Ultra High Precision Bulk Metal

®

Foil Technology

4 Resistor Surface Mount Hermetic Network with

0.5 ppm/°C TCR Tracking and 0.005 % Tolerance Match

SMNH

Vishay Foil Resistors

Document Number: 63092

For any questions, contact:

foil@vishaypg.com

www.foilresistors.com

Revision: 25-Mar-10

1

INTRODUCTION

Vishay model SMNH networks incorporate all the

performance features of Vishay Bulk Metal

®

Foil technology

in a product ready for surface mounting. The 8 pin gull wing

side brazed DIP is the smallest ceramic package. Ceramic

has the advantage of electrical isolation on the underside

and high heat dissipation capability.

Resistors in network form, around the operational amplifier

for example, are called upon to track at changing ambient

temperature, to hold ratio under power and to force the ratio

changes over a period of time to be very low.

The hermeticity, the location of the chips within the package

and the “heat-sink effect” of the ceramic package itself help

preserve uniform conditions inside it. The Bulk Metal Foil

Vishay technology advantage in such a construction assures

remarkable performance due to the following factors:

- fundamentally low TCR

- very small drift with load over time

- common behavior: all drifts move in the same direction

with temperature, load and time

- TCR and tolerance match

- excellent tracking

The major highlights are emphasized by an excellent load life

and shelf life ratio stability.

Vishay hermetic resistor networks are based on fabrication

from a standing inventory of packages and resistor chips.

This permits quick delivery of prototypes since there are no

masks to design or trial processings to be made. Further, it

allows any combination of values, tolerances and circuits.

There are normally no engineering or setup charges, and no

minimum quantities are required. Delivery can be in two

weeks. (See network express prototype service.)

The sequence of fabrication includes selection of chips, die

attachment, wirebonding, value trimming, and hermetic

sealing. The finished product provides the stability

associated with Foil resistors in a hermetically sealed

package.

Hermetic sealing of Vishay’s networks enhances their

already inherently stable environmental performance. The

result is improved load life stability and better performance

during high temperature and moisture exposure.

FEATURES

•

Temperature coefficient of resistance (TCR):

absolute: ± 2 ppm/°C typical

(- 55 °C to + 125 °C, + 25 °C ref.)

tracking: ± 0.5 ppm/°C typical

•

Resistance range: 5

Ω

to 33 k

Ω

•

Vishay Foil resistors are not restricted to standard values;

specific “as required” values can be supplied at no extra

cost or delivery (e.g. 1K2345 vs. 1K)

•

Power rating: at 70 °C

Entire package: 0.4 W

Each resistor: 0.1 W

•

Resistance tolerance match: ± 0.005 %

•

Load life stability per resistor: 0.005 % (0.1 W at 70 °C,

1000 h)

•

Load life stability ratio: 0.005 % (0.1 W at 70 °C)

•

Shelf life stability per resistor: 0.0002 % (2 ppm)

•

Shelf life stability ratio: 0.0001 % (1 ppm)

•

Electrostatic discharge (ESD) up to 25 000 V

•

Short time overload

≤

0.002 % (20 ppm)

•

Non-inductive, non-capacitive design

•

Rise time: 1 ns effectively no ringing

•

Thermal stabilization time < 1 s (nominal value achieved

within 10 ppm of steady state value)

•

Current noise: 0.010 µV

RMS

/V of applied voltage (< - 40 dB)

•

Voltage coefficient: < 0.1 ppm/V

•

Non inductive: < 0.08 µH

•

Non hot spot design

•

Terminal finish: gold plated (lead (Pb)-free)

•

For better performances please contact us

•

Available with Z-Foil technology for improved TCR to

0.2 ppm/°C

•

Compliant to RoHS directive 2002/95/EC

* Pb containing terminations are not RoHS compliant, exemptions may apply

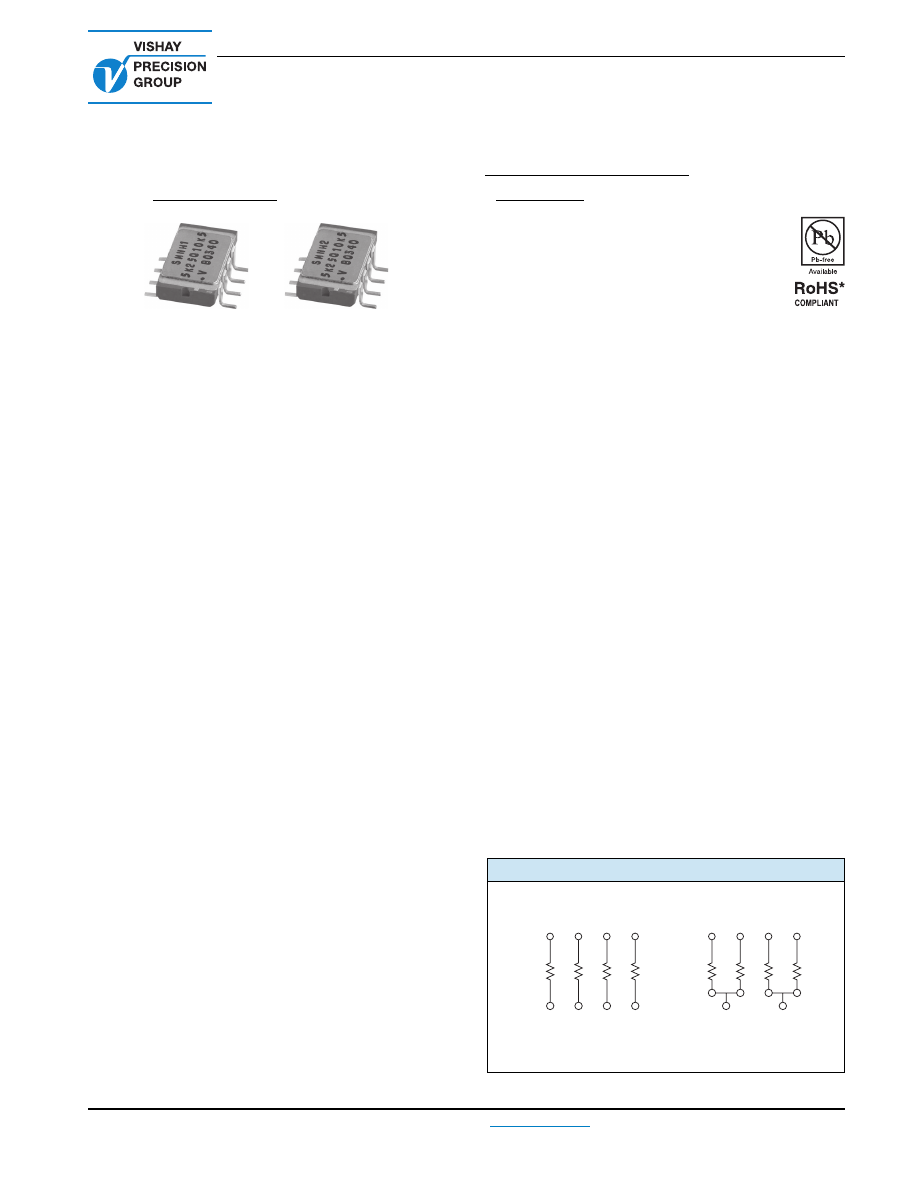

FIGURE 1 - SCHEMATICS

Note:

R

1

and R

2

may

b

e same

v

al

u

e, if desired

SMNH1

R

1

1

8

R

2

3

6

R

2

2

7

R

1

4

5

SMNH2

R

1

8

R

2

3

6

R

2

2

7

R

1

5

smnh-html.html

SMNH

Vishay Foil Resistors

www.foilresistors.com

For any questions, contact:

foil@vishaypg.com

Document Number: 63092

2

Revision: 25-Mar-10

Note

(1)

Each resistor element 0.1 W at + 70 °C (0.4 W per package)

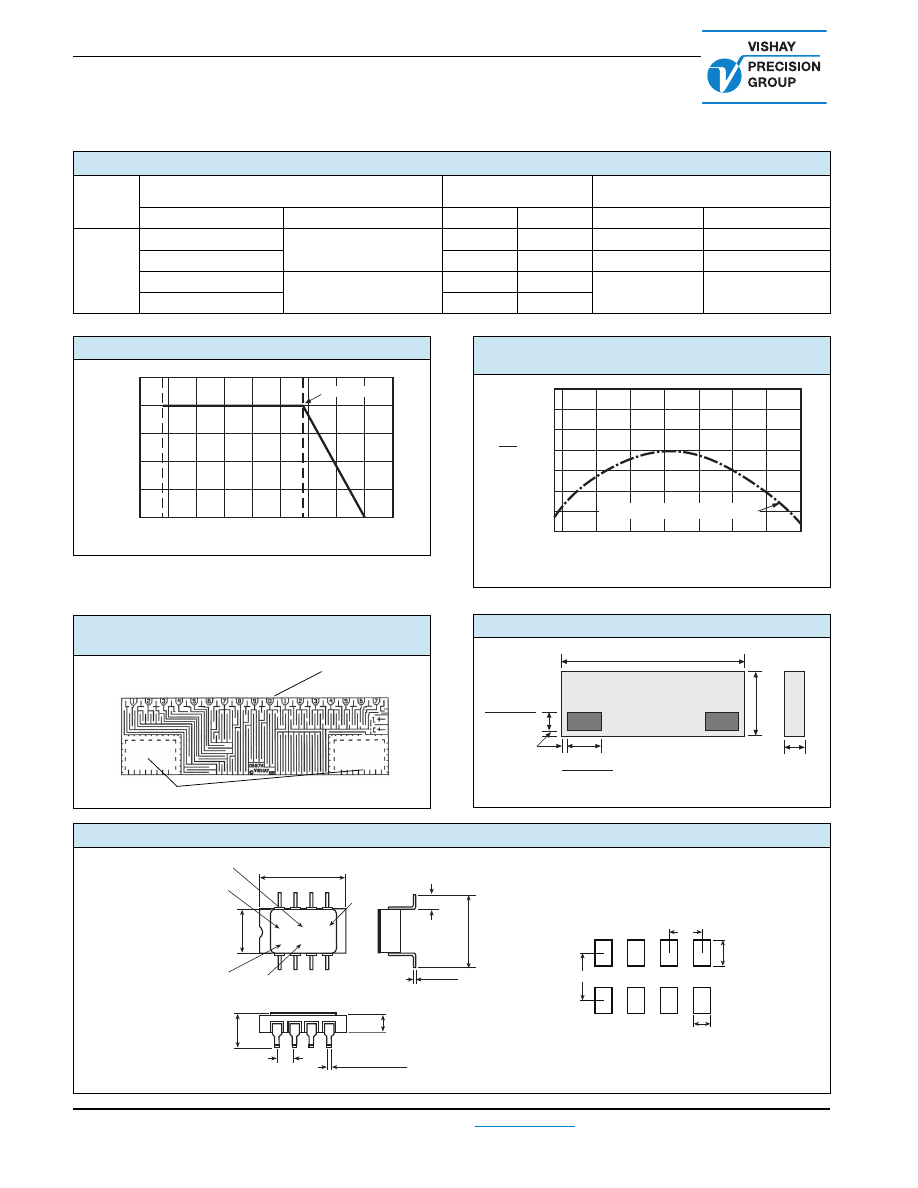

TABLE 1 - MODEL SMNH SPECIFICATIONS

MODEL

ABSOLUTE TCR

(- 55 °C to + 125 °C, + 25 °C ref.)

TOLERANCE

TCR TRACKING (max.)

RESISTANCE VALUES

TYPICAL + MAX. SPREAD ABSOLUTE

MATCH

SAME VALUES

DIFFERENT VALUES

SMNH

500

Ω

to 33 k

Ω

± 2 ± 2.5 ppm/°C

±

0.005 %

0.005 %

0.5 ppm/°C

1 ppm/°C

100

Ω

to 500

Ω

± 0.01 %

0.005 %

2 ppm/°C

3 ppm/°C

10

Ω

to 100

Ω

± 2 ± 3.5 ppm/°C

± 0.02 %

0.01 %

4 ppm/°C

5 ppm/°C

5

Ω

to 10

Ω

± 0.05 %

0.02 %

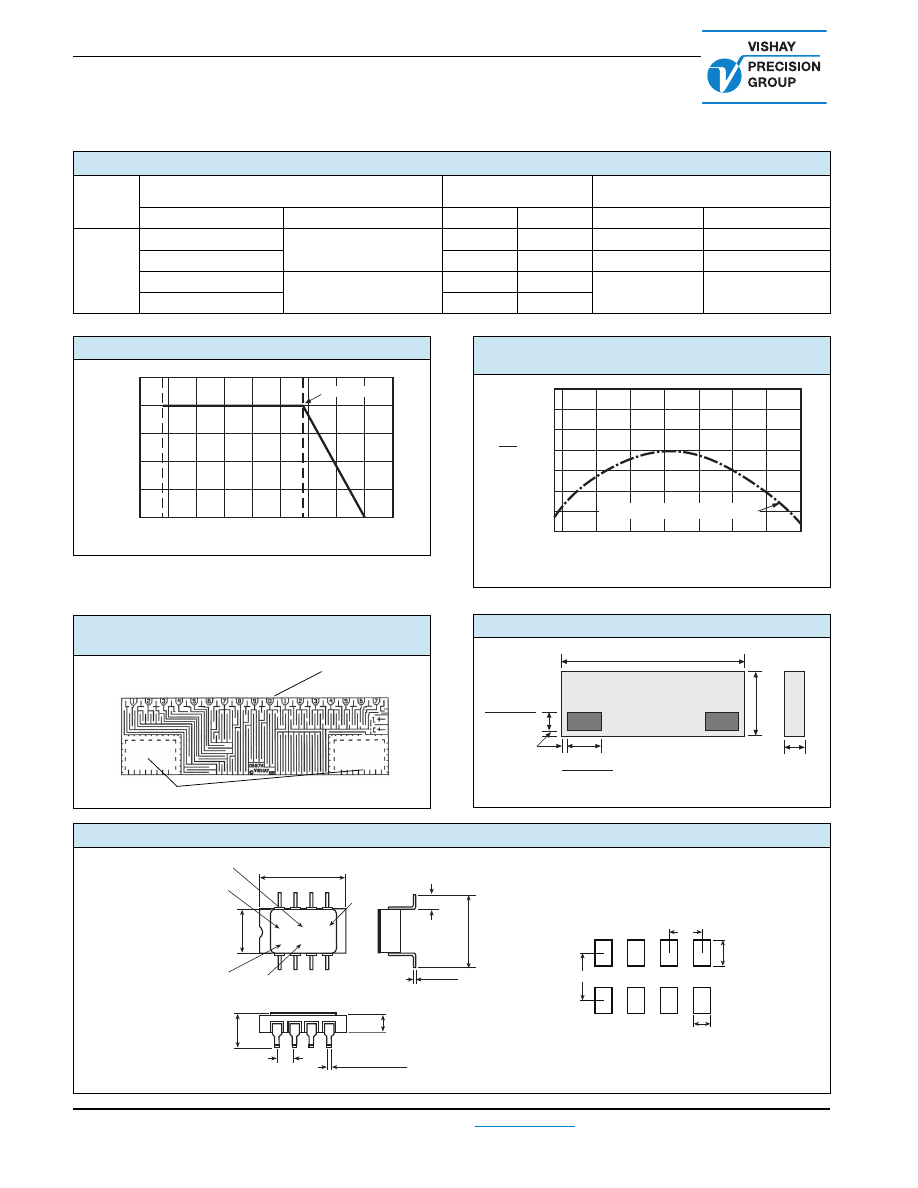

FIGURE 2 - POWER DERATING CURVE

(1)

FIGURE 4 - FORMAT OF CHIP RESISTOR

USED IN HERMETIC NETWORKS

125

100

75

50

25

0

- 75

Ambient Temperature (°C)

Percent of Rated Power

- 55 °C

+ 70 °C

Rated Power

150

125

100

75

50

25

0

- 25

- 50

Trim Points

Gold Plated Pads

V15X5

FIGURE 3 - TYPICAL RESISTANCE/

TEMPERATURE CURVE

FIGURE 5 - DIMENSIONS

in inches (millimeters)

(For more details, see ta

b

le 1)

- 55

± 2 ppm/°C (+ 25 °C Reference)

+ 150

+ 100

+ 50

0

- 50

- 100

- 150

- 200

Δ

R

R

(ppm)

- 50

- 25

0

+ 25

+ 50

+ 100 + 125

+ 75

Ambient Temperature (°C)

V15X5

0.150 ± 0.005

(3.81 ± 0.127)

0.005 ± 0.004

(1.27 ± 0.102)

0.050 ± 0.005

(1.27 ± 0.127)

+ 0.001

- 0.004

0.029

+ 0.025

- 0.102

(0.737 )

+ 0.001

- 0.004

0.019

+ 0.025

- 0.102

(0.483 )

0.020 ± 0.005

(0.508 ± 0.127)

FIGURE 6 - DIMENSIONS AND IMPRINTING EXAMPLE

in inches (millimeters)

0.38

0.024

0.138

0.1

Proposed Land Pattern

SMNH1

10K5Q5K25

.V B0320

0.520 ± 0.020

(13.21 ± 0.51)

0.090 Max.

(2.29)

0.4

70 Max.

(11.94)

0.008 ± 0.016

(0.20 ± 0.41)

Date Code

Value R

2

Pin 1 Identification

Value R

1

Ratio Tolerance Code

0.295 ± 0.010

(7.49 ± 0.25)

0.100 Max.

(2.54)

0.180 Max.

(4.57)

0.100 Typ.

(2.54)

0.015 to 0.022

(0.38 to 0.56)

smnh-html.html

SMNH

Vishay Foil Resistors

Document Number: 63092

For any questions, contact:

foil@vishaypg.com

www.foilresistors.com

Revision: 25-Mar-10

3

Notes

•

Δ

R’s are not cumulative. For purposes of determining reliability calculations, consider the characteristics shown as figures of merit and allow

no more than ± 0.05

Δ

R lifetime. Allow proportionately less if the severity of anticipated environmental stresses are small compared to the

tests as defined in MIL-PRF-83401.

• Post manufacturing operation (PMO) has the effect of minimizing

Δ

R’s. Consult Vishay applications engineering for details.

•

Δ

Ratio refers to the change in ratio between resistors within the network package from before, to after, the specified test.

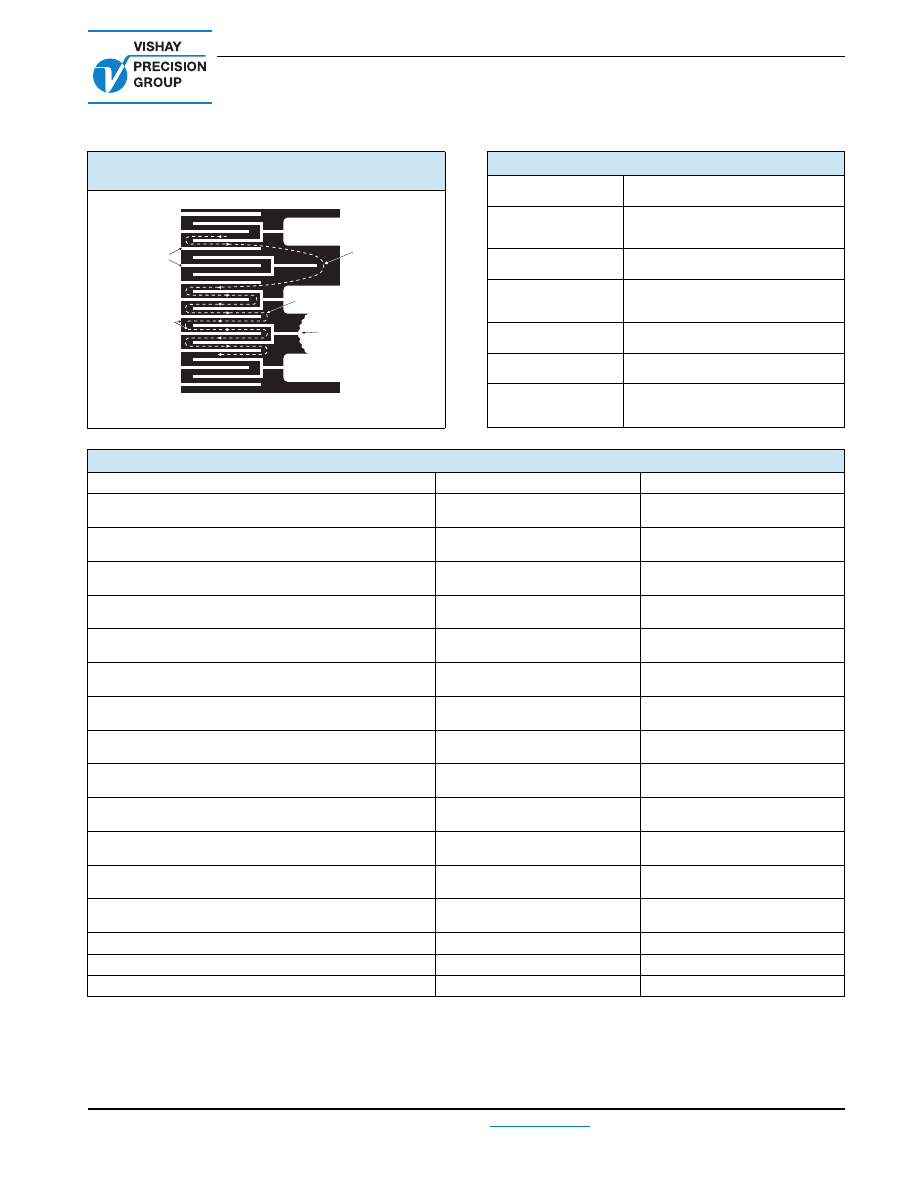

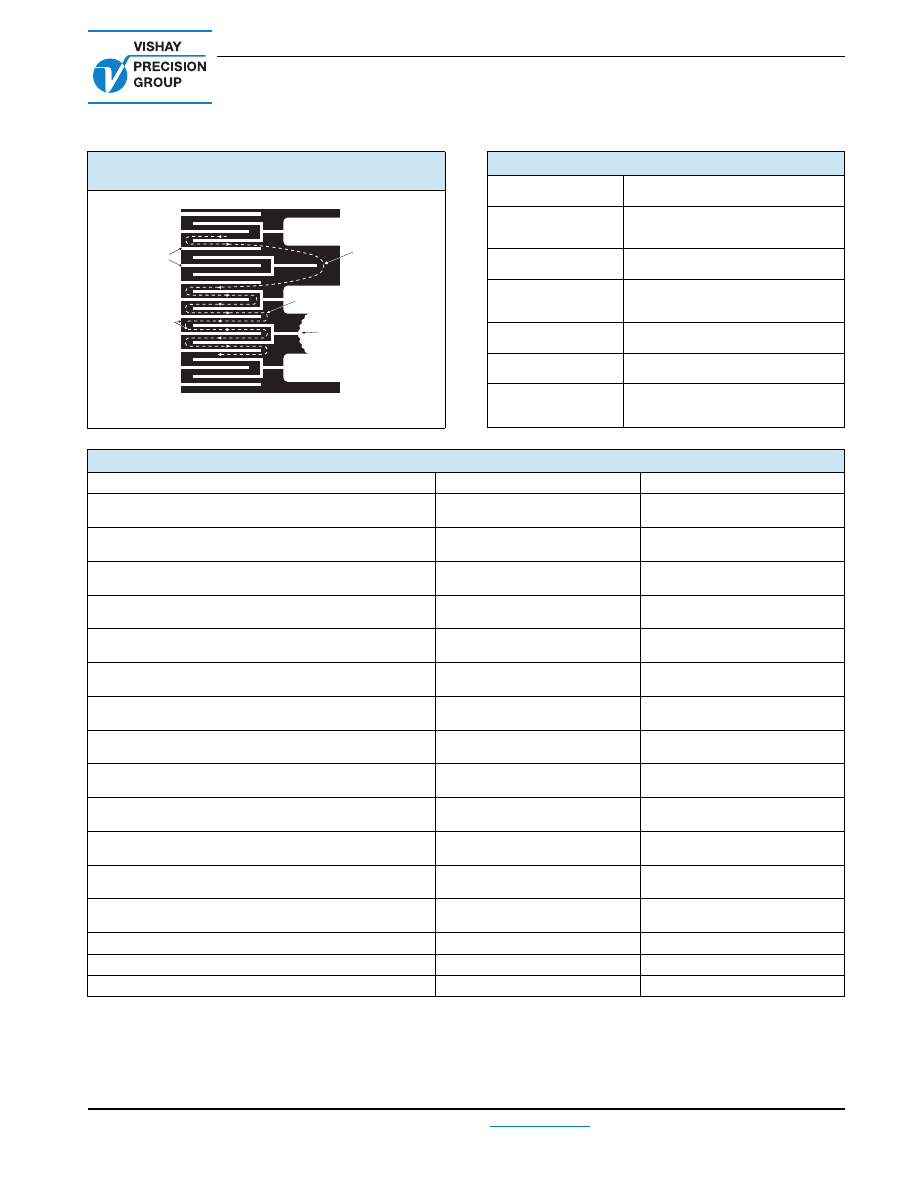

FIGURE 7 - TRIMMING TO VALUES

(Conceptual Illustration)

Note:

Foil sho

w

n in

b

lack, etched spaces in

w

hite

Mutual

Inductance

Reduction due

to Opposin

g

Current in

Adjacent Lines

Current Path

Before Trimmin

g

Interloop

Capacitance

Reduction

in Series

Trimmin

g

Process

Removes this Material

from Shortin

g

Strip Area

Chan

g

in

g

Current Path

and Increasin

g

Resistance

Current Path

After Trimmin

g

TABLE 2 - MECHANICAL SPECIFICATIONS

Resistive Element

High precision Bulk Metal Foil chips

Body

Ceramic package:

94 % alumina (Al

2

O

3

)

Lid

Gold plated kovar

Terminals

Alloy 42 (iron nickel) with 100 µ" gold

plating (MIL-STD-1276, type G-21-A)

Internal Connections

Gold wire bonding

Solderability

Per MIL-PRF-83401

Marking Resistance

to Solvents

Permanency testing per

MIL-PRF-83401

TABLE 3 - PERFORMANCE SPECIFICATIONS (PER MIL-PRF 83401 TEST METHODS)

SPECIFICATIONS

TYPICAL LIMITS

MAXIMUM LIMITS

Thermal Shock

5 x (- 65 °C to + 125 °C) and

Power Conditioning

1.5 rated power at 25 °C, 100 h

Δ

R = 0.003 % (30 ppm)

Δ

Ratio = 0.001 % (10 ppm)

0.015 % (150 ppm)

0.015 % (150 ppm)

Low Temperature Operation

Δ

R = 0.005 % (50 ppm)

Δ

Ratio = 0.005 % (50 ppm)

0.01 % (100 ppm)

0.01 % (100 ppm)

Short Time Overload

6.25 rated power; 5 s

Δ

R = 0.002 % (20 ppm)

Δ

Ratio = 0.002 % (20 ppm)

0.01 % (100 ppm)

0.01 % (100 ppm)

Terminal Strength

Δ

R = 0.001 % (10 ppm)

Δ

Ratio = 0.001 % (10 ppm)

0.01 % (100 ppm)

0.01 % (100 ppm)

Resistance to Soldering Heat

260 °C, 10 s

Δ

R = 0.002 % (20 ppm)

Δ

Ratio = 0.001 % (10 ppm)

0.01 % (100 ppm)

0.01 % (100 ppm)

Moisture Resistance

Δ

R = 0.003 % (30 ppm)

Δ

Ratio = 0.003 % (30 ppm)

0.01 % (100 ppm)

0.01 % (100 ppm)

Shock

100 G, sawtooth

Δ

R = 0.001 % (10 ppm)

Δ

Ratio = 0.001 % (10 ppm)

0.01 % (100 ppm)

0.01 % (100 ppm)

Vibration, High Frequency

Δ

R = 0.001 % (10 ppm)

Δ

Ratio = 0.001 % (10 ppm)

0.01 % (100 ppm)

0.01 % (100 ppm)

Load Life

1000 h at + 70 °C; 0.1 W per resistor

Δ

R = 0.005 % (50 ppm)

Δ

Ratio = 0.005 % (50 ppm)

0.025 % (250 ppm)

0.01 % (100 ppm)

Load Life

1000 h at + 25 °C; 0.1 W per resistor

Δ

R = 0.002 % (20 ppm)

Δ

Ratio = 0.001 % (10 ppm)

0.01 % (100 ppm)

0.01 % (100 ppm)

High Temperature Exposure

100 h at + 125 °C

Δ

R = 0.005 % (50 ppm)

Δ

Ratio = 0.005 % (50 ppm)

0.01 % (100 ppm)

0.01 % (100 ppm)

Low Temperature Storage

24 h at - 65 °C

Δ

R = 0.002 % (20 ppm)

Δ

Ratio = 0.002 % (20 ppm)

0.01 % (100 ppm)

0.01 % (100 ppm)

Shelf Life Stability

(6 years)

Δ

R = 0.0002 % (2 ppm)

Δ

Ratio = 0.0001 % (1 ppm)

Insulation Resistance

100 V (DC)

> 10

4

M

Ω

DWV Atm. Pressure

200 V

Weight

0.95 g

smnh-html.html

SMNH

Vishay Foil Resistors

www.foilresistors.com

For any questions, contact:

foil@vishaypg.com

Document Number: 63092

4

Revision: 25-Mar-10

QUALITY INSPECTION AND TESTING

Network performance is established during the engineering design phase and is dependent on the materials of construction. Most

characteristics are inherent in the Bulk Metal

Foil technology and provide the high order of performance displayed throughout this

catalog. Stability and drift levels can be improved beyond those shown in the catalog. Applications engineering is available to

recommend screen testing beyond the standard outgoing inspection when catalog limits are insufficient. The chart below shows

the standard outgoing testing and the additional user specified screen tests that may be appropriate for a particular application.

TESTING OF COMMERCIAL PRODUCT - VISHAY NETWORKS

Our standard outgoing testing consists of:

1. DC resistance test 100 %

1. 1 Conformity to value

1. 2 Conformity to tolerance

2. Visual and Mechanical 100 %

2. 1 Conformity to physical size

2. 2 Cleanliness of leads

2. 3 Conformity of printing

3. Ship check (sample plan)

3. 1 Conformity of packaging

3. 2 Conformity of count

ADDITIONAL TESTING TO MIL SPEC

Group A testing to MIL-PRF-83401 imposes the following:

1. Thermal shock 100 %

5X from - 65 °C to + 125 °C

2. Power conditioning 100 %

2. 1 100 h at 25 °C, 1.5 x rated power

2. 2

Δ

R and

Δ

Ratio calculation

3. Visual and mechanical after the above tests (sample plan)

3. 1 Conformity to physical size

3. 2 Workmanship

3. 3 Damage due to the above tests

4. 10 % PDA or one piece whichever is greater

5. Solderability (sample plan)

Group B sample testing to MIL-PRF-83401 imposes the following:

1. Temperature coefficient of resistance (sample plan)

2. Resistance to solvents (sample plan)

smnh-html.html

SMNH

Vishay Foil Resistors

Document Number: 63092

For any questions, contact:

foil@vishaypg.com

www.foilresistors.com

Revision: 25-Mar-10

5

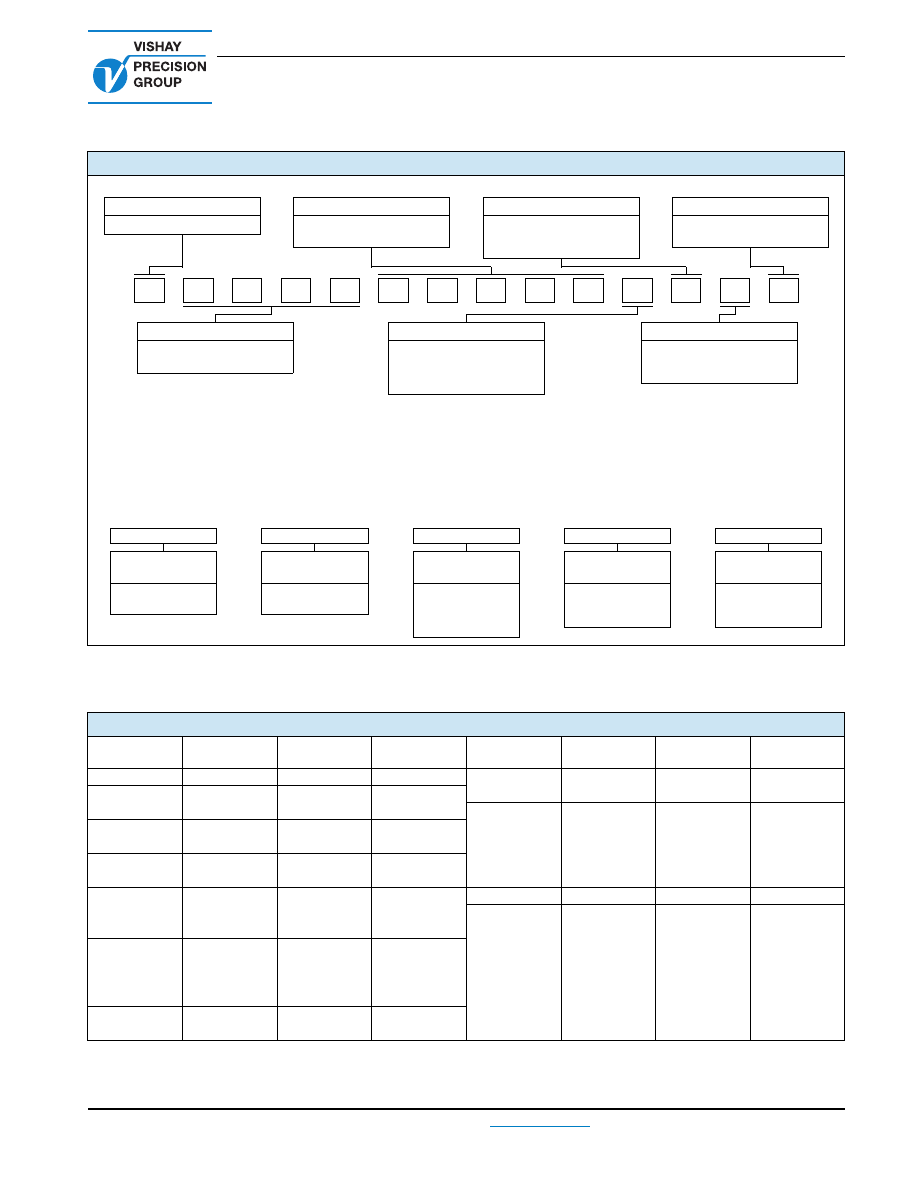

Note

(1)

Application engineering release: for non-standard requests, please contact application engineering

Note

• Other values available upon request

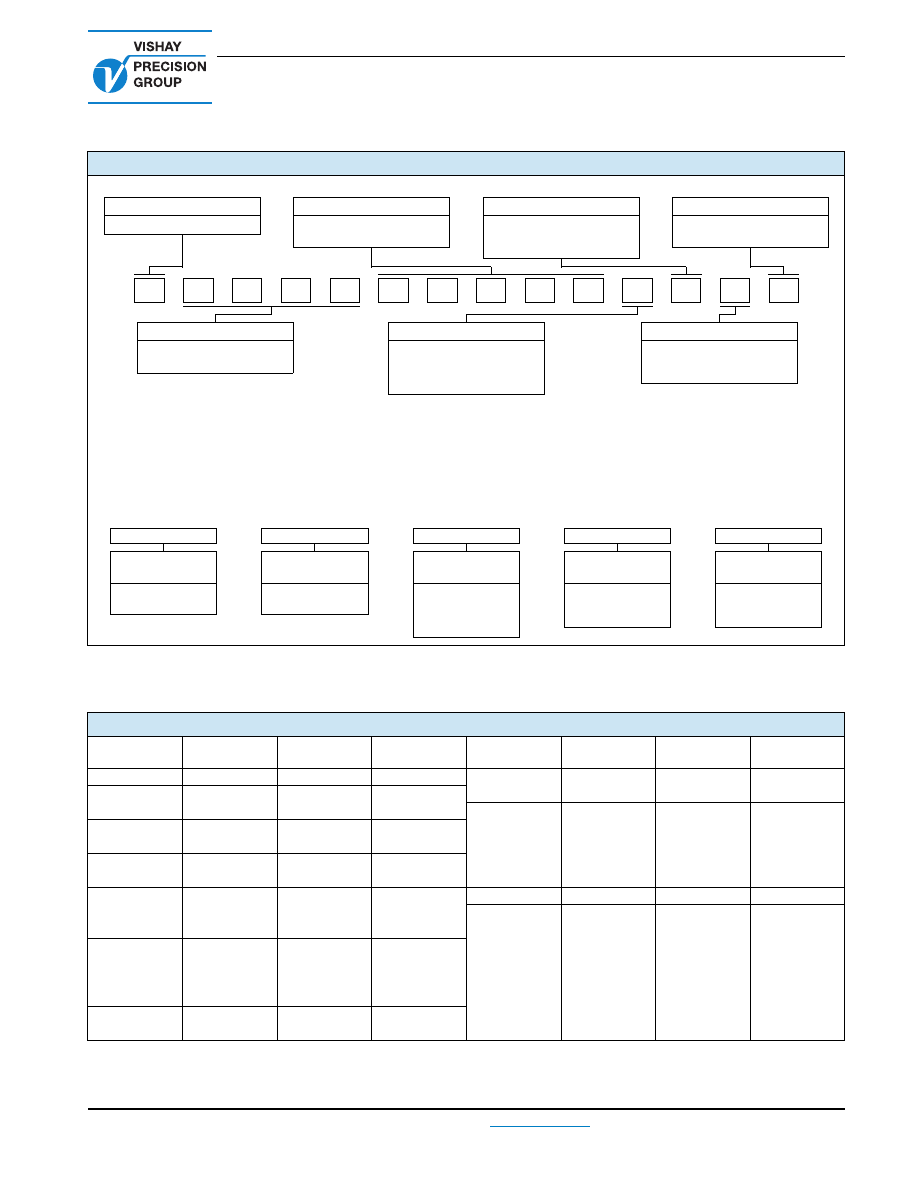

TABLE 4 - GLOBAL PART NUMBER INFORMATION

(1)

NEW GLOBAL PART NUMBER: Y1521V0207TV0L (preferred part number format)

DENOTES PRECISION

VCODE

TOLERANCE MATCH

PACKAGING

Y

RESISTANCE

VALUE CODE

V

= 0.005 %

T

= 0.01 %

Q

= 0.02 %

L

= bulk pack

U

= ESD tubes

PRODUCT CODE

ABSOLUTE TOLERANCE

CHARACTERISTICS

SMNH1

= 1521

SMNH2

= 1522

V

= ± 0.005 %

T

= ± 0.01 %

Q

= ± 0.02 %

A

= ± 0.05 %

0

= gold plated termination

(lead (Pb)-free)

1 to 99

8

= custom

FOR EXAMPLE: ABOVE GLOBAL ORDER Y1521 V0207 T V 0 L:

TYPE: SMNH1

VALUES: 10K/5K (see VCODE V0207 in table 5 below)

ABSOLUTE TOLERANCE: ± 0.01 %

TOLERANCE MATCH: 0.005 %

TERMINATION: gold plated (lead (Pb)-free)

PACKAGING: bulk pack

HISTORICAL PART NUMBER: SMNH1 10K/5K T V B (will continue to be used)

SMNH1

10K/5K

T

V

B

MODEL

RESISTANCE

VALUE

TOLERANCE

TOLERANCE

MATCH

PACKAGING

SMNH1

SMNH2

R

1

= 10 k

Ω

R

2

= 5 k

Ω

V

= ± 0.005 %

T

= ± 0.01 %

Q

= ± 0.02 %

A

= ± 0.05 %

V

= 0.005 %

T

= 0.01 %

Q

= 0.02 %

B

= bulk pack

(ESD plastic box)

U

= ESD tubes

TABLE 5 - RESISTANCE VALUE CODE LIST FOR POPULAR RATIOS

VCODES

R

1

/R

2

RATIO

R

1

R

2

VCODES

R

1

/R

2

RATIO

R

1

R

2

V0201

100

10K

100R

V0189

2.5

1K

400R

V0202

50

10K

200R

V0185

500R

200R

V0197

5K

100R

V0207

2

10K

5K

V0203

25

10K

400R

V0175

2K

1K

V0198

5K

200R

V0190

1K

500R

V0204

20

10K

500R

V0182

400R

200R

V0193

2K

100R

V0179

200R

100R

V0205

10

10K

1K

V0186

1.25

500R

400R

V0194

2K

200R

V0178

V0180

V0183

V0023

V0191

V0176

V0019

V0008

1

100R

200R

400R

500R

1K

2K

5K

10K

100R

200R

400R

500R

1K

2K

5K

10K

V0187

1K

100R

V0200

5

5K

1K

V0195

2K

400R

V0188

1K

200R

V0184

500R

100R

V0196

4

2K

500R

V0181

400R

100R

5

2

1

V

2

0

7

0

Y

1

V

0

T

L

smnh-html.html

Vishay Precision Group

Document No.: 63999

Revision: 27-Apr-2011

www.vishaypg.com

1

Legal Disclaimer Notice

Disclaimer

Legal Disclaimer Notice

Disclaimer

Document No.: 63999

Revision: 27-Apr-2011

ALL PRODUCTS, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Vishay Precision Group, Inc., its affiliates, agents, and employees, and all persons acting on its or their

behalf (collectively, “Vishay Precision Group”), disclaim any and all liability for any errors, inaccuracies or

incompleteness contained herein or in any other disclosure relating to any product.

The product specifications do not expand or otherwise modify Vishay Precision Group’s terms and

conditions of purchase, including but not limited to, the warranty expressed therein.

Vishay Precision Group makes no warranty, representation or guarantee other than as set forth in the terms

and conditions of purchase.

To the maximum extent permitted by applicable law, Vishay Precision

Group disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and

all liability, including without limitation special, consequential or incidental damages, and (iii) any and

all implied warranties, including warranties of fitness for particular purpose, non-infringement and

merchantability.

Information provided in datasheets and/or specifications may vary from actual results in different

applications and performance may vary over time. Statements regarding the suitability of products for

certain types of applications are based on Vishay Precision Group’s knowledge of typical requirements that

are often placed on Vishay Precision Group products. It is the customer’s responsibility to validate that a

particular product with the properties described in the product specification is suitable for use in a particular

application.

No license, express, implied, or otherwise, to any intellectual property rights is granted by this document, or

by any conduct of Vishay Precision Group.

The products shown herein are not designed for use in life-saving or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay Precision Group products not expressly

indicated for use in such applications do so entirely at their own risk and agree to fully indemnify Vishay

Precision Group for any damages arising or resulting from such use or sale. Please contact authorized

Vishay Precision Group personnel to obtain written terms and conditions regarding products designed for

such applications.

Product names and markings noted herein may be trademarks of their respective owners.