SK

™

SELF-CLINCHING

KEYHOLE® FASTENERS

PEM® KEYHOLE® fasteners are

designed for quick panel attachment

and reduction of loose hardware.

H

N

C

B

A

S

M

SK

™

SELF-CLINCHING

KEYHOLE® FASTENERS

PEM® KEYHOLE® fasteners are

designed for quick panel attachment

and reduction of loose hardware.

H

N

C

B

A

S

M

Keyhole® Standoffs And Fasteners

SK-2

PennEngineering •

PEM® KEYHOLE® Standoffs and sheet joining fasteners are designed so that a PC board or panel can be quickly slipped into place

and then removed from an assembly by simply sliding the board sideways and lifting it off. These standoffs and fasteners can save

valuable time and dramatically reduce the amount of loose hardware required.

SKC™/SK4™/SKCF™/SK4F™/

SKSF™ standoffs

SKC-F™/SK4-F™/SKS-R™/HSKC-R™/

HSK4-R™/HSKS-R™/TSKC-R™/

TSK4-R™/TSKS-R™ fasteners

© 2023 PennEngineering.

Drawings and models

are available at

PEM® Dimple

(Registered Trademark)

SKC-F™/SK4-F™/SKS-R™/HSKC-R™/HSK4-R™/HSKS-R™/TSKC-R™/TSK4-R™/TSKS-R™ fasteners

are designed

so that two sheets can be quickly joined flat against each other. Typically, several fasteners are used with one standard PEM®

threaded F™ flush nut (

) which accepts a screw to secure the sheets against any unwanted movement.

• Allow detachable spacing of two sheets

• Clinch feature mounts fastener permanently and flush or sub-flush into metal sheet

• Unique barrel design allows for quick “panel-on-panel” attachment and detachment

• Can be clinched into blind hole where concealed head is required

• Makes horizontal or vertical component mounting possible

• SK4-R™, HSK4-R™, TSK4-R™, SK4-F™, SK4F-F™ and TSK4F-F™ fasteners are available for

installation into stainless steel sheets

• SKS-R™, SKC-R™, SK4-R™, TSKS-R™, HSKS-R™, TSKC-R™, TSK4-R™, HSKC-R™ and

HSK4-R™ fasteners are designed to provide high side-load in vertical component

mounting applications and are available for various top sheet thicknesses and hole sizes

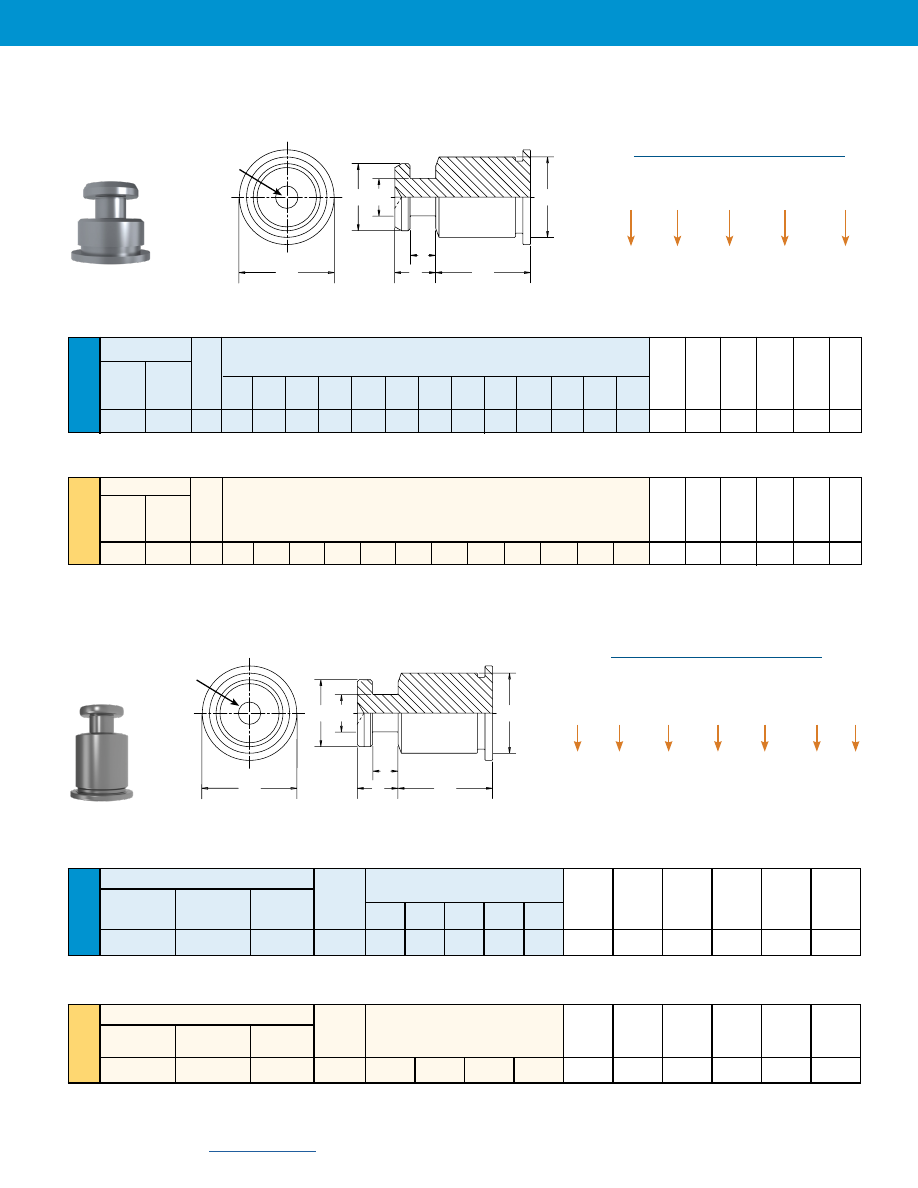

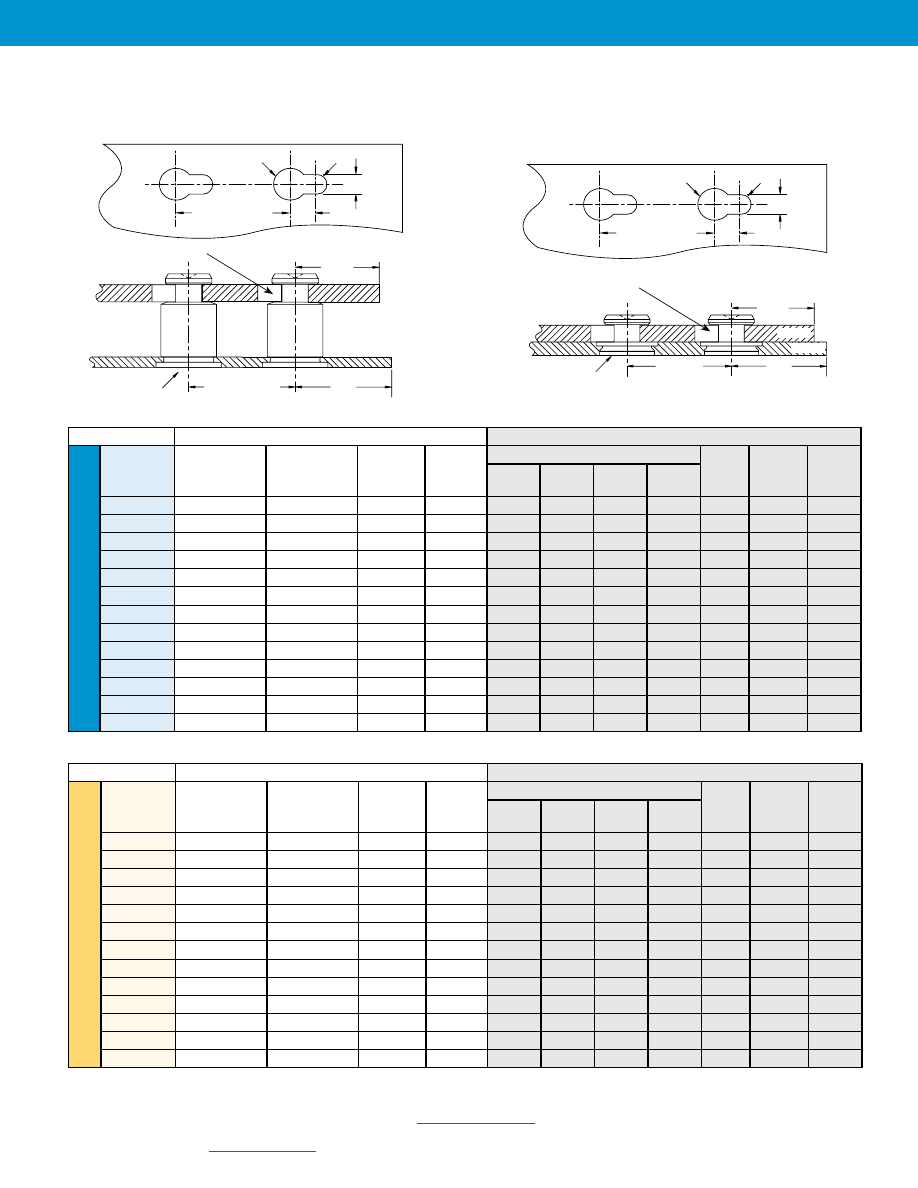

SKC™/SK4™/SKCF™/SK4F™/SKSF™ standoffs

can be used for spacing or mounting of

replaceable components. Typically, several standoffs are used with one standard PEM® threaded

standoff which accepts a screw to secure the board or component against any unwanted movement.

• Allow detachable spacing of two sheets

• Clinch feature mounts fastener permanently and flush into metal sheet

• Unique barrel design allows for quick attachment and detachment

• Makes horizontal or vertical component mounting possible

• SK4™ and SK4F™ standoffs are available for installation into stainless steel sheets

Fastener drawings and models are available at

Custom sizes are available on special order.

for more information.

SKC-F™/SK4-F™ Fasteners

SKS-R™/HSKC-R™/HSK4-R™/

HSKS-R™/TSKC-R™/TSK4-R™/

TSKS-R™ Fasteners

Custom sizes are available

on special order.

for more information.

Uni

fie

d

Me

tric

Uni

fie

d

Me

tric

Keyhole® Standoffs And Fasteners

SK-3

Type Body

Length “L” ± .005

Size -

(Length Code in 32nds of an inch)

A B C S M H

300 Series 400 Series Sheet

± .003 ± .003 Max. ± .003 Max. Nom.

Stainless Stainless Code .063 .125 .188 .250 .312 .375 .437 .500 .562 .625 .750 .875 1.00

Steel Steel

SKC

SK4 6060 2 4

6

8

10 12 14 16 18 20 24 28 32 .099 .177 .212 .068 .108 .250

Type

Body

Length “L” ± 0.13

300 Series 400 Series Size -

(Leng th Code in millimeters)

A B C S M H

Stainless Stainless

Sheet

±

0.08

±

0.08

Max.

±

0.08

Max.

Nom.

Steel (1) Steel

(2) Code

SKC

SK4 61.5 2 4

6

8

10 12

14 16

18 20 22 25 2.51 4.5 5.39 1.73 2.75 6.35

All dimensions are in inches.

All dimensions are in millimeters.

SK C – 6 060 – 12

SK 4 – 6 060 – 12

Type

Body

Size

Code

Length

Code

Material

Code

Sheet

Thickness

Code

SKC™/SK4™ Standoff Dimensional Data

H

L

C

B

A

S

M

PEM “dimple”

registered

trademark.

Clinching profile may vary.

All dimensions are in inches.

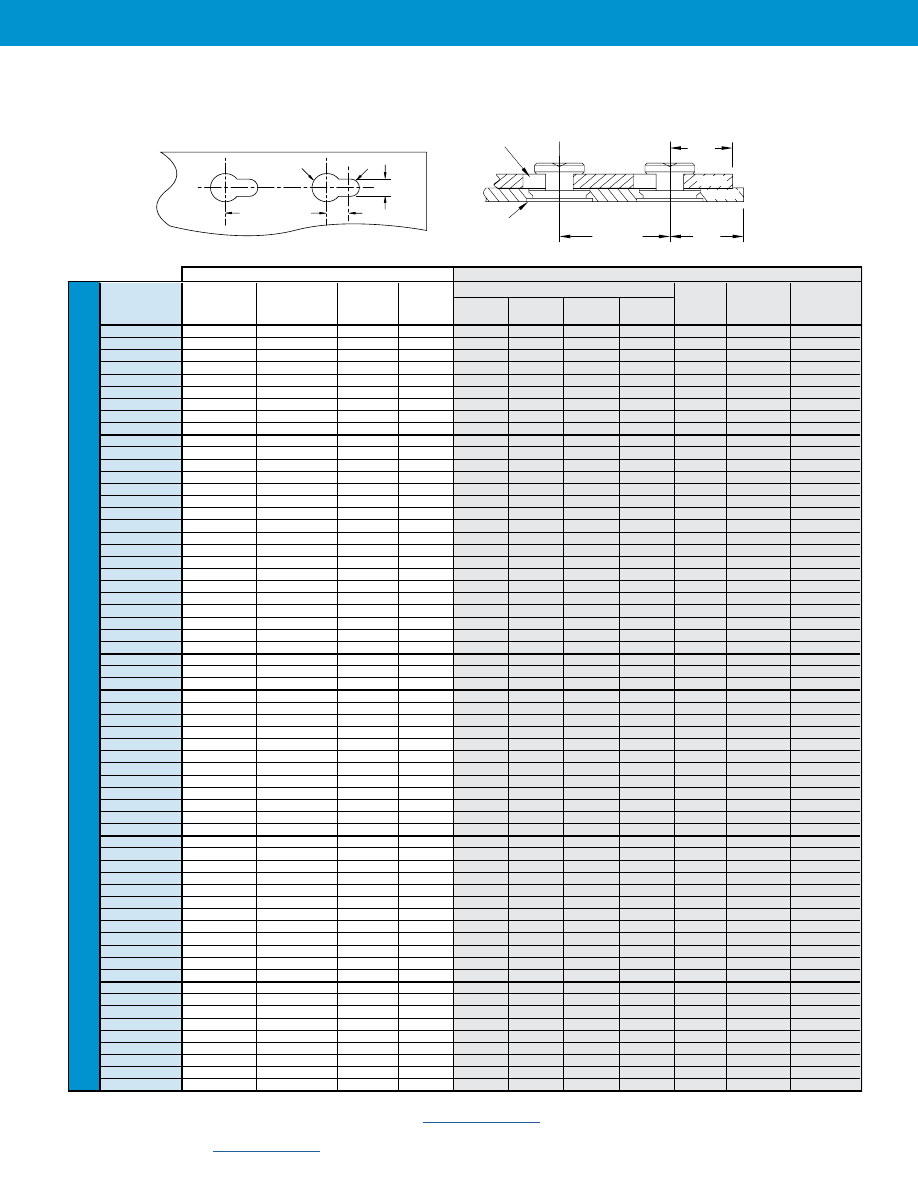

Type

Body Size

Sheet

Code

Length “L” ±.005

(Length Code in 32nds of an inch)

A

±.003

B

±.003

C

Max.

S

±.003

M

Max.

H

Nom.

300 Series Stain-

less Steel

400 Series

Stainless Steel

Hardened

Steel

.125

.188

.250

.312

.375

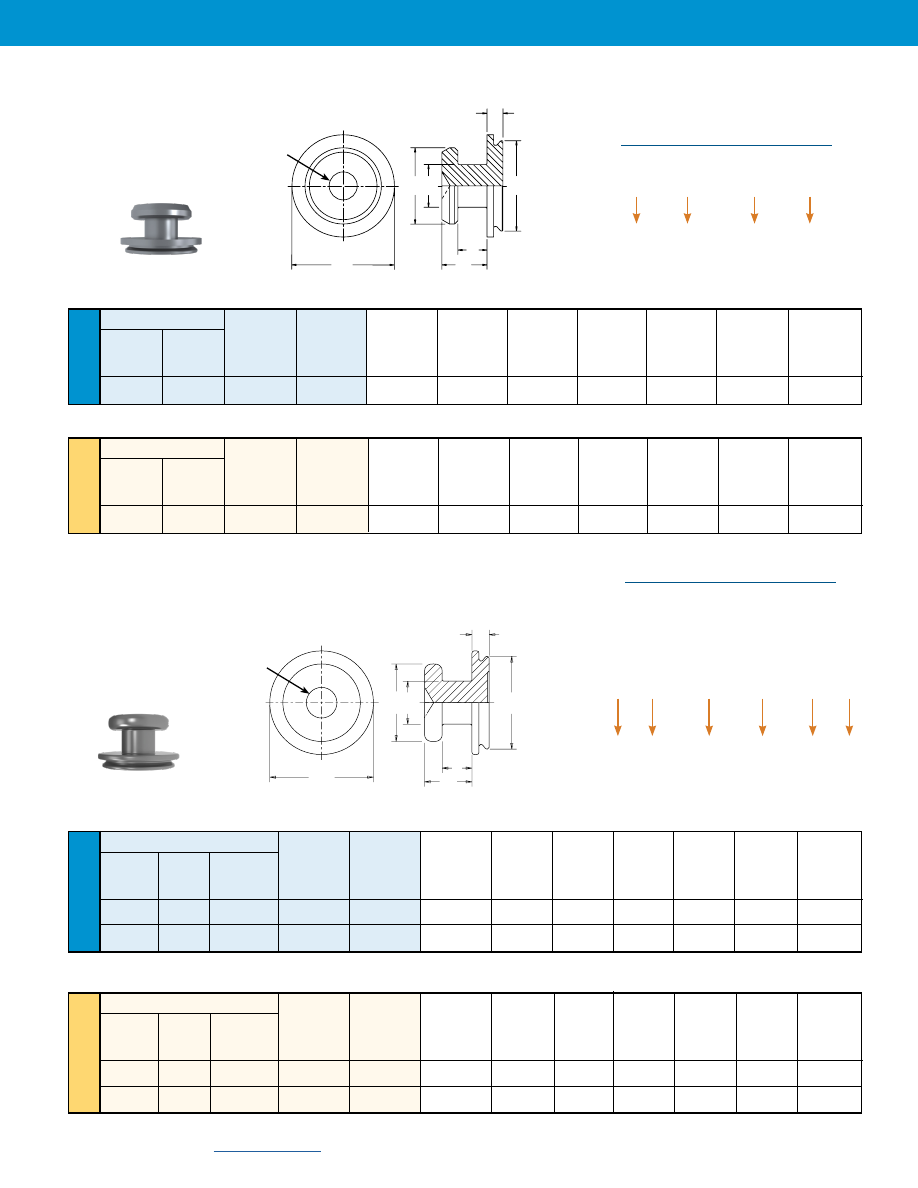

SKCF

SK4F

SKSF

6060

4

6

8

10

12

.099

.177

.212

.068

.108

.250

Type

Body Size

Sheet

Code

Length “L” ±0.13

(Length Code in millimeters)

A

±0.08

B

±0.08

C

Max.

S

±0.08

M

Max.

H

Nom.

300 Series Stain-

less Steel

400 Series

Stainless Steel

Hardened

Steel

SKCF

SK4F

SKSF

61.5

4

6

8

10

2.51

4.5

5.39

1.73

2.75

6.35

All dimensions are in millimeters.

SK C

F - 6 060 - 8

SK 4

F - 6 060 - 8

SK S

F - 6 060 - 8 ZI

Type

Part Number Designation

Material

Code

Body Size

Code

Length

Code

Sheet

Thickness

Code

Finish

Manu-

facturing

Code

SKCF™/SK4F™/SKSF™ Standoff Dimensional Data

H

L

C

B

A

S

M

PEM “dimple”

registered

trademark.

Clinching profile may vary.

Part Number Designation

Uni

fie

d

Me

tric

Uni

fie

d

Me

tric

Keyhole® Standoffs And Fasteners

SK-4

PennEngineering •

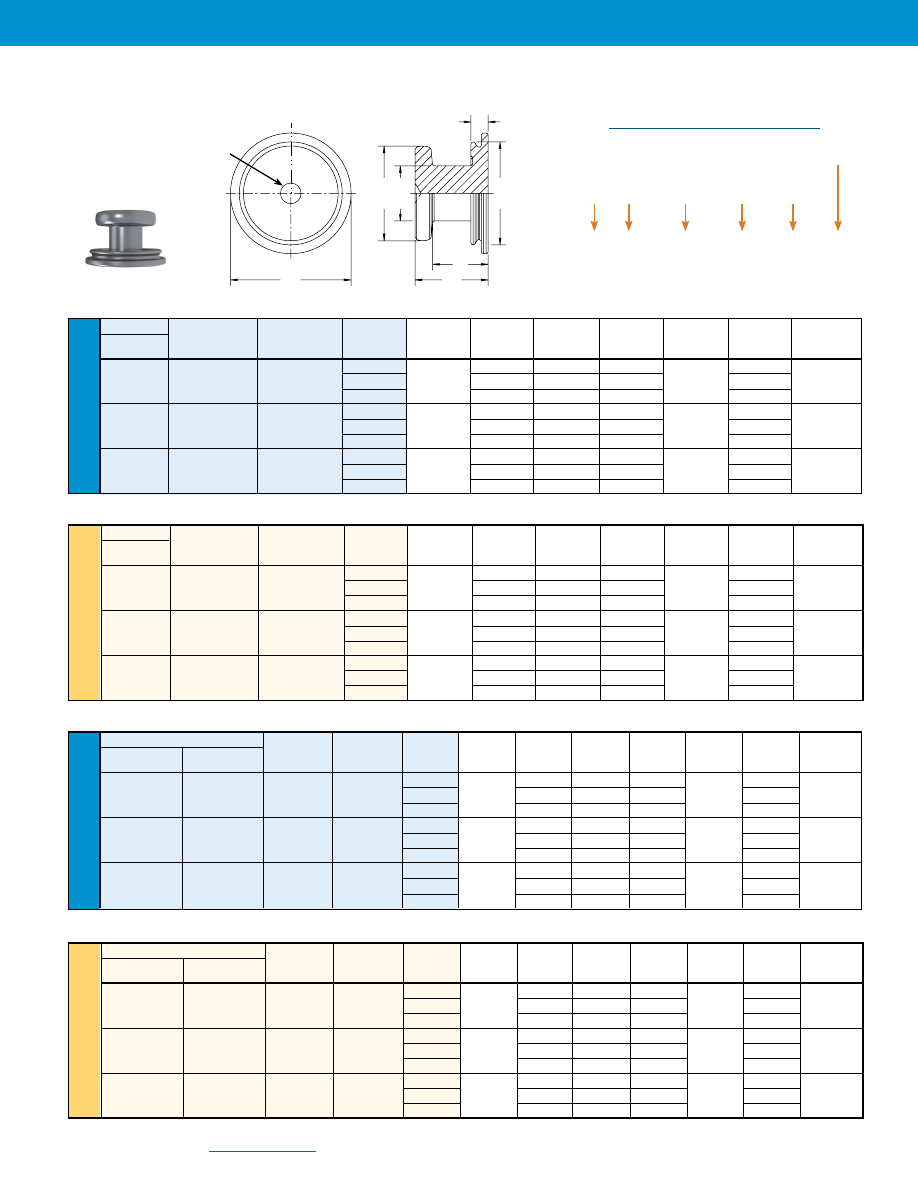

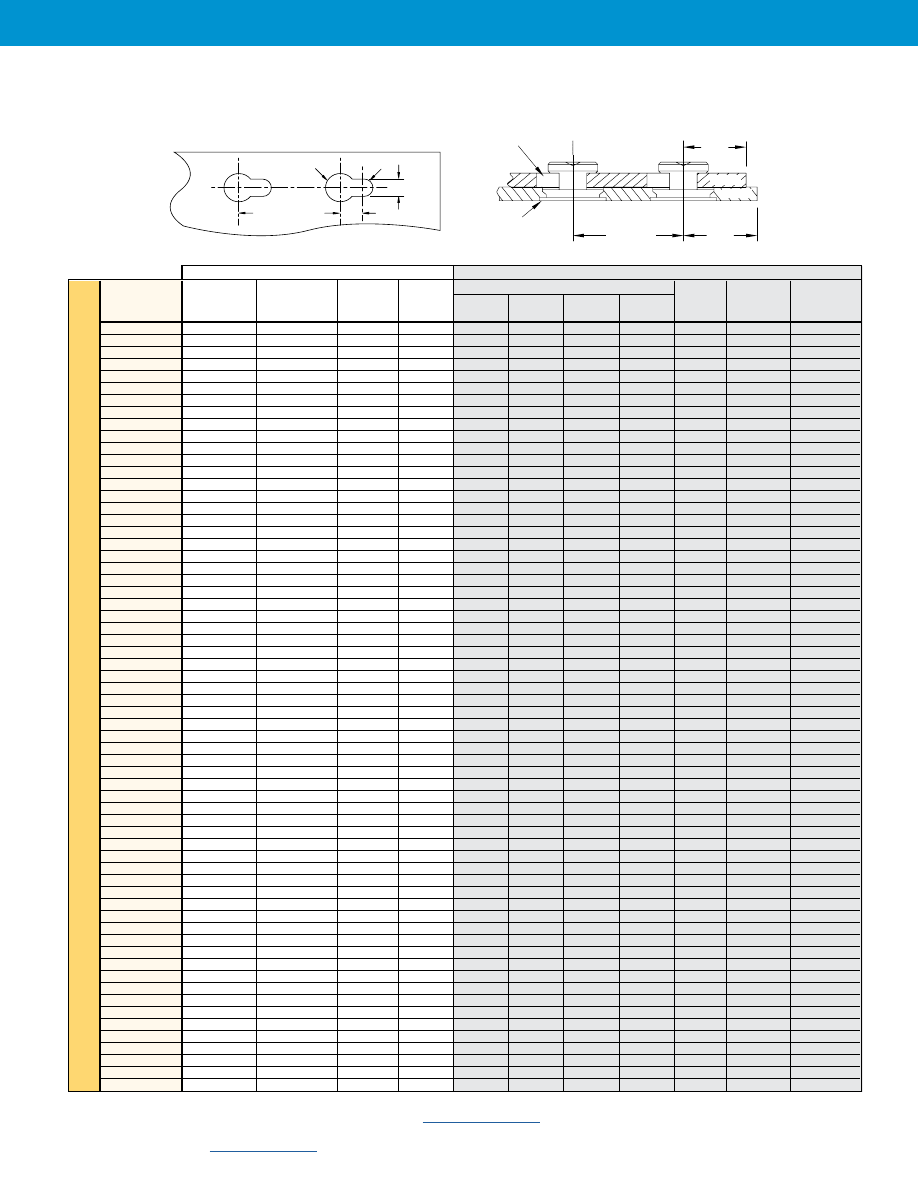

Type

Face

Top Sheet

A

B

C

H

M

N

S

300 Series

400 Series

Mounting

Thickness

Max.

± .003

Max.

Nom.

Max.

± .003

±.003

Stainless

Stainless Designation Code

Steel

Steel

Code

SKC

SK4

F

1.5

.039

.177

.212

.237

.108

.099

.068

Type

Face

Top Sheet

A

B

C

H

M

N

S

300 Series

400 Series

Mounting

Thickness

Max.

± 0.08

Max.

Nom.

Max.

± 0.08

±0.08

Stainless Stainless

Designation Code

Steel

Steel

Code

SKC

SK4

F

1.5

1

4.5

5.39

6.02

2.75

2.5

1.73

All dimensions are in inches.

All dimensions are in millimeters.

SKC-F™/SK4-F™ Fastener Dimensional Data

SK C – F

1.5

SK 4 – F

1.5

Type

Face

Mounting

Designation

Code

Part Number Designation

Material

Code

Sheet

Thickness

Code

H

N

C

B

A

S

M

PEM “dimple”

registered

trademark.

Clinching profile may vary.

Type

Face

Top Sheet

A

B

C

H

M

N

S

300 Series 400 Series

Mounting

Thickness

Max.

± .003

Max.

Nom.

Max.

± .003

±.003

Stainless Stainless

Hardened

Designation Code

Steel

Steel

Steel

Code

SKCF

SK4F

SKSF

F

1.5

.039

.177

.212

.237

.108

.099

.068

TSKCF

TSK4F

TSKSF

F

1.5

.032

.177

.212

.237

.108

.099

.068

Type

Face

Top Sheet

A

B

C

H

M

N

S

300 Series 400 Series

Mounting

Thickness

Max.

± 0.08

Max.

Nom.

Max.

± 0.08

±0.08

Stainless Stainless Hardened

Designation Code

Steel

Steel

Steel

Code

SKCF

SK4F

SKSF

F

1.5

1

4.5

5.39

6.02

2.75

2.5

1.73

TSKCF TSK4F

TSKSF

F

1.5

0.8

4.5

5.39

6.02

2.75

2.5

1.73

All dimensions are in inches.

All dimensions are in millimeters.

SKCF-F™/SK4F-F™/SKSF-F™/ TSKCF-F™/TSK4-F™/TSKSF-F™

Fastener Dimensional Data

Part Number Designation

SK C

F – F

1.5

SK 4

F – F

1.5

SK S

F – F

1.5 - ZI

TSK C

F – F

1.5

TSK 4

F – F

1.5

TSK S

F – F

1.5 - ZI

Type

Face

Mounting

Designation

Code

Material

Code

Sheet

Thickness

Code

Manufacturing

Code

Finish

TSK for .032” / 0.8mm thick panels

H

N

C

B

A

S

M

PEM “dimple”

registered

trademark.

Clinching profile may vary.

Uni

fie

d

Me

tric

Uni

fie

d

Me

tric

Keyhole® Standoffs And Fasteners

SK-5

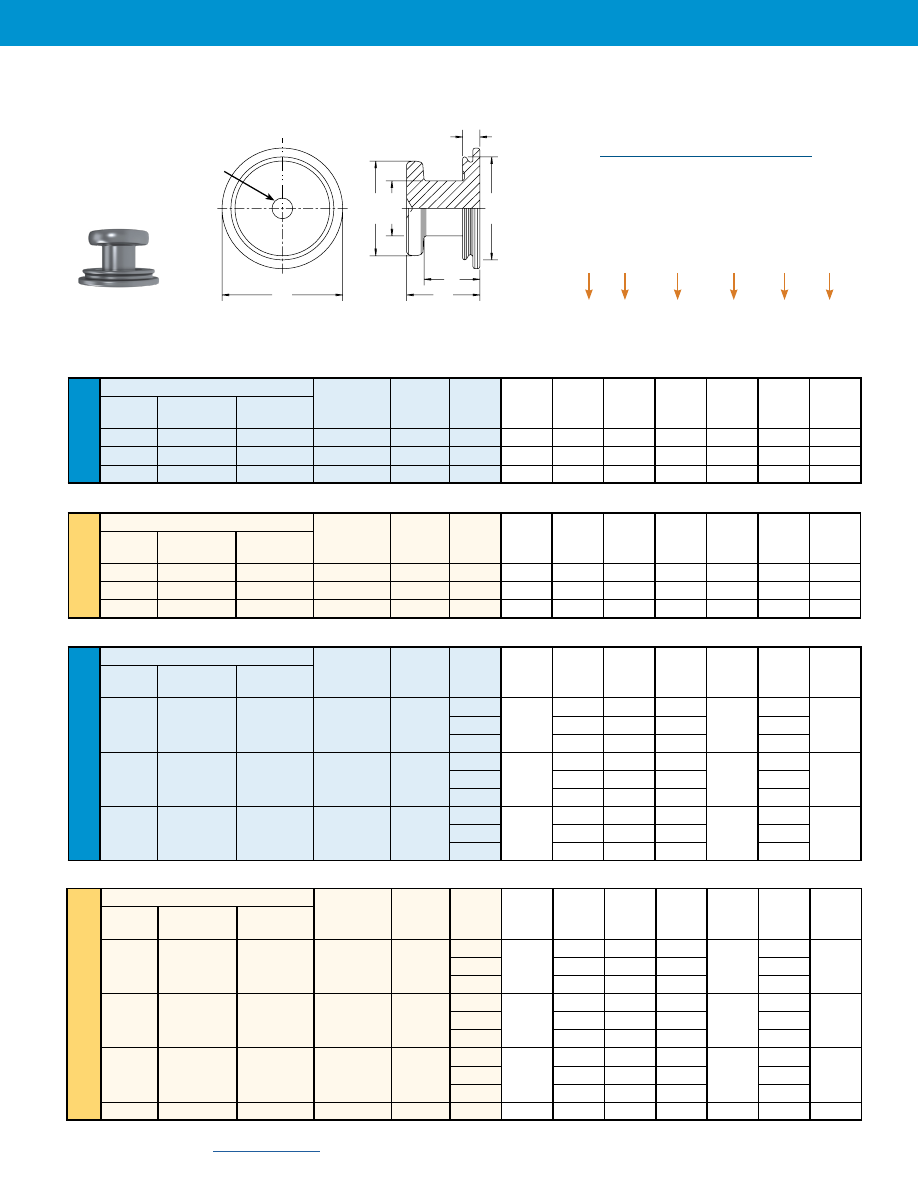

Type

Face Mounting

Top Sheet

Neck

A

B C H M N

S

Hardened

Designation

Thickness

Diameter

(Shank)

±.003 Max. Nom. Max. ±.003 +.003

Steel Code Code

Code

Max. -.008

2.5

.177

.212

.236

.099

SKS R

1.5 3.2 .039 .217 .235 .276 .148 .126 .107

4.0

.256 .275

.307

.157

2.5

.177

.212

.236

.099

SKS R

2.0 3.2 .039 .217 .235 .276 .167 .126 .127

4.0

.256 .275

.307

.157

2.5

.177

.212

.236

.099

SKS R

2.5 3.2 .039 .217 .235 .276 .187 .126 .147

4.0

.256 .275

.307

.157

All dimensions are in inches.

SKS-R™, SKC-R™ AND SK4-R™ Fastener Dimensional Data

All dimensions are in millimeters.

H

N

C

B

A

S

M

PEM “dimple”

registered

trademark.

Clinching profile may vary.

SK S – R

1.5 – 2.5 – ZI

SK C – R

1.5 – 2.5

SK 4 – R

1.5 – 2.5

Type

Face

Mounting

Designation

Code

Part Number Designation

Material

Code

Top Sheet

Thickness

Code

Finish

Neck

Diameter

Code

Type

Face Mounting

Top Sheet

Neck

A

B C H M

N

S

Hardened

Designation

Thickness

Diameter

(Shank)

±0.08 Max. Nom. Max.

±0.08 +0.08

Steel

Code

Code

Code

Max.

-0.21

2.5

4.5

5.39

6

2.5

SKS R

1.5 3.2 1 5.5 5.98 7 3.75 3.2

2.73

4.0

6.5

6.98

7.8

4

2.5

4.5

5.39

6

2.5

SKS R

2.0 3.2 1 5.5 5.98 7 4.25 3.2

3.23

4.0

6.5

6.98

7.8

4

2.5

4.5

5.39

6

2.5

SKS R

2.5 3.2 1 5.5 5.98 7 4.75 3.2

3.73

4.0

6.5

6.98

7.8

4

All dimensions are in millimeters.

Type

Face Mounting

Top Sheet

Neck

A

B C H M N S

300 Series

400 Series

Designation

Thickness

Diameter

(Shank)

±0.08 Max. Nom. Max. ±0.08 ±0.08

Stainless Steel

Stainless Steel

Code

Code

Code

Max.

2.5 4.5 6 7 2.5

SKC SK4 R 1.5 3.2 1 5.5 7 8 3.75 3.2 2.73

4.0 6.5 8 9 4

2.5 4.5 6 7 2.5

SKC SK4 R 2.0 3.2 1 5.5 7 8 4.25 3.2 3.23

4.0 6.5 8 9 4

2.5 4.5 6 7 2.5

SKC SK4 R 2.5 3.2 1 5.5 7 8 4.75 3.2 3.73

4.0 6.5 8 9 4

All dimensions are in inches.

Type

Face Mounting

Top Sheet

Neck

A

B C H M N S

300 Series

400 Series

Designation

Thickness

Diameter

(Shank)

±.003 Max. Nom. Max. ±.003 ±.003

Stainless Steel

Stainless Steel

Code

Code

Code

Max.

2.5 .177 .236 .276 .099

SKC SK4 R

1.5 3.2 .039 .217 .276 .315 .148 .126 .107

4.0 .256 .315 .354 .157

2.5 .177 .236 .276 .099

SKC SK4 R

2.0 3.2 .039 .217 .276 .315 .167 .126 .127

4.0 .256 .315 .354 .157

2.5 .177 .236 .276 .099

SKC SK4 R

2.5 3.2 .039 .217 .276 .315 .187 .126 .147

4.0 .256 .315 .354 .157

Uni

fie

d

Uni

fie

d

Me

tric

Me

tric

Keyhole® Standoffs And Fasteners

SK-6

TSKS-R™, TSKC-R™, TSK4-R™, HSKS-R™, HSKC-R™ AND HSK4-R™

Fastener Dimensional Data

H

N

C

B

A

S

M

PEM “dimple”

registered

trademark.

Clinching profile may vary.

TSK C – R

1.5 – 2.5

TSK 4 – R

1.5 – 2.5

TSK S – R

1.5 – 2.5 – ZI

HSK C – R

1.5 – 2.5

HSK 4 – R

1.5 – 2.5

HSK S – R

1.5 – 2.5 – ZI

Type

Face

Mounting

Designation

Code

Part Number Designation

Material

Code

Top Sheet

Thickness

Code

Finish

Neck

Diameter

Code

All dimensions are in millimeters.

All dimensions are in inches.

TSK for .032” / 0.8mm thick panels

HSK for .047” / 1.2mm thick panels

All dimensions are in millimeters.

All dimensions are in inches.

Type

Face Mounting

Designation

Code

Top Sheet

Thickness

Code

Neck

Diameter

Code

A

(Shank)

Max.

B

±0.08

C

Max.

H

Nom.

M

Max.

N

±0.08

S

±0.08

Hardened

Steel

300 Series

Stainless Steel

400 Series

Stainless Steel

TSKS

TSKC

TSK4

R

1.5

2.5

0.8

4.5

6

7

3.55

2.5

2.53

TSKS

TSKC

TSK4

R

2.0

2.5

0.8

4.5

6

7

4.05

2.5

3.03

TSKS

TSKC

TSK4

R

2.5

2.5

0.8

4.5

6

7

4.55

2.5

3.53

Type

Face Mounting

Designation

Code

Top Sheet

Thickness

Code

Neck

Diameter

Code

A

(Shank)

Max.

B

±.003

C

Max.

H

Nom.

M

Max.

N

±.003

S

±.003

Hardened

Steel

300 Series

Stainless Steel

400 Series

Stainless Steel

TSKS

TSKC

TSK4

R

1.5

2.5

.032

.177

.236

.276

.140

.099

.100

TSKS

TSKC

TSK4

R

2.0

2.5

.032

.177

.236

.276

.159

.099

.119

TSKS

TSKC

TSK4

R

2.5

2.5

.032

.177

.236

.276

.179

.099

.139

Type

Face Mounting

Designation

Code

Top Sheet

Thickness

Code

Neck

Diameter

Code

A

(Shank)

Max.

B

±.003

C

Max.

H

Nom.

M

Max.

N

±.003

S

±.003

Hardened

Steel

300 Series

Stainless Steel

400 Series

Stainless Steel

HSKS

HSKC

HSK4

R

1.5

2.5

.047

.177

.236

.276

.156

.099

.115

3.2

.217

.276

.315

.126

4.0

.256

.315

.354

.157

HSKS

HSKC

HSK4

R

2.0

2.5

.047

.177

.236

.276

.175

.099

.135

3.2

.217

.276

.315

.126

4.0

.256

.315

.354

.157

HSKS

HSKC

HSK4

R

2.5

2.5

.047

.177

.236

.276

.198

.099

.155

3.2

.217

.276

.315

.126

4.0

.256

.315

.354

.157

Type

Face Mounting

Designation

Code

Top Sheet

Thickness

Code

Neck

Diameter

Code

A

(Shank)

Max.

B

±0.08

C

Max.

H

Nom.

M

Max.

N

±0.08

S

±0.08

Hardened

Steel

300 Series

Stainless Steel

400 Series

Stainless Steel

HSKS

HSKC

HSK4

R

1.5

2.5

1.2

4.5

6

7

3.95

2.5

2.93

3.2

5.5

7

8

3.2

4.0

6.5

8

9

4

HSKS

HSKC

HSK4

R

2.0

2.5

1.2

4.5

6

7

4.45

2.5

3.43

3.2

5.5

7

8

3.2

4.0

6.5

8

9

4

HSKS

HSKC

HSK4

R

2.5

2.5

1.2

4.5

6

7

4.95

2.5

3.93

3.2

5.5

7

8

3.2

4.0

6.5

8

9

4

HSKS

—

—

R

1.2

4.0

1.2

7

8

9.5

3.9

4

2.6

Uni

fie

d

Me

tric

Keyhole® Standoffs And Fasteners

SK-7

PennEngineering •

All dimensions are in inches.

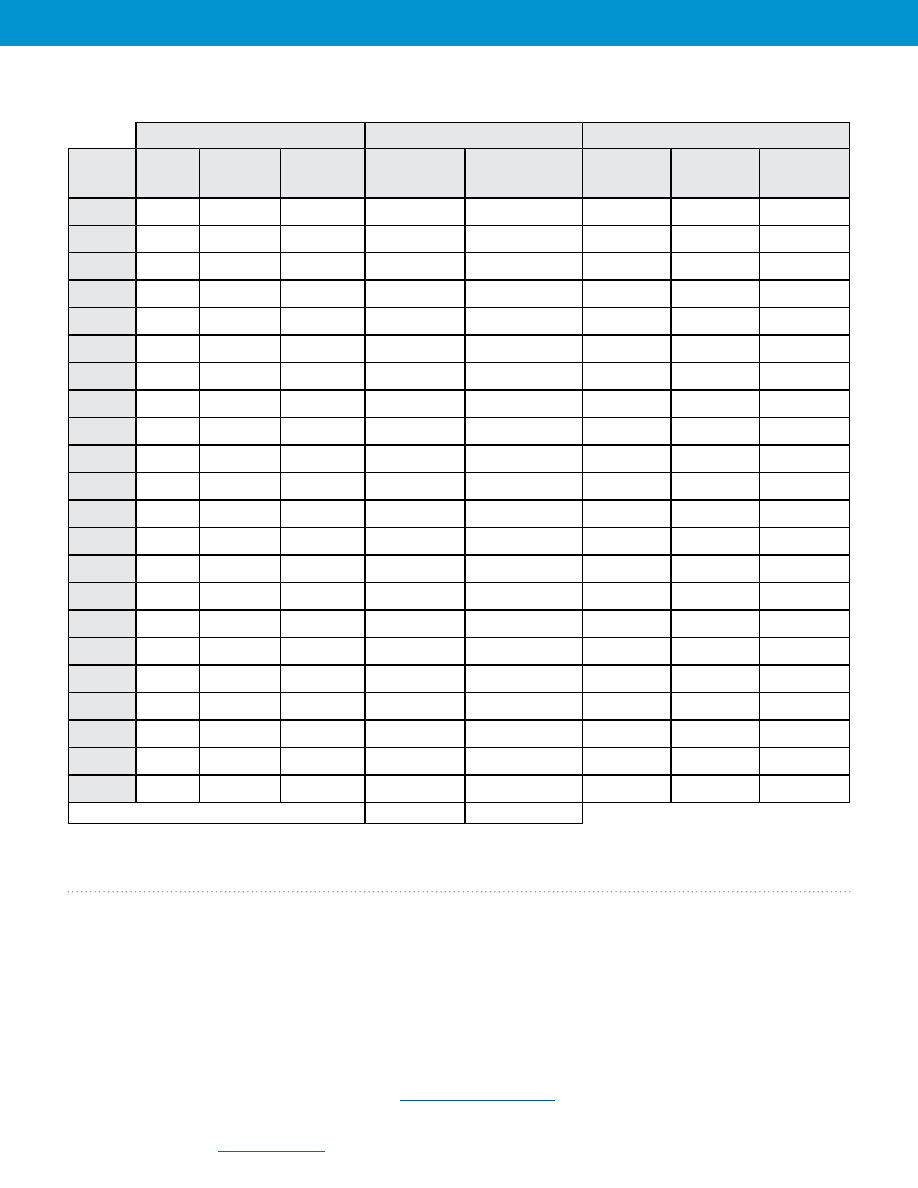

SKC™/SK4™/ SKCF™/SK4F™/SKSF™ Standoffs

A

1

Rad.

A

3

Dia.

Mounting Hole A in Panel 2

Location

Tolerance

±.005” / ±0.13 mm

A

2

A

4

Application Data

Panel 1

Panel 2

Type

Bottom

Mounting Hole B

+.003 –.000

Sheet

Hardness

Max.

(1)

Min. Sheet

Thickness

Edge

Distance

C1 Min.

(4)

Top Mounting Hole A

Material

Thickness

Range

Edge

Distance

C2 Min.

(4)

A1

Nom.

A2

±.003

A3

±.003

A4

Min.

SKC-6060

.213

HRB 70 / HB 125

.040

.260

.059

.118

.197

.148

ANY

.057 - .064

.160

SK4-6060

.213

HRB 88 / HB 183

.040

.260

.059

.118

.197

.148

ANY

.057 - .064

.160

SKCF-6060

.213

HRB 70 / HB 125

.040

.260

.059

.118

.197

.148

ANY

.057 - .064

.160

SK4F-6060

.213

HRB 88 / HB 183

.040

.260

.059

.118

.197

.148

ANY

.057 - .064

.160

SKSF-6060

.213

HRB 80 / HB 150

.040

.260

.059

.118

.197

.148

ANY

.057 - .064

.160

SKC-F1.5

.213

HRB 70 / HB 125

.040

(2)

.150

.059

.118

.197

.148

ANY

.057 - .064

.160

SK4-F1.5

.213

HRB 88 / HB 183

.040

(2)

.150

.059

.118

.197

.148

ANY

.057 - .064

.160

SKCF-F1.5

.213

HRB 70 / HB 125

.040

(2)

.150

.059

.118

.197

.148

ANY

.057 - .064

.160

SK4F-F1.5

.213

HRB 88 / HB 183

.040

(2)

.150

.059

.118

.197

.148

ANY

.057 - .064

.160

SKSF-F1.5

.213

HRB 80 / HB 150

.040

(2)

.150

.059

.118

.197

.148

ANY

.057 - .064

.160

TSKCF-F1.5

.213

HRB 70 / HB 125

.032

(3)

.150

.059

.118

.197

.148

ANY

.057 - .064

.160

TSK4F-F1.5

.213

HRB 88 / HB 183

.032

(3)

.150

.059

.118

.197

.148

ANY

.057 - .064

.160

TSKSF-F1.5

.213

HRB 80 / HB 150

.032

(3)

.150

.059

.118

.197

.148

ANY

.057 - .064

.160

Panel 1

Panel 2

Type

Bottom

Mounting Hole B

+0.08

Sheet

Hardness

Max.

(1)

Min. Sheet

Thickness

Edge

Distance

C1 Min.

(4)

Top Mounting Hole A

Material

Thickness

Range

Edge

Distance

C2 Min.

(4)

A1

Nom.

A2

±0.08

A3

±0.08

A4

Min.

SKC-61.5

5.41

HRB 70 / HB 125

1

6.6

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

SK4-61.5

5.41

HRB 88 / HB 183

1

6.6

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

SKCF-61.5

5.41

HRB 70 / HB 125

1

6.6

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

SK4F-61.5

5.41

HRB 88 / HB 183

1

6.6

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

SKSF-61.5

5.41

HRB 80 / HB 150

1

6.6

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

SKC-F1.5

5.41

HRB 70 / HB 125

1

(2)

3.8

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

SK4-F1.5

5.41

HRB 88 / HB 183

1

(2)

3.8

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

SKCF-F1.5

5.41

HRB 70 / HB 125

1

(2)

3.8

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

SK4F-F1.5

5.41

HRB 88 / HB 183

1

(2)

3.8

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

SKSF-F1.5

5.41

HRB 80 / HB 150

1

(2)

3.8

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

TSKCF-F1.5

5.41

HRB 70 / HB 125

0.8

(3)

3.8

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

TSK4F-F1.5

5.41

HRB 88 / HB 183

0.8

(3)

3.8

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

TSKSF-F1.5

5.41

HRB 80 / HB 150

0.8

(3)

3.8

1.5

3

5

3.75

ANY

1.45 - 1.62

4.1

All dimensions are in millimeters.

(1) HRB - Hardness Rockwell “B” Scale. HB - Hardness Brinell.

(2) SKC-F™/SK4-F™/ SKCF-F™/SK4F-F™/SKSF-F™ fasteners may also be installed into a .043”/1.1mm minimum depth blind milled hole in a .062”/1.6mm minimum sheet thickness.

(3) TSKCF-F™/TSK4F-F™/TSKSF-F™ fasteners may also be installed into a .035”/0.9mm minimum depth blind milled hole in a .055”/1.4mm minimum sheet thickness.

(4) For more information on proximity to bends and distance to other clinch hardware, see

.

SKC-F™/SK4-F™/ SKCF-F™/SK4-F™/SKSF-F™/

TSKCF-F™/TSK4-F™/TSKSF-F™ Fasteners

Edge

C

2

Edge

C

1

PANEL 2

PANEL 1

Mounting Hole B

Mounting Hole A

Mounting

Hole Location

Tolerance

±.005” / ±0.13 mm

A

1

Rad.

A

3

Dia.

Mounting Hole A in Panel 2

Location

Tolerance

±.005” / ±0.13 mm

A

2

A

4

Edge

C

2

Edge

C

1

Mounting Hole B

Mounting Hole A

PANEL 2

PANEL 1

Mounting Hole

Location Tolerance

±.005” / ±0.13 mm

Uni

fie

d

Keyhole® Standoffs And Fasteners

SK-8

All dimensions are in inches.

Bottom Mounting

Edge

Top Mounting Hole A

Edge

Type

Hole B

Sheet Hardness Thickness Distance A

1

A

2

A

3

A

4

Thickness Distance

+ .003 –.000

Max. (1)

Range

C

1

Min. (2)

Nom.

± .003

± .003

Min.

Material

Max.

C

2

Min. (2)

SKS-R1.5-2.5-ZI

.213

HRB 80 / HB 150

.040 - .047

.236

.059

.118

.197

.148

ANY

.060

.160

SKS-R1.5-3.2-ZI

.236

HRB 80 / HB 150

.040 - .047

.236

.073

.146

.236

.181

ANY

.060

.201

SKS-R1.5-4.0-ZI

.276

HRB 80 / HB 150

.040 - .047

.236

.089

.177

.276

.217

ANY

.060

.240

SKS-R2.0-2.5-ZI

.213

HRB 80 / HB 150

.040 - .047

.236

.059

.118

.197

.148

ANY

.080

.160

SKS-R2.0-3.2-ZI

.236

HRB 80 / HB 150

.040 - .047

.236

.073

.146

.236

.181

ANY

.080

.201

SKS-R2.0-4.0-ZI

.276

HRB 80 / HB 150

.040 - .047

.236

.089

.177

.276

.217

ANY

.080

.240

SKS-R2.5-2.5-ZI

.213

HRB 80 / HB 150

.040 - .047

.236

.059

.118

.197

.148

ANY

.100

.160

SKS-R2.5-3.2-ZI

.236

HRB 80 / HB 150

.040 - .047

.236

.073

.146

.236

.181

ANY

.100

.201

SKS-R2.5-4.0-ZI

.276

HRB 80 / HB 150

.040 - .047

.236

.089

.177

.276

.217

ANY

.100

.240

SKC-R1.5-2.5

.237

HRB 70 / HB 125

.040 - .047

.276

.059

.118

.197

.148

ANY

.060

.160

SKC-R1.5-3.2

.277

HRB 70 / HB 125

.040 - .047

.295

.073

.146

.236

.181

ANY

.060

.201

SKC-R1.5-4.0

.316

HRB 70 / HB 125

.040 - .047

.315

.089

.177

.276

.217

ANY

.060

.240

SKC-R2.0-2.5

.237

HRB 70 / HB 125

.040 - .047

.276

.059

.118

.197

.148

ANY

.080

.160

SKC-R2.0-3.2

.277

HRB 70 / HB 125

.040 - .047

.295

.073

.146

.236

.181

ANY

.080

.201

SKC-R2.0-4.0

.316

HRB 70 / HB 125

.040 - .047

.315

.089

.177

.276

.217

ANY

.080

.240

SKC-R2.5-2.5

.237

HRB 70 / HB 125

.040 - .047

.276

.059

.118

.197

.148

ANY

.100

.160

SKC-R2.5-3.2

.277

HRB 70 / HB 125

.040 - .047

.295

.073

.146

.236

.181

ANY

.100

.201

SKC-R2.5-4.0

.316

HRB 70 / HB 125

.040 - .047

.315

.089

.177

.276

.217

ANY

.100

.240

SK4-R1.5-2.5

.237

HRB 88 / HB 183

.040 - .047

.276

.059

.118

.197

.148

ANY

.060

.160

SK4-R1.5-3.2

.277

HRB 88 / HB 183

.040 - .047

.295

.073

.146

.236

.181

ANY

.060

.201

SK4-R1.5-4.0

.316

HRB 88 / HB 183

.040 - .047

.315

.089

.177

.276

.217

ANY

.060

.240

SK4-R2.0-2.5

.237

HRB 88 / HB 183

.040 - .047

.276

.059

.118

.197

.148

ANY

.080

.160

SK4-R2.0-3.2

.277

HRB 88 / HB 183

.040 - .047

.295

.073

.146

.236

.181

ANY

.080

.201

SK4-R2.0-4.0

.316

HRB 88 / HB 183

.040 - .047

.315

.089

.177

.276

.217

ANY

.080

.240

SK4-R2.5-2.5

.237

HRB 88 / HB 183

.040 - .047

.276

.059

.118

.197

.148

ANY

.100

.160

SK4-R2.5-3.2

.277

HRB 88 / HB 183

.040 - .047

.295

.073

.146

.236

.181

ANY

.100

.201

SK4-R2.5-4.0

.316

HRB 88 / HB 183

.040 - .047

.315

.089

.177

.276

.217

ANY

.100

.240

TSKS-R1.5-2.5-ZI

.237

HRB 80 / HB 150

.032 - .038

.276

.059

.118

.197

.148

ANY

.060

.160

TSKS-R2.0-2.5-ZI

.237

HRB 80 / HB 150

.032 - .038

.276

.059

.118

.197

.148

ANY

.080

.160

TSKS-R2.5-2.5-ZI

.237

HRB 80 / HB 150

.032 - .038

.276

.059

.118

.197

.148

ANY

.100

.160

HSKS-R1.5-2.5-ZI

.237

HRB 80 / HB 150

.047 - .055

.276

.059

.118

.197

.148

ANY

.060

.160

HSKS-R1.5-3.2-ZI

.277

HRB 80 / HB 150

.047 - .055

.295

.073

.146

.236

.181

ANY

.060

.201

HSKS-R1.5-4.0-ZI

.316

HRB 80 / HB 150

.047 - .055

.315

.089

.177

.276

.217

ANY

.060

.240

HSKS-R2.0-2.5-ZI

.237

HRB 80 / HB 150

.047 - .055

.276

.059

.118

.197

.148

ANY

.080

.160

HSKS-R2.0-3.2-ZI

.277

HRB 80 / HB 150

.047 - .055

.295

.073

.146

.236

.181

ANY

.080

.201

HSKS-R2.0-4.0-ZI

.316

HRB 80 / HB 150

.047 - .055

.315

.089

.177

.276

.217

ANY

.080

.240

HSKS-R2.5-2.5-ZI

.237

HRB 80 / HB 150

.047 - .055

.276

.059

.118

.197

.148

ANY

.100

.160

HSKS-R2.5-3.2-ZI

.277

HRB 80 / HB 150

.047 - .055

.295

.073

.146

.236

.181

ANY

.100

.201

HSKS-R2.5-4.0-ZI

.316

HRB 80 / HB 150

.047 - .055

.315

.089

.177

.276

.217

ANY

.100

.240

TSKC-R1.5-2.5

.237

HRB 70 / HB 125

.032 - .038

.276

.059

.118

.197

.148

ANY

.060

.160

TSKC-R2.0-2.5

.237

HRB 70 / HB 125

.032 - .038

.276

.059

.118

.197

.148

ANY

.080

.160

TSKC-R2.5-2.5

.237

HRB 70 / HB 125

.032 - .038

.276

.059

.118

.197

.148

ANY

.100

.160

HSKC-R1.5-2.5

.237

HRB 70 / HB 125

.047 - .055

.276

.059

.118

.197

.148

ANY

.060

.160

HSKC-R1.5-3.2

.277

HRB 70 / HB 125

.047 - .055

.295

.073

.146

.236

.181

ANY

.060

.201

HSKC-R1.5-4.0

.316

HRB 70 / HB 125

.047 - .055

.315

.089

.177

.276

.217

ANY

.060

.240

HSKC-R2.0-2.5

.237

HRB 70 / HB 125

.047 - .055

.276

.059

.118

.197

.148

ANY

.080

.160

HSKC-R2.0-3.2

.277

HRB 70 / HB 125

.047 - .055

.295

.073

.146

.236

.181

ANY

.080

.201

HSKC-R2.0-4.0

.316

HRB 70 / HB 125

.047 - .055

.315

.089

.177

.276

.217

ANY

.080

.240

HSKC-R2.5-2.5

.237

HRB 70 / HB 125

.047 - .055

.276

.059

.118

.197

.148

ANY

.100

.160

HSKC-R2.5-3.2

.277

HRB 70 / HB 125

.047 - .055

.295

.073

.146

.236

.181

ANY

.100

.201

HSKC-R2.5-4.0

.316

HRB 70 / HB 125

.047 - .055

.315

.089

.177

.276

.217

ANY

.100

.240

TSK4-R1.5-2.5

.237

HRB 88 / HB 183

.032 - .038

.276

.059

.118

.197

.148

ANY

.060

.160

TSK4-R2.0-2.5

.237

HRB 88 / HB 183

.032 - .038

.276

.059

.118

.197

.148

ANY

.080

.160

TSK4-R2.5-2.5

.237

HRB 88 / HB 183

.032 - .038

.276

.059

.118

.197

.148

ANY

.100

.160

HSK4-R1.5-2.5

.237

HRB 88 / HB 183

.047 - .055

.276

.059

.118

.197

.148

ANY

.060

.160

HSK4-R1.5-3.2

.277

HRB 88 / HB 183

.047 - .055

.295

.073

.146

.236

.181

ANY

.060

.201

HSK4-R1.5-4.0

.316

HRB 88 / HB 183

.047 - .055

.315

.089

.177

.276

.217

ANY

.060

.240

HSK4-R2.0-2.5

.237

HRB 88 / HB 183

.047 - .055

.276

.059

.118

.197

.148

ANY

.080

.160

HSK4-R2.0-3.2

.277

HRB 88 / HB 183

.047 - .055

.295

.073

.146

.236

.181

ANY

.080

.201

HSK4-R2.0-4.0

.316

HRB 88 / HB 183

.047 - .055

.315

.089

.177

.276

.217

ANY

.080

.240

HSK4-R2.5-2.5

.237

HRB 88 / HB 183

.047 - .055

.276

.059

.118

.197

.148

ANY

.100

.160

HSK4-R2.5-3.2

.277

HRB 88 / HB 183

.047 - .055

.295

.073

.146

.236

.181

ANY

.100

.201

HSK4-R2.5-4.0

.316

HRB 88 / HB 183

.047 - .055

.315

.089

.177

.276

.217

ANY

.100

.240

PANEL 1

PANEL 2

Application Data — SKS-R™/SKC-R™/SK4-R™/ TSKS-R™/HSKS-R™/

TSKC-R™/TSK4-R™/HSKC-R™/HSK4-R™ Fasteners

Mounting Hole A in Panel 2

A

1

Rad.

A

3

Dia.

Location

Tolerance

±.005” / ±0.13 mm

A

2

A

4

Edge

C

2

Edge

C

1

PANEL 2

PANEL 1

Mounting

Hole B

Mounting

Hole A

Mounting

Hole Location

Tolerance

±.005” / ±0.13 mm

(1) HRB - Hardness Rockwell “B” Scale. HB - Hardness Brinell.

(2) For more information on proximity to bends and distance to other clinch hardware, see

.

Me

tric

Keyhole® Standoffs And Fasteners

SK-9

PennEngineering •

All dimensions are in millimeterrs.

Bottom Mounting

Edge

Top Mounting Hole A

Edge

Type

Hole B

Sheet Hardness Thickness Distance A

1

A

2

A

3

A

4

Thickness Distance

+ 0.08

Max. (1)

Range

C

1

Min. (2)

Nom.

±0.08

± 0.08

Min.

Material

Max.

C

2

Min. (2)

SKS-R1.5-2.5-ZI

5.41

HRB 80 / HB 150

1-1.19

6

1.5

3

5

3.75

ANY

1.54

4.1

SKS-R1.5-3.2-ZI

6

HRB 80 / HB 150

1-1.19

6

1.85

3.7

6

4.6

ANY

1.54

5.1

SKS-R1.5-4.0-ZI

7

HRB 80 / HB 150

1-1.19

6

2.25

4.5

7

5.5

ANY

1.54

6.1

SKS-R2.0-2.5-ZI

5.41

HRB 80 / HB 150

1-1.19

6

1.5

3

5

3.75

ANY

2.04

4.1

SKS-R2.0-3.2-ZI

6

HRB 80 / HB 150

1-1.19

6

1.85

3.7

6

4.6

ANY

2.04

5.1

SKS-R2.0-4.0-ZI

7

HRB 80 / HB 150

1-1.19

6

2.25

4.5

7

5.5

ANY

2.04

6.1

SKS-R2.5-2.5-ZI

5.41

HRB 80 / HB 150

1-1.19

6

1.5

3

5

3.75

ANY

2.54

4.1

SKS-R2.5-3.2-ZI

6

HRB 80 / HB 150

1-1.19

6

1.85

3.7

6

4.6

ANY

2.54

5.1

SKS-R2.5-4.0-ZI

7

HRB 80 / HB 150

1-1.19

6

2.25

4.5

7

5.5

ANY

2.54

6.1

SKC-R1.5-2.5

6.02

HRB 70 / HB 125

1-1.19

7

1.5

3

5

3.75

ANY

1.54

4.1

SKC-R1.5-3.2

7.02

HRB 70 / HB 125

1-1.19

7.5

1.85

3.7

6

4.6

ANY

1.54

5.1

SKC-R1.5-4.0

8.02

HRB 70 / HB 125

1-1.19

8

2.25

4.5

7

5.5

ANY

1.54

6.1

SKC-R2.0-2.5

6.02

HRB 70 / HB 125

1-1.19

7

1.5

3

5

3.75

ANY

2.04

4.1

SKC-R2.0-3.2

7.02

HRB 70 / HB 125

1-1.19

7.5

1.85

3.7

6

4.6

ANY

2.04

5.1

SKC-R2.0-4.0

8.02

HRB 70 / HB 125

1-1.19

8

2.25

4.5

7

5.5

ANY

2.04

6.1

SKC-R2.5-2.5

6.02

HRB 70 / HB 125

1-1.19

7

1.5

3

5

3.75

ANY

2.54

4.1

SKC-R2.5-3.2

7.02

HRB 70 / HB 125

1-1.19

7.5

1.85

3.7

6

4.6

ANY

2.54

5.1

SKC-R2.5-4.0

8.02

HRB 70 / HB 125

1-1.19

8

2.25

4.5

7

5.5

ANY

2.54

6.1

SK4-R1.5-2.5

6.02

HRB 88 / HB 183

1-1.19

7

1.5

3

5

3.75

ANY

1.54

4.1

SK4-R1.5-3.2

7.02

HRB 88 / HB 183

1-1.19

7.5

1.85

3.7

6

4.6

ANY

1.54

5.1

SK4-R1.5-4.0

8.02

HRB 88 / HB 183

1-1.19

8

2.25

4.5

7

5.5

ANY

1.54

6.1

SK4-R2.0-2.5

6.02

HRB 88 / HB 183

1-1.19

7

1.5

3

5

3.75

ANY

2.04

4.1

SK4-R2.0-3.2

7.02

HRB 88 / HB 183

1-1.19

7.5

1.85

3.7

6

4.6

ANY

2.04

5.1

SK4-R2.0-4.0

8.02

HRB 88 / HB 183

1-1.19

8

2.25

4.5

7

5.5

ANY

2.04

6.1

SK4-R2.5-2.5

6.02

HRB 88 / HB 183

1-1.19

7

1.5

3

5

3.75

ANY

2.54

4.1

SK4-R2.5-3.2

7.02

HRB 88 / HB 183

1-1.19

7.5

1.85

3.7

6

4.6

ANY

2.54

5.1

SK4-R2.5-4.0

8.02

HRB 88 / HB 183

1-1.19

8

2.25

4.5

7

5.5

ANY

2.54

6.1

TSKS-R1.5-2.5-ZI

6.02

HRB 80 / HB 150

0.8-0.95

7

1.5

3

5

3.75

ANY

1.54

4.1

TSKS-R2.0-2.5-ZI

6.02

HRB 80 / HB 150

0.8-0.95

7

1.5

3

5

3.75

ANY

2.04

4.1

TSKS-R2.5-2.5-ZI

6.02

HRB 80 / HB 150

0.8-0.95

7

1.5

3

5

3.75

ANY

2.54

4.1

HSKS-R1.5-2.5-ZI

6.02

HRB 80 / HB 150

1.2-1.39

7

1.5

3

5

3.75

ANY

1.54

4.1

HSKS-R1.5-3.2-ZI

7.02

HRB 80 / HB 150

1.2-1.39

7.5

1.85

3.7

6

4.6

ANY

1.54

5.1

HSKS-R1.5-4.0-ZI

8.02

HRB 80 / HB 150

1.2-1.39

8

2.25

4.5

7

5.5

ANY

1.54

6.1

HSKS-R2.0-2.5-ZI

6.02

HRB 80 / HB 150

1.2-1.39

7

1.5

3

5

3.75

ANY

2.04

4.1

HSKS-R2.0-3.2-ZI

7.02

HRB 80 / HB 150

1.2-1.39

7.5

1.85

3.7

6

4.6

ANY

2.04

5.1

HSKS-R2.0-4.0-ZI

8.02

HRB 80 / HB 150

1.2-1.39

8

2.25

4.5

7

5.5

ANY

2.04

6.1

HSKS-R2.5-2.5-ZI

6.02

HRB 80 / HB 150

1.2-1.39

7

1.5

3

5

3.75

ANY

2.54

4.1

HSKS-R2.5-3.2-ZI

7.02

HRB 80 / HB 150

1.2-1.39

7.5

1.85

3.7

6

4.6

ANY

2.54

5.1

HSKS-R2.5-4.0-ZI

8.02

HRB 80 / HB 150

1.2-1.39

8

2.25

4.5

7

5.5

ANY

2.54

6.1

HSKS-R1.2-4.0-ZI

8.02

HRB 80 / HB 150

1.2-1.39

8

2.25

4.5

7.5

5.75

ANY

1.21

6.6

TSKC-R1.5-2.5

6.02

HRB 70 / HB 125

0.8-0.95

7

1.5

3

5

3.75

ANY

1.54

4.1

TSKC-R2.0-2.5

6.02

HRB 70 / HB 125

0.8-0.95

7

1.5

3

5

3.75

ANY

2.04

4.1

TSKC-R2.5-2.5

6.02

HRB 70 / HB 125

0.8-0.95

7

1.5

3

5

3.75

ANY

2.54

4.1

HSKC-R1.5-2.5

6.02

HRB 70 / HB 125

1.2-1.39

7

1.5

3

5

3.75

ANY

1.54

4.1

HSKC-R1.5-3.2

7.02

HRB 70 / HB 125

1.2-1.39

7.5

1.85

3.7

6

4.6

ANY

1.54

5.1

HSKC-R1.5-4.0

8.02

HRB 70 / HB 125

1.2-1.39

8

2.25

4.5

7

5.5

ANY

1.54

6.1

HSKC-R2.0-2.5

6.02

HRB 70 / HB 125

1.2-1.39

7

1.5

3

5

3.75

ANY

2.04

4.1

HSKC-R2.0-3.2

7.02

HRB 70 / HB 125

1.2-1.39

7.5

1.85

3.7

6

4.6

ANY

2.04

5.1

HSKC-R2.0-4.0

8.02

HRB 70 / HB 125

1.2-1.39

8

2.25

4.5

7

5.5

ANY

2.04

6.1

HSKC-R2.5-2.5

6.02

HRB 70 / HB 125

1.2-1.39

7

1.5

3

5

3.75

ANY

2.54

4.1

HSKC-R2.5-3.2

7.02

HRB 70 / HB 125

1.2-1.39

7.5

1.85

3.7

6

4.6

ANY

2.54

5.1

HSKC-R2.5-4.0

8.02

HRB 70 / HB 125

1.2-1.39

8

2.25

4.5

7

5.5

ANY

2.54

6.1

TSK4-R1.5-2.5

6.02

HRB 88 / HB 183

0.8-0.95

7

1.5

3

5

3.75

ANY

1.54

4.1

TSK4-R2.0-2.5

6.02

HRB 88 / HB 183

0.8-0.95

7

1.5

3

5

3.75

ANY

2.04

4.1

TSK4-R2.5-2.5

6.02

HRB 88 / HB 183

0.8-0.95

7

1.5

3

5

3.75

ANY

2.54

4.1

HSK4-R1.5-2.5

6.02

HRB 88 / HB 183

1.2-1.39

7

1.5

3

5

3.75

ANY

1.54

4.1

HSK4-R1.5-3.2

7.02

HRB 88 / HB 183

1.2-1.39

7.5

1.85

3.7

6

4.6

ANY

1.54

5.1

HSK4-R1.5-4.0

8.02

HRB 88 / HB 183

1.2-1.39

8

2.25

4.5

7

5.5

ANY

1.54

6.1

HSK4-R2.0-2.5

6.02

HRB 88 / HB 183

1.2-1.39

7

1.5

3

5

3.75

ANY

2.04

4.1

HSK4-R2.0-3.2

7.02

HRB 88 / HB 183

1.2-1.39

7.5

1.85

3.7

6

4.6

ANY

2.04

5.1

HSK4-R2.0-4.0

8.02

HRB 88 / HB 183

1.2-1.39

8

2.25

4.5

7

5.5

ANY

2.04

6.1

HSK4-R2.5-2.5

6.02

HRB 88 / HB 183

1.2-1.39

7

1.5

3

5

3.75

ANY

2.54

4.1

HSK4-R2.5-3.2

7.02

HRB 88 / HB 183

1.2-1.39

7.5

1.85

3.7

6

4.6

ANY

2.54

5.1

HSK4-R2.5-4.0

8.02

HRB 88 / HB 183

1.2-1.39

8

2.25

4.5

7

5.5

ANY

2.54

6.1

PANEL 1

PANEL 2

Application Data — SKS-R™/SKC-R™/SK4-R™/ TSKS-R™/HSKS-R™/

TSKC-R™/TSK4-R™/HSKC-R™/HSK4-R™ Fasteners

Mounting Hole A in Panel 2

A

1

Rad.

A

3

Dia.

Location

Tolerance

±.005” / ±0.13 mm

A

2

A

4

Edge

C

2

Edge

C

1

PANEL 2

PANEL 1

Mounting

Hole B

Mounting

Hole A

Mounting

Hole Location

Tolerance

±.005” / ±0.13 mm

(1) HRB - Hardness Rockwell “B” Scale. HB - Hardness Brinell.

(2) For more information on proximity to bends and distance to other clinch hardware, see

.

Keyhole® Standoffs And Fasteners

SK-10

PennEngineering •

A Note About 400 Series Fasteners For Stainless Steel Panels

In order for self-clinching fasteners to work properly, the fastener must be harder than the sheet into which

it is being installed. In the case of stainless steel panels, fasteners made from 300 Series Stainless Steel do

not meet this hardness criteria. It is for this reason that 400 series fasteners (SK4 and SK4-F) are offered.

However, while these 400 Series fasteners install and perform well in 300 Series stainless sheets they should

not be used if the end product:

• Will be exposed to any appreciable corrosive presence.

• Requires non-magnetic fasteners.

• Will be exposed to any temperatures above 300˚F (149˚C)

If any of the these are issues, please contact

for other options.

(1) HRB - Hardness Rockwell “B” Scale. HB - Hardness Brinell.

(2) See PEM Technical Support section of our web site for related plating standards and specifications.

Material And Finish Specifications

Fastener Materials

Standard Finishes

For Use in Sheet Hardness

(1)

Type

Hardened

Steel

300 Series

Stainless Steel

Hardened 400

Series Stainless

Steel

Passivated and/or

tested per ASTM A380

Zinc Plated per ASTM

B633, SC1 (5µm) Type III,

Colorless

(2)

HRB 88 / HB 183

or less

HRB 80 / HB150

or less

HRB 70 / HB 125

or less

SKC

•

•

•

SK4

•

•

•

SKC-F

•

•

•

SK4-F

•

•

•

SKC-R

•

•

•

SK4-R

•

•

•

SKS-R

•

•

•

TSKC-R

•

•

•

TSK4-R

•

•

•

TSKS-R

•

•

•

HSKS-R

•

•

•

HSKC-R

•

•

•

HSK4-R

•

•

•

SKCF-F

•

•

•

SK4F-F

•

•

•

SKSF-F

•

•

•

TSKCF-F

•

•

•

TSK4F-F

•

•

•

TSKSF-F

•

•

•

SKCF

•

•

•

SK4F

•

•

•

SKSF

•

•

•

Part Number Code for Finishes

None

ZI

Uni

fie

d

Uni

fie

d

Me

tric

Me

tric

Keyhole® Standoffs And Fasteners

SK-11

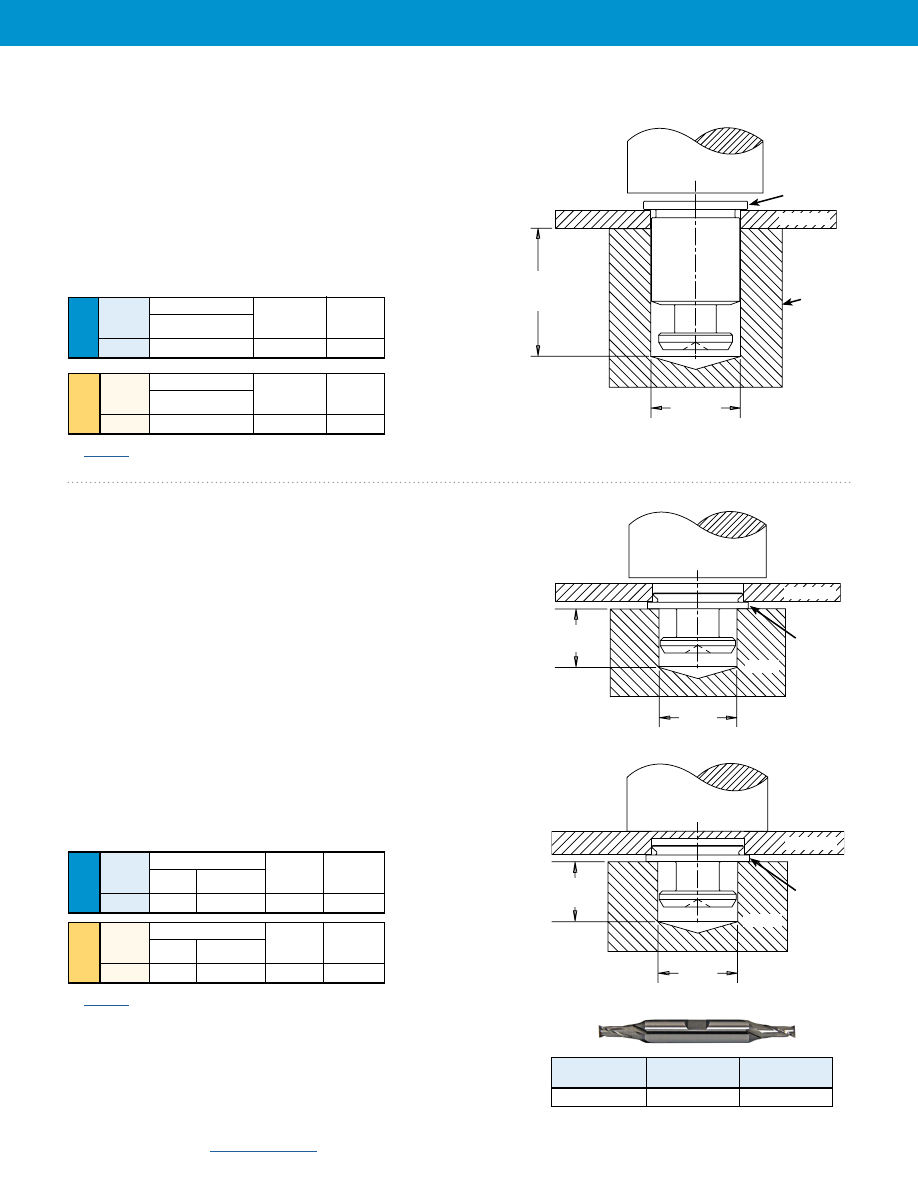

SKC™/SK4™/ SKCF™/SK4F™/SKSF™ Standoffs

1. Prepare properly sized mounting hole in Panel 1.

2. Place the fastener through (punched side of) the mounting hole

and into anvil as shown in figure 1.

3. With installation punch and anvil surfaces parallel, apply only

enough squeezing force to embed the head flush with the panel.

Through Hole Installation Procedure

1. Prepare properly sized mounting hole in Panel 1.

2. Place the fastener into anvil hole as shown in Figure 2.

3. Place the (punch side of) mounting hole over the shank of the fastener.

4. With installation punch and anvil surfaces parallel, apply only enough

squeezing force until flange is flush with panel.

Blind Hole Installation Procedure

1. Mill a properly sized blind hole into Panel 1.

2. Place the fastener into anvil hole as shown in Figure 3.

3. Place the panel mounting hole over the shank of the fastener.

4. With installation punch and anvil surfaces parallel, apply only enough

squeezing force to embed the flange flush with the panel.

SKC-F™/SK4-F™/ SKCF-F™/SK4-F™/SKSF-F™/

TSKCF-F™/TSK4-F™/TSKSF-F™ Fasteners

Installation

Body Size

Anvil Dimension (in.)

Sheet

D

Anvil Part

Punch Part

Code

+.003 -.000 Number Number

6060

.216

970200012300 975200048

Body Size Anvil Dimension (mm)

Sheet

D

Anvil Part

Punch Part

Code

+0.08

Number Number

61.5

5.49

970200012300 975200048

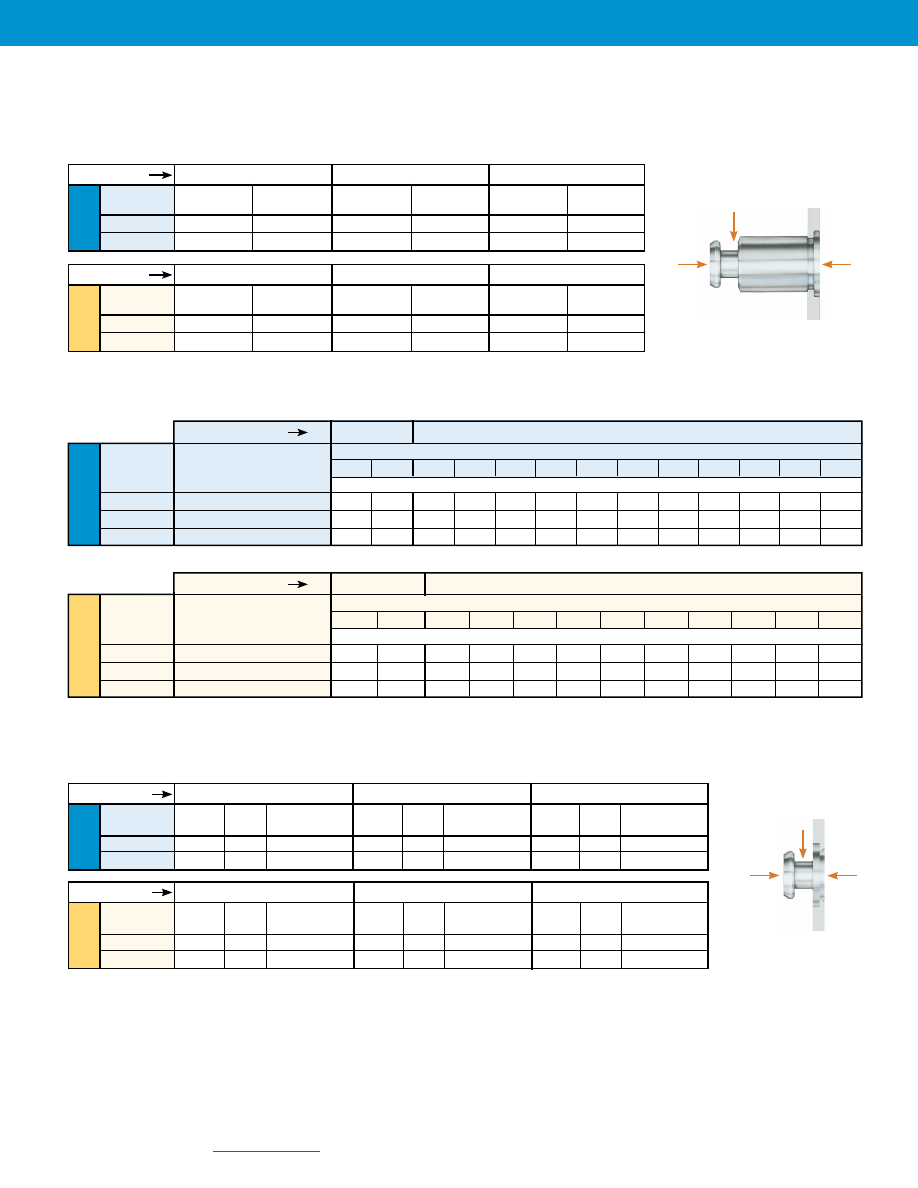

Sheet Anvil Dimensions (in.)

Thickness

L D

Anvil Part

Punch Part

Code

Min.

+.003 -.000 Number Number

1.5 .233

.184

8012608 975200048

Sheet Anvil Dimensions (mm)

Thickness

L D

Anvil Part

Punch Part

Code

Min.

+0.08 Number Number

1.5 5.95

4.67

8012608 975200048

PEMSERTER® Installation Tooling

(1)

PEMSERTER® Installation Tooling

(1)

PUNCH

PANEL 1

L

Min.

Figure 2

FLANGE

D

ANVIL

Figure 3

PUNCH

PANEL 1

L

Min.

FLANGE

D

ANVIL

PUNCH

D

(L+M) +.125” /

(L+M) +3.2 mm

Min.

PANEL 1

Figure 1

HEAD

ANVIL

For “L” and “M”

see page 3.

(1)

for a quote on Haeger® custom installation tooling.

(1)

for a quote on Haeger® custom installation tooling.

Fastener

Required Size

PEM

Type

End Mill

Part No.

SKC-F/SK4-F

.213”

CHM-213

End Mill Information

Double-ended, two-flute H.S.S. center-cutting end mills are available

from stock. PennEngineering does not manufacture center-cutting

end mills, but we do keep a supply in stock for your convenience.

Uni

fie

d

Me

tric

Keyhole® Standoffs And Fasteners

SK-12

PennEngineering •

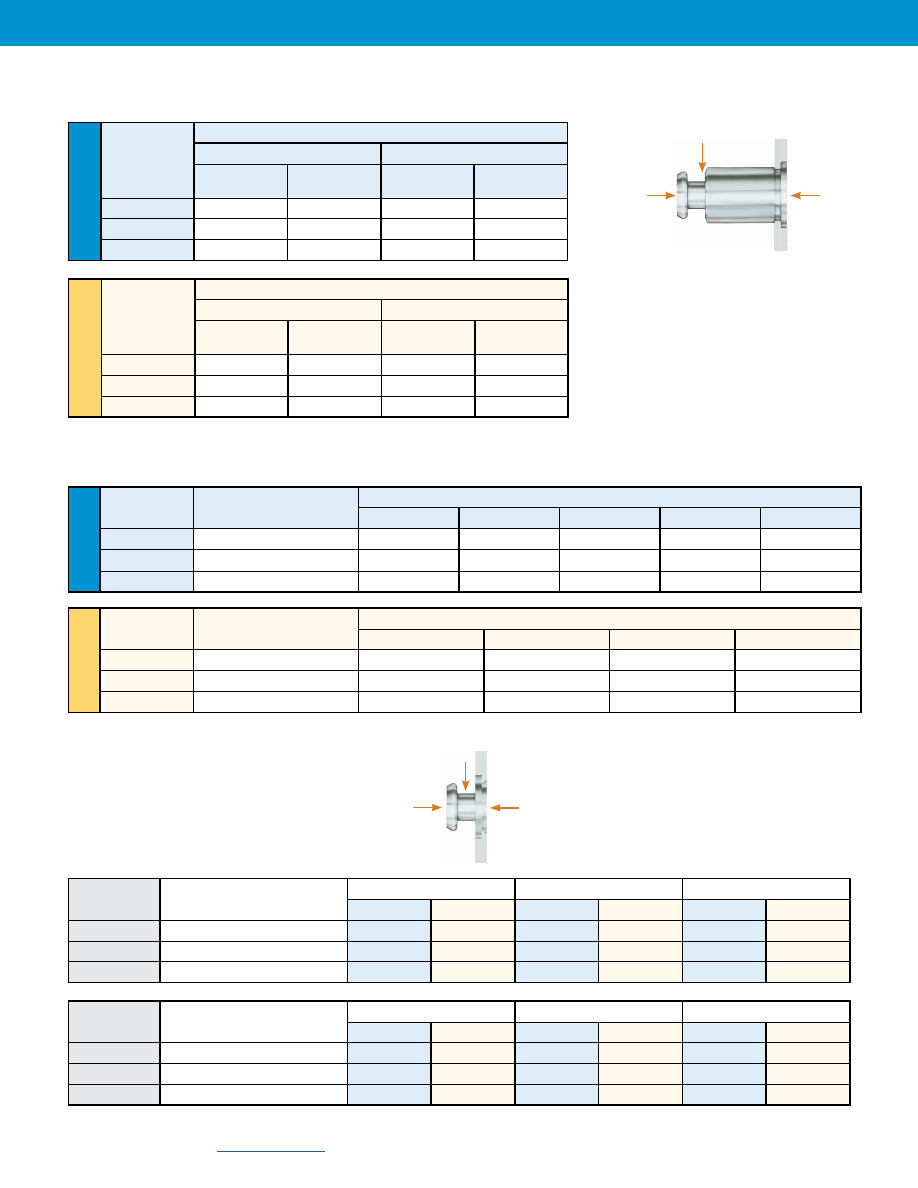

SKS-R™/SKC-R™/SK4-R™/ TSKS-R™/HSKS-R™/ TSKC-R™/

TSK4-R™/HSKC-R™/HSK4-R™ Fasteners

1. Prepare properly sized mounting hole in Panel 1.

2. Place the fastener through (punch side of) the mounting hole

and into anvil as shown.

3. With installation punch and anvil surfaces parallel, apply only

enough squeezing force to embed the head flush with the panel.

Neck Anvil Dimensions (mm)

Diameter

D

Anvil Part

Punch Part

Code

+0.08

Number Number

2.5 4.65 8026244

3.2

5.65

8026245 975200048

4.0

6.65

8026246

PEMSERTER® Installation Tooling

(1)

PUNCH

PANEL 1

M

+.126”/3.2mm

Min.

D

ANVIL

Neck

Anvil Dimensions (in.)

Diameter

D

Anvil Part

Punch Part

Code

+.003 -.000

Number Number

2.5 .183 8026244

3.2

.222

8026245 975200048

4.0

.262

8026246

Installation Notes

• For best results we recommend using a

PEMSERTER® machine for installation of PEM® self-clinching

fasteners. Please check our website for more information.

• Visit the Animation Library on our website to view the

installation process

.

(1)

for a quote on Haeger® custom installation tooling.

For Additional HAEGER® and PEMSERTER® Tooling Information / Part Numbers

Or download the

HAEGER WIZZARD

Phone App

Go to

to access

the Auto and Manual Tooling Wizards

} }

HAEGER® MANUAL TOOLING CATALOG

Uni

fie

d

Uni

fie

d

Uni

fie

d

Me

tric

Me

tric

Me

tric

Keyhole® Standoffs And Fasteners

SK-13

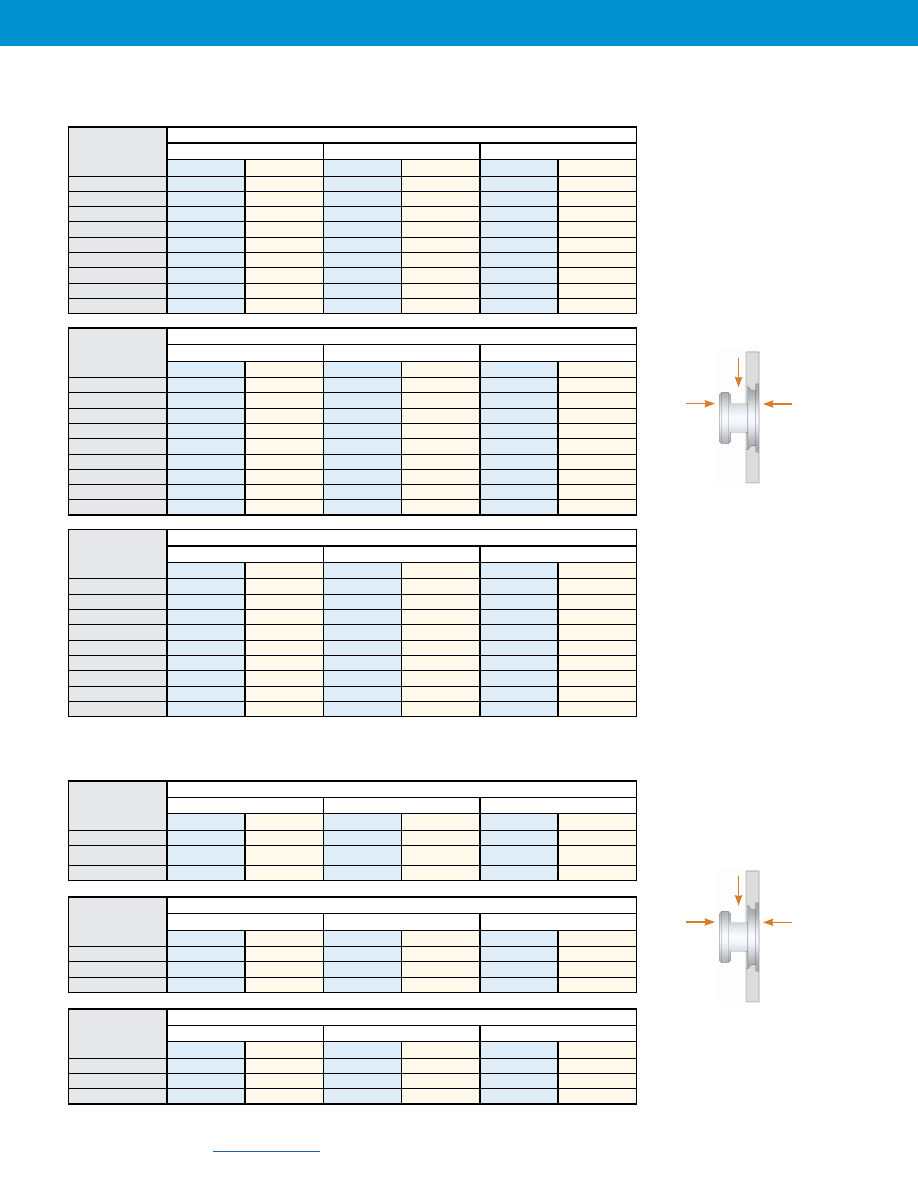

(1) Published installation forces are for general reference. Actual set-up and confirmation of complete installation should be made by observing proper seating of fastener

as described in the installation steps. Other performance values reported are averages when all proper installation parameters and procedures are followed. Variations

in mounting hole size, sheet material, and installation procedure may affect performance. Performance testing this product in your application is recommended. We will

be happy to provide technical assistance and/or samples for this purpose.

(2) .040” / 1 mm test sheet material thickness was used for the -2 and -4 SKC/SK4 standoffs due to the short length of the parts.

Body Size -

Installation

Pushout

Installation

Pushout

Installation

Pushout

Sheet

Code

(lbs.) (lbs.) (lbs.) (lbs.) (lbs.) (lbs.)

SKC-6060

1600

250

3200

600

—

—

SK4-6060

— — — — 9015

720

.060” 5052-H34 Aluminum

.060” Cold-Rolled Steel

Body Size -

Installation

Pushout

Installation

Pushout

Installation

Pushout

Sheet

Code

(kN) (N) (kN) (N) (kN) (N)

SKC-61.5

7.1

1100

14.2

2600

—

—

SK4-61.5

— — — — 40.1

3200

1.52 mm 5052-H34 Aluminum

1.52 mm Cold-Rolled Steel

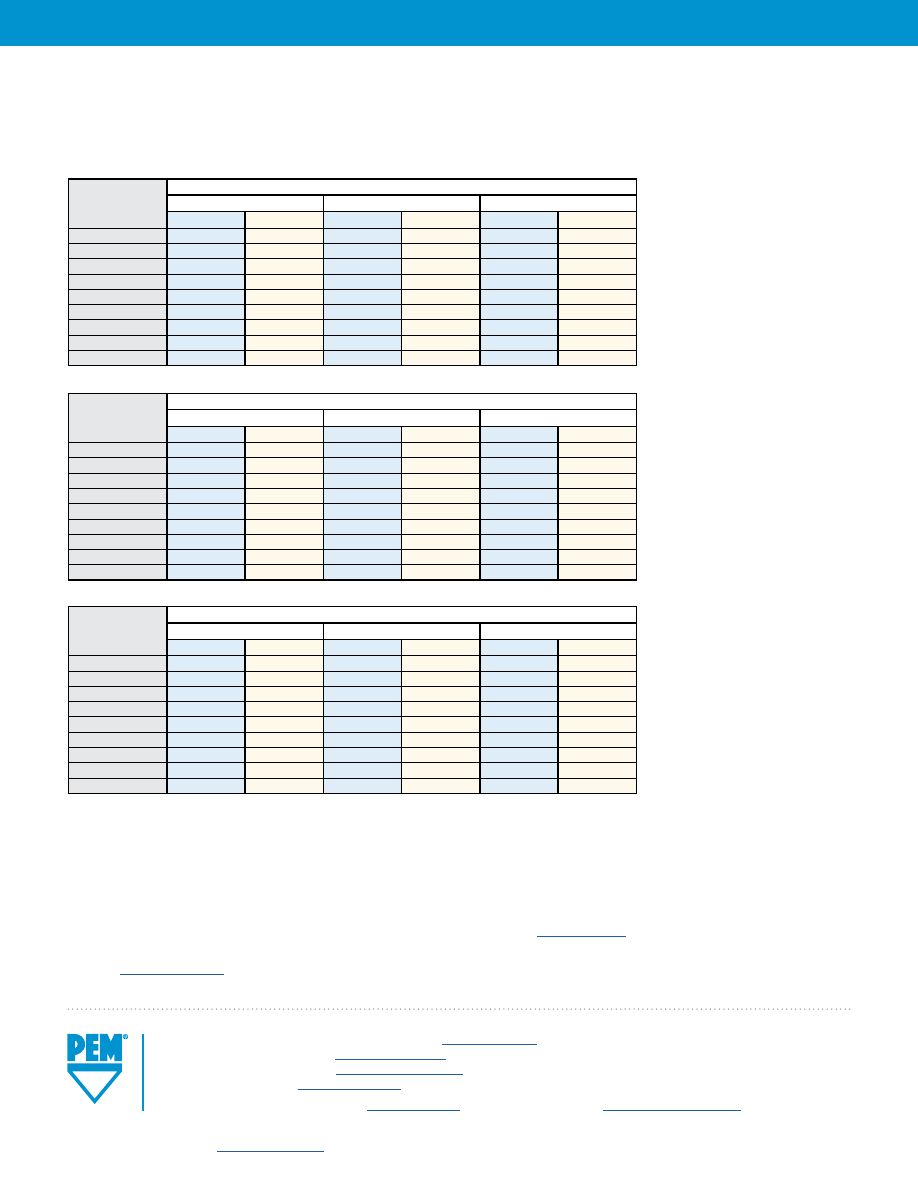

Length Codes

Body Size -

-2 -4 -6 -8 -10 -12 -14 -16 -18 -20 -24 -28 -32

Sheet Code

Test Sheet Material

Side-Load Force Max. (lbs.)

SKC-6060

5052-H34

Aluminum

130 95 82 63 52 44 38 34 30 27 22 19 17

SKC-6060

Cold-Rolled Steel

185

120

197

153

126

106

92

81

71

66

55

47

42

SK4-6060

300 Series Stainless Steel

400

300

220

180

160

140

120

110

100

100

80

70

50

Type

Installation Pushout Side-Load Force Max. Installation Pushout Side-Load Force Max. Installation Pushout Side-Load Force Max.

(lbs.) (lbs.)

(lbs.)

(lbs.) (lbs.)

(lbs.)

(lbs.) (lbs.)

(lbs.)

SKC-F

1100 120

120

2100 160

185

—

—

—

SK4-F

—

—

—

—

—

—

10210 292

202

.060” 5052-H34 Aluminum

.060” Cold-Rolled Steel

Type

Installation Pushout Side-Load Force Max. Installation Pushout Side-Load Force Max. Installation Pushout Side-Load Force Max.

(kN)

(N) (N) (kN)

(N) (N) (kN)

(N) (N)

SKC-F

4.9 533

533

9.3 711

822

— —

—

SK4-F

—

—

—

—

—

—

45.4 1300

900

1.52 mm 5052-H34 Aluminum

1.52 mm Cold-Rolled Steel

SKC™/SK4™ Standoffs

Installation and pushout

SKC-F™/SK4-F™ Fasteners

Installation, Pushout and Side-load

Test Sheet Material

Test Sheet Material

Test Sheet Material

Side-Load

Installation

Force

Pushout

Side-Load

Installation

Force

Pushout

Performance Data

(1)

SKC™/SK4™ Standoffs

Side-load

.060” 300 Series Stainless Steel

1.52 mm 300 Series Stainless Steel

.060” 300 Series Stainless Steel

1.52 mm 300 Series Stainless Steel

Test Sheet Thick.

.040”

(2)

.060”

Length Codes

Body Size -

-2 -4 -6 -8 -10 -12 -14 -16 -18 -20 -22 -25

Sheet Code

Test Sheet Material

Side-Load Force Max. (N)

SKC-61.5

5052-H34 Aluminum

545

370

296

228

184

156

136

116

104

96

88

76

SKC-61.5

Cold-Rolled Steel

735

490

696

540

440

372

320

280

252

228

208

184

SK4-61.5

300 Series Stainless Steel

1690

1140

860

710

610

540

480

440

400

380

320

250

Test Sheet Thick.

1 mm

(2)

1.52 mm

Test Sheet Material

Uni

fie

d

Me

tric

Uni

fie

d

Me

tric

Keyhole® Standoffs And Fasteners

SK-14

Part No.

Test Sheet Material

.060” Cold-Rolled Steel

.060” 300 Series Stainless Steel

Installation

(lbs.)

Pushout

(lbs.)

Installation

(lbs.)

Pushout

(lbs.)

SKCF-6060

3300

450

—

—

SKSF-6060

3300

450

—

—

SK4F-6060

—

—

9000

560

SKCF™/SK4F™/SKSF™ Standoffs

Installation and pushout

Side-Load

Installation

Force

Pushout

SKCF™/SK4F™/SKSF™ Standoffs

Side-load

Part No.

Test Sheet Material

1.5mm Cold-Rolled Steel

1.5mm 300 Series Stainless Steel

Installation

(kN)

Pushout

(N)

Installation

(kN)

Pushout

(N)

SKCF-61.5

14.7

2000

—

—

SKSF-61.5

14.7

2000

—

—

SK4F-61.5

—

—

40.1

2500

Part No.

Test Sheet Material

Side Load Force Max. (lbs.)

-4

-6

-8

-10

-12

SKCF-6060

.060” Cold-Rolled Steel

260

197

153

126

106

SKSF-6060

.060” Cold-Rolled Steel

260

197

153

126

106

SK4F-6060

.060” 300 Series Stainless Steel

300

220

180

160

140

Part No.

Test Sheet Material

Side Load Force Max. (N)

-4

-6

-8

-10

SKCF-61.5

1.5mm Cold-Rolled Steel

1000

696

540

440

SKSF-61.5

1.5mm Cold-Rolled Steel

1000

696

540

440

SK4F-61.5

1.5mm 300 Series Stainless Steel

1300

860

710

610

SKCF-F™/SK4F-F™/SKSF-F™/TSKCF-F™/

TSK4F-F™/TSKSF-F™ Fasteners

Installation pushout and side-load

Part No.

Test Sheet Material

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

SKCF-F1.5

.040 ”/ 1mm Cold-Rolled Steel

2518

11.2

160

711

185

822

SKSF-F1.5-ZI

.040” / 1mm Cold-Rolled Steel

2518

11.2

160

711

185

822

SK4F-F1.5

.040” / 1mm 300 Series Stainless Steel

7600

33.8

225

1000

202

900

Side-Load

Installation

Force

Pushout

Part No.

Test Sheet Material

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

TSKCF-F1.5

.032 ”/ 0.8mm Cold-Rolled Steel

2203

9.8

112

500

41

180

TSKSF-F1.5-ZI

.032” / 0.8mm Cold-Rolled Steel

2203

9.8

112

500

41

180

TSK4F-F1.5

.032” / 0.8mm 300 Series Stainless Steel

6789

30.2

169

750

56

250

Keyhole® Standoffs And Fasteners

SK-15

Part No.

Test Sheet Material - .040” / 1mm Cold-Rolled Steel HRB 67

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

SKC-R1.5-2.5

3507

15.6

180

800

191

850

SKC-R1.5-3.2

4002

17.8

180

800

180

800

SKC-R1.5-4.0

5755

25.6

202

900

169

750

SKC-R2.0-2.5

3507

15.6

180

800

191

850

SKC-R2.0-3.2

4002

17.8

180

800

180

800

SKC-R2.0-4.0

5755

25.6

202

900

169

750

SKC-R2.5-2.5

3507

15.6

180

800

191

850

SKC-R2.5-3.2

4002

17.8

180

800

180

800

SKC-R2.5-4.0

5755

25.6

202

900

169

750

SKS-R™/SKC-R™/SK4-R™ Fasteners

Installation pushout and side-load

Part No.

Test Sheet Material - .040” / 1mm 300 Series Stainless Steel HRB 88

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

SK4-R1.5-2.5

6115

27.2

270

1200

214

950

SK4-R1.5-3.2

6812

30.3

292

1300

202

900

SK4-R1.5-4.0

7419

33

315

1400

191

850

SK4-R2.0-2.5

6115

27.2

270

1200

214

950

SK4-R2.0-3.2

6812

30.3

292

1300

202

900

SK4-R2.0-4.0

7419

33

315

1400

191

850

SK4-R2.5-2.5

6115

27.2

270

1200

214

950

SK4-R2.5-3.2

6812

30.3

292

1300

202

900

SK4-R2.5-4.0

7419

33

315

1400

191

850

TSKC-R™/TSK4-R™/TSKS-R™ Fasteners

Installation pushout and side-load

Part No.

Test Sheet Material - .032” / 0.8mm Cold-Rolled Steel HRB 67

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

TSKC-R1.5-2.5

2518

11.2

124

550

45

200

TSKC-R2.0-2.5

2518

11.2

124

550

41

180

TSKC-R2.5-2.5

2518

11.2

124

550

34

150

Part No.

Test Sheet Material - .032” / 0.8mm 300 Series Stainless Steel HRB 88

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

TSK4-R1.5-2.5

5710

25.4

169

750

68

300

TSK4-R2.0-2.5

5710

25.4

169

750

63

280

TSK4-R2.5-2.5

5710

25.4

169

750

56

250

Part No.

Test Sheet Material - .032” / 0.8mm Cold-Rolled Steel HRB 67

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

TSKS-R1.5-2.5-ZI

2518

11.2

124

550

45

200

TSKS-R2.0-2.5-ZI

2518

11.2

124

550

41

180

TSKS-R2.5-2.5-ZI

2518

11.2

124

550

34

150

Side-Load

Installation

Force

Pushout

Side-Load

Installation

Force

Pushout

Part No.

Test Sheet Material - .040” / 1mm Cold-Rolled Steel HRB 67

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

SKS-R1.5-2.5-ZI

3200

14.2

160

711

191

850

SKS-R1.5-3.2-ZI

4000

17.8

180

800

213

950

SKS-R1.5-4.0-ZI

5000

22.3

180

800

258

1150

SKS-R2.0-2.5-ZI

3200

14.2

160

711

169

750

SKS-R2.0-3.2-ZI

4000

17.8

180

800

191

850

SKS-R2.0-4.0-ZI

5000

22.3

180

800

225

1000

SKS-R2.5-2.5-ZI

3200

14.2

160

711

124

550

SKS-R2.5-3.2-ZI

4000

17.8

180

800

137

610

SKS-R2.5-4.0-ZI

5000

22.3

180

800

182

810

Keyhole® Standoffs And Fasteners

SK-16

Performance Data

HSKC-R™/HSK4-R™/HSKS-R™ Fasteners

Installation pushout and side-load

Part No.

Test Sheet Material - .047” / 1.2mm Cold-Rolled Steel HRB 67

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

HSKC-R1.5-2.5

4002

17.8

225

1000

202

900

HSKC-R1.5-3.2

5013

22.3

247

1100

191

850

HSKC-R1.5-4.0

5508

24.5

270

1200

180

800

HSKC-R2.0-2.5

4002

17.8

225

1000

202

900

HSKC-R2.0-3.2

5013

22.3

247

1100

191

850

HSKC-R2.0-4.0

5508

24.5

2701

1200

180

800

HSKC-R2.5-2.5

4002

17.8

225

1000

202

900

HSKC-R2.5-3.2

5013

22.3

247

1100

191

850

HSKC-R2.5-4.0

5508

24.5

270

1200

180

800

Part No.

Test Sheet Material - .047” / 1.2mm 300 Series Stainless Steel HRB 88

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

HSK4-R1.5-2.5

7194

32

315

1400

225

1000

HSK4-R1.5-3.2

7868

35

337

1500

214

950

HSK4-R1.5-4.0

9442

42

337

1500

202

900

HSK4-R2.0-2.5

7194

32

315

1400

225

1000

HSK4-R2.0-3.2

7868

35

337

1500

214

950

HSK4-R2.0-4.0

9442

42

337

1500

202

900

HSK4-R2.5-2.5

7194

32

315

1400

225

1000

HSK4-R2.5-3.2

7868

35

337

1500

214

950

HSK4-R2.5-4.0

9442

42

337

1500

202

900

Part No.

Test Sheet Material - .047” / 1.2mm Cold-Rolled Steel HRB 67

Installation

Pushout

Side-Load Force Max.

(lbs.)

(kN)

(lbs.)

(N)

(lbs.)

(N)

HSKS-R1.5-2.5-ZI

4002

17.8

225

1000

202

900

HSKS-R1.5-3.2-ZI

5013

22.3

247

1100

191

850

HSKS-R1.5-4.0-ZI

5508

24.5

270

1200

180

800

HSKS-R2.0-2.5-ZI

4002

17.8

225

1000

202

900

HSKS-R2.0-3.2-ZI

5013

22.3

247

1100

191

850

HSKS-R2.0-4.0-ZI

5508

24.5

270

1200

180

800

HSKS-R2.5-2.5-ZI

4002

17.8

225

1000

202

900

HSKS-R2.5-3.2-ZI

5013

22.3

247

1100

191

850

HSKS-R2.5-4.0-ZI

5508

24.5

270

1200

180

800

3/02/23

All PEM® products meet our stringent quality standards. If you require additional industry or other specific

, special procedures and/or part numbers

are required. Please contact your local sales office or representative for further information.

Regulatory

is available in Technical Support section of our website. Specifications subject to change without notice. See our website for the most

current version of this bulletin.

North America:

Danboro, Pennsylvania USA

|

E-mail:

|

Tel: +1-215-766-8853

|

800-237-4736 (USA)

Europe:

Galway, Ireland

|

E-mail:

|

Tel: +353-91-751714

Asia/Pacific:

Singapore

|

E-mail:

|

Tel: +65-6-745-0660

Shanghai, China:

E-mail:

|

Tel: +86-21-5868-3688

Visit our PEMNET™ Resource Center at

•

Technical support e-mail: