1

J. CLASSES OF DIELECTRICS

Dielectric formulations are identified and classified in the industry by the capacitance temperature

coefficient of materials. Two basic groups (Class I and Class II) are used in the manufacture of

ceramic chip capacitors. A third (Class III) identifies the reduced barium titanate barrier-layer

formulations utilized in the production of disc capacitors.

The temperature coefficients are determined by measurement of the capacitance change at various

temperatures from reference room temperature (25°C), using an environmental chamber. The tem-

perature coefficient (T.C.) is expressed as the percent capacitance change (%

∆

C) or parts per mil-

lion per degree C (ppm/°C) change from reference. The T.C. characteristic is usually illustrated

graphically over the standard EIA and MIL temperature ranges (-55

°

C to 85

°

C, and -55

°

C to 125

°

C

respectively). The method of calculation of the temperature coefficient is described in Section K-1.

C

LASS

I D

IELECTRICS

This group identifies the linear dielectrics described in Section 1. These materials display the most

stable characteristics, as they are non-ferroelectric (paraelectric) formulations, based mostly on TiO

2

,

with dielectric constants under 150. The “extended” temperature compensating ceramics are a

subgroup of formulations which utilize small additions of other (ferroelectric) oxides, such as CaTiO

3

or SrTiO

3

and which display near-linear and predictable temperature characteristics with dielectric

constants ranging up to 500. Both categories are used in circuitry requiring stability of the capaci-

tor, i.e. negligible or no aging of the dielectric constant, low loss (DF<.001, or <.002 for the ex-

tended T.C. bodies), negligible or no change in capacitance or dielectric loss with voltage or fre-

quency, and predictable linear behavior with temperature within prescribed tolerances.

A letter-number-letter code which defines the temperature coefficients of Class I dielectrics has been

developed and is defined in the Electronic Industries Association (EIA) Standard 198, as shown in

Table J-1.

The most common Class I dielectric for chip capacitors is the COG designation, i.e. 0 ppm/

°

C ±30

ppm/

°

C temperature coefficient, which is the NPO (negative-positive-zero) MIL specification, for

flat temperature coefficient.

NOVACAP

TECHNICAL BROCHURE

2

Some examples from Table J-1:

R2G

Negative

220 ppm/

°

C

±30 ppm/

°

C

(N220)

S2H

Negative

330 ppm/

°

C

±60 ppm/

°

C

(N330)

U2H Negative

750 ppm/

°

C

±60 ppm/

°

C (N750)

M7G Positive

100 ppm/

°

C

±30 ppm/

°

C

(P100)

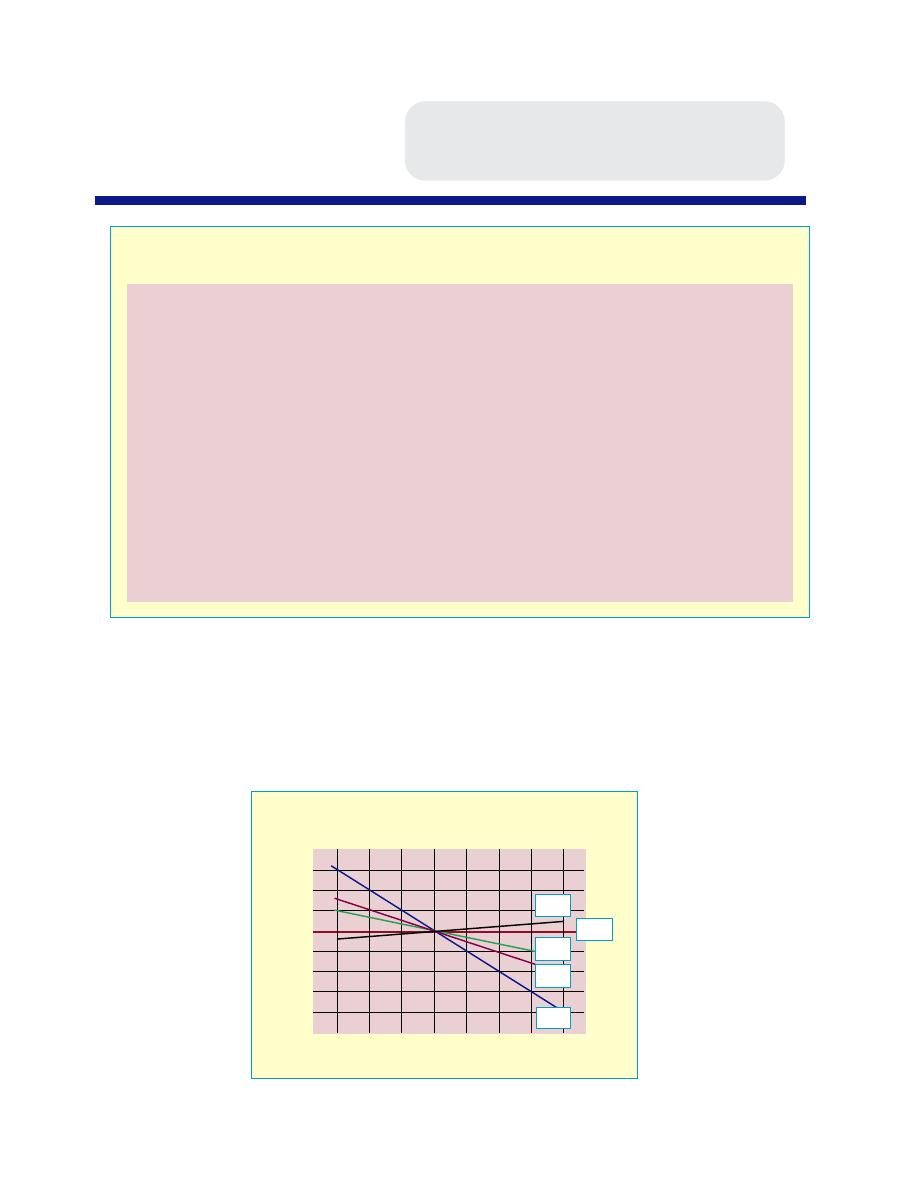

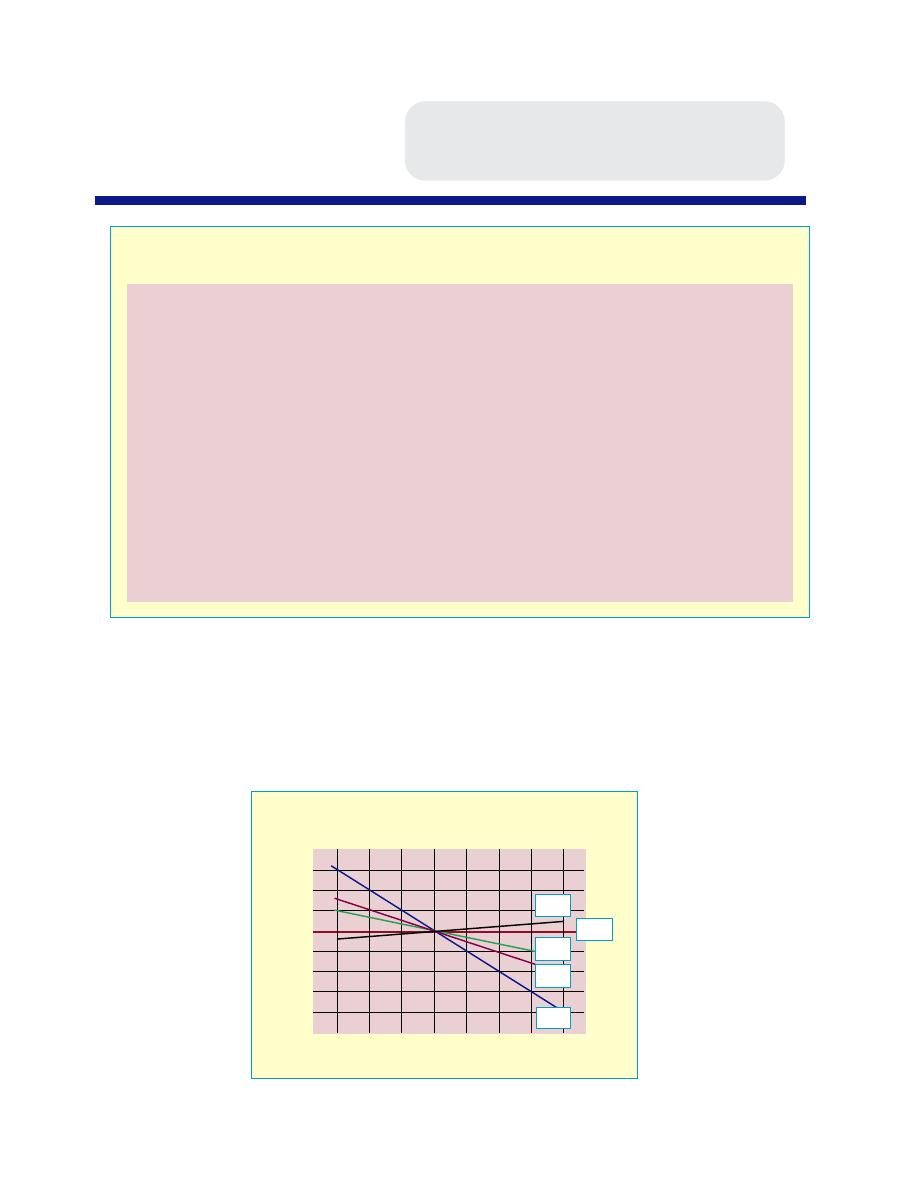

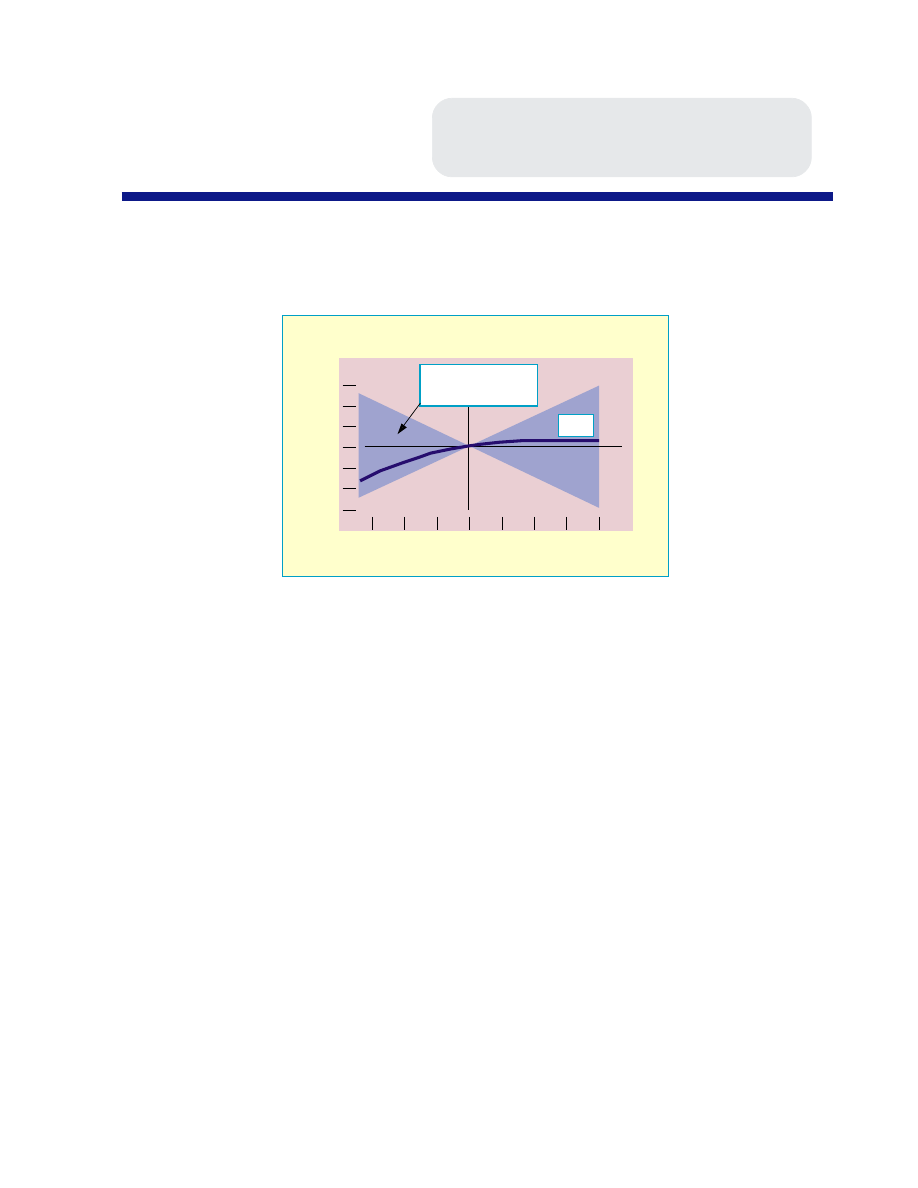

Some of the above examples are illustrated graphically in Figure J-1.

(a)

significant figure

of temp. coeff. of

capacitance (ppm/

o

C)

0.0

1.0

1.5

2.2

3.3

4.7

7.5

(b)

letter code

for (a)

C

M

P

R

S

T

U

(c)

multiplier

applicable to

column (a)

-1.0

-10

-100

-1000

-10000

+1

+10

+100

+1000

+10000

(d)

numerical codes

for column (c)

0

1

2

3

4

5

6

7

8

9

(e)

tolerance of

temp. coeff.

(ppm/

o

C)

30

60

120

250

500

1000

2500

(f)

letter code

for column (e)

G

H

J

K

L

M

N

TABLE J - 1

EIA DESIGNATIONS FOR CLASS I DIELECTRICS

FIGURE J - 1

%

∆

C

-50 -25 0 25 50 75 100 125

temperature,

o

C

T. C. OF LINEAR DIELECTRICS

6.0

4.0

2.0

0

-2.0

-4.0

-6.0

-8.0

1234

1234

1234

M7G

1234

1234

1234

COG

1234

1234

1234

R2G

1234

1234

1234

S2H

1234

1234

1234

U2H

NOVACAP

TECHNICAL BROCHURE

3

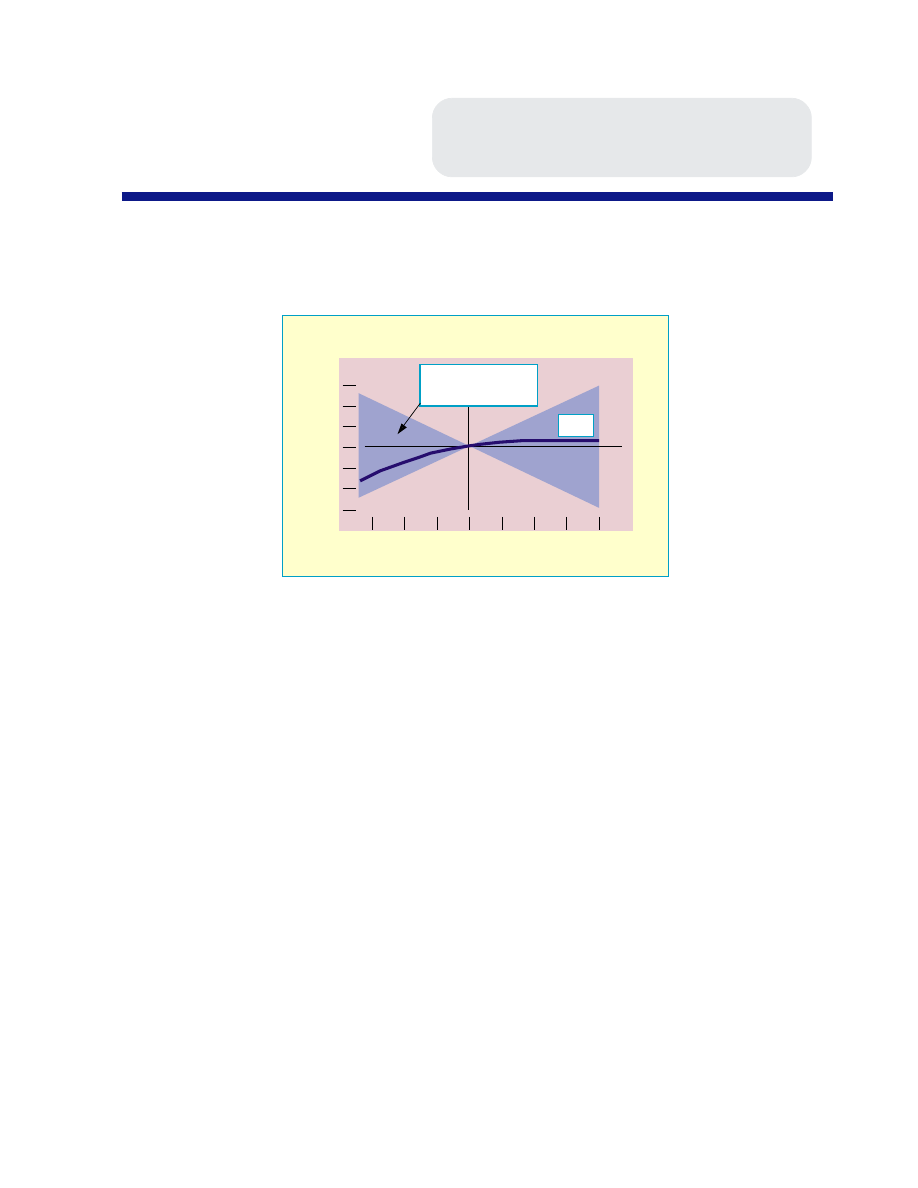

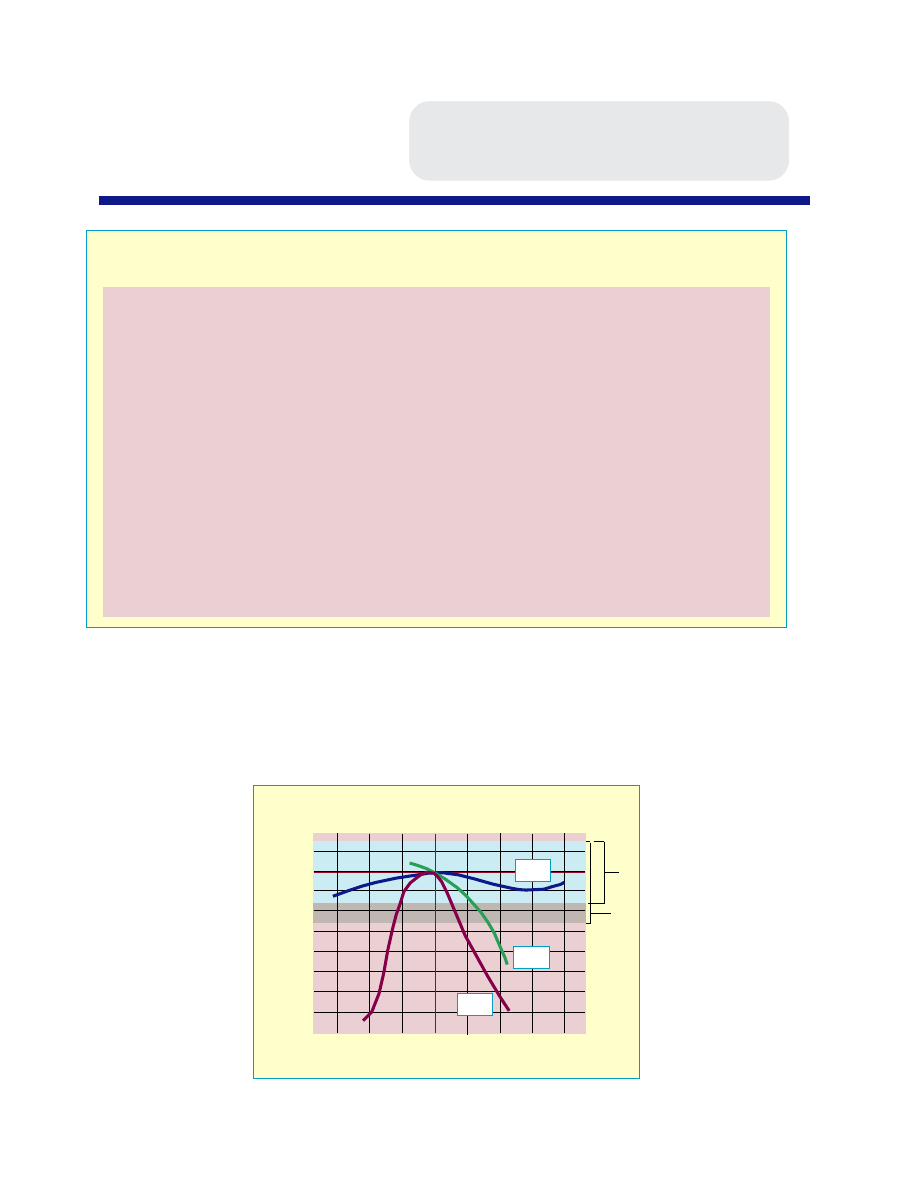

Actual measurements of temperature coefficient may not necessarily be perfectly linear, but are acceptable

if the data fall within the permissible tolerance limits specified by the last letter of the EIA code, as illus-

trated for COG dielectric in Figure J-2.

CLASS II DIELECTRICS

Class II dielectrics comprise the ferroelectric formulations described in Section H. These materials

offer much higher dielectric constants than Class I dielectrics, but with less stable properties with

temperature, voltage, frequency and time. The diverse range of properties of the ferroelectric ce-

ramics requires a subclassification into two categories, defined by the temperature characteristics:

“Stable Mid-K” Class II

, which display a maximum temperature coefficient of ±15% from

25

°

C reference over the temperature range of -55

°

C to 125

°

C. These materials typically have

dielectric constants in the range of 600 to 4000, and meet EIA X7R characteristics.

“High K” Class II

dielectrics, with temperature coefficients exceeding the X7R require-

ments. High K formulations display dielectric constants from 4000 to 18,000, with very

steep temperature coefficients, due to the fact that the Curie Point is shifted towards room

temperature for maximization of the dielectric constant.

Table J-2 shows the EIA 198 descriptions for these dielectrics. The most common Mid-K charac-

teristic used in chip capacitor manufacture is the X7R designation (±15% maximum

∆

C from -55

°

C

to 125

°

C). In the High-K category, the Z5U characteristic (+22% to -56% maximum

∆

C from

+10

°

C to +85

°

C) and Y5V (+22% to - 82% maximum

∆

C from -30

°

C to +85

°

C) are common.

The military specification for ceramic chip capacitors (MIL-C-55681) also defines the Mid-K stable

-50 -25 0 25 50 75 100 125

temperature,

o

C

%

∆

C

0.3

0.2

0.1

0

-0.1

-0.2

-0.3

FIGURE J - 2

TOLERANCE OF TEMPERATURE COEFFICIENT

1234

1234

1234

COG

+/- 30 ppm/

o

C

tolerance envelope

NOVACAP

TECHNICAL BROCHURE

4

dielectric and is designated as “BX” characteristic. The BX specification has voltage temperature

limits in addition to the standard temperature limits discussed previously. BX dielectric is limited to

a ±15% maximum capacitance change from -55

°

C to 125

°

C, and to a +15% -25% maximum change

with working voltage applied. In effect, the BX characteristic is similar to the X7R designation,

with the added condition that the voltage coefficient and temperature coefficient combined do not

exceed +15% -25%

∆

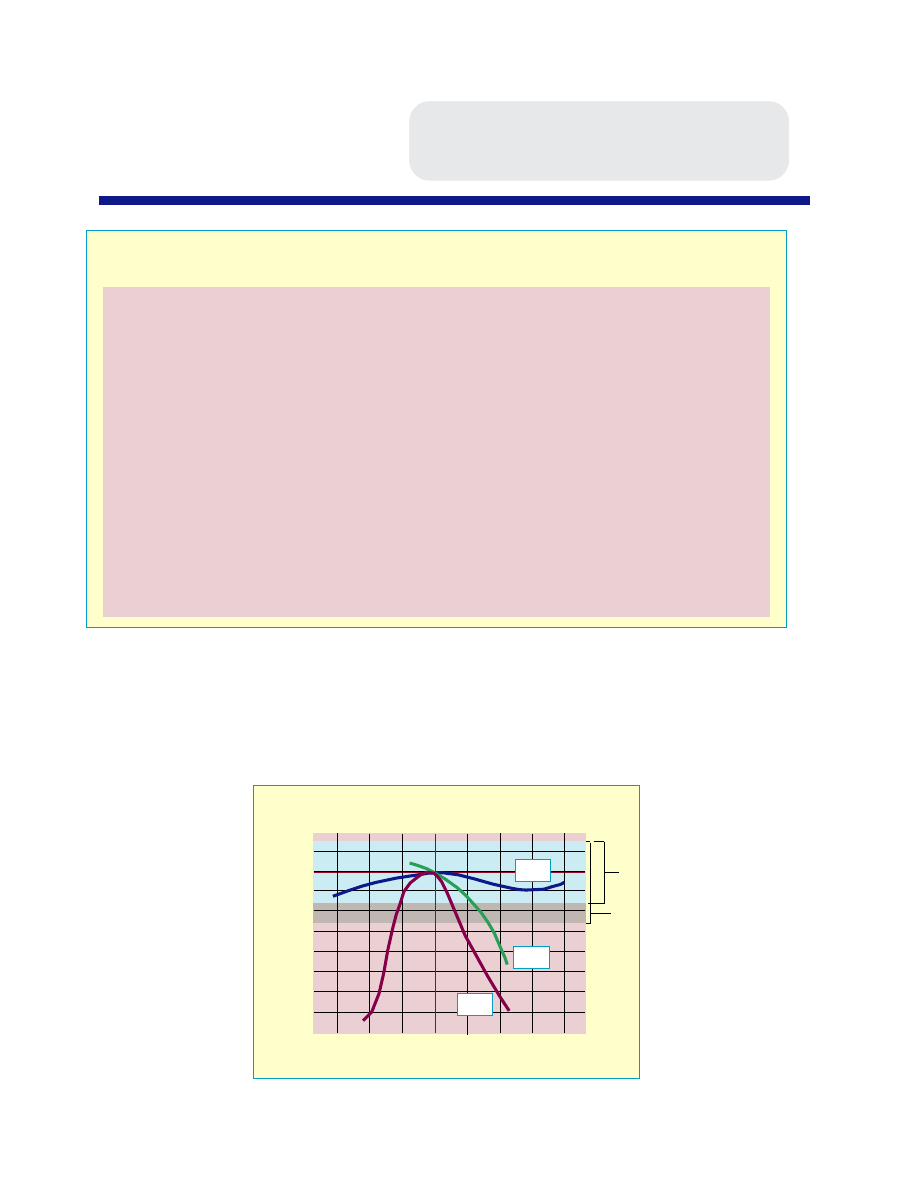

C. Typical Class II T.C. curves are shown in Figure J-3.

(a)

low temperature

requirement

+10

-30

-55

(b)

letter code

for (a)

Z

Y

X

(c)

high temp.

requirement

+45

+65

+85

+105

+125

(d)

numerical codes

for column (c)

2

4

5

6

7

(e)

Max. (+/-)%

∆

C

over temp.

1.0

1.5

2.2

3.3

4.7

7.5

10.0

15.0

22.0

+22-33

+22-56

+22-82

(f)

letter code

for column (e)

A

B

C

D

E

F

P

R

S

T

U

V

TABLE J - 2

EIA DESIGNATIONS FOR CLASS II DIELECTRICS

FIGURE J - 3

%

∆

C

-50 -25 0 25 50 75 100 125

temperature,

o

C

T. C.

OF CLASS II DIELECTRICS

+10

0

-10

-20

-30

-40

-50

-60

-70

1234

1234

1234

X7R

1234

1234

Z5U

1234

1234

1234

Y5V

X7R envelope

BX TVC envelope

NOVACAP

TECHNICAL BROCHURE