Providing Individual Services Through to Full Turnkey Soluti ons.

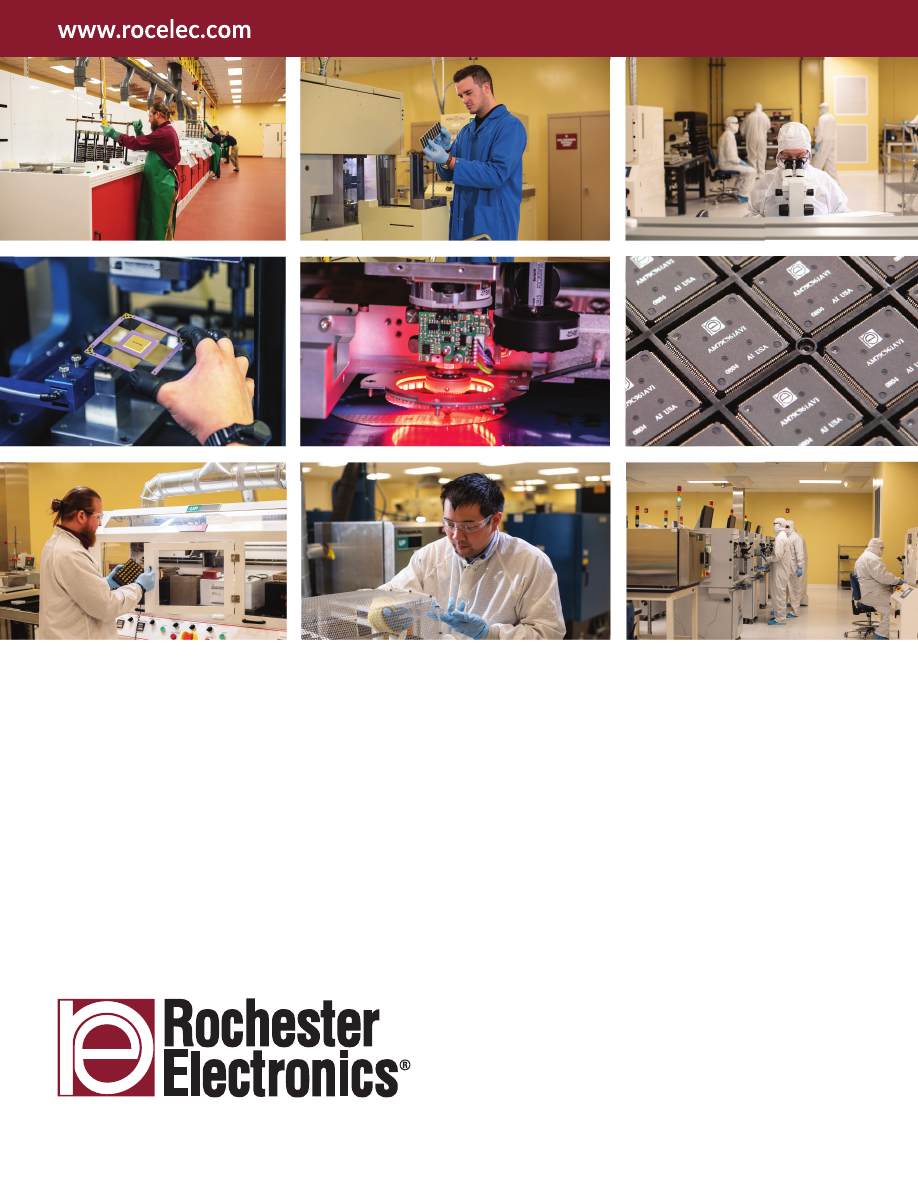

Manufacturing Services

The Semiconductor Lifecycle Soluti on

™

Providing Individual Services Through to Full Turnkey Soluti ons.

Manufacturing Services

The Semiconductor Lifecycle Soluti on

™