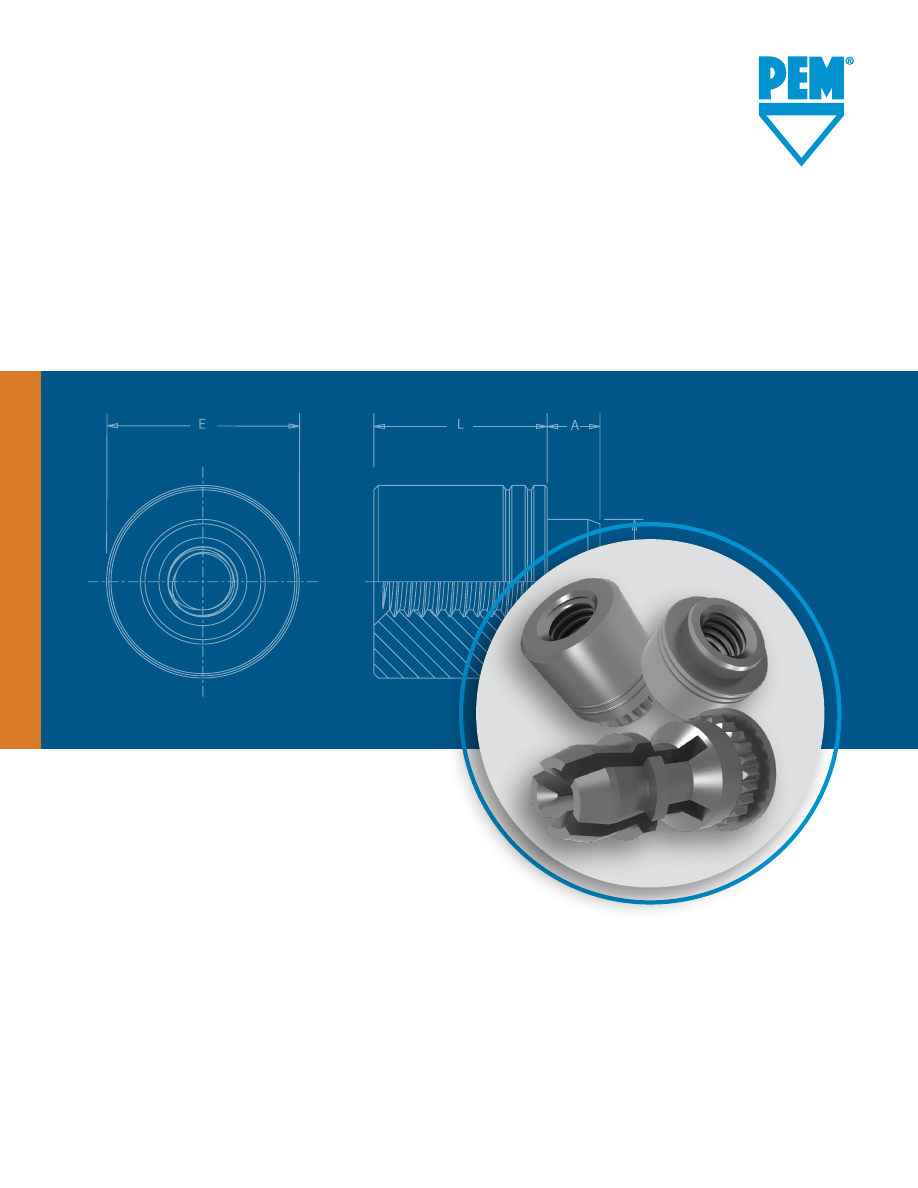

K

™

FASTENERS FOR

USE WITH PC BOARDS

PEM® brand fasteners that utilize,

surface-mount, broaching and flaring

technology for use with PC boards.

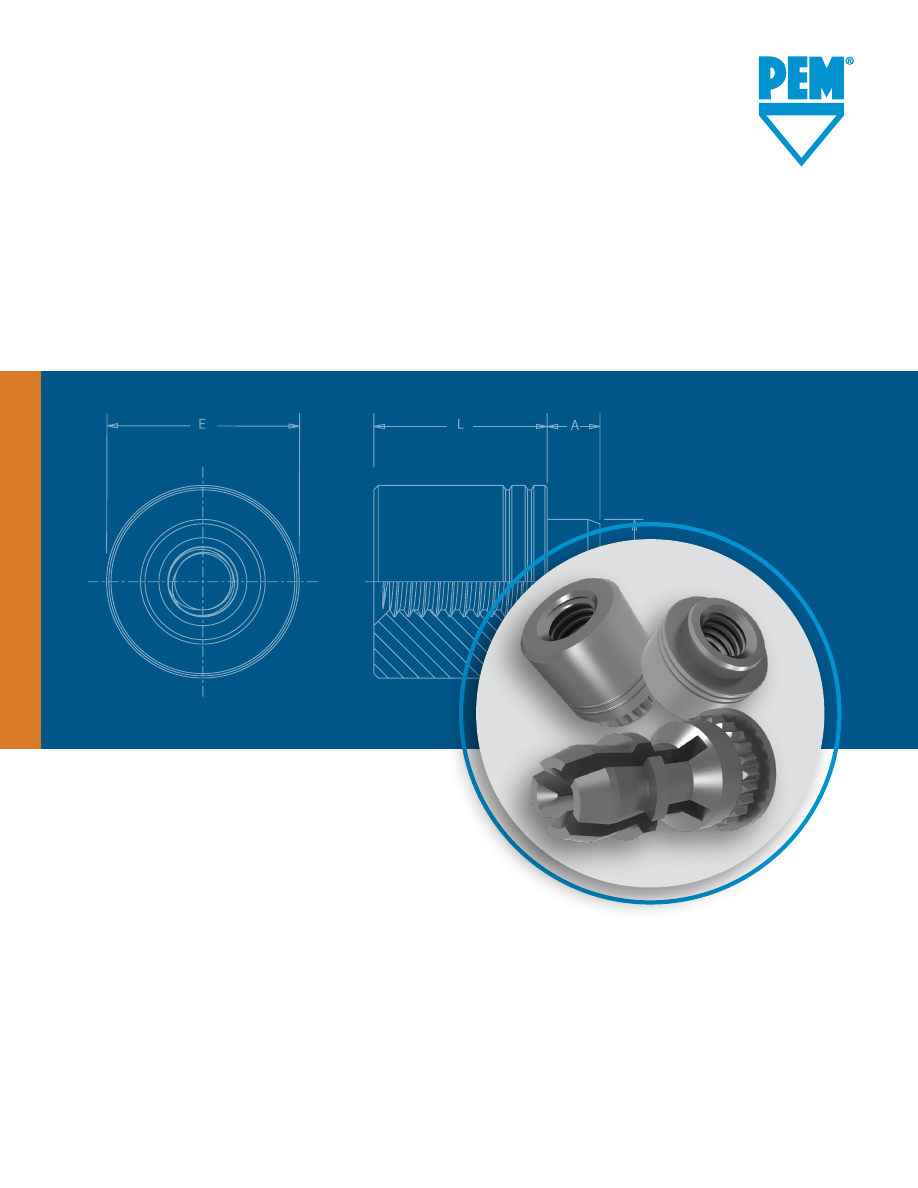

K

™

FASTENERS FOR

USE WITH PC BOARDS

PEM® brand fasteners that utilize,

surface-mount, broaching and flaring

technology for use with PC boards.