ZIERICK MANUFACTURING CORPORATION

131 RADIO CIRCLE, MOUNT KISCO, NY 10549

914.666.2911

n

800.882.8020

n

001.914.666.2911

n

FAX 914.666.0216

www.zierick.com

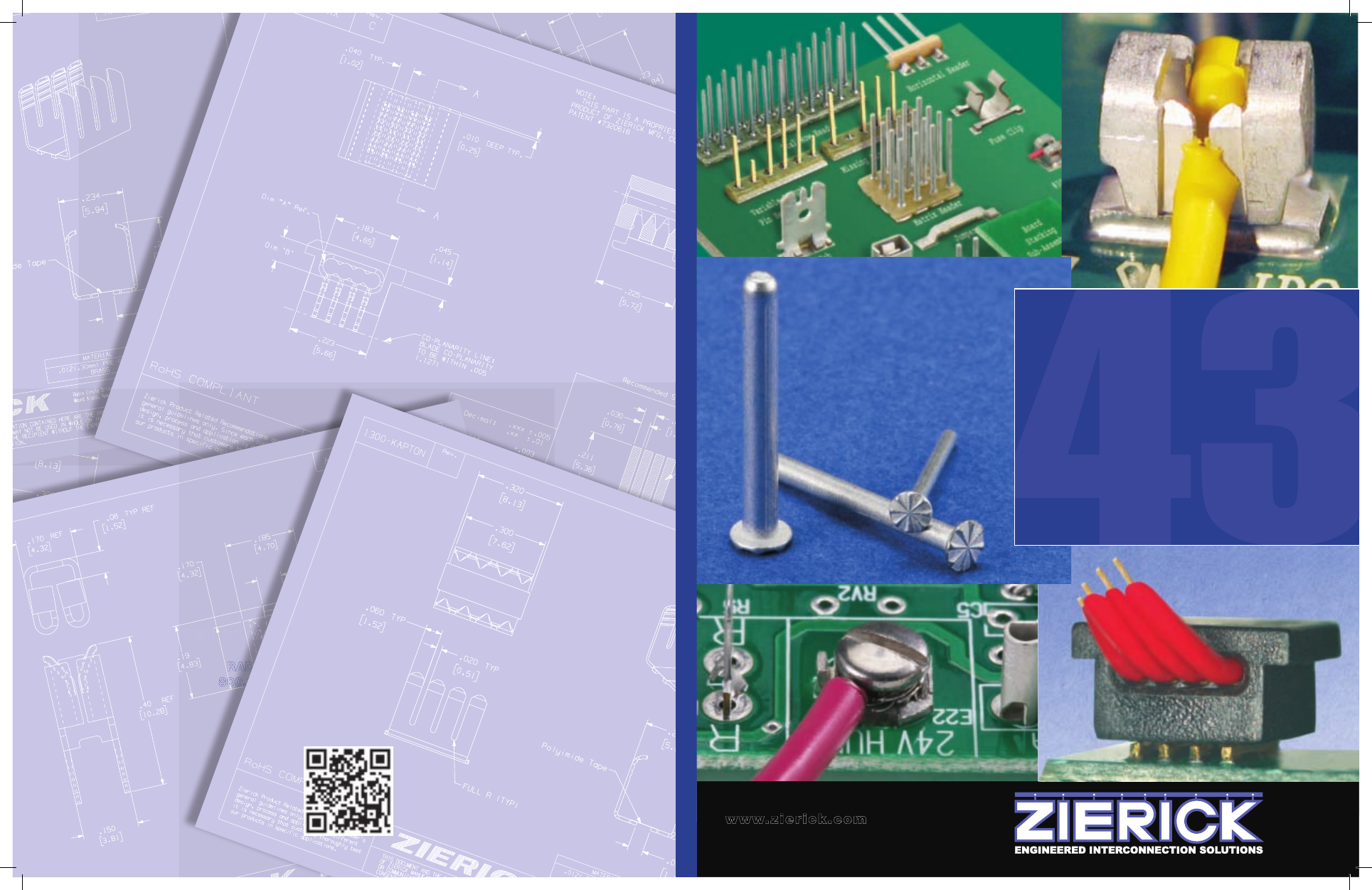

CATALOG

Surface Mount & Through-Hole

Interconnection & Assembly Solutions

www.zierick.com

ZIERICK

MANUF

ACTURING

CORPORA

TION

CA

T

ALOG

43

63259 Zierick Cr.indd 1

11/7/12 10:57 AM