1

H. FERROELECTRIC CERAMICS

Ferroelectric dielectrics differ from the “paraelectric” materials in that a nonlinear response of charge

or polarization versus voltage occurs due to the crystal structure of the material. Ionic displace-

ments in paraelectric ceramics, such as TiO

2

, are totally reversible, as ions return to their original

position once an applied field is removed, and the polarization effect is linear as depicted in Figure

H-1.

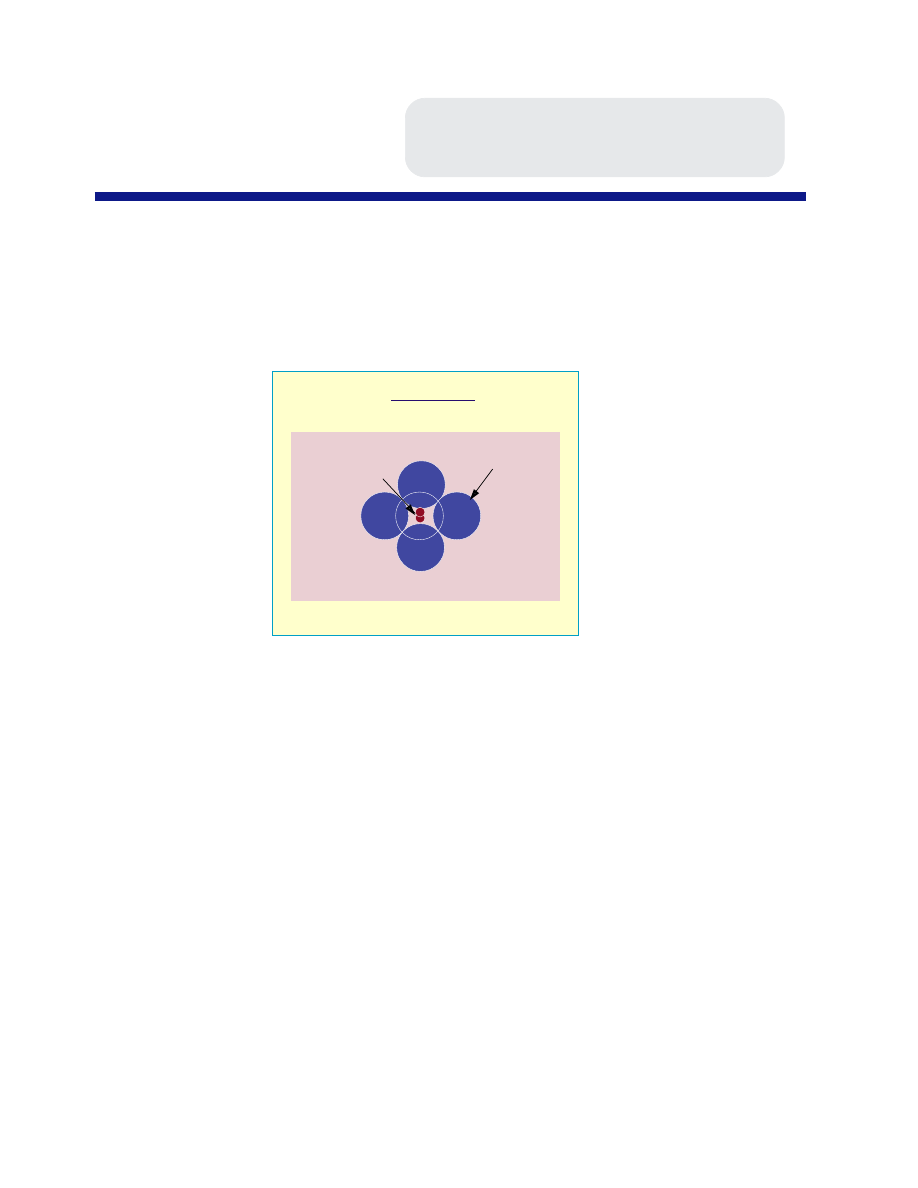

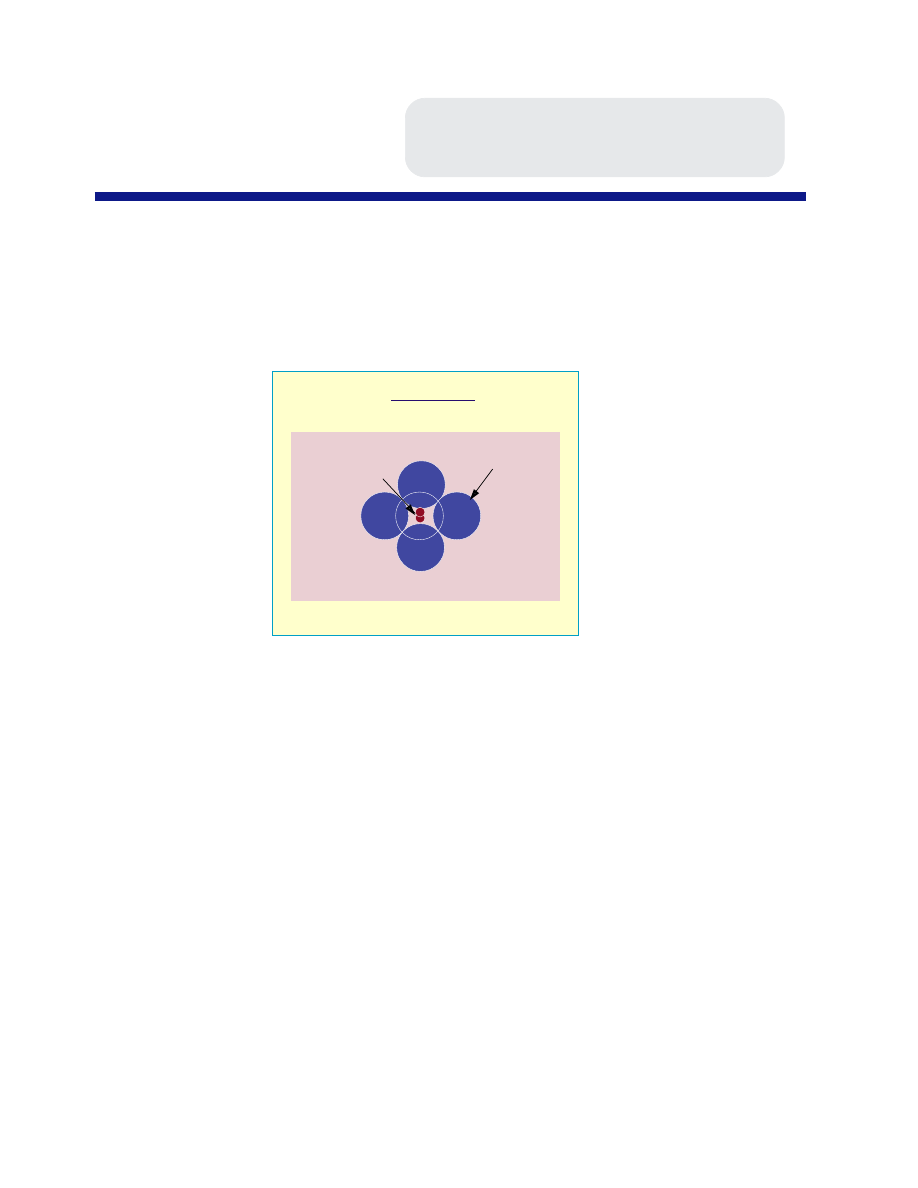

Ferroelectric ceramics are those which display a hysteresis effect of polarization with an applied

field, as shown in Figure H-2. The hysteresis loop is caused by the existence of permanent electric

dipoles in certain materials, (such as barium titanate), which develop spontaneously below the Curie

Temperature, as explained in paragraph G-3. These dipoles arise due to the fact that in the tetrago-

nal unit cell of BaTiO

3

, the Ti

4+

cation is surrounded by Six O

-2

anions in a slightly deformed octahe-

dral configuration, and can occupy one of two asymmetrical sites, as illustrated in Figure H-3. In

FIGURE H - 1

POLARIZATION OF LINEAR DIELECTRIC

polarization (+)

(-)

electric field

(+)

(-)

FIGURE H -2

FERROELECTRIC HYSTERESIS

P

E

P

+

p-

C

D

A

B

NOVACAP

TECHNICAL BROCHURE

2

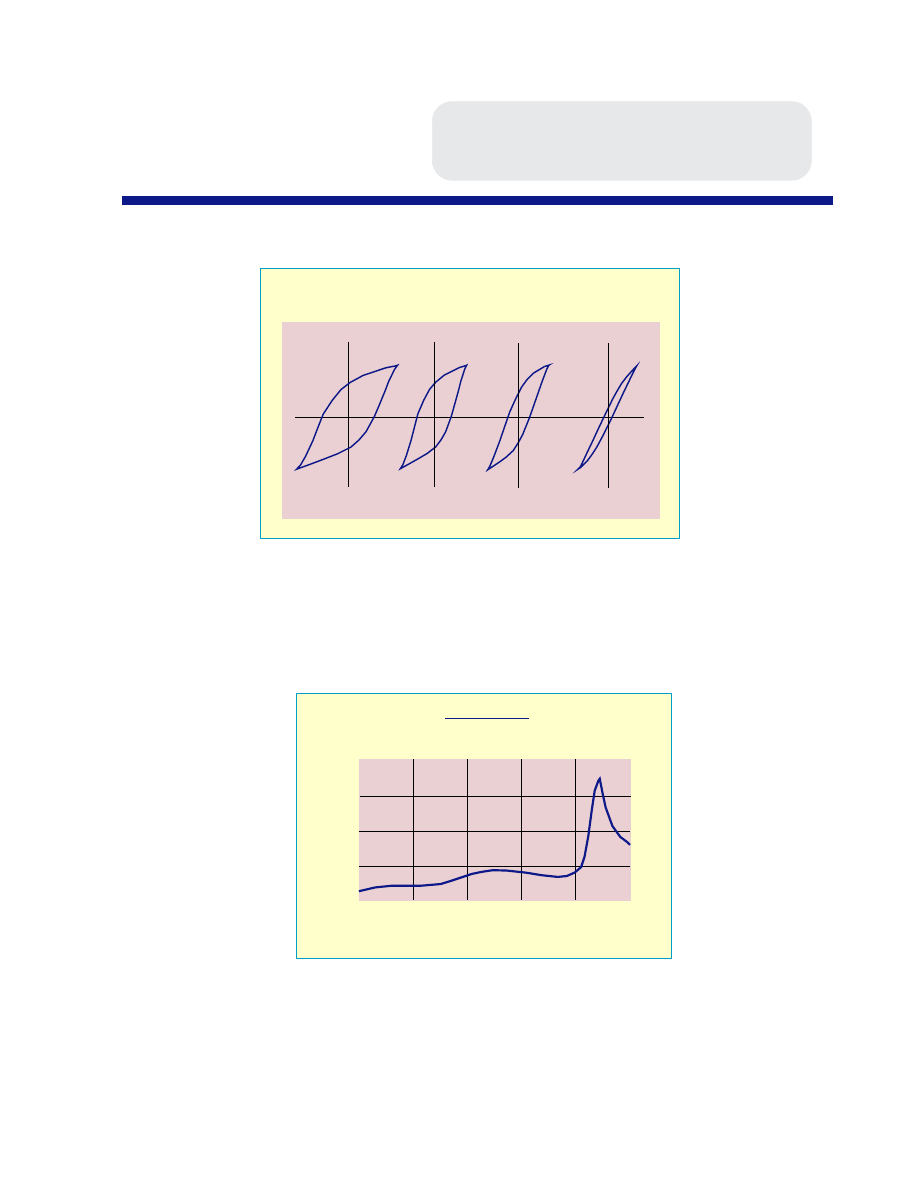

either position, the Ti

4+

cation is not coincident with the negative charge center of the oxygen anions by a

small fraction of an Angstrom, creating an electric dipole. The energy barrier between the two possible Ti

atom positions is sufficiently low to permit motion of the atom between sites by the coercion of an electric

field, and the material can thus be directionally polarized with ease. The interaction between adjacent unit

cells, in fact, is sufficient to create domains of parallel polarity the instant the material assumes its ferroelec-

tric state on cooling through the Curie Point.

Upon creation, the ferroelectric domains are random in orientation, and the material has no polariza-

tion. In reference to Figure H-2, this state is equivalent to point A. If an external field is now

applied, Ti atoms become displaced in the direction of the field, such that domains more favorably

aligned with the field will grow, at the expense of those which are not, creating a rapid and major polarizing

effect until a maximum orientation with the field is achieved (point B). Removal of the field at this point will

eliminate any normal ionic polarization, but as is evident from the model of Figure H-3, the Ti atoms remain

in their now oriented sites, and a remnant polarization (P+) isobserved. In order to remove this polariza-

tion it becomes necessary to apply an opposing field (point C) which reverts half the volume of the domains

to favor the new field direction. Continuation of the field cycle inverts the polarization to a maximum (at

point D) and removal of the negative field leaves a net polarization (P-). Further cycles of the electric field

retrace the original path, creating a continuous hysteresis effect. A condition of zero polarization at 0 volts

(point A) can only be again achieved by short circuiting the capacitor and heating past the Curie Point to

generate a new system of random ferroelectric domains. Ferroelectric domains can actually be observed in

polycrystalline barium titanate, where etched polished surfaces reveal differences in orientation on the grain

structure of the material.

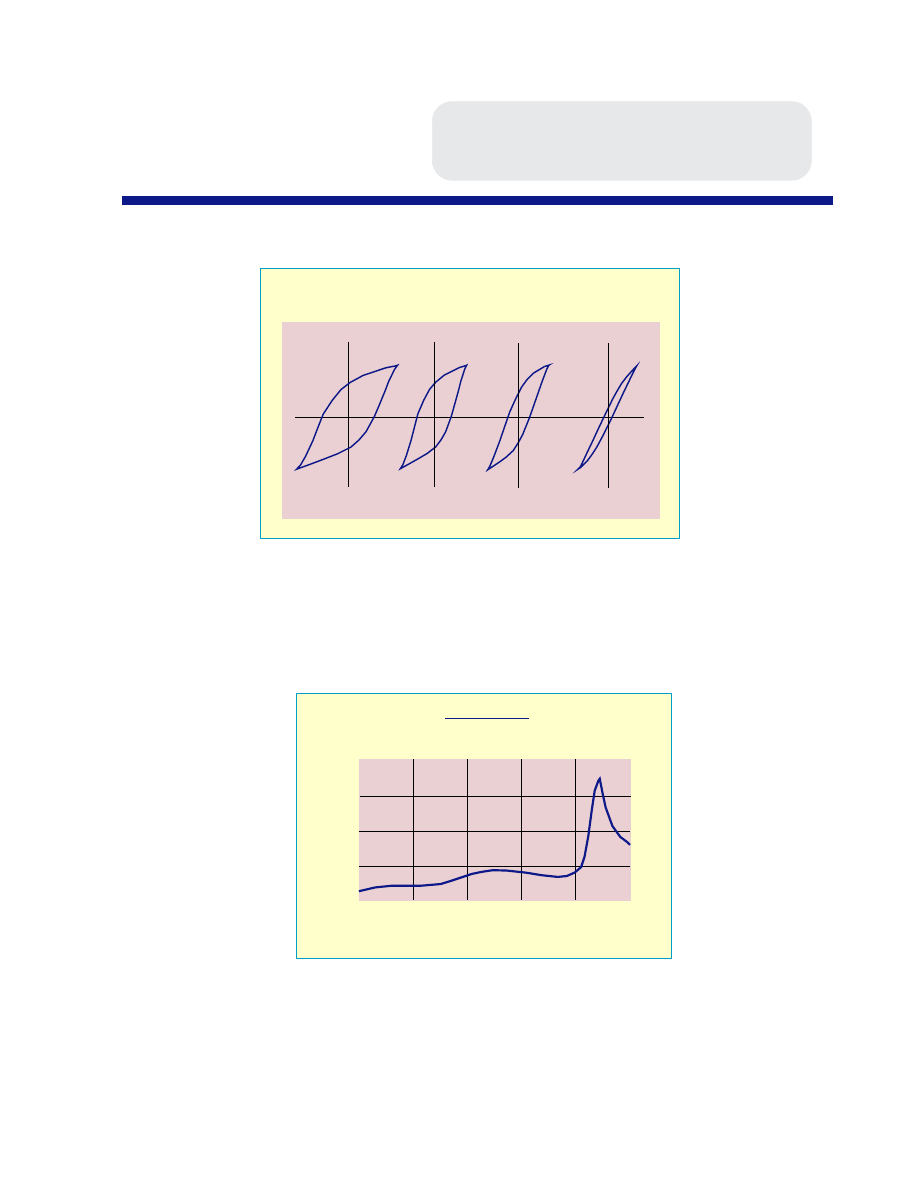

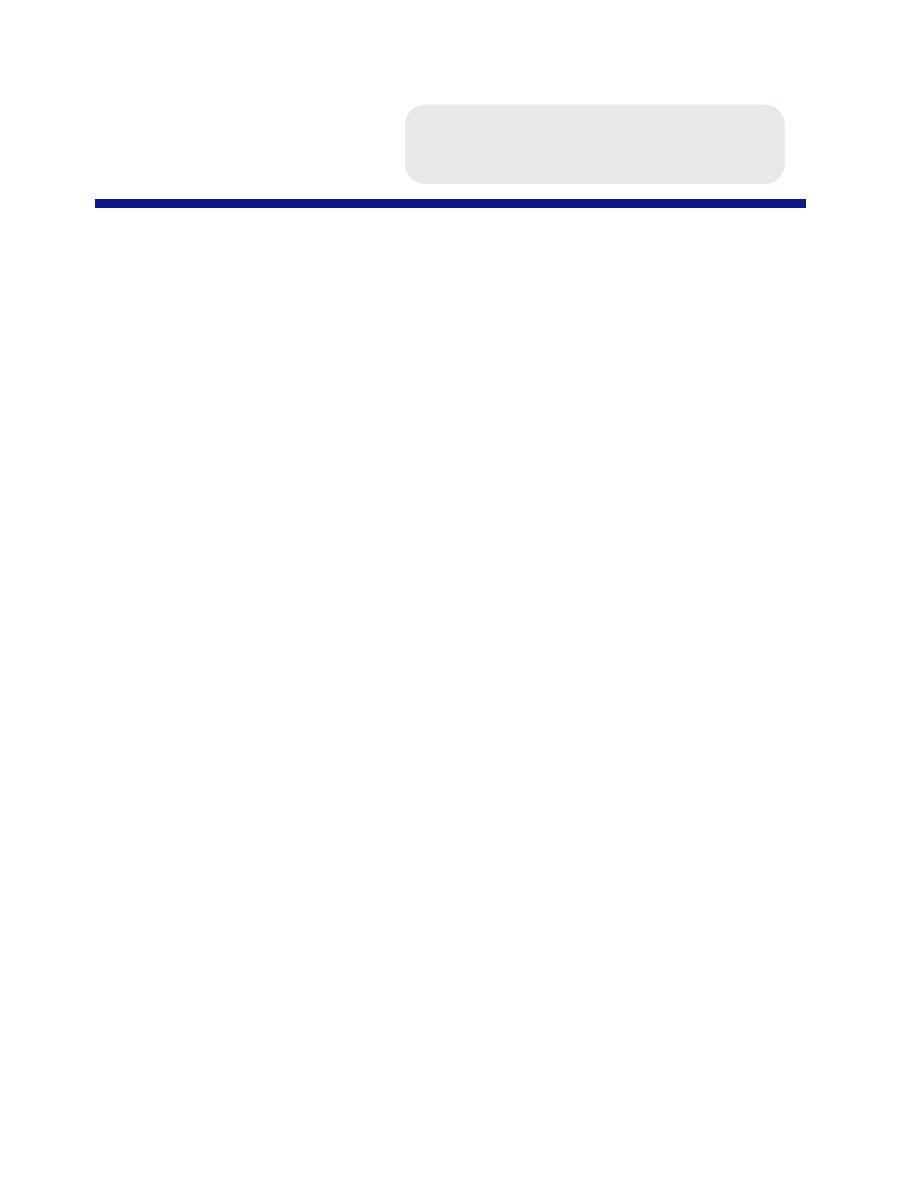

The ferroelectric hysteresis loop varies in shape with temperature. At lower temperatures there is

less thermal motion of atoms and a greater field is required to orient the domains. Measurements at

higher temperatures show that the coercive field required for polarization decreases, until at the

FIGURE H - 3

Ti

4+

CATION IN THE O

2-

OCTAHEDRON

O

2-

Octahedron

Positions for Ti

4+

NOVACAP

TECHNICAL BROCHURE

3

Curie Temperature the hysteresis effect disappears and linearity is approximated (Figure H-4).

It should be noted that barium titanate undergoes other phase transformations below the Curie

Point, which are accompanied by changes in the dielectric constant of the ceramic. In addition to the

cubic to tetragonal transformation on cooling through the 120

°

C Curie Point, a change from tetrago-

nal to orthorhombic occurs at 0

°

C, which then transforms to the rhombohedral crystal habit at -90

°

C.

The variation of the relative dielectric constant with temperature is illustrated in Figure H-5.

The variations of electrical properties of BaTiO

3

, in addition to the changes of these with tempera-

ture, present some obvious problems. The polarization obtained is a function of the electric field

intensity, due to the energy required for domain orientation, i.e. K is a function of the applied field.

FIGURE H-4

HYSTERESIS LOOP AT VARIOUS TEMPERATURES

-55

o

C

0

o

C

60

o

C

120

o

C

FIGURE H - 5

dielectric constant

8000

6000

4000

2000

0

-100 -50 0 50 100 150

temperature,

o

C

BaTiO

3

TEMPERATURE COEFFICIENT FOR

NOVACAP

TECHNICAL BROCHURE

4

In addition, the dielectric constant is highly temperature dependent and practical applications specify sta-

bility over a -55

°

C to 125

°

C temperature range. Also, as indicated previously, ferroelectric ceramics

display aging and piezoelectric effects.

There are, fortunately, other elements which can be incorporated into the BaTiO

3

perovskite crystal

structure to modify its properties. Lead titanate, for example, which also has a perovskite structure,

readily forms solid solutions with BaTiO

3,

i.e. the Pb

2+

cation can substitute the Ba

2+

cation. Other

partial substitutions for Ba

2

+

,

(such as Sr

2+

, Cd

2+

and Ca

2+

), as well as replacement in part for the Ti

4+

cation (by Sn

4+

, Zr

4+

, and Hf

4+

) are also used to modify the dielectric behavior and temperature

dependence of BaTiO

3

. These additives greatly enhance the range of compositions and possible

dielectric characteristics, and much effort has been expended in recent years to optimize these mate-

rials for practical applications.

Specifically, additives are utilized to shift the Curie Point such that the high K properties of the

ferroelectric can be put to work at or near room temperature. Examples of such materials are

SrTiO

3

and CaZrO

3

. Other materials may transfer the Curie Point to more elevated temperatures

(PbTiO

3

). In addition to “shifter” additives, materials which depress the dielectric constant peak at

the Curie Point are utilized, to provide a more stable K value over temperature. These composi-

tional additives are call “depressors,” examples of which are MgZrO

3

and Bi

2

Sn

3

O

9

. These materials

are thus used in careful proportions to maximize the usefulness of the dielectric over the practical

temperature range, i.e. the high K Curie peak is “shifted” towards room temperature, and the spike

effect is depressed to provide a reasonable capacitance temperature coefficient. In polycrystalline

ceramics many individual crystal characteristics can be combined which mask one another to

provide relatively stable characteristics.

Additions which do not form a solid solution, or only a partial solid solution with the host material, also

affect the microstructure, by providing a second intergranular phase. Grain boundary phases which are not

ferroelectric greatly affect the electrical properties of the composite, as these phases somewhat isolate the

ferroelectric grains and thus inhibit domain interaction, depressing the dielectric constant, aging rate and the

piezoelectric effects.

In addition to the purposes described above, other ingredients are used to aid in fabrication of the

multilayer capacitor, such as additives which flux the ceramic to permit sintering at lower and more

reasonable temperature or inhibit excessive grain growth and provide denser microstructure. Often,

minor percentages of certain oxides will determine other electrical properties, such as insulation

resistance at 25

°

C, or at 125

°

C, or dielectric strength.

NOVACAP

TECHNICAL BROCHURE