UL30

SERIES

Unlytic

®

Unlytic

®

Series

The first film dielectric capacitor replacement for electrolytic capacitors. Its

availability establishes a new standard and the ongoing search for better

answers creates a void that UNLYTIC

®

is best able to fill!

FEATURES

STANDARD CONFIGURATION

-

10X greater current density

-

3X greater over voltage

protection

-

Higher voltage ratings

-

Superior performance over

temperature range -55°C to

105°C

-

10 year shelf life

-

Dry construction (no harmful

electrolytes)

-

Non-polar

-

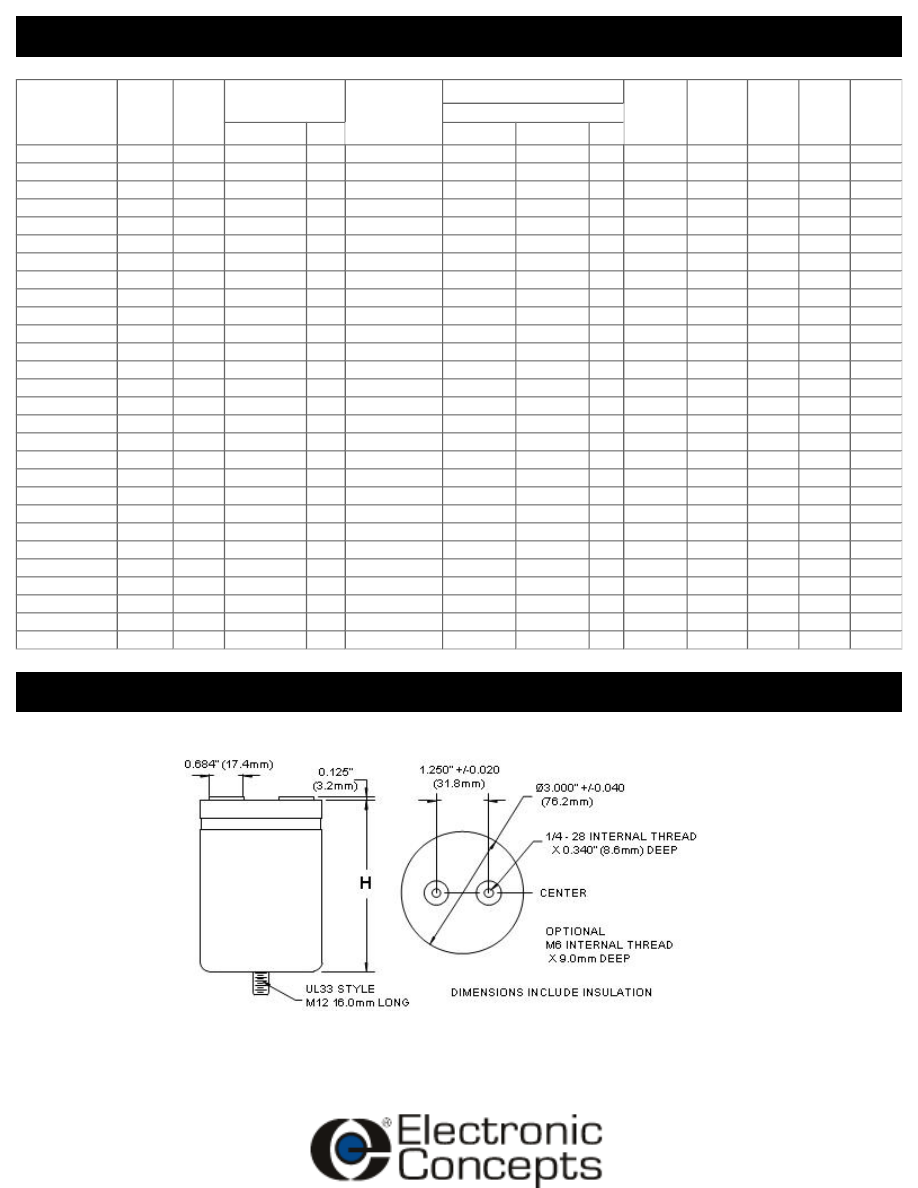

UL30: Flat Mount

-

UL33: Optional Stud Mount

Rev. 2

Specification Summary

Capacitance Range

50.0µF to 1600.0µF

Capacitance Tolerance

Standard capacitance tolerance is ± 10%.

Operating Temperature Range

-55° TO +105°C

Enclosure/ Construction

Aluminum case with high-current terminals. Non-inductive

wound dry film.

Voltage Rating

300VDC to 1000VDC

Quality Control

Capacitors are tested 100% for:

o Capacitance

o Tolerance

o Dissipation Factor

o Dielectric withstanding voltage

o Insulation Resistance

o Equivalent Series Resistance (ESR)

Process and inspection data are maintained on file and available

on special request.

Environmental

Parameter

Method

Condition

Vibration

204

D

Immersion

104

C

Shock

213

I

Humidity

106

-

Thermal Shock

107

B

Life

108

F

Reference MIL-STD-202

Characteristics

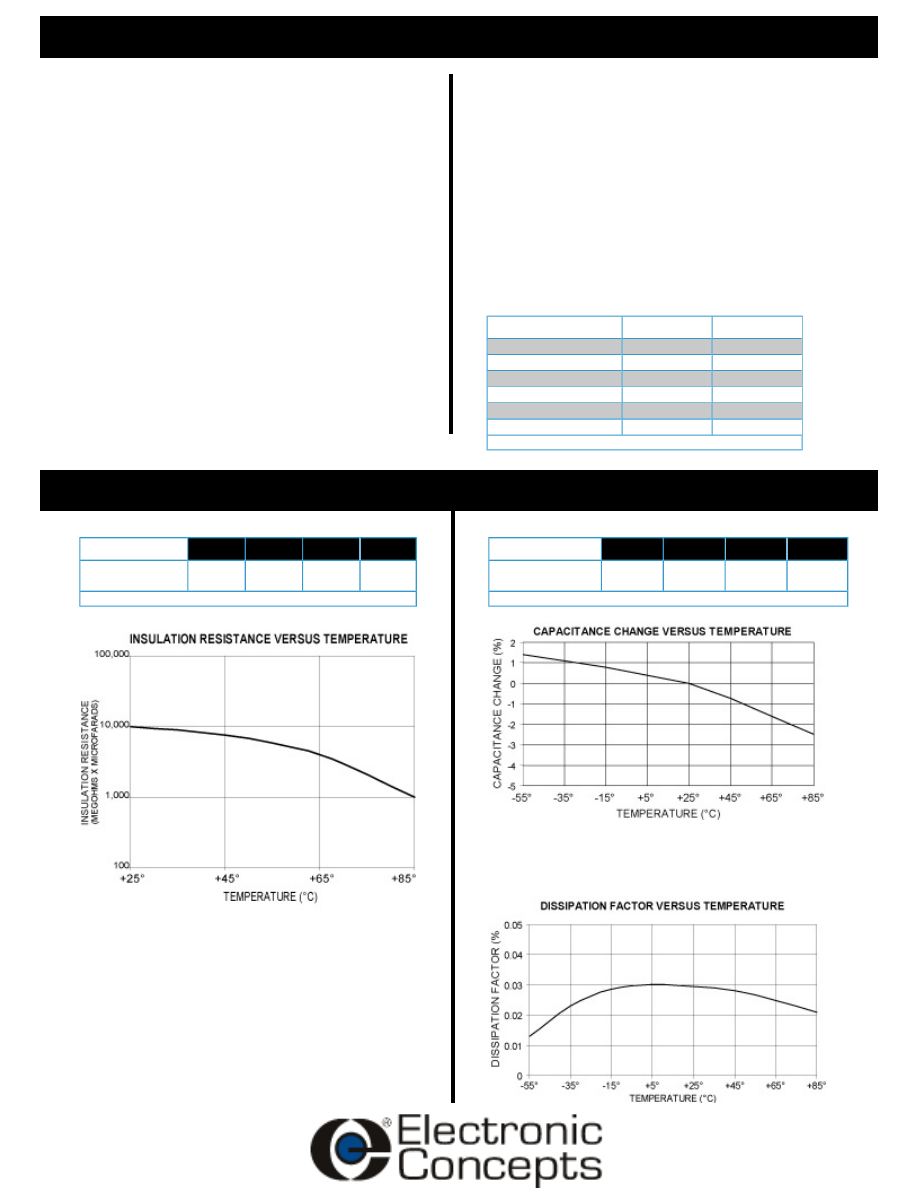

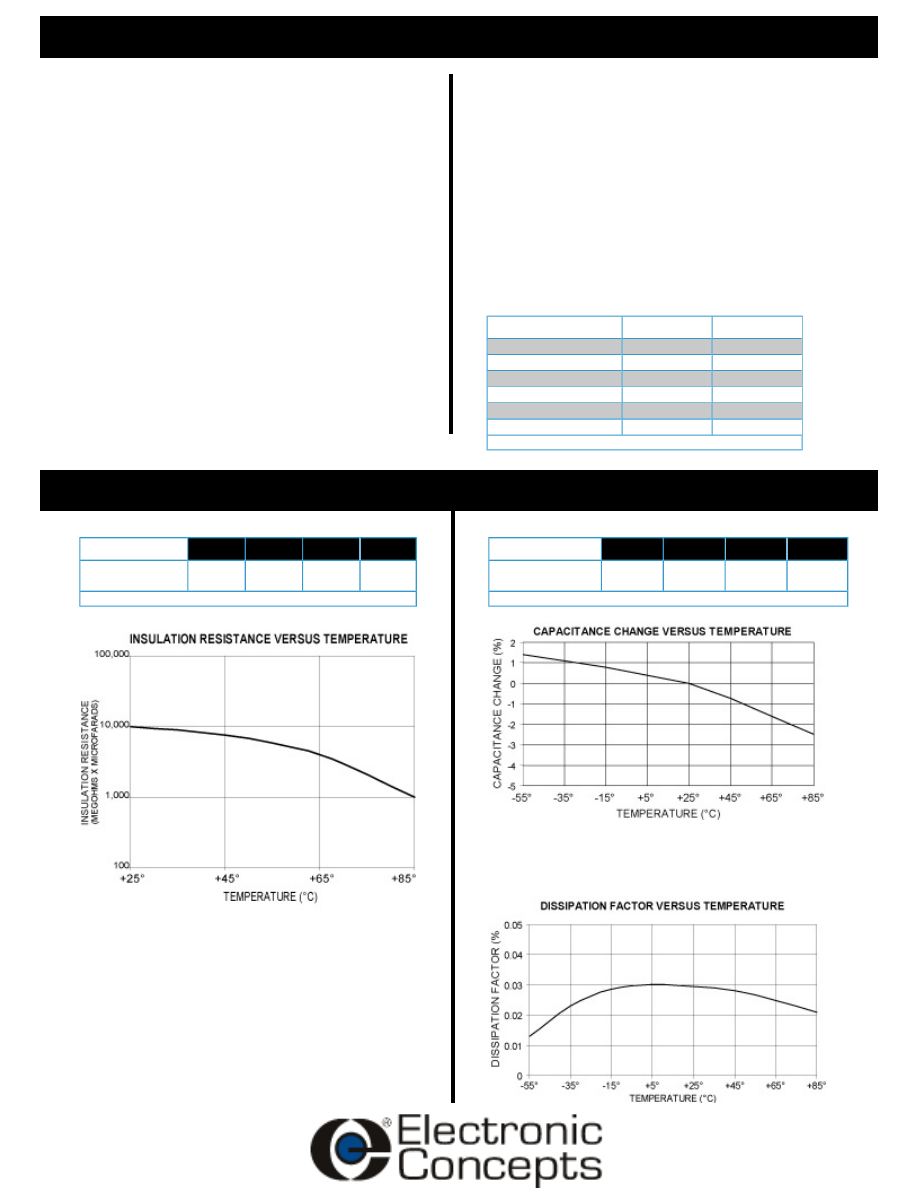

Insulation Resistance

Temperature(°C)

25

85

105

Megaohmsx

Microfarads

10,000

1,000

Insulation Resistance

Dielectric Strength

Capacitors withstand a DC potential of 130% rated

voltage for two (2) minutes without damage or

breakdown. Test voltage is applied and discharged

through a resistance of 1 ohm per volt minimum, and at

25°C.

Capacitance Change

Temperature(°C)

-55

25

65

85

PercentageChange

(typical)

1.4

0

-1.5

-3.5

CapacitanceChange

Dissipation Factor

When measured at the frequency specified for capacitance

measurement, the dissipation factor will not exceed 0.1%.

Rev. 2

ADDITIONAL INFORMATION

With our patented advances in dry film technology...the impossible is now practical! Now for the first time,

all of the superior performance characteristics of film capacitors are available in values and sizes

previously achieved only by electrolytics! This will improve how high power systems are designed - by

improving reliability, extending service life, allowing for miniaturization, lowering production costs and

maximizing performance.

In addition, the packaging dimensions of the UNLYTIC

®

are identical to electrolytics for a direct

replacement. Therefore, conceptual changes in system design are not required.

HOW TO ORDER

TYPE

Metallized Polypropylene

UL3

STYLE / VOLTAGE

0: Flat mount, 3: Optional stud mount / DC Voltage Rating: AT=300VDC,

AX=400VDC, etc.

3 AT

CAPACITANCE

IN MICROFARADS

Last 4 characters represent capacitance. 1600 = 1600uF

1600

TOLERANCE

K=±10%

K

Marking And Date Code

All capacitors are marked with company initials "EC", corporate logo or EC trademark—in addition to type UL30, capacitance,

tolerance, rated DC working voltage and date code. The first two digits of the date code represent the year, the second two digits the

week, i.e., 0952 is the 52nd week of 2009, 0902 is the second week of 2009.

Quality Assurance

Major emphasis is placed on quality assurance. EC is an ISO 9001-2000 and AS9100:2004 Certified Company. Raw material

inspection and the use of SPC manufacturing procedures assure the highest quality standards. Procedures are fully described in the

EC Quality Control Manual. Electronic Concepts will continue to advance the state-of-the-art by utilizing leading edge technology,

compact capacitor designs and establishing reliability procedures.

Sales Offices

United States

Europe

Eastern:

*Headquarters*

P.O. Box 1278

Eatontown,NJ 07724

Tel: 732-542-7880

Fax: 732-542-0524

Central:

Illinois 630-668-8747

email: sales@ecicaps.com

website:www.ecicaps.com

Ireland

Electronic ConceptsEurope LTD

IDA Estate, Oughterad

Co. Galway, Ireland

tel: +353-91-552385,552432

fax: +353-91-552387

email: sales@ecicaps.ie

website:www.electronicconcepts.ie

Rev. 2