High Precision Foil Surface Mount Current Sensing Chip

Resistors with TCR of ± 2 ppm/°C, Load Life Stability of ± 0.02 %,

ESD Immunity up to 25 kV and Fast Thermal Stabilization

VCS1610 (Kelvin Connection)

Vishay Foil Resistors

Document Number: 63137

For any questions, contact:

foil@vishaypg.com

www.foilresistors.com

Revision: 25-Mar-10

1

TERMINATIONS

Two lead (Pb)-free options are available:

Gold plated or tin plated

Tin/lead plated

Note

• Tighter tolerances and higher values are available. Please

contact application engineering

foil@vishaypg.com

FEATURES

Temperature coefficient of resistance (TCR):

± 2.0 ppm/°C typical (- 55 °C to + 125 °C,

+ 25 °C ref.) (see table 1)

Tolerance: to ± 0.5 %

Load life stability:

± 0.02 % at 70 °C, 2000 h at rated power

Power rating: 0.25 W at + 70 °C

Resistance range: 0.1

to 1

(for higher or lower

values please contact Vishay application engineering

department)

Vishay Foil resistors are not restricted to standard values;

specific “as required” values can be supplied at no extra

cost or delivery (e.g. 0.2345

vs. 0.2

)

Electrostatic discharge (ESD) up to 25 000 V

Thermal stabilization time < 1 s

Short time overload

0.005 %

Non-inductive, non-capacitive design

Thermal EMF: 0.05 µV/°C typical

Current noise: < - 42 dB

Rise time: 1 ns effectively no ringing

Voltage coefficient: < 0.1 ppm/V

Non inductive: < 0.08 µH

Weight: 0.027 mg

Compliant to RoHS directive 2002/95/EC

Prototype quantities available in just 5 working days

or sooner. For more information, please contact

foil@vishaypg.com

For improved performances, please see VCS1610Z

INTRODUCTION

Why should I use the VCS1610?

The VCS1610 is a current sensing solution that was

developed with a low TCR to meet demands for new and

stable resistive product solutions in the industry today. This

resistor is most-often used to monitor a current that is directly

proportional to some physical characteristic (such as

pressure, weight, etc) being measured by an analog sensor.

The resistor converts the current to a voltage that is

representative of the physical characteristic and feeds that

voltage into control circuits, instrumentation, or other

indicators.

Variations induced in the resistor, not representative of the

monitored characteristic, can be caused by high TCR

response to both ambient temperature and self-heating and

can feed erroneous signals into the system. Resistance is

usually kept low to reduce the I²R self-heating (Joule effect)

portion of the error while minimizing the stresses that cause

long-term resistance changes. It is critical for this resistor to

reach thermal equilibrium quickly in circuits that require fast

response or where the current changes quickly.

The VCS1610 is used where the emphasis is on accuracy

and repeatability under stress conditions in applications

requiring precision resistor performance up to 0.25 W and up

to 70 °C. Applications as EB systems, switching power

supplies, force-balanced scales all rely on current sense

resistors to develop a precise voltage proportional to the

current. The VCS1610 is a four terminal resistor which is

essential to achieve high accuracy and stability.

Why use Kelvin connections?

Four-terminal connections or Kelvin connections are

required in these low ohmic value resistors to measure a

precise voltage drop across the resistive element. The

4-terminal configuration eliminates the IR-drop error voltage

that would be present in the voltage sense leads if a standard

two-terminal resistor were used.

In current sense resistors the contact resistance and the

terminations resistance may be greater than that of the

resistive element itself so lead connection errors can be

significant if only two terminal connections are used.

* Pb containing terminations are not RoHS compliant, exemptions may apply

TABLE 1 - TOLERANCE AND TCR VS.

RESISTANCE VALUE

(- 55 °C to + 125 °C, + 25° Ref.)

VALUE

(

)

TOLERANCE

TYPICAL

TCR

MAXIMUM

TCR

0R5 to 1R

0.5 %, 1 %

± 2 ppm/°C

± 10 ppm/°C

0R1 to 0R5

0.5 %, 1 %

± 2 ppm/°C

± 15 ppm/°C

VCS1610 (Kelvin Connection)

Vishay Foil Resistors

www.foilresistors.com

For any questions, contact:

foil@vishaypg.com

Document Number: 63137

2

Revision: 25-Mar-10

Why is the VCS1610 vital to avoid Thermal EMF

(parasitic effect)?

When the junction of two dissimilar metals is heated, a

voltage is generated across the junction creating a DC-offset

error signal. This voltage is proportional to the temperature

difference across the junction and is called a Thermal

Electro-motive Force (Thermal EMF), or thermocouple.

Thermal EMF is an important consideration in low ohmic

current sensing resistors used mostly in DC circuits (there is

no effect in AC circuitry). The VCS1610 is the ideal solution

to minimize the effect of thermal EMF through the use of

appropriate materials between the resistive layer and the

terminations.

Should I be concerned about ESD impact on my

resistor?

Electrostatic Discharge (ESD) is known to produce

catastrophic failures in thin-film and thick-film (cermet)

resistors at only 3000 V. On the other hand, the Bulk Metal

Foil resistor withstands ESD events up to 25 000 V because

its thicker resistance element and greater metallic mass

afford much higher energy-handling capability than either the

much thinner thin-film resistor or the sparse,

non-homogeneous metallic content of the thick film resistor.

Should I be concerned about stability?

In order to select the resistor technology most appropriate to

the application, a designer must take into account all normal

and extraordinary stresses the resistor will experience in the

application. In addition, the designer must consider the cost

and reliability impact involved when it becomes necessary to

add costly additional compensating circuitry when

inadequate resistors are selected. The stability of Bulk Metal

Foil resistors, together with the advantages already

mentioned, as well as the other basic advantages apparent

in their specifications will not only provide unequalled

performance in the circuit but will eliminate all the costs

associated with extra compensation circuitry.

With VCS1610, only a minimal shift in resistance value will

occur during its entire lifetime. Most of this shift takes place

during the first few hundred hours of operation, and virtually

no change is noted thereafter.

Note

(1)

Power rating: 0.25 W at + 70 °C

FIGURE 1 - POWER DERATING CURVE

(1)

100

75

50

25

0

- 75

- 50

- 25

0

+ 25

+ 50

+ 75 + 100 + 125 + 150 + 175

Ambient Temperature (°C)

Percent of Rated Power

+ 70 °C

- 55 °C

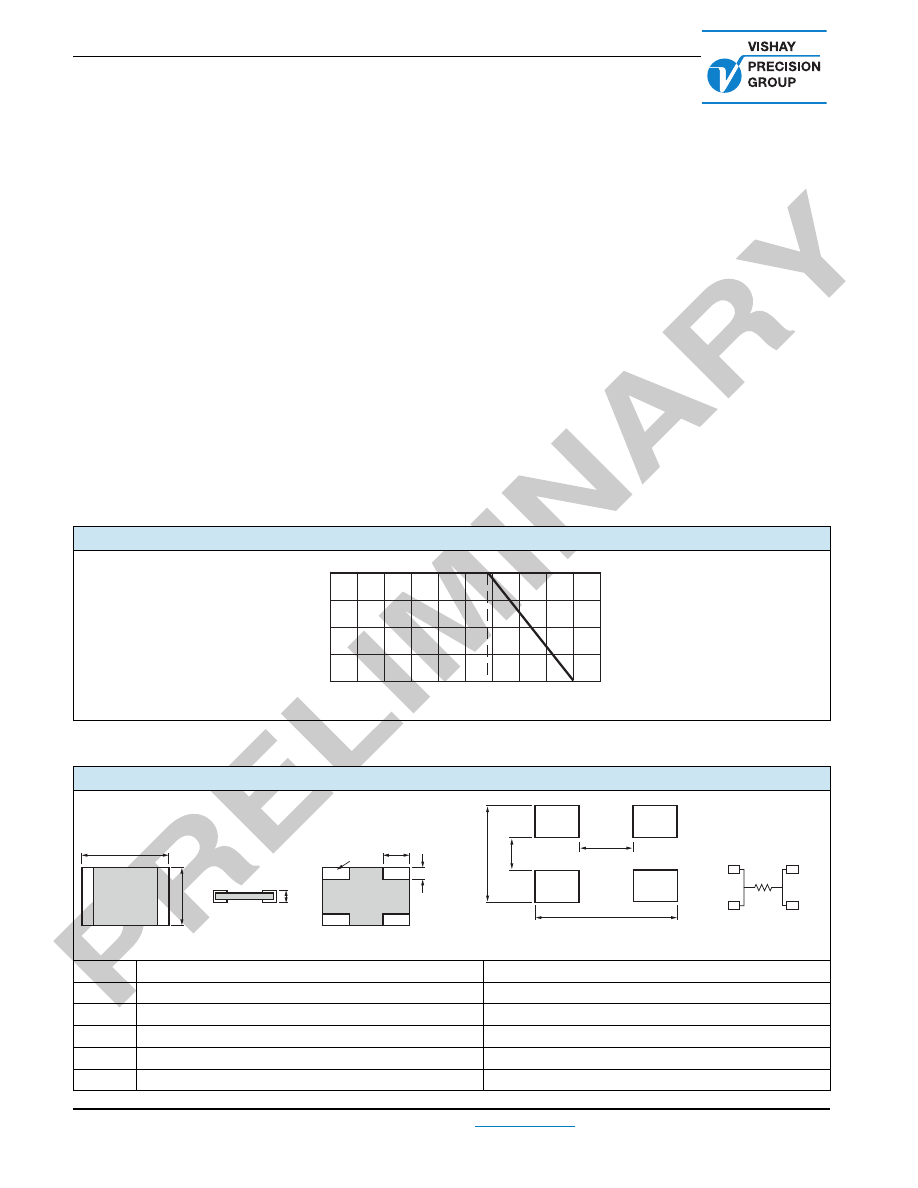

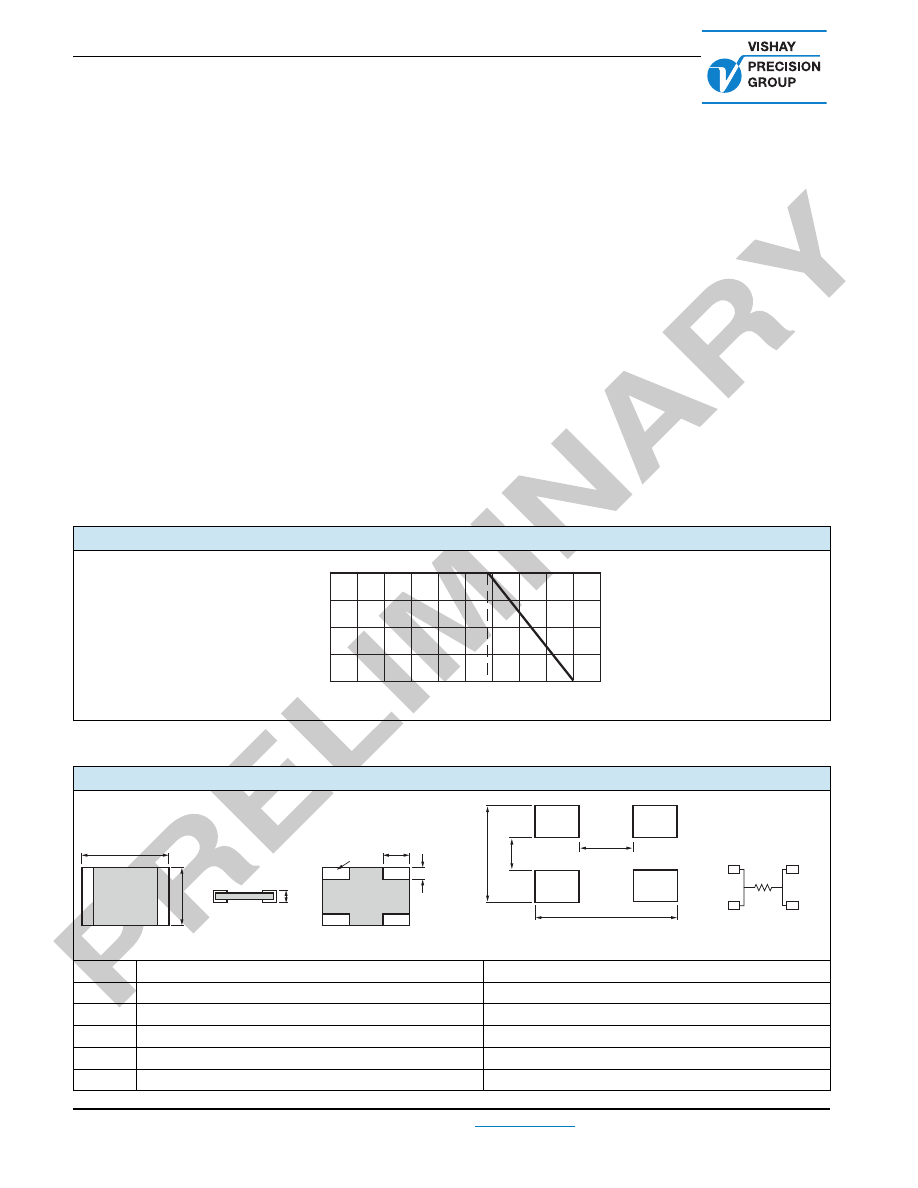

FIGURE 2 - DIMENSIONS

in inches (millimeters)

INCHES

MILLIMETERS

L

0.160 ± 0.010

4.06 ± 0.25

H

0.100 ± 0.010

2.54 ± 0.25

W

0.040 maximum

1.02 maximum

A

0.045 ± 0.005

1.14 ± 0.13

B

0.030 ± 0.010

0.76 ± 0.25

W

L

H

Top View

A

B

E

1

I

1

Bottom View

Mountin

g

Pads (4)

I

2

E

2

Solder Pad Layout

0.110

0.200

(5.08)

(2.794)

0.020

(0.508)

0.060

(1.524)

I

1

E

2

E

1

I

2

R

Electrical Schematic

VCS1610 (Kelvin Connection)

Vishay Foil Resistors

Document Number: 63137

For any questions, contact:

foil@vishaypg.com

www.foilresistors.com

Revision: 25-Mar-10

3

Note

• Measurement error 0.001 R

Note

(1)

For non-standard requests or additional values, please contact application engineering.

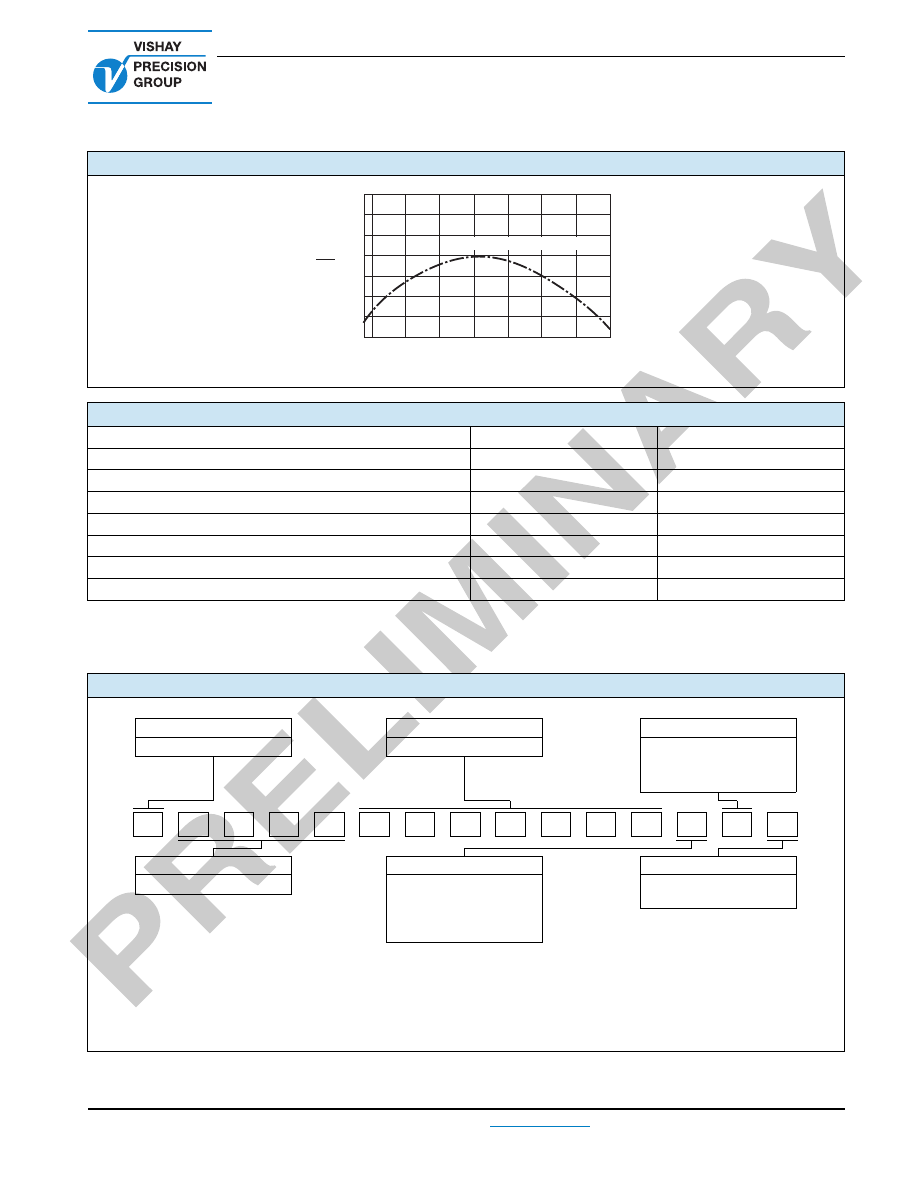

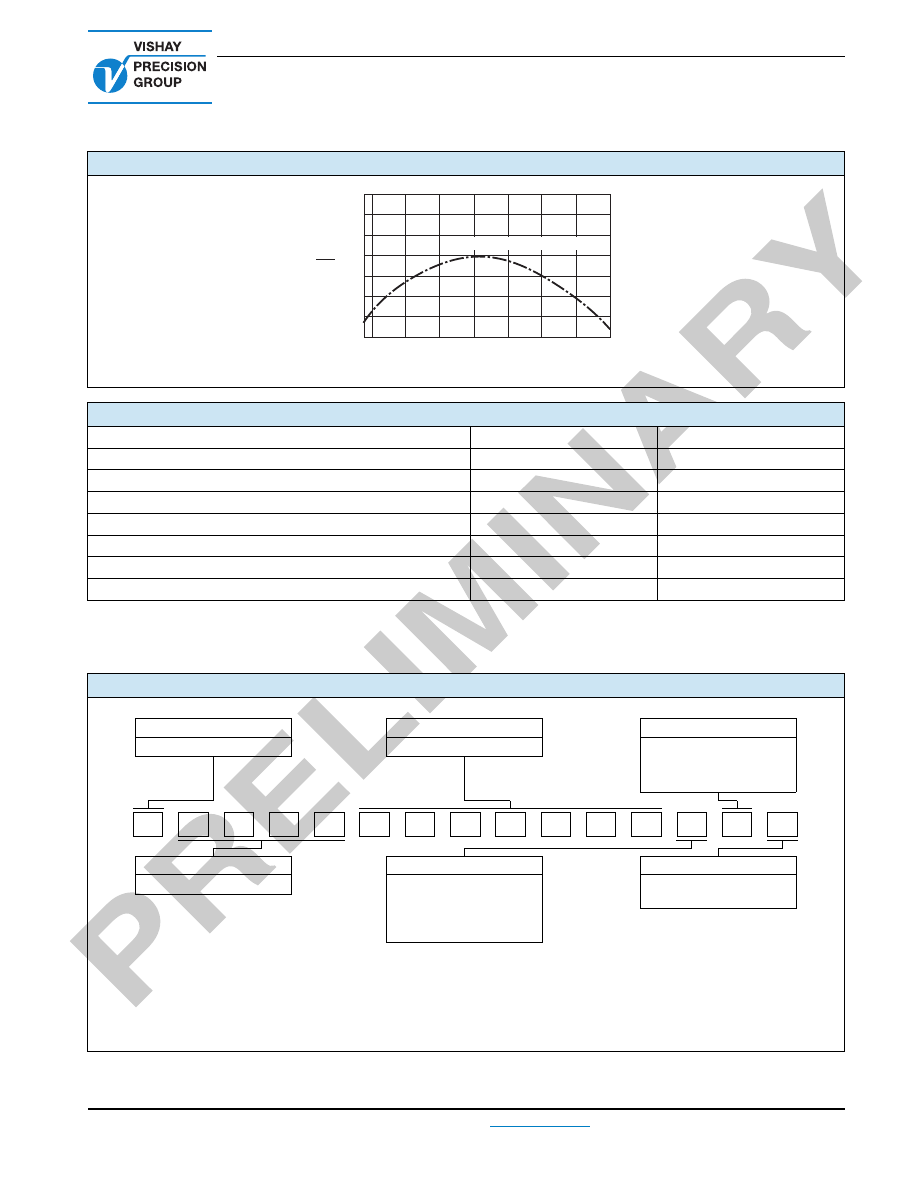

FIGURE 3 - TYPICAL RESISTANCE/TEMPERATURE CURVE

TABLE 2 - PERFORMANCE SPECIFICATIONS

TEST

MIL-PRF-55342

R LIMITS

TYPICAL

R LIMITS

Thermal Shock 5 x (- 65 °C to + 150 °C)

± 0.10 %

± 0.005 % (50 ppm)

Low Temperature Operation

± 0.10 %

± 0.005 % (50 ppm)

Short Time Overload

± 0.10 %

± 0.005 % (50 ppm)

High Temperature Exposure

± 0.10 %

± 0.01 % (100 ppm)

Resistance to Soldering Heat

± 0.2 %

± 0.01 % (100 ppm)

Moisture Resistance

± 0.2 %

± 0.01 % (100 ppm)

Load Life 2000 h at 70 °C

± 0.5 %

± 0.02 % (200 ppm)

TABLE 3 - GLOBAL PART NUMBER INFORMATION

(1)

NEW GLOBAL PART NUMBER: Y11200R40500D9W (preferred part number format)

DENOTES PRECISION

VALUE

CHARACTERISTICS

Y

R

=

0

= tin/lead plated

9

= tin plated

19

= gold plated

1 to 999

= custom

PRODUCT CODE

RESISTANCE TOLERANCE

PACKAGING

1120

= VCS1610

D

= ± 0.5 %

F

= ± 1.0 %

G

= ± 2.0 %

J

= ± 5.0 %

K

= ± 10.0 %

W

= waffle pack

R

= tape and reel

FOR EXAMPLE: ABOVE GLOBAL ORDER Y1120 0R40500 D 9 W:

TYPE: VCS1610

VALUES: 0.405

ABSOLUTE TOLERANCE: ± 0.5 %

TERMINATION: lead (Pb)-free

PACKAGING: waffle pack

+ 75

+ 150

+ 100

+ 50

0

- 50

- 100

- 150

- 200

Ambient Temperature (°C)

Δ

R

R

(ppm)

± 2 ppm/°C (+ 25 °C Reference)

+ 100

+ 125

- 25

0

+ 25

+ 50

- 50

1

2

0

0

4

0

5

R

Y

1

0

9

0

W

D

Vishay Precision Group

Document No.: 63999

Revision: 27-Apr-2011

www.vishaypg.com

1

Legal Disclaimer Notice

Disclaimer

Legal Disclaimer Notice

Disclaimer

Document No.: 63999

Revision: 27-Apr-2011

ALL PRODUCTS, PRODUCT SPECIFICATIONS AND DATA ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Vishay Precision Group, Inc., its affiliates, agents, and employees, and all persons acting on its or their

behalf (collectively, “Vishay Precision Group”), disclaim any and all liability for any errors, inaccuracies or

incompleteness contained herein or in any other disclosure relating to any product.

The product specifications do not expand or otherwise modify Vishay Precision Group’s terms and

conditions of purchase, including but not limited to, the warranty expressed therein.

Vishay Precision Group makes no warranty, representation or guarantee other than as set forth in the terms

and conditions of purchase.

To the maximum extent permitted by applicable law, Vishay Precision

Group disclaims (i) any and all liability arising out of the application or use of any product, (ii) any and

all liability, including without limitation special, consequential or incidental damages, and (iii) any and

all implied warranties, including warranties of fitness for particular purpose, non-infringement and

merchantability.

Information provided in datasheets and/or specifications may vary from actual results in different

applications and performance may vary over time. Statements regarding the suitability of products for

certain types of applications are based on Vishay Precision Group’s knowledge of typical requirements that

are often placed on Vishay Precision Group products. It is the customer’s responsibility to validate that a

particular product with the properties described in the product specification is suitable for use in a particular

application.

No license, express, implied, or otherwise, to any intellectual property rights is granted by this document, or

by any conduct of Vishay Precision Group.

The products shown herein are not designed for use in life-saving or life-sustaining applications unless

otherwise expressly indicated. Customers using or selling Vishay Precision Group products not expressly

indicated for use in such applications do so entirely at their own risk and agree to fully indemnify Vishay

Precision Group for any damages arising or resulting from such use or sale. Please contact authorized

Vishay Precision Group personnel to obtain written terms and conditions regarding products designed for

such applications.

Product names and markings noted herein may be trademarks of their respective owners.