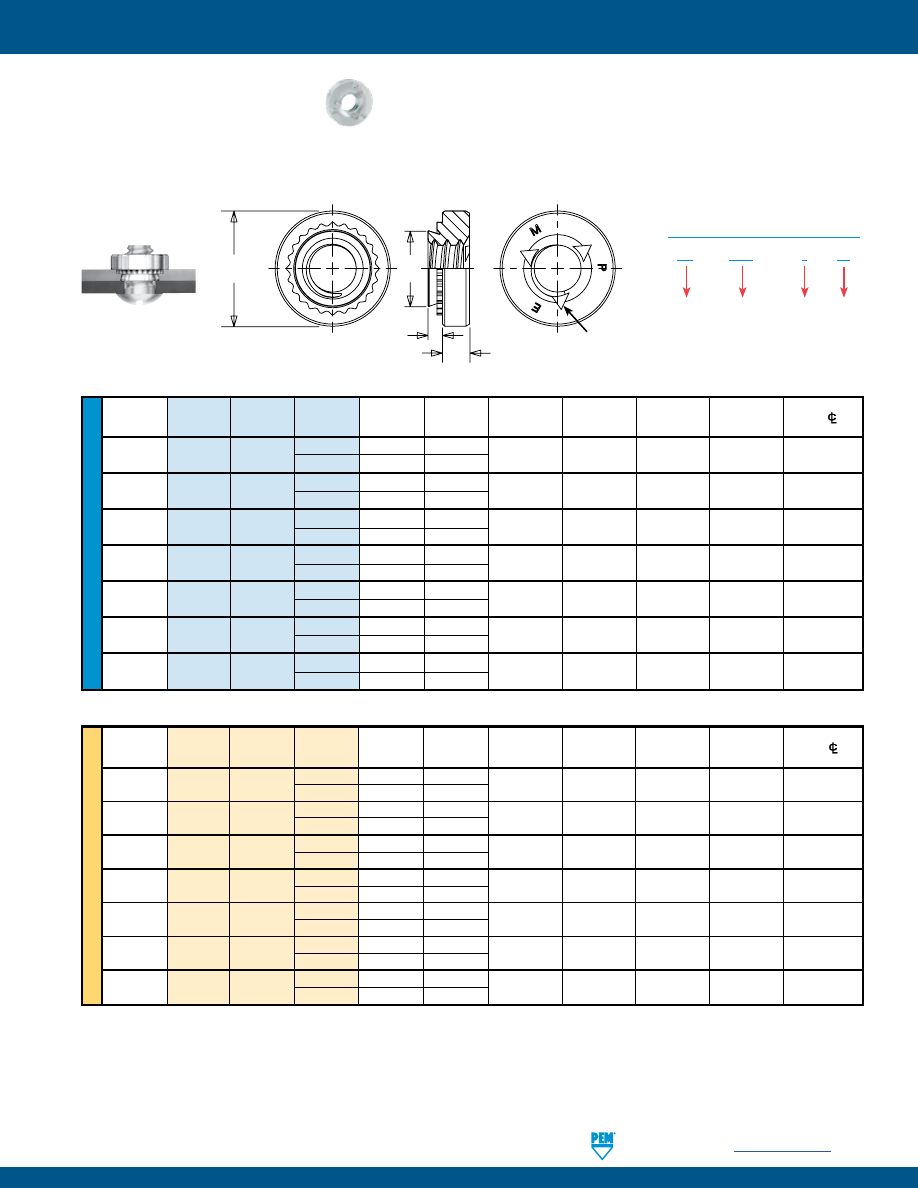

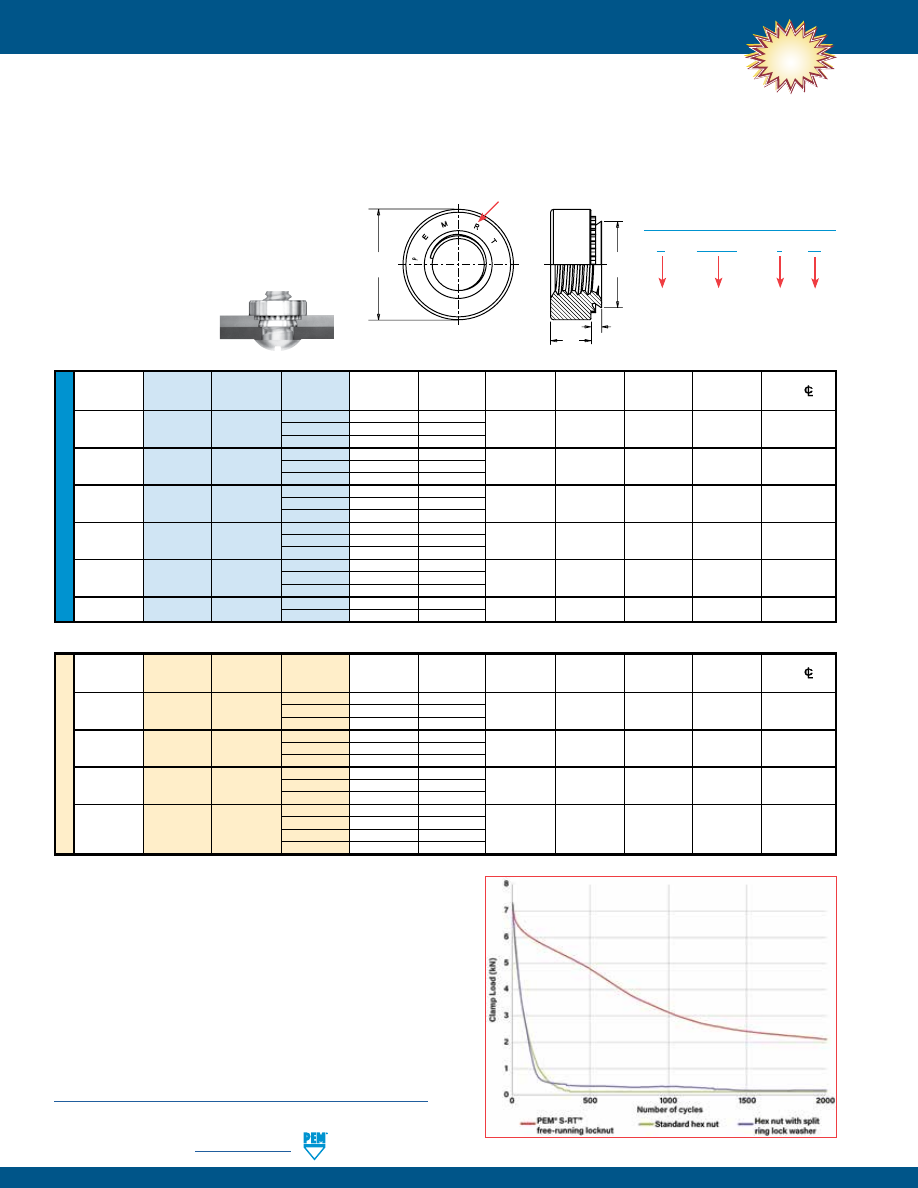

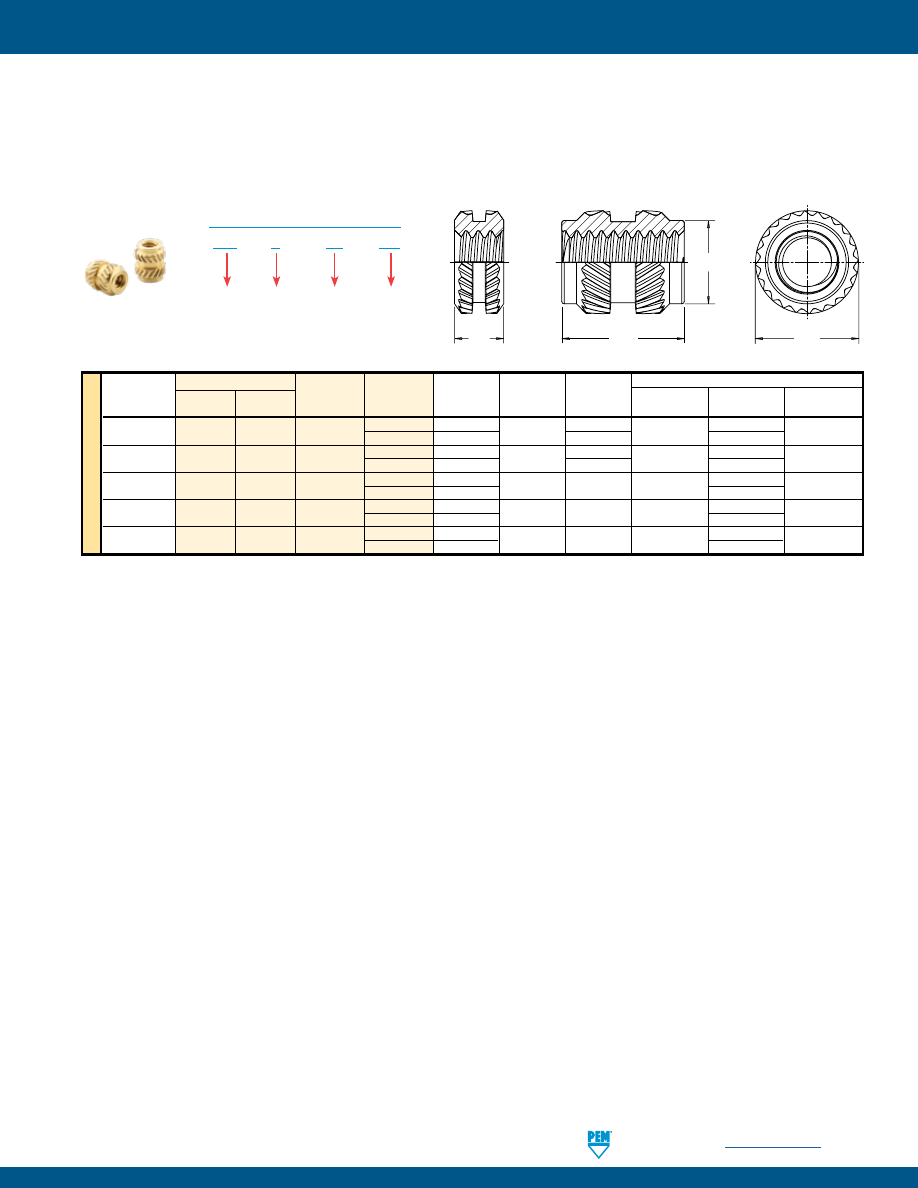

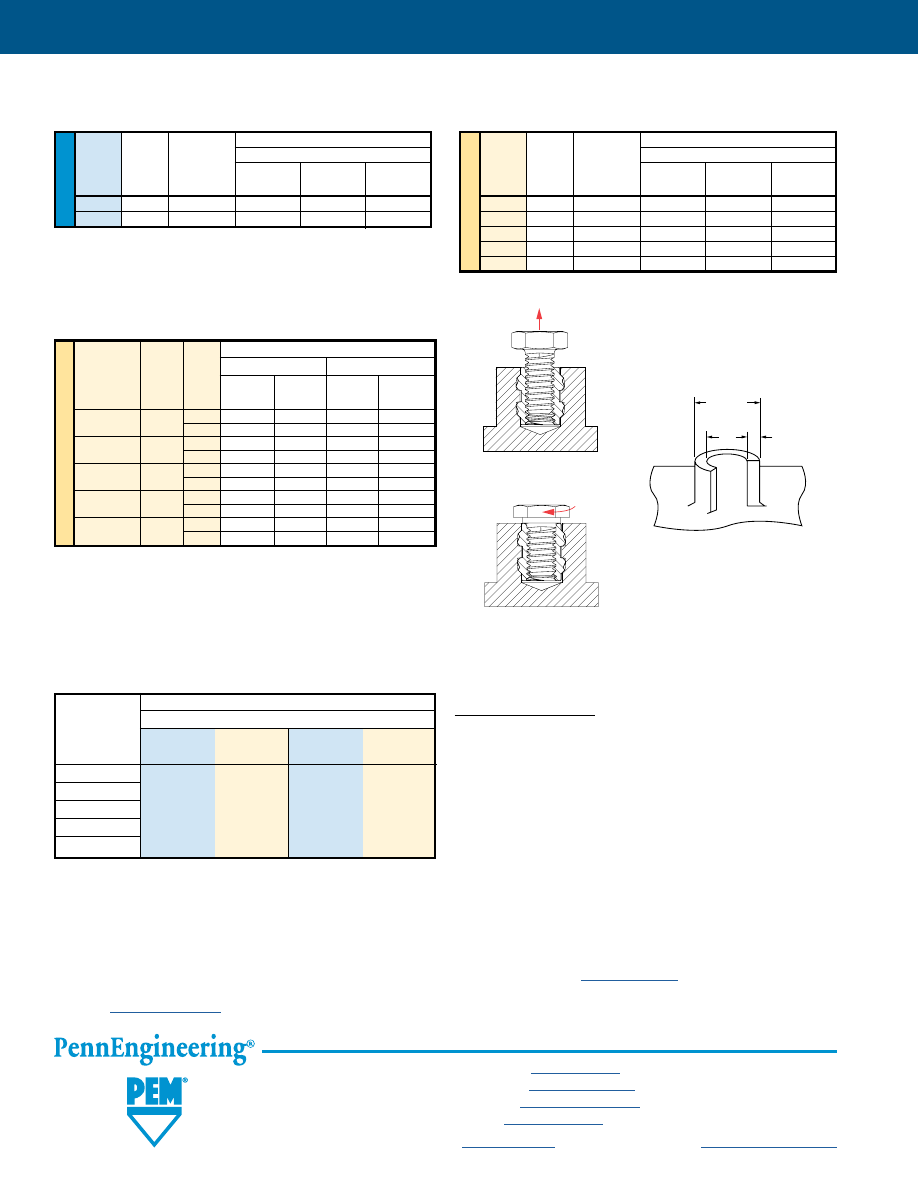

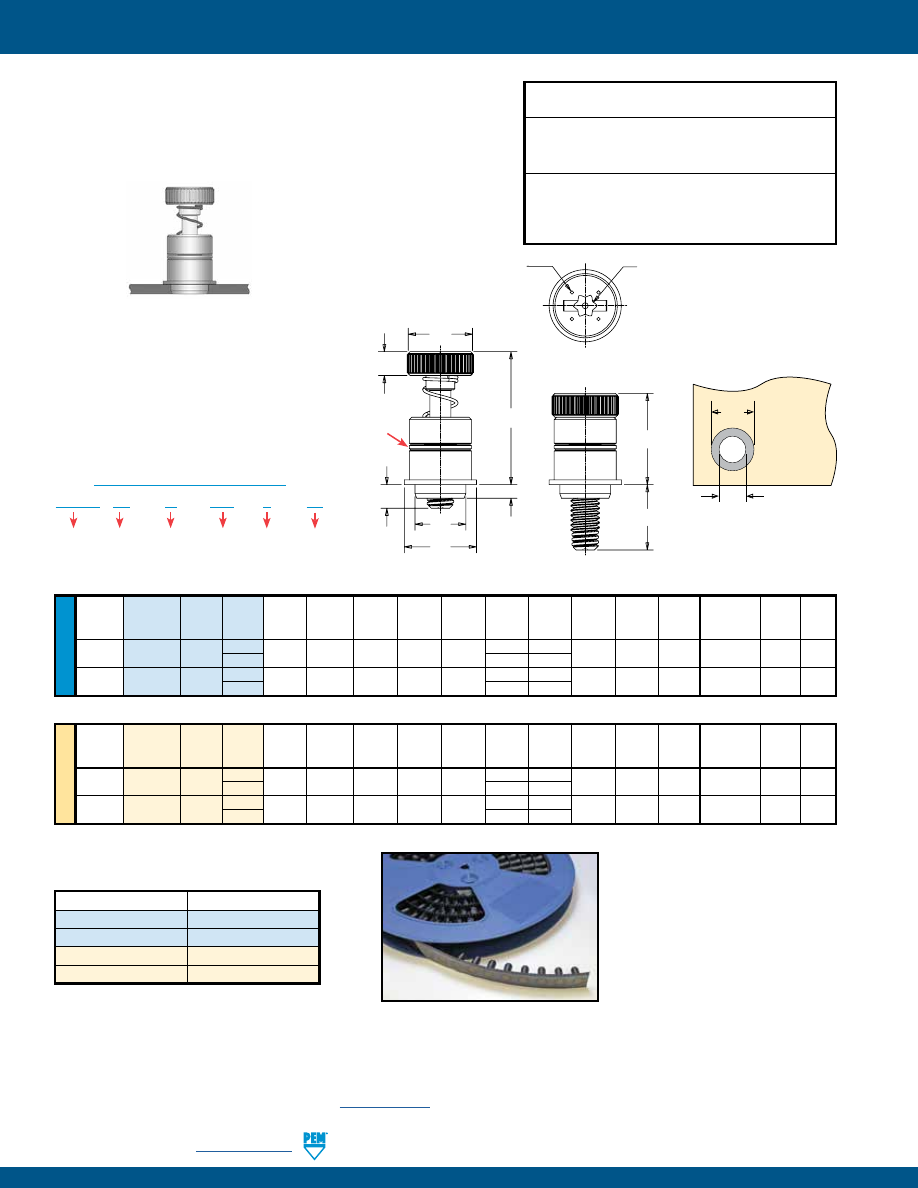

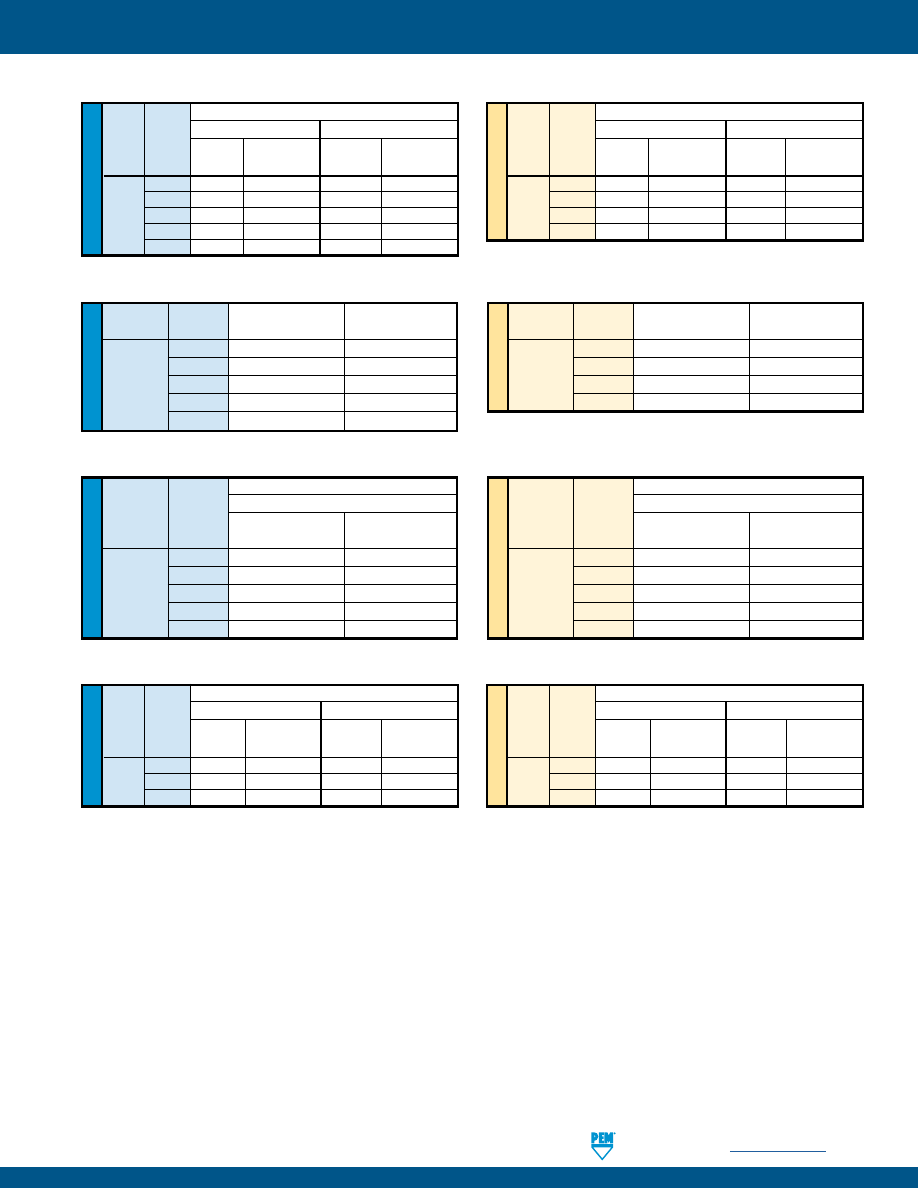

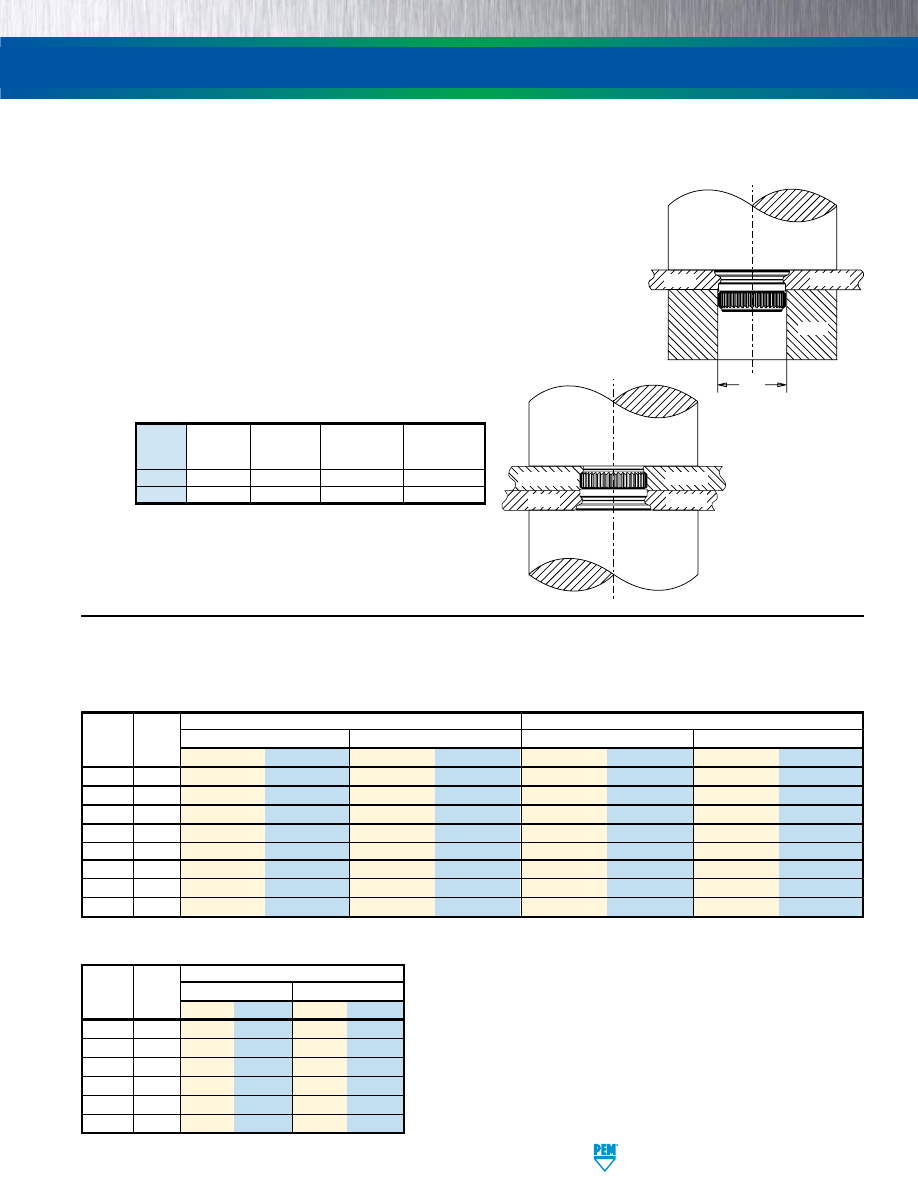

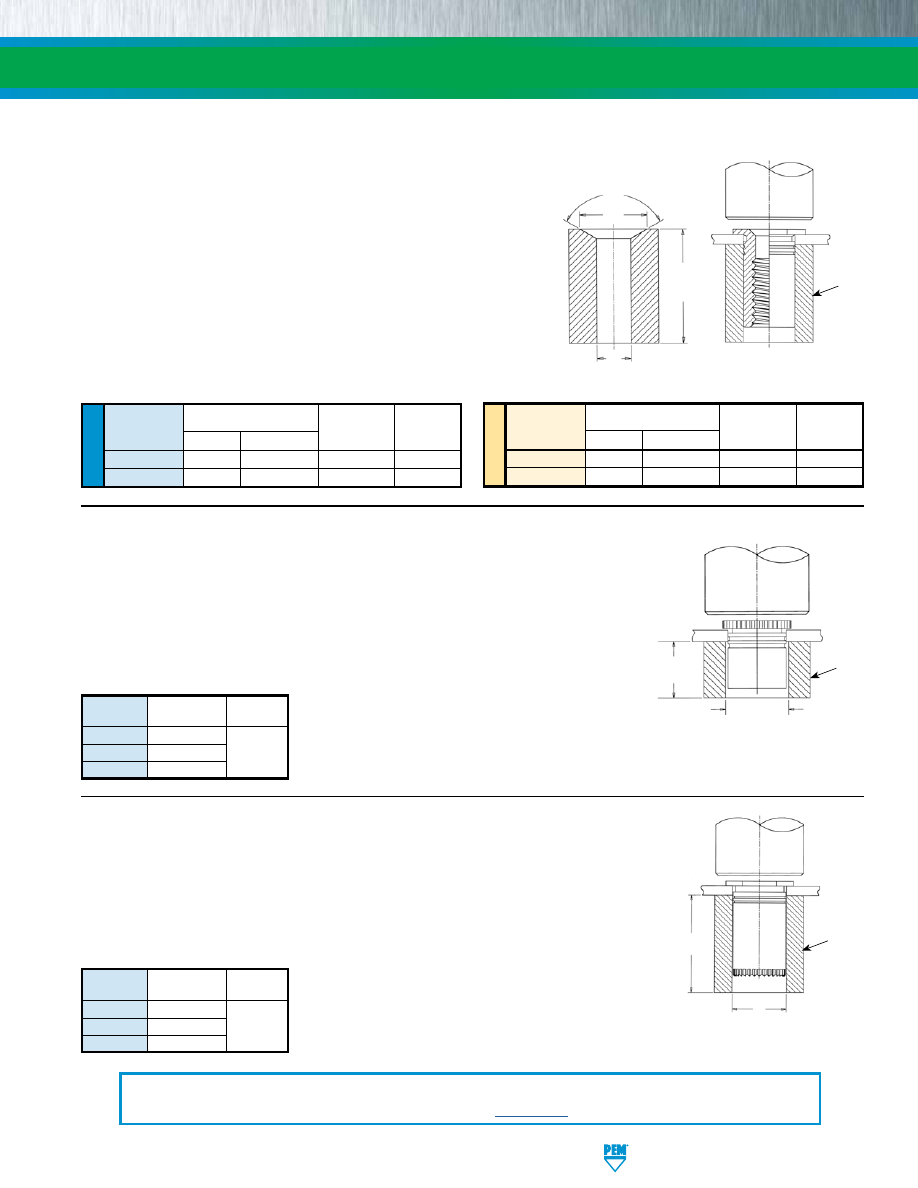

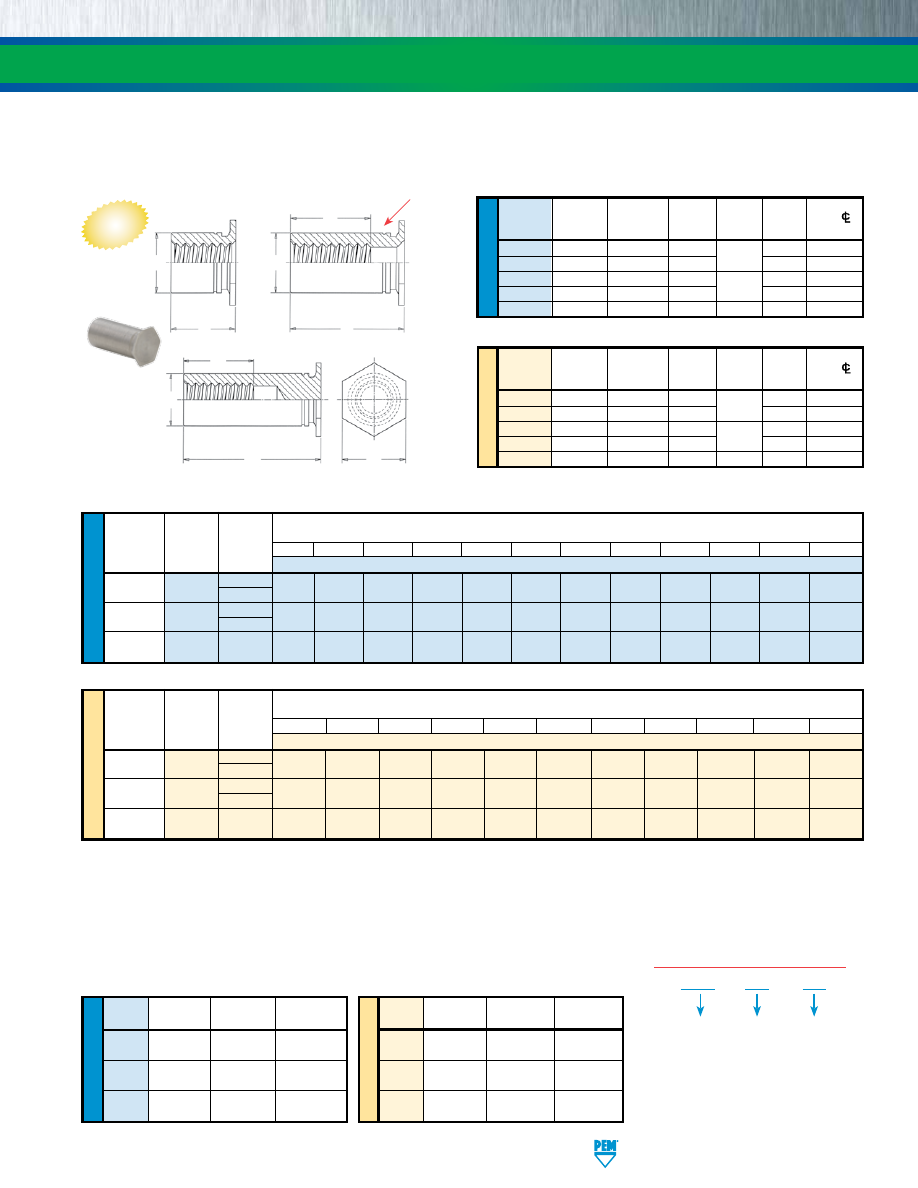

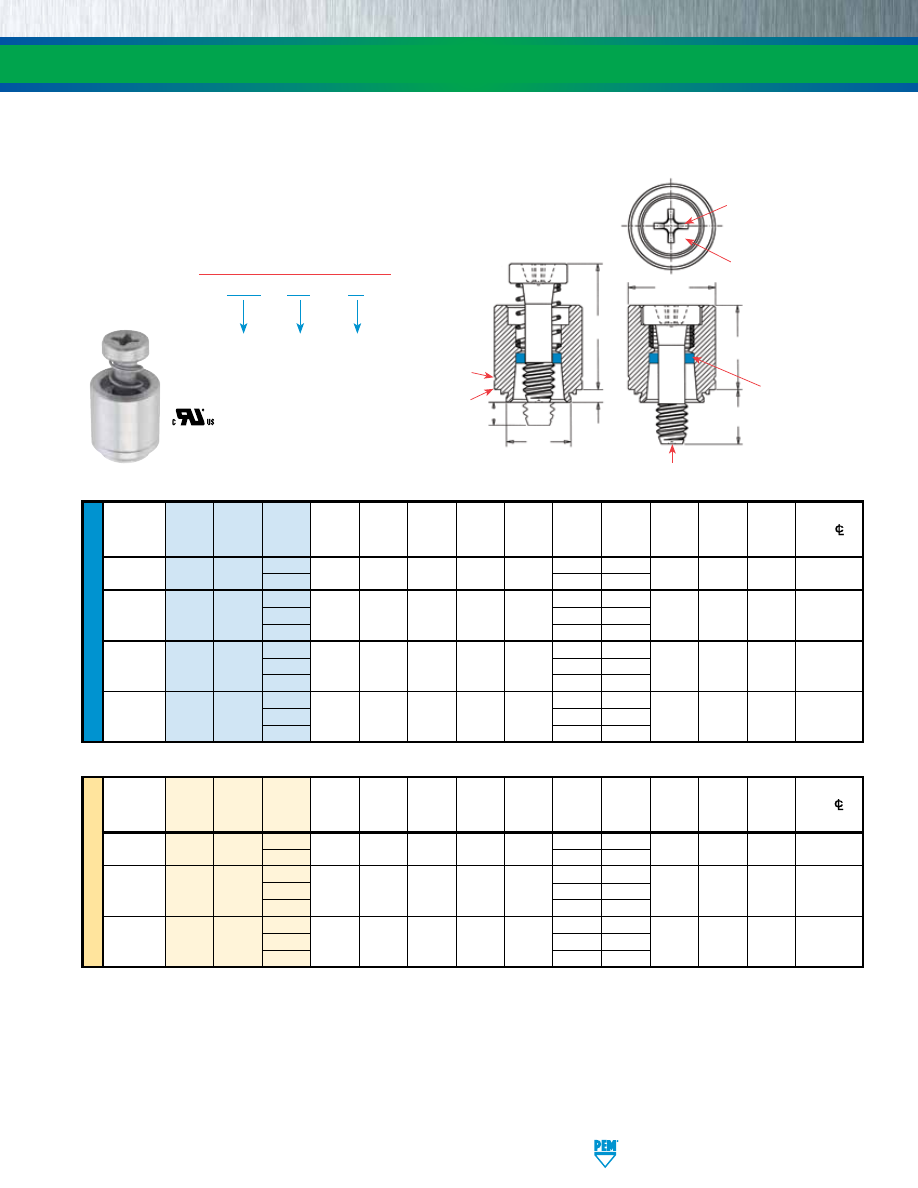

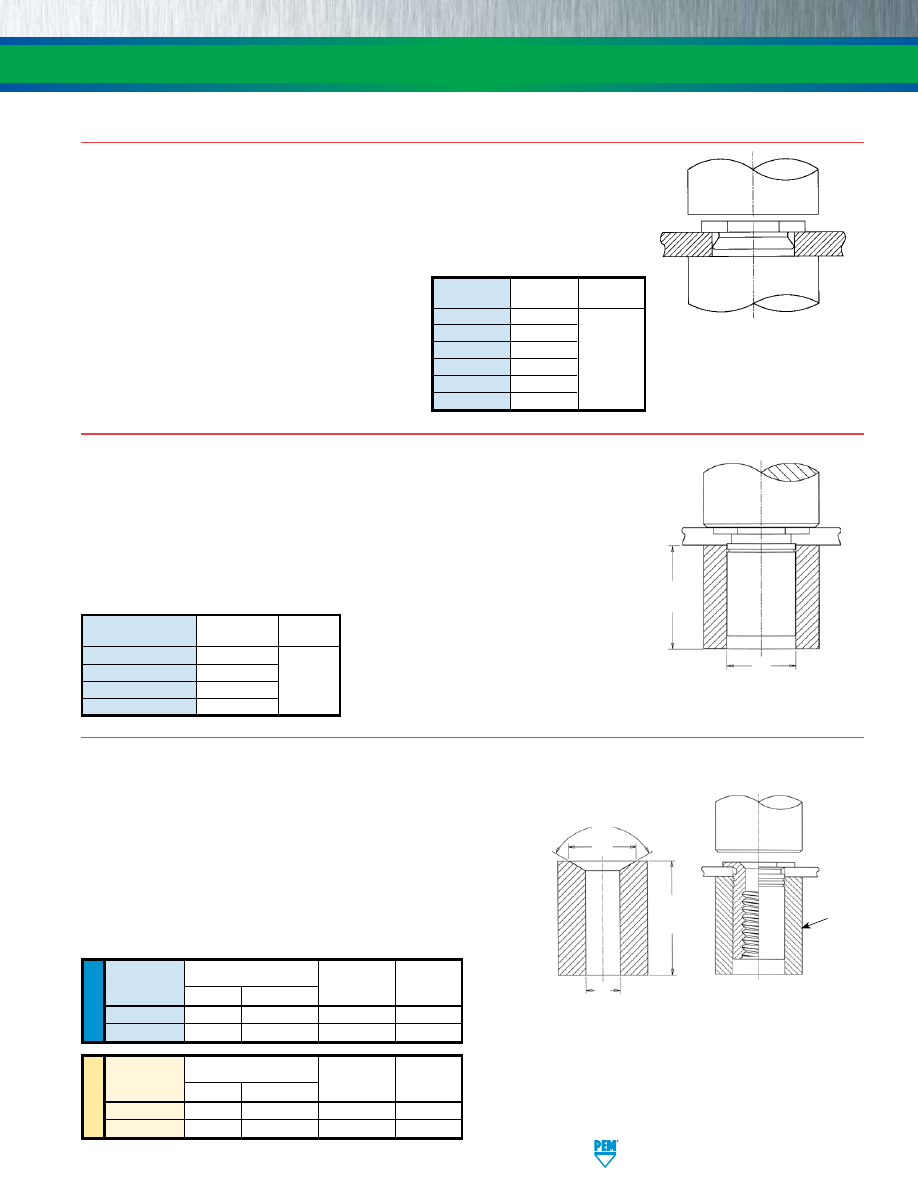

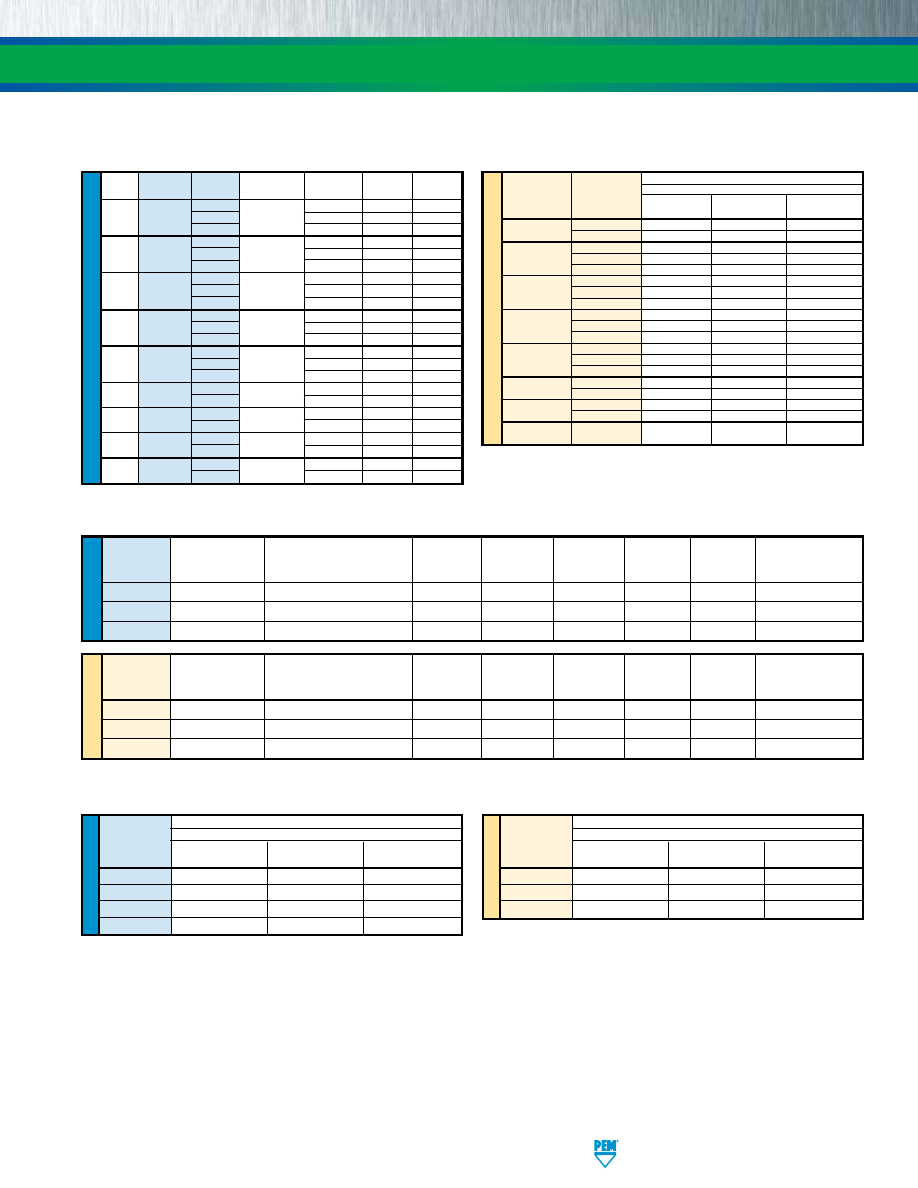

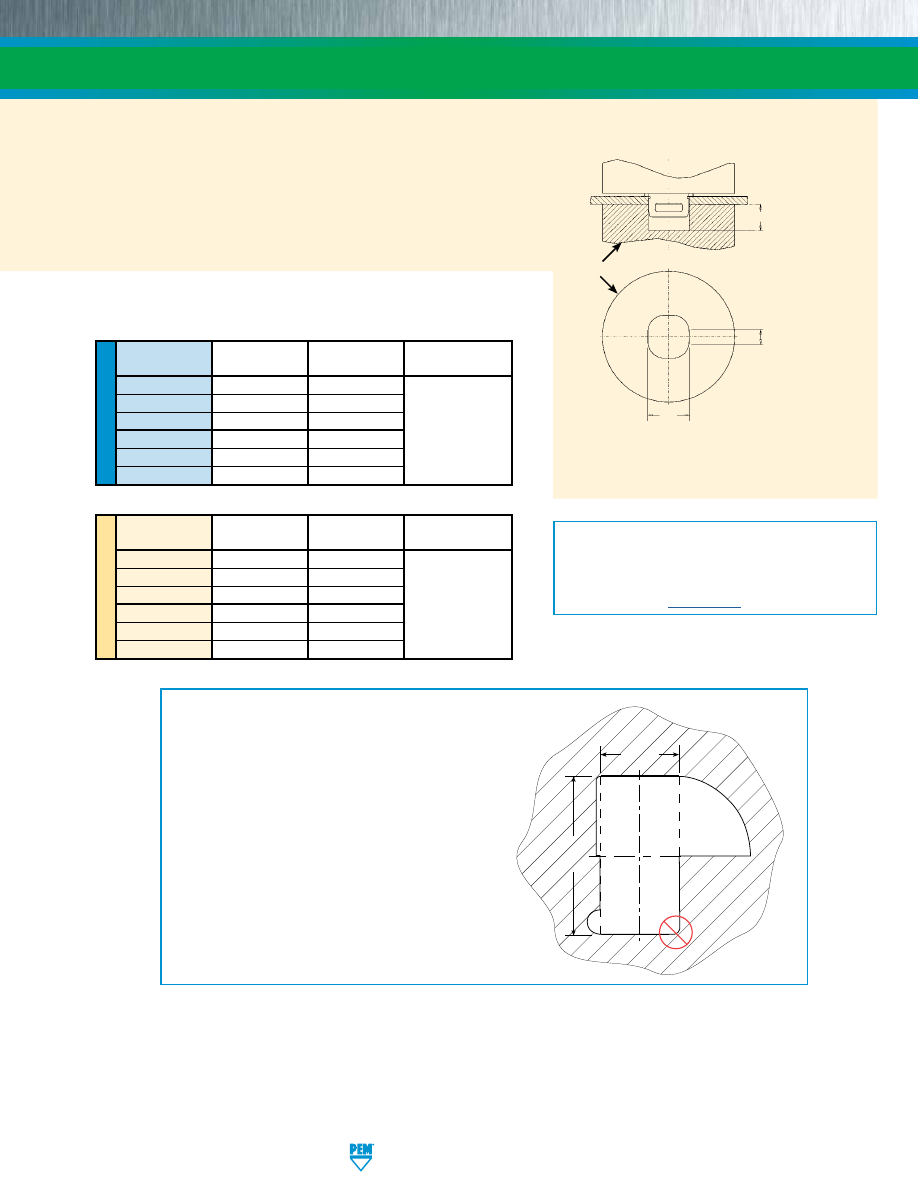

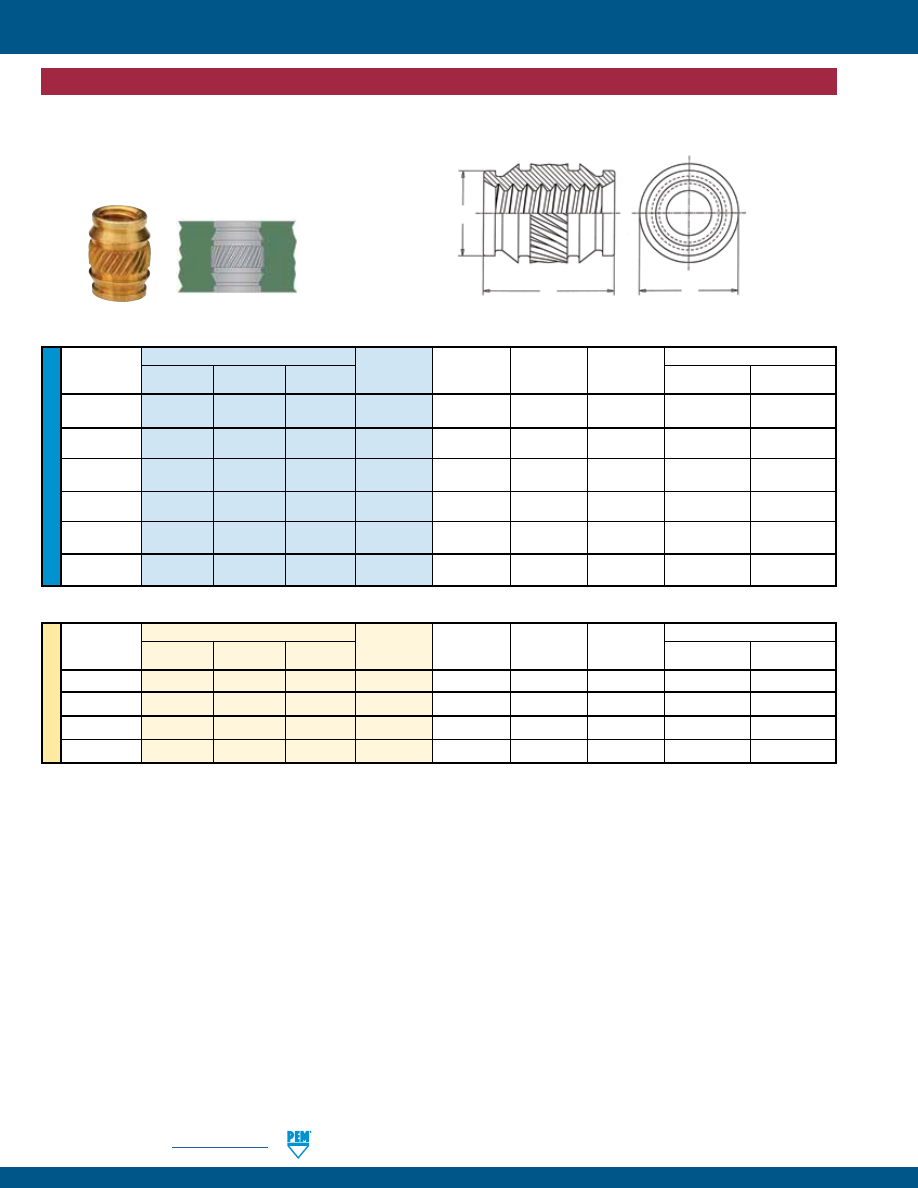

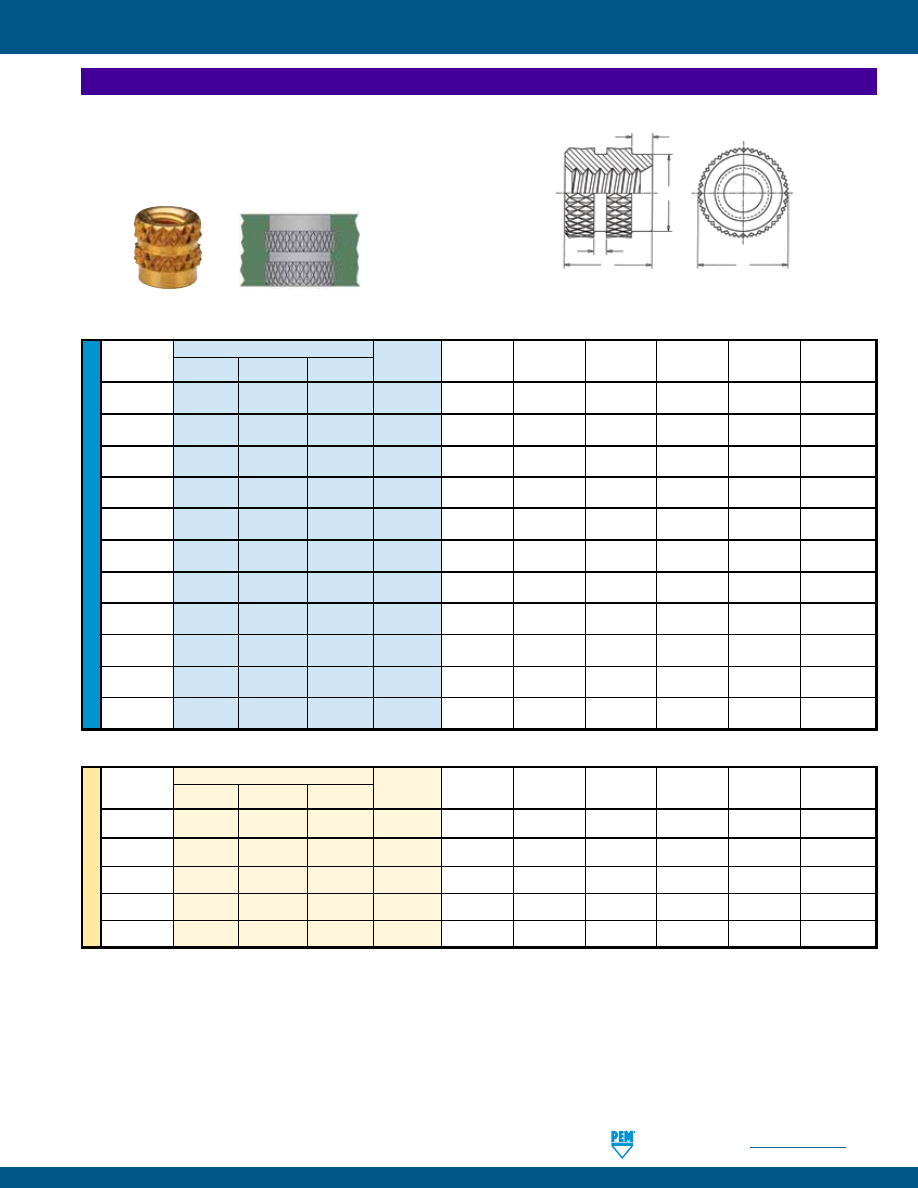

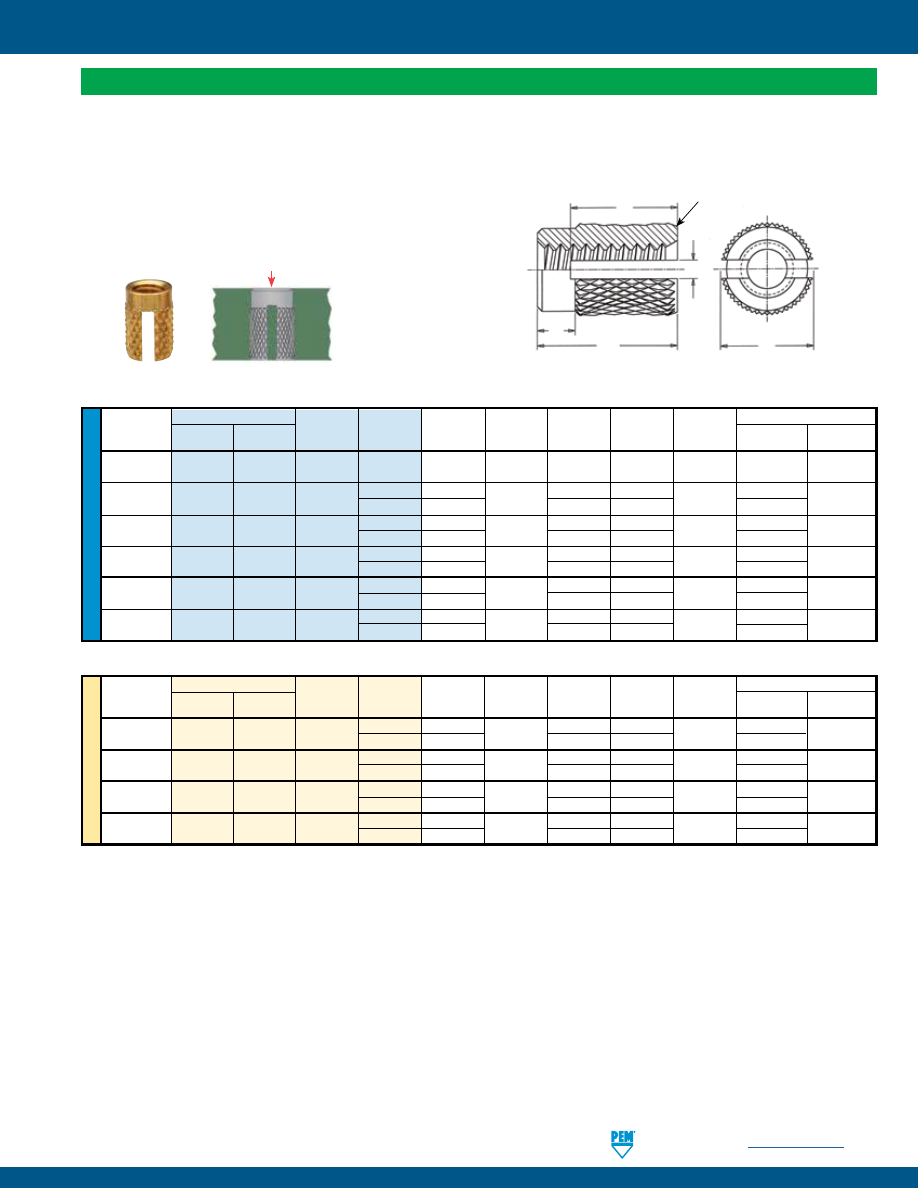

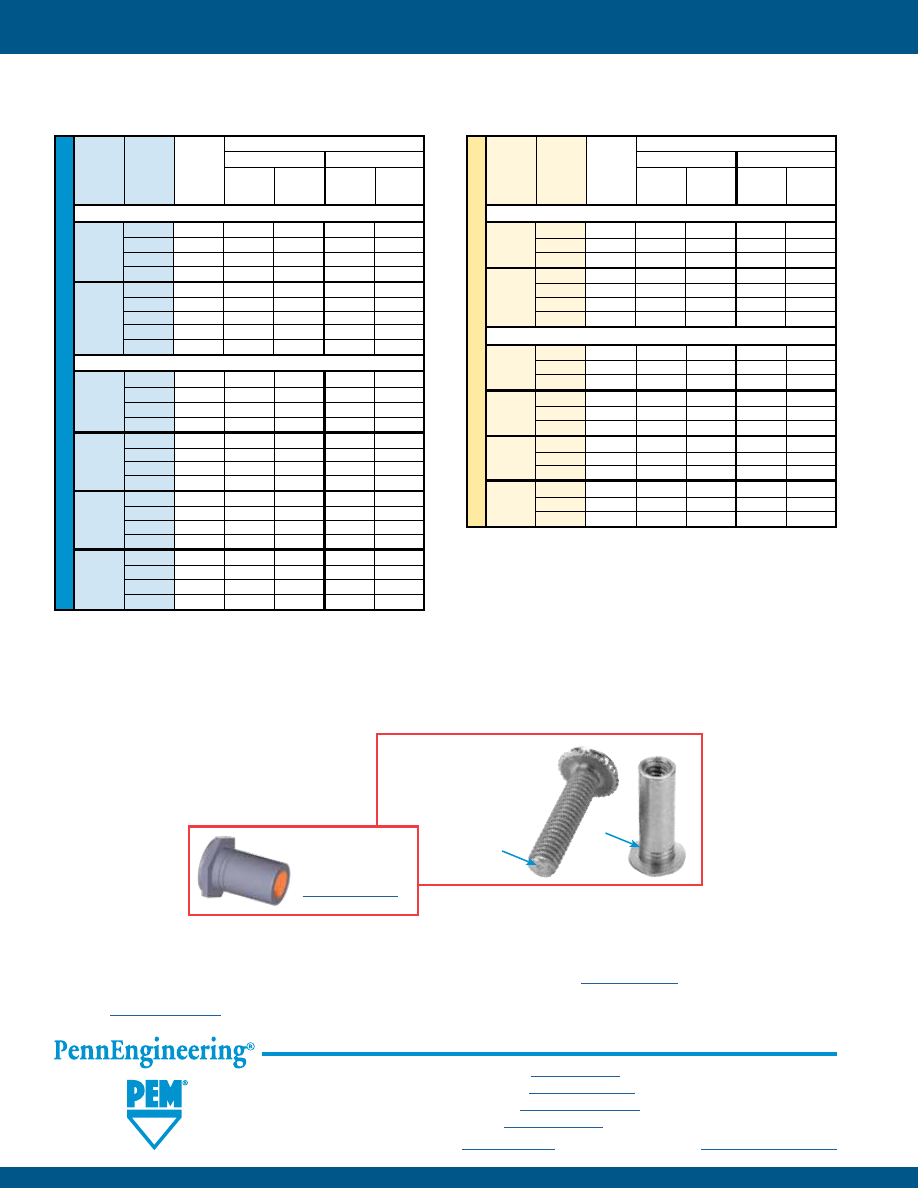

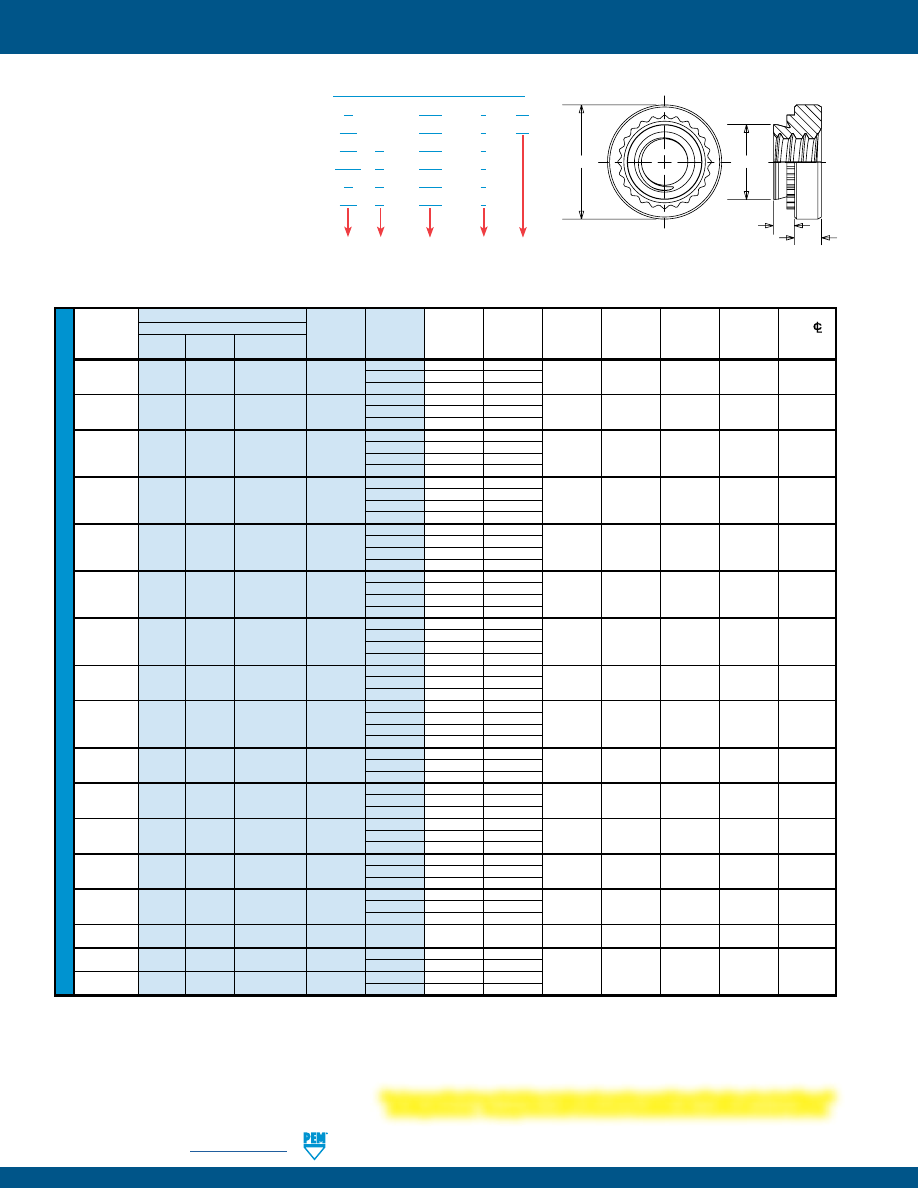

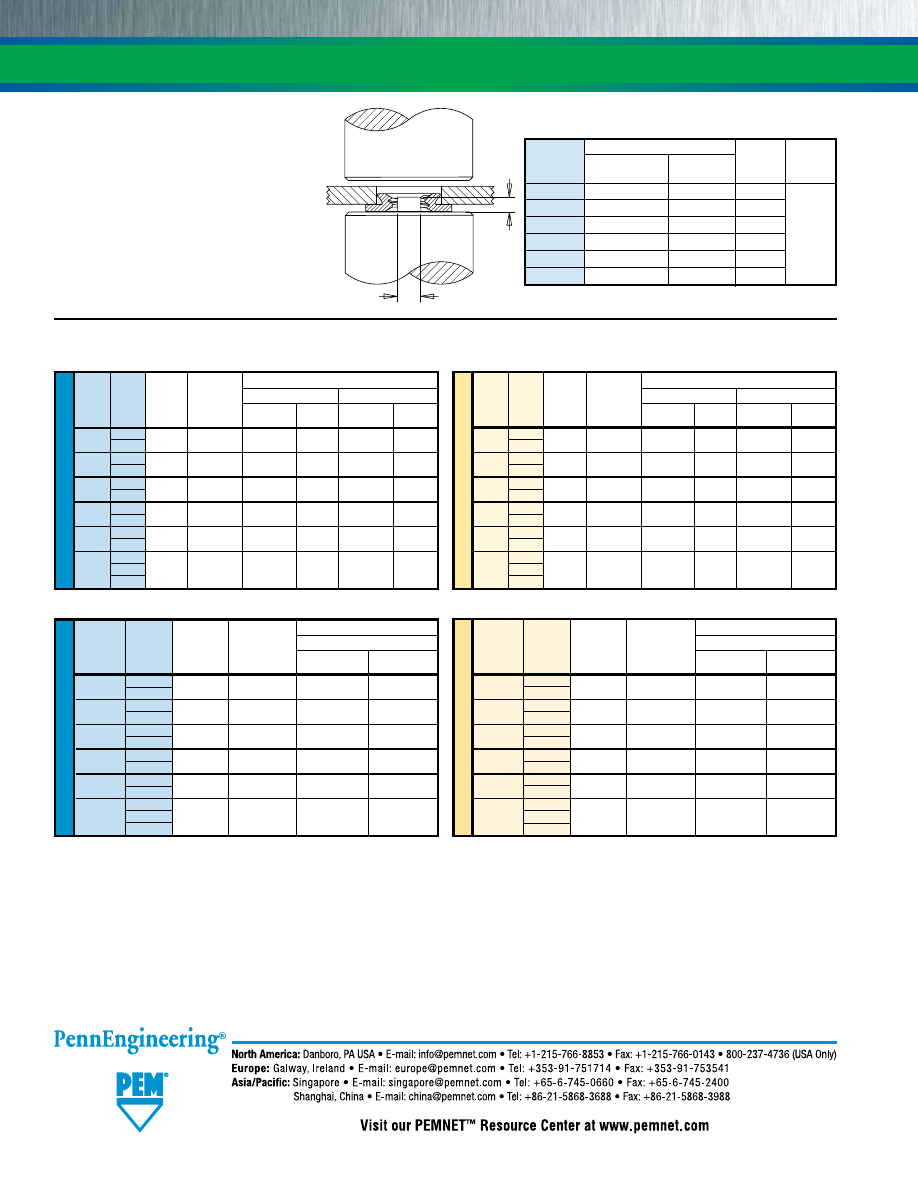

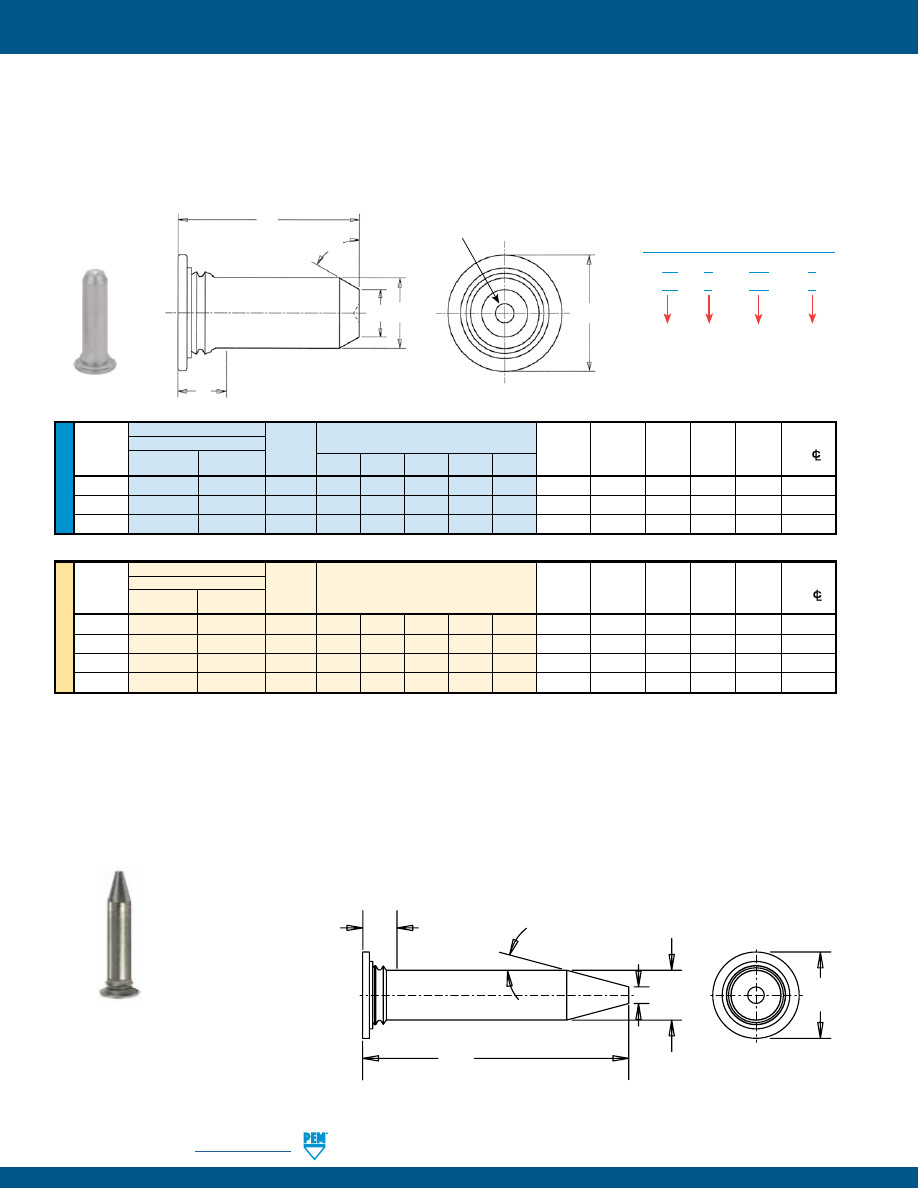

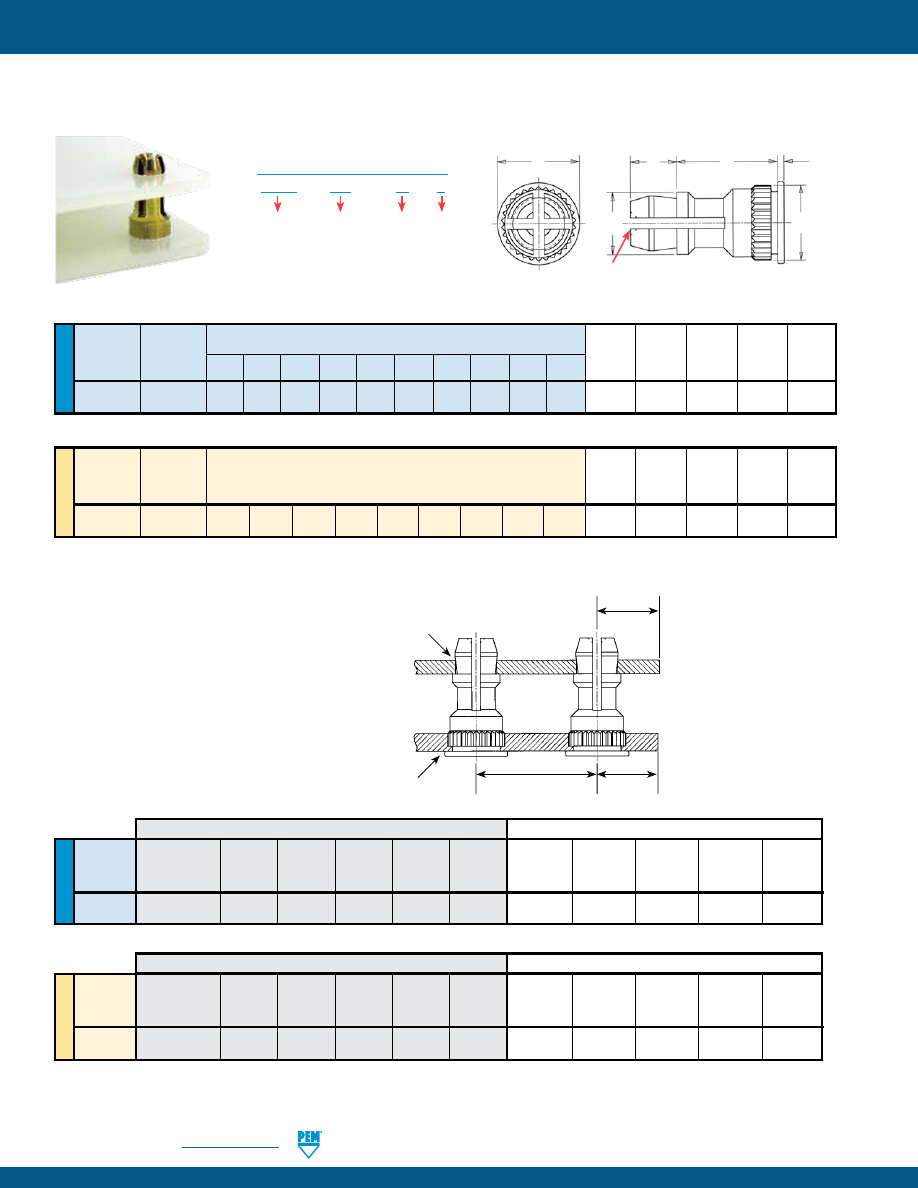

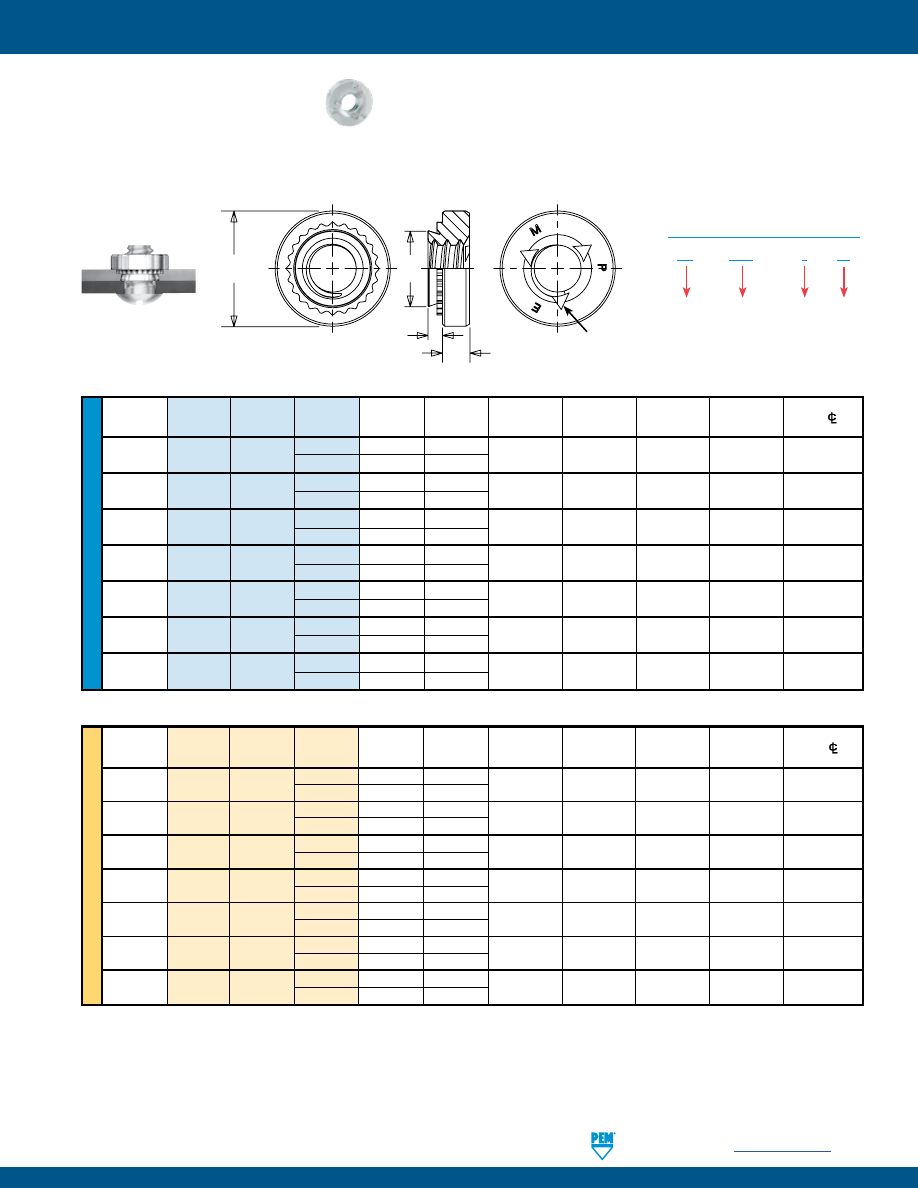

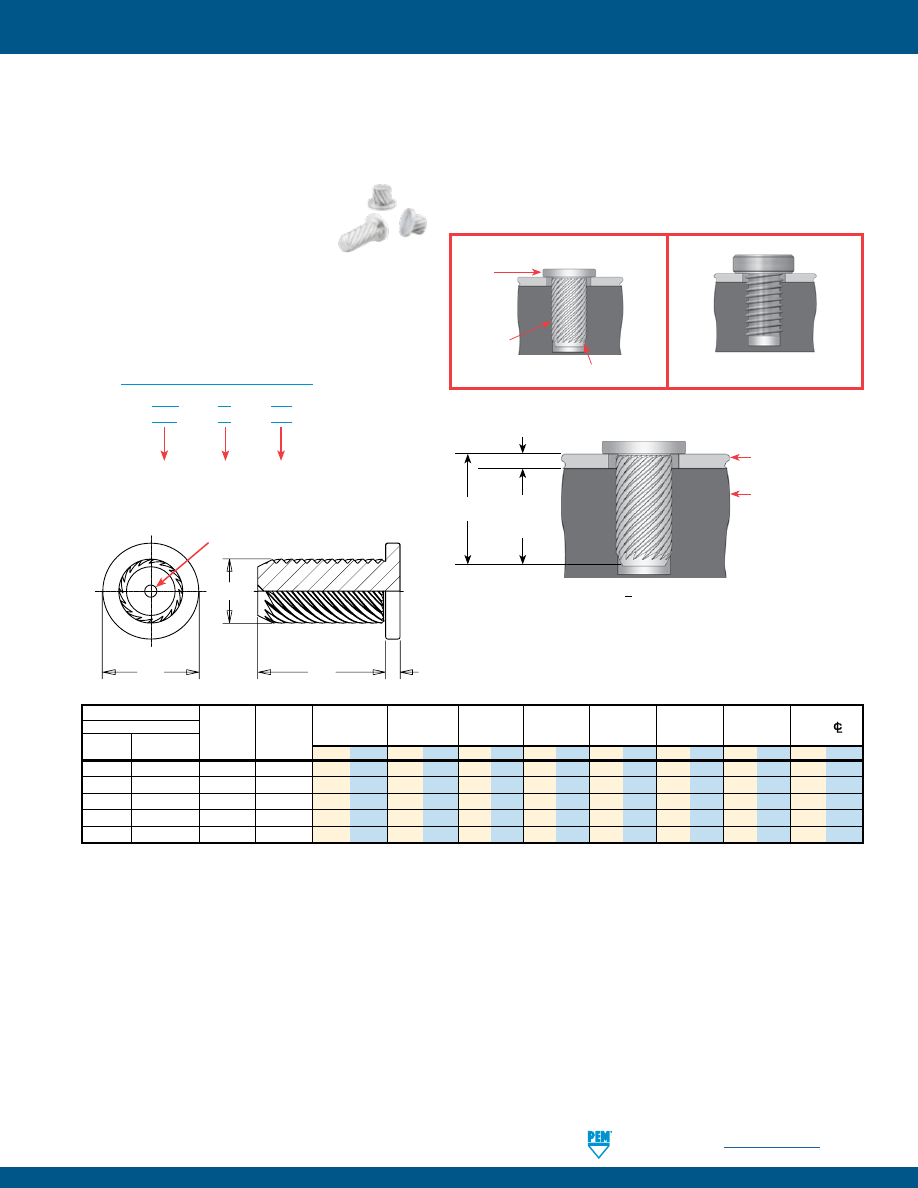

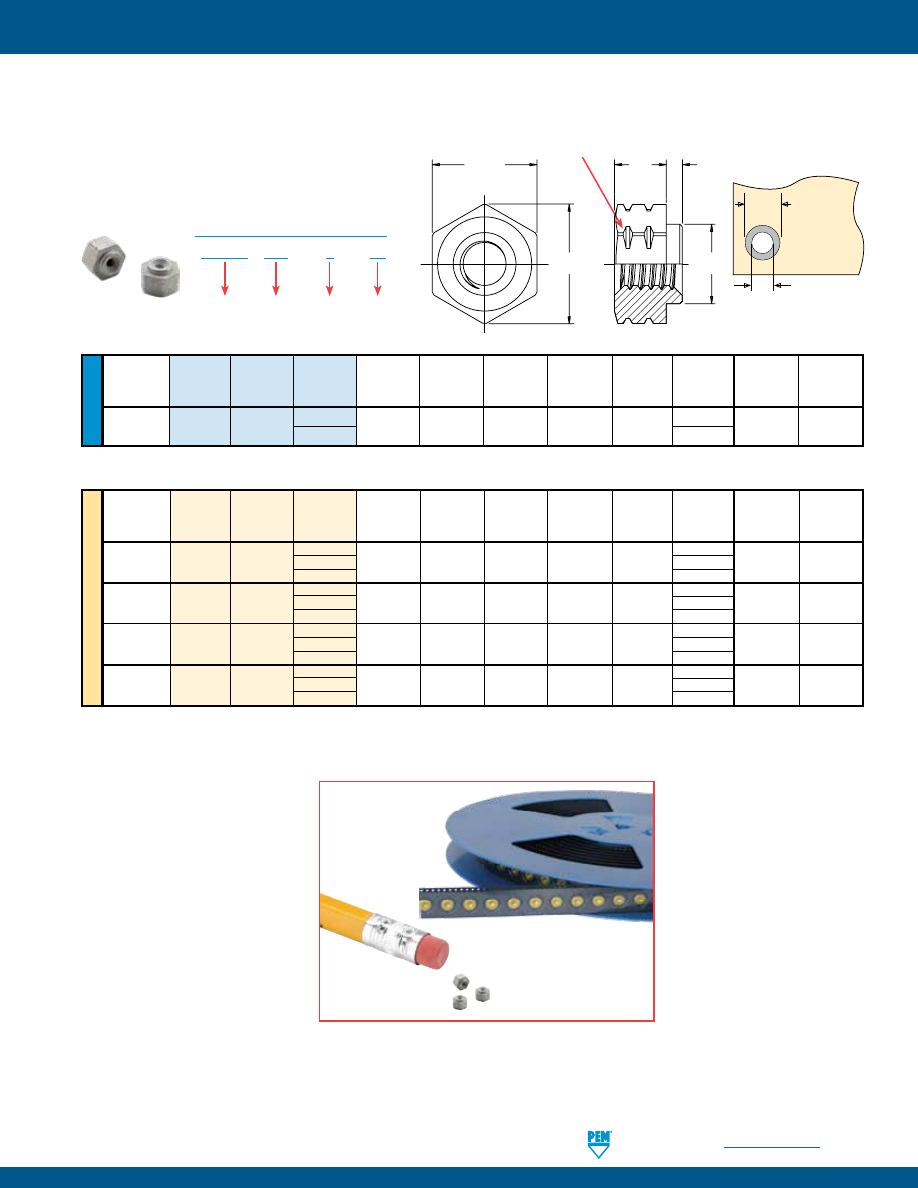

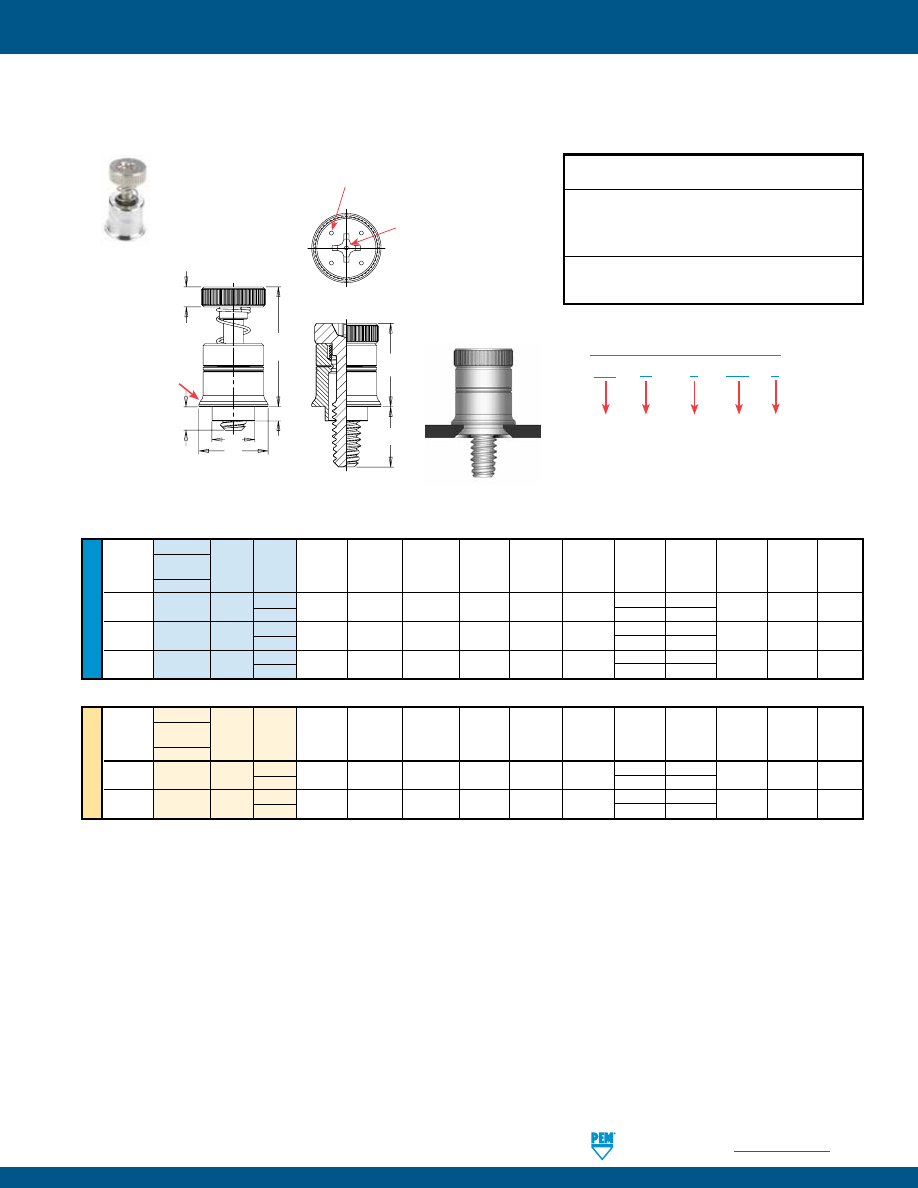

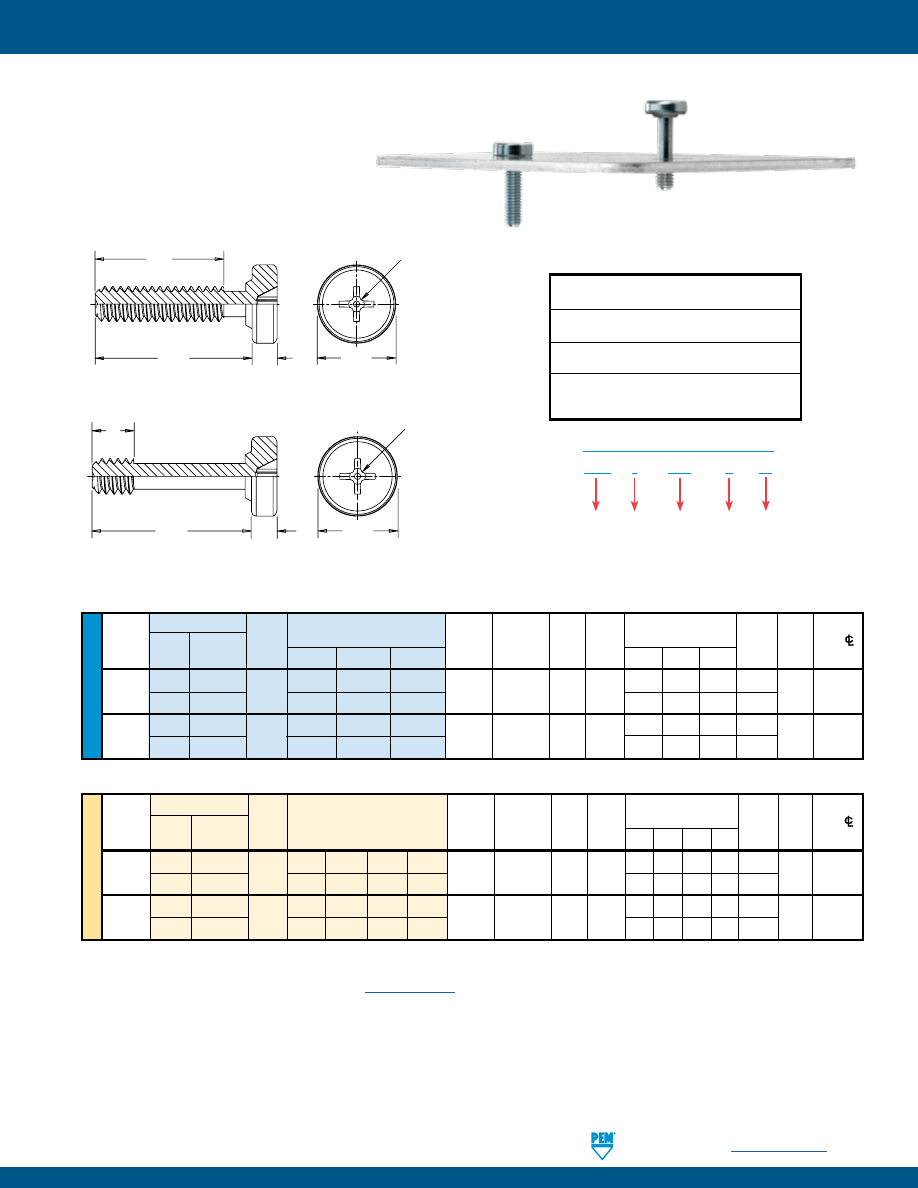

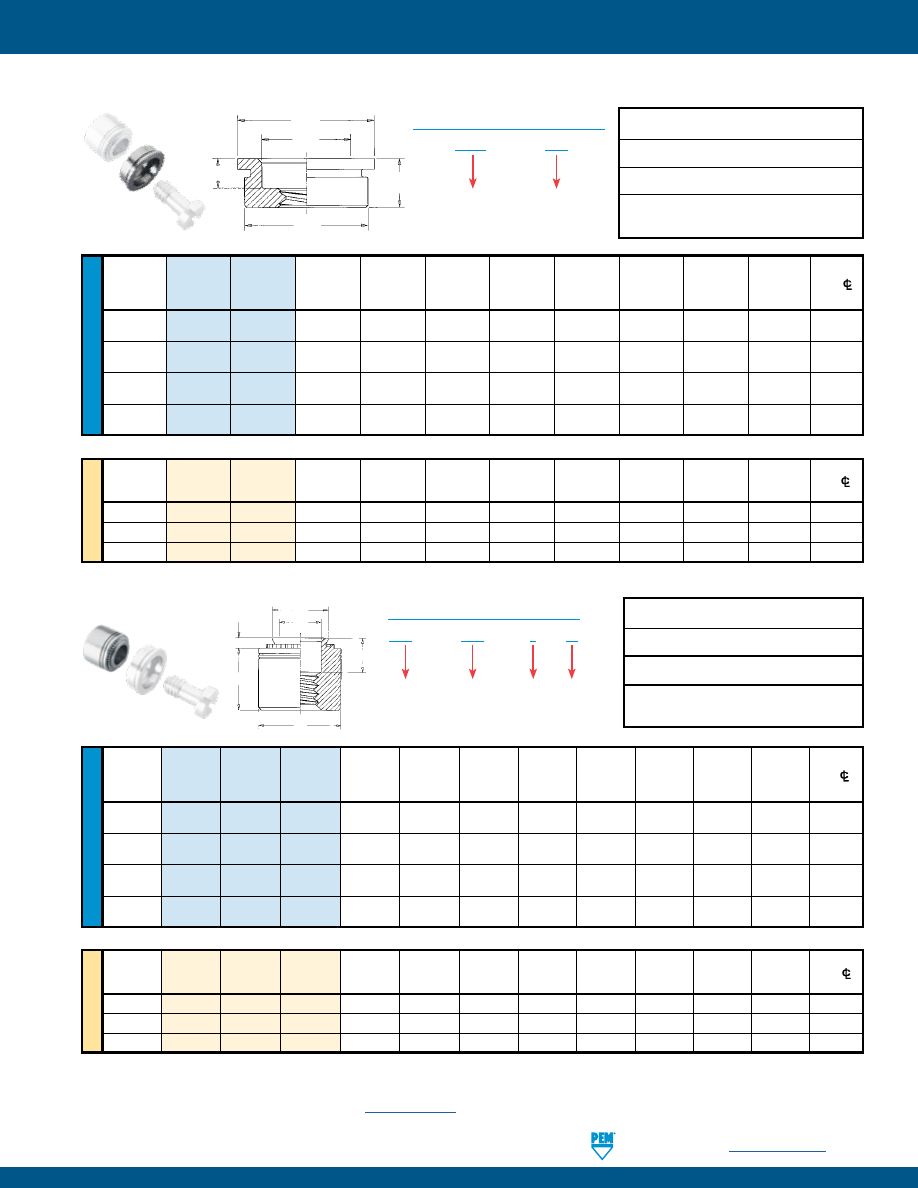

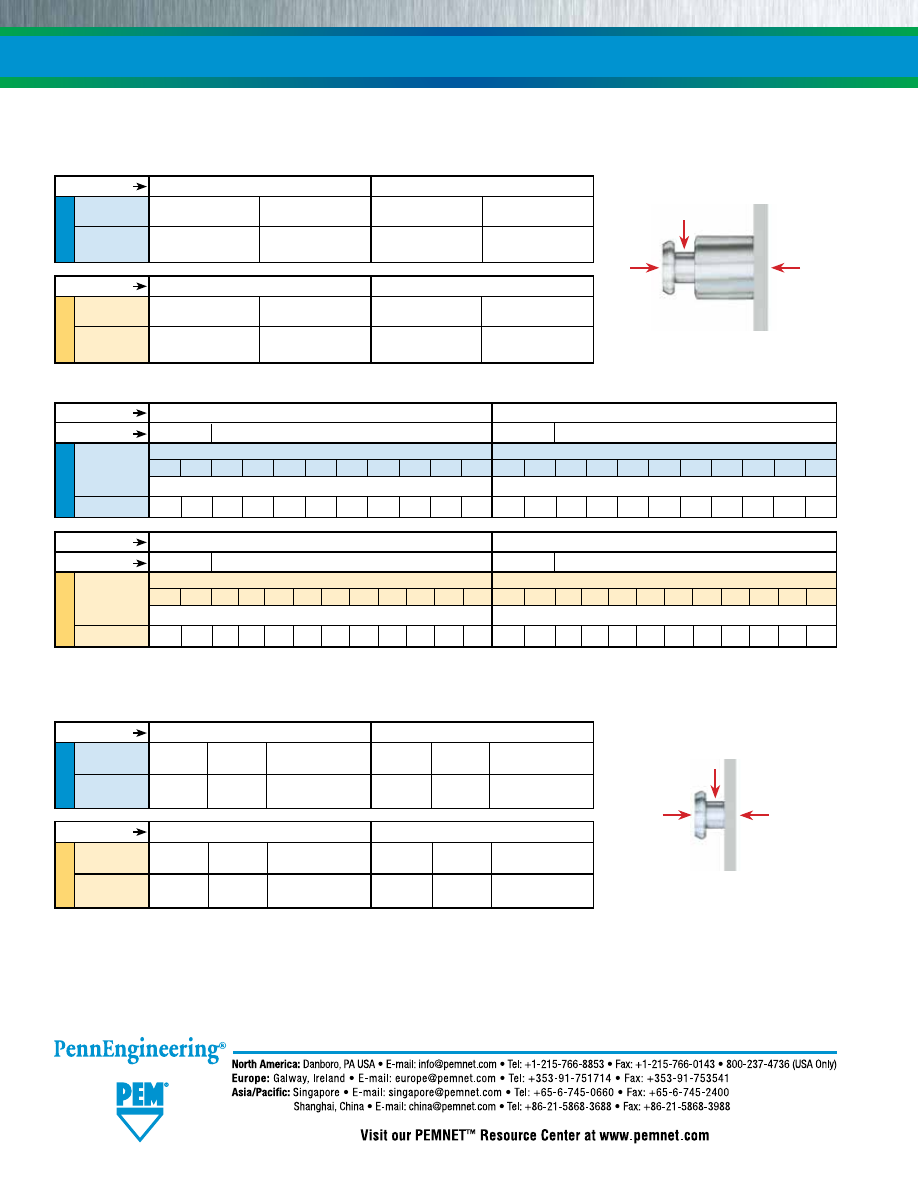

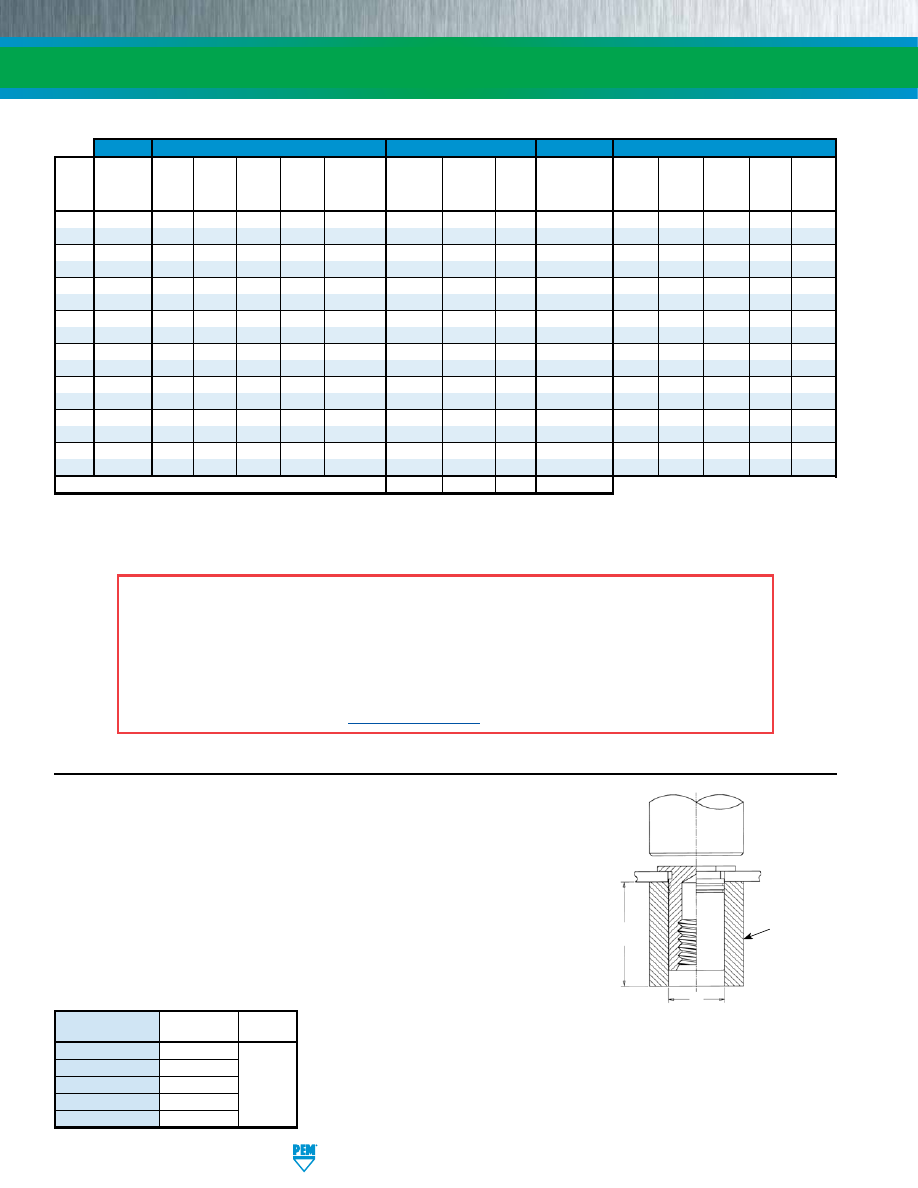

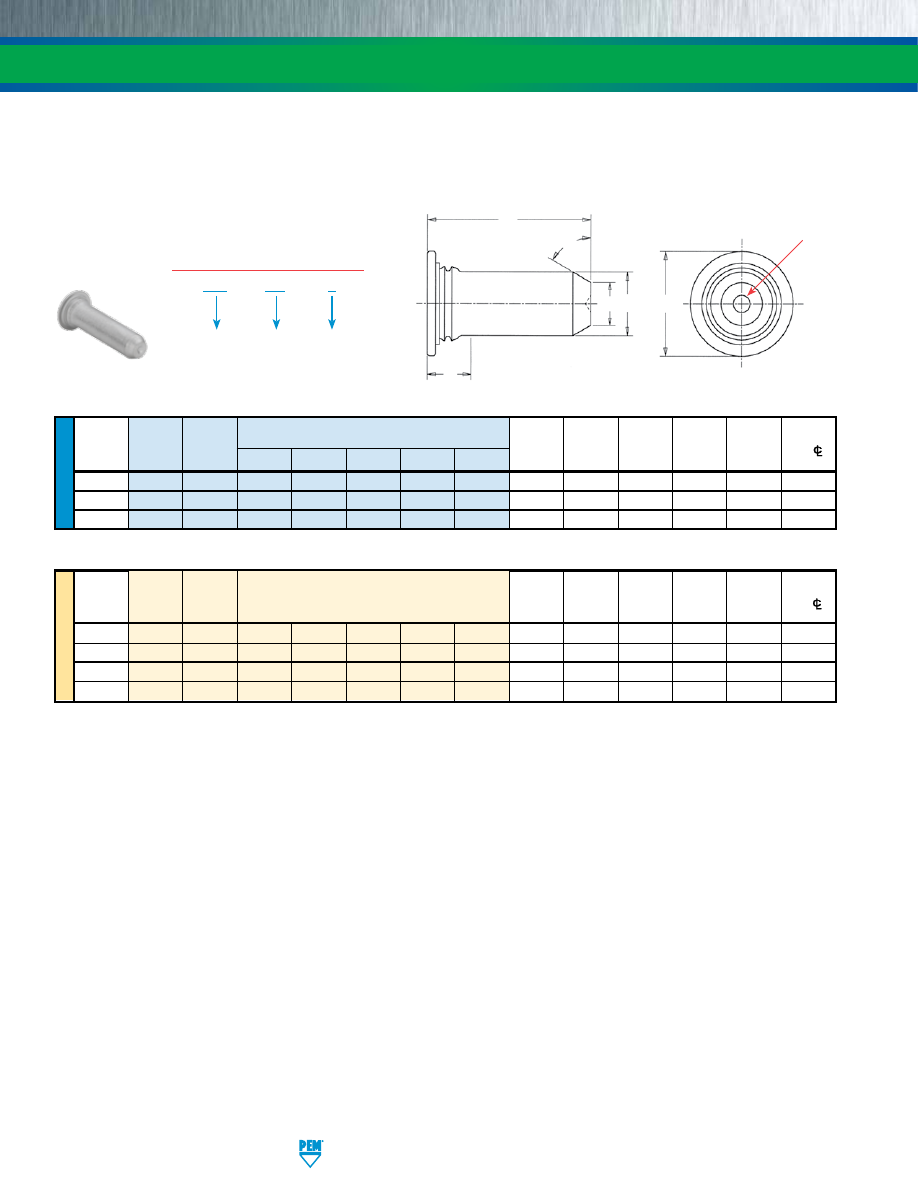

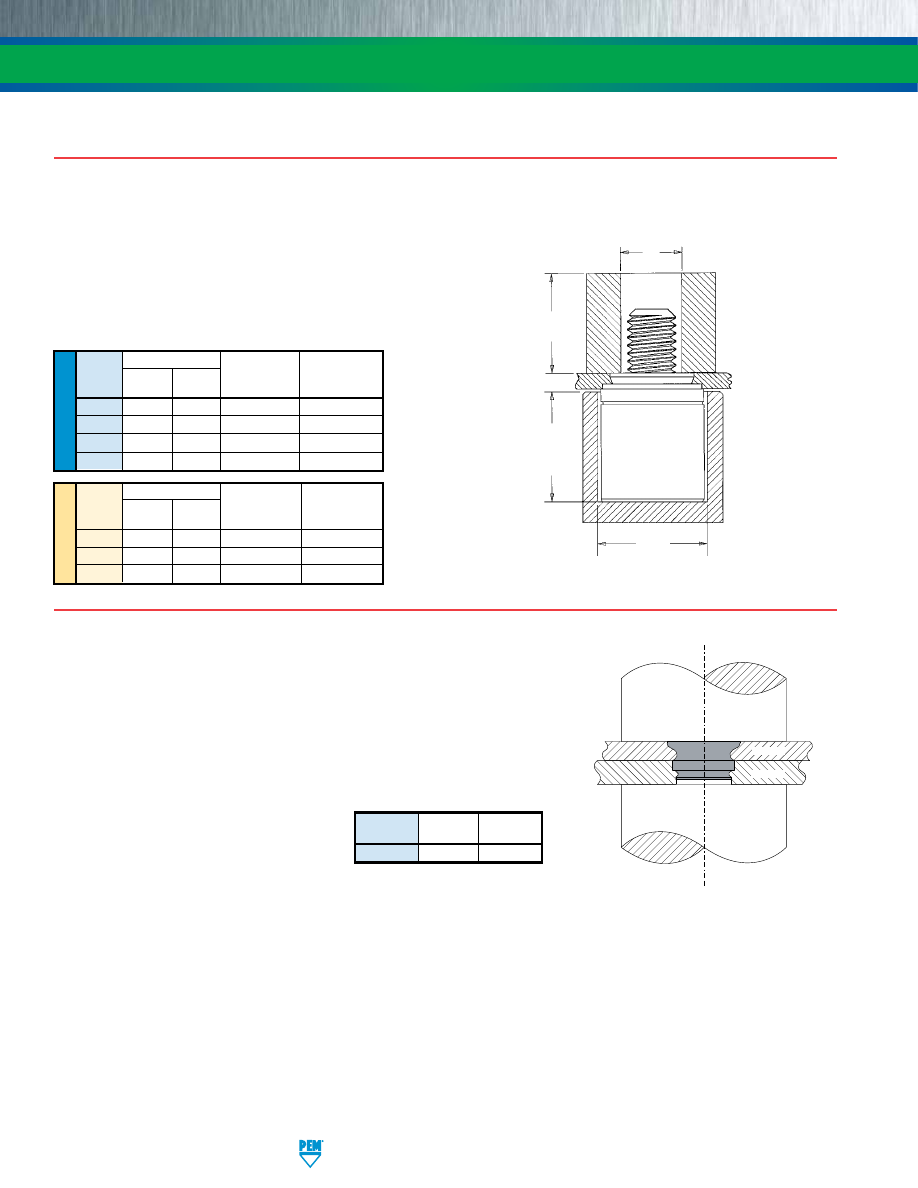

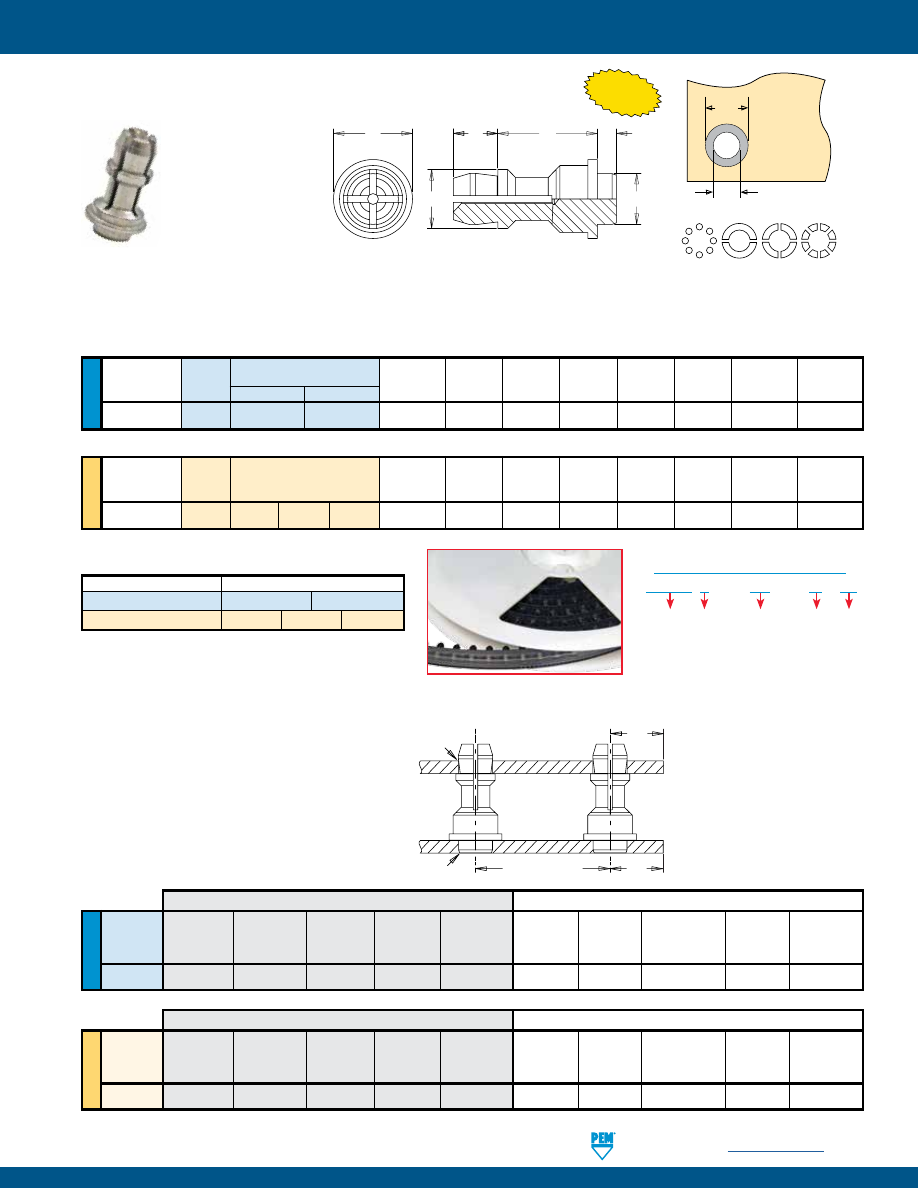

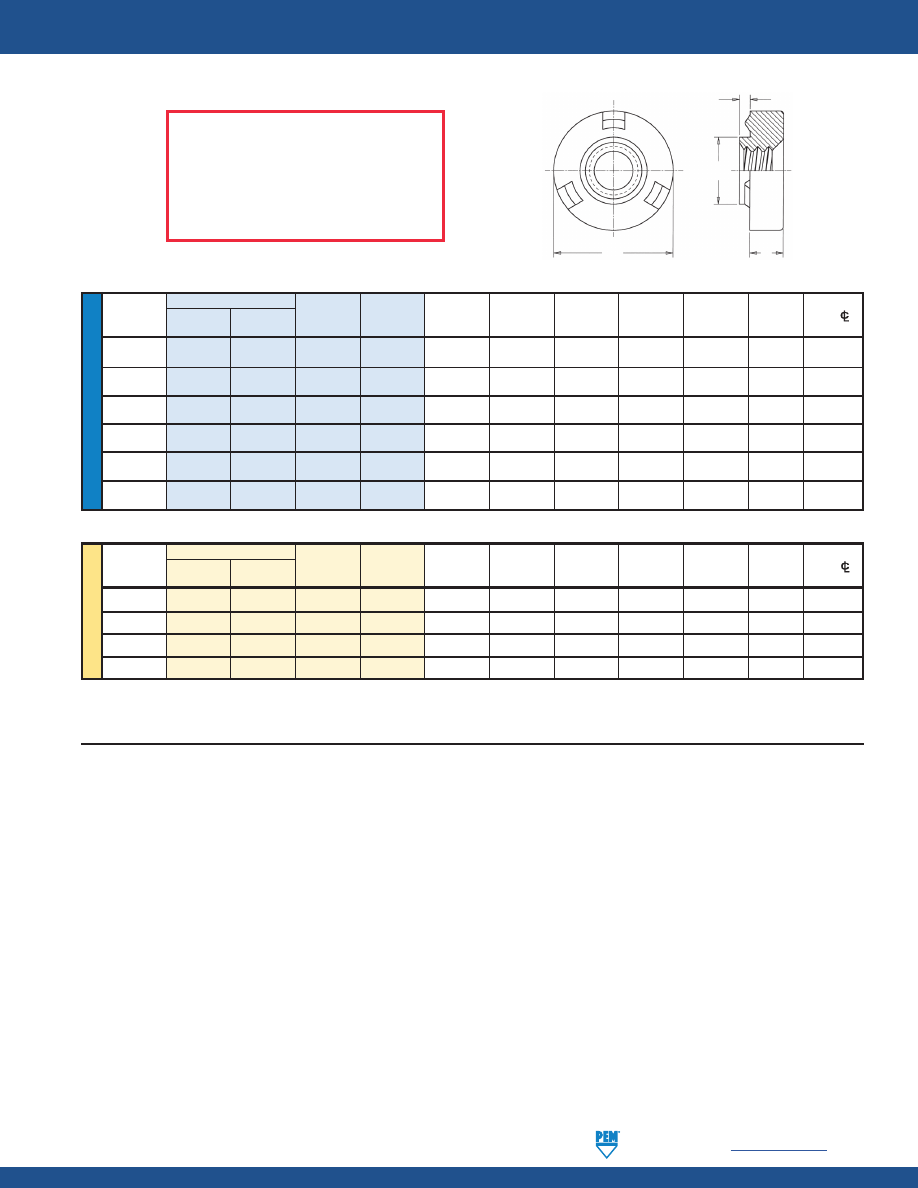

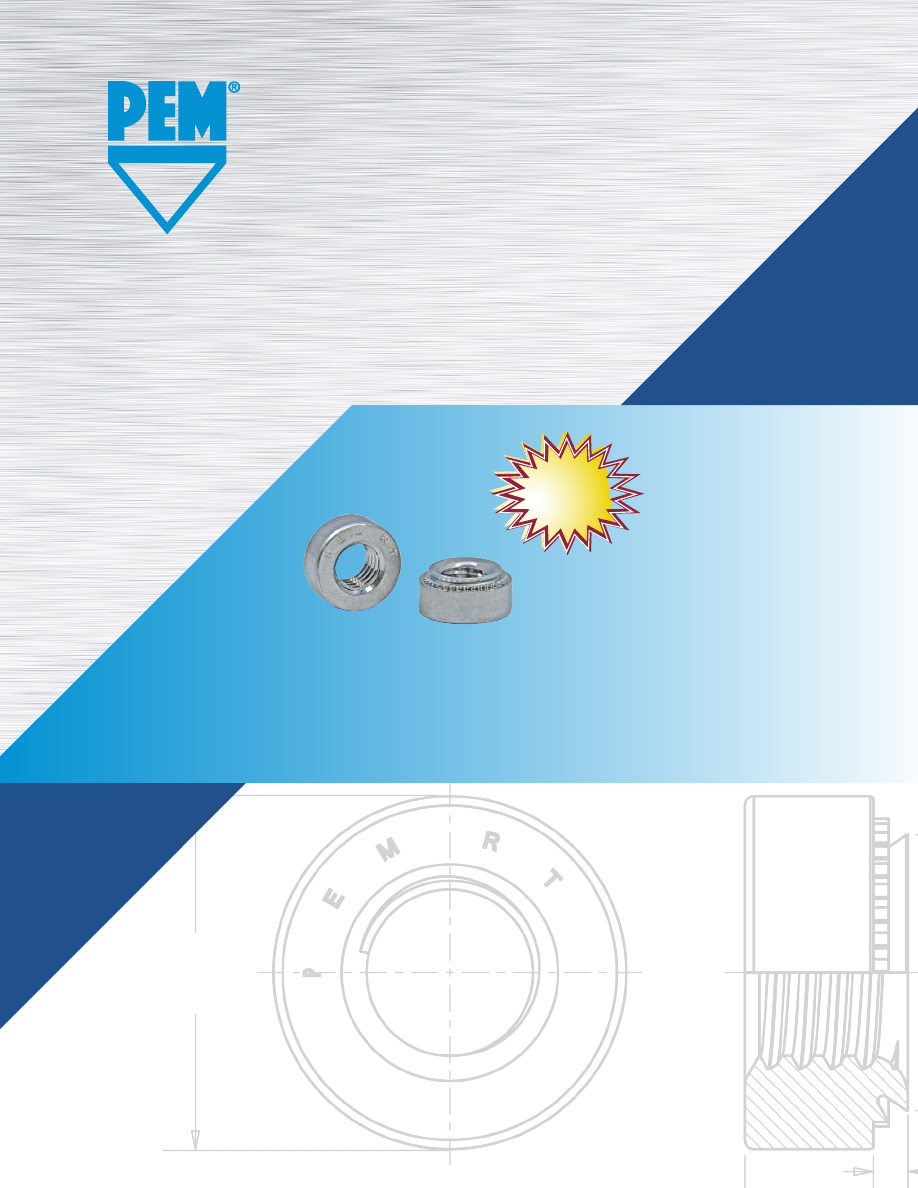

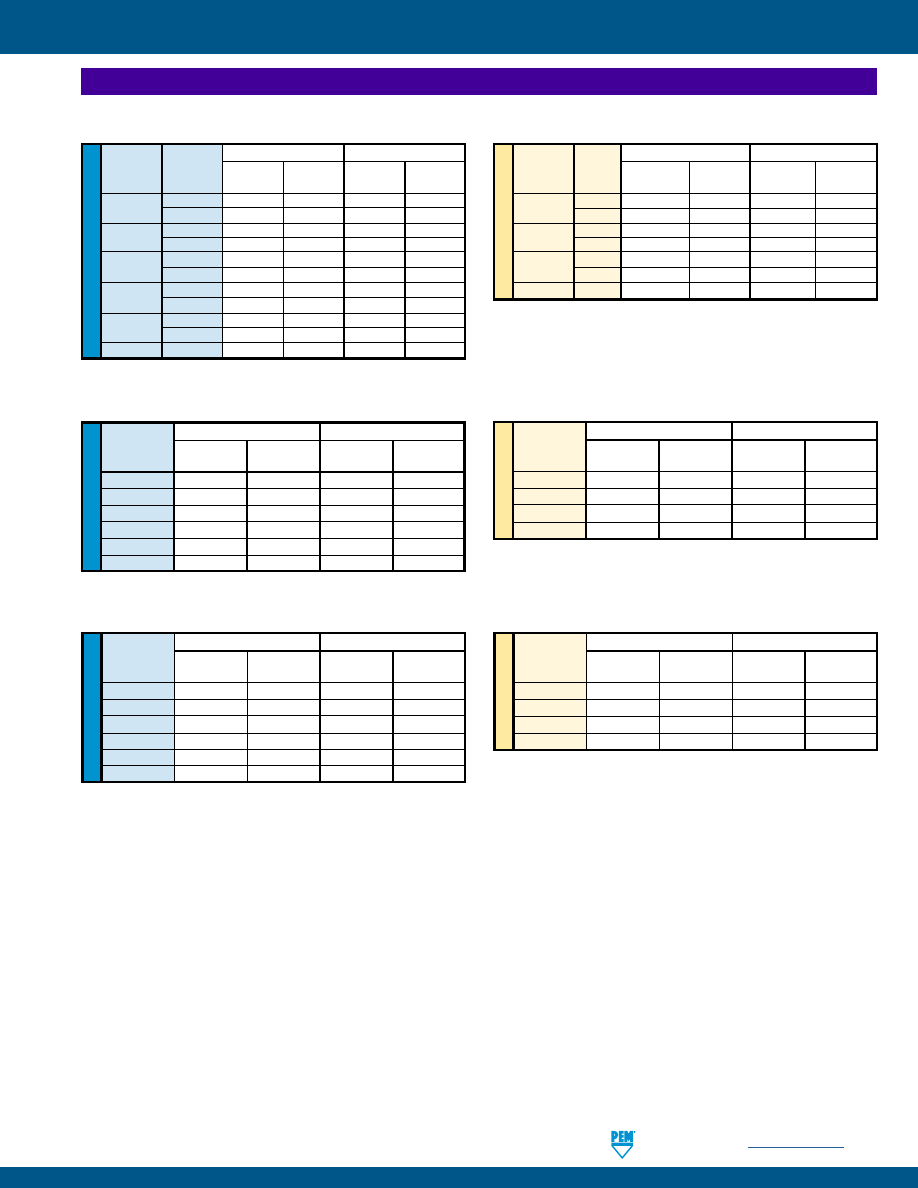

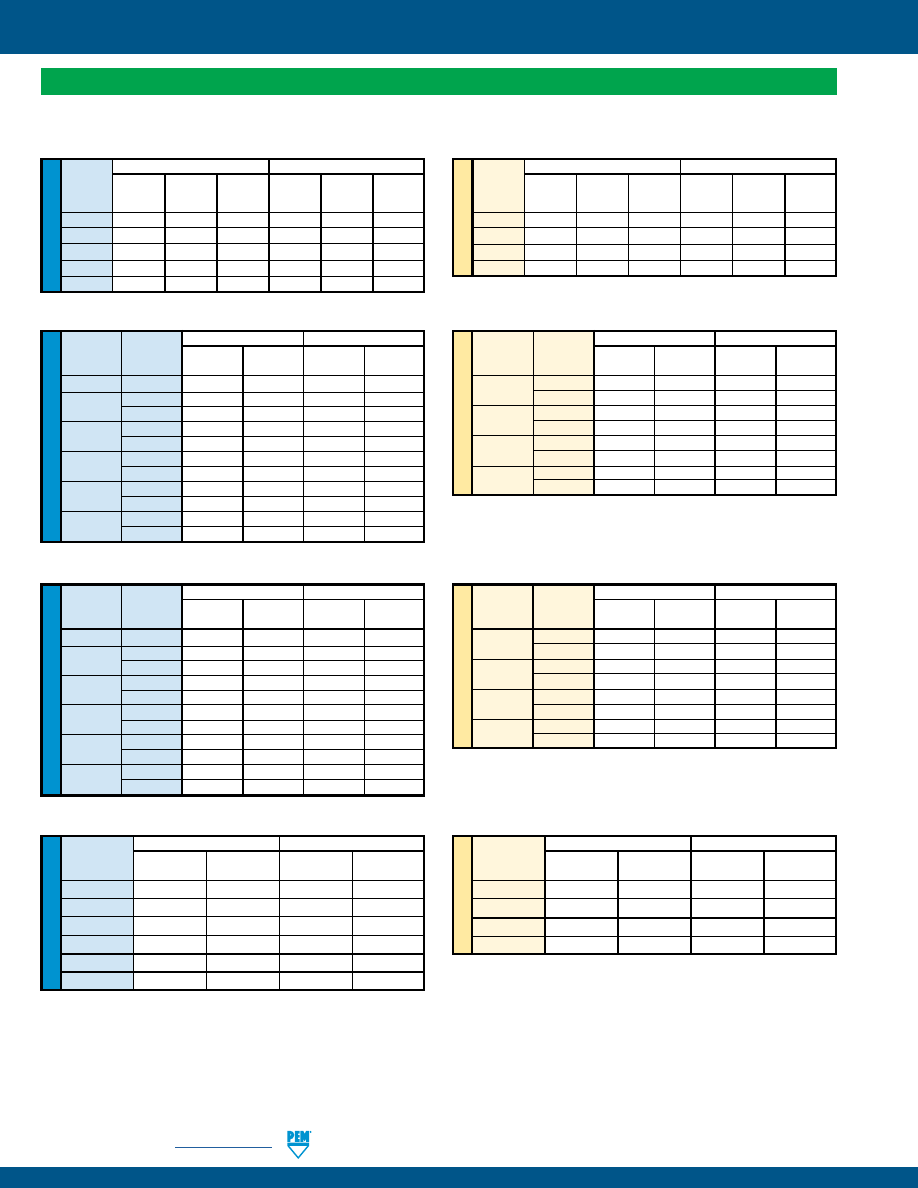

CL

™

SELF-CLINCHING

NUTS

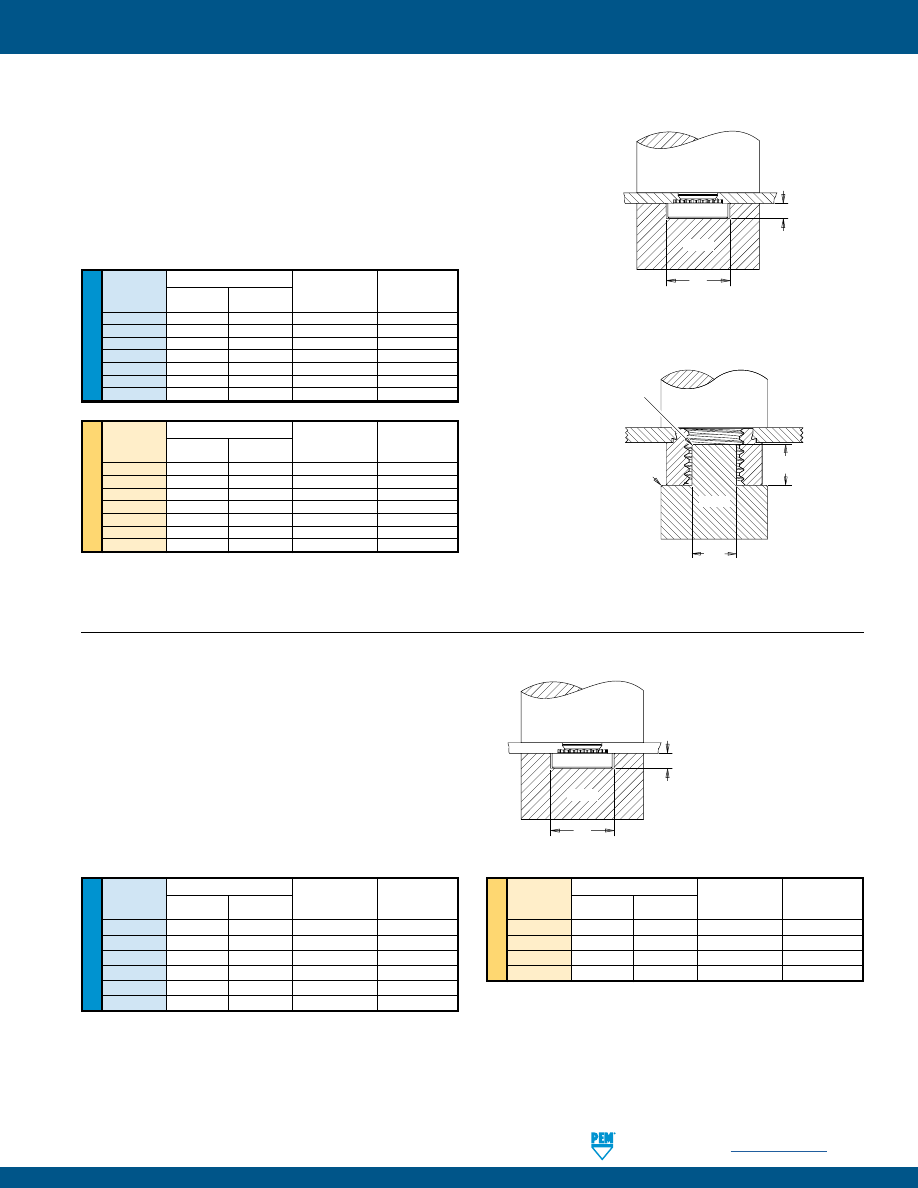

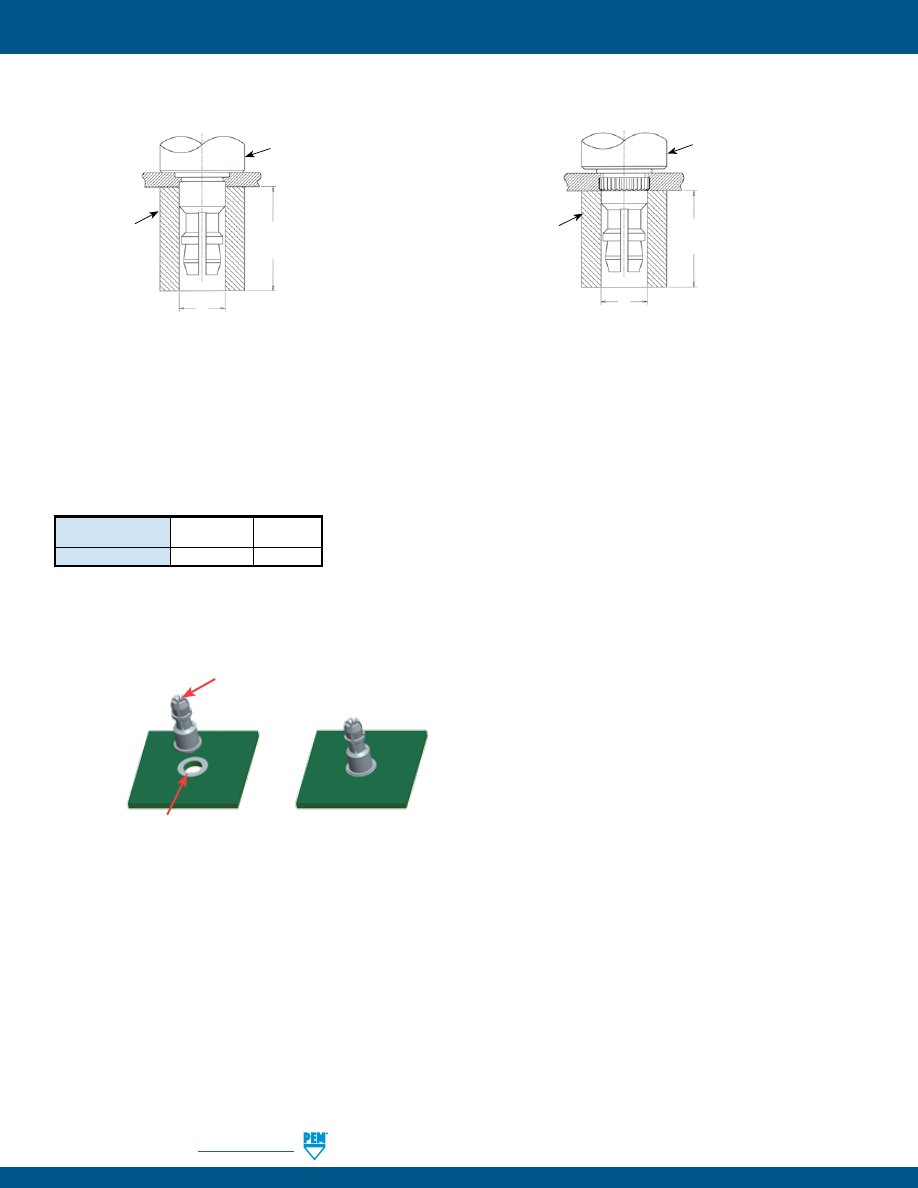

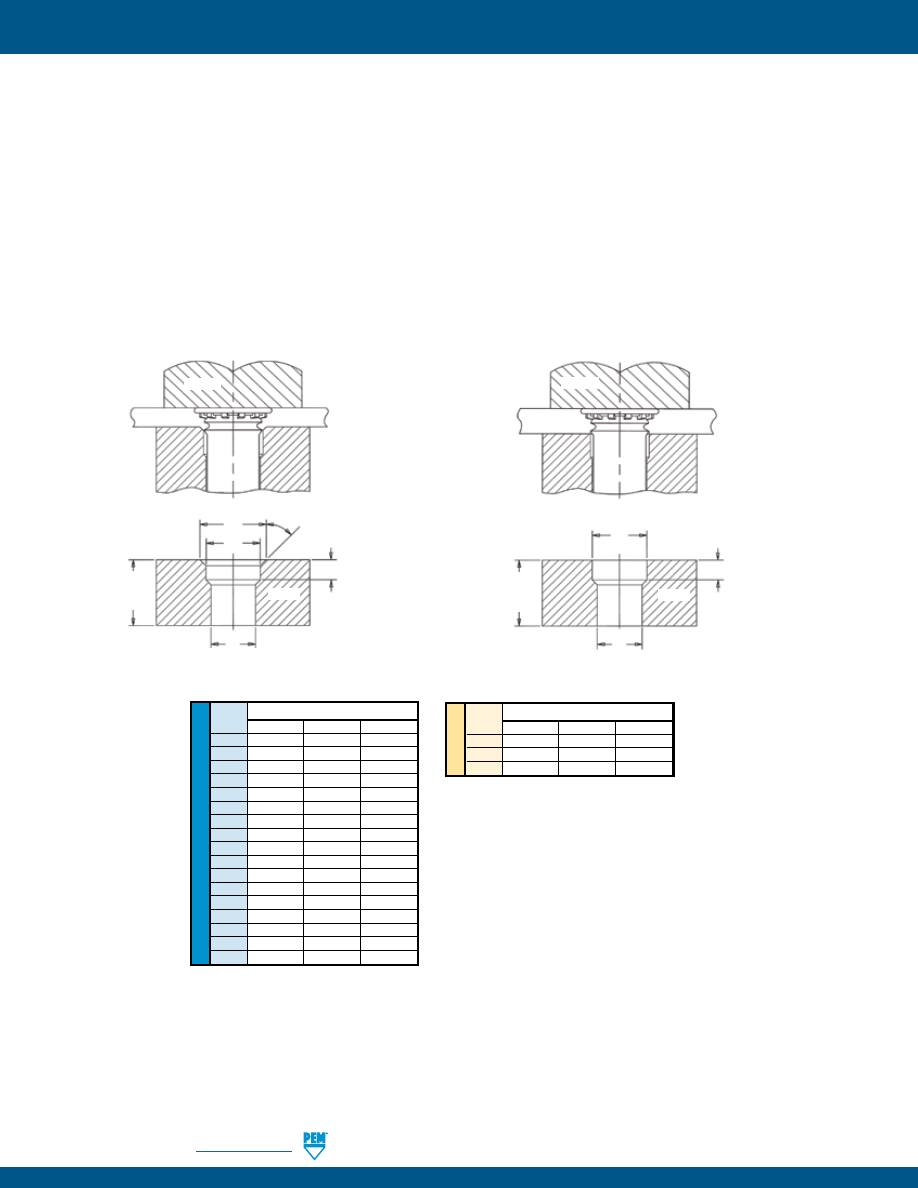

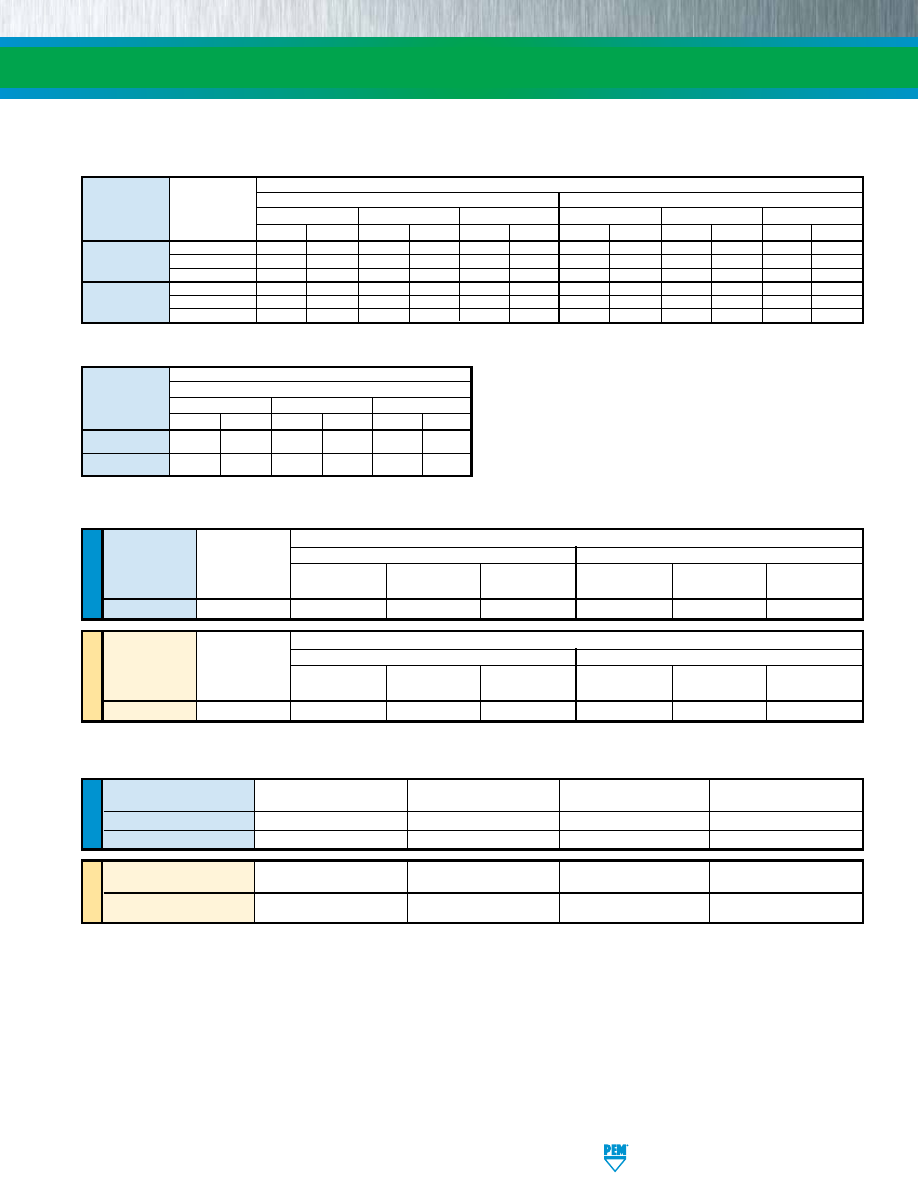

PEM® brand self-clinching nuts install

permanently in aluminum, steel or

stainless steel sheets.

Bulletin CL-1016

Rev. 118

pem-html.html

CL-2

PennEngineering •

www.pemnet.com

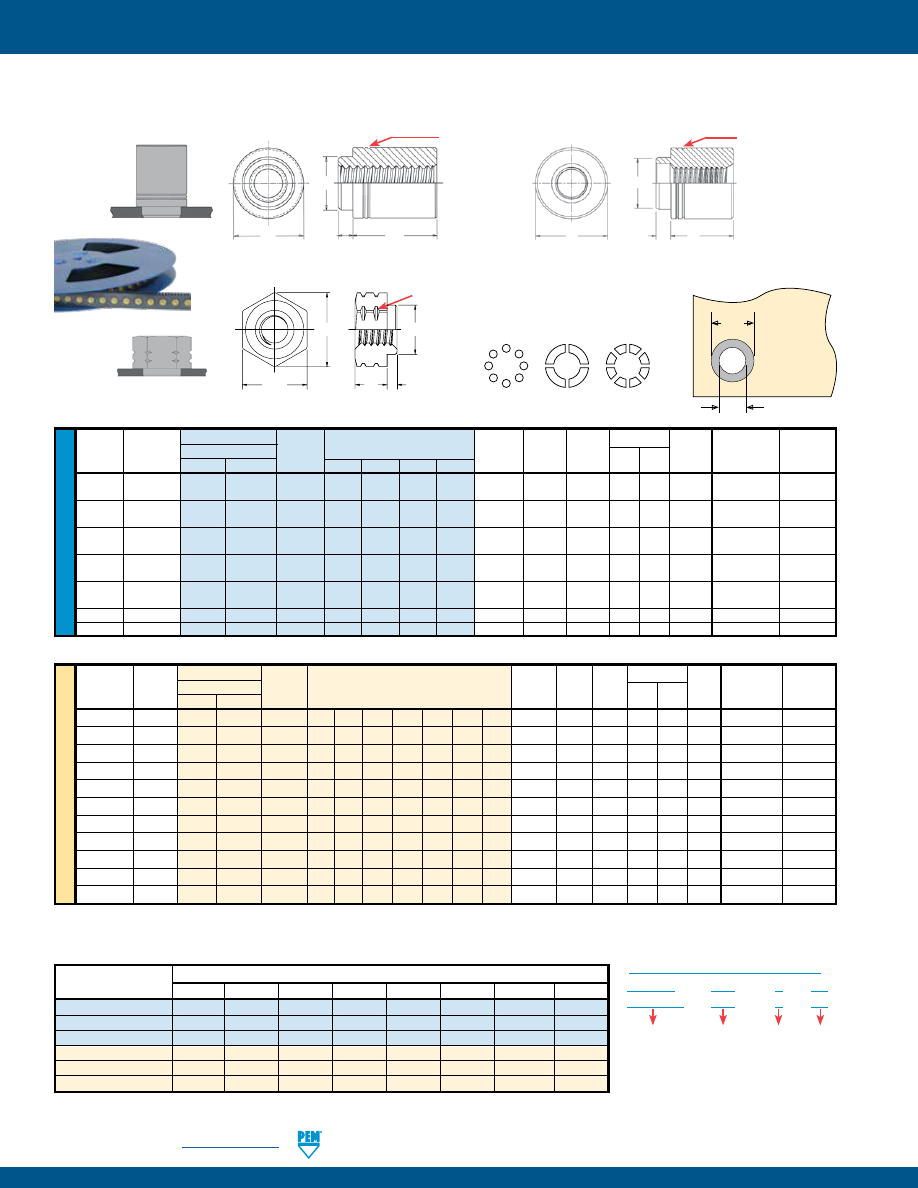

SELF-CLINCHING NUTS

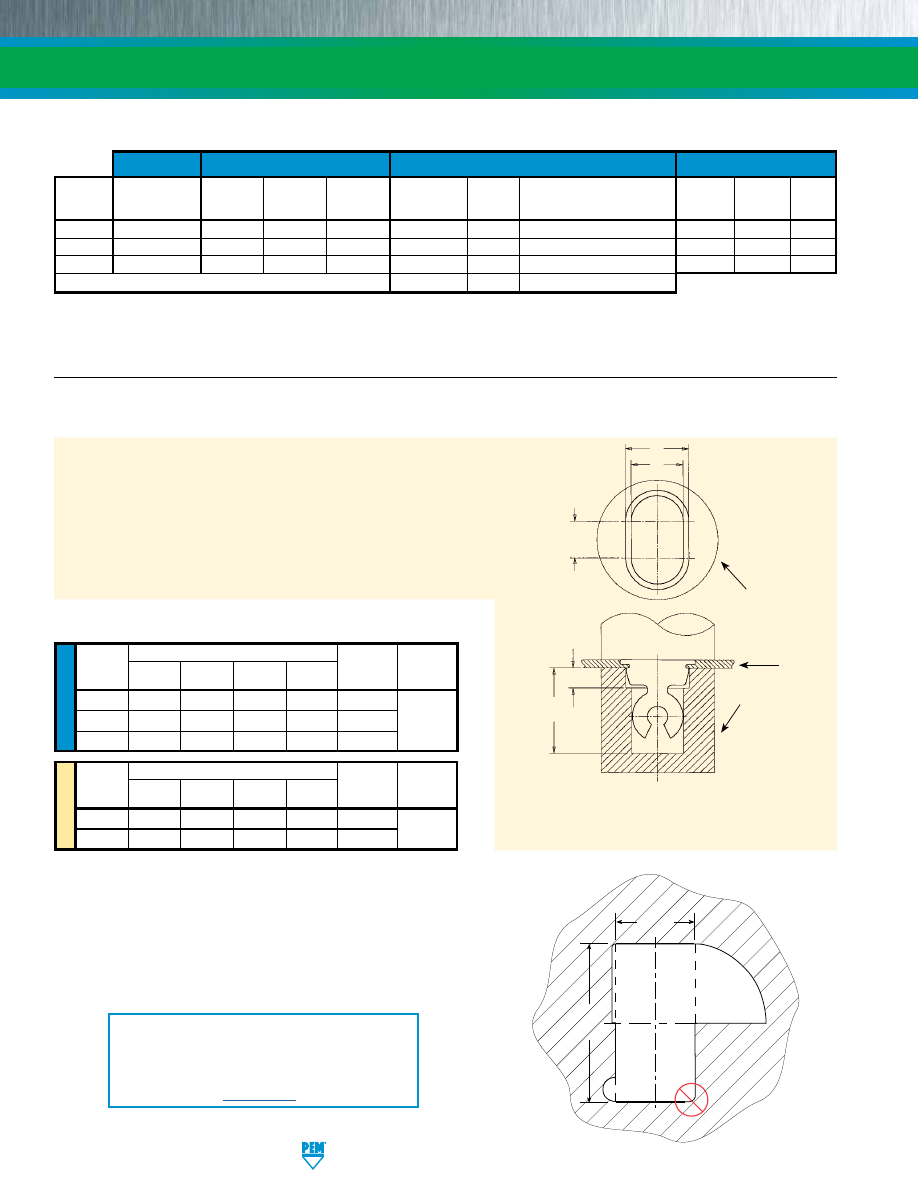

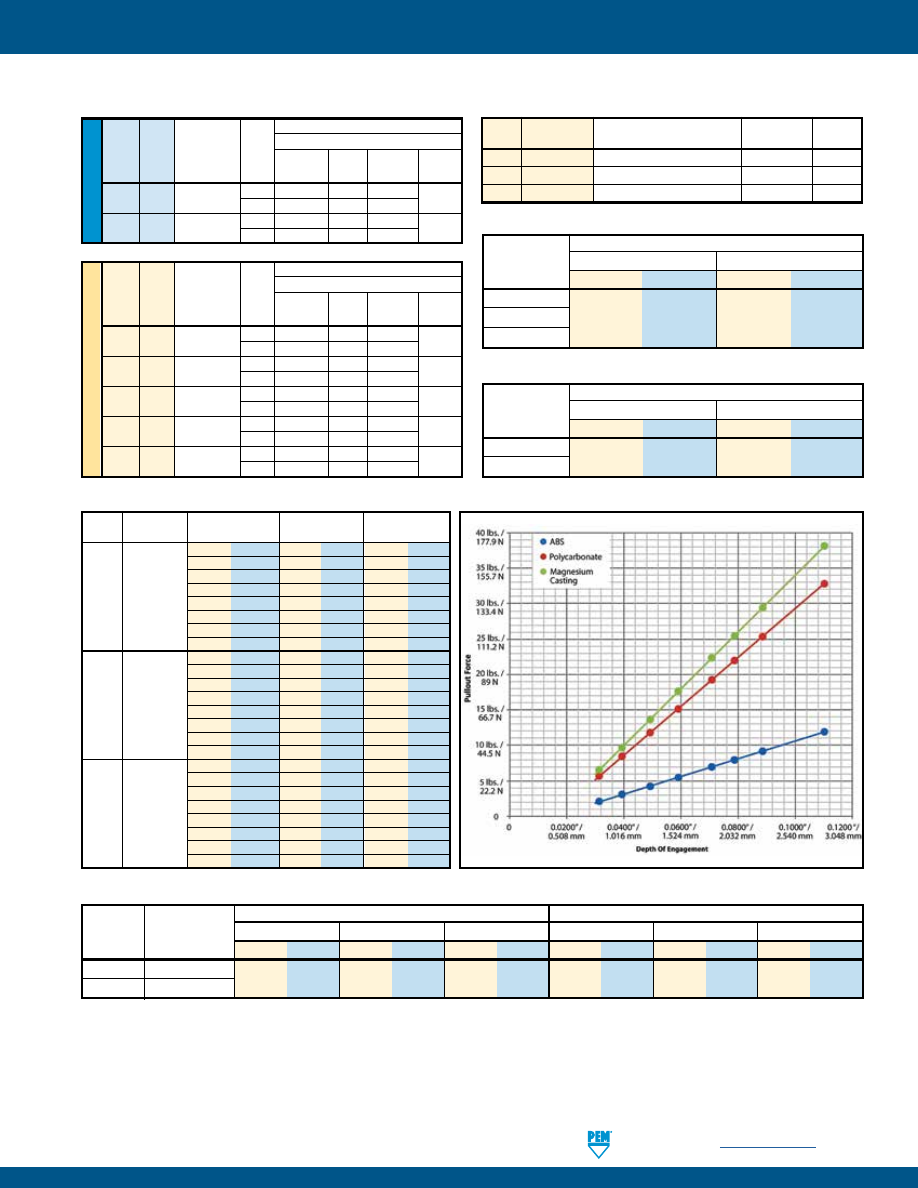

Many PEM self-clinching nuts in this bulletin are dimensionally equivalent to nuts manufactured to NASM45938/1 specifications. Consult our Marketing

department for a complete Military Specifications and National Aerospace Standards guide (Bulletin NASM) on our website.

Screws for use with PEM self-clinching locking fasteners should be Class 3A/4h fit or no smaller than Class 2A/6g.

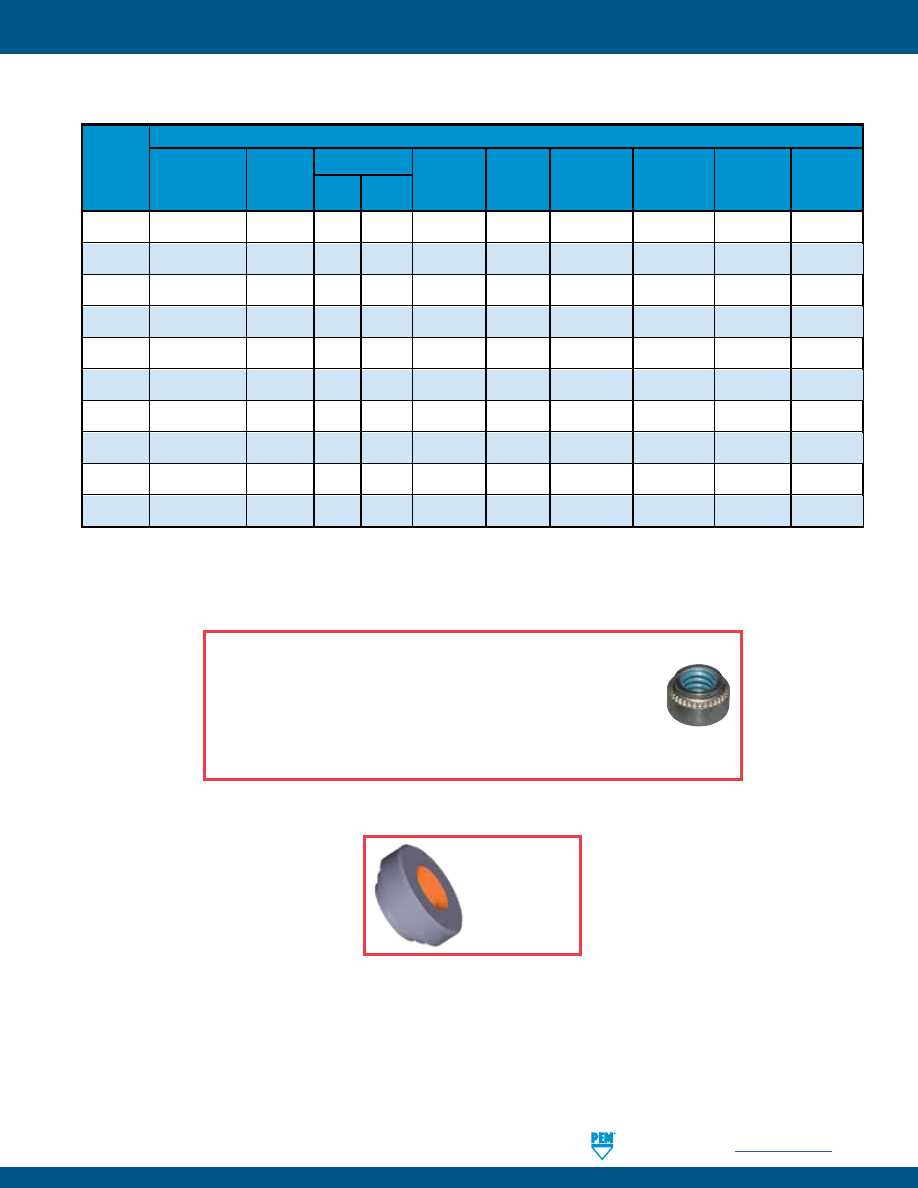

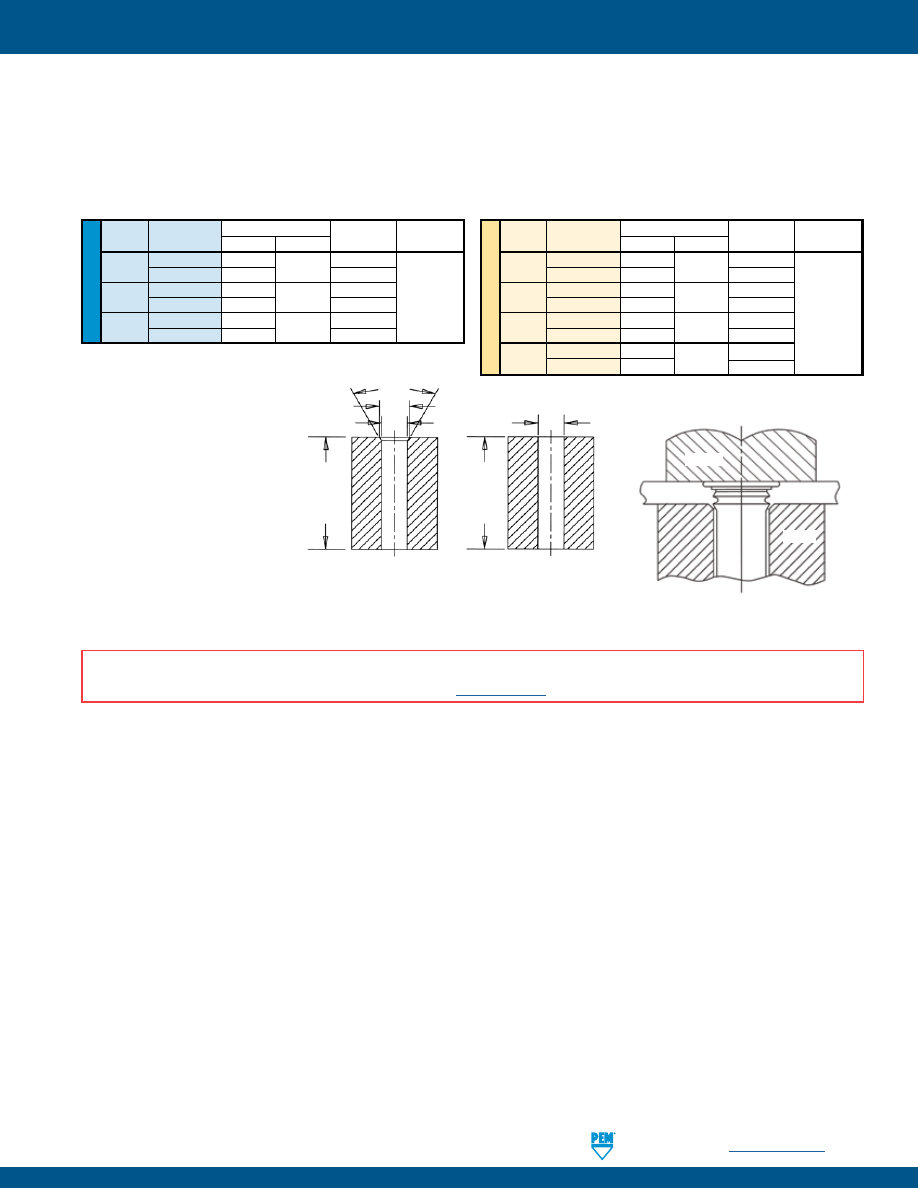

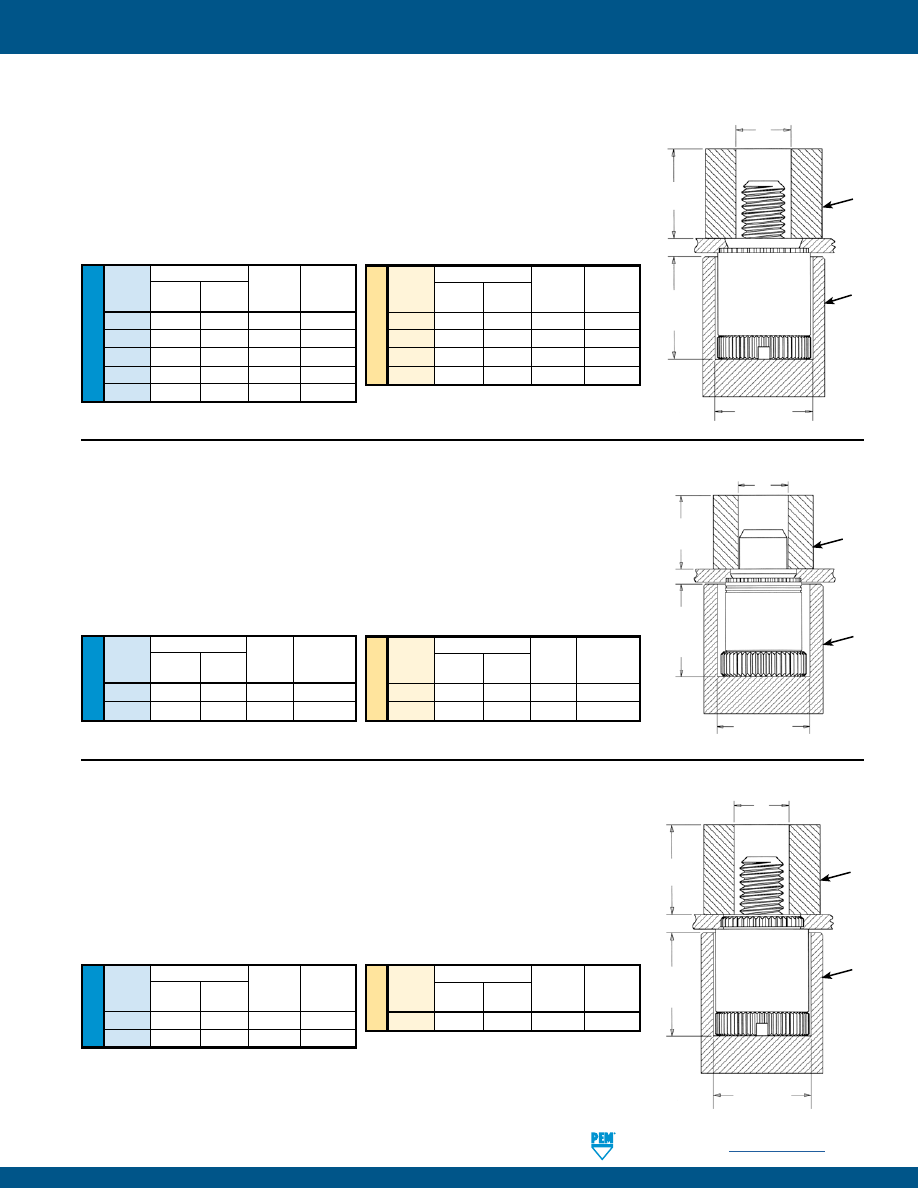

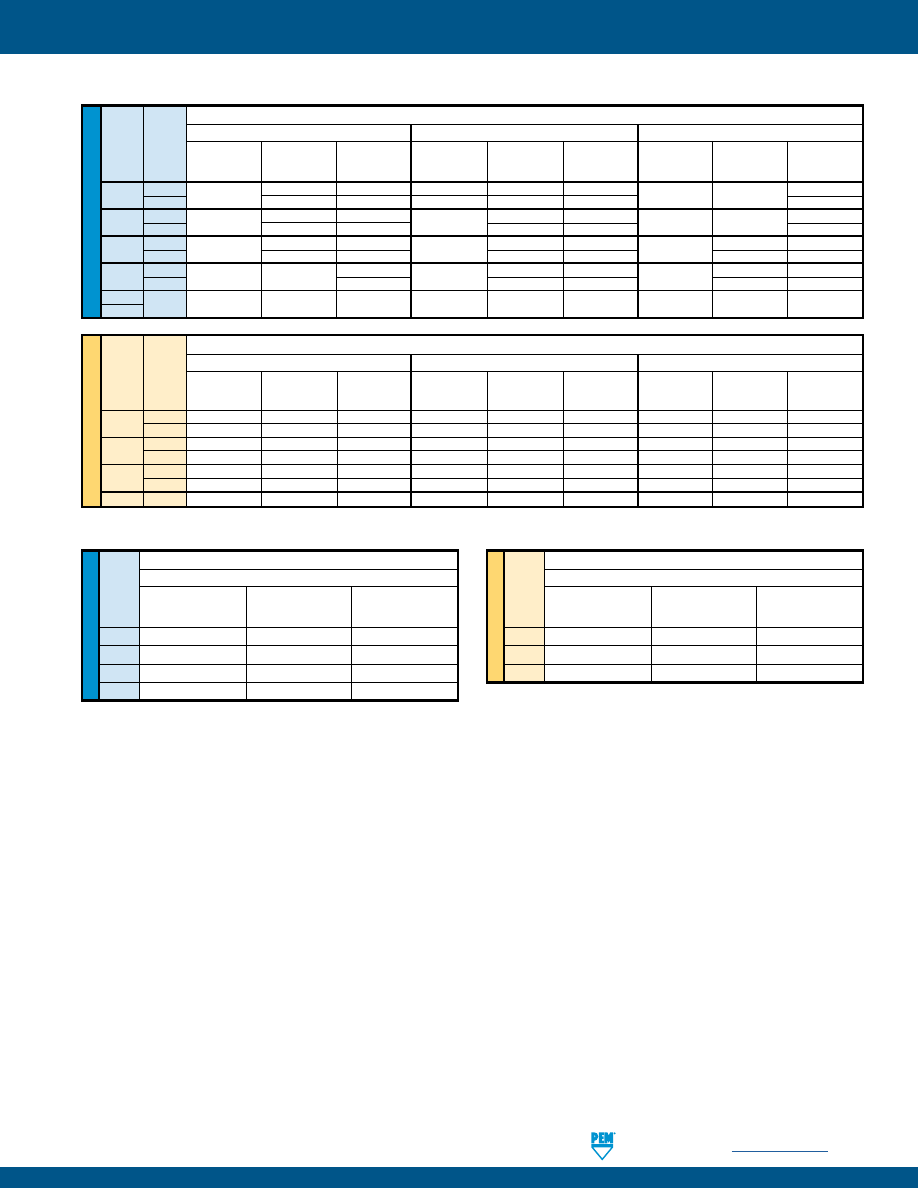

S™/SS™/CLA™/CLS™/CLSS™ nuts

provide load-bearing threads in thin

sheets with high pushout and torque-out

resistance

-

PAGES 4 and 5

SP™, PEM 300® nuts

provide strong

load-bearing threads in stainless steel

sheets as thin as .030”/0.8 mm

-

PAGES 4 and 5

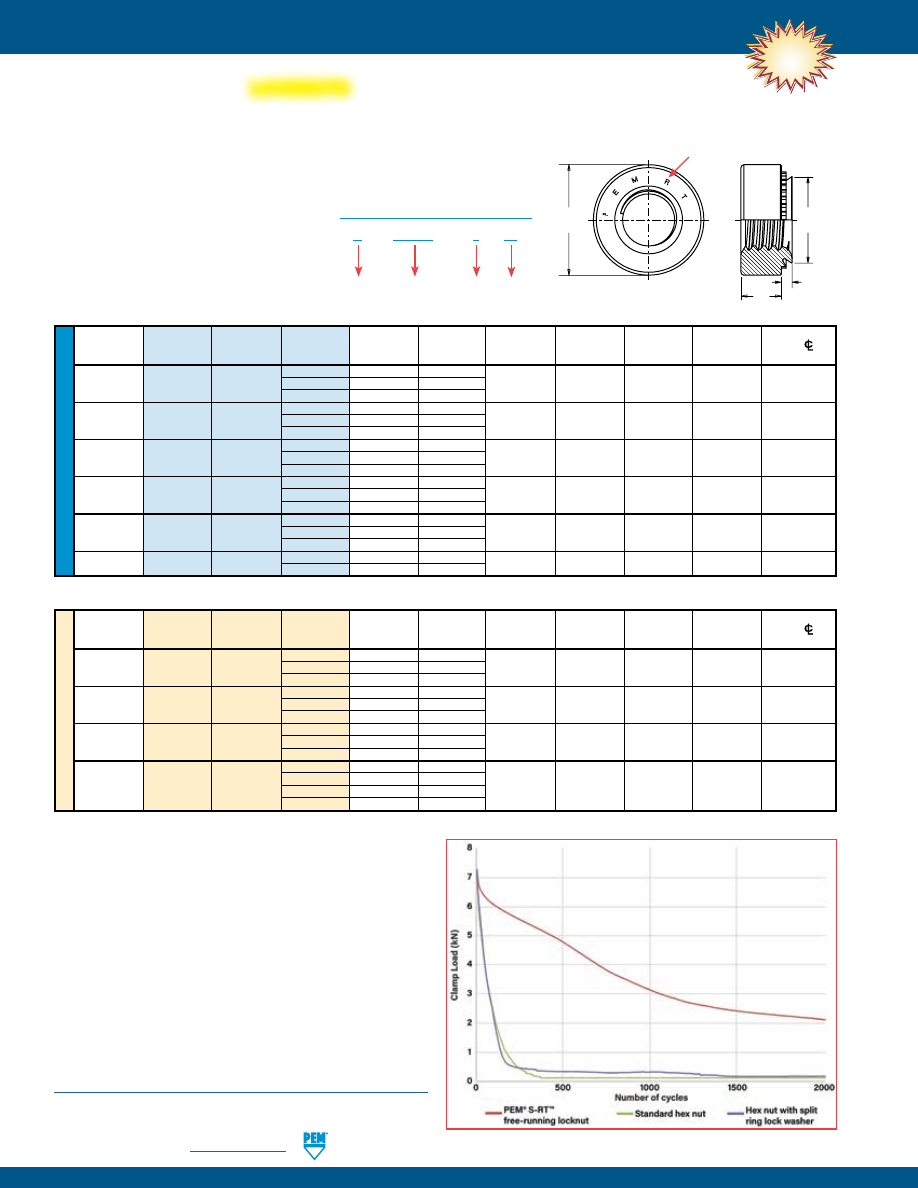

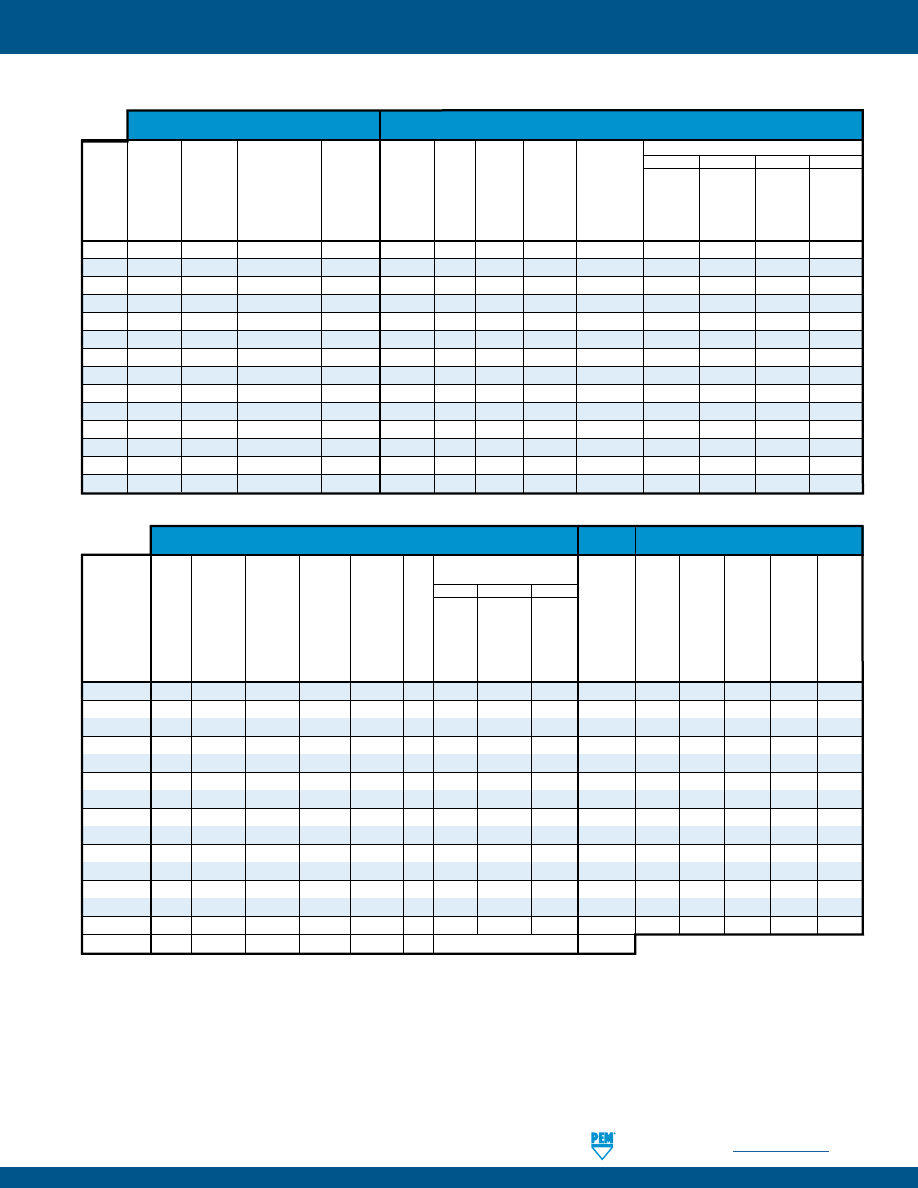

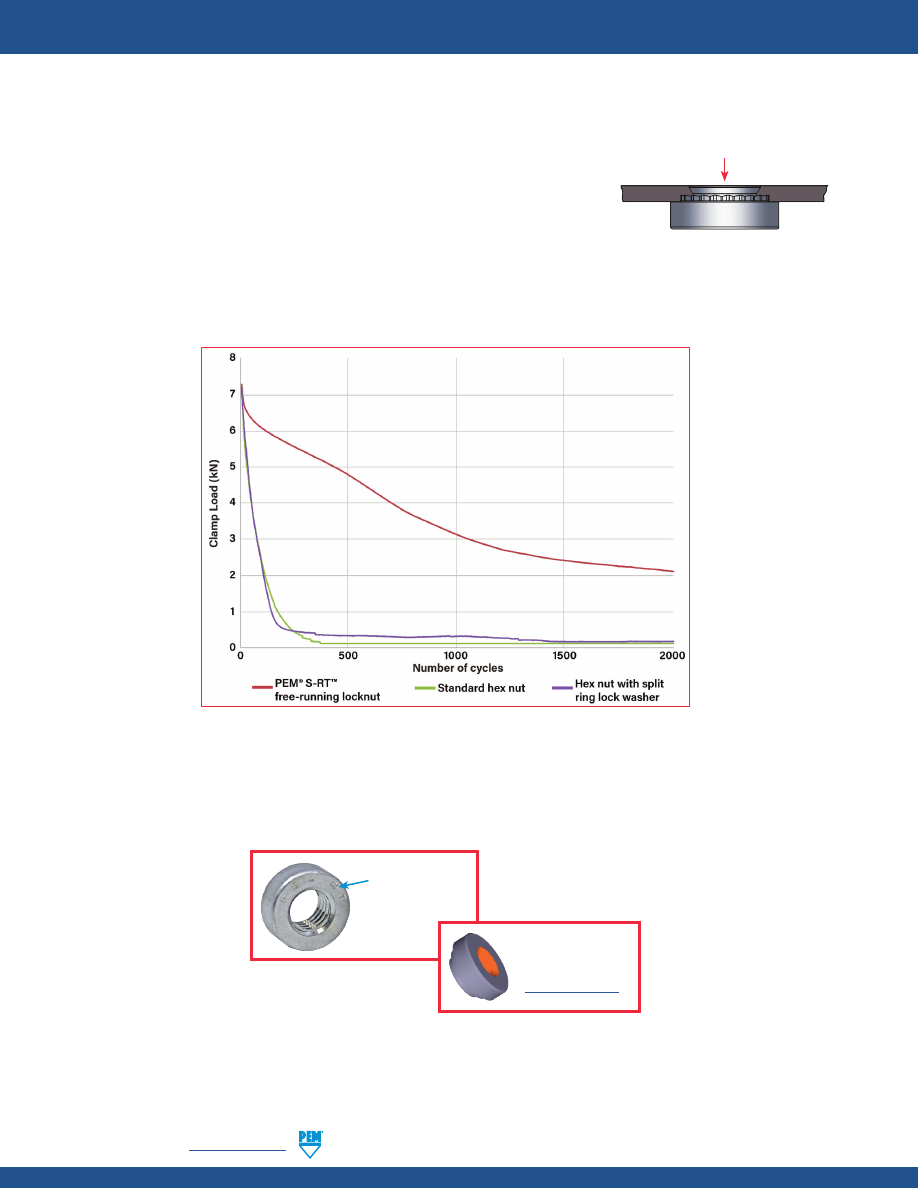

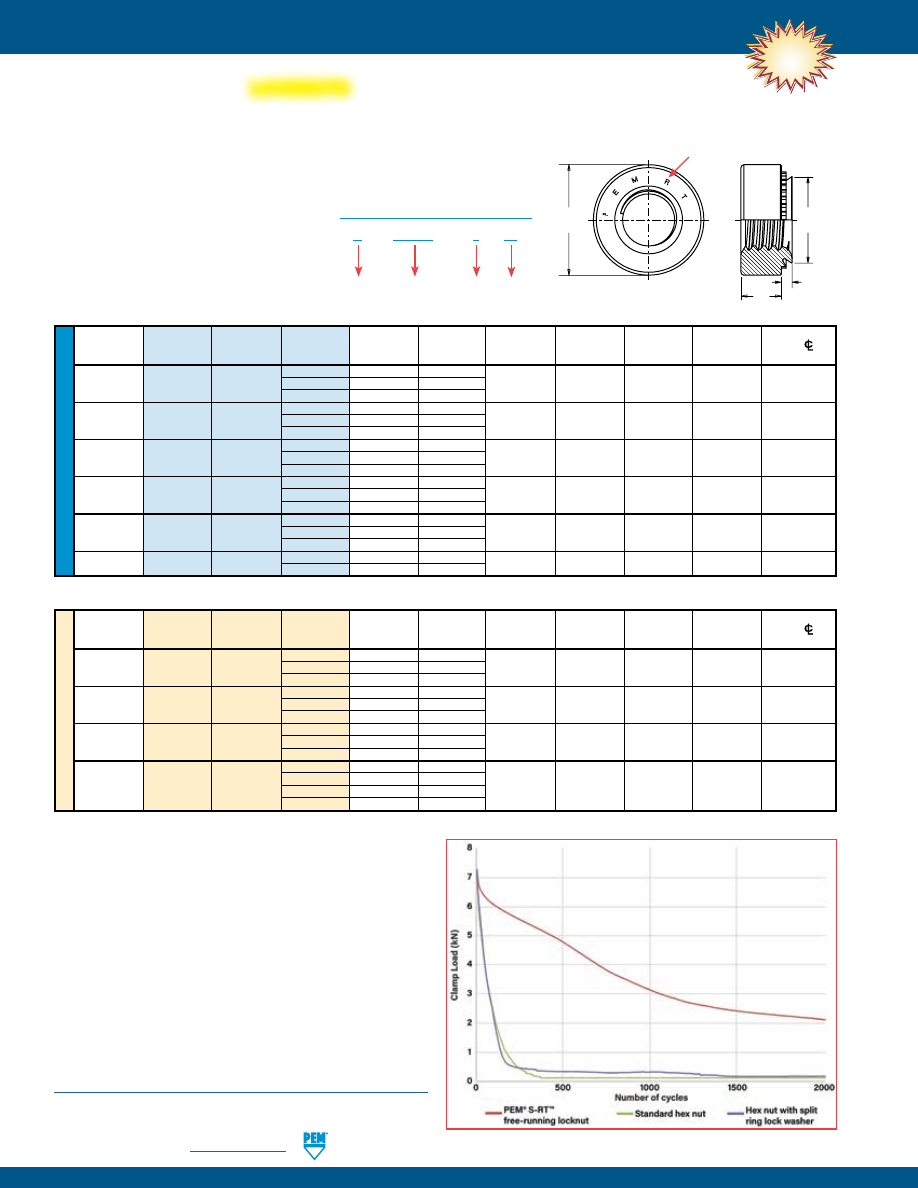

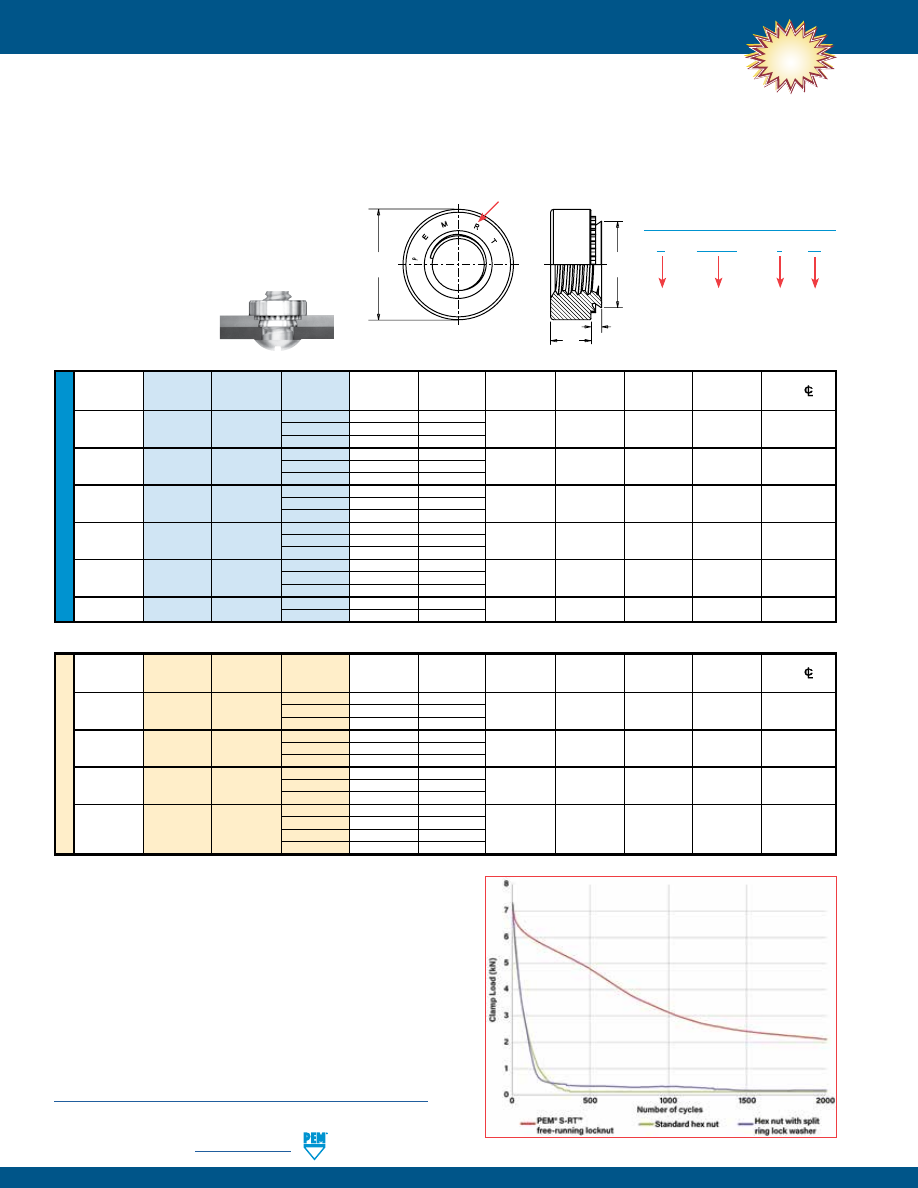

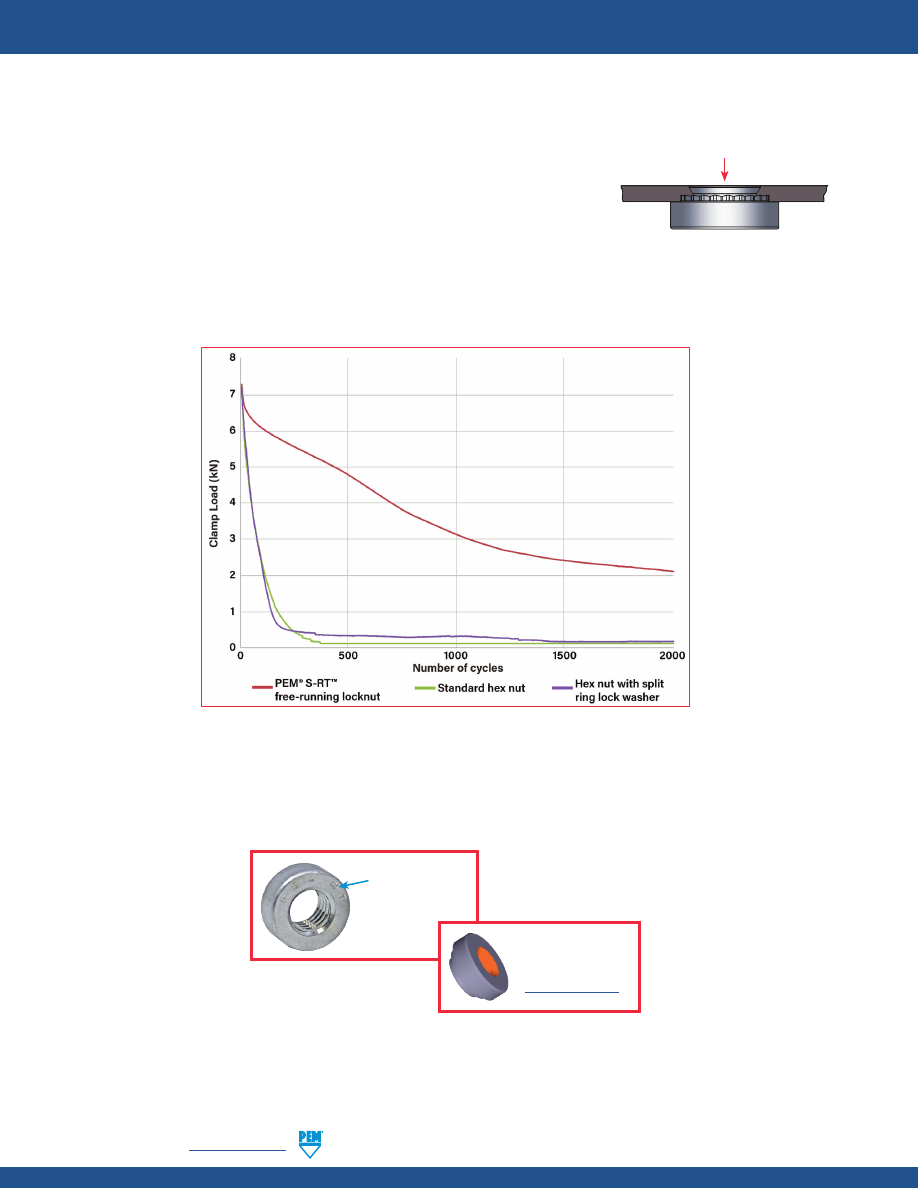

S-RT™ free-running locknuts

are free-

running until clamp load is induced. A

modified thread angle on the loaded flank

provides the vibration resistant locking

feature

-

PAGE 6

SL™ self-locking nuts

are designed with

a unique and economical TRI-DENT®

locking feature, meeting 3 cycle locking

performance requirements

-

PAGE 7

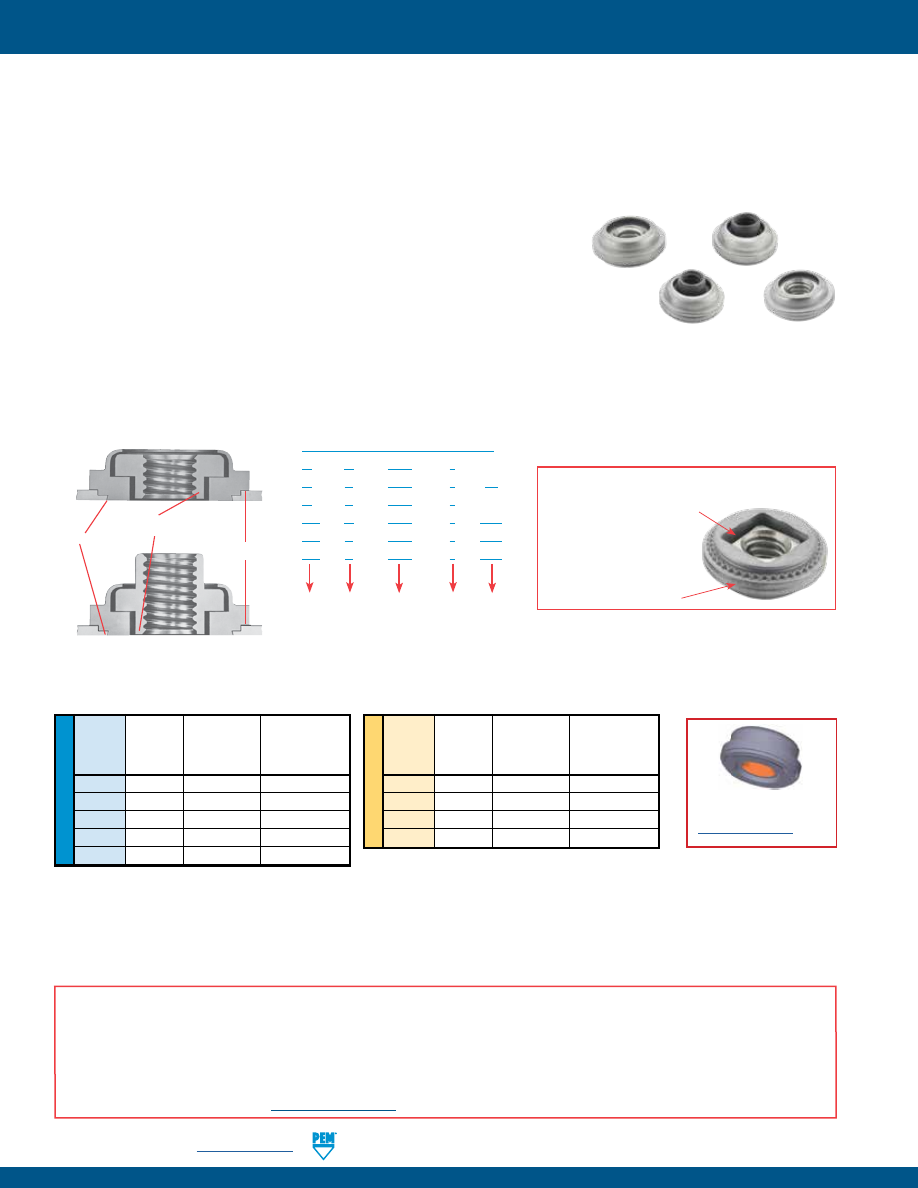

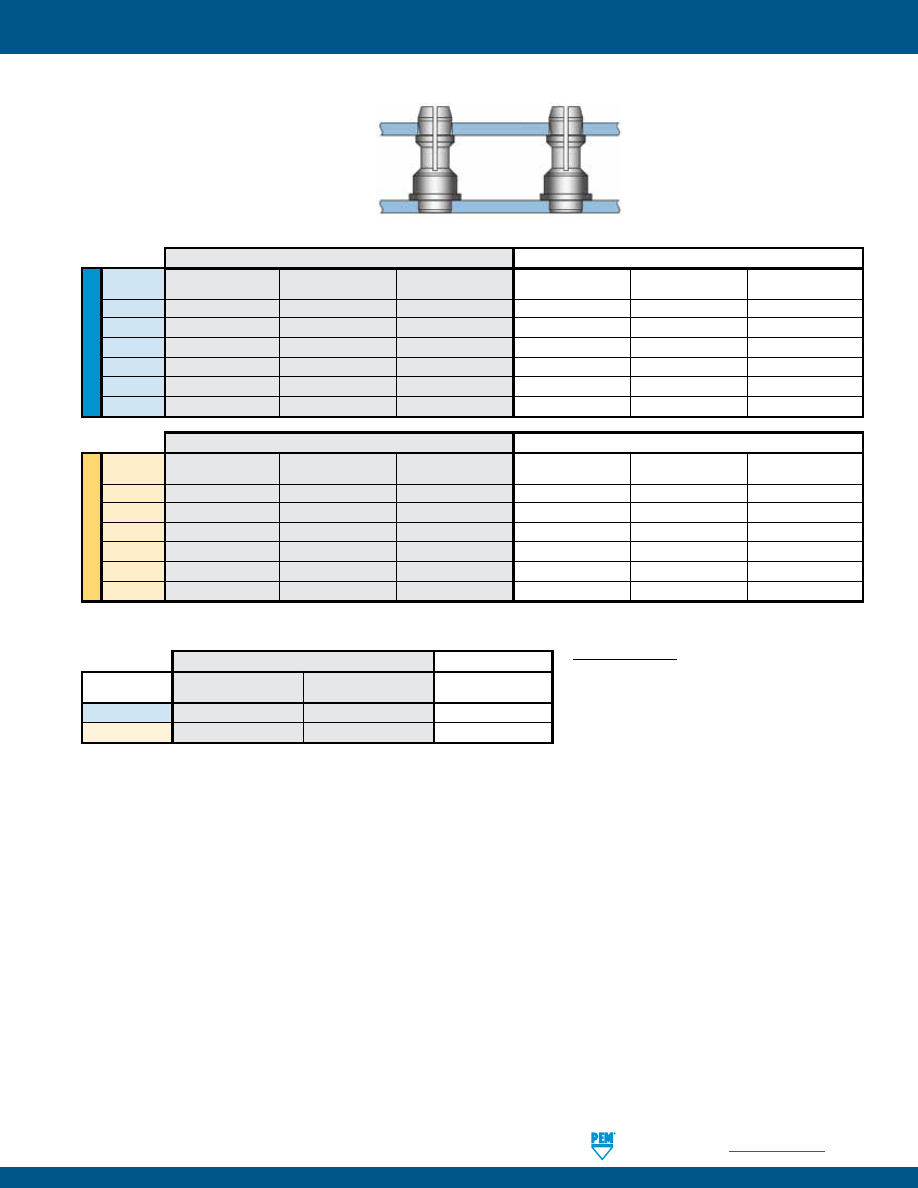

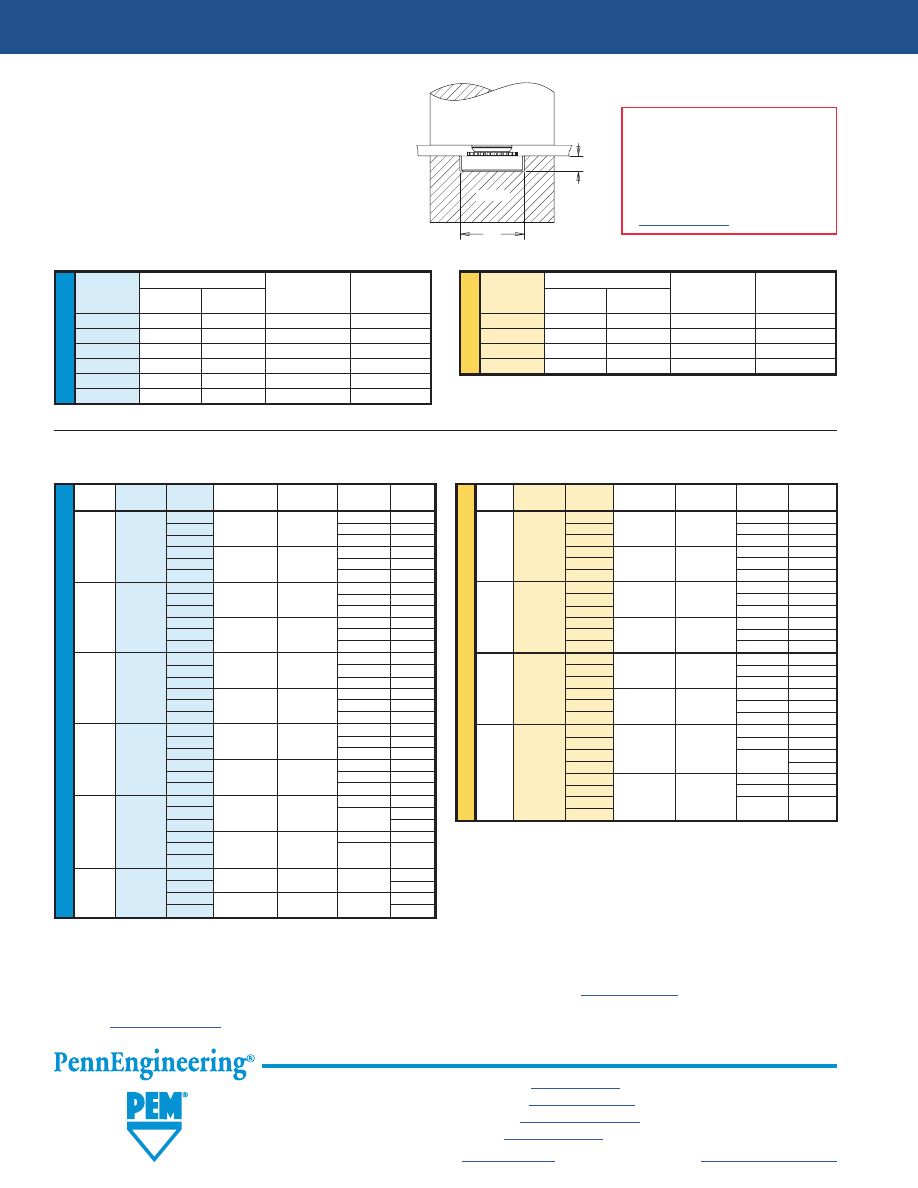

Self-clinching nuts are installed by placing them in properly sized holes in sheets and

applying a parallel squeezing force to the head of the nut. The sheet metal surrounding the

head cold flows into an undercut thereby making the fastener an integral part of the sheet.

A serrated clinching ring prevents the fastener from rotating after installation.

H™ (non-locking) and HNL™ (locking)

nuts

have threads that provide high

pushout and torque-out resistance

-

PAGE 8

SH™ hard panel nuts

install into thin,

harder, high strength steel materials -

PAGE 8

SMPS™/SMPP™ nuts

are for thinner

sheet/close-to-edge applications

-

PAGE 9

Material and finish specifications -

PAGE 9

Installation -

PAGES 10 and 11

Performance data -

PAGES 12 - 15

© 2017 PennEngineering.

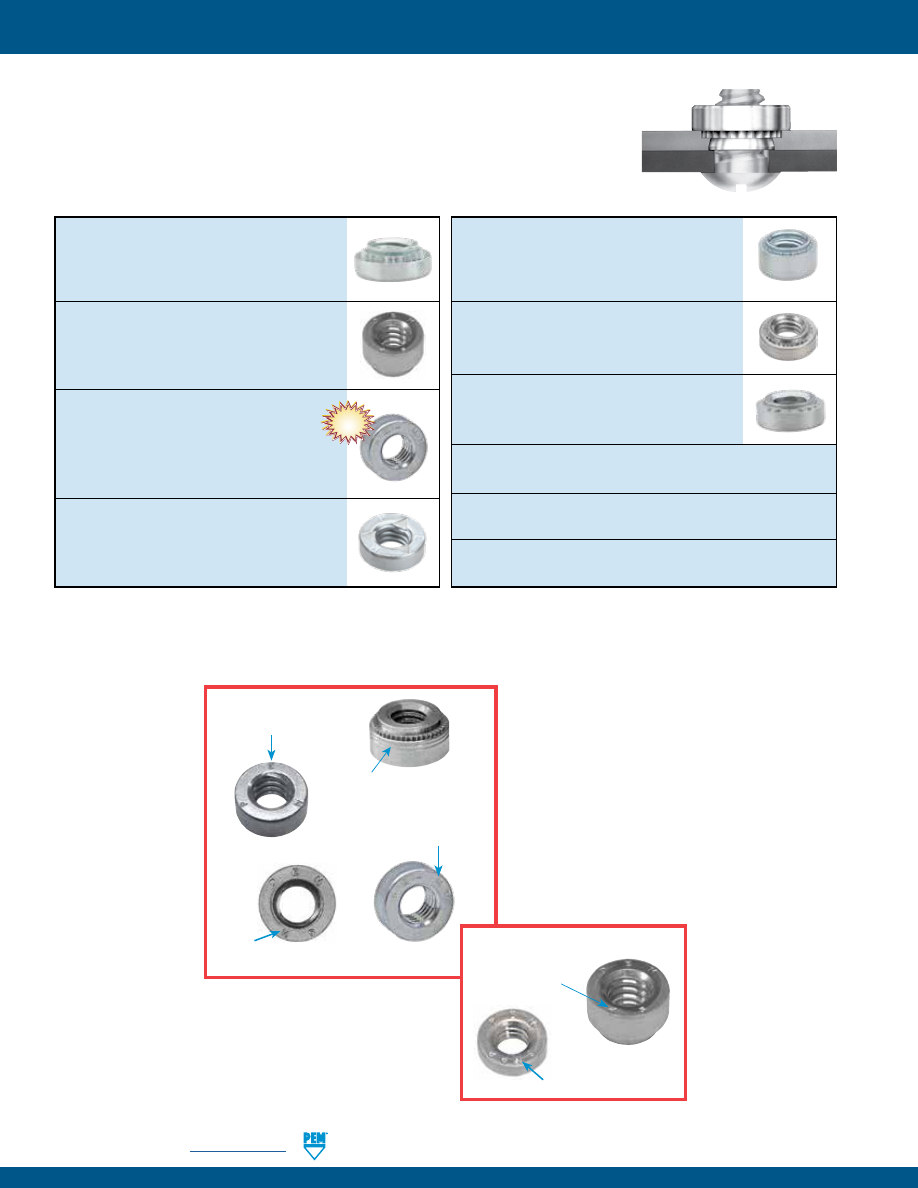

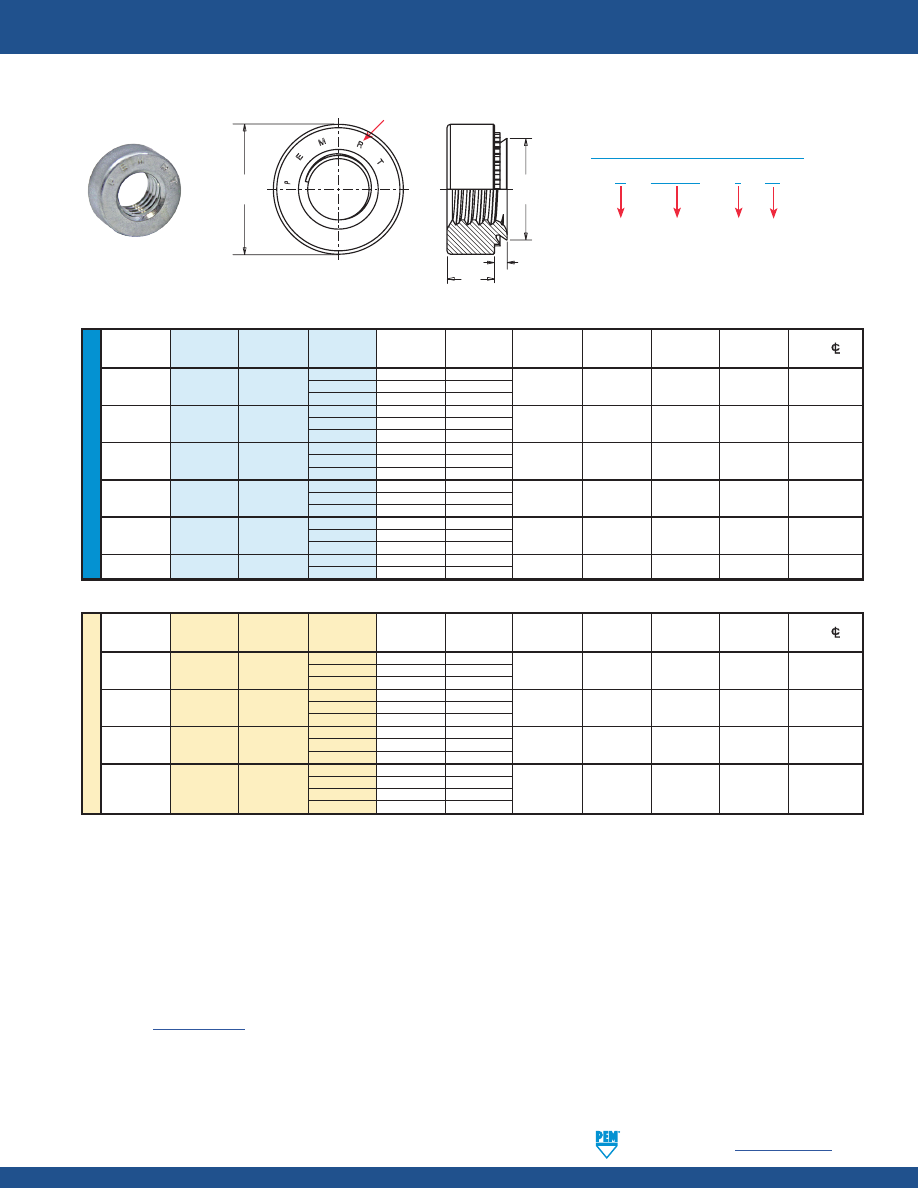

PEM® Two Groove

(Registered Trademark)

PEM® Stamp

(Registered Trademark)

SH

(Registered Trademark)

“PEM RT” Stamp

(Trademark)

NEW!

SP

Identification

Mark

Fasteners For Stainless Steel

SMPP

Identification Mark

pem-html.html

PennEngineering •

www.pemnet.com

CL-3

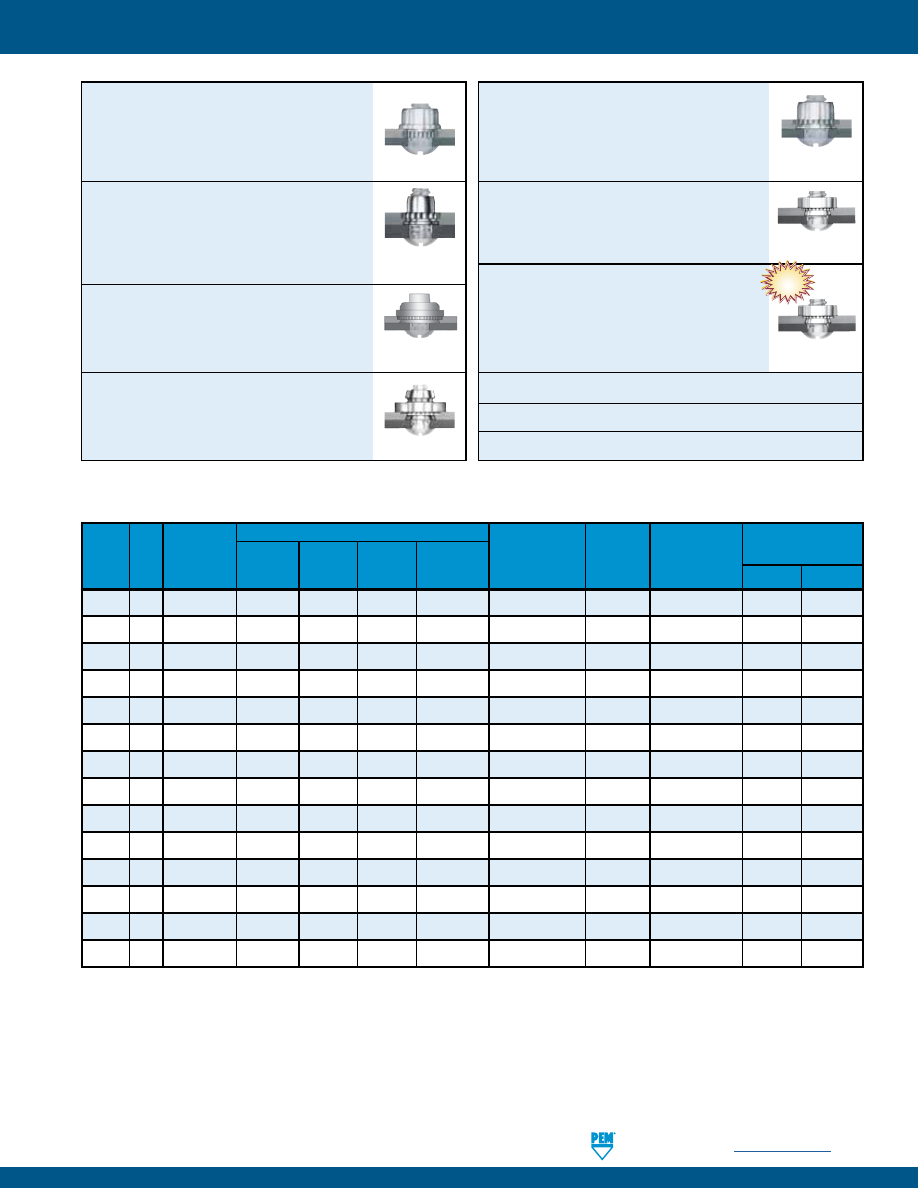

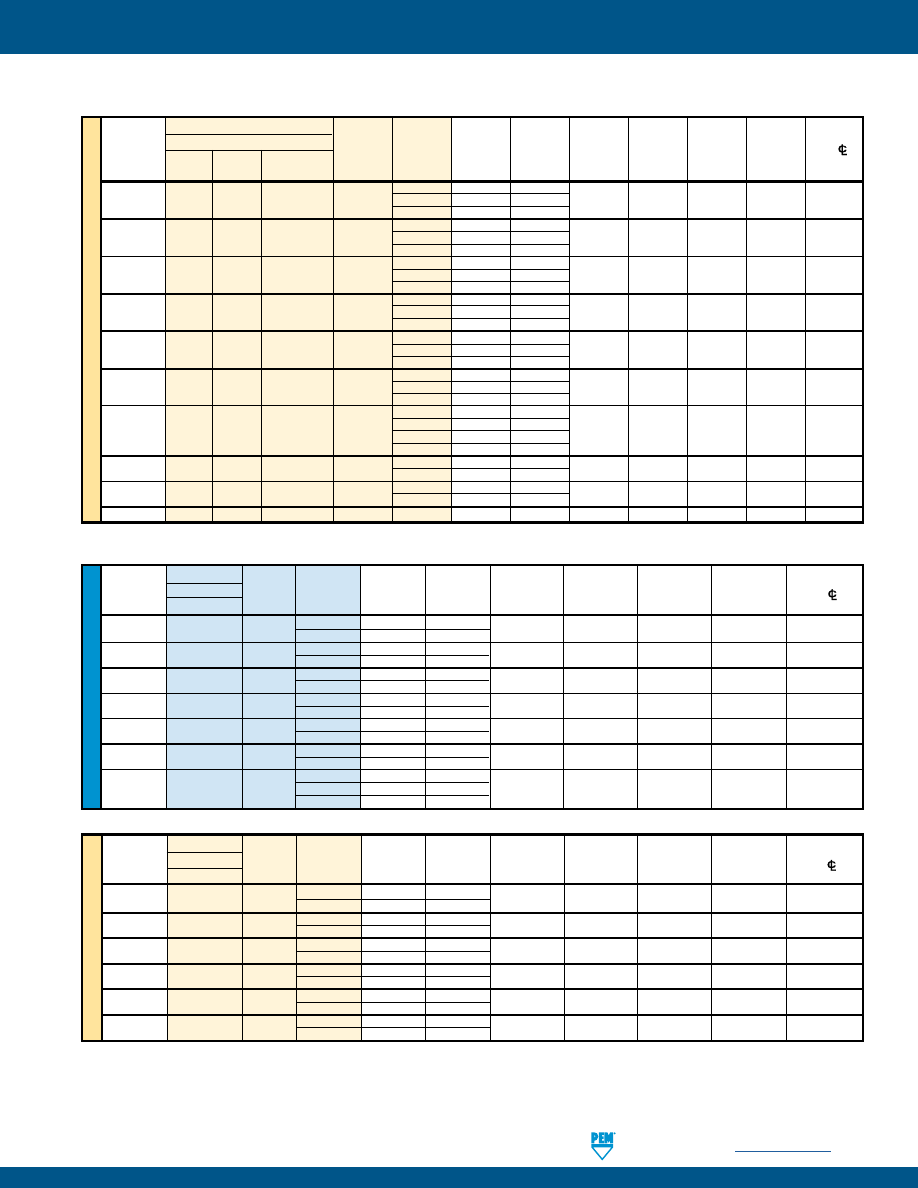

SELF-CLINCHING NUTS

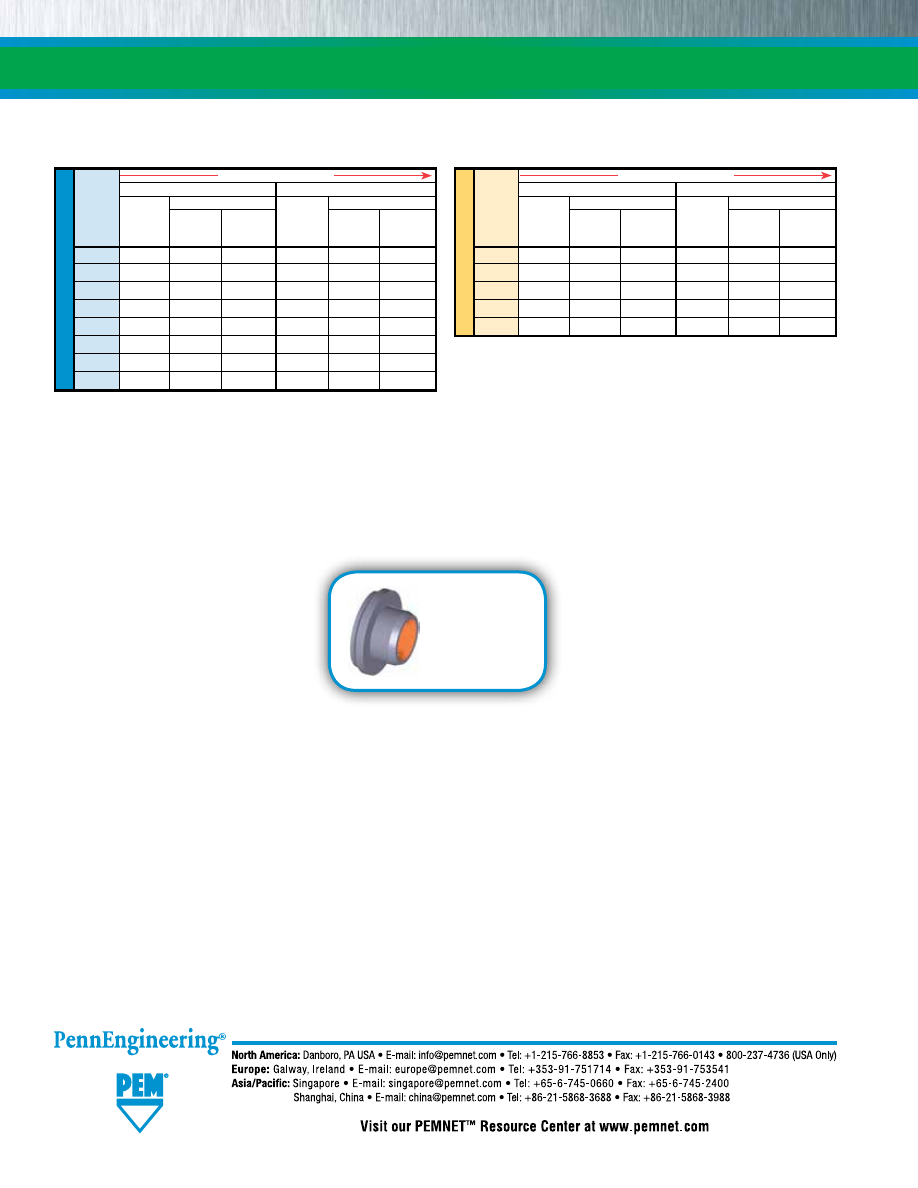

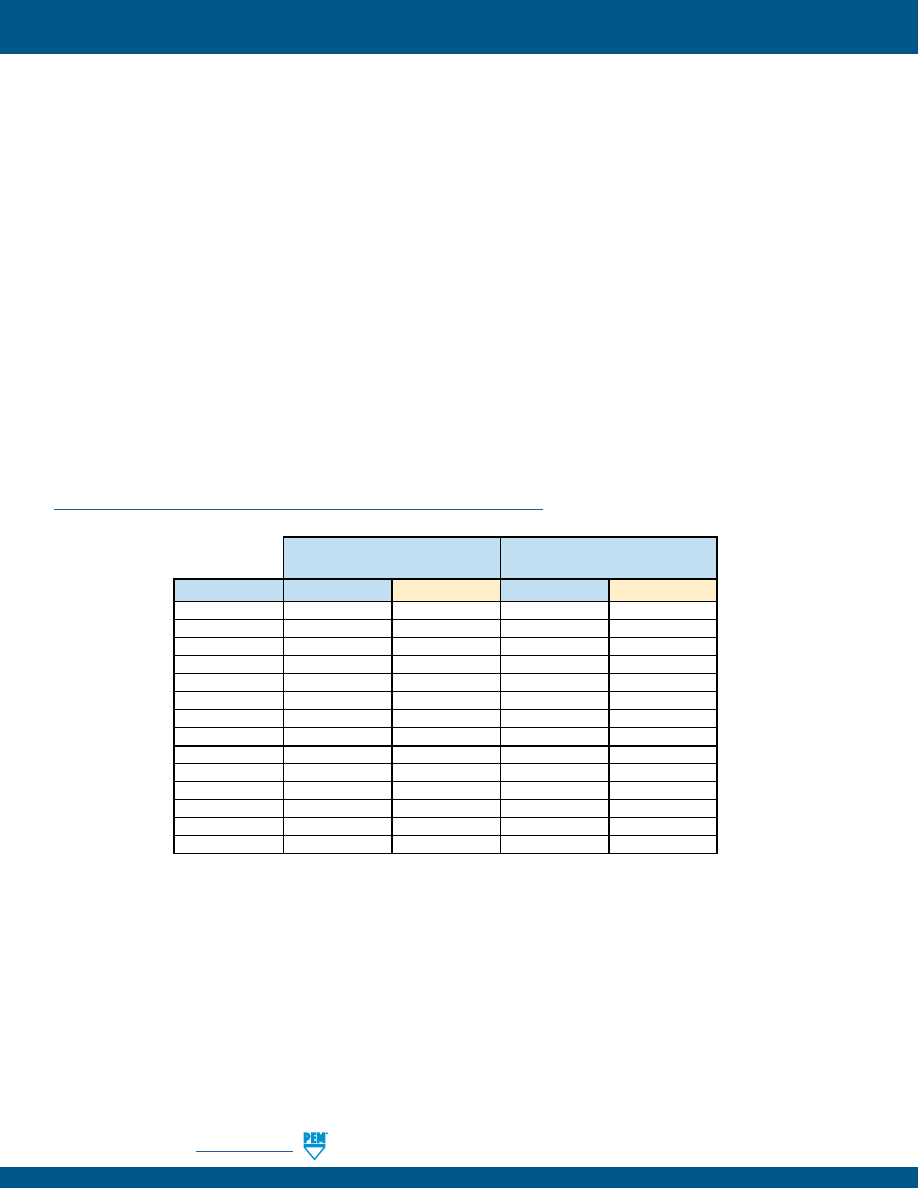

Recommended

Thinnest Locking Threads Closest Superior Recommended Compatible Harder

panel

sheet

centerline-to-

corrosion

for installation

with aluminum

high strength

material

(1)

.025” /

Free- Prevailing edge distance

resistance

into stainless

anodizing

steel material Non-magnetic

0.64 mm

running

torque

steel sheets

A p p l i c a t i o n R e q u i r e s :

PEM

Nut

Type

S/SS/H

steel / aluminum

CLS/CLSS

steel / aluminum

• •

CLA

aluminum

• • •

SP

stainless steel

• • •

S-RT

steel / aluminum

•

SL

steel / aluminum

•

HNL

aluminum

•

SH

hardened alloy steel

•

SMPS

steel / aluminum

• •

•

•

SMPP

stainless steel

• •

•

•

•

PEM® SELF-CLINCHING NUT SELECTOR GUIDE

Thread Mask

PEM® Blu-Coat™ thread mask is available for applications where hardware is installed

prior to painting. During assembly, the threads of the mating hardware will remove

paint, electro deposited automotive under coatings, and weld spatter upon application

of torque. PEM nuts can be specially ordered with thread mask applied.

“BC” suffix will be added to part number to designate Blu-Coat thread mask to fastener.

Fastener drawings

and models are

available at

www.pemnet.com

(1) Describes “best practice” for typical applications. Fasteners can be used in other panel materials not listed here if specified hardness limits are met. In

all cases “For Use in Sheet Hardness” information is shown in chart on page 9.

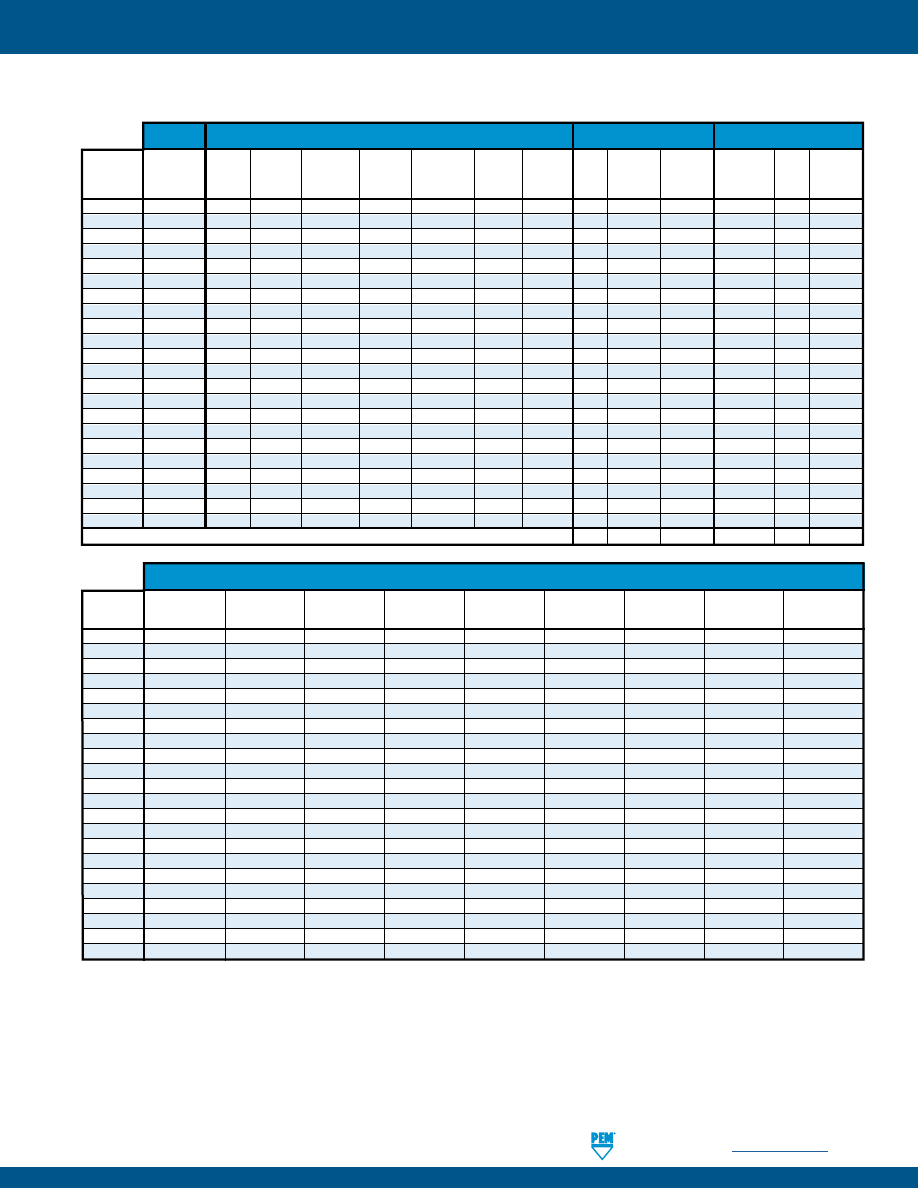

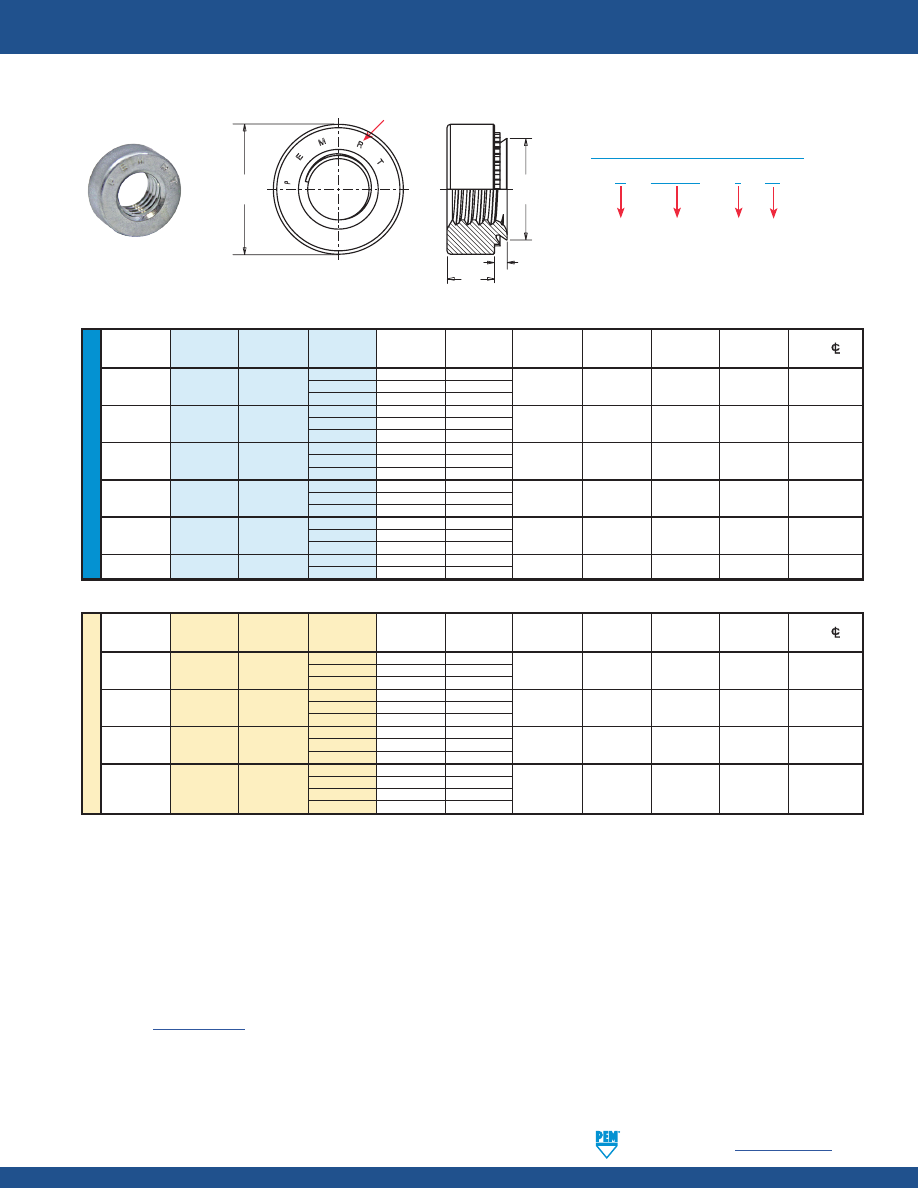

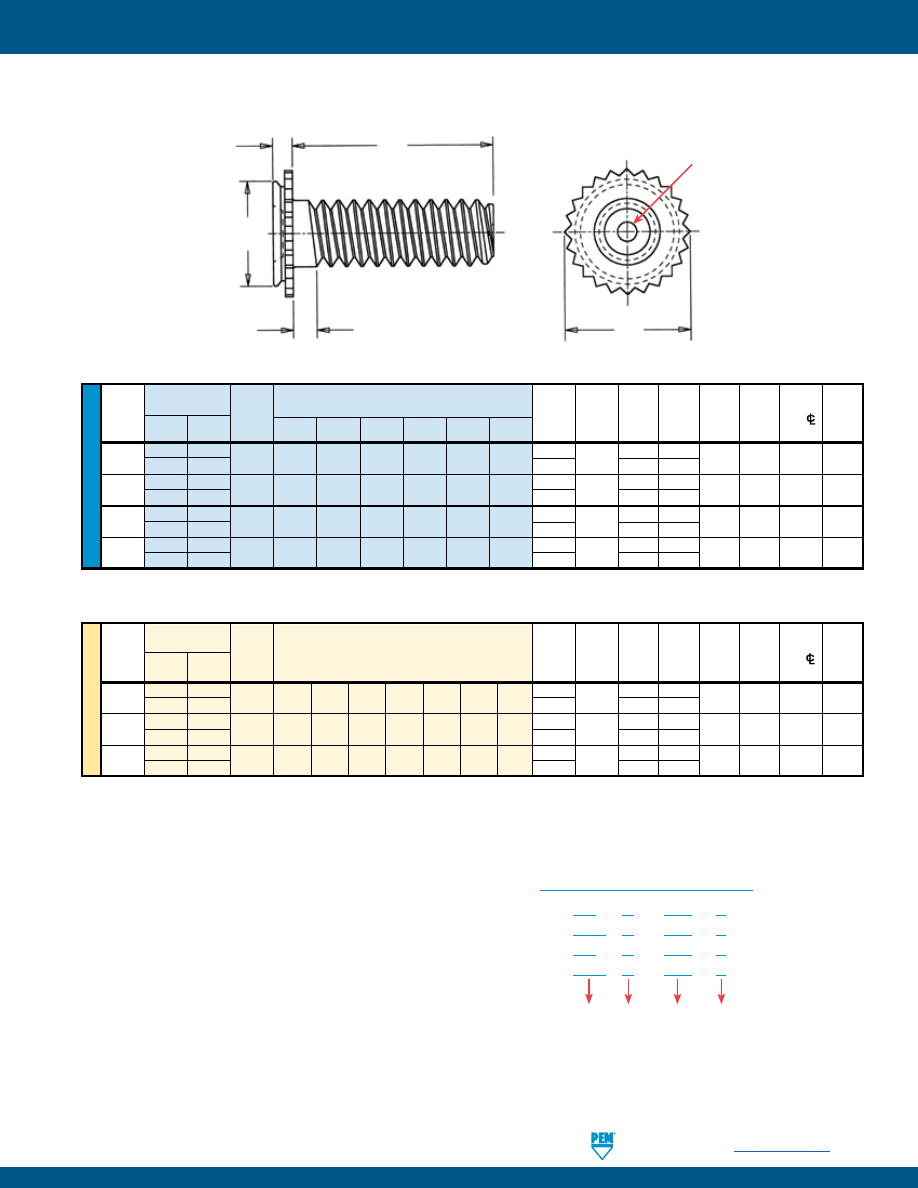

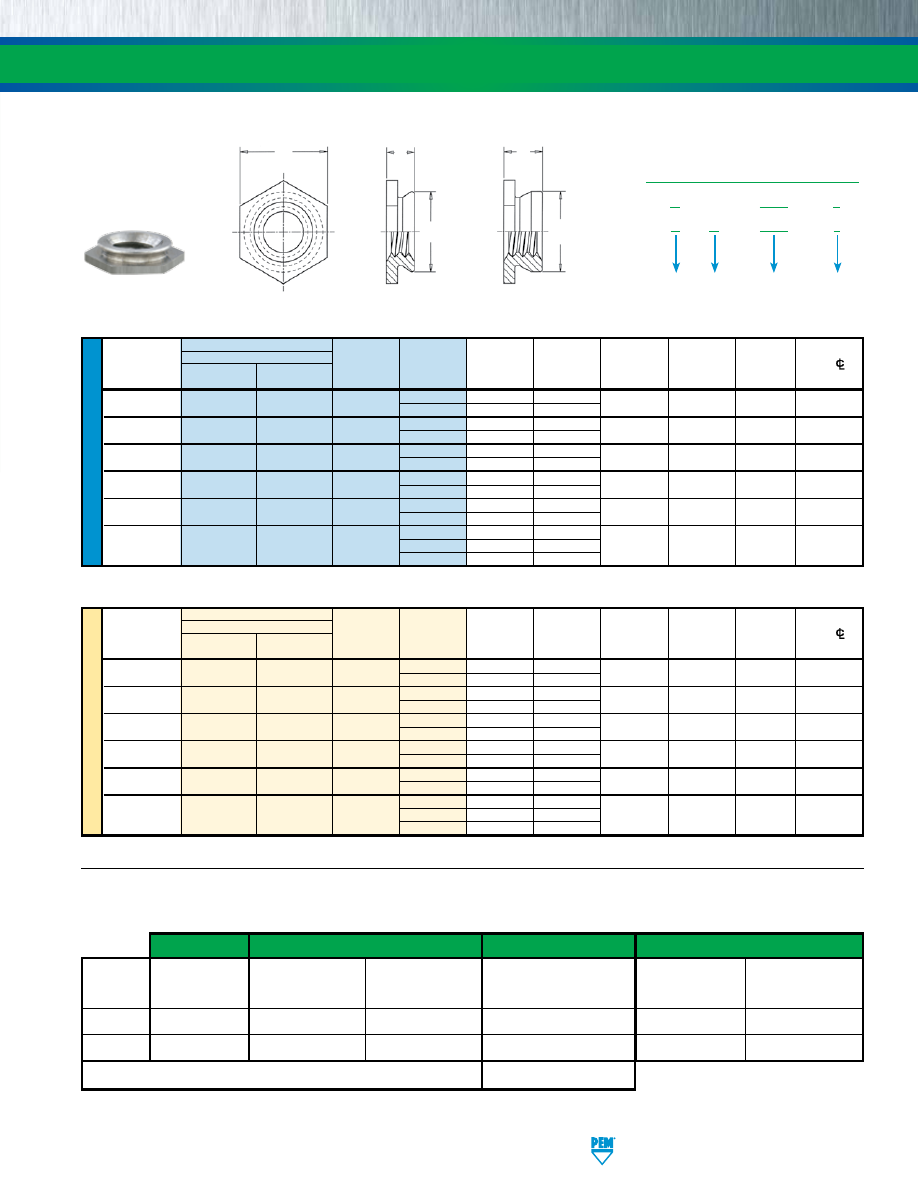

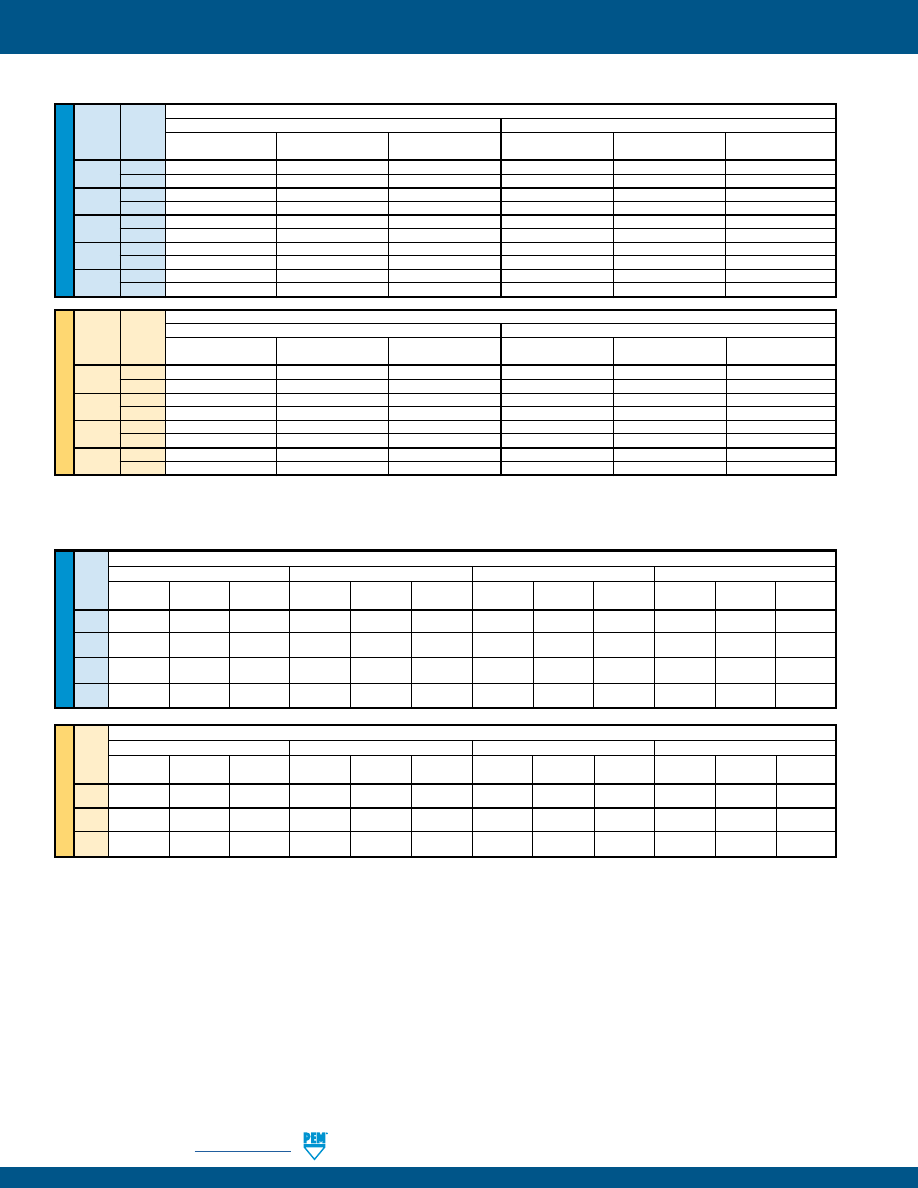

pem-html.html

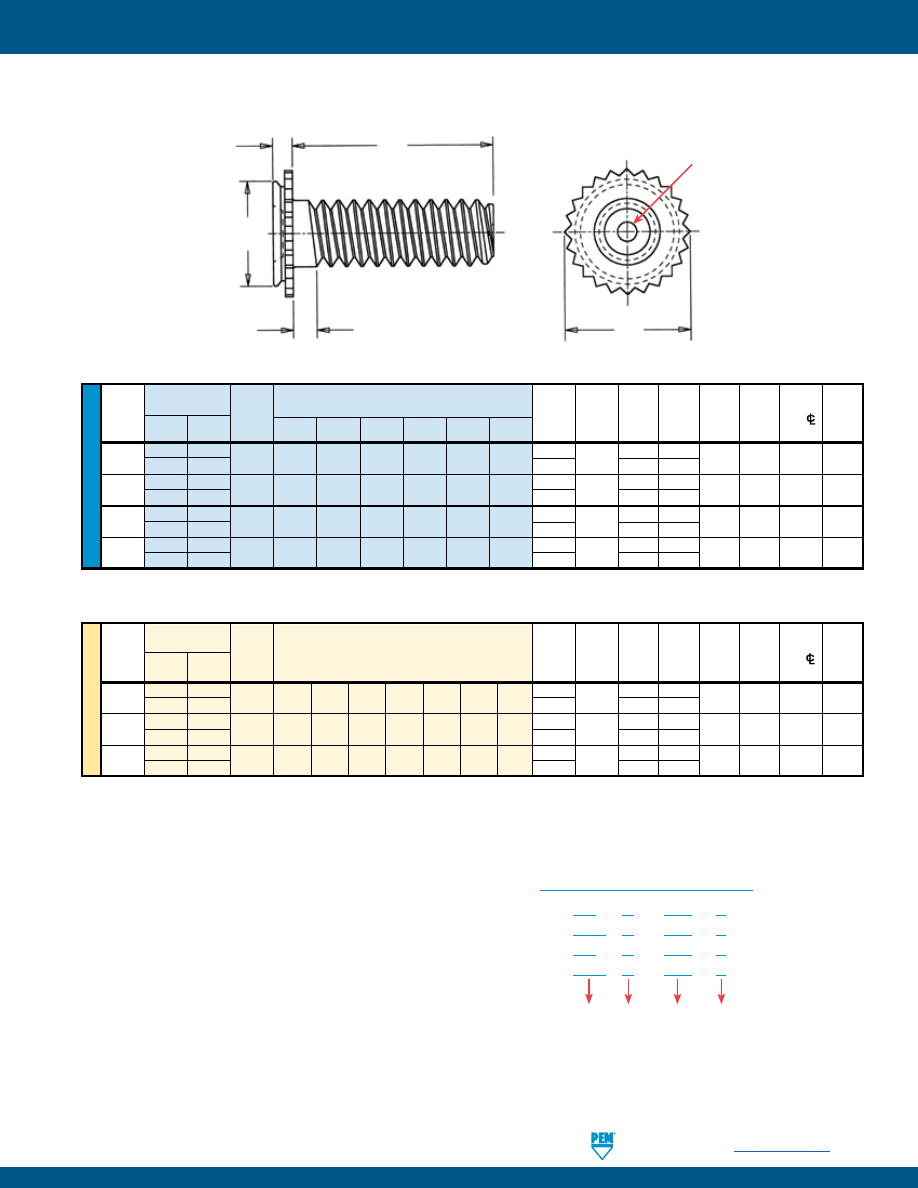

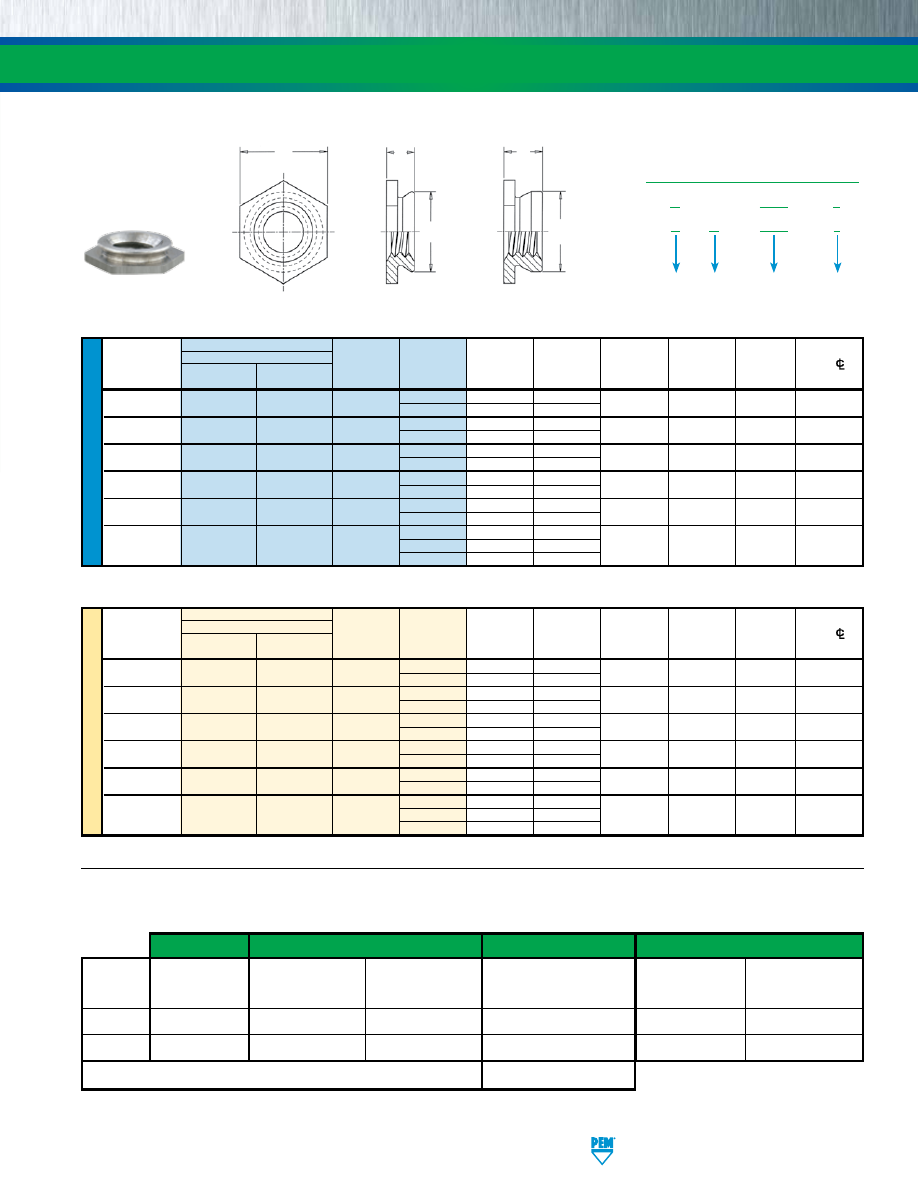

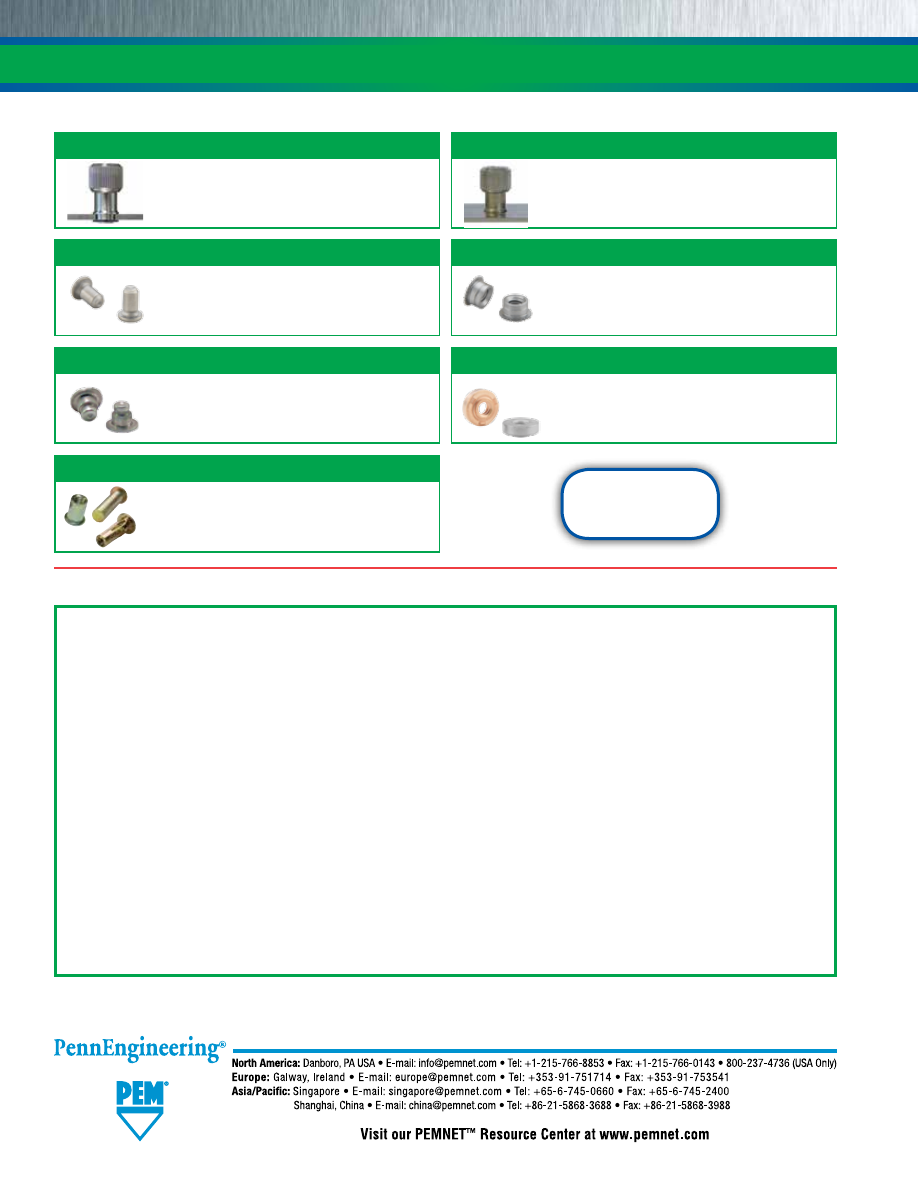

CL-4

PennEngineering •

www.pemnet.com

SELF-CLINCHING NUTS

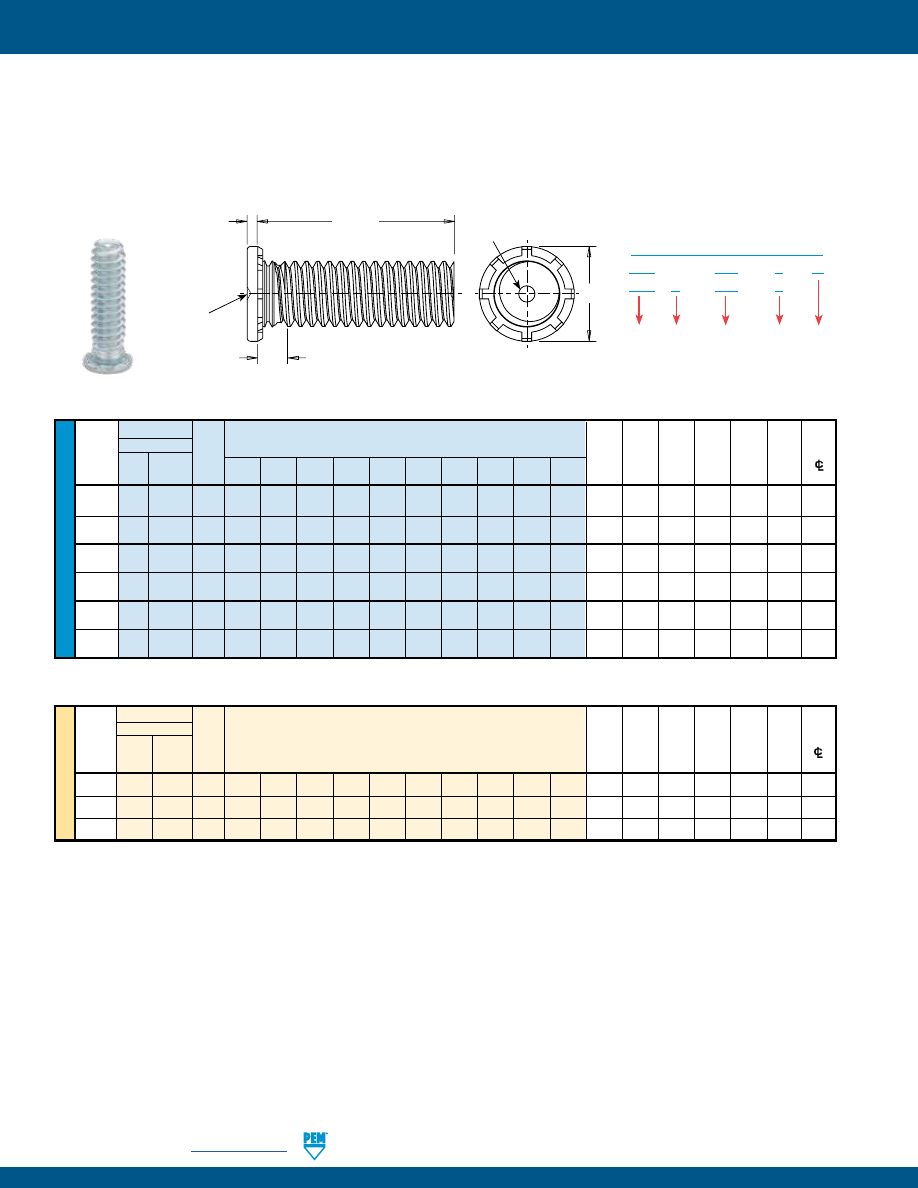

U

NIF

IE

D

Type

Min. Dist.

Thread Fastener Material

Thread

Shank

A

Rec.

Hole Size C E T Hole

CL

Size

Carbon

Stainless Hardened

Code

Code

(Shank)

Min. Sheet

In Sheet

Max.

±.010

±.010

To Edge

Steel

Steel

Stainless Steel

Max.

Thickness (1)

+.003 –.000

.086-56

0 .030 .030

(#2-56) S CLS SP

256 1

.038 .040 .166 .165 .250 .070 .19

2

.054

.056

.099-48

0 .030 .030

(#3-48) S CLS —

348 1

.038 .040 .166 .165 .250 .070 .19

2

.054

.056

0

.030

.030

.112-40

S CLS SP

440 1 .038 .040 .166 .165 .250 .070 .19

(#4-40)

2

.054

.056

3

(2)

.087 .090

0

.030

.030

.138-32

S CLS SP

632 1 .038 .040 .1875 .187 .280 .070 .22

(#6-32)

2

.054

.056

3

(2)

.087 .090

0

.030

.030

.164-32

S CLS SP

832 1 .038 .040 .213 .212 .310 .090 .27

(#8-32)

2

.054

.056

3

(2)

.087 .090

0

.030

.030

.190-24

SS CLSS

SP

024 1 .038 .040 .250 .249 .340 .090 .28

(#10-24)

2

.054

.056

3

(2)

.087 .090

0

.030

.030

.190-32

SS CLSS

SP

032 1 .038 .040 .250 .249 .340 .090 .28

(#10-32)

2

.054

.056

3

(2)

.087 .090

.216-24

1 .038 .040

(#12-24) S CLS —

1224 2 .054 .056 .277 .276 .370 .130 .31

3

.087

.090

0

.045

.047

.250-20

S

(3)

CLS

SP

0420 1 .054 .056 .344 .343 .440 .170 .34

(1/4-20)

2

.087

.090

3

(2)

.120 .125

.250-28

1 .054 .056

(1/4-28) S CLS —

0428 2 .087 .090 .344 .343 .440 .170 .34

3 .120

.125

.313-18

1 .054 .056

(5/16-18) S

(3)

CLS

SP

0518

2

.087 .090 .413 .412 .500 .230 .38

3

(2)

.120 .125

.313-24

1 .054 .056

(5/16-24) S CLS SP 0524 2 .087 .090 .413 .412 .500 .230 .38

3

(2)

.120 .125

.375-16

1 .087 .090

(3/8-16) S CLS SP

0616 2 .120 .125 .500 .499 .560 .270 .44

3

(2)

.235 .250

.375-24

1 .087 .090

(3/8-24) S CLS SP

0624 2 .120 .125 .500 .499 .560 .270 .44

3

(2)

.235 .250

.438-20

S — — 0720 1 .087 .092 .562 .561 .687 .311 .562

(7/16-20)

.500-13

S CLS —

0813 1 .120 .125

(1/2-13)

2 .235 .250 .656 .655 .810 .360 .63

.500-20

S CLS —

0820 1 .120 .125

(1/2-20)

2 .235 .250

(Clinching profile may vary)

Due to manufacturing procedure, parts

may have a counterbore at shank end.

(1) For maximum performance, we recommend that you use the maximum shank length for your sheet thickness.

(2) This shank code not available for SP nuts.

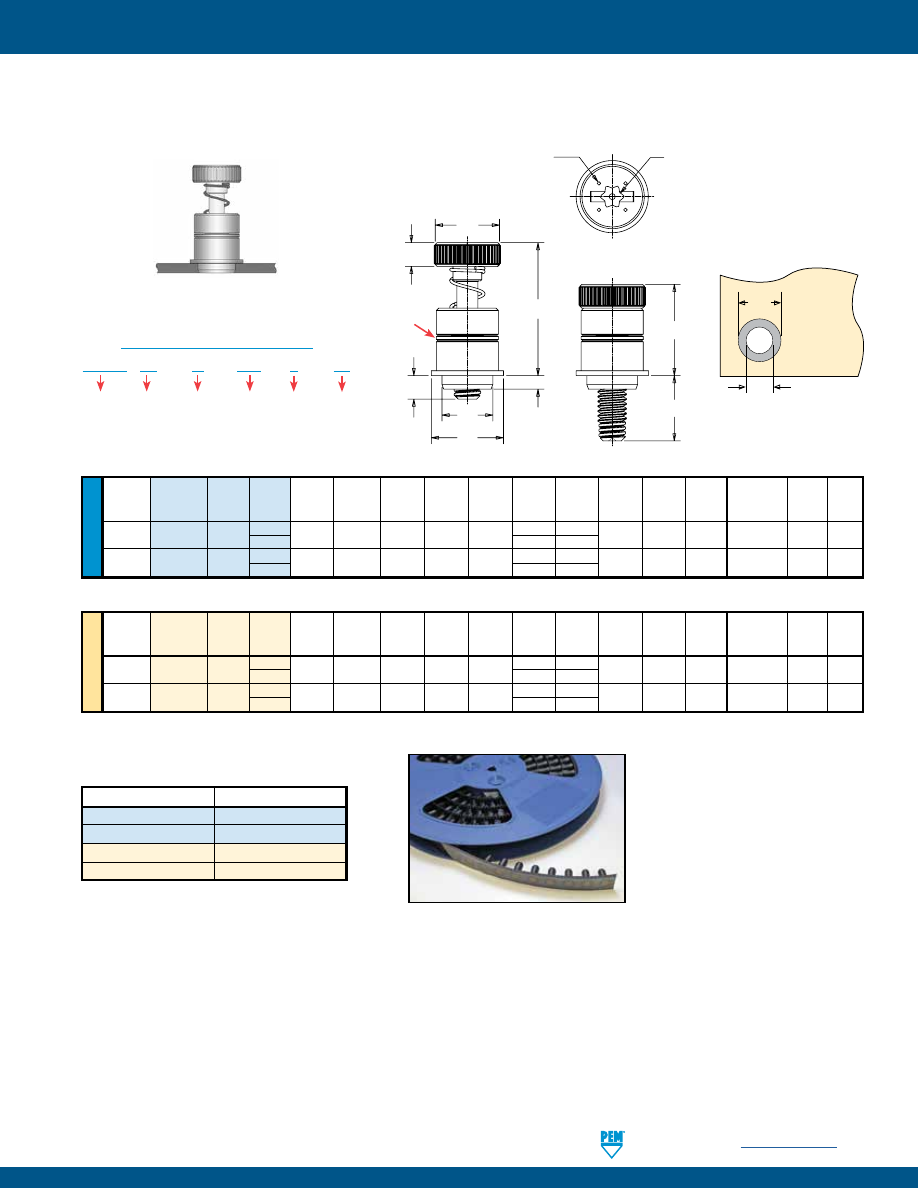

(3) This thread size S nut, with a -2 shank code, can be installed successfully without the need to pre punch a mounting hole in a separate operation. See

page 15 for more information.

All dimensions are in inches.

•

S/SS nuts are recommended for use in steel

or aluminum sheets HRB 80 / HB 150 or

less.

•

CLS/CLSS nuts are recommended for use

in steel or aluminum sheets HRB 70 / HB

125 or less.

•

SP nuts are recommended for use in

stainless steel sheets HRB 90 / HB 192 or

less.

•

CLA nuts are recommended for use in steel

or aluminum sheets HRB 50 / HB 82 or less.

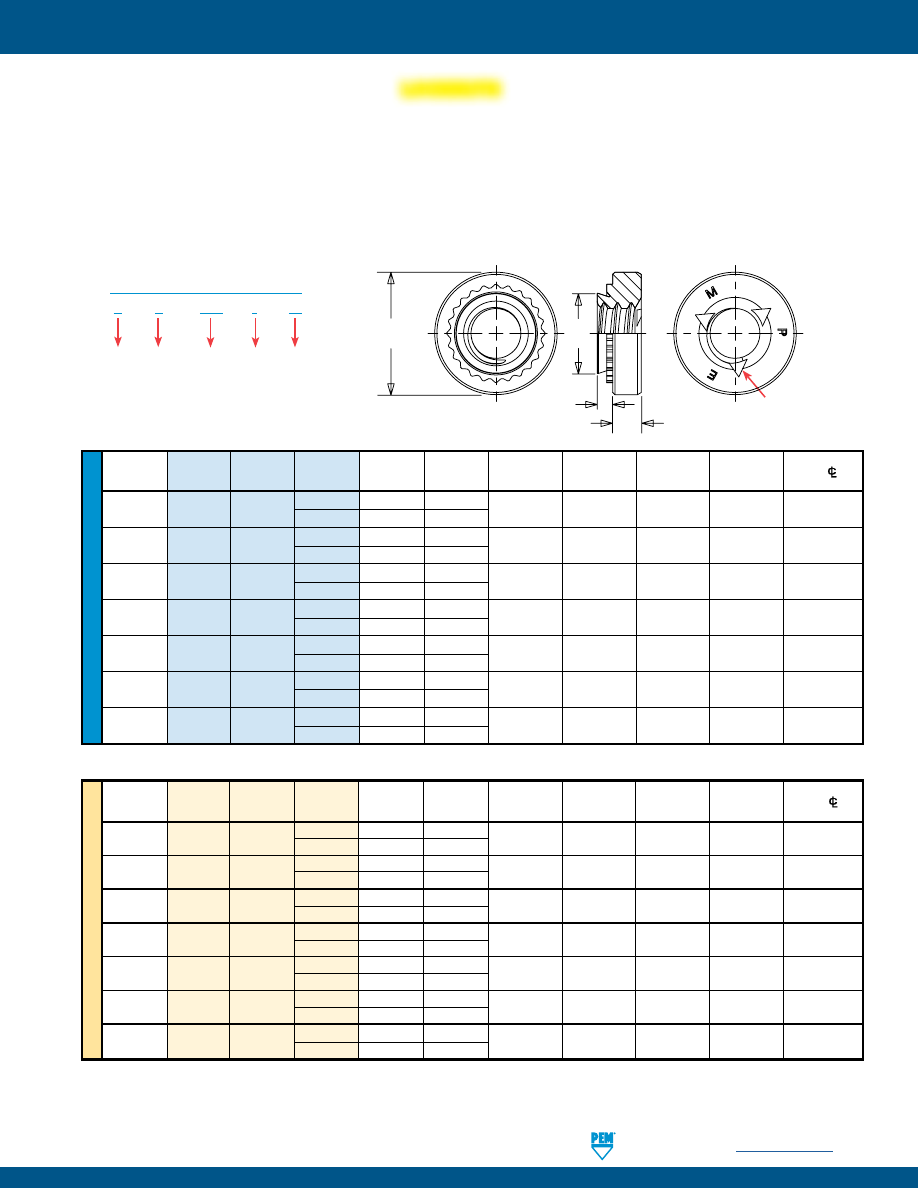

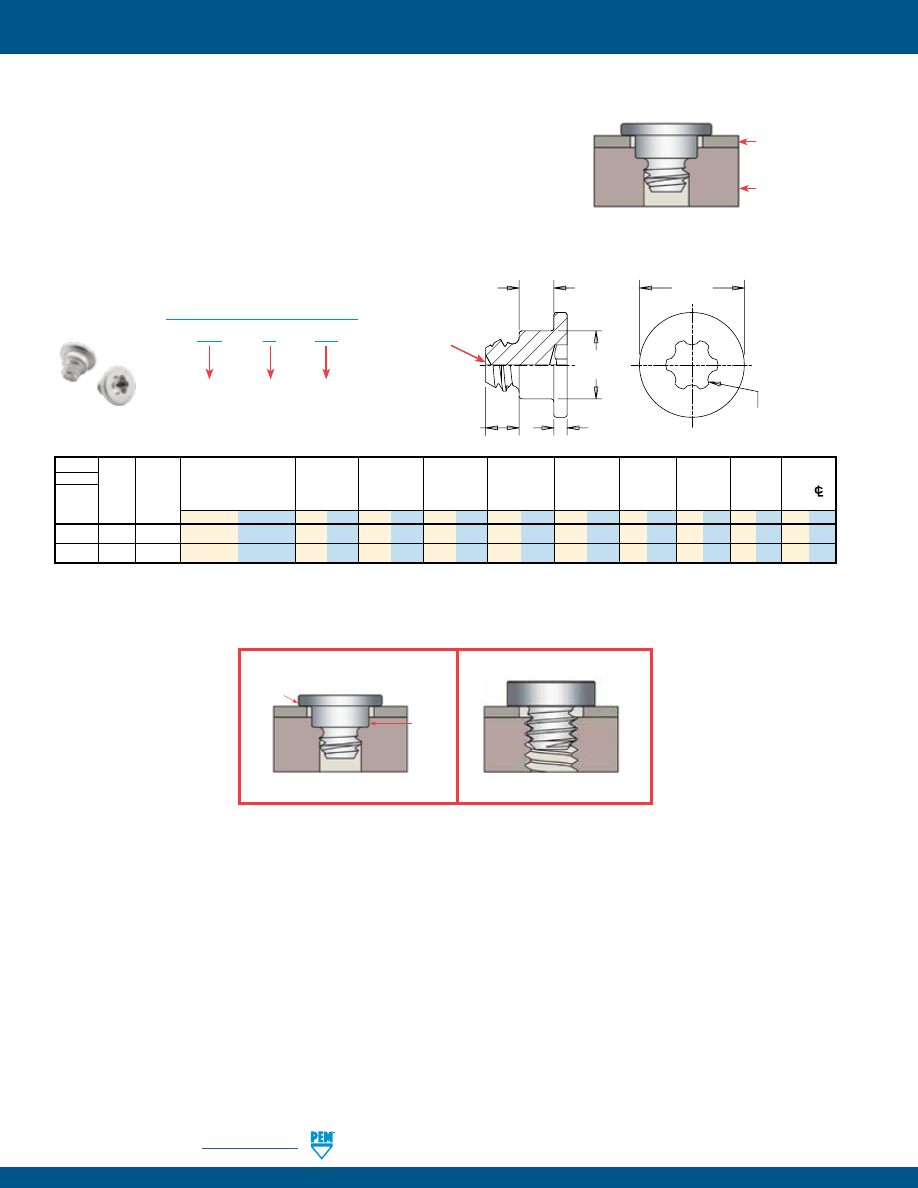

S™/SS™/CLS™/CLSS™/SP™ NUTS

The increased hardness of stainless steel panels requires careful consideration when installing self-

clinching fasteners. See page 16 or refer to Fastener Installation Dos and Don’ts on our web site.

C

E

A

T

Type

S – 632 – 1

ZI

SS – 032 – 1

ZI

CL S – 632 – 1

CLS S – 032 – 1

S P – 632 – 1

CL A – 632 – 1

Shank

Code

Thread

Size

Code

Finish

Material

Code

PART NUMBER DESIGNATION

pem-html.html

PennEngineering •

www.pemnet.com

CL-5

SELF-CLINCHING NUTS

(1) For maximum performance, we recommend that you use the maximum shank length for your sheet thickness.

(2) This shank code not available for SP nuts.

(3) This thread size S nut, with a -2 shank code, can be installed successfully without the need to pre punch a mounting hole in a separate operation. See

page 15 for more information.

ME

TR

IC

U

NIF

IE

D

(See drawing at top of page 4) All dimensions are in millimeters.

Type

Thread

Fastener Material

A

Min. Sheet

Hole Size

Min. Dist.

Size x

Thread

Shank

(Shank)

Thickness

In Sheet

C

E

T

Hole

CL

Pitch Aluminum Code Code Max.

(1)

+0.08

Max.

±0.25

±0.25

To Edge

1 0.98 1

M2 x 0.4 CLA M2 2 1.38 1.4 4.22 4.2 6.35 1.5 4.8

1 0.98 1

M3 x 0.5 CLA M3 2 1.38 1.4 4.75 4.73 6.35 2 5.6

1 0.98 1

M3.5 x 0.6 CLA M3.5 2 1.38 1.4 5.41 5.38 7.11 2 6.9

1 0.98 1

M4 x 0.7 CLA M4 2 1.38 1.4 5.94 5.92 7.8 3 7.1

1 0.98 1

M5 x 0.8 CLA M5 2 1.38 1.4 7.52 7.49 9.4 3.8 7.9

1 1.38 1.4

M6 x 1

CLA

M6 2 2.21 2.3 8.75 8.73 11.18 4.08 8.6

(See drawing at top of page 4) All dimensions are in inches.

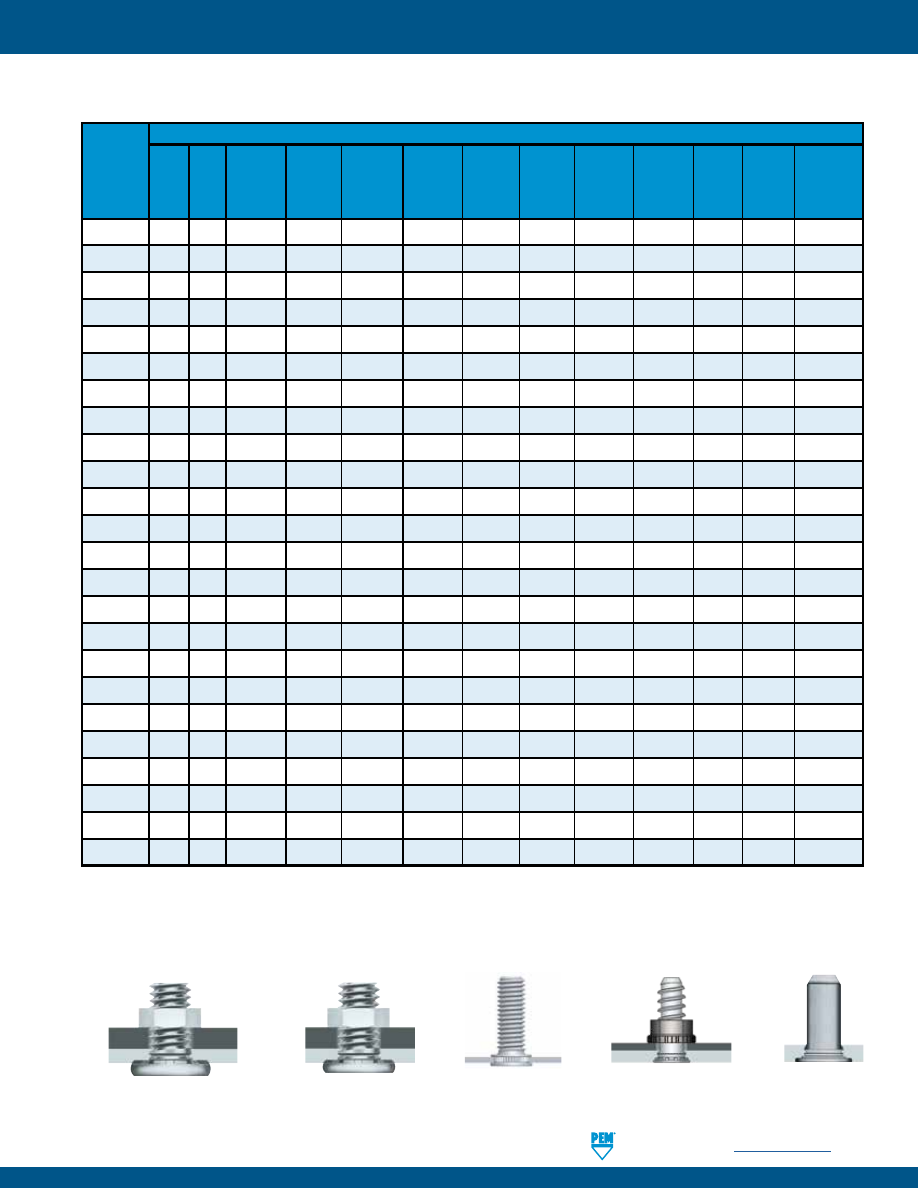

Type